sensor SUZUKI SWIFT 2000 1.G RG413 Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 657 of 698

6E1-36 ENGINE AND EMISSION CONTROL SYSTEM

OUTPUT SIGNALS OF THROTTLE VALVE OPENING

AND ENGINE COOLANT TEMP. (VEHICLE WITH A/T

ONLY)

THROTTLE VALVE OPENING SIGNAL INSPECTION

Check throttle valve opening (throttle position) signal referring to

step 1 of DTC P1700 (No.32 or 33) Flow Table in Section 7B. If

check result is not satisfactory, check each wire harness, circuit

connections and TP sensor.

ENGINE COOLANT TEMP. SIGNAL INSPECTION

Check engine coolant temp. signal referring to step 1 of DTC

P1705 (NO.51) Flow Table in Section 7B.

If check result is not satisfactory, check each wire harness, circuit

connection and ECT sensor.

EMISSION CONTROL SYSTEM

EGR SYSTEM

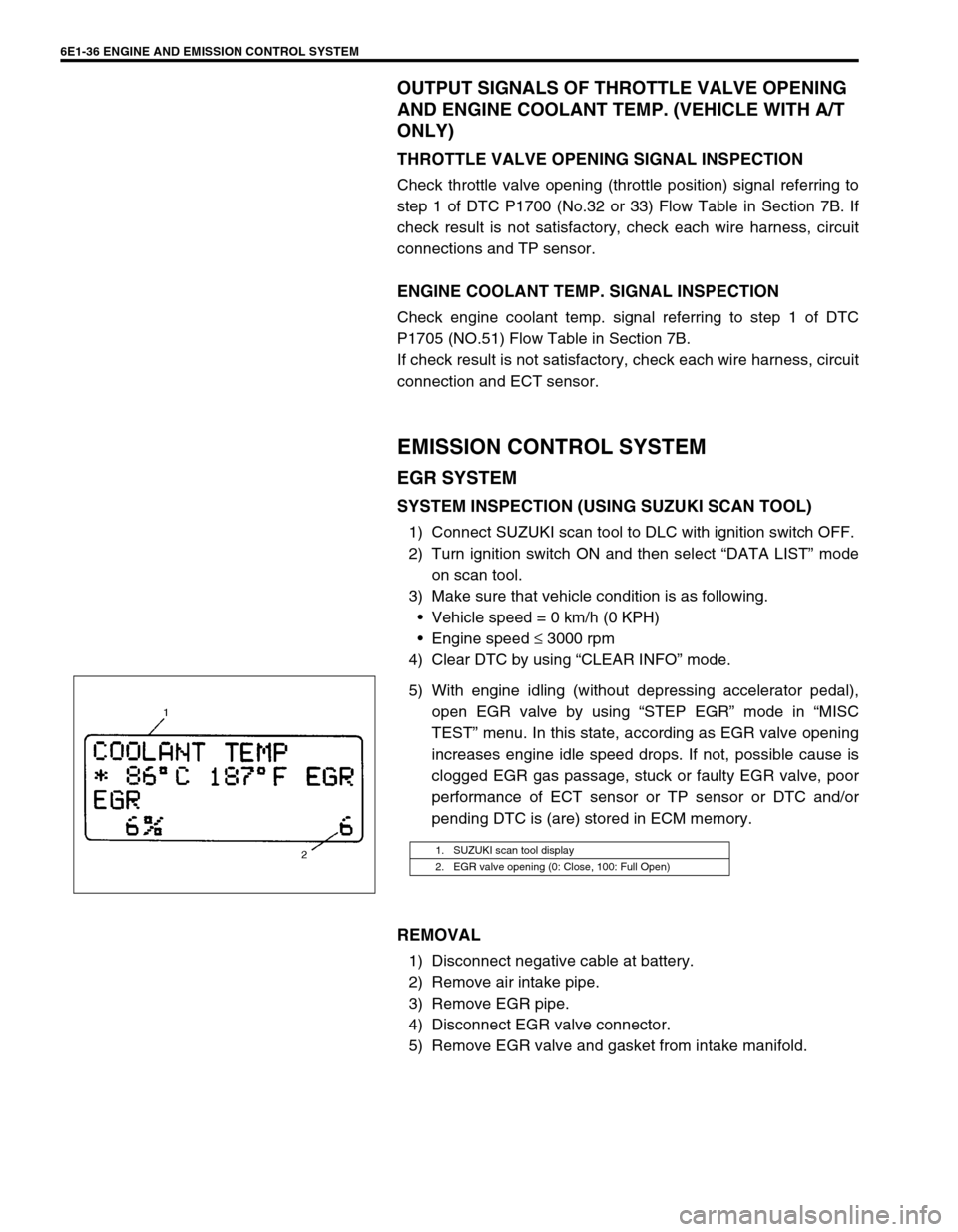

SYSTEM INSPECTION (USING SUZUKI SCAN TOOL)

1) Connect SUZUKI scan tool to DLC with ignition switch OFF.

2) Turn ignition switch ON and then select “DATA LIST” mode

on scan tool.

3) Make sure that vehicle condition is as following.

Vehicle speed = 0 km/h (0 KPH)

Engine speed ≤ 3000 rpm

4) Clear DTC by using “CLEAR INFO” mode.

5) With engine idling (without depressing accelerator pedal),

open EGR valve by using “STEP EGR” mode in “MISC

TEST” menu. In this state, according as EGR valve opening

increases engine idle speed drops. If not, possible cause is

clogged EGR gas passage, stuck or faulty EGR valve, poor

performance of ECT sensor or TP sensor or DTC and/or

pending DTC is (are) stored in ECM memory.

REMOVAL

1) Disconnect negative cable at battery.

2) Remove air intake pipe.

3) Remove EGR pipe.

4) Disconnect EGR valve connector.

5) Remove EGR valve and gasket from intake manifold.

1. SUZUKI scan tool display

2. EGR valve opening (0: Close, 100: Full Open)

Page 659 of 698

6E1-38 ENGINE AND EMISSION CONTROL SYSTEM

3) Connect purge hose to EVAP canister and warm up engine

to normal operating temperature.

4) Disconnect purge hose from EVAP canister.

5) Also check that vacuum is felt when engine is running at idle

speed.

If check result is not satisfactory, check vacuum passage,

hoses, EVAP canister purge valve, wire harness and ECM.

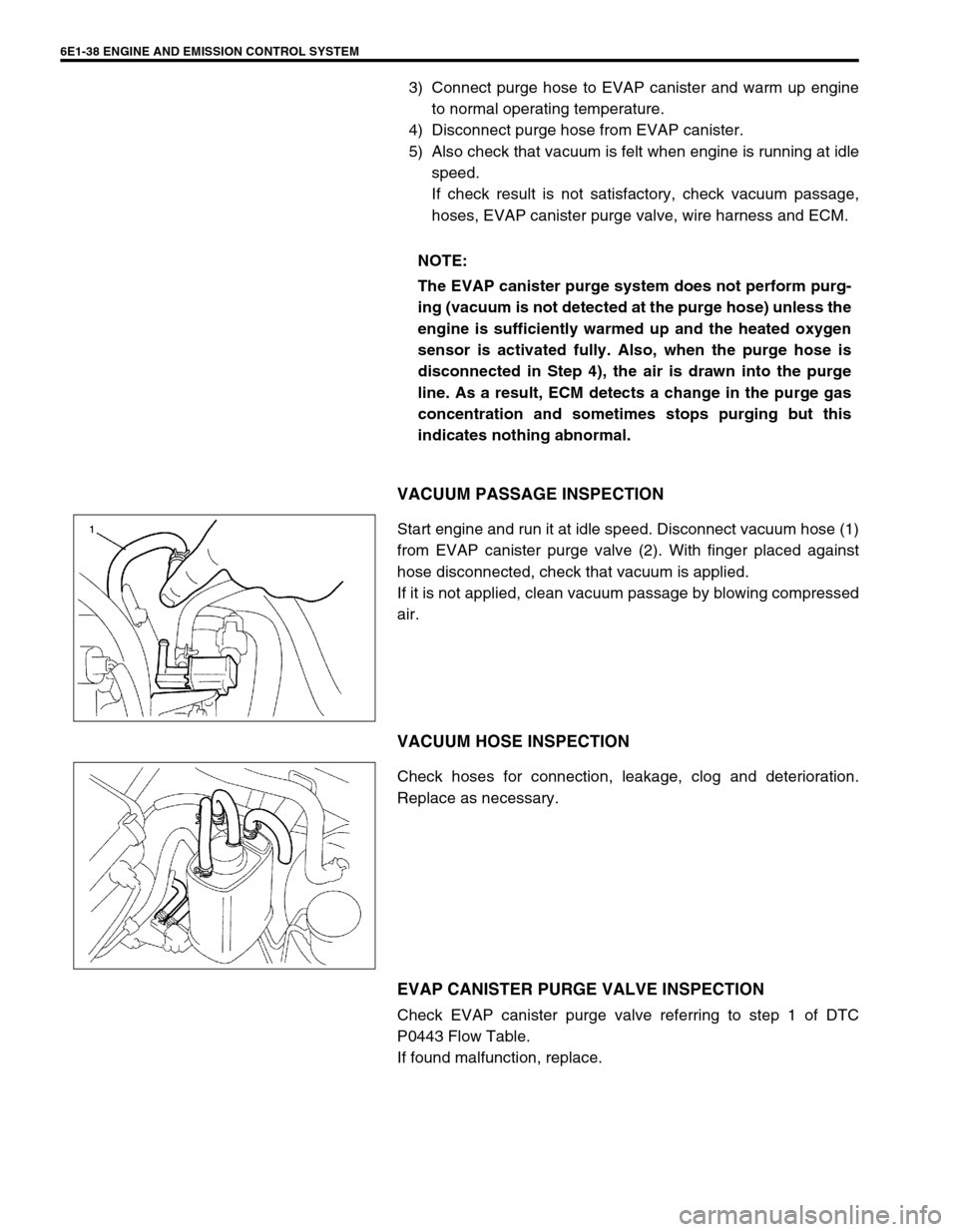

VACUUM PASSAGE INSPECTION

Start engine and run it at idle speed. Disconnect vacuum hose (1)

from EVAP canister purge valve (2). With finger placed against

hose disconnected, check that vacuum is applied.

If it is not applied, clean vacuum passage by blowing compressed

air.

VACUUM HOSE INSPECTION

Check hoses for connection, leakage, clog and deterioration.

Replace as necessary.

EVAP CANISTER PURGE VALVE INSPECTION

Check EVAP canister purge valve referring to step 1 of DTC

P0443 Flow Table.

If found malfunction, replace.NOTE:

The EVAP canister purge system does not perform purg-

ing (vacuum is not detected at the purge hose) unless the

engine is sufficiently warmed up and the heated oxygen

sensor is activated fully. Also, when the purge hose is

disconnected in Step 4), the air is drawn into the purge

line. As a result, ECM detects a change in the purge gas

concentration and sometimes stops purging but this

indicates nothing abnormal.

Page 662 of 698

ENGINE AND EMISSION CONTROL SYSTEM 6E1-41

TIGHTENING TORQUE SPECIFICATION

09931-76030

16/14 pin DLC cable

NOTE:

“A”: This kit includes the following items.

1. Tool body & washer, 2. Body plug, 3. Body attachment-1, 4. Holder, 5. Return hose & clamp,

6. Body attachment-2 & washer, 7. Hose attachment-1, 8. Hose attachment-2

“B”: This kit includes the following items.

1. Storage case, 2. Operator’s manual, 3. Tech 1A, 4. DLC cable (14/26 pin, 09931-76040),

5. Test lead/probe, 6. Power source cable, 7. DLC cable adaptor, 8. Self-test adaptor

Fastening partTightening torque

Nm kg-m lb-ft

TP sensor mounting screw 2.5 0.25 1.8

IAC valve 3.5 0.35 2.5

ECT sensor 15 1.5 11.5

Heated oxygen sensor-1 and -2 45 4.5 32.5

Camshaft position sensor 10 1.0 7.5

Page 663 of 698

IGNITION SYSTEM (ELECTRONIC IGNITION SYSTEM) 6F1-1

6G

6F2

6G

6H

6K

6F1

7A

7A1

7A1

7D

7E

7F

8A

8B

8C

8D

8E

9

10

10A

10B

SECTION 6F1

IGNITION SYSTEM

(ELECTRONIC IGNITION SYSTEM)

CONTENTS

GENERAL DESCRIPTION ............................. 6F1-2

DIAGNOSIS .................................................... 6F1-3

ON-VEHICLE SERVICE ................................. 6F1-5

IGNITION SPARK TEST ............................. 6F1-5

HIGH-TENSION CORDS ............................ 6F1-5

SPARK PLUGS ........................................... 6F1-6IGNITION COIL ASSEMBLY

(INCLUDING IGNITOR) .............................. 6F1-7

CRANKSHAFT POSITION SENSOR

(CKP SENSOR) .......................................... 6F1-7

IGNITION TIMING ...................................... 6F1-8

SPECIAL TOOL ............................................. 6F1-9

WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System:

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

Page 664 of 698

6F1-2 IGNITION SYSTEM (ELECTRONIC IGNITION SYSTEM)

GENERAL DESCRIPTION

The ignition system is an electronic (distributorless) ignition system. Its consists of the parts as described below

and has an electronic ignition control system.

ECM

It detects the engine and vehicle conditions through the signals from the sensors, determines the most suit-

able ignition timing and time for electricity to flow to the primary coil and sends a signal to the ignitor (power

unit) in the ignition coil assembly.

Ignition coil assembly (including an igniter)

The ignition coil assembly has a built-in ignitor which turns ON and OFF the current flow to the primary coil

according to the signal from ECM. When the current flow to the primary coil is turned OFF, a high voltage is

induced in the secondary coil.

High tension cords and spark plugs.

CMP sensor (Camshaft position sensor) and CKP sensor (Crankshaft position sensor)

Using signals from these sensors, ECM identifies the specific cylinder whose piston is in the compression

stroke, detects the crank angle and adjusts initial ignition timing automatically.

TP sensor, ECT sensor, MAP sensor and other sensors/switches

Refer to Section 6E1 for details.

Although this ignition system does not have a distributor, it has two ignition coil assemblies (one is for No.1 and

No.4 spark plugs and the other is for No.2 and No.3 spark plugs). When an ignition signal is sent from ECM to

the ignitor in the ignition coil assembly for No.1 and No.4 spark plugs, a high voltage is induced in the secondary

coil and that passes through the high-tension cords and causes No.1 and No.4 spark plugs to spark simulta-

neously. Likewise, when an ignition signal is sent to the ignitor in the other ignition coil assembly, No.2 and No.3

spark plugs spark simultaneously.

SYSTEM COMPONENTS

1. ECM 6. MAP sensor 11. Transmission range switch (A/T)

2. Ignition coil assembly for No.1 and No.4 spark plugs 7. ECT sensor 12. High-tension cords

3. Ignition coil assembly for No.2 and No.3 spark plugs 8. IAT sensor 13. Monitor connector

4. CMP sensor 9. TP sensor 14. Knock sensor (if equipped)

5. CKP sensor 10. VSS 15. Data link connector

Page 665 of 698

IGNITION SYSTEM (ELECTRONIC IGNITION SYSTEM 6F1-3

SYSTEM WIRING DIAGRAM

DIAGNOSIS

1. Ignition switch 7. No.1 spark plug

2. Main relay 8. No.2 spark plug

3. Ignition coil assembly for No.1 and No.4 spark plugs 9. No.3 spark plug

4. Ignition coil assembly for No.2 and No.3 spark plugs 10. No.4 spark plug

5. CMP sensor 11. Sensed information (MAP sensor, ECT sensor, IAT sensor, TP sensor, Knock sensor (if

equipped), VSS, Park/Neutral position signal, Electric load signal, Engine start signal, Test switch

terminal (Vehicle without immobilizer indicator lamp))

6. CKP sensor

Condition Possible Cause Correction

Engine cranks, but will

not start or hard to

start (No spark)Blown fuse for ignition coil Replace.

Loose connection or disconnection of lead wire

or high-tension cord(s)Connect securely.

Faulty high-tension cord(s) Replace.

Faulty spark plug(s) Adjust, clean or replace.

Faulty ignition coil Replace ignition coil assembly.

Faulty CKP sensor or CKP sensor plate Clean, tighten or replace.

Faulty ECM Replace.

Poor fuel economy or

engine performanceIncorrect ignition timing Check related sensors and CKP

sensor plate.

Faulty spark plug(s) or high-tension cord(s) Adjust, clean or replace.

Faulty ignition coil assembly Replace.

Faulty CKP sensor or CKP sensor plate Clean, tighten or replace.

Faulty ECM Replace.

Page 666 of 698

6F1-4 IGNITION SYSTEM (ELECTRONIC IGNITION SYSTEM)

IGNITION SYSTEM DIAGNOSTIC FLOW TABLE

Step Action Yes No

1Was “ENGINE DIAG. FLOW TABLE” in Section 6 per-

formed?Go to Step 2. Go to “ENGINE DIAG.

FLOW TABLE” in Sec-

tion 6.

2Ignition Spark Test

1) Check all spark plugs for condition and type refer-

ring to “Spark Plugs” section.

2) If OK, perform ignition spark test, referring to “Igni-

tion Spark Test” in this section.

Is spark emitted from all spark plugs?Go to Step 11. Go to Step 3.

3Diagnostic Trouble Code (DTC) Check Is DTC stored

in ECM?Go to applicable DTC

Diag. Flow Table in

Section 6.Go to Step 4.

4Electrical Connection Check

1) Check ignition coil assemblies and high-tension

cords for electrical connection.

Are they connected securely?Go to Step 5. Connect securely.

5High-tension Cords Check

1) Check high-tension cord for resistance referring to

“High-Tension Cords” in this section.

Is check result satisfactory?Go to Step 6. Replace high-tension

cord(s).

6Ignition Coil Assembly Power Supply and Ground Cir-

cuit Check

1) Check ignition coil assembly power supply and

ground circuits for open and short.

Are circuits in good condition?Go to Step 7. Repair or replace.

7Ignition Coil Assembly Check

1) Check ignition coil for resistance referring to “Igni-

tion Coil Assembly” in this section.

Is check result satisfactory?Go to Step 8. Replace ignition coil

assembly.

8Crankshaft Position (CKP) Sensor Check

1) Check crankshaft position sensor referring to Step

3 and 4 of “DTC P0335 (No.23) Diag. Flow Table”

in Section 6.

Is check result satisfactory?Go to Step 9. Tighten CKP sensor

bolt, replace CKP sen-

sor or CKP sensor

plate.

9Ignition Trigger Signal Circuit Check

1) Check ignition trigger signal wire for open, short

and poor connection.

Is circuit in good condition?Go to Step 10. Repair or replace.

10A Known-good Ignition Coil Assembly Substitution

1) Substitute a known-good ignition coil assembly

and then repeat Step 2.

Is check result of Step 2 satisfactory?Go to Step 11. Substitute a known-

good ECM and then

repeat Step 2.

11Ignition Timing Check

1) Check initial ignition timing and ignition timing

advance referring to “Ignition Timing” in this sec-

tion.

Is check result satisfactory?System is in good con-

dition.Check CKP sensor,

CKP sensor plate and

input signals related to

this system.

Page 669 of 698

IGNITION SYSTEM (ELECTRONIC IGNITION SYSTEM 6F1-7

6) Install spark plugs and torque them to specification.

Tightening torque

Spark plug : 25 N·m (2.5 kg-m, 18.0 lb-ft)

7) Install ignition coil assemblies referring to IGNITION COIL

ASSEMBLY in this section.

8) Install high-tension cords securely by gripping their caps.

9) Install cylinder head upper cover and air intake pipe.

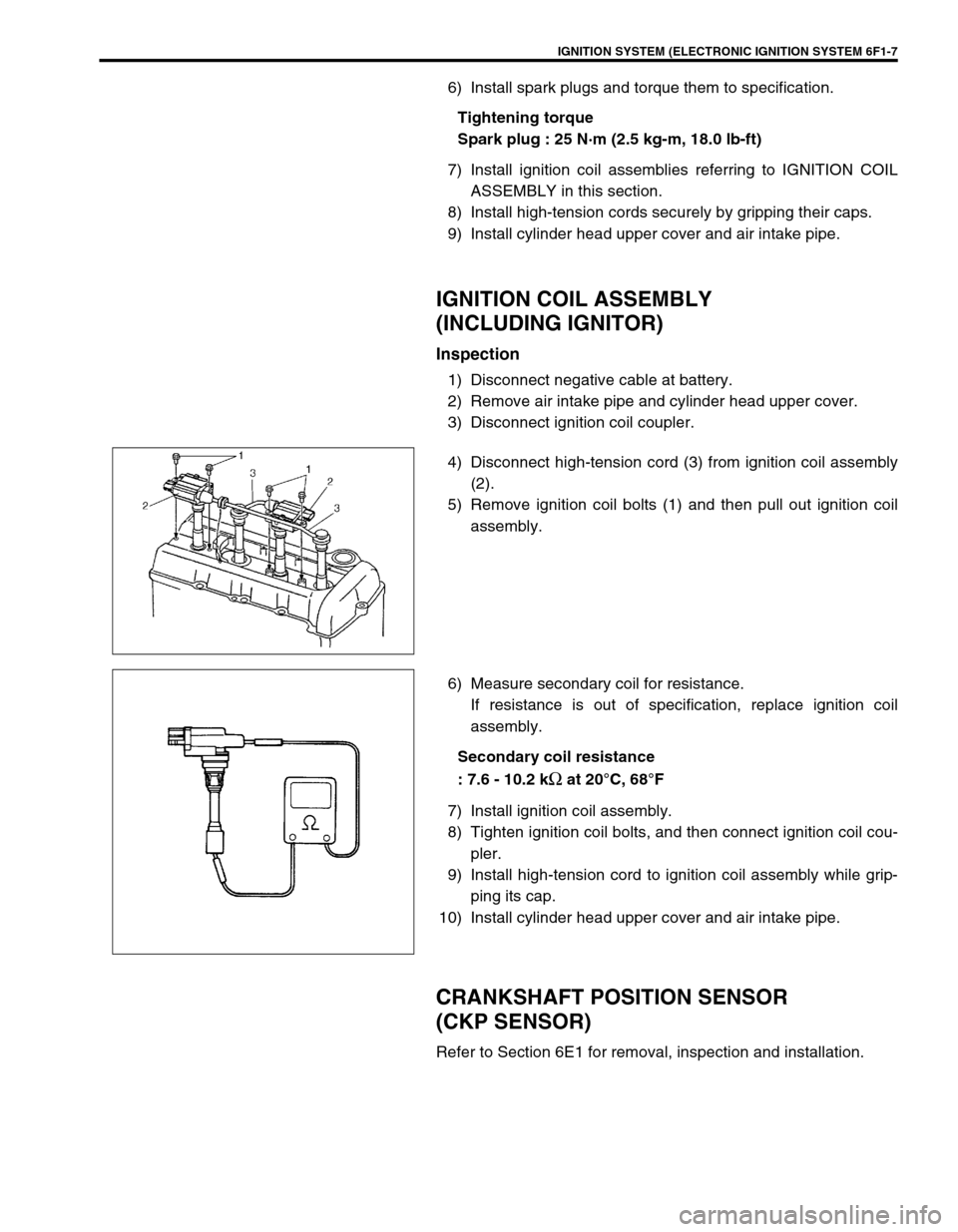

IGNITION COIL ASSEMBLY

(INCLUDING IGNITOR)

Inspection

1) Disconnect negative cable at battery.

2) Remove air intake pipe and cylinder head upper cover.

3) Disconnect ignition coil coupler.

4) Disconnect high-tension cord (3) from ignition coil assembly

(2).

5) Remove ignition coil bolts (1) and then pull out ignition coil

assembly.

6) Measure secondary coil for resistance.

If resistance is out of specification, replace ignition coil

assembly.

Secondary coil resistance

: 7.6 - 10.2 k

Ω at 20°C, 68°F

7) Install ignition coil assembly.

8) Tighten ignition coil bolts, and then connect ignition coil cou-

pler.

9) Install high-tension cord to ignition coil assembly while grip-

ping its cap.

10) Install cylinder head upper cover and air intake pipe.

CRANKSHAFT POSITION SENSOR

(CKP SENSOR)

Refer to Section 6E1 for removal, inspection and installation.

Page 671 of 698

IGNITION SYSTEM (ELECTRONIC IGNITION SYSTEM 6F1-9

7) If ignition timing is out of specification, check the followings:

CKP sensor

CKP sensor plate

TP sensor

Test switch signal circuit

VSS

Timing chain cover installation

8) After checking Initial Ignition Timing, release ignition timing

fixation by using SUZUKI scan tool or disconnect service

wire from monitor connector.

9) With engine idling (test switch terminal ungrounded, throttle

opening at closed position and car stopped), check that igni-

tion timing is about 7°–17° BTDC. (Constant variation within

a few degrees from 7°–17° indicates no abnormality but

proves operation of electronic timing control system.) Also,

check that increasing engine speed advances ignition timing.

If above check results are not satisfactory, check CKP sen-

sor, test switch terminal circuit and ECM.

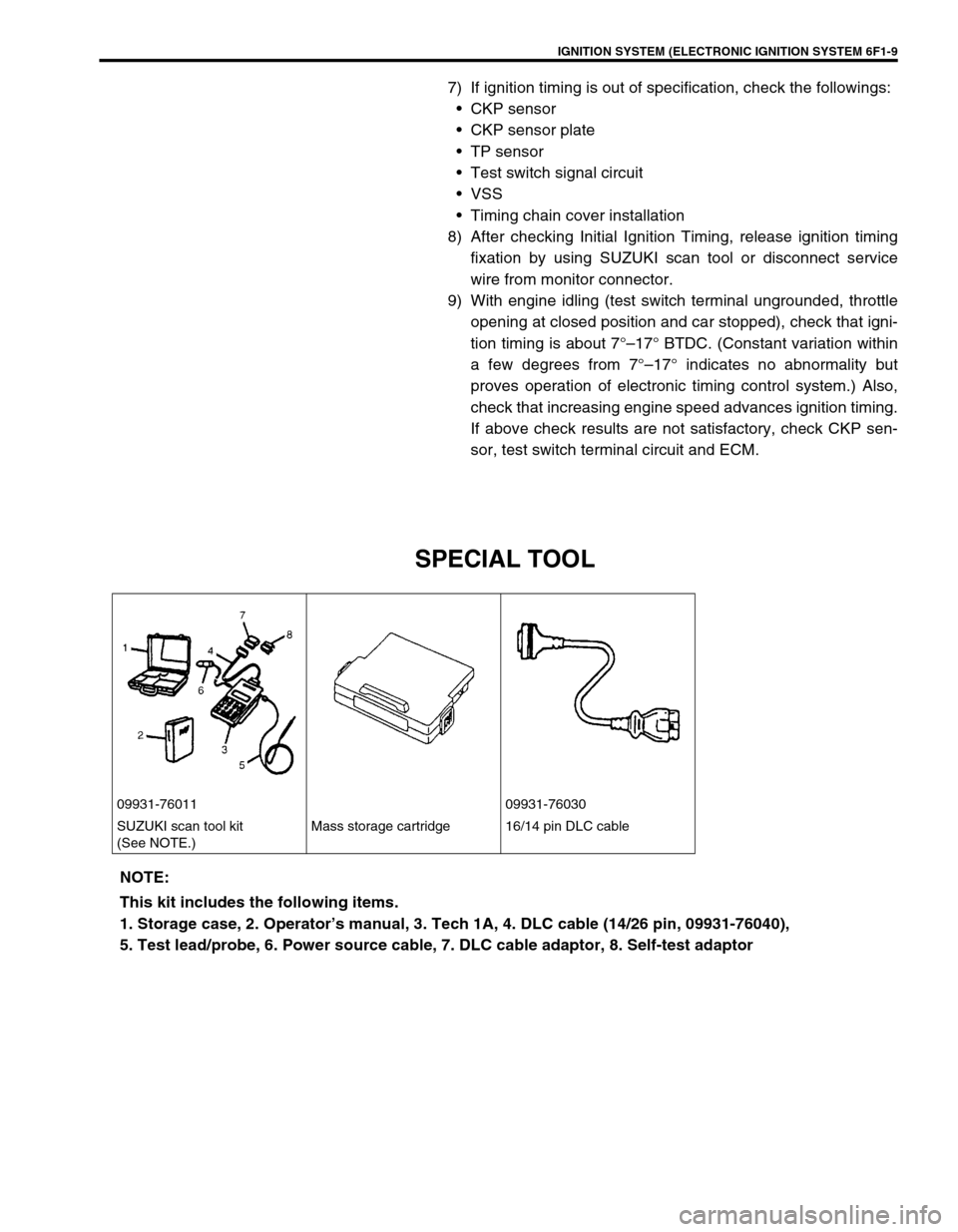

SPECIAL TOOL

09931-76011 09931-76030

SUZUKI scan tool kit

(See NOTE.)Mass storage cartridge 16/14 pin DLC cable

NOTE:

This kit includes the following items.

1. Storage case, 2. Operator’s manual, 3. Tech 1A, 4. DLC cable (14/26 pin, 09931-76040),

5. Test lead/probe, 6. Power source cable, 7. DLC cable adaptor, 8. Self-test adaptor

Page 697 of 698

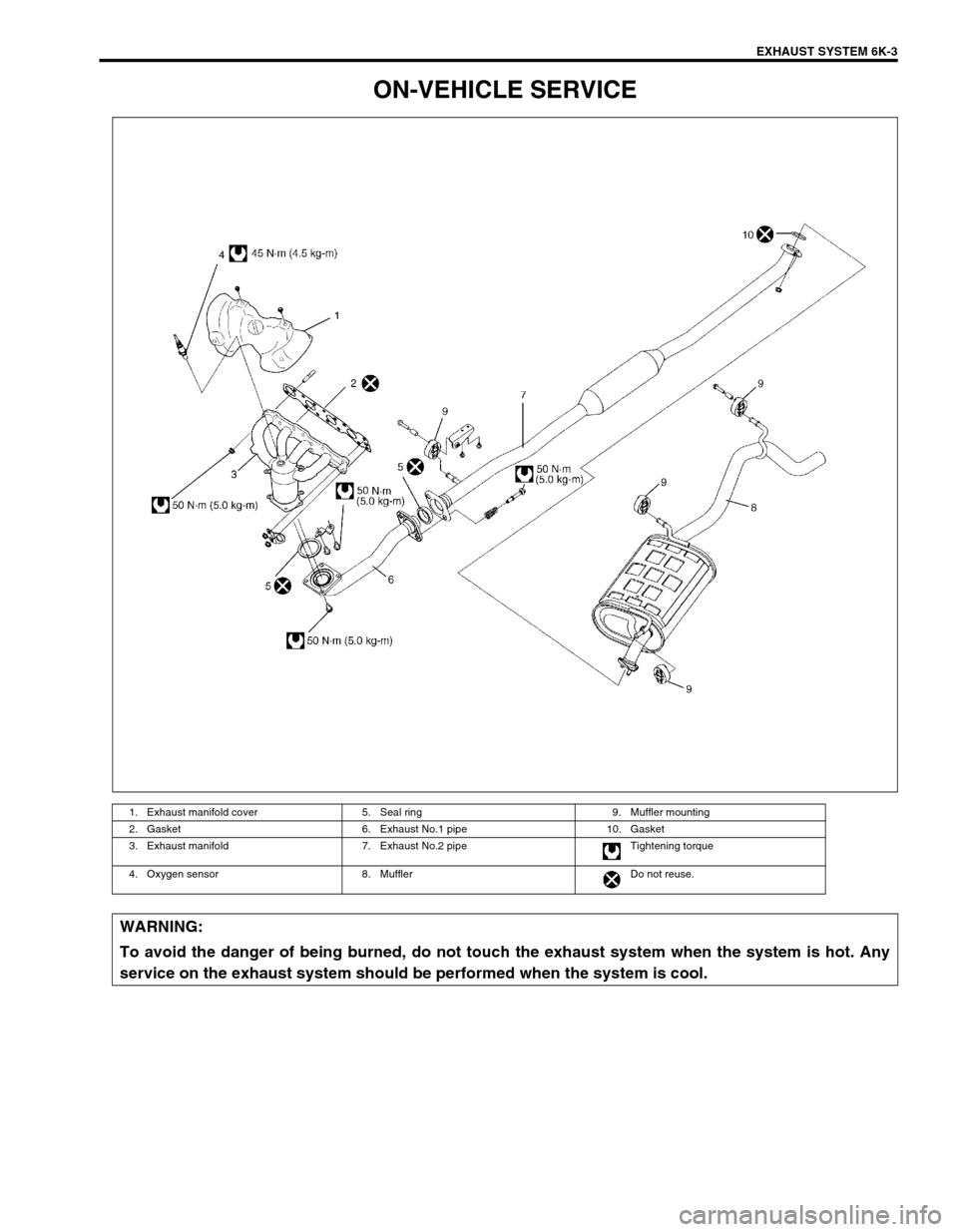

EXHAUST SYSTEM 6K-3

ON-VEHICLE SERVICE

1. Exhaust manifold cover 5. Seal ring 9. Muffler mounting

2. Gasket 6. Exhaust No.1 pipe 10. Gasket

3. Exhaust manifold 7. Exhaust No.2 pipe Tightening torque

4. Oxygen sensor 8. Muffler Do not reuse.

WARNING:

To avoid the danger of being burned, do not touch the exhaust system when the system is hot. Any

service on the exhaust system should be performed when the system is cool.