ESP SUZUKI SWIFT 2000 1.G RG413 Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 181 of 698

3C-8 STEERING WHEEL AND COLUMN

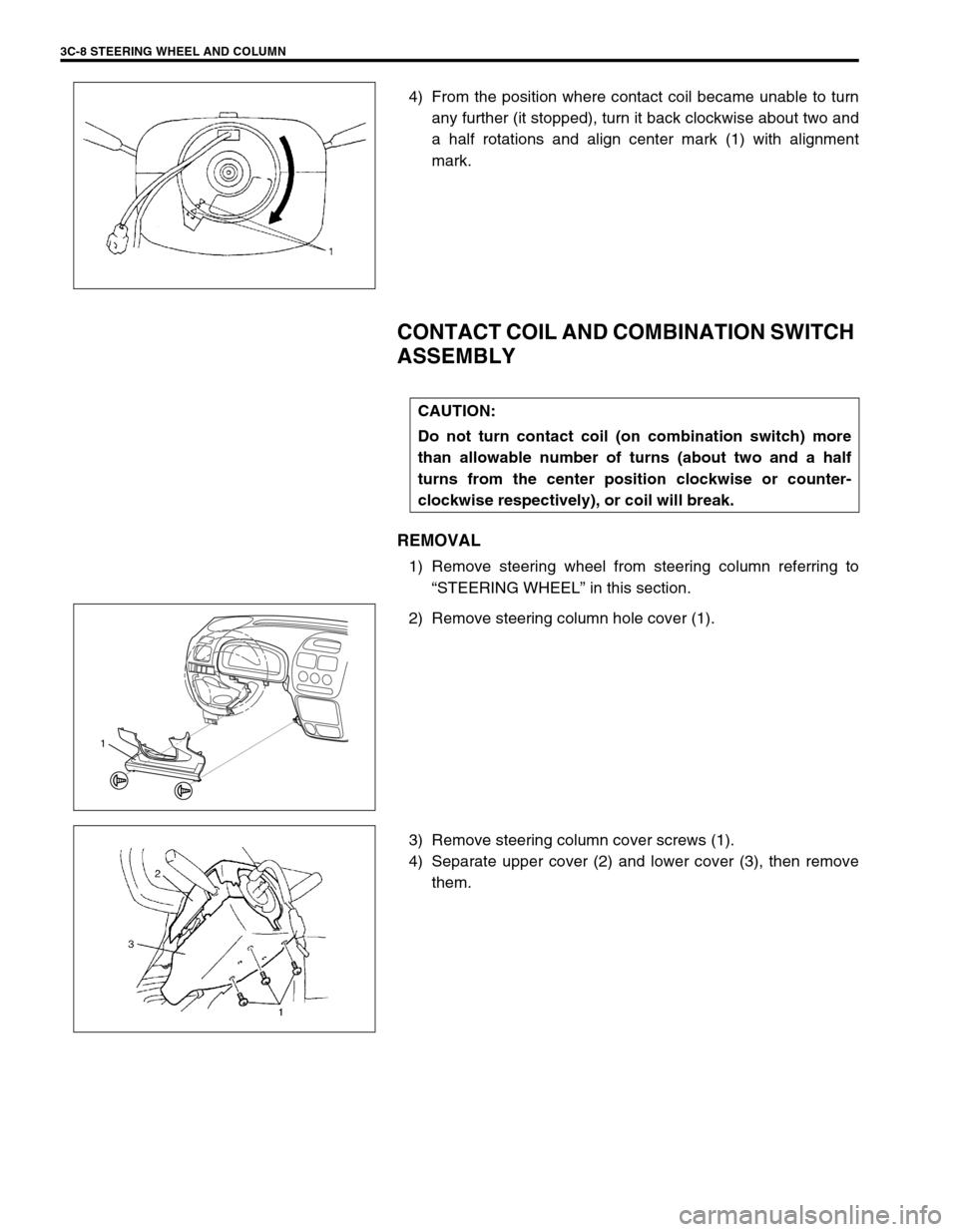

4) From the position where contact coil became unable to turn

any further (it stopped), turn it back clockwise about two and

a half rotations and align center mark (1) with alignment

mark.

CONTACT COIL AND COMBINATION SWITCH

ASSEMBLY

REMOVAL

1) Remove steering wheel from steering column referring to

“STEERING WHEEL” in this section.

2) Remove steering column hole cover (1).

3) Remove steering column cover screws (1).

4) Separate upper cover (2) and lower cover (3), then remove

them.

CAUTION:

Do not turn contact coil (on combination switch) more

than allowable number of turns (about two and a half

turns from the center position clockwise or counter-

clockwise respectively), or coil will break.

1

Page 251 of 698

3F-6 WHEELS AND TIRES

INFLATION OF TIRES

The pressure recommended for any model is carefully calculated to give a satisfactory ride, stability, steering,

tread wear, tire life and resistance to bruises.

Tire pressure, with tires cold, (after vehicle has set for 3 hours or more, or driven less than one mile) should be

checked monthly or before any extended trip. Set to the specifications on the “Tire Placard” located on the left

door (right door for right-hand side steering vehicle) lock pillar.

It is normal for tire pressure to increase when the tires become hot during driving.

Do not bleed or reduce tire pressure after driving. Bleeding reduces the “Cold Inflation Pressure”.

Higher than recommended pressure can cause :

Hard ride

Tire bruising or carcass damage

Rapid tread wear at center of tire

Unequal pressure on same axle can cause :

Uneven braking

Steering lead

Reduced handling

Swerve on acceleration

Lower than recommended pressure can cause :

Tire squeal on turns

Hard Steering

Rapid and uneven wear on the edges of the tread

Tire rim bruises and rupture

Tire cord breakage

High tire temperature

Reduced handling

High fuel consumption

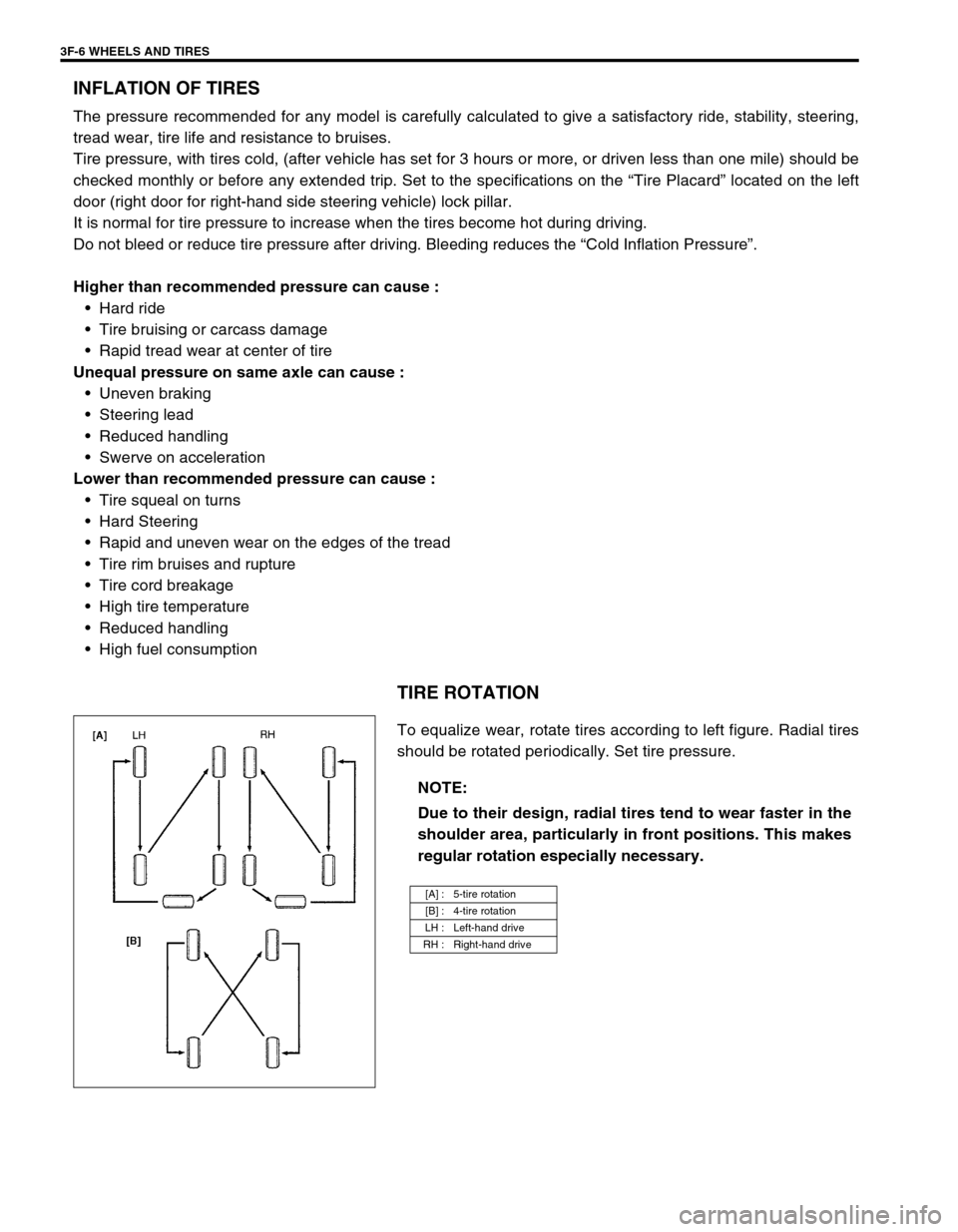

TIRE ROTATION

To equalize wear, rotate tires according to left figure. Radial tires

should be rotated periodically. Set tire pressure.

NOTE:

Due to their design, radial tires tend to wear faster in the

shoulder area, particularly in front positions. This makes

regular rotation especially necessary.

[A] : 5-tire rotation

[B] : 4-tire rotation

LH : Left-hand drive

RH : Right-hand drive

Page 261 of 698

4A-8 FRONT DRIVE SHAFT

5) Remove circlip (1) by using flat end rod or the like.

6) Remove center bearing (2) from center bearing support.

ASSEMBLY

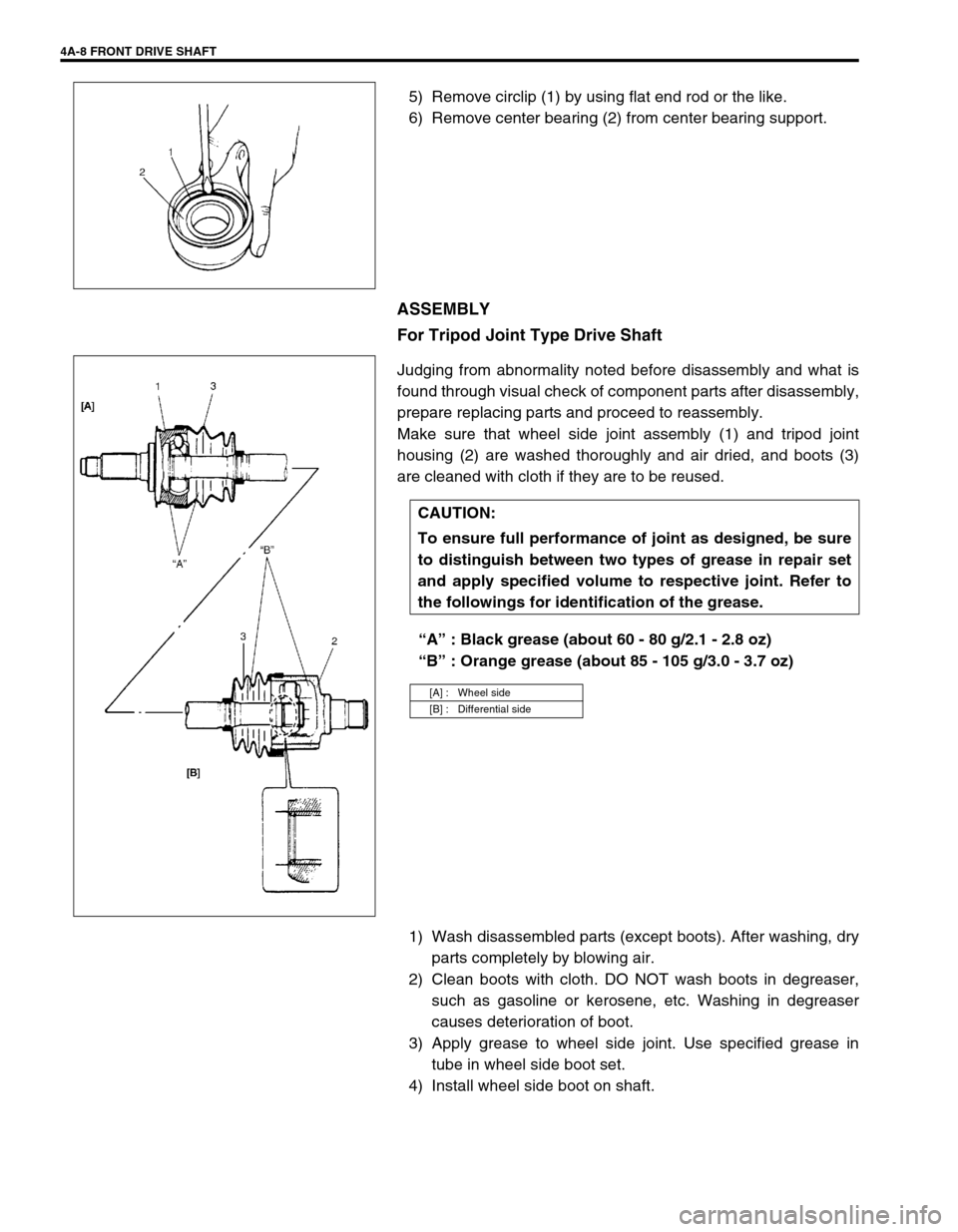

For Tripod Joint Type Drive Shaft

Judging from abnormality noted before disassembly and what is

found through visual check of component parts after disassembly,

prepare replacing parts and proceed to reassembly.

Make sure that wheel side joint assembly (1) and tripod joint

housing (2) are washed thoroughly and air dried, and boots (3)

are cleaned with cloth if they are to be reused.

“A” : Black grease (about 60 - 80 g/2.1 - 2.8 oz)

“B” : Orange grease (about 85 - 105 g/3.0 - 3.7 oz)

1) Wash disassembled parts (except boots). After washing, dry

parts completely by blowing air.

2) Clean boots with cloth. DO NOT wash boots in degreaser,

such as gasoline or kerosene, etc. Washing in degreaser

causes deterioration of boot.

3) Apply grease to wheel side joint. Use specified grease in

tube in wheel side boot set.

4) Install wheel side boot on shaft.

CAUTION:

To ensure full performance of joint as designed, be sure

to distinguish between two types of grease in repair set

and apply specified volume to respective joint. Refer to

the followings for identification of the grease.

[A] : Wheel side

[B] : Differential side

Page 264 of 698

FRONT DRIVE SHAFT 4A-11

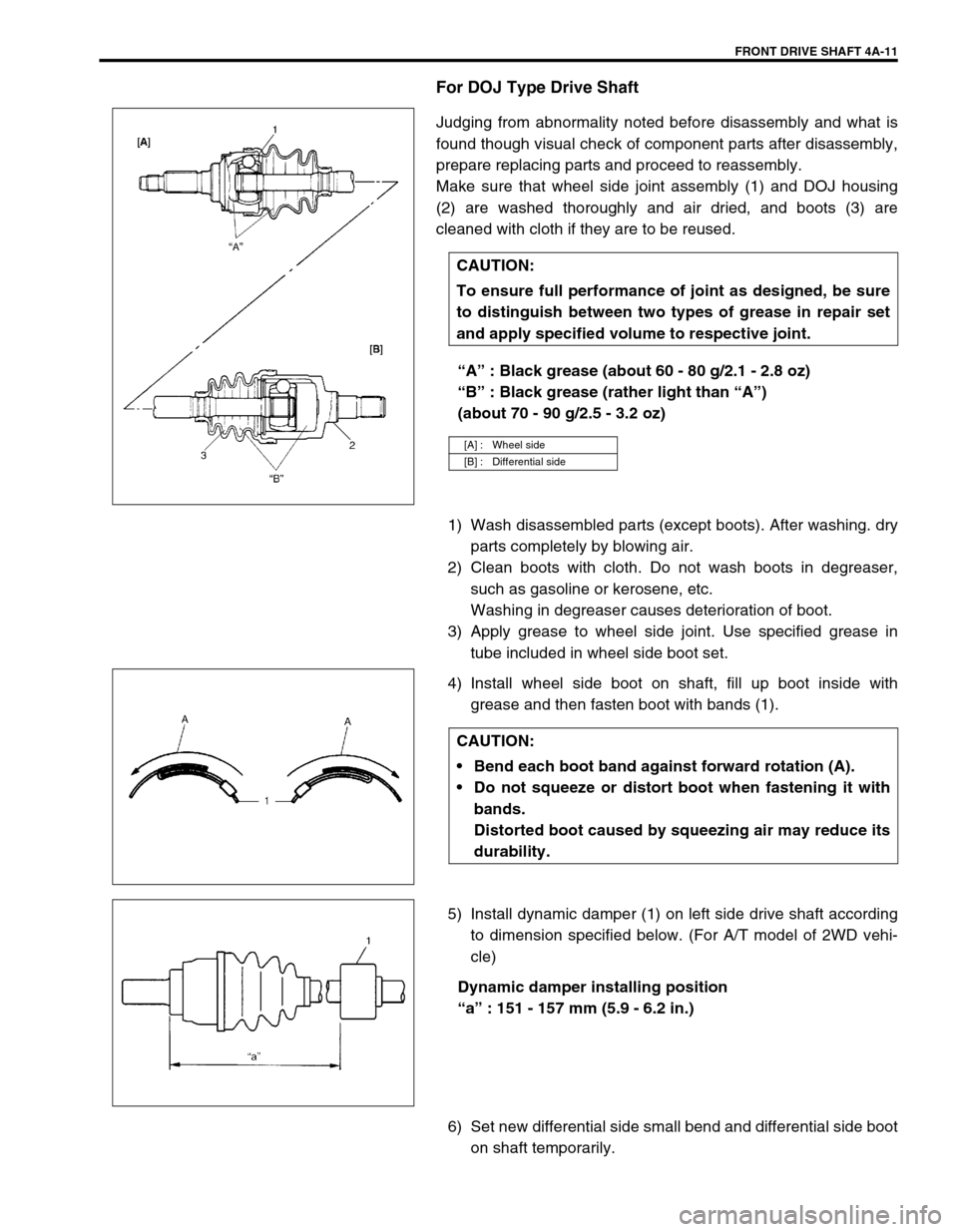

For DOJ Type Drive Shaft

Judging from abnormality noted before disassembly and what is

found though visual check of component parts after disassembly,

prepare replacing parts and proceed to reassembly.

Make sure that wheel side joint assembly (1) and DOJ housing

(2) are washed thoroughly and air dried, and boots (3) are

cleaned with cloth if they are to be reused.

“A” : Black grease (about 60 - 80 g/2.1 - 2.8 oz)

“B” : Black grease (rather light than “A”)

(about 70 - 90 g/2.5 - 3.2 oz)

1) Wash disassembled parts (except boots). After washing. dry

parts completely by blowing air.

2) Clean boots with cloth. Do not wash boots in degreaser,

such as gasoline or kerosene, etc.

Washing in degreaser causes deterioration of boot.

3) Apply grease to wheel side joint. Use specified grease in

tube included in wheel side boot set.

4) Install wheel side boot on shaft, fill up boot inside with

grease and then fasten boot with bands (1).

5) Install dynamic damper (1) on left side drive shaft according

to dimension specified below. (For A/T model of 2WD vehi-

cle)

Dynamic damper installing position

“a” : 151 - 157 mm (5.9 - 6.2 in.)

6) Set new differential side small bend and differential side boot

on shaft temporarily. CAUTION:

To ensure full performance of joint as designed, be sure

to distinguish between two types of grease in repair set

and apply specified volume to respective joint.

[A] : Wheel side

[B] : Differential side

CAUTION:

Bend each boot band against forward rotation (A).

Do not squeeze or distort boot when fastening it with

bands.

Distorted boot caused by squeezing air may reduce its

durability.

Page 283 of 698

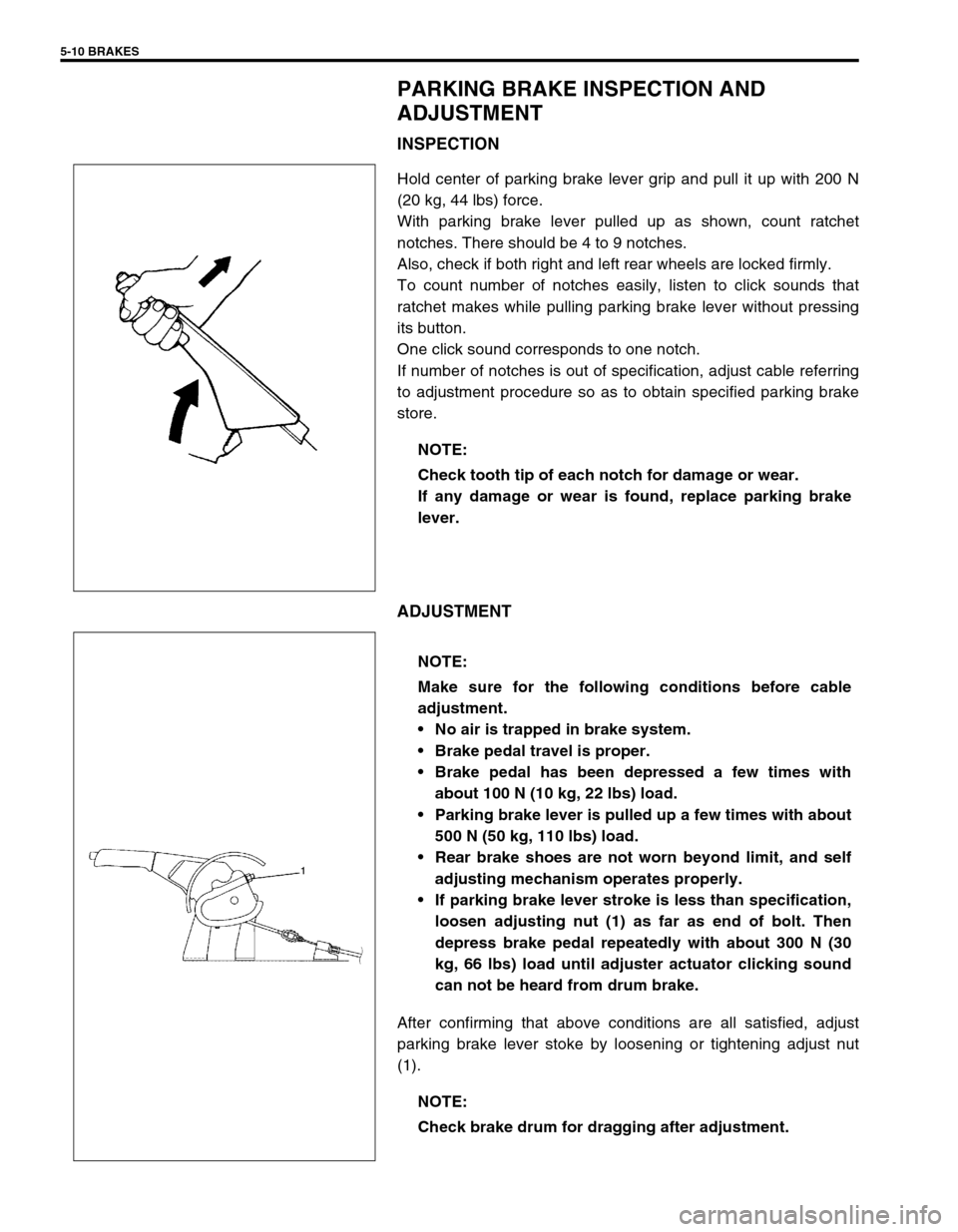

5-10 BRAKES

PARKING BRAKE INSPECTION AND

ADJUSTMENT

INSPECTION

Hold center of parking brake lever grip and pull it up with 200 N

(20 kg, 44 lbs) force.

With parking brake lever pulled up as shown, count ratchet

notches. There should be 4 to 9 notches.

Also, check if both right and left rear wheels are locked firmly.

To count number of notches easily, listen to click sounds that

ratchet makes while pulling parking brake lever without pressing

its button.

One click sound corresponds to one notch.

If number of notches is out of specification, adjust cable referring

to adjustment procedure so as to obtain specified parking brake

store.

ADJUSTMENT

After confirming that above conditions are all satisfied, adjust

parking brake lever stoke by loosening or tightening adjust nut

(1).NOTE:

Check tooth tip of each notch for damage or wear.

If any damage or wear is found, replace parking brake

lever.

NOTE:

Make sure for the following conditions before cable

adjustment.

No air is trapped in brake system.

Brake pedal travel is proper.

Brake pedal has been depressed a few times with

about 100 N (10 kg, 22 lbs) load.

Parking brake lever is pulled up a few times with about

500 N (50 kg, 110 lbs) load.

Rear brake shoes are not worn beyond limit, and self

adjusting mechanism operates properly.

If parking brake lever stroke is less than specification,

loosen adjusting nut (1) as far as end of bolt. Then

depress brake pedal repeatedly with about 300 N (30

kg, 66 lbs) load until adjuster actuator clicking sound

can not be heard from drum brake.

NOTE:

Check brake drum for dragging after adjustment.

Page 286 of 698

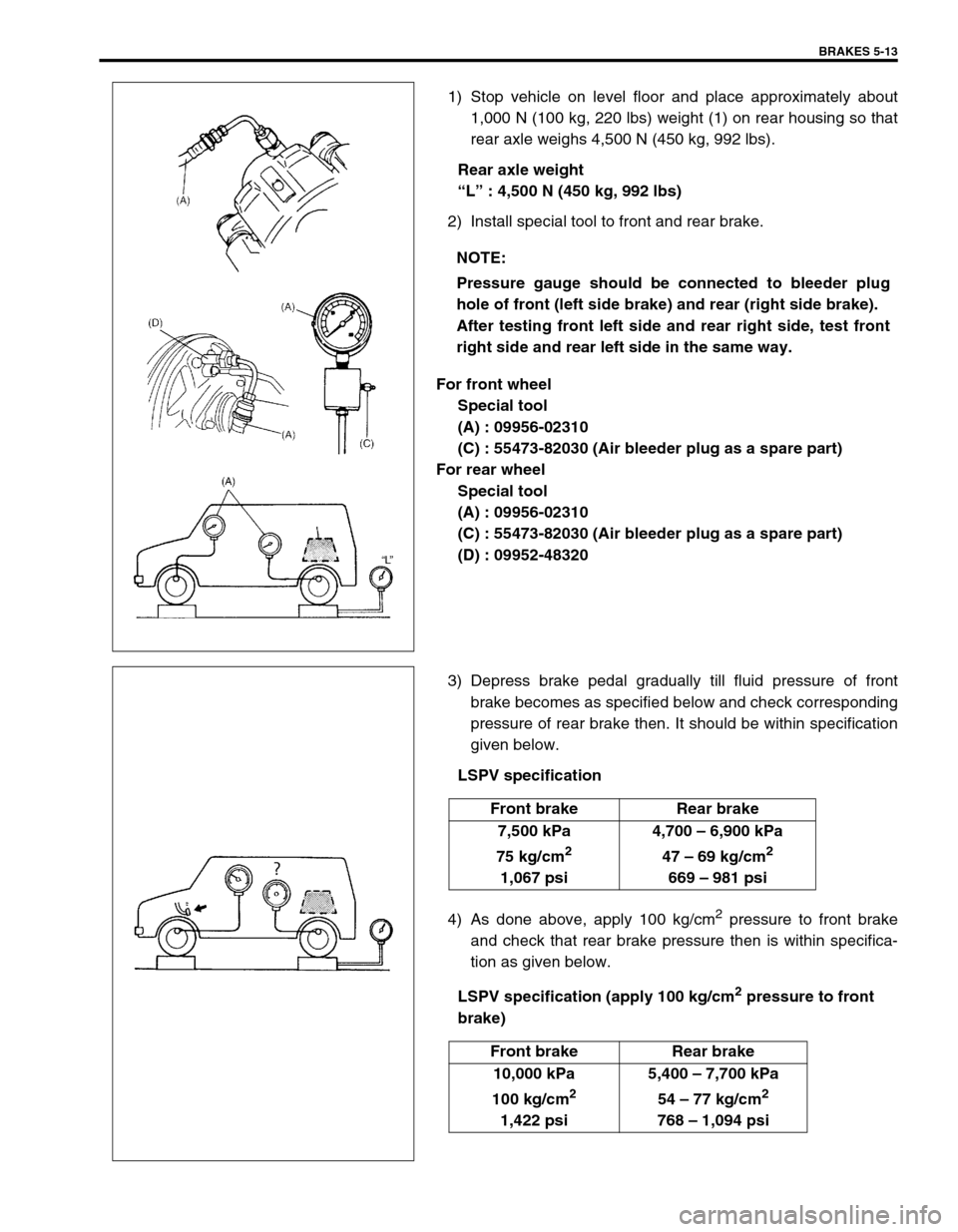

BRAKES 5-13

1) Stop vehicle on level floor and place approximately about

1,000 N (100 kg, 220 lbs) weight (1) on rear housing so that

rear axle weighs 4,500 N (450 kg, 992 lbs).

Rear axle weight

“L” : 4,500 N (450 kg, 992 lbs)

2) Install special tool to front and rear brake.

For front wheel

Special tool

(A) : 09956-02310

(C) : 55473-82030 (Air bleeder plug as a spare part)

For rear wheel

Special tool

(A) : 09956-02310

(C) : 55473-82030 (Air bleeder plug as a spare part)

(D) : 09952-48320

3) Depress brake pedal gradually till fluid pressure of front

brake becomes as specified below and check corresponding

pressure of rear brake then. It should be within specification

given below.

LSPV specification

4) As done above, apply 100 kg/cm

2 pressure to front brake

and check that rear brake pressure then is within specifica-

tion as given below.

LSPV specification (apply 100 kg/cm

2 pressure to front

brake) NOTE:

Pressure gauge should be connected to bleeder plug

hole of front (left side brake) and rear (right side brake).

After testing front left side and rear right side, test front

right side and rear left side in the same way.

Front brake Rear brake

7,500 kPa

75 kg/cm

2

1,067 psi4,700 – 6,900 kPa

47 – 69 kg/cm

2

669 – 981 psi

Front brake Rear brake

10,000 kPa

100 kg/cm

2

1,422 psi5,400 – 7,700 kPa

54 – 77 kg/cm

2

768 – 1,094 psi

Page 322 of 698

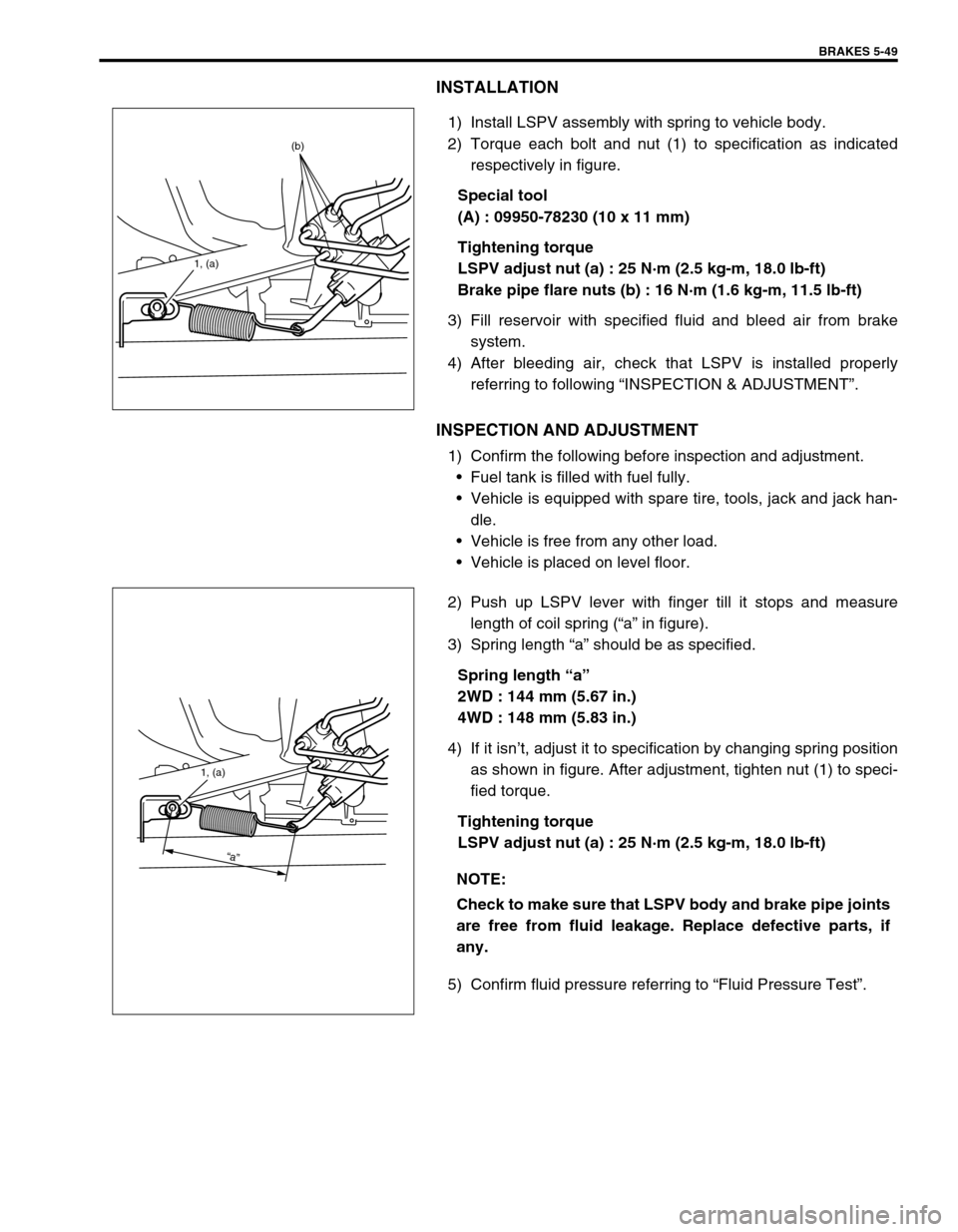

BRAKES 5-49

INSTALLATION

1) Install LSPV assembly with spring to vehicle body.

2) Torque each bolt and nut (1) to specification as indicated

respectively in figure.

Special tool

(A) : 09950-78230 (10 x 11 mm)

Tightening torque

LSPV adjust nut (a) : 25 N·m (2.5 kg-m, 18.0 lb-ft)

Brake pipe flare nuts (b) : 16 N·m (1.6 kg-m, 11.5 lb-ft)

3) Fill reservoir with specified fluid and bleed air from brake

system.

4) After bleeding air, check that LSPV is installed properly

referring to following “INSPECTION & ADJUSTMENT”.

INSPECTION AND ADJUSTMENT

1) Confirm the following before inspection and adjustment.

Fuel tank is filled with fuel fully.

Vehicle is equipped with spare tire, tools, jack and jack han-

dle.

Vehicle is free from any other load.

Vehicle is placed on level floor.

2) Push up LSPV lever with finger till it stops and measure

length of coil spring (“a” in figure).

3) Spring length “a” should be as specified.

Spring length “a”

2WD : 144 mm (5.67 in.)

4WD : 148 mm (5.83 in.)

4) If it isn’t, adjust it to specification by changing spring position

as shown in figure. After adjustment, tighten nut (1) to speci-

fied torque.

Tightening torque

LSPV adjust nut (a) : 25 N·m (2.5 kg-m, 18.0 lb-ft)

5) Confirm fluid pressure referring to “Fluid Pressure Test”.

1, (a)

(b)

NOTE:

Check to make sure that LSPV body and brake pipe joints

are free from fluid leakage. Replace defective parts, if

any.

1, (a)

“a”

Page 350 of 698

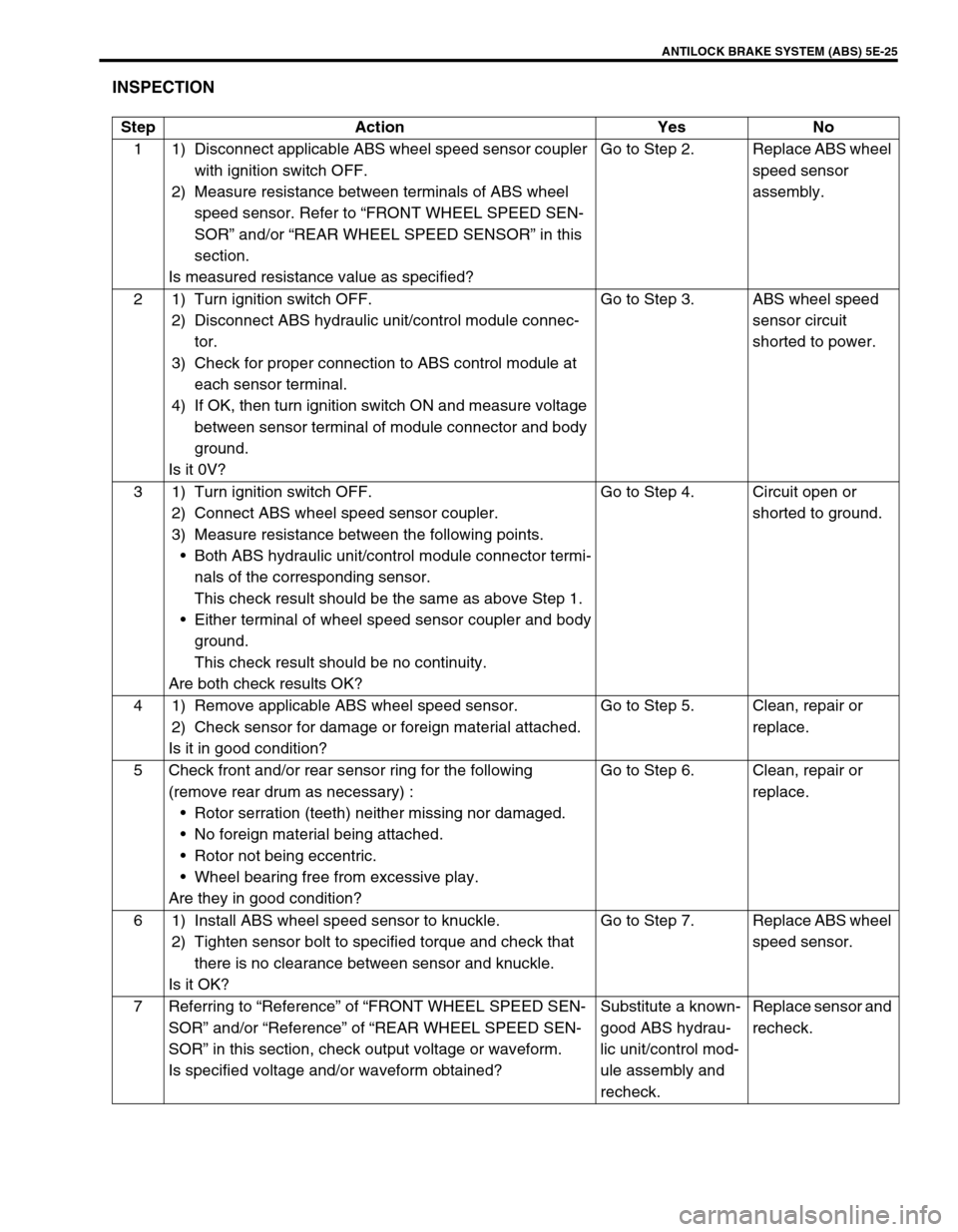

ANTILOCK BRAKE SYSTEM (ABS) 5E-25

INSPECTION

Step Action Yes No

1 1) Disconnect applicable ABS wheel speed sensor coupler

with ignition switch OFF.

2) Measure resistance between terminals of ABS wheel

speed sensor. Refer to “FRONT WHEEL SPEED SEN-

SOR” and/or “REAR WHEEL SPEED SENSOR” in this

section.

Is measured resistance value as specified?Go to Step 2. Replace ABS wheel

speed sensor

assembly.

2 1) Turn ignition switch OFF.

2) Disconnect ABS hydraulic unit/control module connec-

tor.

3) Check for proper connection to ABS control module at

each sensor terminal.

4) If OK, then turn ignition switch ON and measure voltage

between sensor terminal of module connector and body

ground.

Is it 0V?Go to Step 3. ABS wheel speed

sensor circuit

shorted to power.

3 1) Turn ignition switch OFF.

2) Connect ABS wheel speed sensor coupler.

3) Measure resistance between the following points.

Both ABS hydraulic unit/control module connector termi-

nals of the corresponding sensor.

This check result should be the same as above Step 1.

Either terminal of wheel speed sensor coupler and body

ground.

This check result should be no continuity.

Are both check results OK?Go to Step 4. Circuit open or

shorted to ground.

4 1) Remove applicable ABS wheel speed sensor.

2) Check sensor for damage or foreign material attached.

Is it in good condition?Go to Step 5. Clean, repair or

replace.

5 Check front and/or rear sensor ring for the following

(remove rear drum as necessary) :

Rotor serration (teeth) neither missing nor damaged.

No foreign material being attached.

Rotor not being eccentric.

Wheel bearing free from excessive play.

Are they in good condition?Go to Step 6. Clean, repair or

replace.

6 1) Install ABS wheel speed sensor to knuckle.

2) Tighten sensor bolt to specified torque and check that

there is no clearance between sensor and knuckle.

Is it OK?Go to Step 7. Replace ABS wheel

speed sensor.

7 Referring to “Reference” of “FRONT WHEEL SPEED SEN-

SOR” and/or “Reference” of “REAR WHEEL SPEED SEN-

SOR” in this section, check output voltage or waveform.

Is specified voltage and/or waveform obtained?Substitute a known-

good ABS hydrau-

lic unit/control mod-

ule assembly and

recheck.Replace sensor and

recheck.

Page 371 of 698

6-2 ENGINE GENERAL INFORMATION AND DIAGNOSIS

ENGINE DIAGNOSIS ......................................... 6-6

GENERAL DESCRIPTION ............................. 6-6

ON-BOARD DIAGNOSTIC SYSTEM

(VEHICLE WITH IMMOBILIZER INDICATOR

LAMP) ............................................................. 6-7

ON-BOARD DIAGNOSTIC SYSTEM

(VEHICLE WITHOUT IMMOBILIZER

INDICATOR LAMP) ...................................... 6-10

PRECAUTION IN DIAGNOSING

TROUBLE ..................................................... 6-11

ENGINE DIAGNOSTIC FLOW TABLE ......... 6-12

CUSTOMER PROBLEM INSPECTION

FORM (EXAMPLE) ................................... 6-14

MALFUNCTION INDICATOR LAMP (MIL)

CHECK...................................................... 6-15

DIAGNOSTIC TROUBLE CODE (DTC)

CHECK...................................................... 6-15

DIAGNOSTIC TROUBLE CODE (DTC)

CLEARANCE ............................................ 6-16

DIAGNOSTIC TROUBLE CODE (DTC)

TABLE ....................................................... 6-17

FAIL-SAFE TABLE.................................... 6-20

VISUAL INSPECTION .............................. 6-22

ENGINE BASIC INSPECTION.................. 6-23

ENGINE DIAGNOSIS TABLE ................... 6-26

SCAN TOOL DATA....................................... 6-31

INSPECTION OF ECM AND ITS

CIRCUITS ..................................................... 6-36

ECM VOLTAGE VALUES TABLE............. 6-37

TERMINAL RESISTANCE TABLE............ 6-43

COMPONENT LOCATION ........................... 6-45

TABLE A-1 MALFUNCTION INDICATOR

LAMP CIRCUIT CHECK - LAMP DOES NOT

COME “ON” AT IGNITION SWITCH ON

(BUT ENGINE AT STOP) ............................. 6-46

TABLE A-2 MALFUNCTION INDICATOR

LAMP CIRCUIT CHECK - LAMP REMAINS

“ON” AFTER ENGINE STARTS ................... 6-47

TABLE A-3 MIL CHECK - MIL FLASHES

AT IGNITION SWITCH ON (VEHICLE

WITHOUT IMMOBILIZER INDICATOR

LAMP) ........................................................... 6-48

TABLE A-4 MIL CHECK - MIL DOES NOT

FLASH OR JUST REMAINS ON EVEN

WITH GROUNDING DIAGNOSIS SWITCH

TERMINAL (VEHICLE WITHOUT

IMMOBILIZER INDICATOR LAMP) .............. 6-48

TABLE A-5 ECM POWER AND GROUND

CIRCUIT CHECK - MIL DOESN’T LIGHT

AT IGNITION SWITCH ON AND ENGINE

DOESN’T START THOUGH IT IS

CRANKED UP .............................................. 6-49

DTC P0105 (DTC NO.11) MANIFOLD

ABSOLUTE PRESSURE (MAP) CIRCUIT

MALFUNCTION ............................................ 6-52

DTC P0110 (DTC NO.18) INTAKE AIR

TEMP. (IAT) CIRCUIT MALFUNCTION ....... 6-55

DTC P0115 (DTC NO.19) ENGINE

COOLANT TEMPERATURE (ECT) CIRCUIT

MALFUNCTION ............................................ 6-57DTC P0120 (DTC NO.13) THROTTLE

POSITION CIRCUIT MALFUNCTION ........... 6-60

DTC P0121 THROTTLE POSITION CIRCUIT

RANGE/PERFORMANCE PROBLEM .......... 6-63

DTC P0130 (DTC NO.14) HEATED OXYGEN

SENSOR (HO2S) CIRCUIT MALFUNCTION

(SENSOR-1) .................................................. 6-66

DTC P0133 HEATED OXYGEN SENSOR

(HO2S) CIRCUIT SLOW RESPONSE

(SENSOR-1) .................................................. 6-68

DTC P0134 HEATED OXYGEN SENSOR

(HO2S) CIRCUIT NO ACTIVITY DETECTED

(SENSOR-1) .................................................. 6-69

DTC P0135 (DTC NO.14) HEATED OXYGEN

SENSOR (HO2S) HEATER CIRCUIT

MALFUNCTION (SENSOR-1) ....................... 6-70

DTC P0136 HEATED OXYGEN SENSOR

(HO2S) CIRCUIT MALFUNCTION

(SENSOR-2) .................................................. 6-72

DTC P0141 HEATED OXYGEN SENSOR

(HO2S) HEATER CIRCUIT MALFUNCTION

(SENSOR-2) .................................................. 6-74

DTC P0171 FUEL SYSTEM TOO LEAN ....... 6-76

DTC P0172 FUEL SYSTEM TOO RICH ....... 6-76

DTC P0300 RANDOM MISFIRE DETECTED

(MISFIRE DETECTED AT 2 OR MORE

CYLINDERS) ................................................. 6-81

DTC P0301 CYLINDER 1 MISFIRE

DETECTED ................................................... 6-81

DTC P0302 CYLINDER 2 MISFIRE

DETECTED ................................................... 6-81

DTC P0303 CYLINDER 3 MISFIRE

DETECTED ................................................... 6-81

DTC P0304 CYLINDER 4 MISFIRE

DETECTED ................................................... 6-81

DTC P0325 (DTC NO.17) KNOCK SENSOR

CIRCUIT MALFUNCTION ............................. 6-86

DTC P0335 (DTC NO.23) CRANKSHAFT

POSITION (CKP) SENSOR CIRCUIT

MALFUNCTION ............................................. 6-88

DTC P0340 (DTC NO.15) CAMSHAFT

POSITION (CMP) SENSOR CIRCUIT

MALFUNCTION ............................................. 6-91

DTC P0400 EXHAUST GAS

RECIRCULATION FLOW MALFUNCTION ... 6-94

DTC P0420 CATALYST SYSTEM

EFFICIENCY BELOW THRESHOLD ............ 6-97

DTC P0443 PURGE CONTROL VALVE

CIRCUIT MALFUNCTION ........................... 6-100

DTC P0480 RADIATOR COOLING FAN

CONTROL SYSTEM MALFUNCTION ........ 6-101

DTC P0500 (DTC NO.16) VEHICLE SPEED

SENSOR (VSS) MALFUNCTION ................ 6-103

DTC P0505 (DTC NO.26) IDLE CONTROL

SYSTEM MALFUNCTION ........................... 6-105

DTC P1450 BAROMETRIC PRESSURE

SENSOR LOW/HIGH INPUT....................... 6-108

DTC P1451 BAROMETRIC PRESSURE

SENSOR PERFORMANCE PROBLEM ...... 6-108

Page 380 of 698

ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-11

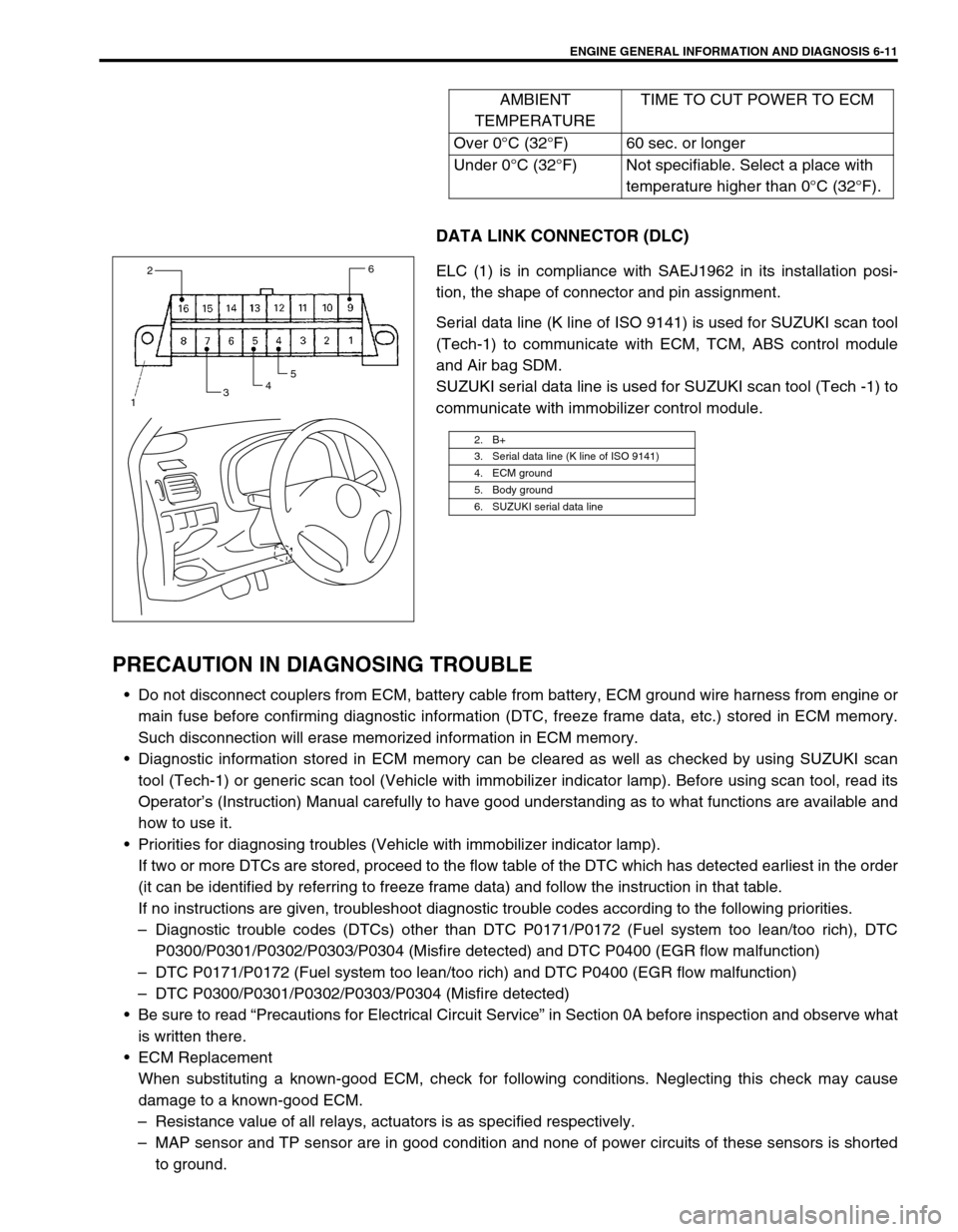

DATA LINK CONNECTOR (DLC)

ELC (1) is in compliance with SAEJ1962 in its installation posi-

tion, the shape of connector and pin assignment.

Serial data line (K line of ISO 9141) is used for SUZUKI scan tool

(Tech-1) to communicate with ECM, TCM, ABS control module

and Air bag SDM.

SUZUKI serial data line is used for SUZUKI scan tool (Tech -1) to

communicate with immobilizer control module.

PRECAUTION IN DIAGNOSING TROUBLE

Do not disconnect couplers from ECM, battery cable from battery, ECM ground wire harness from engine or

main fuse before confirming diagnostic information (DTC, freeze frame data, etc.) stored in ECM memory.

Such disconnection will erase memorized information in ECM memory.

Diagnostic information stored in ECM memory can be cleared as well as checked by using SUZUKI scan

tool (Tech-1) or generic scan tool (Vehicle with immobilizer indicator lamp). Before using scan tool, read its

Operator’s (Instruction) Manual carefully to have good understanding as to what functions are available and

how to use it.

Priorities for diagnosing troubles (Vehicle with immobilizer indicator lamp).

If two or more DTCs are stored, proceed to the flow table of the DTC which has detected earliest in the order

(it can be identified by referring to freeze frame data) and follow the instruction in that table.

If no instructions are given, troubleshoot diagnostic trouble codes according to the following priorities.

–Diagnostic trouble codes (DTCs) other than DTC P0171/P0172 (Fuel system too lean/too rich), DTC

P0300/P0301/P0302/P0303/P0304 (Misfire detected) and DTC P0400 (EGR flow malfunction)

–DTC P0171/P0172 (Fuel system too lean/too rich) and DTC P0400 (EGR flow malfunction)

–DTC P0300/P0301/P0302/P0303/P0304 (Misfire detected)

Be sure to read “Precautions for Electrical Circuit Service” in Section 0A before inspection and observe what

is written there.

ECM Replacement

When substituting a known-good ECM, check for following conditions. Neglecting this check may cause

damage to a known-good ECM.

–Resistance value of all relays, actuators is as specified respectively.

–MAP sensor and TP sensor are in good condition and none of power circuits of these sensors is shorted

to ground.AMBIENT

TEMPERATURETIME TO CUT POWER TO ECM

Over 0°C (32°F) 60 sec. or longer

Under 0°C (32°F) Not specifiable. Select a place with

temperature higher than 0°C (32°F).

2. B+

3. Serial data line (K line of ISO 9141)

4. ECM ground

5. Body ground

6. SUZUKI serial data line

2

3456

1