Ecm SUZUKI SWIFT 2000 1.G RG413 Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 377 of 698

6-8 ENGINE GENERAL INFORMATION AND DIAGNOSIS

FREEZE FRAME DATA

ECM stores the engine and driving conditions (in the from of data

as shown in the figure) at the moment of the detection of a mal-

function in its memory. This data is called “Freeze frame data”.

Therefore, it is possible to know engine and driving conditions

(e.g., whether the engine was warm or not, whether the vehicle

was running or stopped, whether air/fuel mixture was lean or rich)

when a malfunction was detected by checking the freeze frame

data. Also, ECM has a function to store each freeze frame data

for three different malfunctions in the order as the malfunction is

detected. Utilizing this function, it is possible to know the order of

malfunctions that have been detected. Its use is helpful when

rechecking or diagnosing a trouble.

Priority of freeze frame data :

ECM has 4 frames where the freeze frame data can be stored.

The first frame stores the freeze frame data of the malfunction

which was detected first. However, the freeze frame data stored

in this frame is updated according to the priority described below.

(If malfunction as described in the upper square “1” below is

detected while the freeze frame data in the lower square “2” has

been stored, the freeze frame data “2” will be updated by the

freeze frame data “1”.)

In the 2nd through the 4th frames, the freeze frame data of each

malfunction is stored in the order as the malfunction is detected.

These data are not updated.

Shown in the table below are examples of how freeze frame data

are stored when two or more malfunctions are detected.

[A] : An Example of Freeze Frame Data

[B] : 1st, 2nd or 3rd in parentheses here represents which position in the order

the malfunction is detected.

PRIORITY FREEZE FRAME DATA IN FRAME 1

1 Freeze frame data at initial detection of mal-

function among misfire detected (P0300-

P0304), fuel system too lean (P0171) and fuel

system too rich (P0172)

2 Freeze frame data when a malfunction other

than those in “1” above is detected

Page 378 of 698

ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-9

Freeze Frame Data Clearance :

The freeze frame data is cleared at the same time as clearance of

diagnostic trouble code (DTC).

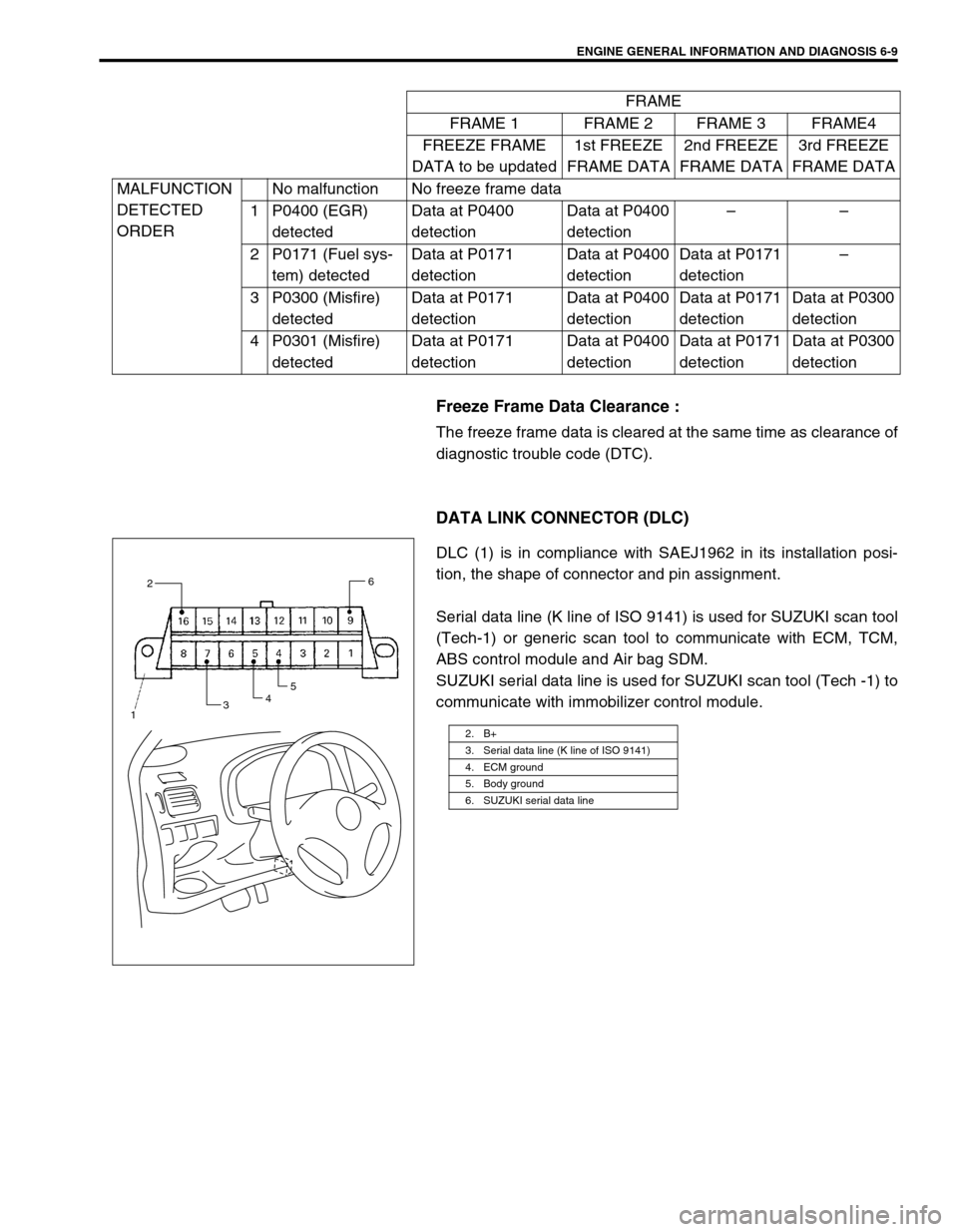

DATA LINK CONNECTOR (DLC)

DLC (1) is in compliance with SAEJ1962 in its installation posi-

tion, the shape of connector and pin assignment.

Serial data line (K line of ISO 9141) is used for SUZUKI scan tool

(Tech-1) or generic scan tool to communicate with ECM, TCM,

ABS control module and Air bag SDM.

SUZUKI serial data line is used for SUZUKI scan tool (Tech -1) to

communicate with immobilizer control module.FRAME

FRAME 1 FRAME 2 FRAME 3 FRAME4

FREEZE FRAME

DATA to be updated1st FREEZE

FRAME DATA2nd FREEZE

FRAME DATA3rd FREEZE

FRAME DATA

MALFUNCTION

DETECTED

ORDERNo malfunction No freeze frame data

1 P0400 (EGR)

detectedData at P0400

detectionData at P0400

detection––

2 P0171 (Fuel sys-

tem) detectedData at P0171

detectionData at P0400

detectionData at P0171

detection–

3 P0300 (Misfire)

detectedData at P0171

detectionData at P0400

detectionData at P0171

detectionData at P0300

detection

4 P0301 (Misfire)

detectedData at P0171

detectionData at P0400

detectionData at P0171

detectionData at P0300

detection

2. B+

3. Serial data line (K line of ISO 9141)

4. ECM ground

5. Body ground

6. SUZUKI serial data line

2

3456

1

Page 379 of 698

6-10 ENGINE GENERAL INFORMATION AND DIAGNOSIS

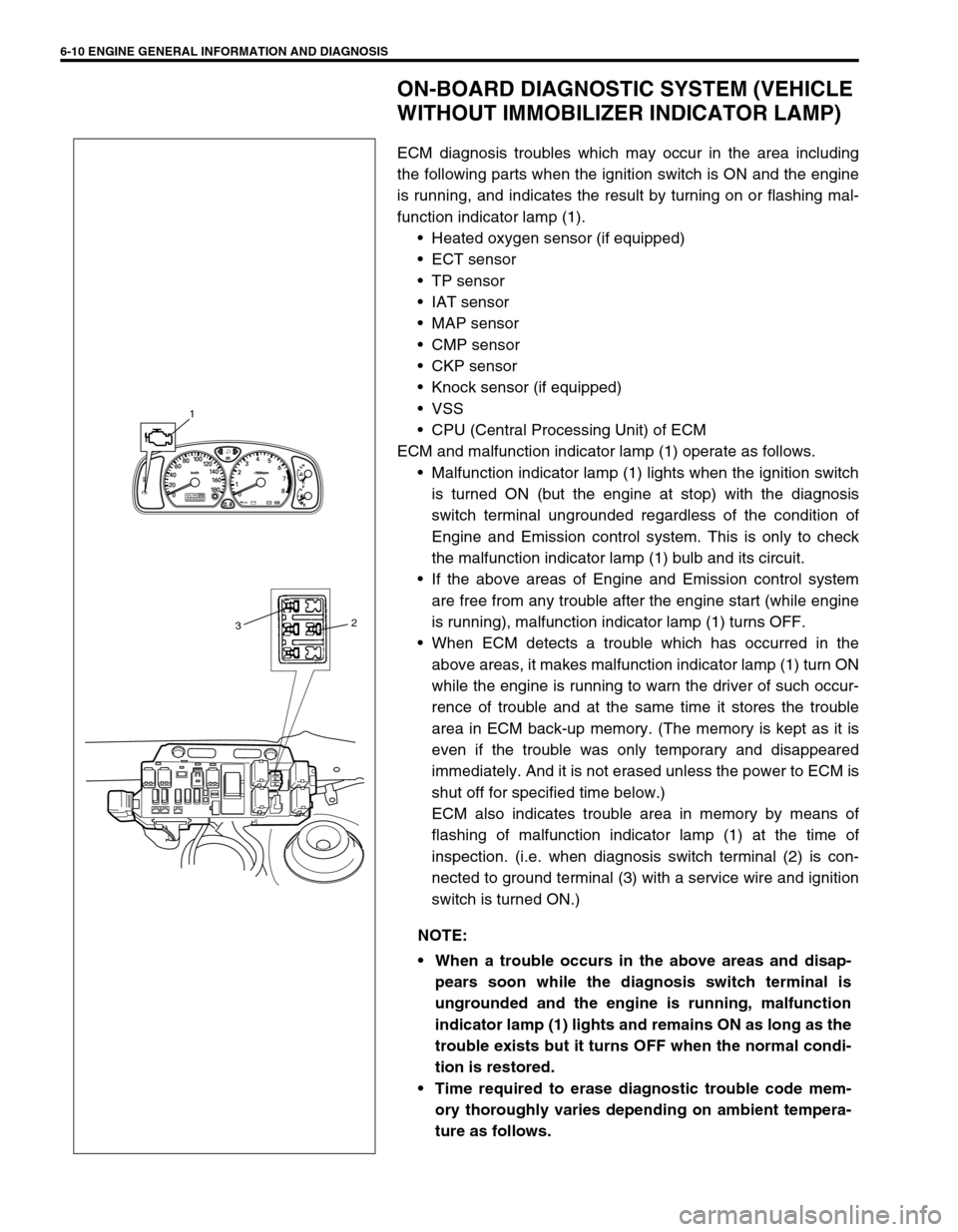

ON-BOARD DIAGNOSTIC SYSTEM (VEHICLE

WITHOUT IMMOBILIZER INDICATOR LAMP)

ECM diagnosis troubles which may occur in the area including

the following parts when the ignition switch is ON and the engine

is running, and indicates the result by turning on or flashing mal-

function indicator lamp (1).

Heated oxygen sensor (if equipped)

ECT sensor

TP sensor

IAT sensor

MAP sensor

CMP sensor

CKP sensor

Knock sensor (if equipped)

VSS

CPU (Central Processing Unit) of ECM

ECM and malfunction indicator lamp (1) operate as follows.

Malfunction indicator lamp (1) lights when the ignition switch

is turned ON (but the engine at stop) with the diagnosis

switch terminal ungrounded regardless of the condition of

Engine and Emission control system. This is only to check

the malfunction indicator lamp (1) bulb and its circuit.

If the above areas of Engine and Emission control system

are free from any trouble after the engine start (while engine

is running), malfunction indicator lamp (1) turns OFF.

When ECM detects a trouble which has occurred in the

above areas, it makes malfunction indicator lamp (1) turn ON

while the engine is running to warn the driver of such occur-

rence of trouble and at the same time it stores the trouble

area in ECM back-up memory. (The memory is kept as it is

even if the trouble was only temporary and disappeared

immediately. And it is not erased unless the power to ECM is

shut off for specified time below.)

ECM also indicates trouble area in memory by means of

flashing of malfunction indicator lamp (1) at the time of

inspection. (i.e. when diagnosis switch terminal (2) is con-

nected to ground terminal (3) with a service wire and ignition

switch is turned ON.)

NOTE:

When a trouble occurs in the above areas and disap-

pears soon while the diagnosis switch terminal is

ungrounded and the engine is running, malfunction

indicator lamp (1) lights and remains ON as long as the

trouble exists but it turns OFF when the normal condi-

tion is restored.

Time required to erase diagnostic trouble code mem-

ory thoroughly varies depending on ambient tempera-

ture as follows.

ODO TRIP AB

1

32

Page 380 of 698

ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-11

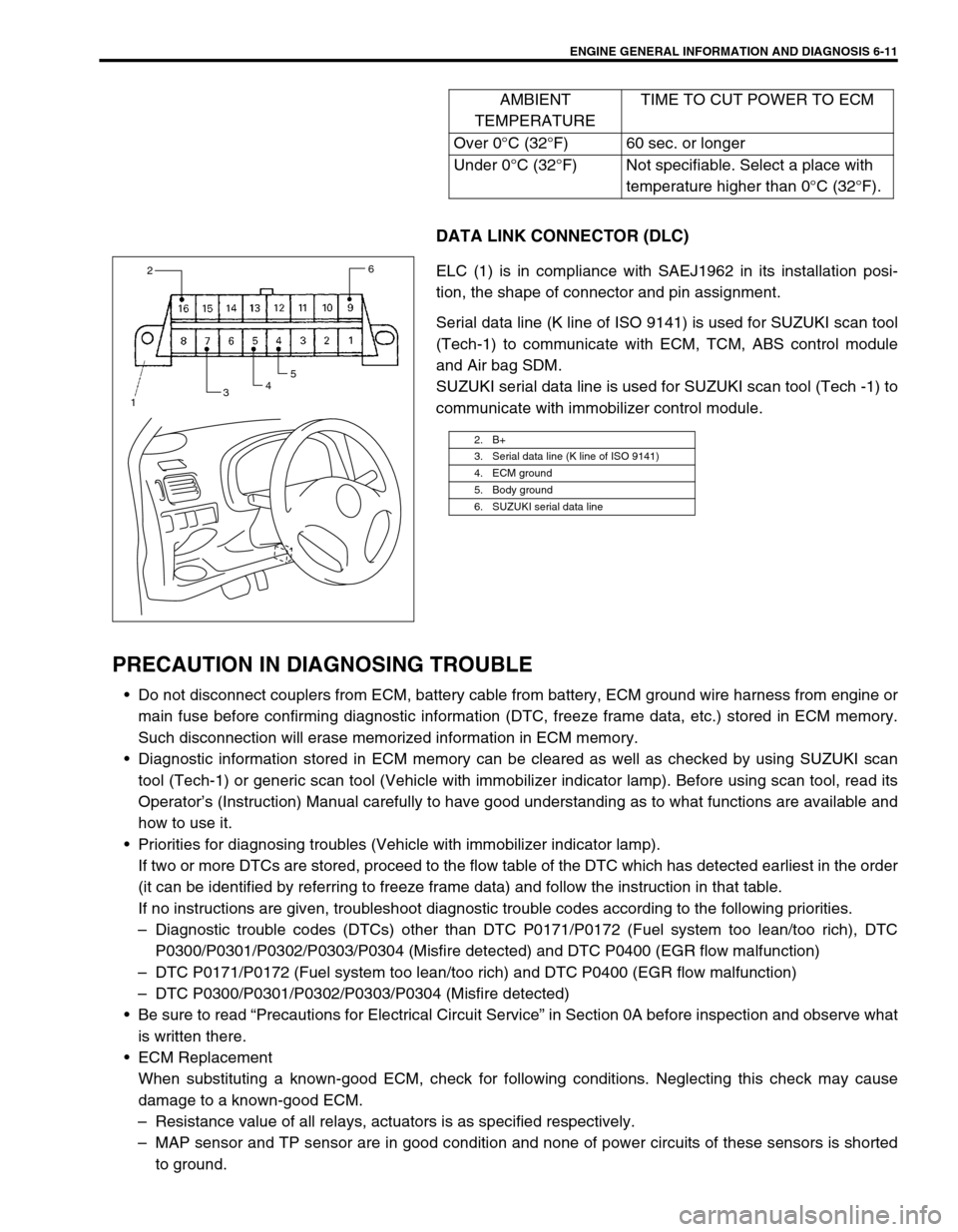

DATA LINK CONNECTOR (DLC)

ELC (1) is in compliance with SAEJ1962 in its installation posi-

tion, the shape of connector and pin assignment.

Serial data line (K line of ISO 9141) is used for SUZUKI scan tool

(Tech-1) to communicate with ECM, TCM, ABS control module

and Air bag SDM.

SUZUKI serial data line is used for SUZUKI scan tool (Tech -1) to

communicate with immobilizer control module.

PRECAUTION IN DIAGNOSING TROUBLE

Do not disconnect couplers from ECM, battery cable from battery, ECM ground wire harness from engine or

main fuse before confirming diagnostic information (DTC, freeze frame data, etc.) stored in ECM memory.

Such disconnection will erase memorized information in ECM memory.

Diagnostic information stored in ECM memory can be cleared as well as checked by using SUZUKI scan

tool (Tech-1) or generic scan tool (Vehicle with immobilizer indicator lamp). Before using scan tool, read its

Operator’s (Instruction) Manual carefully to have good understanding as to what functions are available and

how to use it.

Priorities for diagnosing troubles (Vehicle with immobilizer indicator lamp).

If two or more DTCs are stored, proceed to the flow table of the DTC which has detected earliest in the order

(it can be identified by referring to freeze frame data) and follow the instruction in that table.

If no instructions are given, troubleshoot diagnostic trouble codes according to the following priorities.

–Diagnostic trouble codes (DTCs) other than DTC P0171/P0172 (Fuel system too lean/too rich), DTC

P0300/P0301/P0302/P0303/P0304 (Misfire detected) and DTC P0400 (EGR flow malfunction)

–DTC P0171/P0172 (Fuel system too lean/too rich) and DTC P0400 (EGR flow malfunction)

–DTC P0300/P0301/P0302/P0303/P0304 (Misfire detected)

Be sure to read “Precautions for Electrical Circuit Service” in Section 0A before inspection and observe what

is written there.

ECM Replacement

When substituting a known-good ECM, check for following conditions. Neglecting this check may cause

damage to a known-good ECM.

–Resistance value of all relays, actuators is as specified respectively.

–MAP sensor and TP sensor are in good condition and none of power circuits of these sensors is shorted

to ground.AMBIENT

TEMPERATURETIME TO CUT POWER TO ECM

Over 0°C (32°F) 60 sec. or longer

Under 0°C (32°F) Not specifiable. Select a place with

temperature higher than 0°C (32°F).

2. B+

3. Serial data line (K line of ISO 9141)

4. ECM ground

5. Body ground

6. SUZUKI serial data line

2

3456

1

Page 382 of 698

ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-13

1. CUSTOMER COMPLAINT ANALYSIS

Record details of the problem (failure, complaint) and how it occurred as described by the customer. For this

purpose, use of such an inspection form will facilitate collecting information to the point required for proper anal-

ysis and diagnosis.

2. DTC/FREEZE FRAME DATA CHECK, RECORD AND CLEARANCE

First, check DTC (including pending DTC), referring to “DTC check” section. If DTC is indicated, print it and

freeze frame data or write them down and then clear them by referring to “DTC clearance” section. DTC indi-

cates malfunction that occurred in the system but does not indicate whether it exists now or it occurred in the

past and the normal condition has been restored now. To check which case applies, check the symptom in

question according to Step 4 and recheck DTC according to Step 5.

Attempt to diagnose a trouble based on DTC in this step only or failure to clear the DTC in this step will lead to

incorrect diagnosis, trouble diagnosis of a normal circuit or difficulty in troubleshooting.

3. and 4. VISUAL INSPECTION

As a preliminary step, be sure to perform visual check of the items that support proper function of the engine

referring to “Visual Inspection” section.

5. TROUBLE SYMPTOM CONFIRMATION

Based on information obtained in Step 1 Customer complaint analysis and Step 2 DTC/freeze frame data check,

confirm trouble symptoms. Also, reconfirm DTC according to “DTC Confirmation Procedure” described in each

DTC Diagnosis section.

6. and 7. RECHECKING AND RECORD OF DTC/FREEZE FRAME DATA

Refer to “DTC check” section for checking procedure.

8. ENGINE BASIC INSPECTION AND ENGINE DIAGNOSIS TABLE

Perform basic engine check according to the “Engine Basic Inspection Flow Table” first. When the end of the

flow table has been reached, check the parts of the system suspected as a possible cause referring to ENGINE

DIAGNOSIS TABLE and based on symptoms appearing on the vehicle (symptoms obtained through steps of

customer complaint analysis, trouble symptom confirmation and/or basic engine check) and repair or replace

faulty parts, if any.

9. TROUBLESHOOTING FOR DTC (See each DTC Diag. Flow Table)

Based on the DTC indicated in Step 5 and referring to the applicable DTC diag. flow table in this section, locate

the cause of the trouble, namely in a sensor, switch, wire harness, connector, actuator, ECM or other part and

repair or replace faulty parts.

10. CHECK FOR INTERMITTENT PROBLEM

Check parts where an intermittent trouble is easy to occur (e.g., wire harness, connector, etc.), referring to

“INTERMITTENT AND POOR CONNECTION” in Section 0A and related circuit of DTC recorded in Step 2.

11. FINAL CONFIRMATION TEST

Confirm that the problem symptom has gone and the engine is free from any abnormal conditions. If what has

been repaired is related to the DTC, clear the DTC once, perform DTC confirmation procedure and confirm that

no DTC is indicated.NOTE:

If only Automatic transmission DTCs (P0702-P1709) or Immobilizer DTCs (P1620-P1623) are indicated

in this step, perform trouble diagnosis according to “Diagnosis” in Section 7B or Section 8G.

Page 384 of 698

ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-15

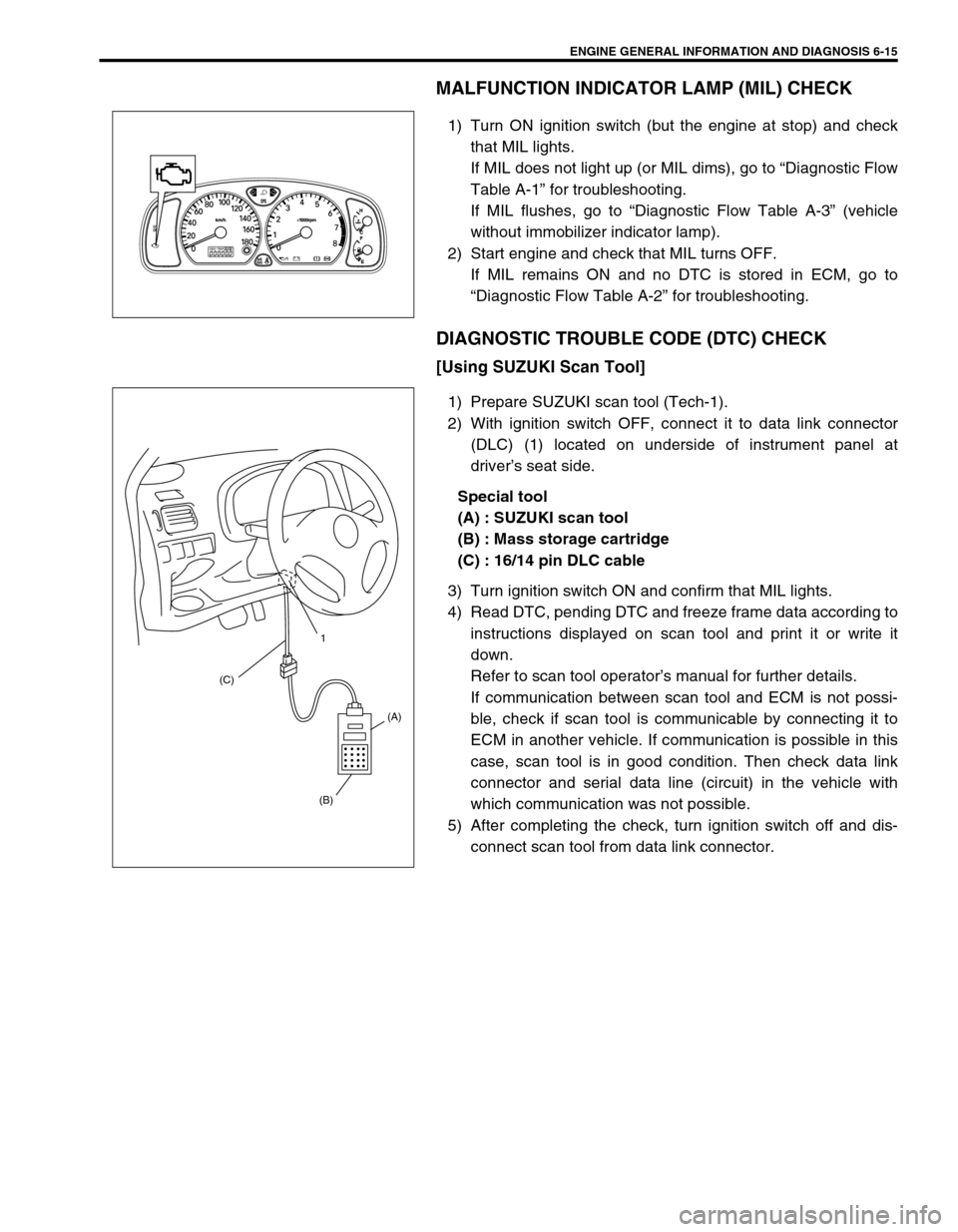

MALFUNCTION INDICATOR LAMP (MIL) CHECK

1) Turn ON ignition switch (but the engine at stop) and check

that MIL lights.

If MIL does not light up (or MIL dims), go to “Diagnostic Flow

Table A-1” for troubleshooting.

If MIL flushes, go to “Diagnostic Flow Table A-3” (vehicle

without immobilizer indicator lamp).

2) Start engine and check that MIL turns OFF.

If MIL remains ON and no DTC is stored in ECM, go to

“Diagnostic Flow Table A-2” for troubleshooting.

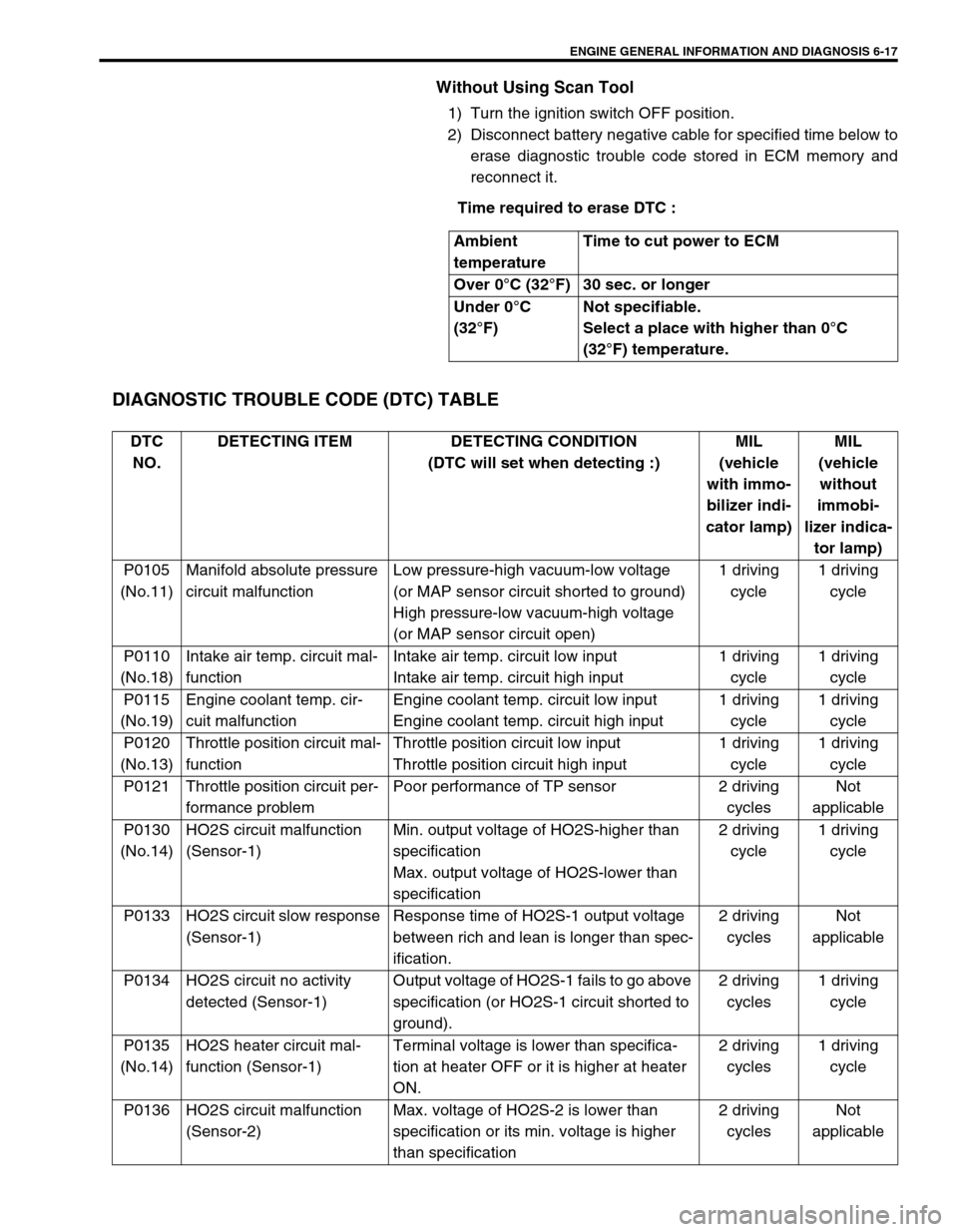

DIAGNOSTIC TROUBLE CODE (DTC) CHECK

[Using SUZUKI Scan Tool]

1) Prepare SUZUKI scan tool (Tech-1).

2) With ignition switch OFF, connect it to data link connector

(DLC) (1) located on underside of instrument panel at

driver’s seat side.

Special tool

(A) : SUZUKI scan tool

(B) : Mass storage cartridge

(C) : 16/14 pin DLC cable

3) Turn ignition switch ON and confirm that MIL lights.

4) Read DTC, pending DTC and freeze frame data according to

instructions displayed on scan tool and print it or write it

down.

Refer to scan tool operator’s manual for further details.

If communication between scan tool and ECM is not possi-

ble, check if scan tool is communicable by connecting it to

ECM in another vehicle. If communication is possible in this

case, scan tool is in good condition. Then check data link

connector and serial data line (circuit) in the vehicle with

which communication was not possible.

5) After completing the check, turn ignition switch off and dis-

connect scan tool from data link connector.

ODO TRIP AB

1

(A)

(B) (C)

Page 385 of 698

![SUZUKI SWIFT 2000 1.G RG413 Service Owners Manual 6-16 ENGINE GENERAL INFORMATION AND DIAGNOSIS

[Without Using SUZUKI Scan Tool] (Vehicle without Immo-

bilizer Indicator Lamp)

1) Check malfunction indicator lamp referring to “Malfunction

Indicator SUZUKI SWIFT 2000 1.G RG413 Service Owners Manual 6-16 ENGINE GENERAL INFORMATION AND DIAGNOSIS

[Without Using SUZUKI Scan Tool] (Vehicle without Immo-

bilizer Indicator Lamp)

1) Check malfunction indicator lamp referring to “Malfunction

Indicator](/img/20/7606/w960_7606-384.png)

6-16 ENGINE GENERAL INFORMATION AND DIAGNOSIS

[Without Using SUZUKI Scan Tool] (Vehicle without Immo-

bilizer Indicator Lamp)

1) Check malfunction indicator lamp referring to “Malfunction

Indicator Lamp Check” in this section.

2) With the ignition switch OFF position, disconnect SUZUKI

scan tool if connected and using service wire (4), connect

diagnosis switch terminal (1) to ground terminal (2) in moni-

tor coupler (3).

3) With the ignition switch ON position and leaving engine OFF,

read DTC from flashing pattern of malfunction indicator

lamp. Refer to “Diagnostic Trouble Code Table”.

If lamp remains ON, go to “Diagnostic Flow Table A-4”.

4) After completing the check, turn the ignition switch OFF posi-

tion and disconnect service wire from monitor coupler.

DIAGNOSTIC TROUBLE CODE (DTC) CLEARANCE

Using Scan Tool

1) Connect SUZUKI scan tool (Tech-1) or generic scan tool

(Vehicle with immobilizer indicator lamp) to data link connec-

tor in the same manner as when making this connection for

DTC check.

2) Turn ignition switch ON.

3) Erase DTC and pending DTC according to instructions dis-

played on scan tool. Refer to scan tool operator’s manual for

further details.

4) After completing the clearance, turn ignition switch off and

disconnect scan tool from data link connector. NOTE:

If abnormality or malfunction lies in two or more areas,

malfunction indicator lamp indicates applicable codes

three times each.

And flashing of these codes is repeated as long as

diagnosis terminal is grounded and ignition switch is

held at ON position.

Take a note of diagnostic trouble code indicated first.

2

14

3

NOTE:

DTC and freeze frame data stored in ECM memory are

also cleared in following cases. Be careful not to clear

them before keeping their record.

When power to ECM is cut off (by disconnecting bat-

tery cable, removing fuse or disconnecting ECM con-

nectors)

When the same malfunction (DTC) is not detected

again during 40 engine warm-up cycles. (Vehicle with

immobilizer indicator lamp)

Page 386 of 698

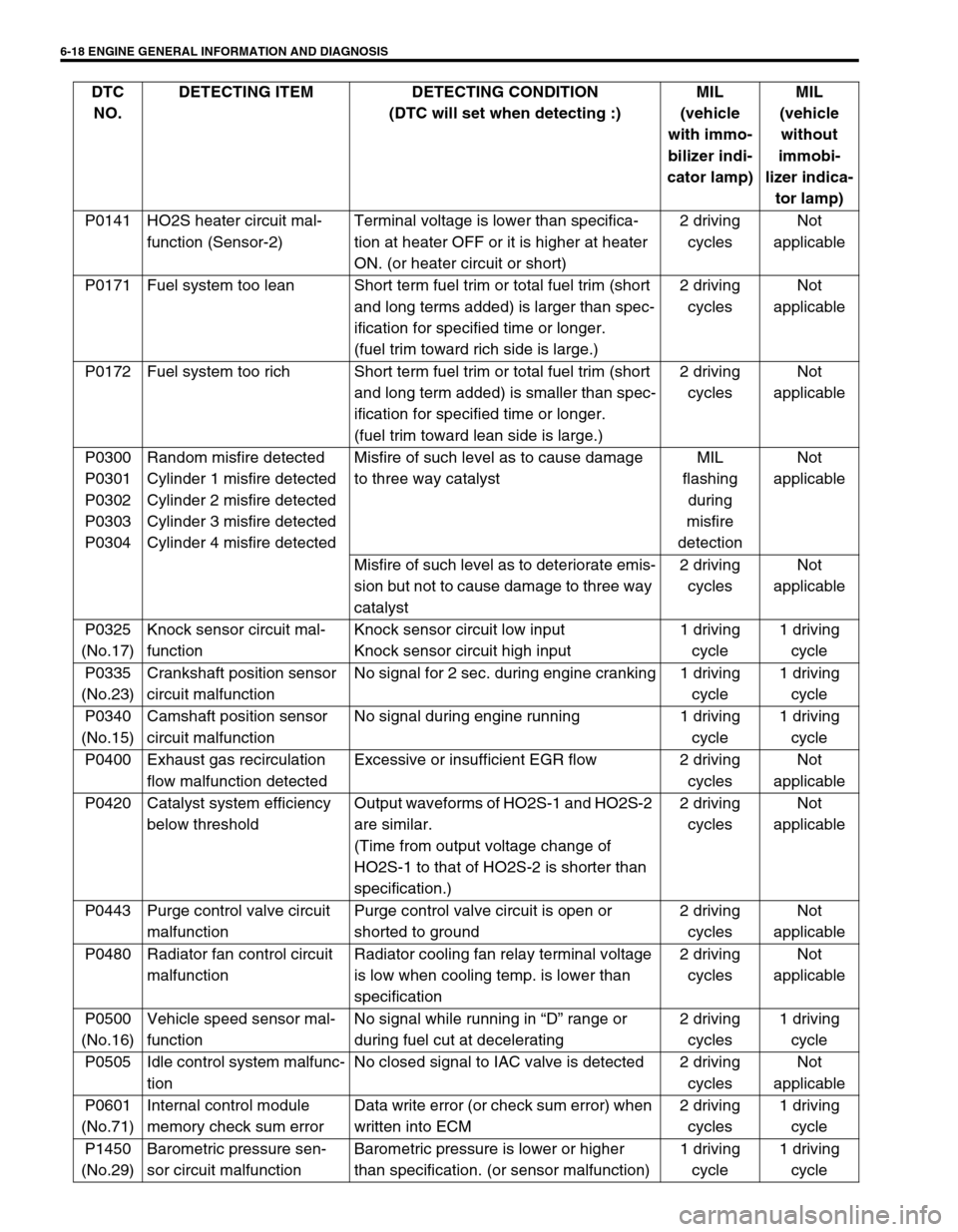

ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-17

Without Using Scan Tool

1) Turn the ignition switch OFF position.

2) Disconnect battery negative cable for specified time below to

erase diagnostic trouble code stored in ECM memory and

reconnect it.

Time required to erase DTC :

DIAGNOSTIC TROUBLE CODE (DTC) TABLE

Ambient

temperatureTime to cut power to ECM

Over 0°C (32°F) 30 sec. or longer

Under 0°C

(32°F)Not specifiable.

Select a place with higher than 0°C

(32°F) temperature.

DTC

NO.DETECTING ITEM DETECTING CONDITION

(DTC will set when detecting :)MIL

(vehicle

with immo-

bilizer indi-

cator lamp)MIL

(vehicle

without

immobi-

lizer indica-

tor lamp)

P0105

(No.11)Manifold absolute pressure

circuit malfunctionLow pressure-high vacuum-low voltage

(or MAP sensor circuit shorted to ground)

High pressure-low vacuum-high voltage

(or MAP sensor circuit open)1 driving

cycle1 driving

cycle

P0110

(No.18)Intake air temp. circuit mal-

functionIntake air temp. circuit low input

Intake air temp. circuit high input1 driving

cycle1 driving

cycle

P0115

(No.19)Engine coolant temp. cir-

cuit malfunctionEngine coolant temp. circuit low input

Engine coolant temp. circuit high input1 driving

cycle1 driving

cycle

P0120

(No.13)Throttle position circuit mal-

functionThrottle position circuit low input

Throttle position circuit high input1 driving

cycle1 driving

cycle

P0121 Throttle position circuit per-

formance problemPoor performance of TP sensor 2 driving

cyclesNot

applicable

P0130

(No.14)HO2S circuit malfunction

(Sensor-1)Min. output voltage of HO2S-higher than

specification

Max. output voltage of HO2S-lower than

specification2 driving

cycle1 driving

cycle

P0133 HO2S circuit slow response

(Sensor-1)Response time of HO2S-1 output voltage

between rich and lean is longer than spec-

ification.2 driving

cyclesNot

applicable

P0134 HO2S circuit no activity

detected (Sensor-1)Output voltage of HO2S-1 fails to go above

specification (or HO2S-1 circuit shorted to

ground).2 driving

cycles1 driving

cycle

P0135

(No.14)HO2S heater circuit mal-

function (Sensor-1)Terminal voltage is lower than specifica-

tion at heater OFF or it is higher at heater

ON.2 driving

cycles1 driving

cycle

P0136 HO2S circuit malfunction

(Sensor-2)Max. voltage of HO2S-2 is lower than

specification or its min. voltage is higher

than specification2 driving

cyclesNot

applicable

Page 387 of 698

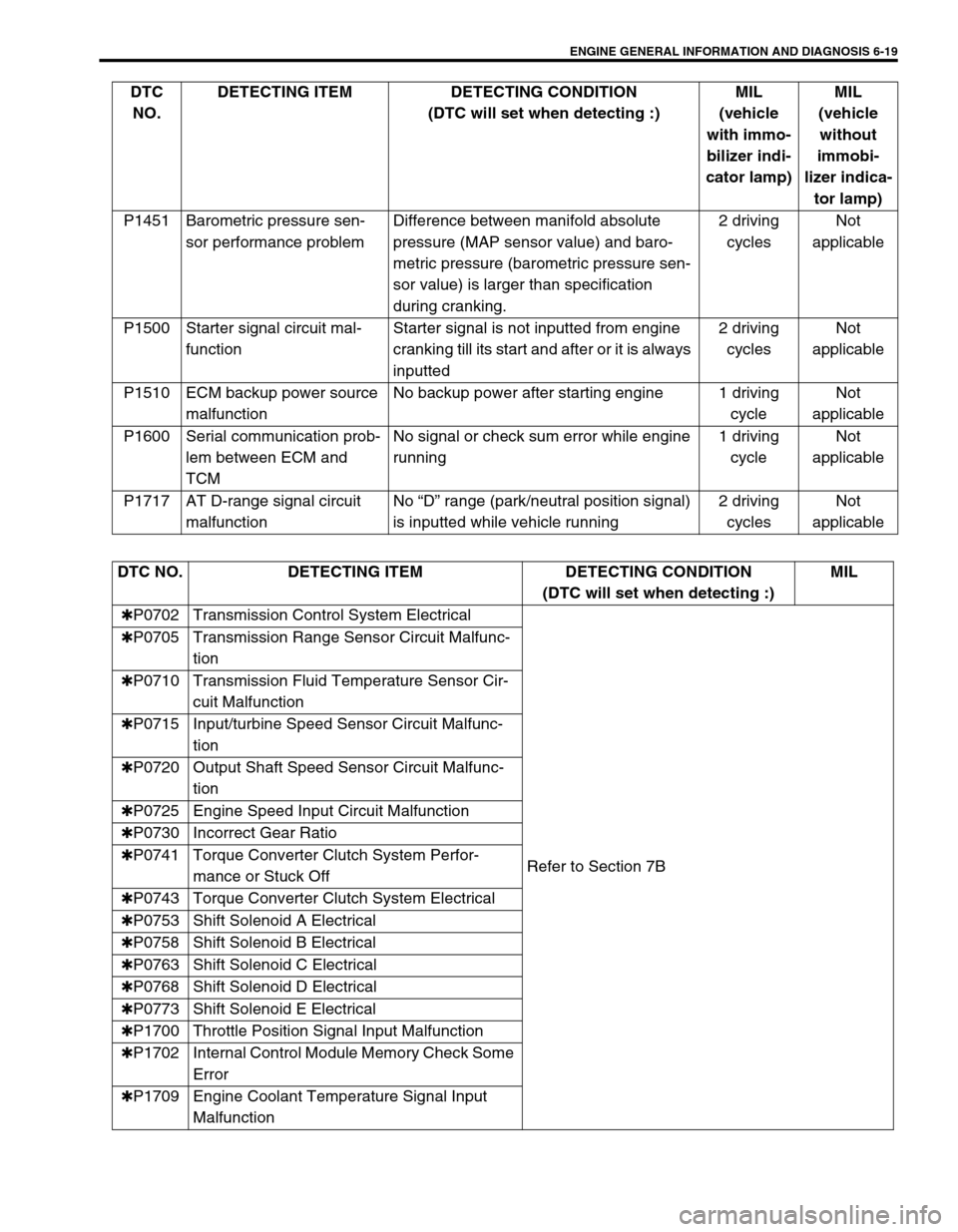

6-18 ENGINE GENERAL INFORMATION AND DIAGNOSIS

P0141 HO2S heater circuit mal-

function (Sensor-2)Terminal voltage is lower than specifica-

tion at heater OFF or it is higher at heater

ON. (or heater circuit or short)2 driving

cyclesNot

applicable

P0171 Fuel system too lean Short term fuel trim or total fuel trim (short

and long terms added) is larger than spec-

ification for specified time or longer.

(fuel trim toward rich side is large.)2 driving

cyclesNot

applicable

P0172 Fuel system too rich Short term fuel trim or total fuel trim (short

and long term added) is smaller than spec-

ification for specified time or longer.

(fuel trim toward lean side is large.)2 driving

cyclesNot

applicable

P0300

P0301

P0302

P0303

P0304Random misfire detected

Cylinder 1 misfire detected

Cylinder 2 misfire detected

Cylinder 3 misfire detected

Cylinder 4 misfire detectedMisfire of such level as to cause damage

to three way catalystMIL

flashing

during

misfire

detectionNot

applicable

Misfire of such level as to deteriorate emis-

sion but not to cause damage to three way

catalyst2 driving

cyclesNot

applicable

P0325

(No.17)Knock sensor circuit mal-

functionKnock sensor circuit low input

Knock sensor circuit high input1 driving

cycle1 driving

cycle

P0335

(No.23)Crankshaft position sensor

circuit malfunctionNo signal for 2 sec. during engine cranking 1 driving

cycle1 driving

cycle

P0340

(No.15)Camshaft position sensor

circuit malfunctionNo signal during engine running 1 driving

cycle1 driving

cycle

P0400 Exhaust gas recirculation

flow malfunction detectedExcessive or insufficient EGR flow 2 driving

cyclesNot

applicable

P0420 Catalyst system efficiency

below thresholdOutput waveforms of HO2S-1 and HO2S-2

are similar.

(Time from output voltage change of

HO2S-1 to that of HO2S-2 is shorter than

specification.)2 driving

cyclesNot

applicable

P0443 Purge control valve circuit

malfunctionPurge control valve circuit is open or

shorted to ground2 driving

cyclesNot

applicable

P0480 Radiator fan control circuit

malfunctionRadiator cooling fan relay terminal voltage

is low when cooling temp. is lower than

specification2 driving

cyclesNot

applicable

P0500

(No.16)Vehicle speed sensor mal-

functionNo signal while running in “D” range or

during fuel cut at decelerating2 driving

cycles1 driving

cycle

P0505 Idle control system malfunc-

tionNo closed signal to IAC valve is detected 2 driving

cyclesNot

applicable

P0601

(No.71)Internal control module

memory check sum errorData write error (or check sum error) when

written into ECM2 driving

cycles1 driving

cycle

P1450

(No.29)Barometric pressure sen-

sor circuit malfunctionBarometric pressure is lower or higher

than specification. (or sensor malfunction)1 driving

cycle1 driving

cycle DTC

NO.DETECTING ITEM DETECTING CONDITION

(DTC will set when detecting :)MIL

(vehicle

with immo-

bilizer indi-

cator lamp)MIL

(vehicle

without

immobi-

lizer indica-

tor lamp)

Page 388 of 698

ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-19

P1451 Barometric pressure sen-

sor performance problemDifference between manifold absolute

pressure (MAP sensor value) and baro-

metric pressure (barometric pressure sen-

sor value) is larger than specification

during cranking.2 driving

cyclesNot

applicable

P1500 Starter signal circuit mal-

functionStarter signal is not inputted from engine

cranking till its start and after or it is always

inputted2 driving

cyclesNot

applicable

P1510 ECM backup power source

malfunctionNo backup power after starting engine 1 driving

cycleNot

applicable

P1600 Serial communication prob-

lem between ECM and

TCMNo signal or check sum error while engine

running1 driving

cycleNot

applicable

P1717 AT D-range signal circuit

malfunctionNo “D” range (park/neutral position signal)

is inputted while vehicle running2 driving

cyclesNot

applicable DTC

NO.DETECTING ITEM DETECTING CONDITION

(DTC will set when detecting :)MIL

(vehicle

with immo-

bilizer indi-

cator lamp)MIL

(vehicle

without

immobi-

lizer indica-

tor lamp)

DTC NO. DETECTING ITEM DETECTING CONDITION

(DTC will set when detecting :)MIL

✱P0702 Transmission Control System Electrical

Refer to Section 7B ✱P0705 Transmission Range Sensor Circuit Malfunc-

tion

✱P0710 Transmission Fluid Temperature Sensor Cir-

cuit Malfunction

✱P0715 Input/turbine Speed Sensor Circuit Malfunc-

tion

✱P0720 Output Shaft Speed Sensor Circuit Malfunc-

tion

✱P0725 Engine Speed Input Circuit Malfunction

✱P0730 Incorrect Gear Ratio

✱P0741 Torque Converter Clutch System Perfor-

mance or Stuck Off

✱P0743 Torque Converter Clutch System Electrical

✱P0753 Shift Solenoid A Electrical

✱P0758 Shift Solenoid B Electrical

✱P0763 Shift Solenoid C Electrical

✱P0768 Shift Solenoid D Electrical

✱P0773 Shift Solenoid E Electrical

✱P1700 Throttle Position Signal Input Malfunction

✱P1702 Internal Control Module Memory Check Some

Error

✱P1709 Engine Coolant Temperature Signal Input

Malfunction