Ecm SUZUKI SWIFT 2000 1.G RG413 Service Owner's Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 389 of 698

6-20 ENGINE GENERAL INFORMATION AND DIAGNOSIS

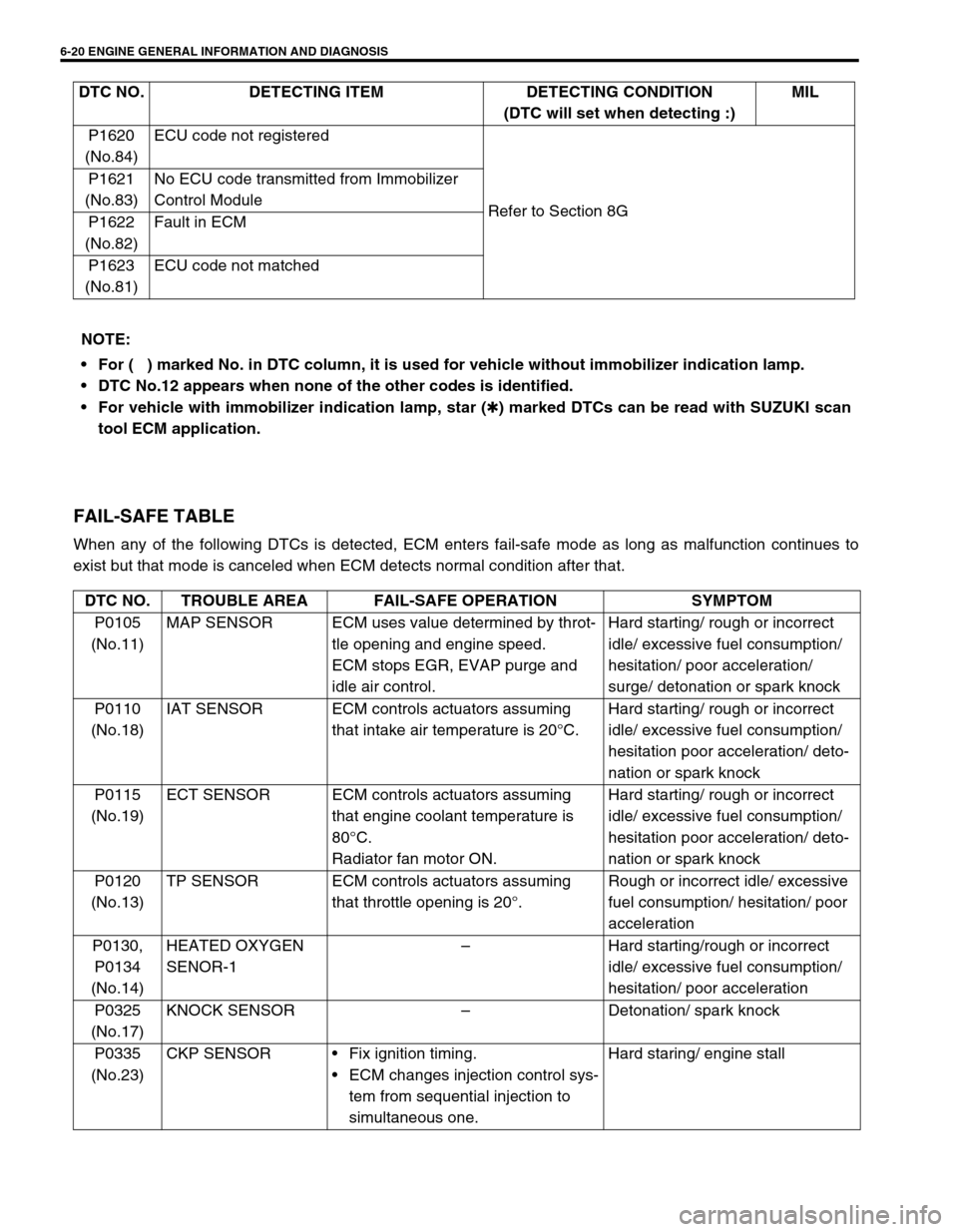

FAIL-SAFE TABLE

When any of the following DTCs is detected, ECM enters fail-safe mode as long as malfunction continues to

exist but that mode is canceled when ECM detects normal condition after that.P1620

(No.84)ECU code not registered

Refer to Section 8G P1621

(No.83)No ECU code transmitted from Immobilizer

Control Module

P1622

(No.82)Fault in ECM

P1623

(No.81)ECU code not matched DTC NO. DETECTING ITEM DETECTING CONDITION

(DTC will set when detecting :)MIL

NOTE:

For (

) marked No. in DTC column, it is used for vehicle without immobilizer indication lamp.

DTC No.12 appears when none of the other codes is identified.

For vehicle with immobilizer indication lamp, star (

✱) marked DTCs can be read with SUZUKI scan

tool ECM application.

DTC NO. TROUBLE AREA FAIL-SAFE OPERATION SYMPTOM

P0105

(No.11)MAP SENSOR ECM uses value determined by throt-

tle opening and engine speed.

ECM stops EGR, EVAP purge and

idle air control.Hard starting/ rough or incorrect

idle/ excessive fuel consumption/

hesitation/ poor acceleration/

surge/ detonation or spark knock

P0110

(No.18)IAT SENSOR ECM controls actuators assuming

that intake air temperature is 20°C.Hard starting/ rough or incorrect

idle/ excessive fuel consumption/

hesitation poor acceleration/ deto-

nation or spark knock

P0115

(No.19)ECT SENSOR ECM controls actuators assuming

that engine coolant temperature is

80°C.

Radiator fan motor ON.Hard starting/ rough or incorrect

idle/ excessive fuel consumption/

hesitation poor acceleration/ deto-

nation or spark knock

P0120

(No.13)TP SENSOR ECM controls actuators assuming

that throttle opening is 20°.Rough or incorrect idle/ excessive

fuel consumption/ hesitation/ poor

acceleration

P0130,

P0134

(No.14)HEATED OXYGEN

SENOR-1–Hard starting/rough or incorrect

idle/ excessive fuel consumption/

hesitation/ poor acceleration

P0325

(No.17)KNOCK SENSOR–Detonation/ spark knock

P0335

(No.23)CKP SENSORFix ignition timing.

ECM changes injection control sys-

tem from sequential injection to

simultaneous one.Hard staring/ engine stall

Page 390 of 698

ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-21

P0340

(No.15)CMP SENSOR ECM changes injection control sys-

tem from sequential injection to simul-

taneous one.Hard starting

P0400 EGR VALVE–Hard starting/rough or incorrect

idle/ excessive fuel consumption/

hesitation/ poor acceleration/

surge/ detonation or spark knock/

engine stall

P0420 CATALYST––

P0443 PURGE CONTROL

VALVE–Rough or incorrect idle/ surge/

hard starting/ engine stall

P0480 RADIATOR FAN

CONTROL SYSTEM–Engine overheating

P0500

(No.16)VEHICLE SPEED

SENSORECM stops idle air control. Rough or incorrect idle

P0505 IDLE CONTROL

SYSTEM–Engine stall/ rough or incorrect idle

P0601

(No.71)ECM INTERNAL–Hard starting/ rough or incorrect

idle/ excessive fuel consumption/

detonation or spark knock/ hesita-

tion poor acceleration/

P1450

(No.29)BAROMETRIC

PRESSURE SEN-

SORECM controls actuators assuming

that barometric pressure is

100 kPa (760 mmHg).Hard starting/ rough or incorrect

idle DTC NO. TROUBLE AREA FAIL-SAFE OPERATION SYMPTOM

Page 392 of 698

ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-23

ENGINE BASIC INSPECTION

This check is very important for troubleshooting when ECM has detected no DTC and no abnormality has been

found in visual inspection.

Follow the flow table carefully.

Step Action Yes No

1Was “ENGINE DIAG. FLOW TABLE” per-

formed?Go to Step 2. Go to “ENGINE DIAG.

FLOW TABLE”.

2 Check battery voltage.

Is it 11 V or more?Go to Step 3. Charge or replace battery.

3 Is engine cranked? Go to Step 4. Go to “DIAGNOSIS” in

Section 6G.

4 Does engine start? Go to Step 5. Go to Step 7.

5 Check idle speed as follows :

1) Warm up engine to normal operating temp.

2) Shift transmission to neutral position for M/T

(“P” position for A/T).

3) All of electrical loads are switched off.

4) Check engine idle speed with scan tool.

See Fig. 1.

Is it 650 – 750 r/min (700 – 800 r/min. for A/T

vehicle)?Go to Step 6. Go to “ENGINE DIAGNO-

SIS TABLE”.

6 Check ignition timing as follows :

1) When SUZUKI scan tool is not available,

disconnect scan tool from DLC and connect

test switch terminal of monitor connector to

ground. See Fig. 2.

When using SUZUKI scan tool, select

“MISC” mode on SUZUKI scan tool and fix

ignition timing to initial one. See Fig. 3.

2) Using timing light (1), check initial ignition

timing. See Fig. 4.

Is it 5° ± 3° BTDC at specified idle speed?Go to “ENGINE DIAGNO-

SIS TABLE”.Check ignition control

related parts referring to

Section 6F1.

7 Is immobilizer control system equipped? Go to Step 8. Go to Step 9.

8 Check immobilizer system malfunction as fol-

lows.

1) Check immobilizer indicator lamp or MIL

(malfunction indicator lamp) for flashing.

Is it flashing when ignition switch is turned to

ON position?Go to “DIAGNOSIS” in

Section 8G.Go to Step 9.

9 Check fuel supply as follows :

1) Check to make sure that enough fuel is

filled in fuel tank.

2) Turn ON ignition switch for 2 seconds and

then OFF. See Fig. 5.

Is fuel pressure felt from fuel feed hose (1)

when ignition switch is turned ON?Go to Step 11. Go to Step 10.

10 Check fuel pump for operating.

Was fuel pump operating sound heard from fuel

filler for about 10 seconds after ignition switch

ON and stop?Go to “DIAG. FLOW

TABLE B-3”.Go to “DIAG. FLOW

TABLE B-2”.

Page 395 of 698

6-26 ENGINE GENERAL INFORMATION AND DIAGNOSIS

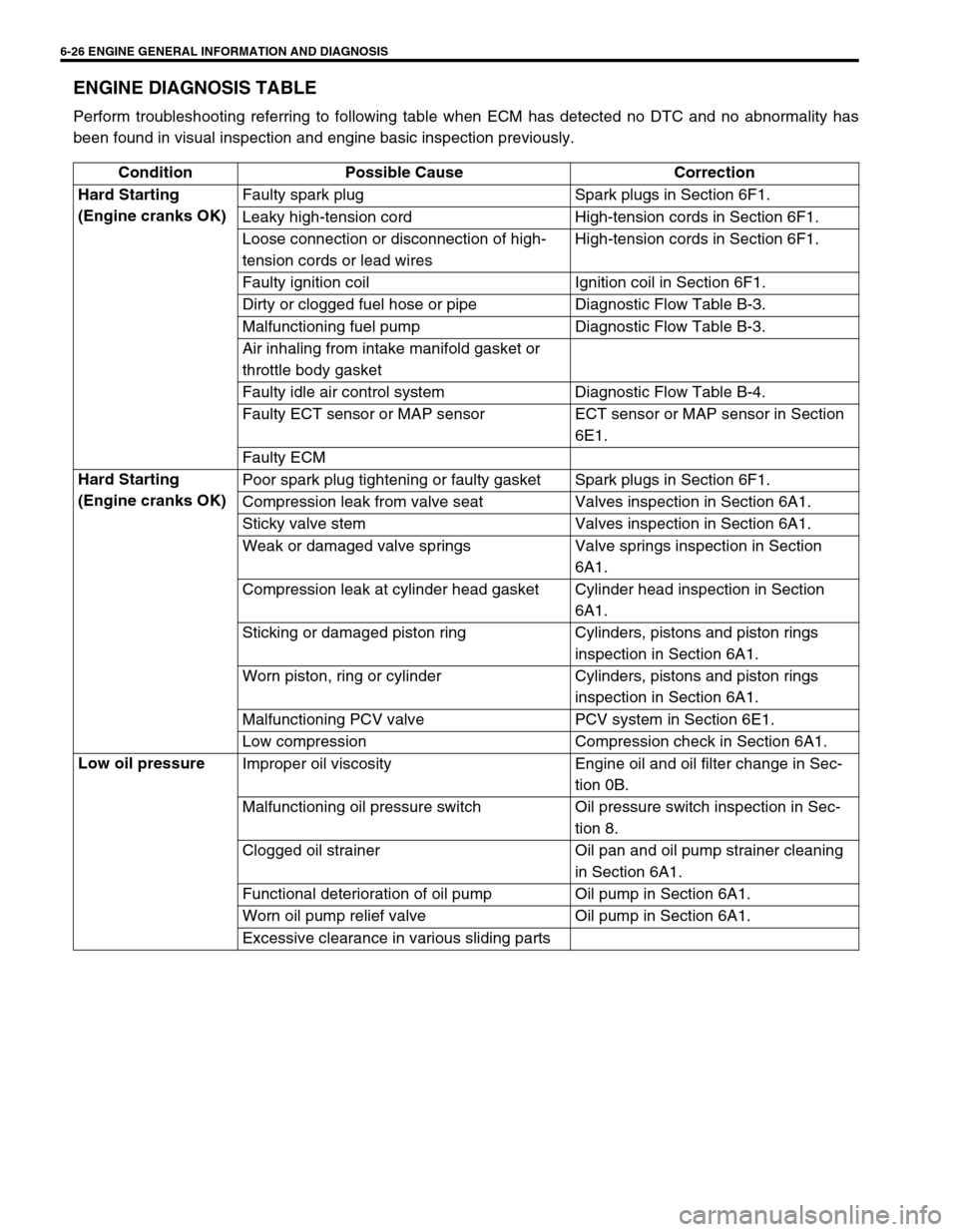

ENGINE DIAGNOSIS TABLE

Perform troubleshooting referring to following table when ECM has detected no DTC and no abnormality has

been found in visual inspection and engine basic inspection previously.

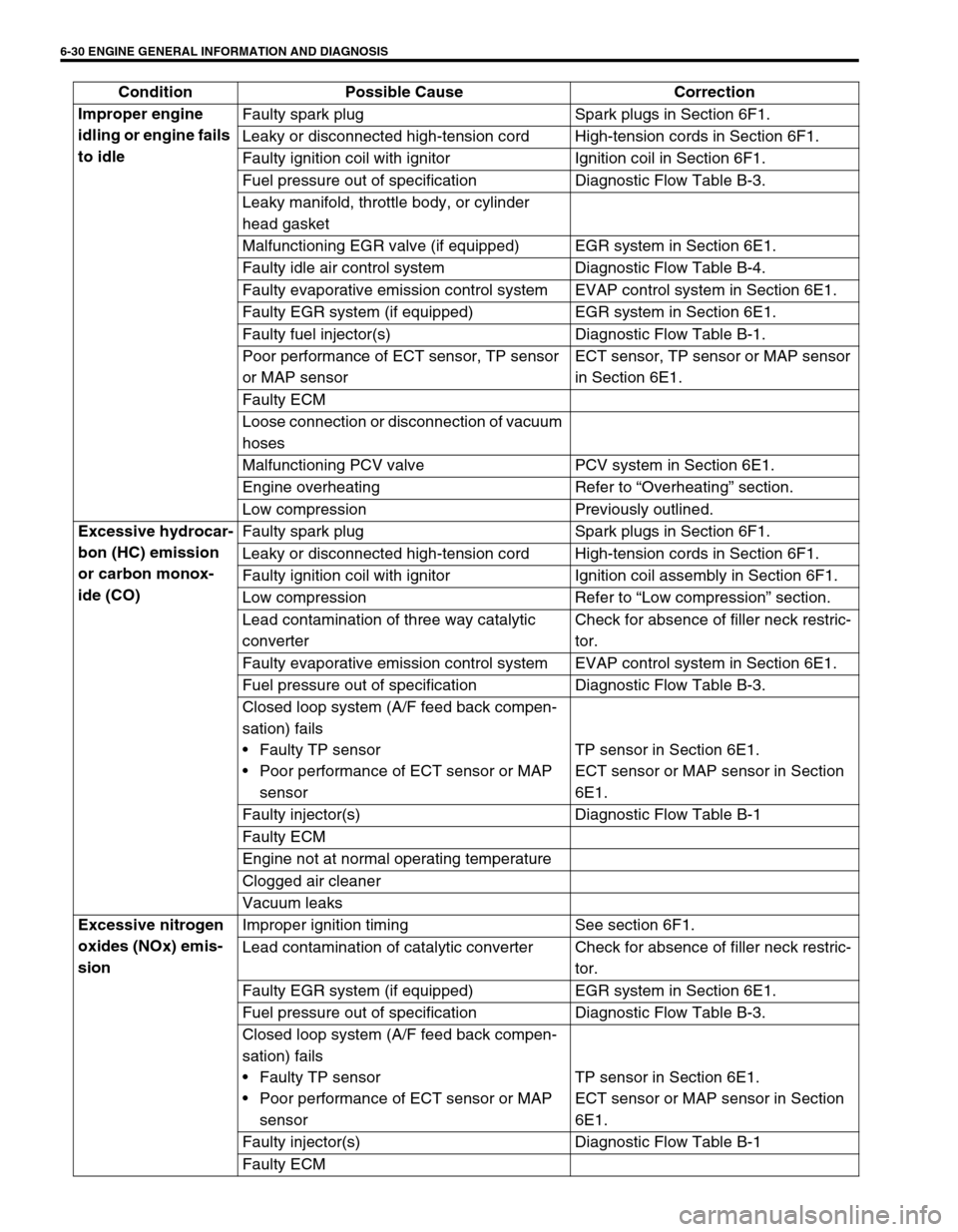

Condition Possible Cause Correction

Hard Starting

(Engine cranks OK) Faulty spark plug Spark plugs in Section 6F1.

Leaky high-tension cord High-tension cords in Section 6F1.

Loose connection or disconnection of high-

tension cords or lead wiresHigh-tension cords in Section 6F1.

Faulty ignition coil Ignition coil in Section 6F1.

Dirty or clogged fuel hose or pipe Diagnostic Flow Table B-3.

Malfunctioning fuel pump Diagnostic Flow Table B-3.

Air inhaling from intake manifold gasket or

throttle body gasket

Faulty idle air control system Diagnostic Flow Table B-4.

Faulty ECT sensor or MAP sensor ECT sensor or MAP sensor in Section

6E1.

Faulty ECM

Hard Starting

(Engine cranks OK) Poor spark plug tightening or faulty gasket Spark plugs in Section 6F1.

Compression leak from valve seat Valves inspection in Section 6A1.

Sticky valve stem Valves inspection in Section 6A1.

Weak or damaged valve springs Valve springs inspection in Section

6A1.

Compression leak at cylinder head gasket Cylinder head inspection in Section

6A1.

Sticking or damaged piston ring Cylinders, pistons and piston rings

inspection in Section 6A1.

Worn piston, ring or cylinder Cylinders, pistons and piston rings

inspection in Section 6A1.

Malfunctioning PCV valve PCV system in Section 6E1.

Low compression Compression check in Section 6A1.

Low oil pressure

Improper oil viscosity Engine oil and oil filter change in Sec-

tion 0B.

Malfunctioning oil pressure switch Oil pressure switch inspection in Sec-

tion 8.

Clogged oil strainer Oil pan and oil pump strainer cleaning

in Section 6A1.

Functional deterioration of oil pump Oil pump in Section 6A1.

Worn oil pump relief valve Oil pump in Section 6A1.

Excessive clearance in various sliding parts

Page 397 of 698

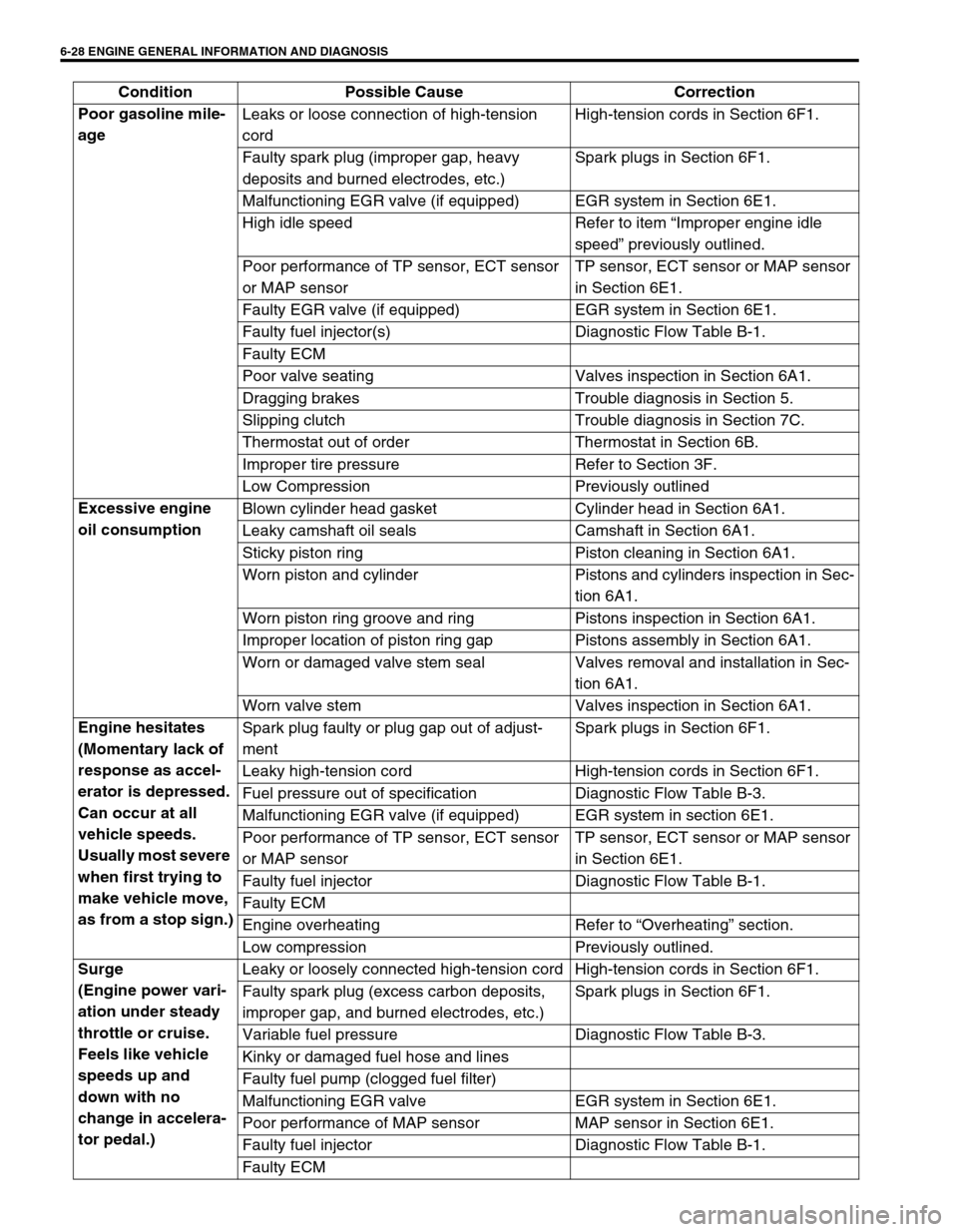

6-28 ENGINE GENERAL INFORMATION AND DIAGNOSIS

Poor gasoline mile-

age Leaks or loose connection of high-tension

cordHigh-tension cords in Section 6F1.

Faulty spark plug (improper gap, heavy

deposits and burned electrodes, etc.)Spark plugs in Section 6F1.

Malfunctioning EGR valve (if equipped) EGR system in Section 6E1.

High idle speed Refer to item “Improper engine idle

speed” previously outlined.

Poor performance of TP sensor, ECT sensor

or MAP sensorTP sensor, ECT sensor or MAP sensor

in Section 6E1.

Faulty EGR valve (if equipped) EGR system in Section 6E1.

Faulty fuel injector(s) Diagnostic Flow Table B-1.

Faulty ECM

Poor valve seating Valves inspection in Section 6A1.

Dragging brakes Trouble diagnosis in Section 5.

Slipping clutch Trouble diagnosis in Section 7C.

Thermostat out of order Thermostat in Section 6B.

Improper tire pressure Refer to Section 3F.

Low Compression Previously outlined

Excessive engine

oil consumption Blown cylinder head gasket Cylinder head in Section 6A1.

Leaky camshaft oil seals Camshaft in Section 6A1.

Sticky piston ring Piston cleaning in Section 6A1.

Worn piston and cylinder Pistons and cylinders inspection in Sec-

tion 6A1.

Worn piston ring groove and ring Pistons inspection in Section 6A1.

Improper location of piston ring gap Pistons assembly in Section 6A1.

Worn or damaged valve stem seal Valves removal and installation in Sec-

tion 6A1.

Worn valve stem Valves inspection in Section 6A1.

Engine hesitates

(Momentary lack of

response as accel-

erator is depressed.

Can occur at all

vehicle speeds.

Usually most severe

when first trying to

make vehicle move,

as from a stop sign.)Spark plug faulty or plug gap out of adjust-

mentSpark plugs in Section 6F1.

Leaky high-tension cord High-tension cords in Section 6F1.

Fuel pressure out of specification Diagnostic Flow Table B-3.

Malfunctioning EGR valve (if equipped) EGR system in section 6E1.

Poor performance of TP sensor, ECT sensor

or MAP sensorTP sensor, ECT sensor or MAP sensor

in Section 6E1.

Faulty fuel injector Diagnostic Flow Table B-1.

Faulty ECM

Engine overheating Refer to “Overheating” section.

Low compression Previously outlined.

Surge

(Engine power vari-

ation under steady

throttle or cruise.

Feels like vehicle

speeds up and

down with no

change in accelera-

tor pedal.)Leaky or loosely connected high-tension cord High-tension cords in Section 6F1.

Faulty spark plug (excess carbon deposits,

improper gap, and burned electrodes, etc.)Spark plugs in Section 6F1.

Variable fuel pressure Diagnostic Flow Table B-3.

Kinky or damaged fuel hose and lines

Faulty fuel pump (clogged fuel filter)

Malfunctioning EGR valve EGR system in Section 6E1.

Poor performance of MAP sensor MAP sensor in Section 6E1.

Faulty fuel injector Diagnostic Flow Table B-1.

Faulty ECM Condition Possible Cause Correction

Page 398 of 698

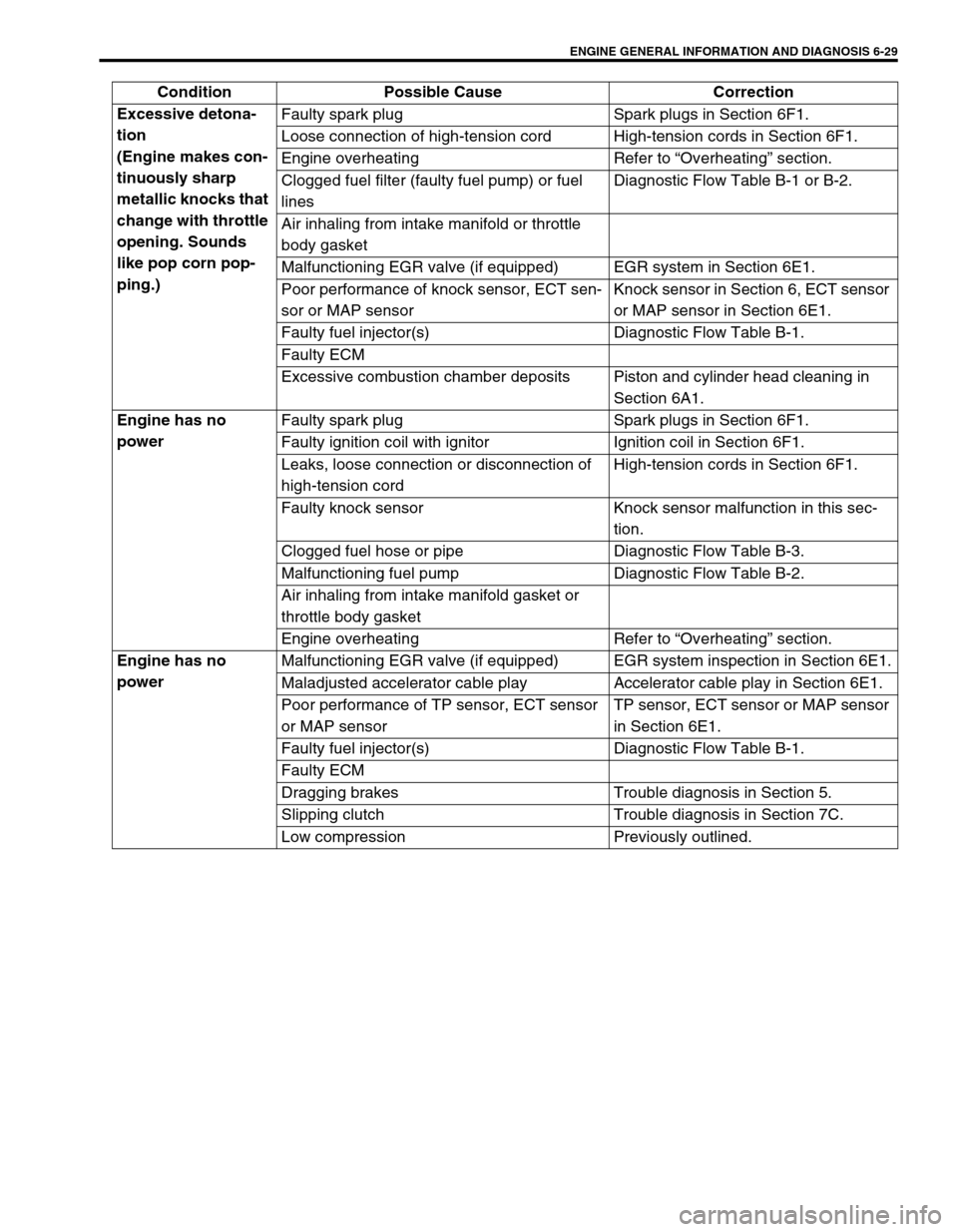

ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-29

Excessive detona-

tion

(Engine makes con-

tinuously sharp

metallic knocks that

change with throttle

opening. Sounds

like pop corn pop-

ping.)Faulty spark plug Spark plugs in Section 6F1.

Loose connection of high-tension cord High-tension cords in Section 6F1.

Engine overheating Refer to “Overheating” section.

Clogged fuel filter (faulty fuel pump) or fuel

linesDiagnostic Flow Table B-1 or B-2.

Air inhaling from intake manifold or throttle

body gasket

Malfunctioning EGR valve (if equipped) EGR system in Section 6E1.

Poor performance of knock sensor, ECT sen-

sor or MAP sensorKnock sensor in Section 6, ECT sensor

or MAP sensor in Section 6E1.

Faulty fuel injector(s) Diagnostic Flow Table B-1.

Faulty ECM

Excessive combustion chamber deposits Piston and cylinder head cleaning in

Section 6A1.

Engine has no

powerFaulty spark plug Spark plugs in Section 6F1.

Faulty ignition coil with ignitor Ignition coil in Section 6F1.

Leaks, loose connection or disconnection of

high-tension cordHigh-tension cords in Section 6F1.

Faulty knock sensor Knock sensor malfunction in this sec-

tion.

Clogged fuel hose or pipe Diagnostic Flow Table B-3.

Malfunctioning fuel pump Diagnostic Flow Table B-2.

Air inhaling from intake manifold gasket or

throttle body gasket

Engine overheating Refer to “Overheating” section.

Engine has no

powerMalfunctioning EGR valve (if equipped) EGR system inspection in Section 6E1.

Maladjusted accelerator cable play Accelerator cable play in Section 6E1.

Poor performance of TP sensor, ECT sensor

or MAP sensorTP sensor, ECT sensor or MAP sensor

in Section 6E1.

Faulty fuel injector(s) Diagnostic Flow Table B-1.

Faulty ECM

Dragging brakes Trouble diagnosis in Section 5.

Slipping clutch Trouble diagnosis in Section 7C.

Low compression Previously outlined. Condition Possible Cause Correction

Page 399 of 698

6-30 ENGINE GENERAL INFORMATION AND DIAGNOSIS

Improper engine

idling or engine fails

to idleFaulty spark plug Spark plugs in Section 6F1.

Leaky or disconnected high-tension cord High-tension cords in Section 6F1.

Faulty ignition coil with ignitor Ignition coil in Section 6F1.

Fuel pressure out of specification Diagnostic Flow Table B-3.

Leaky manifold, throttle body, or cylinder

head gasket

Malfunctioning EGR valve (if equipped) EGR system in Section 6E1.

Faulty idle air control system Diagnostic Flow Table B-4.

Faulty evaporative emission control system EVAP control system in Section 6E1.

Faulty EGR system (if equipped) EGR system in Section 6E1.

Faulty fuel injector(s) Diagnostic Flow Table B-1.

Poor performance of ECT sensor, TP sensor

or MAP sensorECT sensor, TP sensor or MAP sensor

in Section 6E1.

Faulty ECM

Loose connection or disconnection of vacuum

hoses

Malfunctioning PCV valve PCV system in Section 6E1.

Engine overheating Refer to “Overheating” section.

Low compression Previously outlined.

Excessive hydrocar-

bon (HC) emission

or carbon monox-

ide (CO)Faulty spark plug Spark plugs in Section 6F1.

Leaky or disconnected high-tension cord High-tension cords in Section 6F1.

Faulty ignition coil with ignitor Ignition coil assembly in Section 6F1.

Low compression Refer to “Low compression” section.

Lead contamination of three way catalytic

converterCheck for absence of filler neck restric-

tor.

Faulty evaporative emission control system EVAP control system in Section 6E1.

Fuel pressure out of specification Diagnostic Flow Table B-3.

Closed loop system (A/F feed back compen-

sation) fails

Faulty TP sensor

Poor performance of ECT sensor or MAP

sensorTP sensor in Section 6E1.

ECT sensor or MAP sensor in Section

6E1.

Faulty injector(s) Diagnostic Flow Table B-1

Faulty ECM

Engine not at normal operating temperature

Clogged air cleaner

Vacuum leaks

Excessive nitrogen

oxides (NOx) emis-

sionImproper ignition timing See section 6F1.

Lead contamination of catalytic converter Check for absence of filler neck restric-

tor.

Faulty EGR system (if equipped) EGR system in Section 6E1.

Fuel pressure out of specification Diagnostic Flow Table B-3.

Closed loop system (A/F feed back compen-

sation) fails

Faulty TP sensor

Poor performance of ECT sensor or MAP

sensorTP sensor in Section 6E1.

ECT sensor or MAP sensor in Section

6E1.

Faulty injector(s) Diagnostic Flow Table B-1

Faulty ECM Condition Possible Cause Correction

Page 400 of 698

ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-31

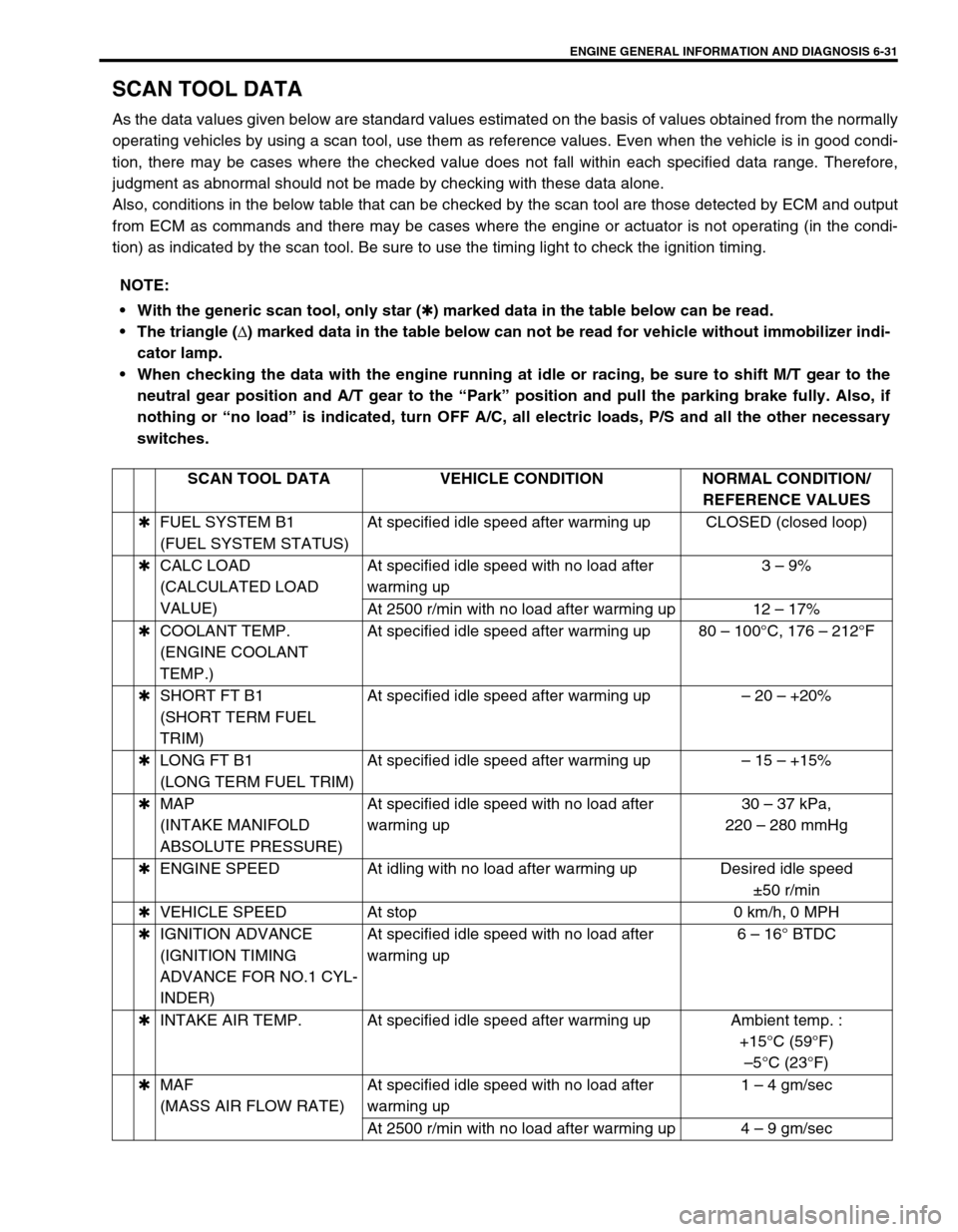

SCAN TOOL DATA

As the data values given below are standard values estimated on the basis of values obtained from the normally

operating vehicles by using a scan tool, use them as reference values. Even when the vehicle is in good condi-

tion, there may be cases where the checked value does not fall within each specified data range. Therefore,

judgment as abnormal should not be made by checking with these data alone.

Also, conditions in the below table that can be checked by the scan tool are those detected by ECM and output

from ECM as commands and there may be cases where the engine or actuator is not operating (in the condi-

tion) as indicated by the scan tool. Be sure to use the timing light to check the ignition timing.

NOTE:

With the generic scan tool, only star (

✱) marked data in the table below can be read.

The triangle (

∆) marked data in the table below can not be read for vehicle without immobilizer indi-

cator lamp.

When checking the data with the engine running at idle or racing, be sure to shift M/T gear to the

neutral gear position and A/T gear to the “Park” position and pull the parking brake fully. Also, if

nothing or “no load” is indicated, turn OFF A/C, all electric loads, P/S and all the other necessary

switches.

SCAN TOOL DATA VEHICLE CONDITION NORMAL CONDITION/

REFERENCE VALUES

✱FUEL SYSTEM B1

(FUEL SYSTEM STATUS)At specified idle speed after warming up CLOSED (closed loop)

✱CALC LOAD

(CALCULATED LOAD

VALUE)At specified idle speed with no load after

warming up3 – 9%

At 2500 r/min with no load after warming up 12 – 17%

✱COOLANT TEMP.

(ENGINE COOLANT

TEMP.)At specified idle speed after warming up 80 – 100°C, 176 – 212°F

✱SHORT FT B1

(SHORT TERM FUEL

TRIM)At specified idle speed after warming up– 20 – +20%

✱LONG FT B1

(LONG TERM FUEL TRIM)At specified idle speed after warming up– 15 – +15%

✱MAP

(INTAKE MANIFOLD

ABSOLUTE PRESSURE)At specified idle speed with no load after

warming up30 – 37 kPa,

220 – 280 mmHg

✱ENGINE SPEED At idling with no load after warming up Desired idle speed

±50 r/min

✱VEHICLE SPEED At stop 0 km/h, 0 MPH

✱IGNITION ADVANCE

(IGNITION TIMING

ADVANCE FOR NO.1 CYL-

INDER)At specified idle speed with no load after

warming up6 – 16° BTDC

✱INTAKE AIR TEMP. At specified idle speed after warming up Ambient temp. :

+15°C (59°F)

–5°C (23°F)

✱MAF

(MASS AIR FLOW RATE)At specified idle speed with no load after

warming up1 – 4 gm/sec

At 2500 r/min with no load after warming up 4 – 9 gm/sec

Page 402 of 698

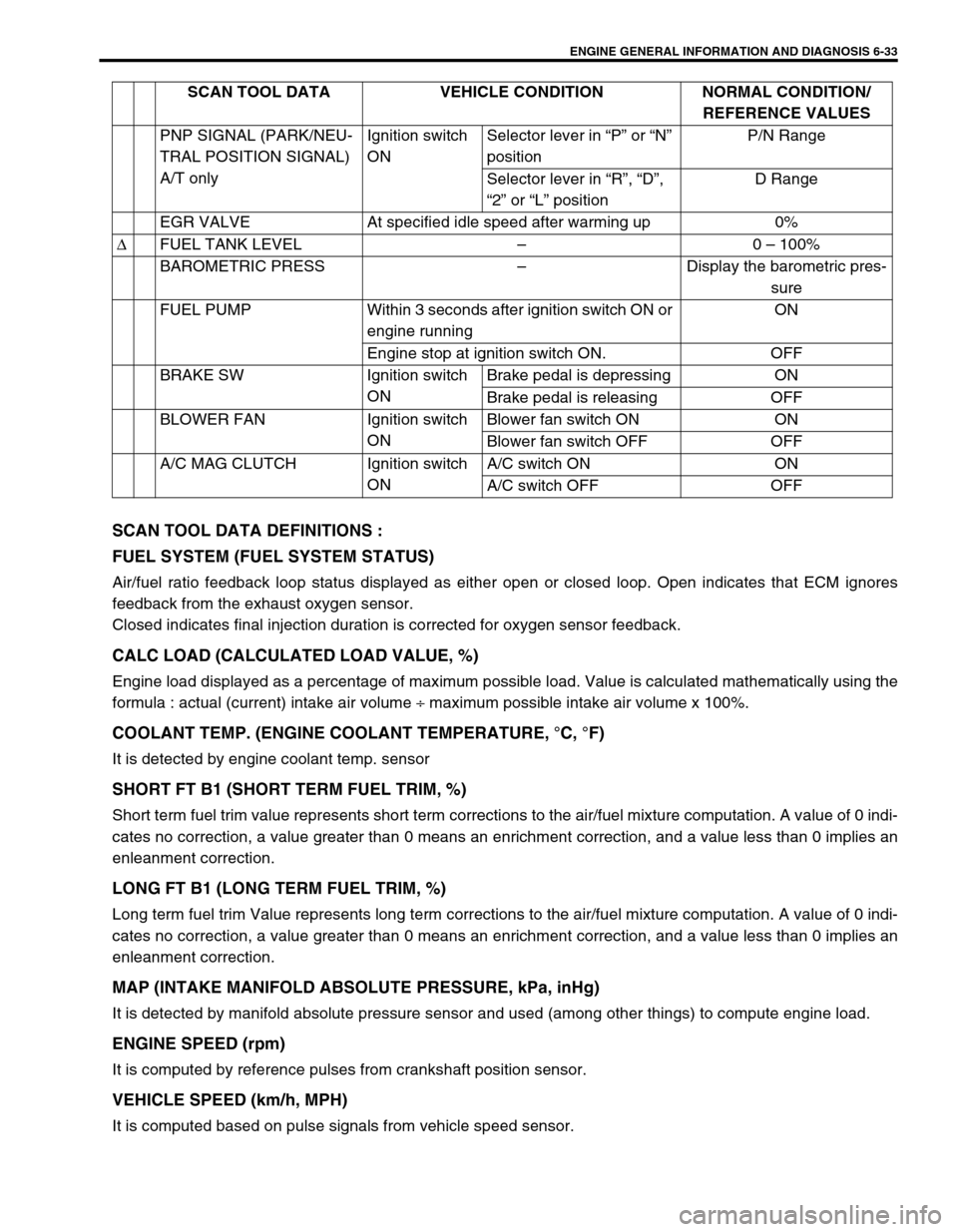

ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-33

SCAN TOOL DATA DEFINITIONS :

FUEL SYSTEM (FUEL SYSTEM STATUS)

Air/fuel ratio feedback loop status displayed as either open or closed loop. Open indicates that ECM ignores

feedback from the exhaust oxygen sensor.

Closed indicates final injection duration is corrected for oxygen sensor feedback.

CALC LOAD (CALCULATED LOAD VALUE, %)

Engine load displayed as a percentage of maximum possible load. Value is calculated mathematically using the

formula : actual (current) intake air volume ÷ maximum possible intake air volume x 100%.

COOLANT TEMP. (ENGINE COOLANT TEMPERATURE, °C, °F)

It is detected by engine coolant temp. sensor

SHORT FT B1 (SHORT TERM FUEL TRIM, %)

Short term fuel trim value represents short term corrections to the air/fuel mixture computation. A value of 0 indi-

cates no correction, a value greater than 0 means an enrichment correction, and a value less than 0 implies an

enleanment correction.

LONG FT B1 (LONG TERM FUEL TRIM, %)

Long term fuel trim Value represents long term corrections to the air/fuel mixture computation. A value of 0 indi-

cates no correction, a value greater than 0 means an enrichment correction, and a value less than 0 implies an

enleanment correction.

MAP (INTAKE MANIFOLD ABSOLUTE PRESSURE, kPa, inHg)

It is detected by manifold absolute pressure sensor and used (among other things) to compute engine load.

ENGINE SPEED (rpm)

It is computed by reference pulses from crankshaft position sensor.

VEHICLE SPEED (km/h, MPH)

It is computed based on pulse signals from vehicle speed sensor.PNP SIGNAL (PARK/NEU-

TRAL POSITION SIGNAL)

A/T onlyIgnition switch

ONSelector lever in “P” or “N”

positionP/N Range

Selector lever in “R”, “D”,

“2” or “L” positionD Range

EGR VALVE At specified idle speed after warming up 0%

∆FUEL TANK LEVEL–0 – 100%

BAROMETRIC PRESS–Display the barometric pres-

sure

FUEL PUMP Within 3 seconds after ignition switch ON or

engine runningON

Engine stop at ignition switch ON. OFF

BRAKE SW Ignition switch

ONBrake pedal is depressing ON

Brake pedal is releasing OFF

BLOWER FAN Ignition switch

ONBlower fan switch ON ON

Blower fan switch OFF OFF

A/C MAG CLUTCH Ignition switch

ONA/C switch ON ON

A/C switch OFF OFF SCAN TOOL DATA VEHICLE CONDITION NORMAL CONDITION/

REFERENCE VALUES

Page 403 of 698

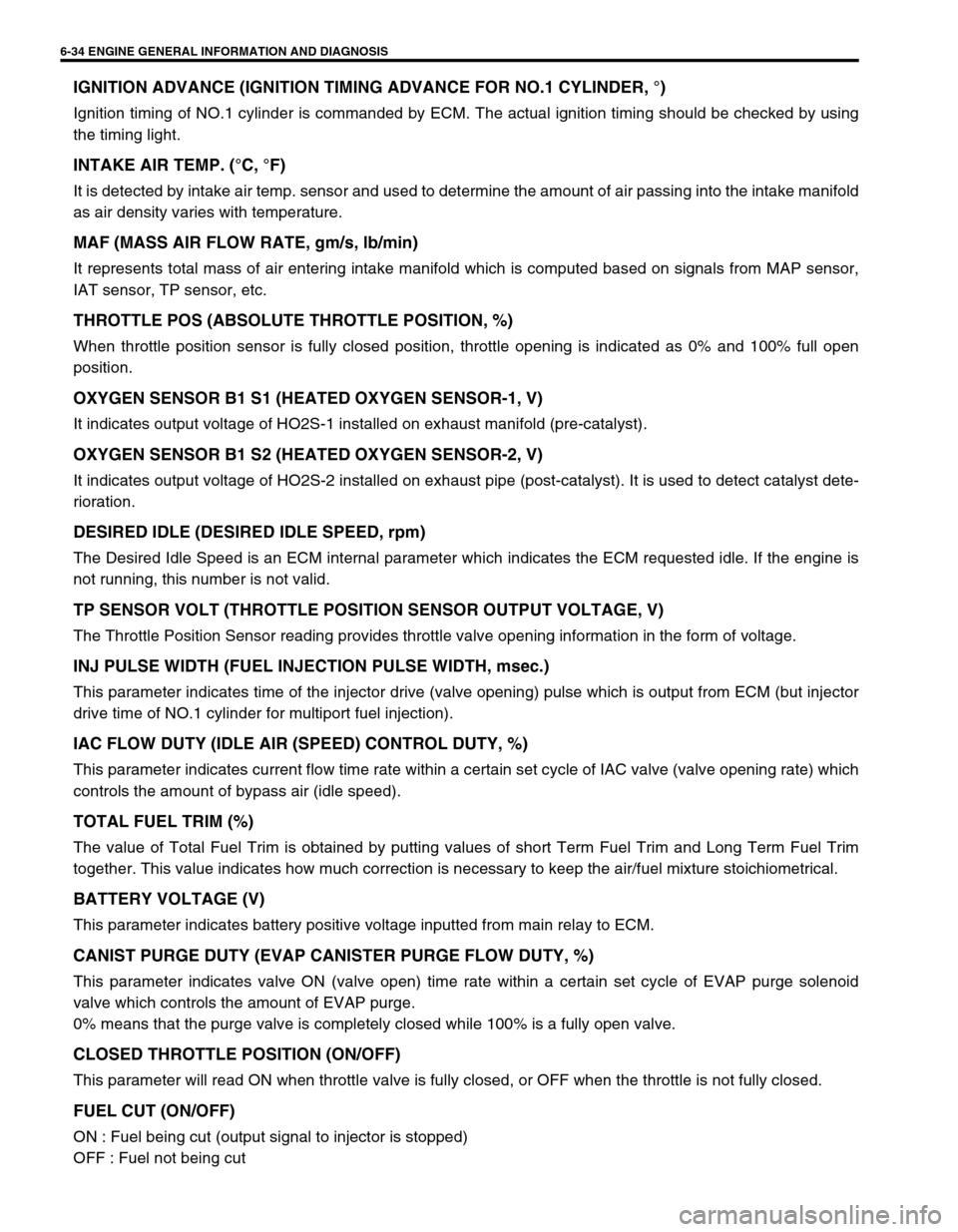

6-34 ENGINE GENERAL INFORMATION AND DIAGNOSIS

IGNITION ADVANCE (IGNITION TIMING ADVANCE FOR NO.1 CYLINDER, °)

Ignition timing of NO.1 cylinder is commanded by ECM. The actual ignition timing should be checked by using

the timing light.

INTAKE AIR TEMP. (°C, °F)

It is detected by intake air temp. sensor and used to determine the amount of air passing into the intake manifold

as air density varies with temperature.

MAF (MASS AIR FLOW RATE, gm/s, lb/min)

It represents total mass of air entering intake manifold which is computed based on signals from MAP sensor,

IAT sensor, TP sensor, etc.

THROTTLE POS (ABSOLUTE THROTTLE POSITION, %)

When throttle position sensor is fully closed position, throttle opening is indicated as 0% and 100% full open

position.

OXYGEN SENSOR B1 S1 (HEATED OXYGEN SENSOR-1, V)

It indicates output voltage of HO2S-1 installed on exhaust manifold (pre-catalyst).

OXYGEN SENSOR B1 S2 (HEATED OXYGEN SENSOR-2, V)

It indicates output voltage of HO2S-2 installed on exhaust pipe (post-catalyst). It is used to detect catalyst dete-

rioration.

DESIRED IDLE (DESIRED IDLE SPEED, rpm)

The Desired Idle Speed is an ECM internal parameter which indicates the ECM requested idle. If the engine is

not running, this number is not valid.

TP SENSOR VOLT (THROTTLE POSITION SENSOR OUTPUT VOLTAGE, V)

The Throttle Position Sensor reading provides throttle valve opening information in the form of voltage.

INJ PULSE WIDTH (FUEL INJECTION PULSE WIDTH, msec.)

This parameter indicates time of the injector drive (valve opening) pulse which is output from ECM (but injector

drive time of NO.1 cylinder for multiport fuel injection).

IAC FLOW DUTY (IDLE AIR (SPEED) CONTROL DUTY, %)

This parameter indicates current flow time rate within a certain set cycle of IAC valve (valve opening rate) which

controls the amount of bypass air (idle speed).

TOTAL FUEL TRIM (%)

The value of Total Fuel Trim is obtained by putting values of short Term Fuel Trim and Long Term Fuel Trim

together. This value indicates how much correction is necessary to keep the air/fuel mixture stoichiometrical.

BATTERY VOLTAGE (V)

This parameter indicates battery positive voltage inputted from main relay to ECM.

CANIST PURGE DUTY (EVAP CANISTER PURGE FLOW DUTY, %)

This parameter indicates valve ON (valve open) time rate within a certain set cycle of EVAP purge solenoid

valve which controls the amount of EVAP purge.

0% means that the purge valve is completely closed while 100% is a fully open valve.

CLOSED THROTTLE POSITION (ON/OFF)

This parameter will read ON when throttle valve is fully closed, or OFF when the throttle is not fully closed.

FUEL CUT (ON/OFF)

ON : Fuel being cut (output signal to injector is stopped)

OFF : Fuel not being cut