air bag SUZUKI SWIFT 2000 1.G RG413 Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 175 of 698

3C-2 STEERING WHEEL AND COLUMN

GENERAL DESCRIPTION

STEERING COLUMN

This double tube type steering column has following three important features in addition to the steering function

:

The column is energy absorbing, designed to compress in a front-end collision.

The ignition switch and lock are mounted conveniently on this column.

With the column mounted lock, the ignition and steering operations can be locked to inhibit theft of the vehi-

cle.

To insure the energy absorbing action, it is important that only the specified screws, bolts, and nuts be used as

designated and that they are tightened to the specified torque.

When the column assembly is removed from the vehicle, special care must be taken in handling it. Use of a

steering wheel puller other than the one recommended in this manual or a sharp blow on the end of the steering

shaft, leaning on the assembly, or dropping the assembly could shear the plastic shear pins which maintain col-

umn length and position.

STEERING WHEEL AND DRIVER AIR BAG (INFLATOR) MODULE

The driver air bag (inflator) module is one of the supplemental restraint (air bag) system components and is

mounted to the center of the steering wheel. During certain frontal crashes, the air bag system supplements the

restraint of the driver’s and passenger’s seat belts by deploying the air bags.

The air bag (inflator) module should be handled with care to prevent accidental deployment. When servicing, be

sure to observe all WARNINGS and CAUTIONS and “SERVICE PRECAUTIONS” under “ON-VEHICLE SER-

VICE” in Section 10B.

DIAGNOSIS

For maintenance service of the steering wheel and column, refer to Section 0B.

For diagnosis of the steering wheel and column, refer to Section 3.

For diagnosis of the air bag system, refer to Section 10B.

INSPECTION AND REPAIR REQUIRED AFTER ACCIDENT

After an accident, whether the air bag has been deployed or not, be sure to perform checks, inspections and

repairs described under “CHECKING STEERING COLUMN ASSEMBLY AND LOWER SHAFT FOR ACCI-

DENT DAMAGE” as well as “REPAIRS AND INSPECTIONS REQUIRED AFTER ACCIDENT” under “DIAGNO-

SIS” in Section 10B.

Page 176 of 698

STEERING WHEEL AND COLUMN 3C-3

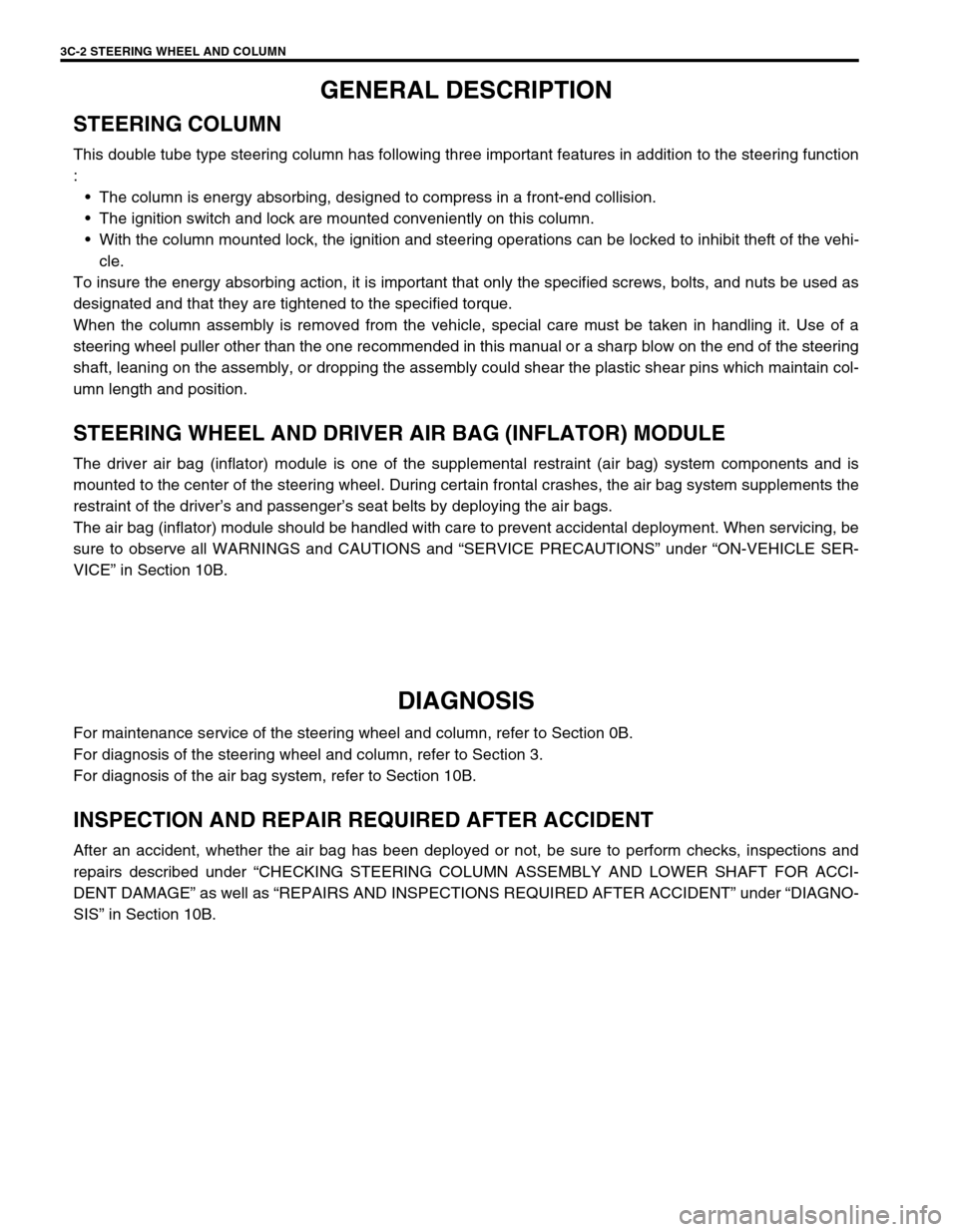

ON-VEHICLE SERVICE

SERVICE PRECAUTIONS

For service precautions, refer to “SERVICE PRECAUTIONS” under “ON-VEHICLE SERVICE” in Section 10B.

SERVICE AND DIAGNOSIS

For diagnosis and servicing, refer to “SERVICE AND DIAGNOSIS” under “SERVICE PRECAUTIONS” in Sec-

tion 10B.

DISABLING AIR BAG SYSTEM

For disabling air bag system, refer to “DISABLING AIR BAG SYSTEM” under “SERVICE PRECAUTIONS” in

Section 10B.

ENABLING AIR BAG SYSTEM

For enabling air bag system, refer to “ENABLING AIR BAG SYSTEM” under “SERVICE PRECAUTIONS” in

Section 10B.

1. Driver air bag (inflator) module 7. Steering column assembly 13. Immobilizer control module (if equipped)

2. Steering wheel 8. Steering lock assembly (ignition switch) 14. Upper and lower joint bolt

: After tightening lower joint bolt, tighten upper joint bolt.

3. Steering wheel nut 9. P/S control module (if equipped) 15. Steering column mounting nut

: After tightening lower nut, tightening upper nut.

4. Contact coil and combination

switch assembly10. Motor for P/S system (if equipped) Tightening torque

5. Steering column upper cover 11. Steering lower shaft

6. Steering column lower cover 12. Steering joint cover

Page 177 of 698

3C-4 STEERING WHEEL AND COLUMN

HANDLING AND STORAGE

For handling and storage, refer to “HANDLING AND STORAGE” under “SERVICE PRECAUTIONS” in Section

10B.

DISPOSAL

For disposal, refer to “DISPOSAL” under “SERVICE PRECAUTIONS” in Section 10B.

DRIVER AIR BAG (INFLATOR) MODULE

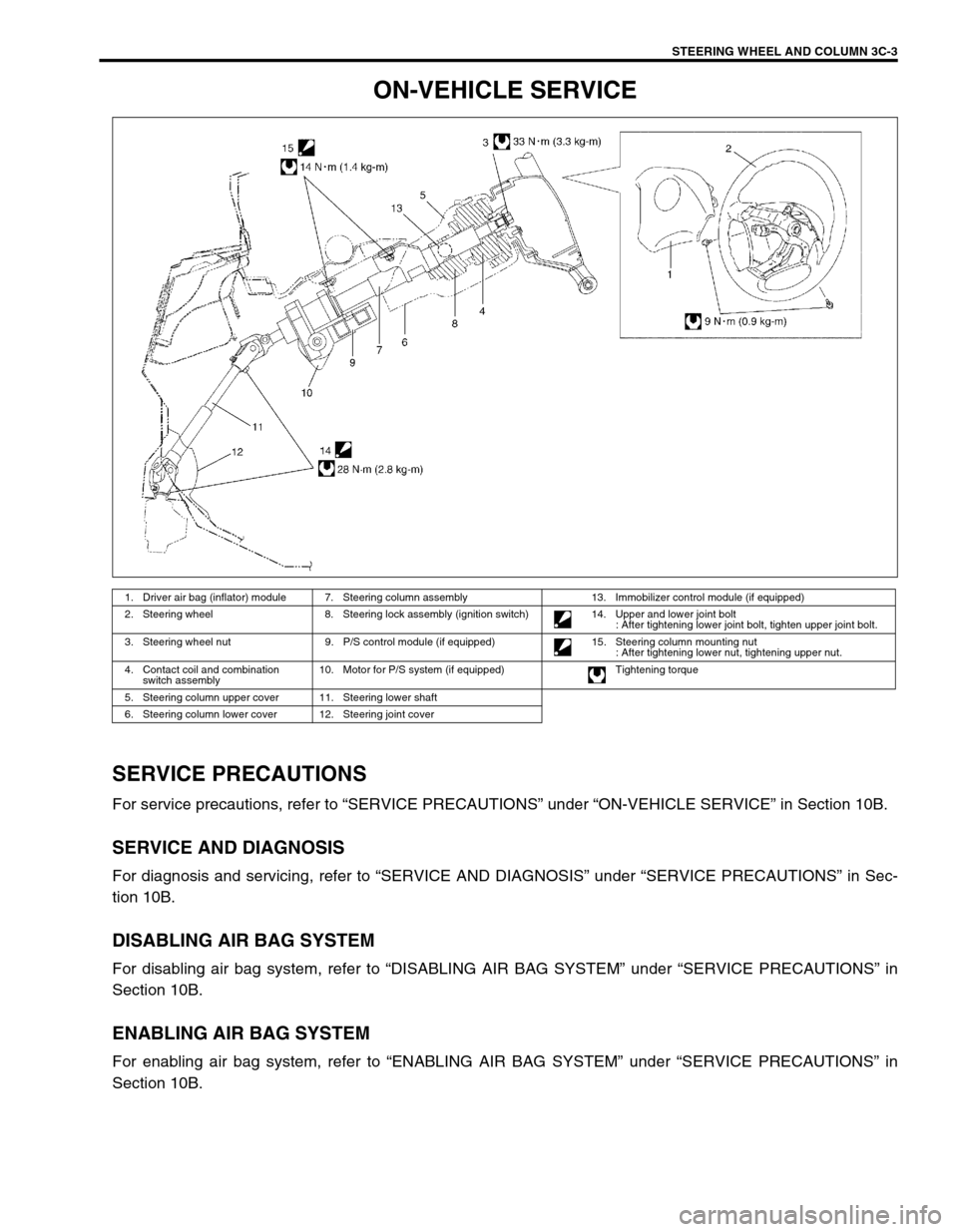

REMOVAL

1) Disconnect negative cable at battery.

2) Disable air bag system. Refer to “DISABLING AIR BAG

SYSTEM” under “SERVICE PRECAUTIONS” in Section

10B.

3) Loosen 2 bolts (1) mounting driver air bag (inflator) module

on its both side.

4) Remove driver air bag (inflator) module (3) from steering

wheel.

5) Disconnect yellow connector (1) of driver air bag (inflator)

module and horn connector (2) in order a) – d) shown in fig-

ure. WARNING:

When handling an air bag (inflator) module, be sure to

read “SERVICE PRECAUTIONS” in Section 10B and

observe each instruction. Failure to follow them could

cause a damage to the air bag (inflator) module or result

in personal injury.

Page 178 of 698

STEERING WHEEL AND COLUMN 3C-5

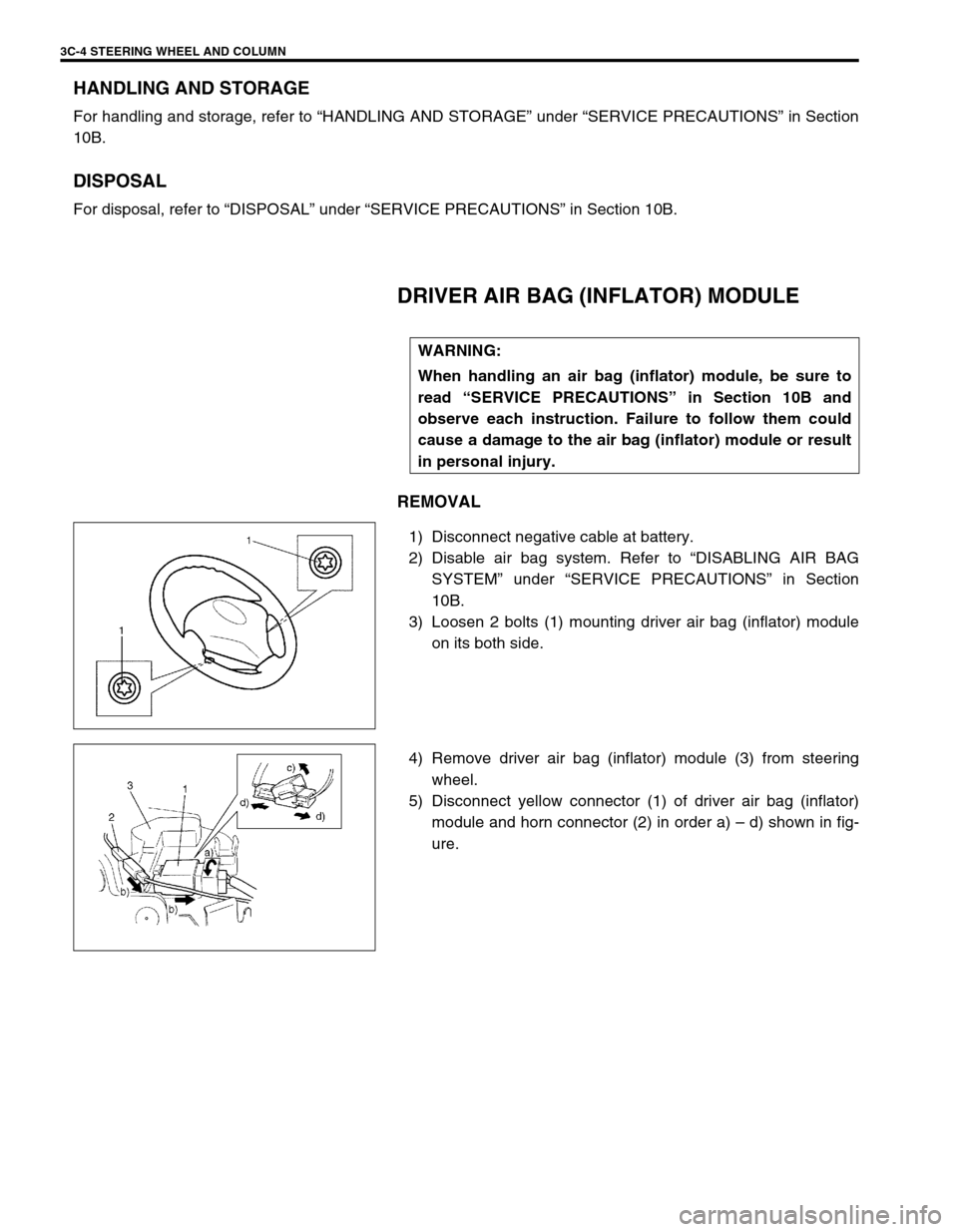

INSPECTION

Check air bag (inflator) module visually and if any of the following

is found, replace it with a new one.

Air bag being deployed

Trim cover (pad surface) (1) being cracked

Wire harness or connector (2) being damaged

Air bag (inflator) module being damaged or having been

exposed to strong impact (dropped)

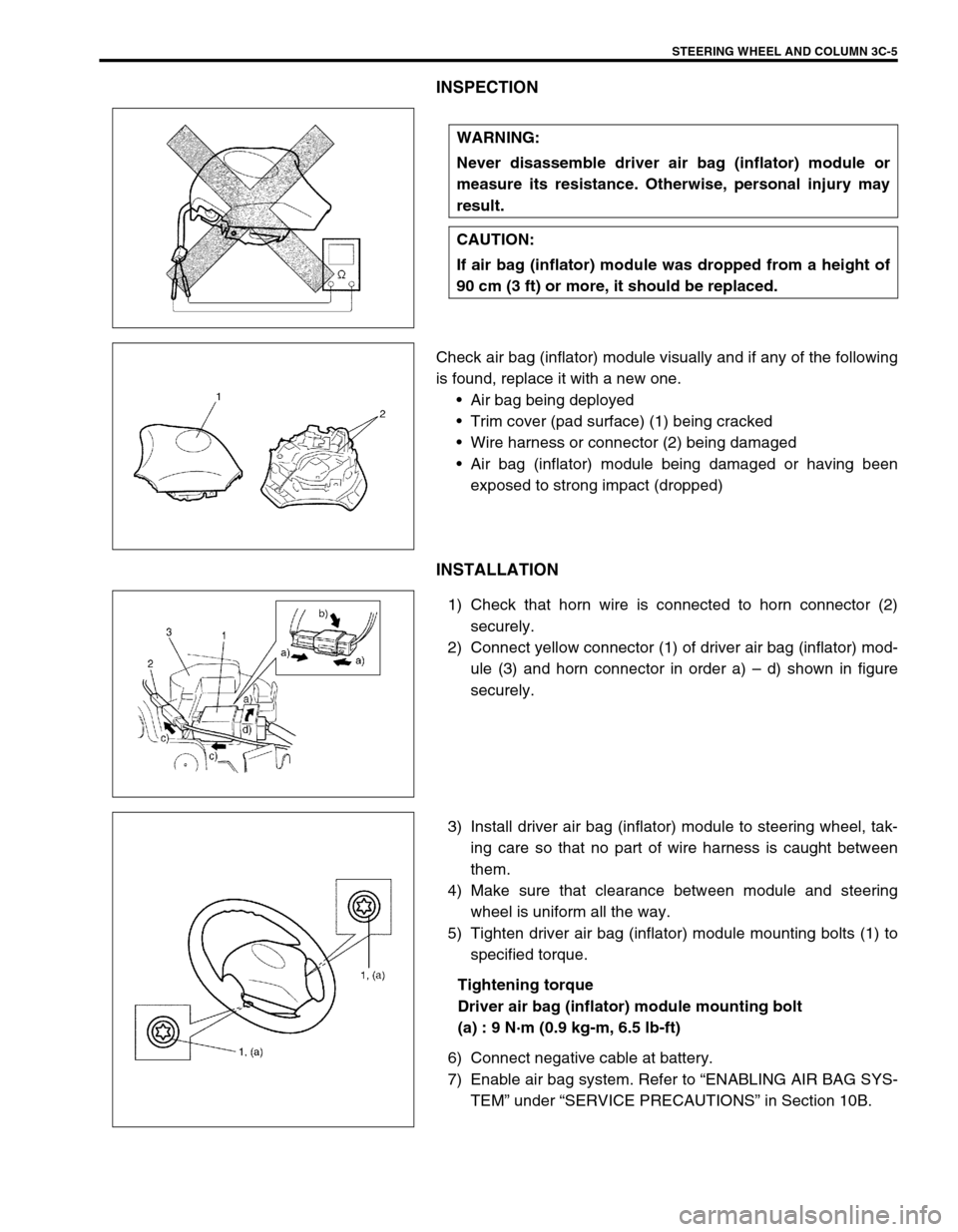

INSTALLATION

1) Check that horn wire is connected to horn connector (2)

securely.

2) Connect yellow connector (1) of driver air bag (inflator) mod-

ule (3) and horn connector in order a) – d) shown in figure

securely.

3) Install driver air bag (inflator) module to steering wheel, tak-

ing care so that no part of wire harness is caught between

them.

4) Make sure that clearance between module and steering

wheel is uniform all the way.

5) Tighten driver air bag (inflator) module mounting bolts (1) to

specified torque.

Tightening torque

Driver air bag (inflator) module mounting bolt

(a) : 9 N·m (0.9 kg-m, 6.5 lb-ft)

6) Connect negative cable at battery.

7) Enable air bag system. Refer to “ENABLING AIR BAG SYS-

TEM” under “SERVICE PRECAUTIONS” in Section 10B. WARNING:

Never disassemble driver air bag (inflator) module or

measure its resistance. Otherwise, personal injury may

result.

CAUTION:

If air bag (inflator) module was dropped from a height of

90 cm (3 ft) or more, it should be replaced.

Page 179 of 698

3C-6 STEERING WHEEL AND COLUMN

STEERING WHEEL

REMOVAL

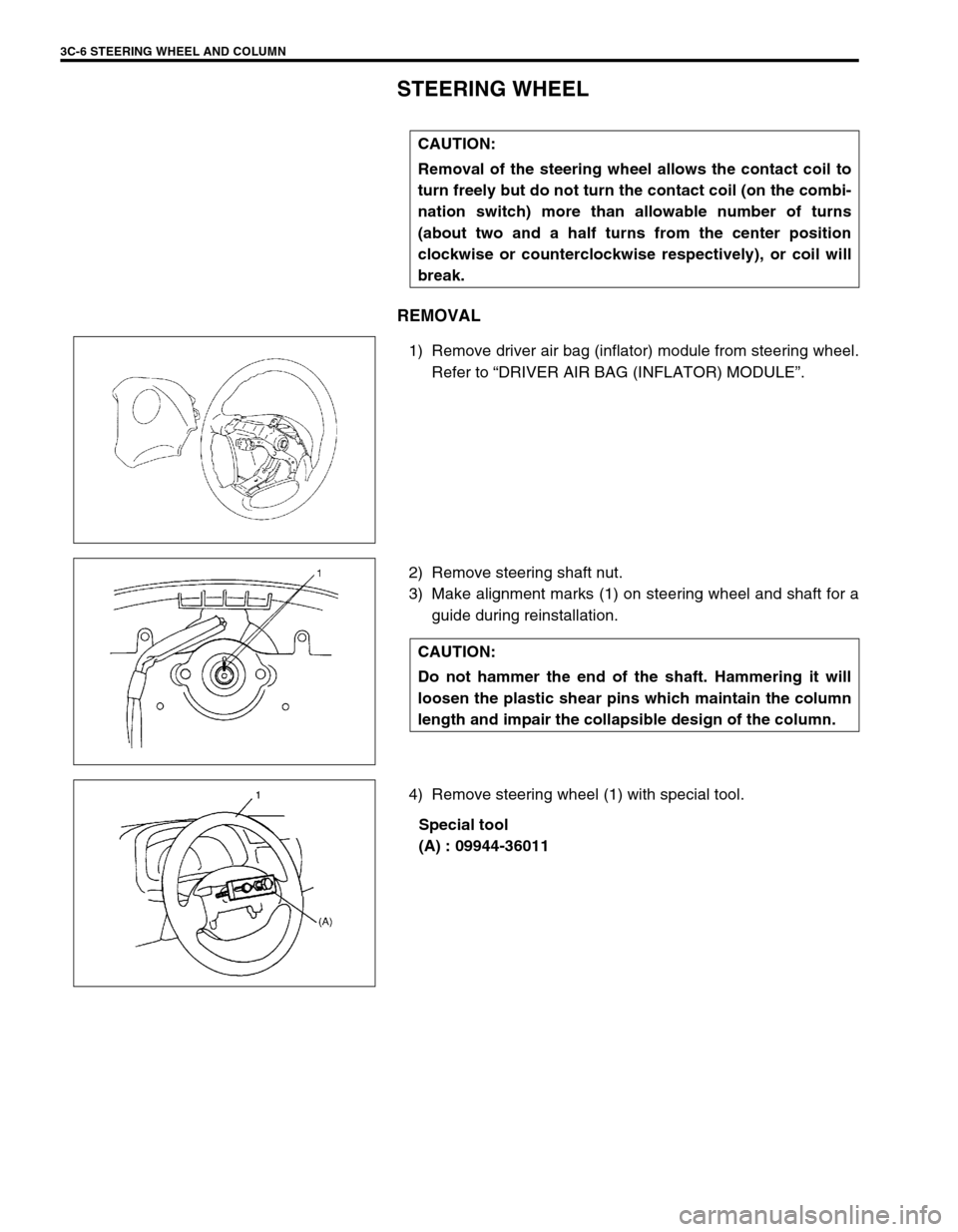

1) Remove driver air bag (inflator) module from steering wheel.

Refer to “DRIVER AIR BAG (INFLATOR) MODULE”.

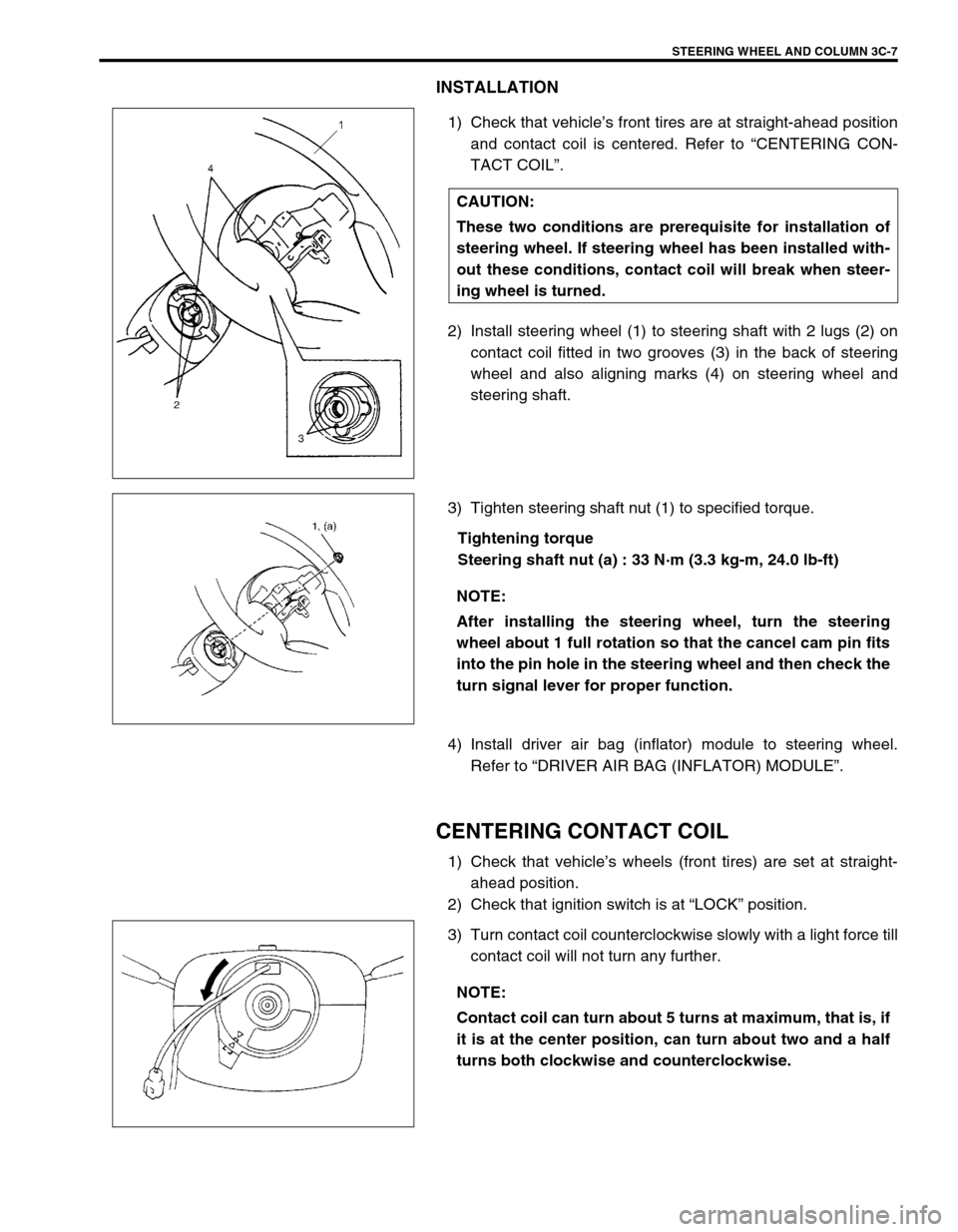

2) Remove steering shaft nut.

3) Make alignment marks (1) on steering wheel and shaft for a

guide during reinstallation.

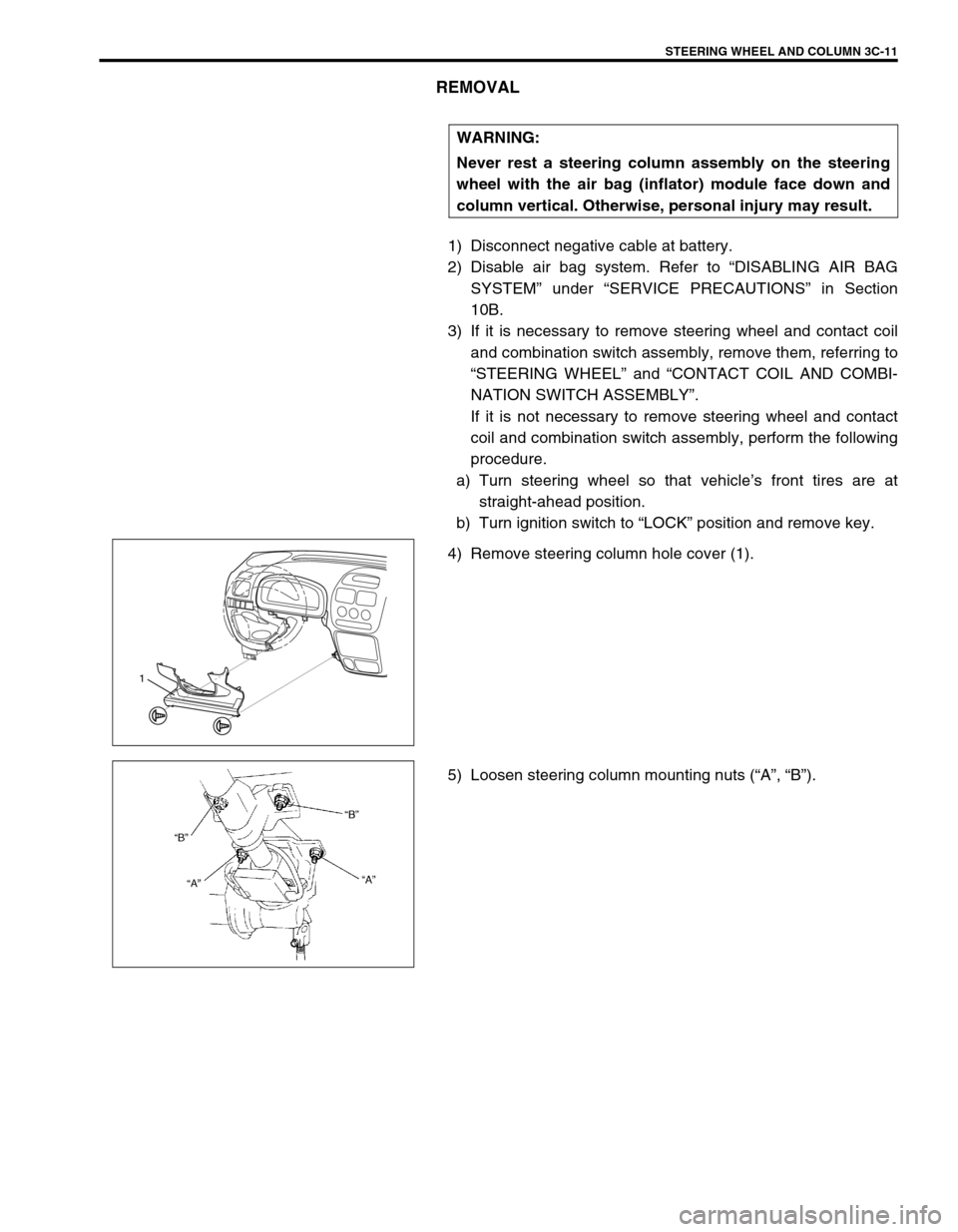

4) Remove steering wheel (1) with special tool.

Special tool

(A) : 09944-36011 CAUTION:

Removal of the steering wheel allows the contact coil to

turn freely but do not turn the contact coil (on the combi-

nation switch) more than allowable number of turns

(about two and a half turns from the center position

clockwise or counterclockwise respectively), or coil will

break.

CAUTION:

Do not hammer the end of the shaft. Hammering it will

loosen the plastic shear pins which maintain the column

length and impair the collapsible design of the column.

Page 180 of 698

STEERING WHEEL AND COLUMN 3C-7

INSTALLATION

1) Check that vehicle’s front tires are at straight-ahead position

and contact coil is centered. Refer to “CENTERING CON-

TACT COIL”.

2) Install steering wheel (1) to steering shaft with 2 lugs (2) on

contact coil fitted in two grooves (3) in the back of steering

wheel and also aligning marks (4) on steering wheel and

steering shaft.

3) Tighten steering shaft nut (1) to specified torque.

Tightening torque

Steering shaft nut (a) : 33 N·m (3.3 kg-m, 24.0 lb-ft)

4) Install driver air bag (inflator) module to steering wheel.

Refer to “DRIVER AIR BAG (INFLATOR) MODULE”.

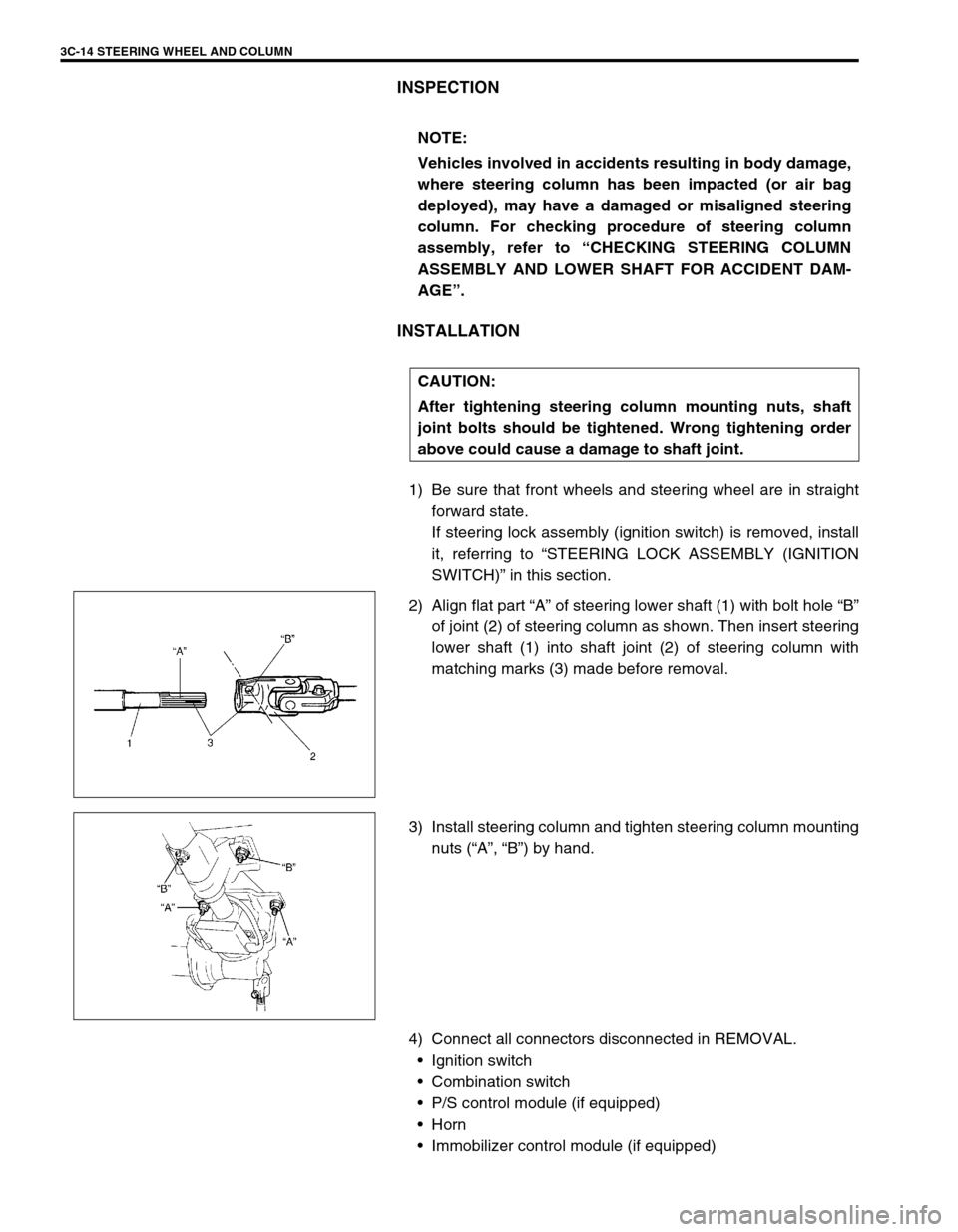

CENTERING CONTACT COIL

1) Check that vehicle’s wheels (front tires) are set at straight-

ahead position.

2) Check that ignition switch is at “LOCK” position.

3) Turn contact coil counterclockwise slowly with a light force till

contact coil will not turn any further. CAUTION:

These two conditions are prerequisite for installation of

steering wheel. If steering wheel has been installed with-

out these conditions, contact coil will break when steer-

ing wheel is turned.

NOTE:

After installing the steering wheel, turn the steering

wheel about 1 full rotation so that the cancel cam pin fits

into the pin hole in the steering wheel and then check the

turn signal lever for proper function.

NOTE:

Contact coil can turn about 5 turns at maximum, that is, if

it is at the center position, can turn about two and a half

turns both clockwise and counterclockwise.

Page 184 of 698

STEERING WHEEL AND COLUMN 3C-11

REMOVAL

1) Disconnect negative cable at battery.

2) Disable air bag system. Refer to “DISABLING AIR BAG

SYSTEM” under “SERVICE PRECAUTIONS” in Section

10B.

3) If it is necessary to remove steering wheel and contact coil

and combination switch assembly, remove them, referring to

“STEERING WHEEL” and “CONTACT COIL AND COMBI-

NATION SWITCH ASSEMBLY”.

If it is not necessary to remove steering wheel and contact

coil and combination switch assembly, perform the following

procedure.

a) Turn steering wheel so that vehicle’s front tires are at

straight-ahead position.

b) Turn ignition switch to “LOCK” position and remove key.

4) Remove steering column hole cover (1).

5) Loosen steering column mounting nuts (“A”, “B”). WARNING:

Never rest a steering column assembly on the steering

wheel with the air bag (inflator) module face down and

column vertical. Otherwise, personal injury may result.

1

Page 187 of 698

3C-14 STEERING WHEEL AND COLUMN

INSPECTION

INSTALLATION

1) Be sure that front wheels and steering wheel are in straight

forward state.

If steering lock assembly (ignition switch) is removed, install

it, referring to “STEERING LOCK ASSEMBLY (IGNITION

SWITCH)” in this section.

2) Align flat part “A” of steering lower shaft (1) with bolt hole “B”

of joint (2) of steering column as shown. Then insert steering

lower shaft (1) into shaft joint (2) of steering column with

matching marks (3) made before removal.

3) Install steering column and tighten steering column mounting

nuts (“A”, “B”) by hand.

4) Connect all connectors disconnected in REMOVAL.

Ignition switch

Combination switch

P/S control module (if equipped)

Horn

Immobilizer control module (if equipped) NOTE:

Vehicles involved in accidents resulting in body damage,

where steering column has been impacted (or air bag

deployed), may have a damaged or misaligned steering

column. For checking procedure of steering column

assembly, refer to “CHECKING STEERING COLUMN

ASSEMBLY AND LOWER SHAFT FOR ACCIDENT DAM-

AGE”.

CAUTION:

After tightening steering column mounting nuts, shaft

joint bolts should be tightened. Wrong tightening order

above could cause a damage to shaft joint.

Page 188 of 698

STEERING WHEEL AND COLUMN 3C-15

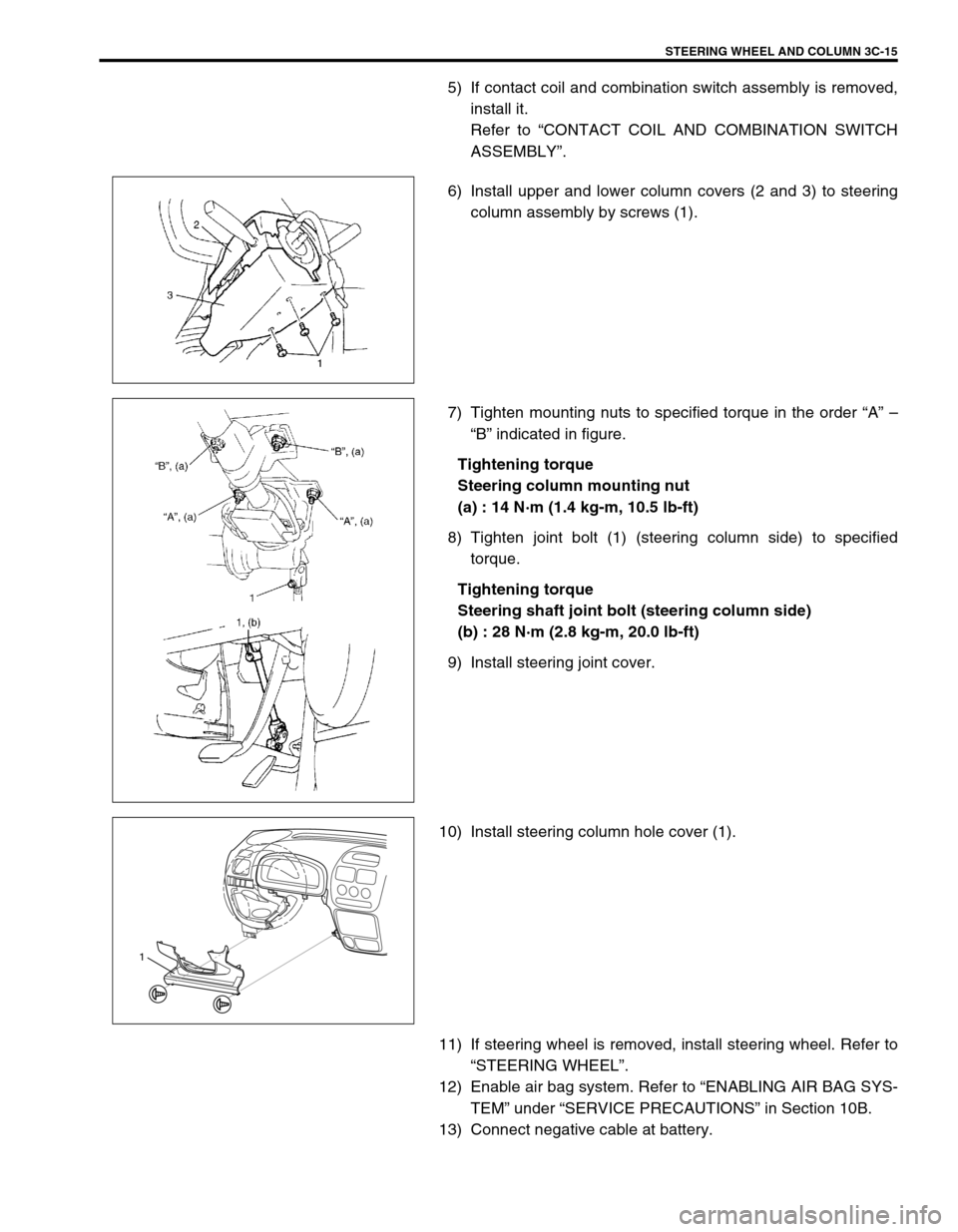

5) If contact coil and combination switch assembly is removed,

install it.

Refer to “CONTACT COIL AND COMBINATION SWITCH

ASSEMBLY”.

6) Install upper and lower column covers (2 and 3) to steering

column assembly by screws (1).

7) Tighten mounting nuts to specified torque in the order “A” –

“B” indicated in figure.

Tightening torque

Steering column mounting nut

(a) : 14 N·m (1.4 kg-m, 10.5 lb-ft)

8) Tighten joint bolt (1) (steering column side) to specified

torque.

Tightening torque

Steering shaft joint bolt (steering column side)

(b) : 28 N·m (2.8 kg-m, 20.0 lb-ft)

9) Install steering joint cover.

10) Install steering column hole cover (1).

11) If steering wheel is removed, install steering wheel. Refer to

“STEERING WHEEL”.

12) Enable air bag system. Refer to “ENABLING AIR BAG SYS-

TEM” under “SERVICE PRECAUTIONS” in Section 10B.

13) Connect negative cable at battery.

1

Page 191 of 698

3C-18 STEERING WHEEL AND COLUMN

INSTALLATION

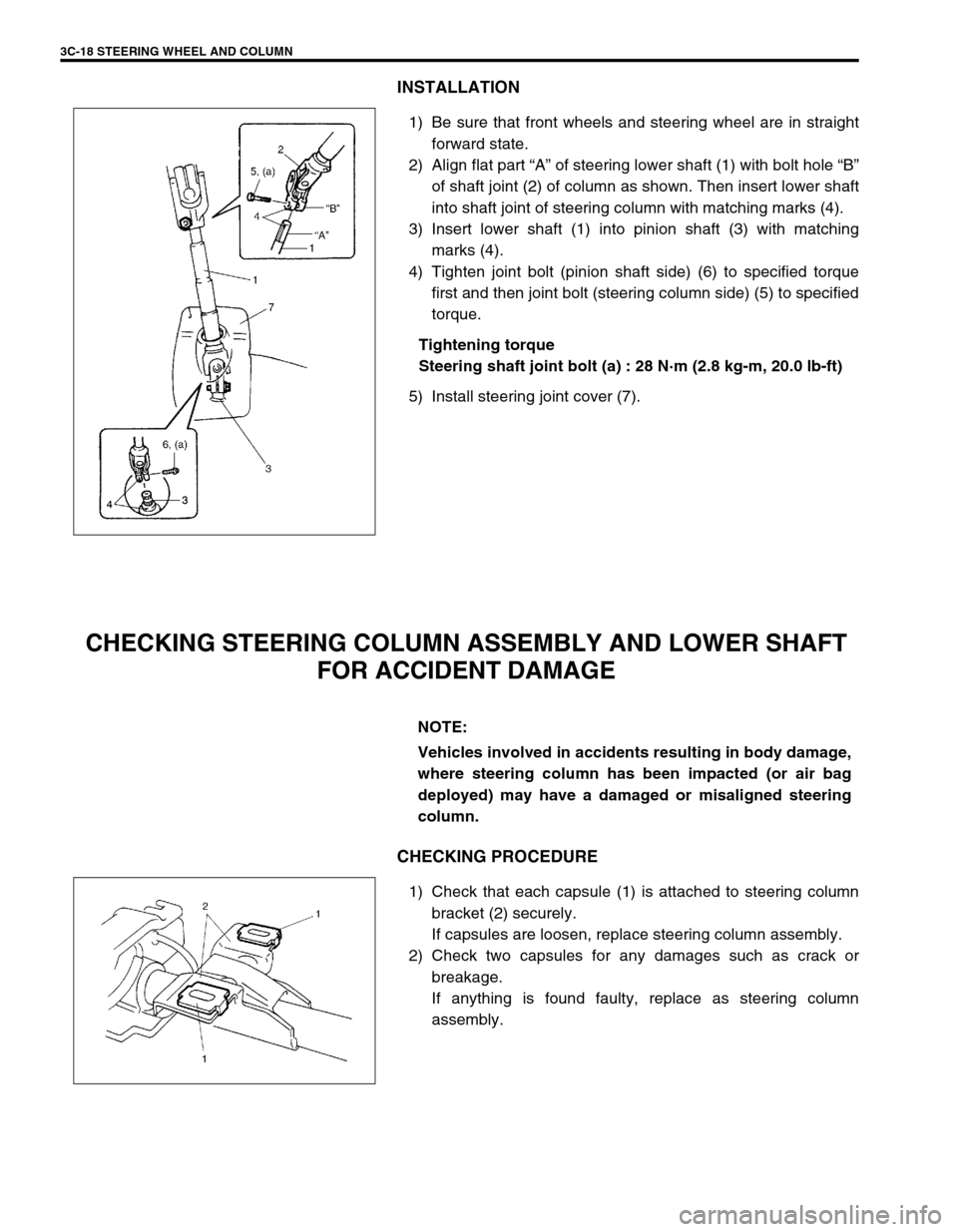

1) Be sure that front wheels and steering wheel are in straight

forward state.

2) Align flat part “A” of steering lower shaft (1) with bolt hole “B”

of shaft joint (2) of column as shown. Then insert lower shaft

into shaft joint of steering column with matching marks (4).

3) Insert lower shaft (1) into pinion shaft (3) with matching

marks (4).

4) Tighten joint bolt (pinion shaft side) (6) to specified torque

first and then joint bolt (steering column side) (5) to specified

torque.

Tightening torque

Steering shaft joint bolt (a) : 28 N·m (2.8 kg-m, 20.0 lb-ft)

5) Install steering joint cover (7).

CHECKING STEERING COLUMN ASSEMBLY AND LOWER SHAFT

FOR ACCIDENT DAMAGE

CHECKING PROCEDURE

1) Check that each capsule (1) is attached to steering column

bracket (2) securely.

If capsules are loosen, replace steering column assembly.

2) Check two capsules for any damages such as crack or

breakage.

If anything is found faulty, replace as steering column

assembly.

NOTE:

Vehicles involved in accidents resulting in body damage,

where steering column has been impacted (or air bag

deployed) may have a damaged or misaligned steering

column.