battery SUZUKI SWIFT 2000 1.G RG413 Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 99 of 698

1B-34 AIR CONDITIONING (OPTIONAL)

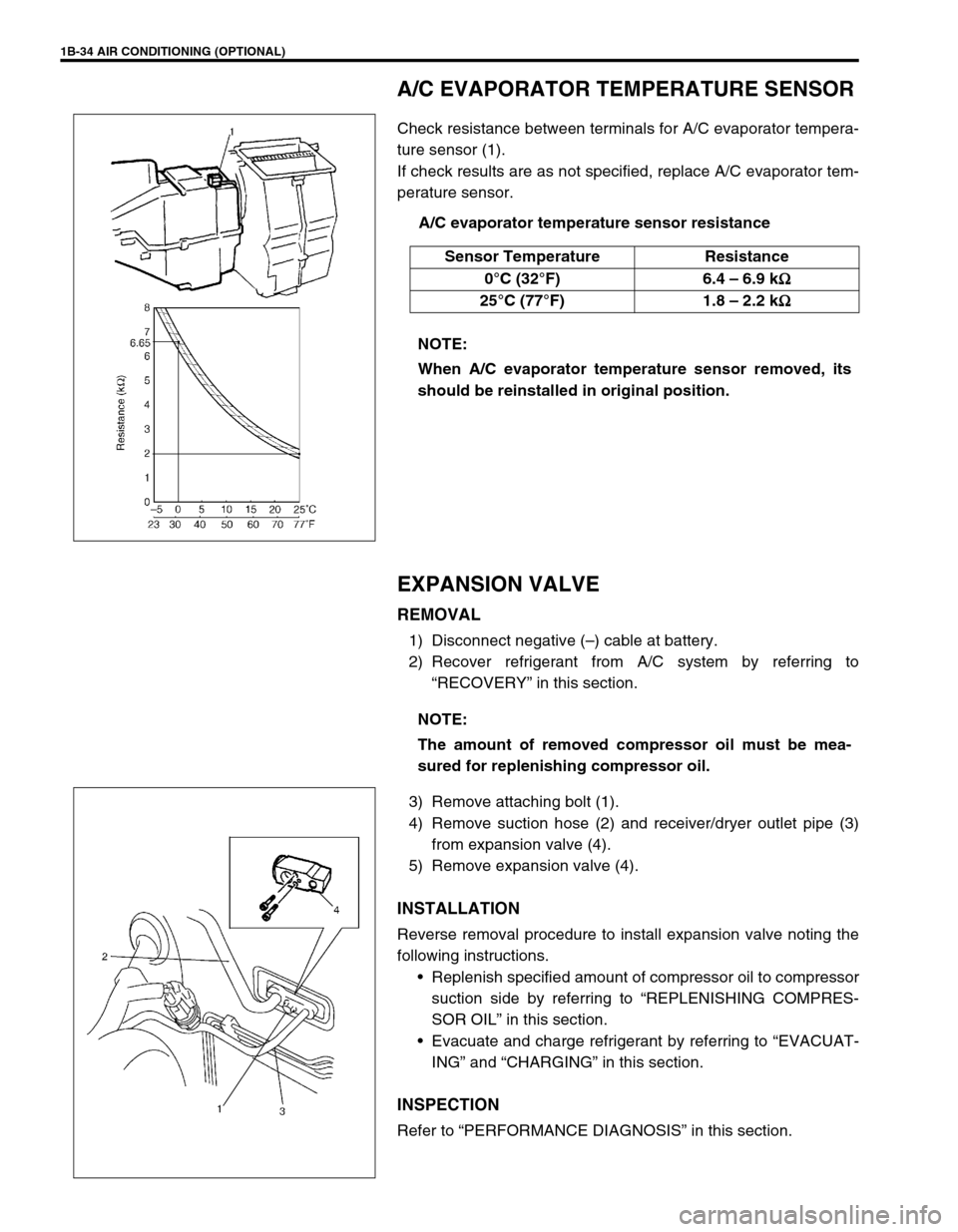

A/C EVAPORATOR TEMPERATURE SENSOR

Check resistance between terminals for A/C evaporator tempera-

ture sensor (1).

If check results are as not specified, replace A/C evaporator tem-

perature sensor.

A/C evaporator temperature sensor resistance

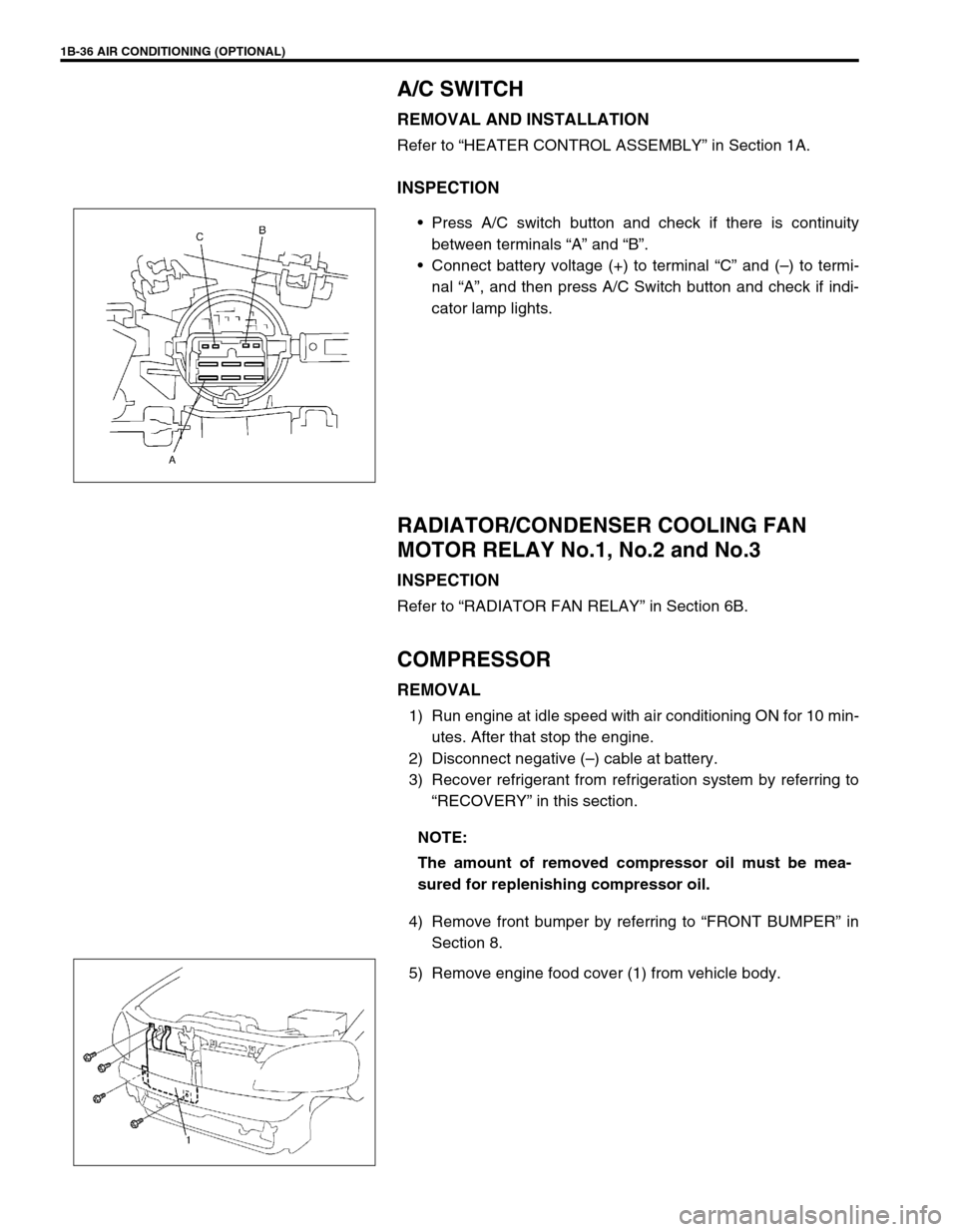

EXPANSION VALVE

REMOVAL

1) Disconnect negative (–) cable at battery.

2) Recover refrigerant from A/C system by referring to

“RECOVERY” in this section.

3) Remove attaching bolt (1).

4) Remove suction hose (2) and receiver/dryer outlet pipe (3)

from expansion valve (4).

5) Remove expansion valve (4).

INSTALLATION

Reverse removal procedure to install expansion valve noting the

following instructions.

Replenish specified amount of compressor oil to compressor

suction side by referring to “REPLENISHING COMPRES-

SOR OIL” in this section.

Evacuate and charge refrigerant by referring to “EVACUAT-

ING” and “CHARGING” in this section.

INSPECTION

Refer to “PERFORMANCE DIAGNOSIS” in this section. Sensor Temperature Resistance

0°C (32°F) 6.4 – 6.9 k

Ω

ΩΩ Ω

25°C (77°F) 1.8 – 2.2 k

Ω

ΩΩ Ω

NOTE:

When A/C evaporator temperature sensor removed, its

should be reinstalled in original position.

NOTE:

The amount of removed compressor oil must be mea-

sured for replenishing compressor oil.

Page 101 of 698

1B-36 AIR CONDITIONING (OPTIONAL)

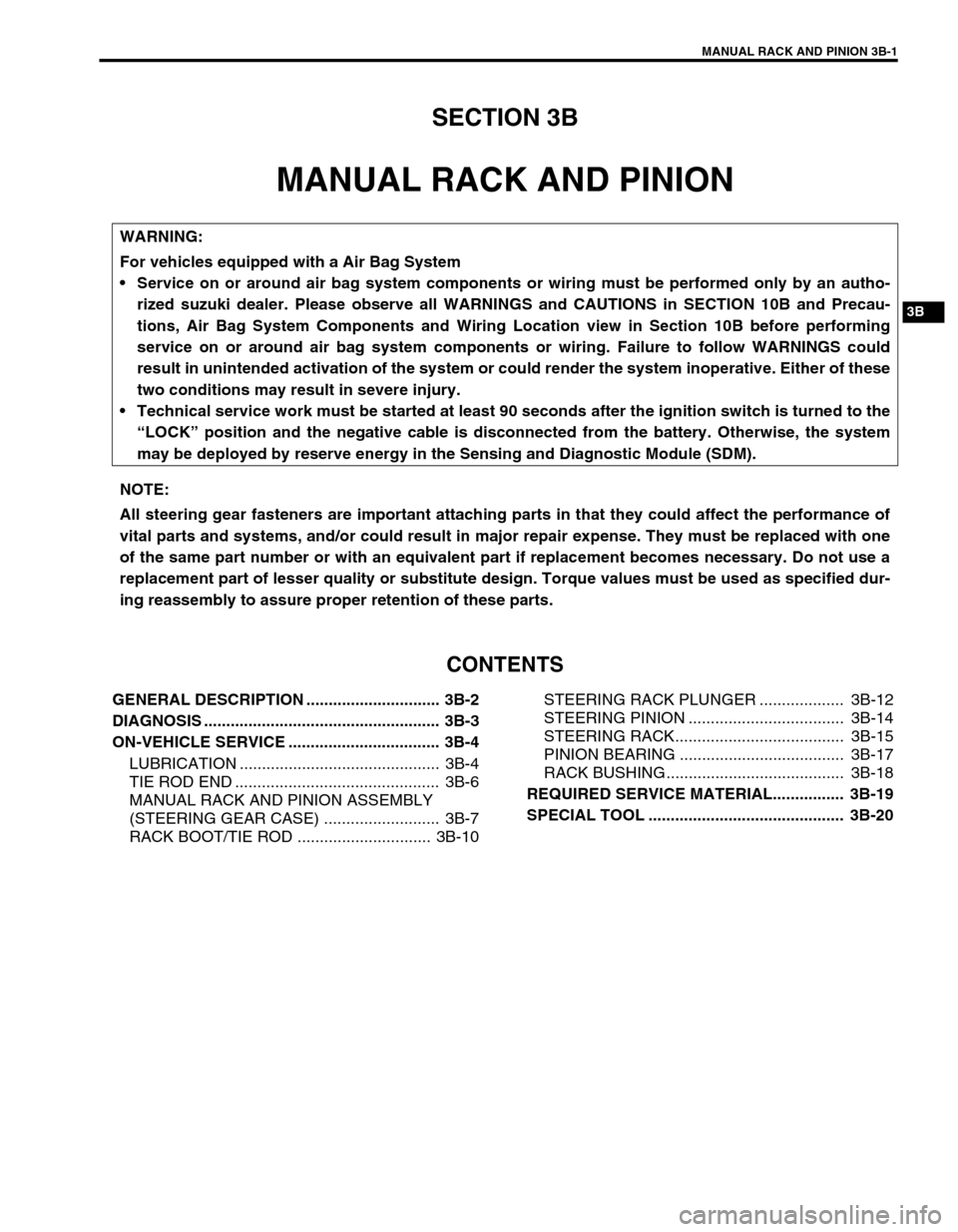

A/C SWITCH

REMOVAL AND INSTALLATION

Refer to “HEATER CONTROL ASSEMBLY” in Section 1A.

INSPECTION

Press A/C switch button and check if there is continuity

between terminals “A” and “B”.

Connect battery voltage (+) to terminal “C” and (–) to termi-

nal “A”, and then press A/C Switch button and check if indi-

cator lamp lights.

RADIATOR/CONDENSER COOLING FAN

MOTOR RELAY No.1, No.2 and No.3

INSPECTION

Refer to “RADIATOR FAN RELAY” in Section 6B.

COMPRESSOR

REMOVAL

1) Run engine at idle speed with air conditioning ON for 10 min-

utes. After that stop the engine.

2) Disconnect negative (–) cable at battery.

3) Recover refrigerant from refrigeration system by referring to

“RECOVERY” in this section.

4) Remove front bumper by referring to “FRONT BUMPER” in

Section 8.

5) Remove engine food cover (1) from vehicle body.

NOTE:

The amount of removed compressor oil must be mea-

sured for replenishing compressor oil.

Page 122 of 698

MANUAL RACK AND PINION 3B-1

6F1

6F2

6G

6H

7A

3B

7C1

7D

7E

7F

8A

8B

8C

8D

8E

9

10

10A

10B

SECTION 3B

MANUAL RACK AND PINION

CONTENTS

GENERAL DESCRIPTION .............................. 3B-2

DIAGNOSIS ..................................................... 3B-3

ON-VEHICLE SERVICE .................................. 3B-4

LUBRICATION ............................................. 3B-4

TIE ROD END .............................................. 3B-6

MANUAL RACK AND PINION ASSEMBLY

(STEERING GEAR CASE) .......................... 3B-7

RACK BOOT/TIE ROD .............................. 3B-10STEERING RACK PLUNGER ................... 3B-12

STEERING PINION ................................... 3B-14

STEERING RACK...................................... 3B-15

PINION BEARING ..................................... 3B-17

RACK BUSHING ........................................ 3B-18

REQUIRED SERVICE MATERIAL................ 3B-19

SPECIAL TOOL ............................................ 3B-20

WARNING:

For vehicles equipped with a Air Bag System

Service on or around air bag system components or wiring must be performed only by an autho-

rized suzuki dealer. Please observe all WARNINGS and CAUTIONS in SECTION 10B and Precau-

tions, Air Bag System Components and Wiring Location view in Section 10B before performing

service on or around air bag system components or wiring. Failure to follow WARNINGS could

result in unintended activation of the system or could render the system inoperative. Either of these

two conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be deployed by reserve energy in the Sensing and Diagnostic Module (SDM).

NOTE:

All steering gear fasteners are important attaching parts in that they could affect the performance of

vital parts and systems, and/or could result in major repair expense. They must be replaced with one

of the same part number or with an equivalent part if replacement becomes necessary. Do not use a

replacement part of lesser quality or substitute design. Torque values must be used as specified dur-

ing reassembly to assure proper retention of these parts.

Page 142 of 698

ELECTRICAL POWER STEERING (P/S) SYSTEM 3B1-1

6F1

6F2

6G

6H

6K

7A

7A1

3B1

7D

7E

7F

8A

8B

8C

8D

8E

9

10

10A

10B

SECTION 3B1

ELECTRICAL POWER STEERING (P/S) SYSTEM

CONTENTS

GENERAL DESCRIPTION .............................3B1-2

SYSTEM COMPONENTS ........................... 3B1-2

WIRING DIAGRAM ..................................... 3B1-3

DIAGNOSIS ....................................................3B1-4

ON-BOARD DIAGNOSTIC SYSTEM .......... 3B1-4

PRECAUTIONS IN DIAGNOSING

TROUBLES ................................................. 3B1-4

SYSTEM CHECK FLOW TABLE ................ 3B1-5

MALFUNCTION INDICATOR LAMP

(“EPS” WARNING LAMP) CHECK.............. 3B1-7

DTC CHECK ............................................... 3B1-8

DTC CLEARANCE ...................................... 3B1-9

SERIAL DATA LINK CIRCUIT CHECK ..... 3B1-10

DTC TABLE .............................................. 3B1-11

TABLE A - MALFUNCTION INDICATOR

LAMP DOES NOT COME ON AT

IGNITION SWITCH ON BUT LEAVING

ENGINE OFF ............................................ 3B1-13

TABLE B - MALFUNCTION INDICATOR

LAMP FLASHES AT IGNITION SWITCH

ON ............................................................. 3B1-15

TABLE C - MALFUNCTION INDICATOR

LAMP DOES NOT FLASH, JUST

REMAINS ON OR JUST REMAINS OFF

EVEN WITH DIAGNOSIS SWITCH

TERMINAL GROUNDED .......................... 3B1-15

DTC C1111 (DTC No.11) TORQUE

SENSOR MAIN CIRCUIT FAILURE ......... 3B1-16

DTC C1113 (DTC No.13) TORQUE

SENSOR MAIN AND SUB CIRCUIT

FAILURE ................................................... 3B1-16DTC C1115 (DTC No.15) TORQUE

SENSOR SUB CIRCUIT FAILURE........... 3B1-16

DTC C1114 (DTC No.14) TORQUE

SENSOR 5V POWER SUPPLY CIRCUIT

FAILURE ................................................... 3B1-17

DTC C1116 (DTC No.16) TORQUE

SENSOR 8V POWER SUPPLY CIRCUIT

FAILURE ................................................... 3B1-18

DTC C1121/C1123/C1124

(DTC No.21/23/24) VSS CIRCUIT

FAILURE ................................................... 3B1-19

DTC C1122 (DTC No.22) ENGINE

SPEED SIGNAL CIRCUIT FAILURE ........ 3B1-20

DTC C1141/C1142/C1143/C1144/C1145

(DTC No.41/42/43/44/45) MOTOR

CIRCUIT FAILURE ................................... 3B1-21

DTC C1151 (DTC No.51) CLUTCH

CIRCUIT FAILURE ................................... 3B1-22

DTC C1153(DTC No.53) P/S CONTROL

MODULE POWER SUPPLY CIRCUIT

FAILURE ................................................... 3B1-24

DTC C1152/C1154/C1155

(DTC No.52/54/55) P/S CONTROL

MODULE FAILURE .................................. 3B1-24

TROUBLE DIAGNOSIS (FOR TROUBLE

NOT INDICATED BY ON BOARD

DIAGNOSTIC SYSTEM)........................... 3B1-25

INSPECTION OF P/S CONTROL

MODULE AND ITS CIRCUITS ................. 3B1-26

STEERING WHEEL PLAY

INSPECTION ............................................ 3B1-28 WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System :

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

Page 143 of 698

3B1-2 ELECTRICAL POWER STEERING (P/S) SYSTEM

STEERING FORCE INSPECTION ........... 3B1-28

ON-VEHICLE SERVICE ............................... 3B1-29

P/S CONTROL MODULE ......................... 3B1-29

TORQUE SENSOR .................................. 3B1-29MOTOR AND CLUTCH ............................ 3B1-30

STEERING COLUMN ASSEMBLY .......... 3B1-31

SPECIAL TOOL ........................................... 3B1-31

GENERAL DESCRIPTION

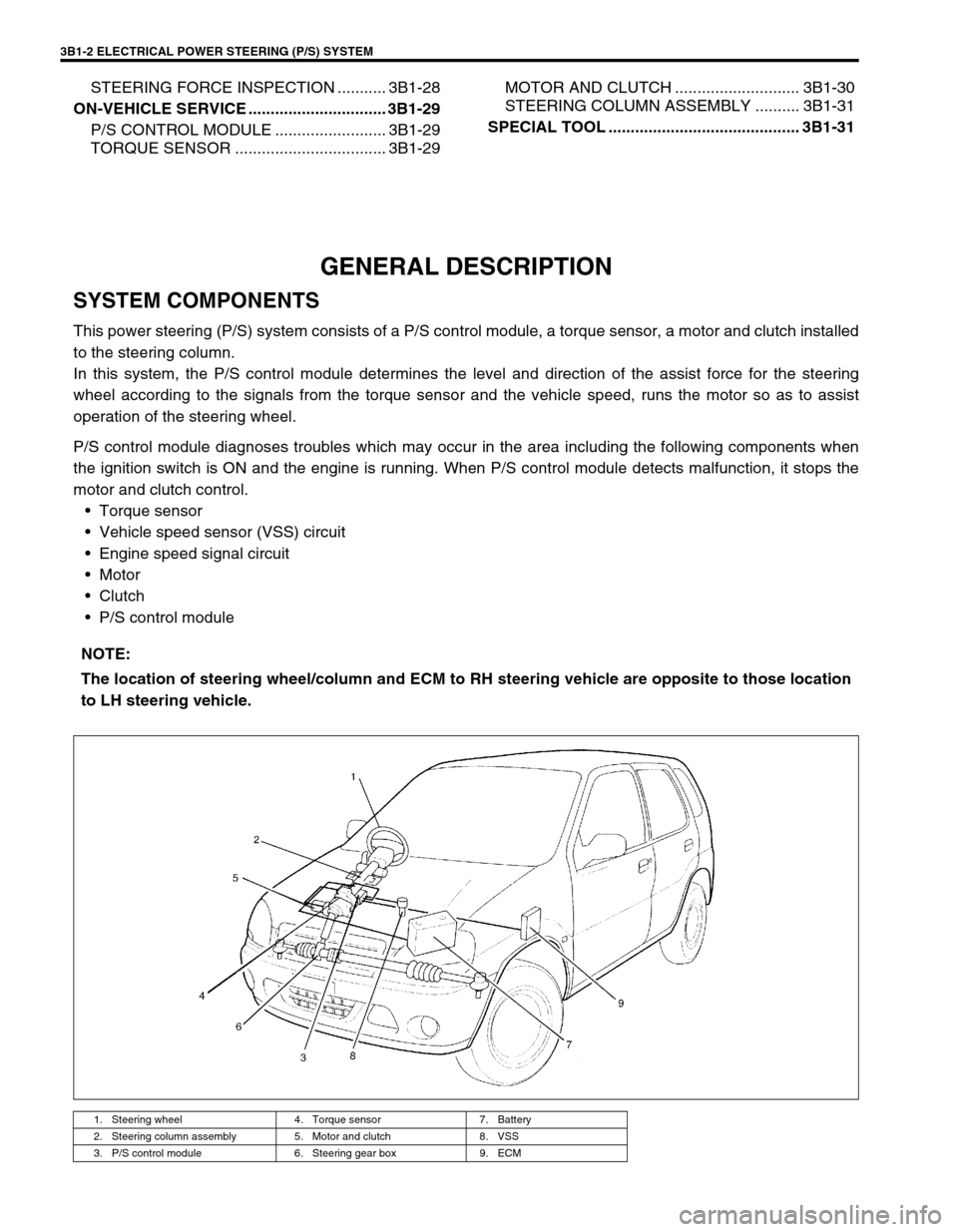

SYSTEM COMPONENTS

This power steering (P/S) system consists of a P/S control module, a torque sensor, a motor and clutch installed

to the steering column.

In this system, the P/S control module determines the level and direction of the assist force for the steering

wheel according to the signals from the torque sensor and the vehicle speed, runs the motor so as to assist

operation of the steering wheel.

P/S control module diagnoses troubles which may occur in the area including the following components when

the ignition switch is ON and the engine is running. When P/S control module detects malfunction, it stops the

motor and clutch control.

Torque sensor

Vehicle speed sensor (VSS) circuit

Engine speed signal circuit

Motor

Clutch

P/S control module

NOTE:

The location of steering wheel/column and ECM to RH steering vehicle are opposite to those location

to LH steering vehicle.

1. Steering wheel 4. Torque sensor 7. Battery

2. Steering column assembly 5. Motor and clutch 8. VSS

3. P/S control module 6. Steering gear box 9. ECM

Page 167 of 698

3B1-26 ELECTRICAL POWER STEERING (P/S) SYSTEM

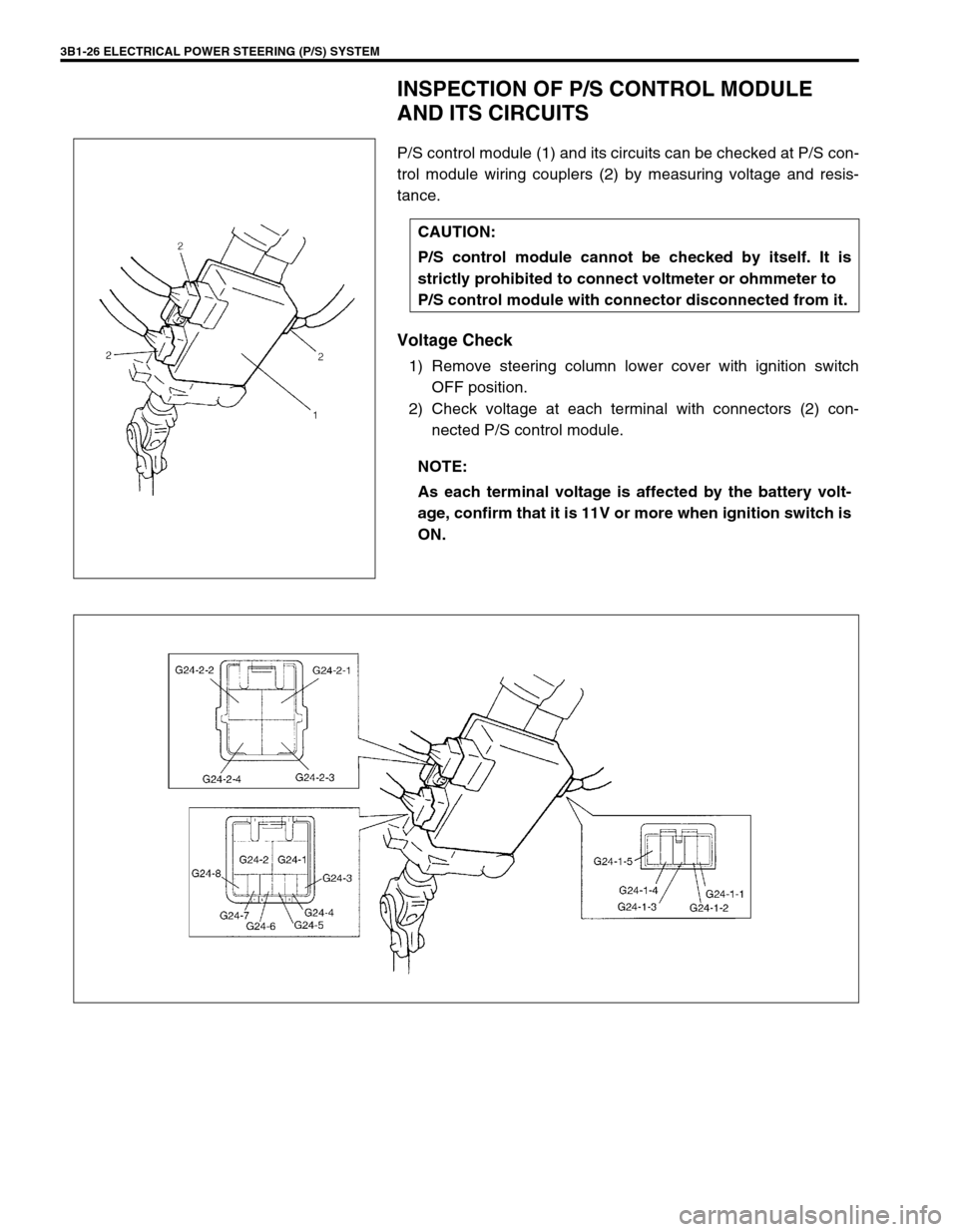

INSPECTION OF P/S CONTROL MODULE

AND ITS CIRCUITS

P/S control module (1) and its circuits can be checked at P/S con-

trol module wiring couplers (2) by measuring voltage and resis-

tance.

Voltage Check

1) Remove steering column lower cover with ignition switch

OFF position.

2) Check voltage at each terminal with connectors (2) con-

nected P/S control module. CAUTION:

P/S control module cannot be checked by itself. It is

strictly prohibited to connect voltmeter or ohmmeter to

P/S control module with connector disconnected from it.

NOTE:

As each terminal voltage is affected by the battery volt-

age, confirm that it is 11V or more when ignition switch is

ON.

Page 168 of 698

ELECTRICAL POWER STEERING (P/S) SYSTEM 3B1-27

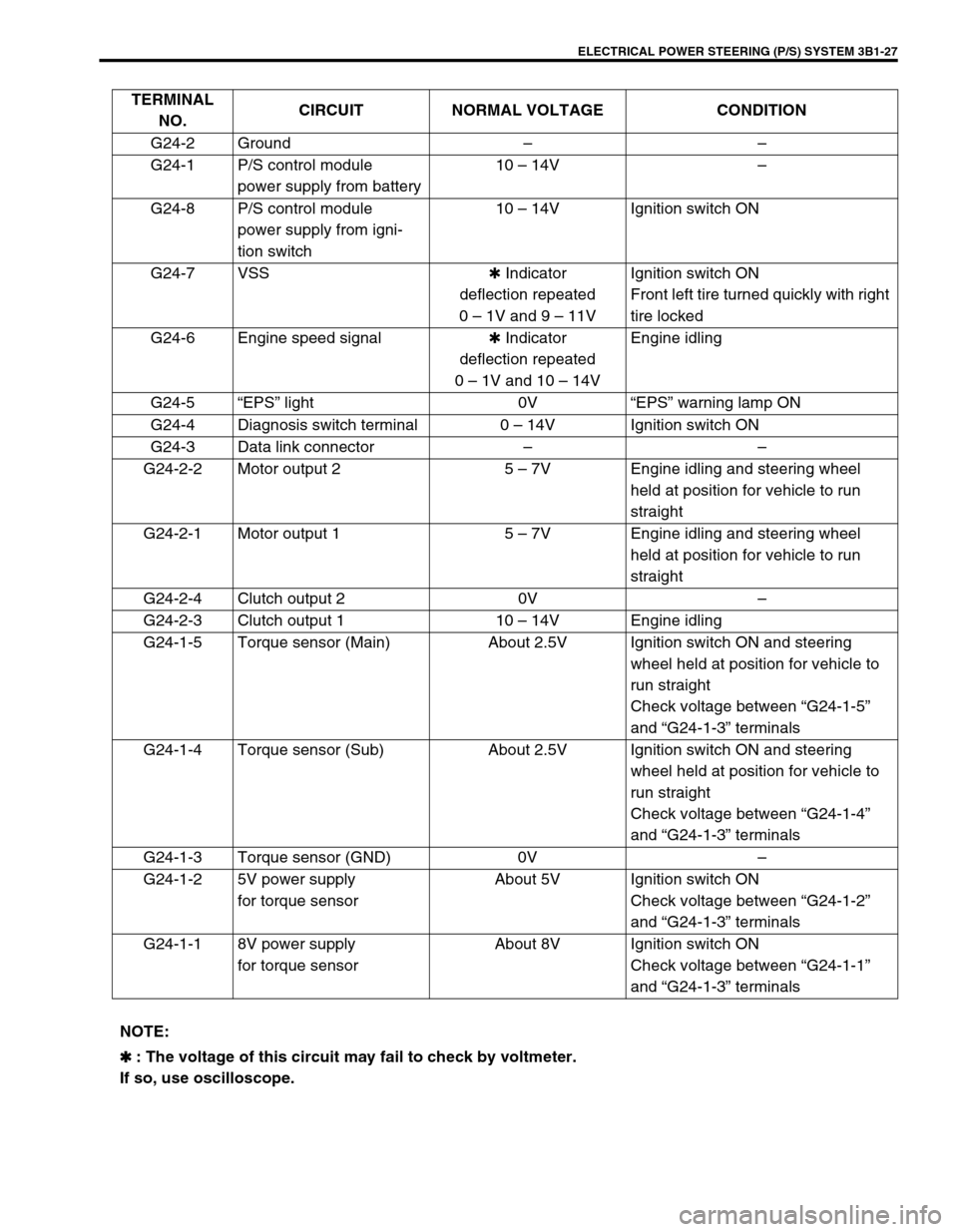

TERMINAL

NO.CIRCUIT NORMAL VOLTAGE CONDITION

G24-2 Ground––

G24-1 P/S control module

power supply from battery10 – 14V–

G24-8 P/S control module

power supply from igni-

tion switch10 – 14V Ignition switch ON

G24-7 VSS✱ Indicator

deflection repeated

0 – 1V and 9 – 11VIgnition switch ON

Front left tire turned quickly with right

tire locked

G24-6 Engine speed signal✱ Indicator

deflection repeated

0 – 1V and 10 – 14VEngine idling

G24-5“EPS” light 0V“EPS” warning lamp ON

G24-4 Diagnosis switch terminal 0 – 14V Ignition switch ON

G24-3 Data link connector––

G24-2-2 Motor output 2 5 – 7V Engine idling and steering wheel

held at position for vehicle to run

straight

G24-2-1 Motor output 1 5 – 7V Engine idling and steering wheel

held at position for vehicle to run

straight

G24-2-4 Clutch output 2 0V–

G24-2-3 Clutch output 1 10 – 14V Engine idling

G24-1-5 Torque sensor (Main) About 2.5V Ignition switch ON and steering

wheel held at position for vehicle to

run straight

Check voltage between “G24-1-5”

and “G24-1-3” terminals

G24-1-4 Torque sensor (Sub) About 2.5V Ignition switch ON and steering

wheel held at position for vehicle to

run straight

Check voltage between “G24-1-4”

and “G24-1-3” terminals

G24-1-3 Torque sensor (GND) 0V–

G24-1-2 5V power supply

for torque sensorAbout 5V Ignition switch ON

Check voltage between “G24-1-2”

and “G24-1-3” terminals

G24-1-1 8V power supply

for torque sensorAbout 8V Ignition switch ON

Check voltage between “G24-1-1”

and “G24-1-3” terminals

NOTE:

✱

✱✱ ✱ : The voltage of this circuit may fail to check by voltmeter.

If so, use oscilloscope.

Page 170 of 698

ELECTRICAL POWER STEERING (P/S) SYSTEM 3B1-29

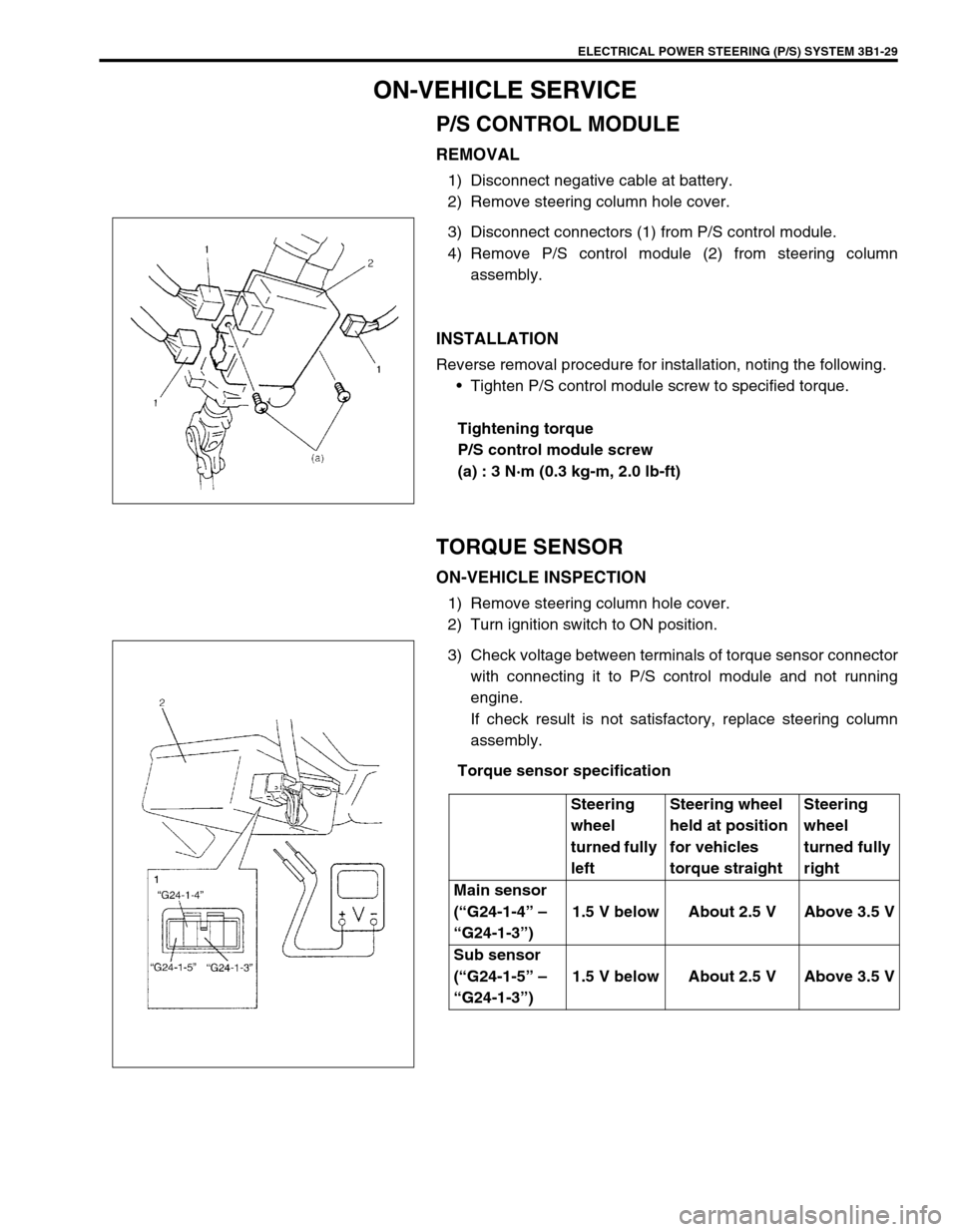

ON-VEHICLE SERVICE

P/S CONTROL MODULE

REMOVAL

1) Disconnect negative cable at battery.

2) Remove steering column hole cover.

3) Disconnect connectors (1) from P/S control module.

4) Remove P/S control module (2) from steering column

assembly.

INSTALLATION

Reverse removal procedure for installation, noting the following.

Tighten P/S control module screw to specified torque.

Tightening torque

P/S control module screw

(a) : 3 N·m (0.3 kg-m, 2.0 lb-ft)

TORQUE SENSOR

ON-VEHICLE INSPECTION

1) Remove steering column hole cover.

2) Turn ignition switch to ON position.

3) Check voltage between terminals of torque sensor connector

with connecting it to P/S control module and not running

engine.

If check result is not satisfactory, replace steering column

assembly.

Torque sensor specification

Steering

wheel

turned fully

leftSteering wheel

held at position

for vehicles

torque straightSteering

wheel

turned fully

right

Main sensor

(“G24-1-4” –

“G24-1-3”)1.5 V below About 2.5 V Above 3.5 V

Sub sensor

(“G24-1-5” –

“G24-1-3”)1.5 V below About 2.5 V Above 3.5 V

Page 171 of 698

3B1-30 ELECTRICAL POWER STEERING (P/S) SYSTEM

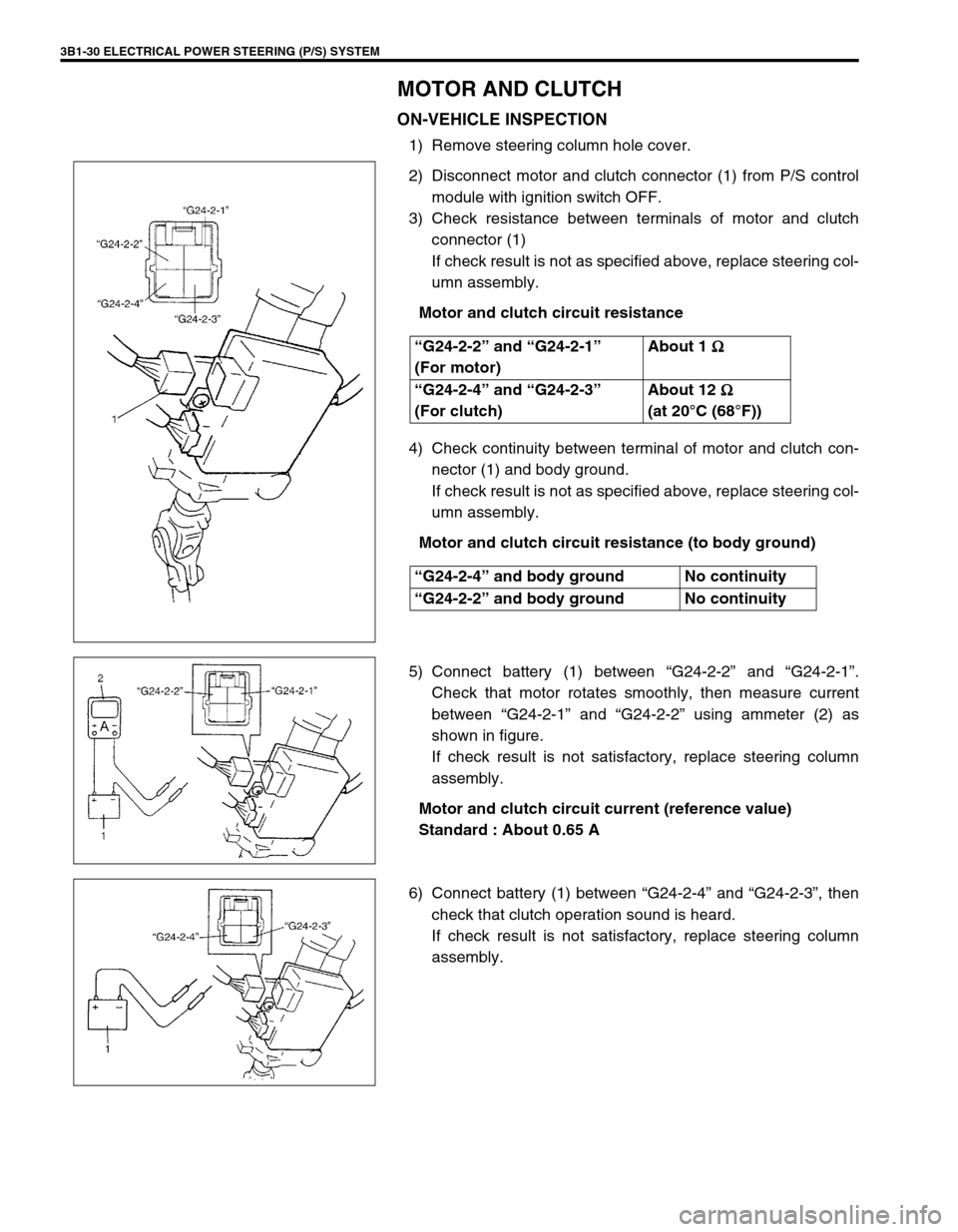

MOTOR AND CLUTCH

ON-VEHICLE INSPECTION

1) Remove steering column hole cover.

2) Disconnect motor and clutch connector (1) from P/S control

module with ignition switch OFF.

3) Check resistance between terminals of motor and clutch

connector (1)

If check result is not as specified above, replace steering col-

umn assembly.

Motor and clutch circuit resistance

4) Check continuity between terminal of motor and clutch con-

nector (1) and body ground.

If check result is not as specified above, replace steering col-

umn assembly.

Motor and clutch circuit resistance (to body ground)

5) Connect battery (1) between “G24-2-2” and “G24-2-1”.

Check that motor rotates smoothly, then measure current

between “G24-2-1” and “G24-2-2” using ammeter (2) as

shown in figure.

If check result is not satisfactory, replace steering column

assembly.

Motor and clutch circuit current (reference value)

Standard : About 0.65 A

6) Connect battery (1) between “G24-2-4” and “G24-2-3”, then

check that clutch operation sound is heard.

If check result is not satisfactory, replace steering column

assembly. “G24-2-2” and “G24-2-1”

(For motor)About 1

Ω

ΩΩ Ω

“G24-2-4” and “G24-2-3”

(For clutch)About 12

Ω

ΩΩ Ω

(at 20°C (68°F))

“G24-2-4” and body ground No continuity

“G24-2-2” and body ground No continuity

Page 177 of 698

3C-4 STEERING WHEEL AND COLUMN

HANDLING AND STORAGE

For handling and storage, refer to “HANDLING AND STORAGE” under “SERVICE PRECAUTIONS” in Section

10B.

DISPOSAL

For disposal, refer to “DISPOSAL” under “SERVICE PRECAUTIONS” in Section 10B.

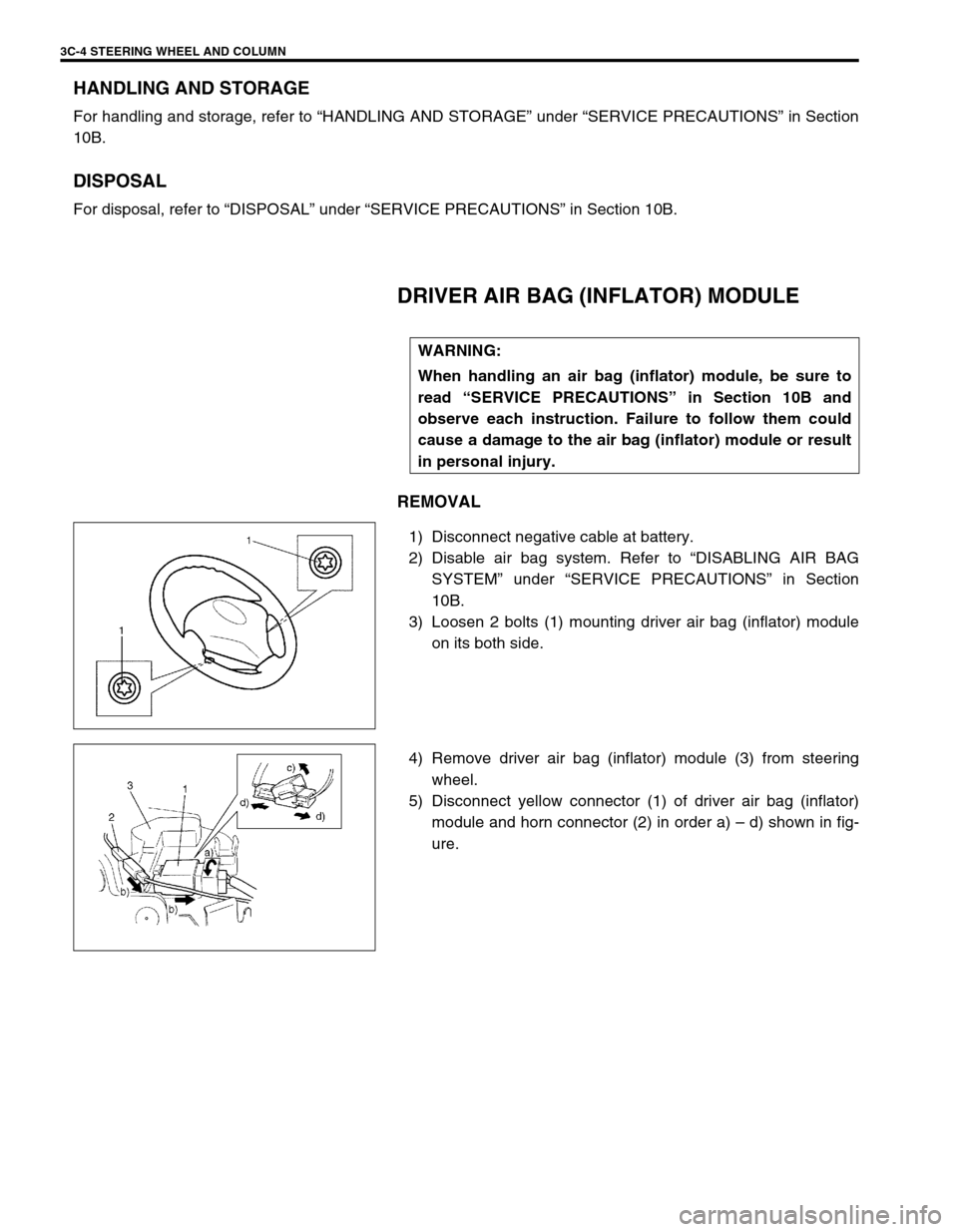

DRIVER AIR BAG (INFLATOR) MODULE

REMOVAL

1) Disconnect negative cable at battery.

2) Disable air bag system. Refer to “DISABLING AIR BAG

SYSTEM” under “SERVICE PRECAUTIONS” in Section

10B.

3) Loosen 2 bolts (1) mounting driver air bag (inflator) module

on its both side.

4) Remove driver air bag (inflator) module (3) from steering

wheel.

5) Disconnect yellow connector (1) of driver air bag (inflator)

module and horn connector (2) in order a) – d) shown in fig-

ure. WARNING:

When handling an air bag (inflator) module, be sure to

read “SERVICE PRECAUTIONS” in Section 10B and

observe each instruction. Failure to follow them could

cause a damage to the air bag (inflator) module or result

in personal injury.