boot SUZUKI SWIFT 2000 1.G RG413 Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 262 of 698

FRONT DRIVE SHAFT 4A-9

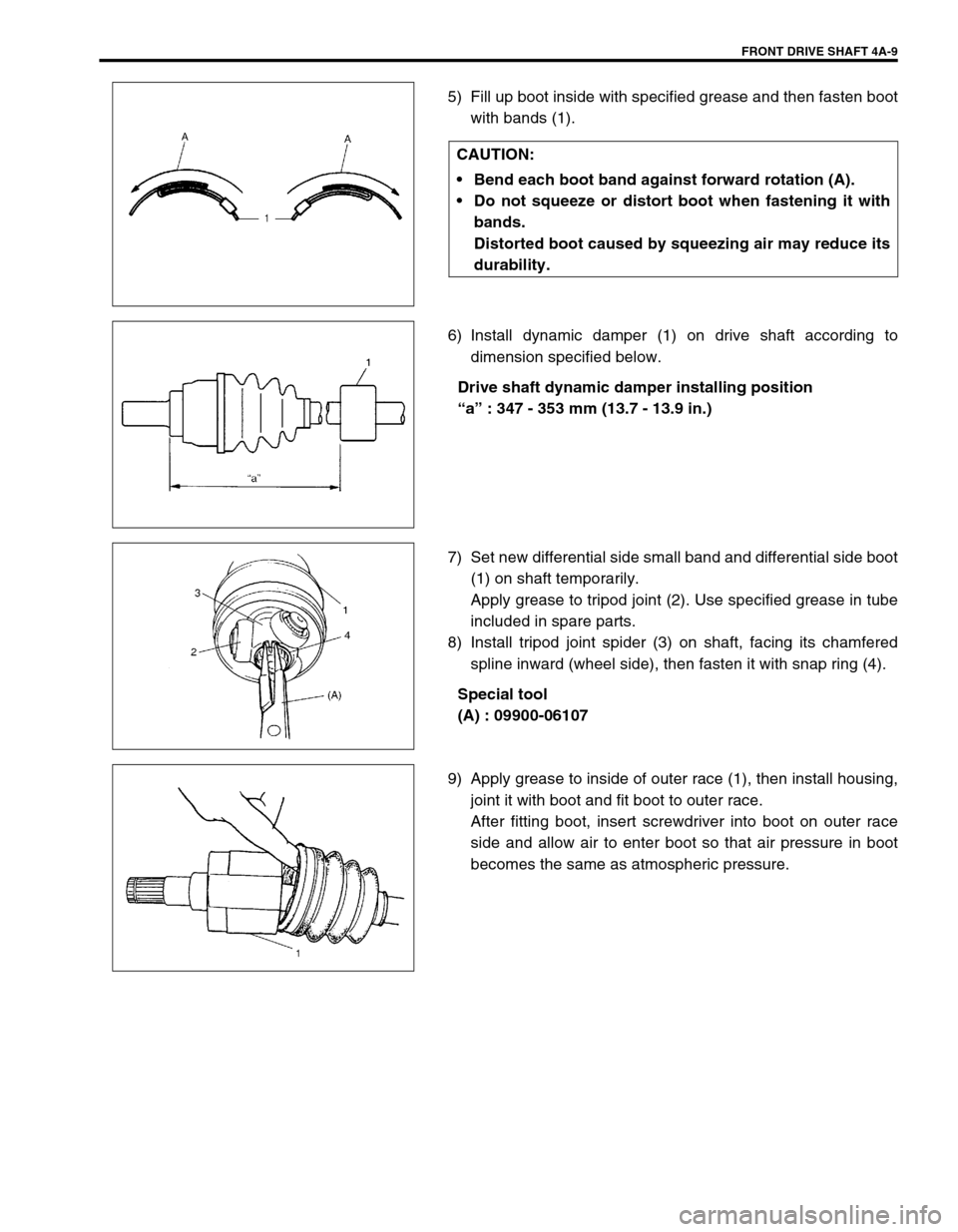

5) Fill up boot inside with specified grease and then fasten boot

with bands (1).

6) Install dynamic damper (1) on drive shaft according to

dimension specified below.

Drive shaft dynamic damper installing position

โaโ : 347 - 353 mm (13.7 - 13.9 in.)

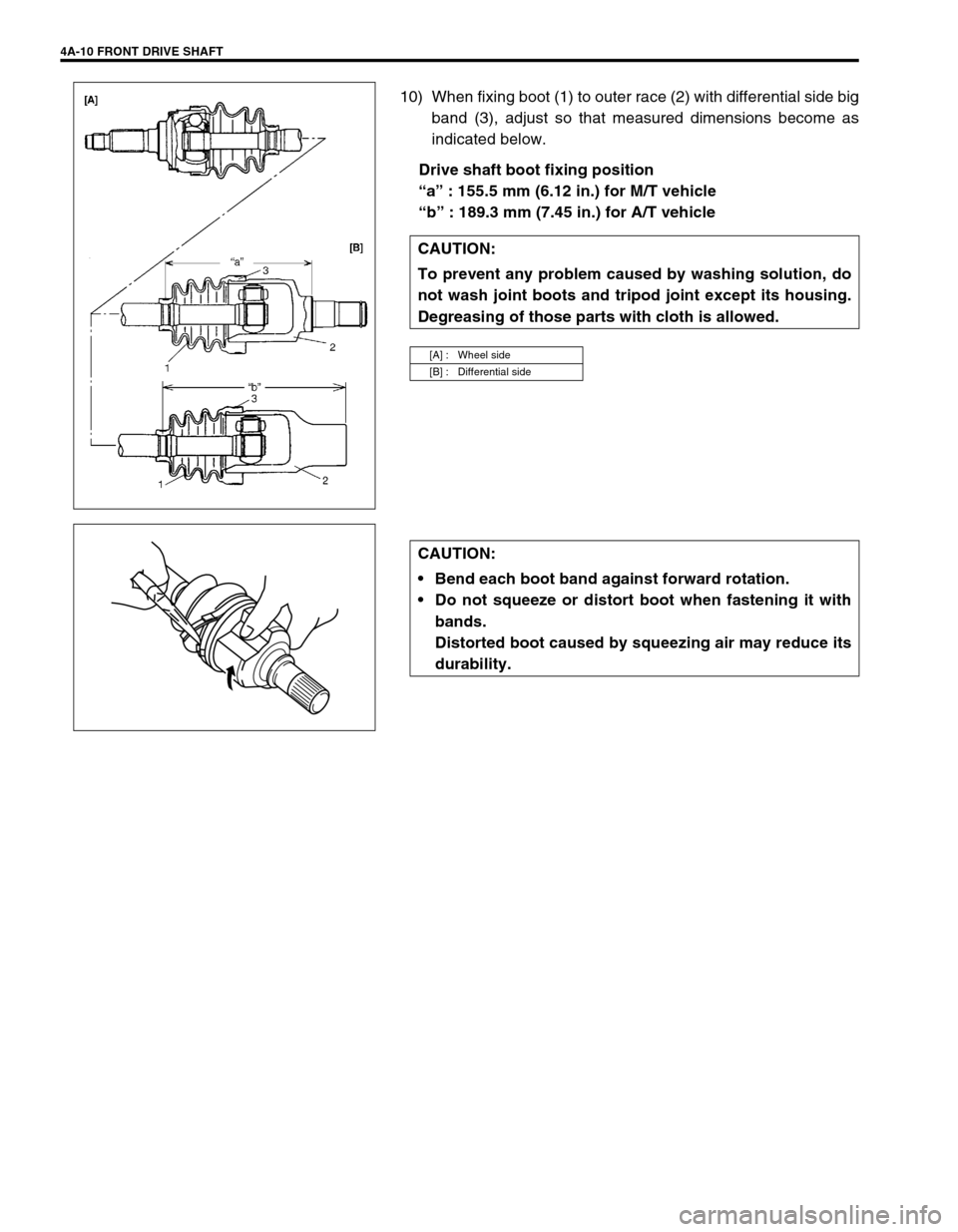

7) Set new differential side small band and differential side boot

(1) on shaft temporarily.

Apply grease to tripod joint (2). Use specified grease in tube

included in spare parts.

8) Install tripod joint spider (3) on shaft, facing its chamfered

spline inward (wheel side), then fasten it with snap ring (4).

Special tool

(A) : 09900-06107

9) Apply grease to inside of outer race (1), then install housing,

joint it with boot and fit boot to outer race.

After fitting boot, insert screwdriver into boot on outer race

side and allow air to enter boot so that air pressure in boot

becomes the same as atmospheric pressure. CAUTION:

Bend each boot band against forward rotation (A).

Do not squeeze or distort boot when fastening it with

bands.

Distorted boot caused by squeezing air may reduce its

durability.

Page 263 of 698

4A-10 FRONT DRIVE SHAFT

10) When fixing boot (1) to outer race (2) with differential side big

band (3), adjust so that measured dimensions become as

indicated below.

Drive shaft boot fixing position

โaโ : 155.5 mm (6.12 in.) for M/T vehicle

โbโ : 189.3 mm (7.45 in.) for A/T vehicle

CAUTION:

To prevent any problem caused by washing solution, do

not wash joint boots and tripod joint except its housing.

Degreasing of those parts with cloth is allowed.

[A] : Wheel side

[B] : Differential side

CAUTION:

Bend each boot band against forward rotation.

Do not squeeze or distort boot when fastening it with

bands.

Distorted boot caused by squeezing air may reduce its

durability.

Page 264 of 698

FRONT DRIVE SHAFT 4A-11

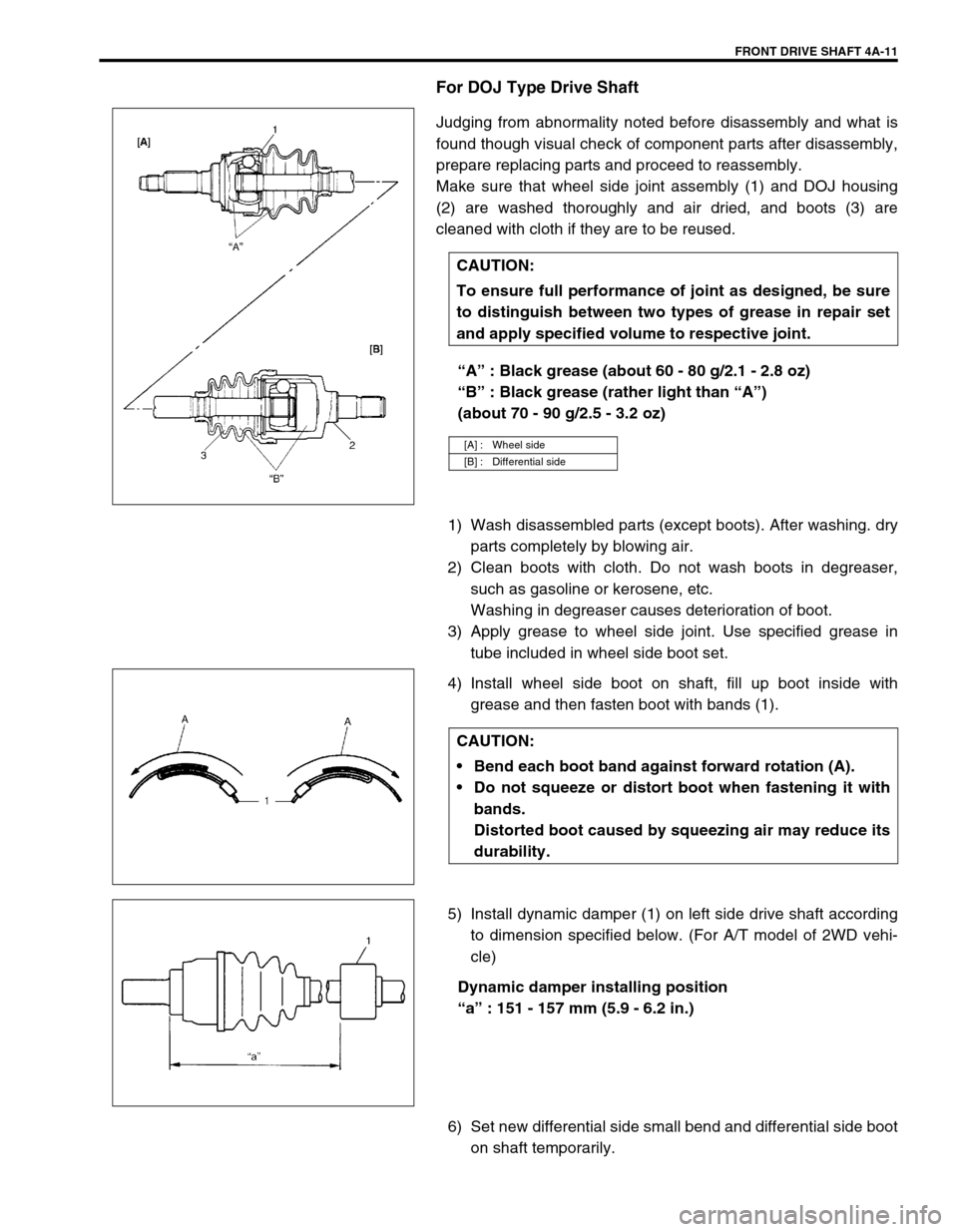

For DOJ Type Drive Shaft

Judging from abnormality noted before disassembly and what is

found though visual check of component parts after disassembly,

prepare replacing parts and proceed to reassembly.

Make sure that wheel side joint assembly (1) and DOJ housing

(2) are washed thoroughly and air dried, and boots (3) are

cleaned with cloth if they are to be reused.

โAโ : Black grease (about 60 - 80 g/2.1 - 2.8 oz)

โBโ : Black grease (rather light than โAโ)

(about 70 - 90 g/2.5 - 3.2 oz)

1) Wash disassembled parts (except boots). After washing. dry

parts completely by blowing air.

2) Clean boots with cloth. Do not wash boots in degreaser,

such as gasoline or kerosene, etc.

Washing in degreaser causes deterioration of boot.

3) Apply grease to wheel side joint. Use specified grease in

tube included in wheel side boot set.

4) Install wheel side boot on shaft, fill up boot inside with

grease and then fasten boot with bands (1).

5) Install dynamic damper (1) on left side drive shaft according

to dimension specified below. (For A/T model of 2WD vehi-

cle)

Dynamic damper installing position

โaโ : 151 - 157 mm (5.9 - 6.2 in.)

6) Set new differential side small bend and differential side boot

on shaft temporarily. CAUTION:

To ensure full performance of joint as designed, be sure

to distinguish between two types of grease in repair set

and apply specified volume to respective joint.

[A] : Wheel side

[B] : Differential side

CAUTION:

Bend each boot band against forward rotation (A).

Do not squeeze or distort boot when fastening it with

bands.

Distorted boot caused by squeezing air may reduce its

durability.

Page 265 of 698

4A-12 FRONT DRIVE SHAFT

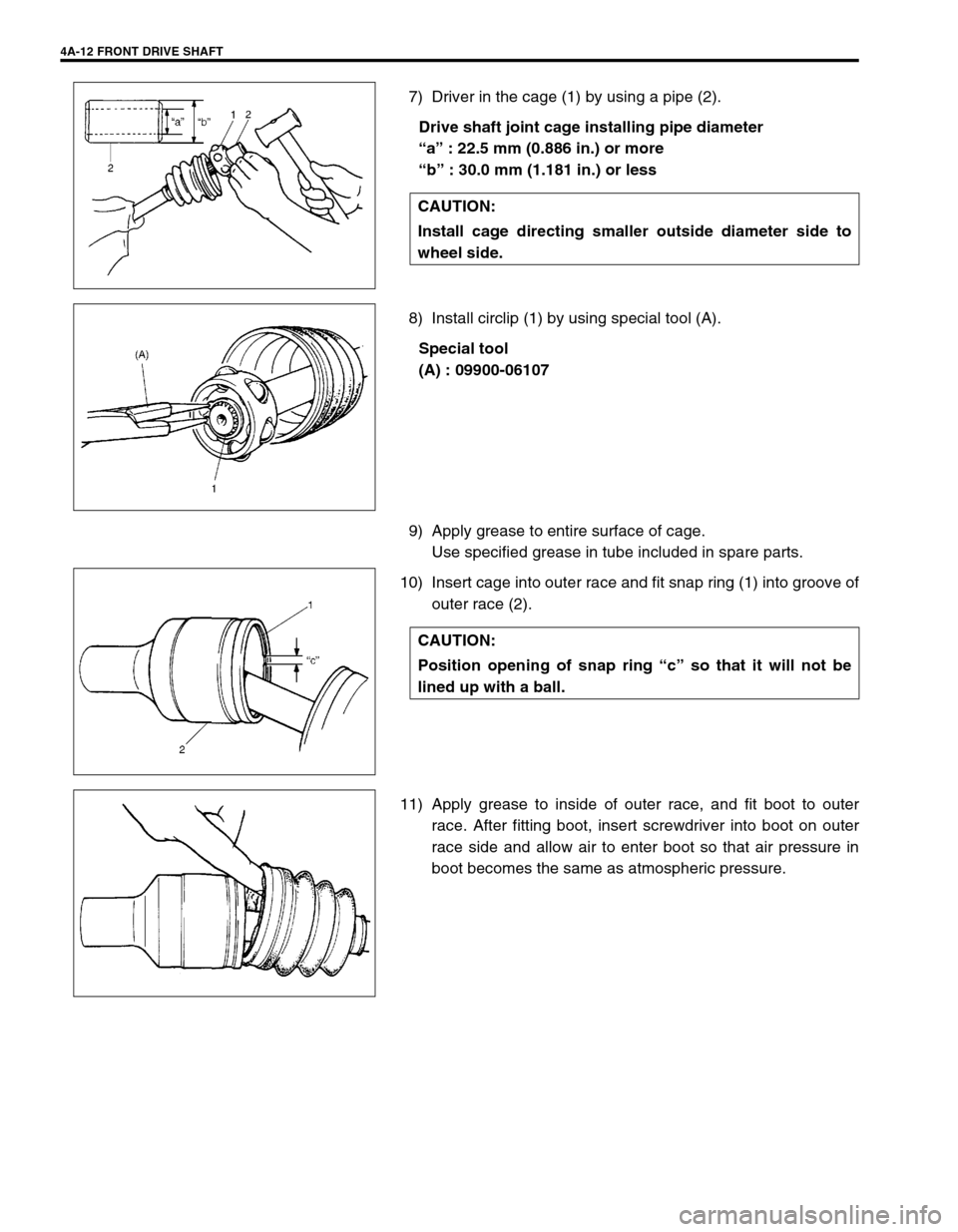

7) Driver in the cage (1) by using a pipe (2).

Drive shaft joint cage installing pipe diameter

โaโ : 22.5 mm (0.886 in.) or more

โbโ : 30.0 mm (1.181 in.) or less

8) Install circlip (1) by using special tool (A).

Special tool

(A) : 09900-06107

9) Apply grease to entire surface of cage.

Use specified grease in tube included in spare parts.

10) Insert cage into outer race and fit snap ring (1) into groove of

outer race (2).

11) Apply grease to inside of outer race, and fit boot to outer

race. After fitting boot, insert screwdriver into boot on outer

race side and allow air to enter boot so that air pressure in

boot becomes the same as atmospheric pressure. CAUTION:

Install cage directing smaller outside diameter side to

wheel side.

CAUTION:

Position opening of snap ring โcโ so that it will not be

lined up with a ball.

Page 266 of 698

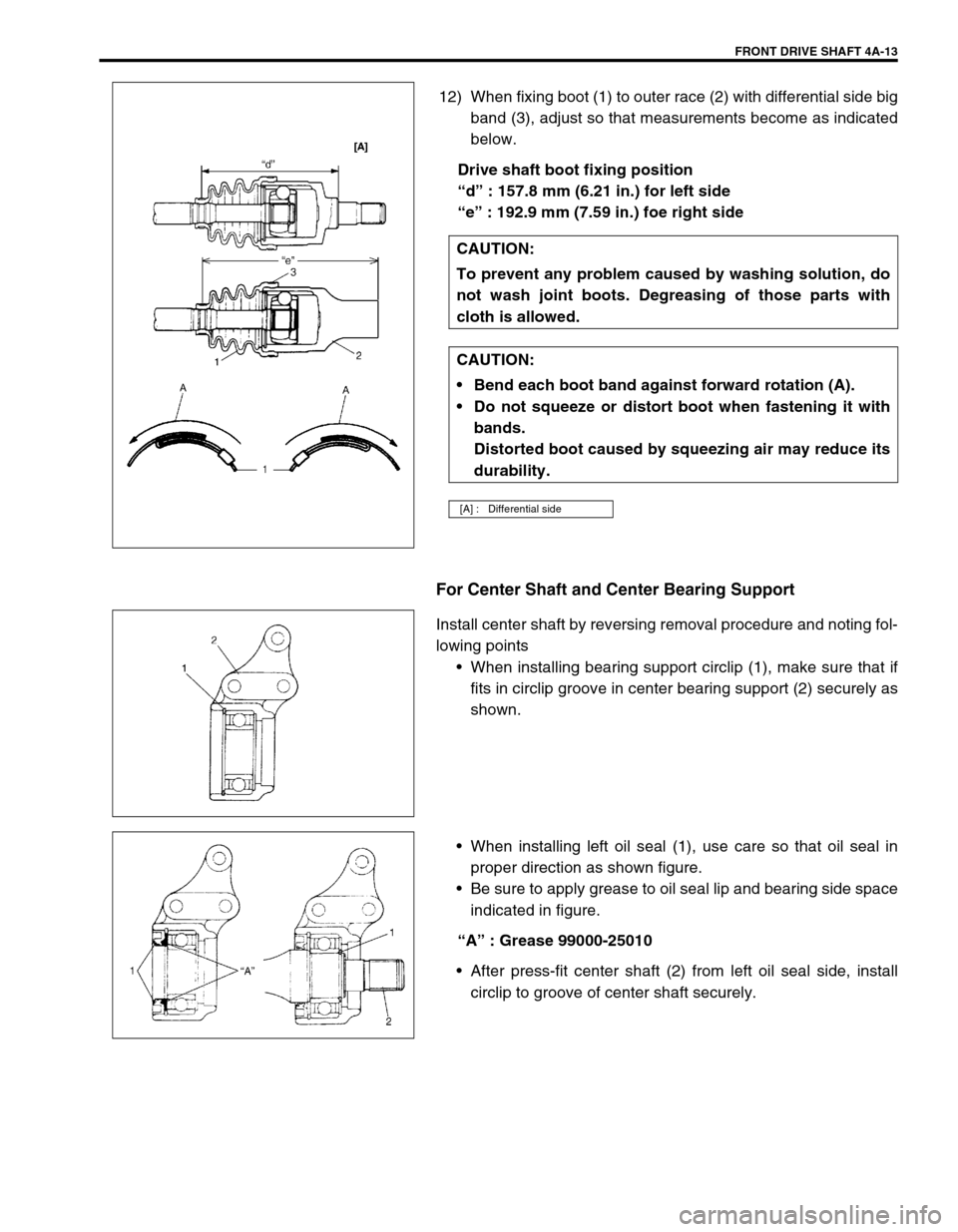

FRONT DRIVE SHAFT 4A-13

12) When fixing boot (1) to outer race (2) with differential side big

band (3), adjust so that measurements become as indicated

below.

Drive shaft boot fixing position

โdโ : 157.8 mm (6.21 in.) for left side

โeโ : 192.9 mm (7.59 in.) foe right side

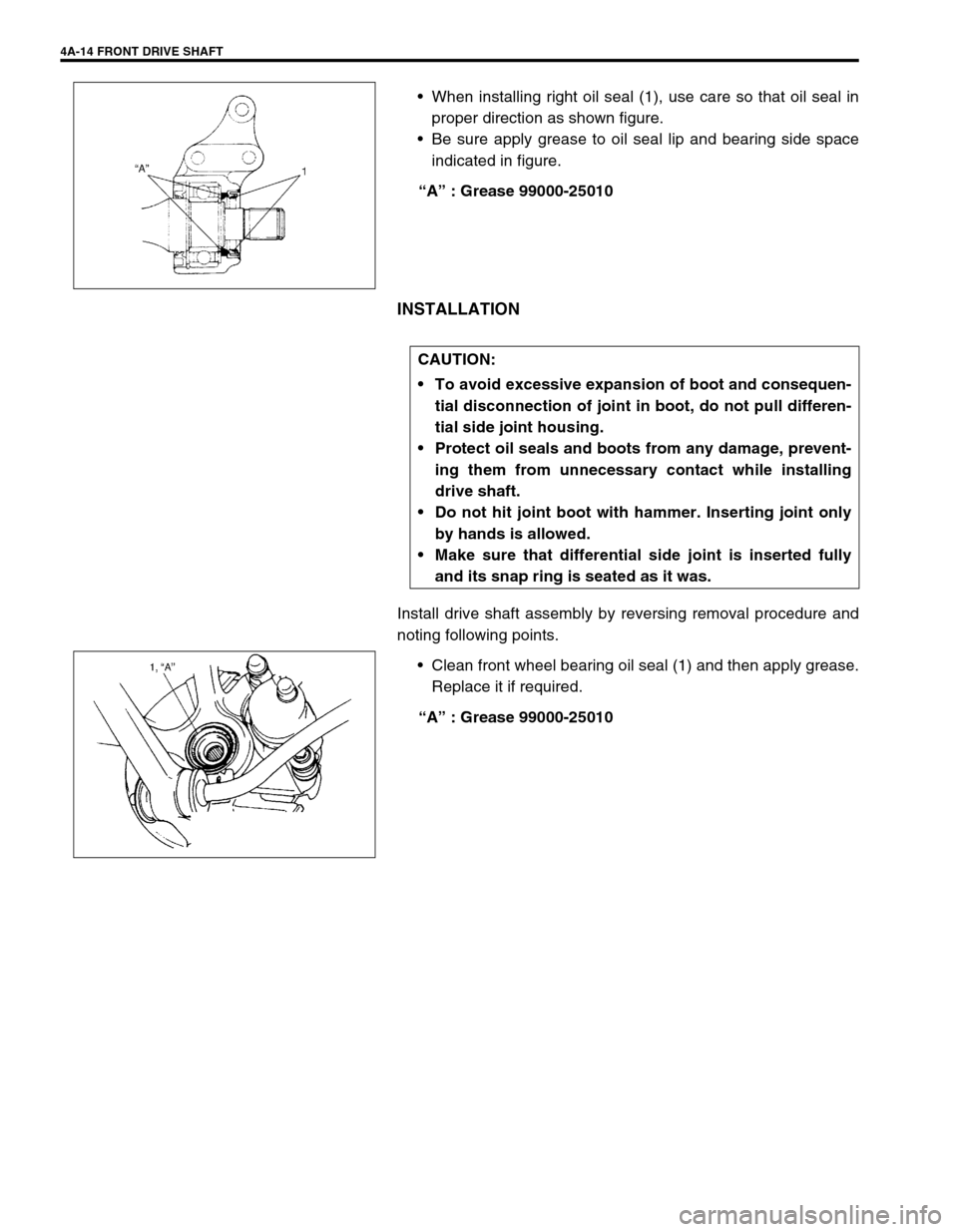

For Center Shaft and Center Bearing Support

Install center shaft by reversing removal procedure and noting fol-

lowing points

When installing bearing support circlip (1), make sure that if

fits in circlip groove in center bearing support (2) securely as

shown.

When installing left oil seal (1), use care so that oil seal in

proper direction as shown figure.

Be sure to apply grease to oil seal lip and bearing side space

indicated in figure.

โAโ : Grease 99000-25010

After press-fit center shaft (2) from left oil seal side, install

circlip to groove of center shaft securely. CAUTION:

To prevent any problem caused by washing solution, do

not wash joint boots. Degreasing of those parts with

cloth is allowed.

CAUTION:

Bend each boot band against forward rotation (A).

Do not squeeze or distort boot when fastening it with

bands.

Distorted boot caused by squeezing air may reduce its

durability.

[A] : Differential side

Page 267 of 698

4A-14 FRONT DRIVE SHAFT

When installing right oil seal (1), use care so that oil seal in

proper direction as shown figure.

Be sure apply grease to oil seal lip and bearing side space

indicated in figure.

โAโ : Grease 99000-25010

INSTALLATION

Install drive shaft assembly by reversing removal procedure and

noting following points.

Clean front wheel bearing oil seal (1) and then apply grease.

Replace it if required.

โAโ : Grease 99000-25010

CAUTION:

To avoid excessive expansion of boot and consequen-

tial disconnection of joint in boot, do not pull differen-

tial side joint housing.

Protect oil seals and boots from any damage, prevent-

ing them from unnecessary contact while installing

drive shaft.

Do not hit joint boot with hammer. Inserting joint only

by hands is allowed.

Make sure that differential side joint is inserted fully

and its snap ring is seated as it was.

Page 290 of 698

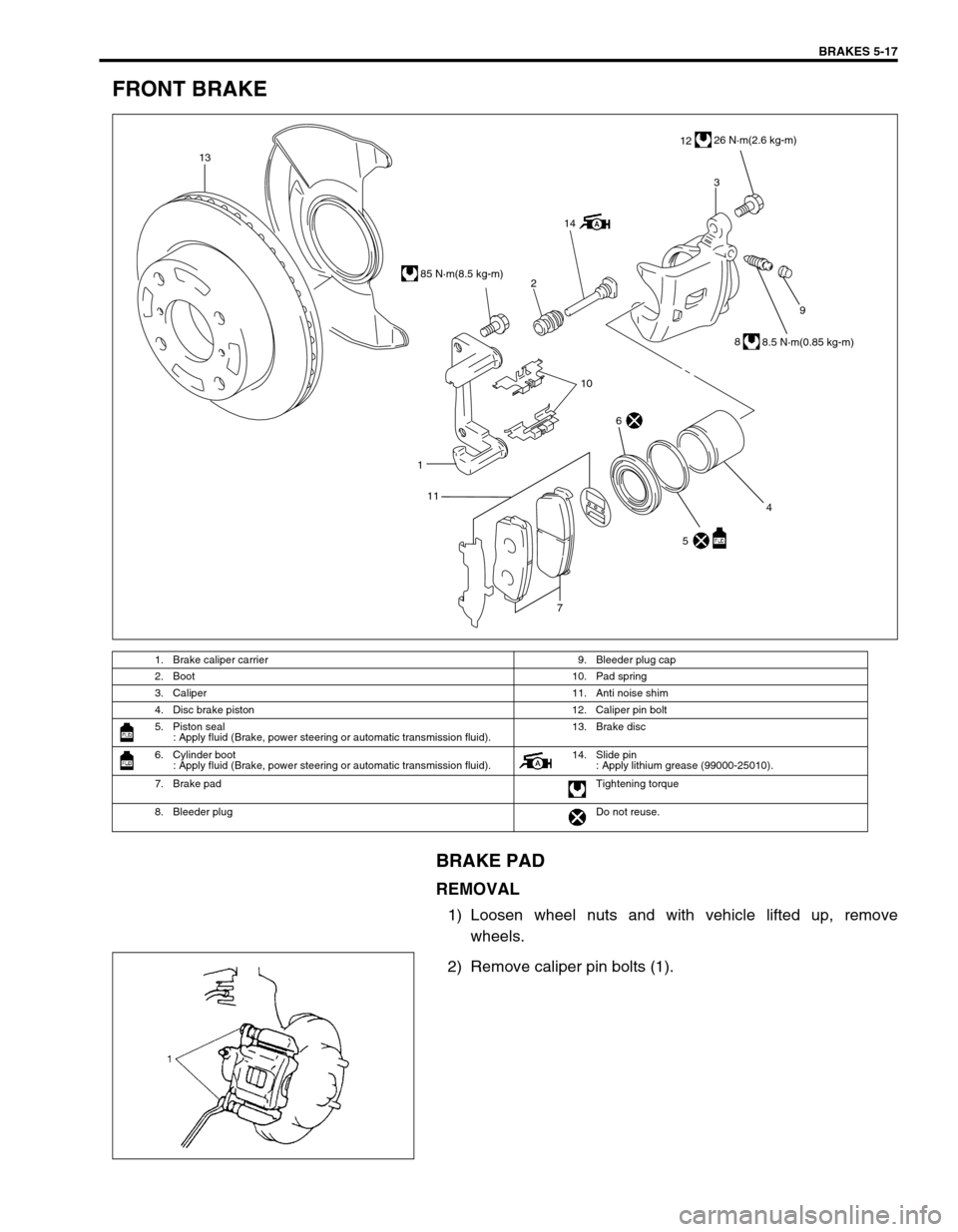

BRAKES 5-17

FRONT BRAKE

BRAKE PAD

REMOVAL

1) Loosen wheel nuts and with vehicle lifted up, remove

wheels.

2) Remove caliper pin bolts (1).

1. Brake caliper carrier 9. Bleeder plug cap

2. Boot 10. Pad spring

3. Caliper 11. Anti noise shim

4. Disc brake piston 12. Caliper pin bolt

5. Piston seal

: Apply fluid (Brake, power steering or automatic transmission fluid).13. Brake disc

6. Cylinder boot

: Apply fluid (Brake, power steering or automatic transmission fluid).14. Slide pin

: Apply lithium grease (99000-25010).

7. Brake pad Tightening torque

8. Bleeder plugDo not reuse.

9

1

7

13

2

143

1226 Nยทm(2.6 kg-m)

85 Nยทm(8.5 kg-m)

8

8.5 Nยทm(0.85 kg-m)

10

5 4

6

11

Page 293 of 698

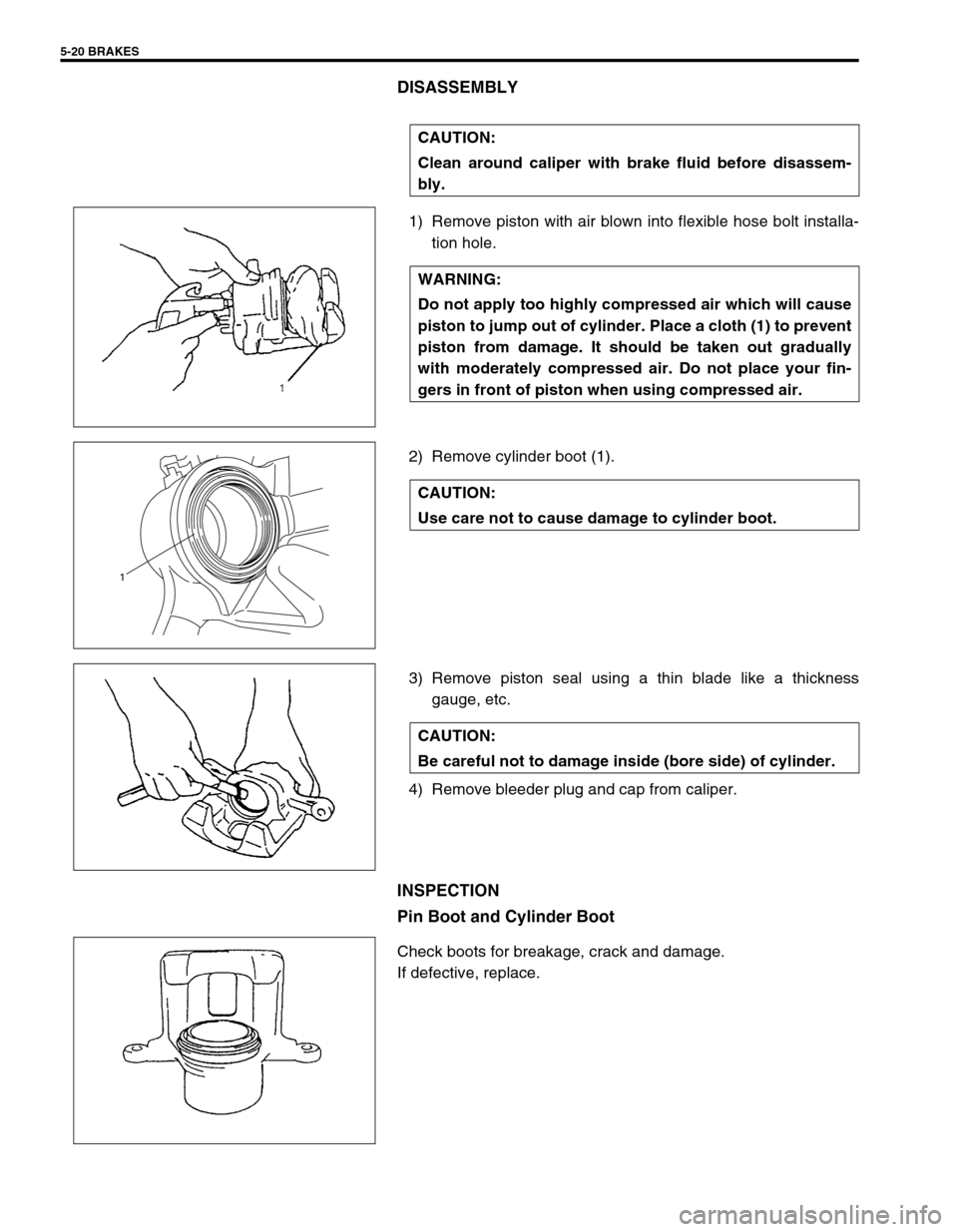

5-20 BRAKES

DISASSEMBLY

1) Remove piston with air blown into flexible hose bolt installa-

tion hole.

2) Remove cylinder boot (1).

3) Remove piston seal using a thin blade like a thickness

gauge, etc.

4) Remove bleeder plug and cap from caliper.

INSPECTION

Pin Boot and Cylinder Boot

Check boots for breakage, crack and damage.

If defective, replace.CAUTION:

Clean around caliper with brake fluid before disassem-

bly.

WARNING:

Do not apply too highly compressed air which will cause

piston to jump out of cylinder. Place a cloth (1) to prevent

piston from damage. It should be taken out gradually

with moderately compressed air. Do not place your fin-

gers in front of piston when using compressed air.

CAUTION:

Use care not to cause damage to cylinder boot.

1

CAUTION:

Be careful not to damage inside (bore side) of cylinder.

Page 295 of 698

5-22 BRAKES

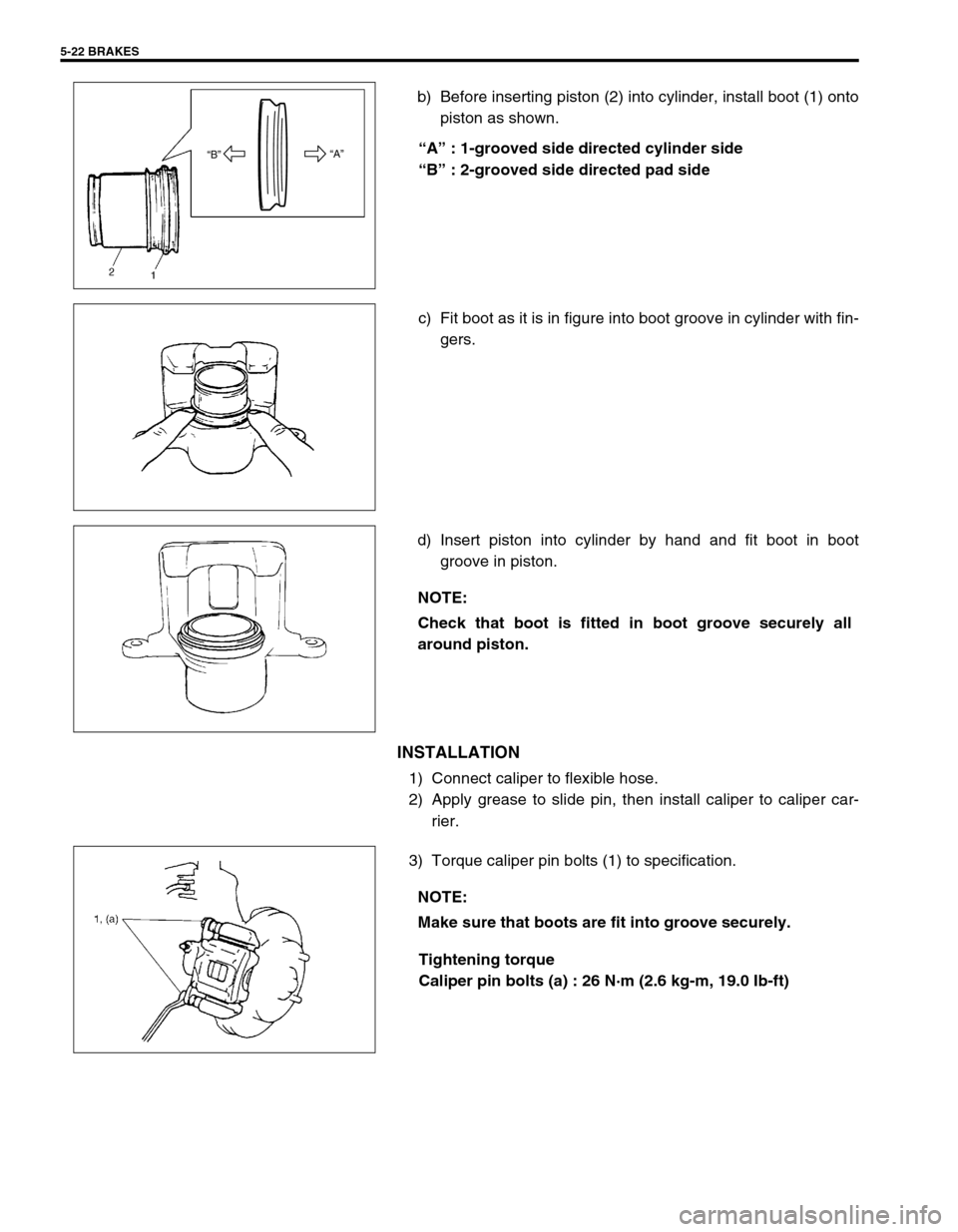

b) Before inserting piston (2) into cylinder, install boot (1) onto

piston as shown.

โAโ : 1-grooved side directed cylinder side

โBโ : 2-grooved side directed pad side

c) Fit boot as it is in figure into boot groove in cylinder with fin-

gers.

d) Insert piston into cylinder by hand and fit boot in boot

groove in piston.

INSTALLATION

1) Connect caliper to flexible hose.

2) Apply grease to slide pin, then install caliper to caliper car-

rier.

3) Torque caliper pin bolts (1) to specification.

Tightening torque

Caliper pin bolts (a) : 26 Nยทm (2.6 kg-m, 19.0 Ib-ft)

โAโ

โBโ

NOTE:

Check that boot is fitted in boot groove securely all

around piston.

NOTE:

Make sure that boots are fit into groove securely.