ecu SUZUKI SWIFT 2000 1.G RG413 Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 243 of 698

3E-30 REAR SUSPENSION

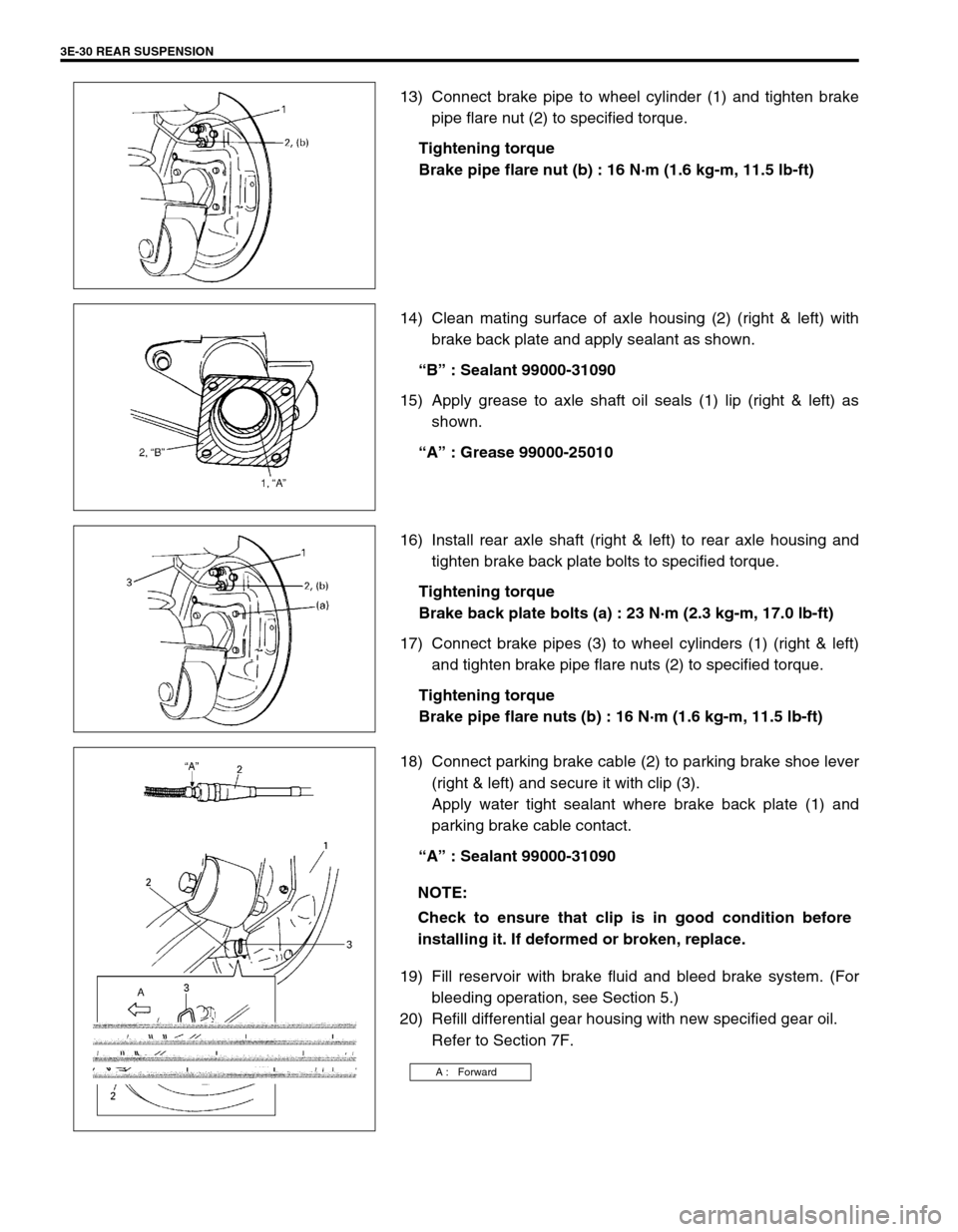

13) Connect brake pipe to wheel cylinder (1) and tighten brake

pipe flare nut (2) to specified torque.

Tightening torque

Brake pipe flare nut (b) : 16 N·m (1.6 kg-m, 11.5 lb-ft)

14) Clean mating surface of axle housing (2) (right & left) with

brake back plate and apply sealant as shown.

“B” : Sealant 99000-31090

15) Apply grease to axle shaft oil seals (1) lip (right & left) as

shown.

“A” : Grease 99000-25010

16) Install rear axle shaft (right & left) to rear axle housing and

tighten brake back plate bolts to specified torque.

Tightening torque

Brake back plate bolts (a) : 23 N·m (2.3 kg-m, 17.0 lb-ft)

17) Connect brake pipes (3) to wheel cylinders (1) (right & left)

and tighten brake pipe flare nuts (2) to specified torque.

Tightening torque

Brake pipe flare nuts (b) : 16 N·m (1.6 kg-m, 11.5 lb-ft)

18) Connect parking brake cable (2) to parking brake shoe lever

(right & left) and secure it with clip (3).

Apply water tight sealant where brake back plate (1) and

parking brake cable contact.

“A” : Sealant 99000-31090

19) Fill reservoir with brake fluid and bleed brake system. (For

bleeding operation, see Section 5.)

20) Refill differential gear housing with new specified gear oil.

Refer to Section 7F.

NOTE:

Check to ensure that clip is in good condition before

installing it. If deformed or broken, replace.

A : Forward

Page 248 of 698

WHEELS AND TIRES 3F-3

HOW TO MEASURE WHEEL RUNOUT

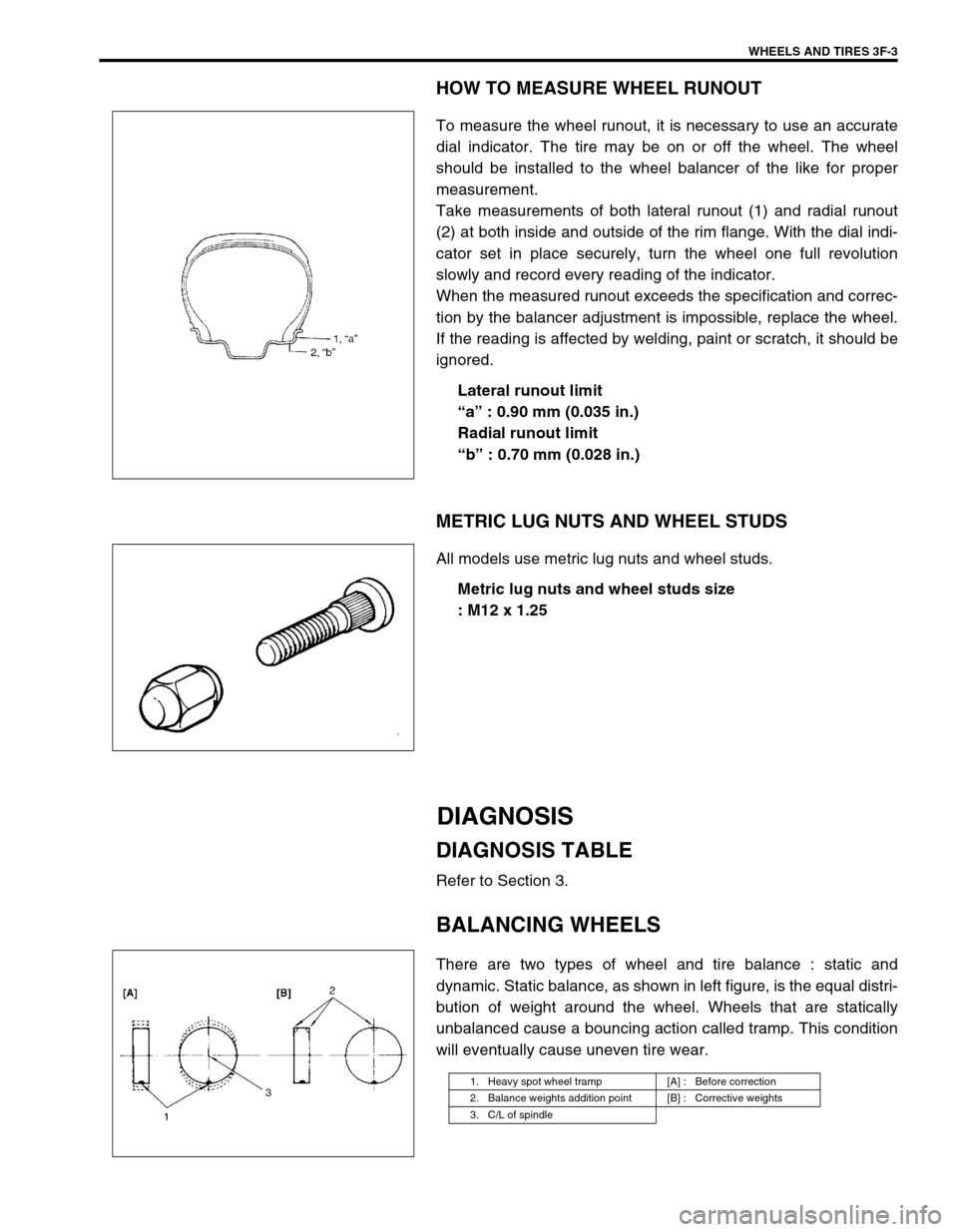

To measure the wheel runout, it is necessary to use an accurate

dial indicator. The tire may be on or off the wheel. The wheel

should be installed to the wheel balancer of the like for proper

measurement.

Take measurements of both lateral runout (1) and radial runout

(2) at both inside and outside of the rim flange. With the dial indi-

cator set in place securely, turn the wheel one full revolution

slowly and record every reading of the indicator.

When the measured runout exceeds the specification and correc-

tion by the balancer adjustment is impossible, replace the wheel.

If the reading is affected by welding, paint or scratch, it should be

ignored.

Lateral runout limit

“a” : 0.90 mm (0.035 in.)

Radial runout limit

“b” : 0.70 mm (0.028 in.)

METRIC LUG NUTS AND WHEEL STUDS

All models use metric lug nuts and wheel studs.

Metric lug nuts and wheel studs size

: M12 x 1.25

DIAGNOSIS

DIAGNOSIS TABLE

Refer to Section 3.

BALANCING WHEELS

There are two types of wheel and tire balance : static and

dynamic. Static balance, as shown in left figure, is the equal distri-

bution of weight around the wheel. Wheels that are statically

unbalanced cause a bouncing action called tramp. This condition

will eventually cause uneven tire wear.

1. Heavy spot wheel tramp [A] : Before correction

2. Balance weights addition point [B] : Corrective weights

3. C/L of spindle

Page 266 of 698

FRONT DRIVE SHAFT 4A-13

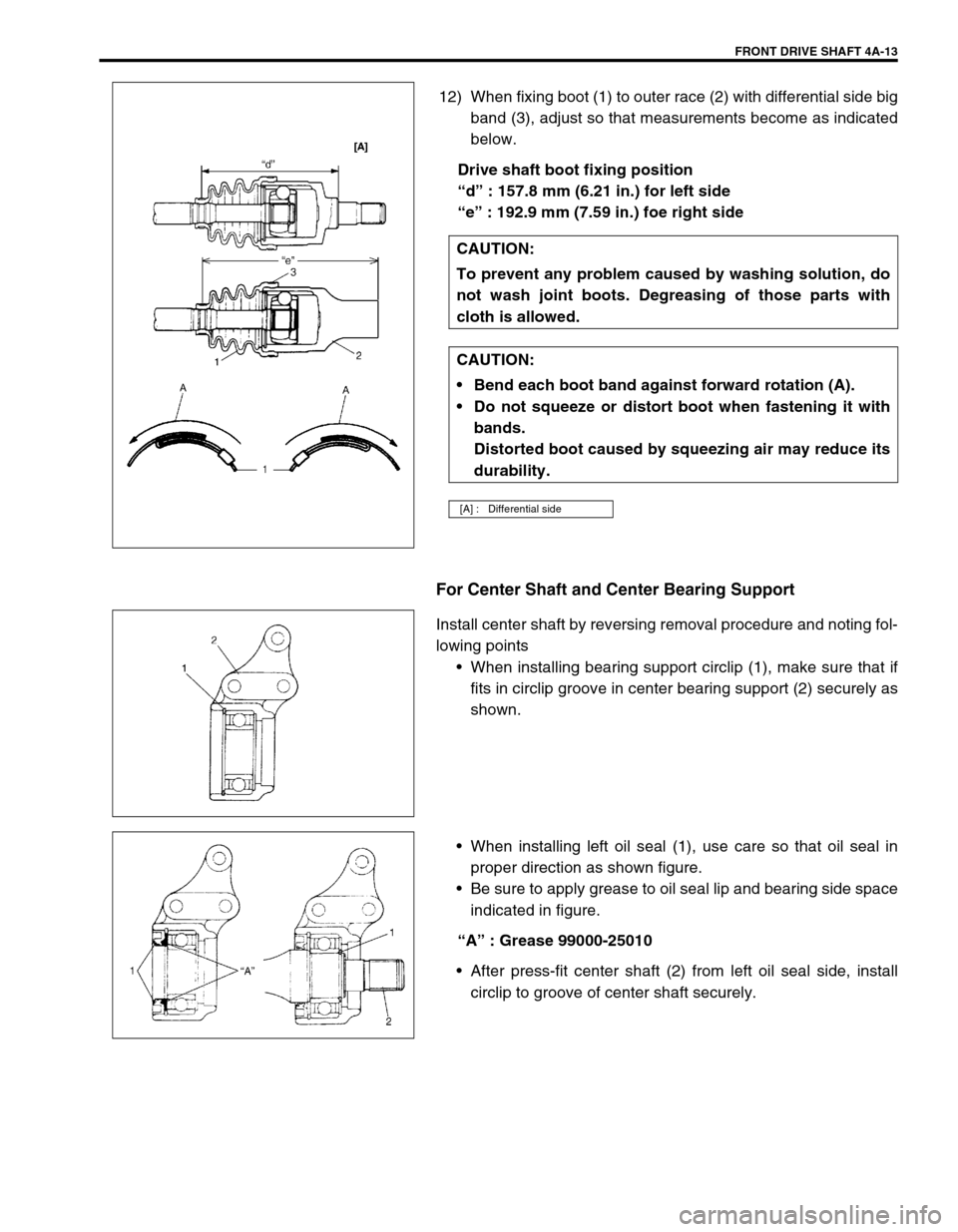

12) When fixing boot (1) to outer race (2) with differential side big

band (3), adjust so that measurements become as indicated

below.

Drive shaft boot fixing position

“d” : 157.8 mm (6.21 in.) for left side

“e” : 192.9 mm (7.59 in.) foe right side

For Center Shaft and Center Bearing Support

Install center shaft by reversing removal procedure and noting fol-

lowing points

When installing bearing support circlip (1), make sure that if

fits in circlip groove in center bearing support (2) securely as

shown.

When installing left oil seal (1), use care so that oil seal in

proper direction as shown figure.

Be sure to apply grease to oil seal lip and bearing side space

indicated in figure.

“A” : Grease 99000-25010

After press-fit center shaft (2) from left oil seal side, install

circlip to groove of center shaft securely. CAUTION:

To prevent any problem caused by washing solution, do

not wash joint boots. Degreasing of those parts with

cloth is allowed.

CAUTION:

Bend each boot band against forward rotation (A).

Do not squeeze or distort boot when fastening it with

bands.

Distorted boot caused by squeezing air may reduce its

durability.

[A] : Differential side

Page 279 of 698

5-6 BRAKES

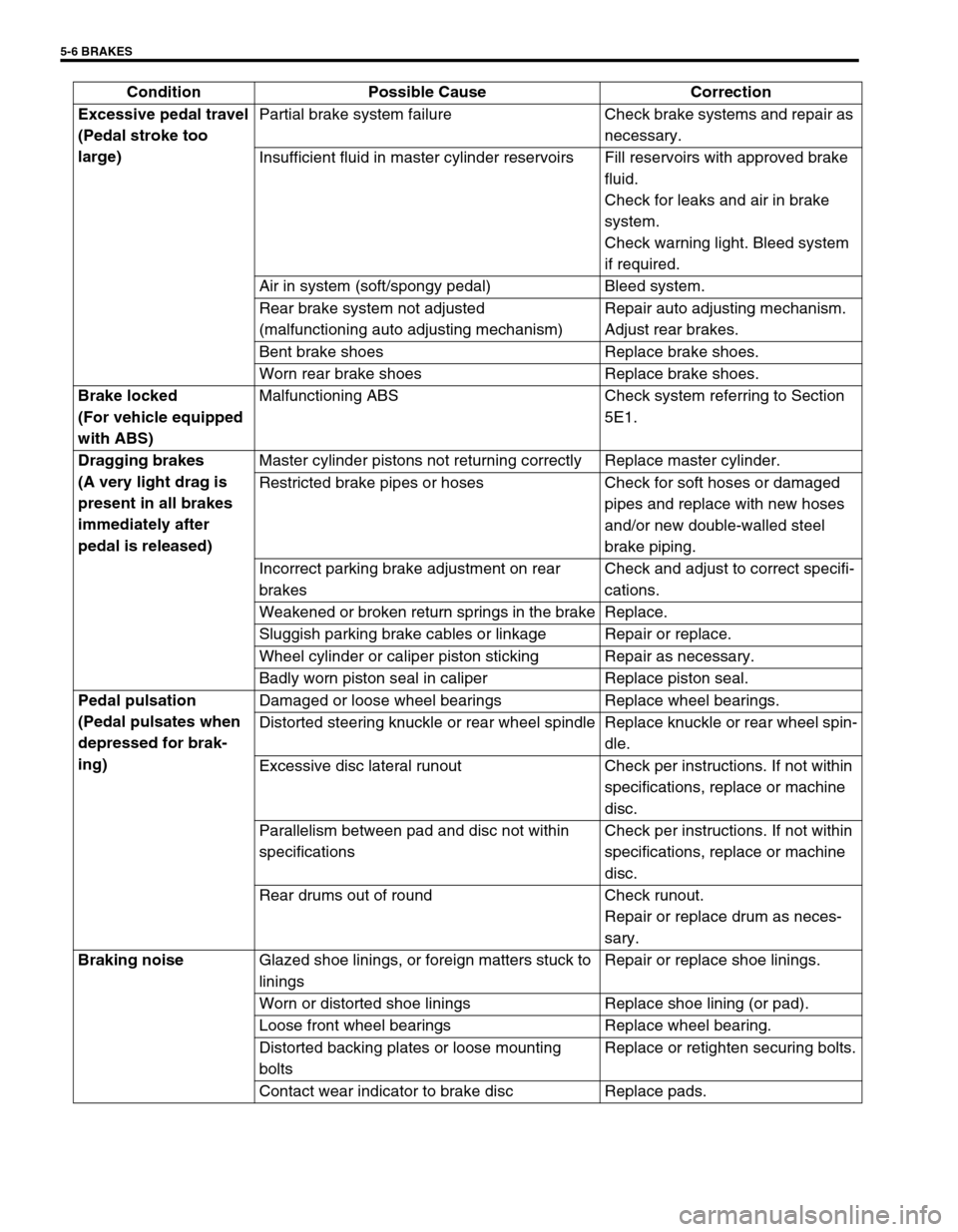

Excessive pedal travel

(Pedal stroke too

large)Partial brake system failure Check brake systems and repair as

necessary.

Insufficient fluid in master cylinder reservoirs Fill reservoirs with approved brake

fluid.

Check for leaks and air in brake

system.

Check warning light. Bleed system

if required.

Air in system (soft/spongy pedal) Bleed system.

Rear brake system not adjusted

(malfunctioning auto adjusting mechanism)Repair auto adjusting mechanism.

Adjust rear brakes.

Bent brake shoes Replace brake shoes.

Worn rear brake shoes Replace brake shoes.

Brake locked

(For vehicle equipped

with ABS)Malfunctioning ABS Check system referring to Section

5E1.

Dragging brakes

(A very light drag is

present in all brakes

immediately after

pedal is released)Master cylinder pistons not returning correctly Replace master cylinder.

Restricted brake pipes or hoses Check for soft hoses or damaged

pipes and replace with new hoses

and/or new double-walled steel

brake piping.

Incorrect parking brake adjustment on rear

brakesCheck and adjust to correct specifi-

cations.

Weakened or broken return springs in the brake Replace.

Sluggish parking brake cables or linkage Repair or replace.

Wheel cylinder or caliper piston sticking Repair as necessary.

Badly worn piston seal in caliper Replace piston seal.

Pedal pulsation

(Pedal pulsates when

depressed for brak-

ing)Damaged or loose wheel bearings Replace wheel bearings.

Distorted steering knuckle or rear wheel spindle Replace knuckle or rear wheel spin-

dle.

Excessive disc lateral runout Check per instructions. If not within

specifications, replace or machine

disc.

Parallelism between pad and disc not within

specificationsCheck per instructions. If not within

specifications, replace or machine

disc.

Rear drums out of round Check runout.

Repair or replace drum as neces-

sary.

Braking noise

Glazed shoe linings, or foreign matters stuck to

liningsRepair or replace shoe linings.

Worn or distorted shoe linings Replace shoe lining (or pad).

Loose front wheel bearings Replace wheel bearing.

Distorted backing plates or loose mounting

boltsReplace or retighten securing bolts.

Contact wear indicator to brake disc Replace pads. Condition Possible Cause Correction

Page 294 of 698

BRAKES 5-21

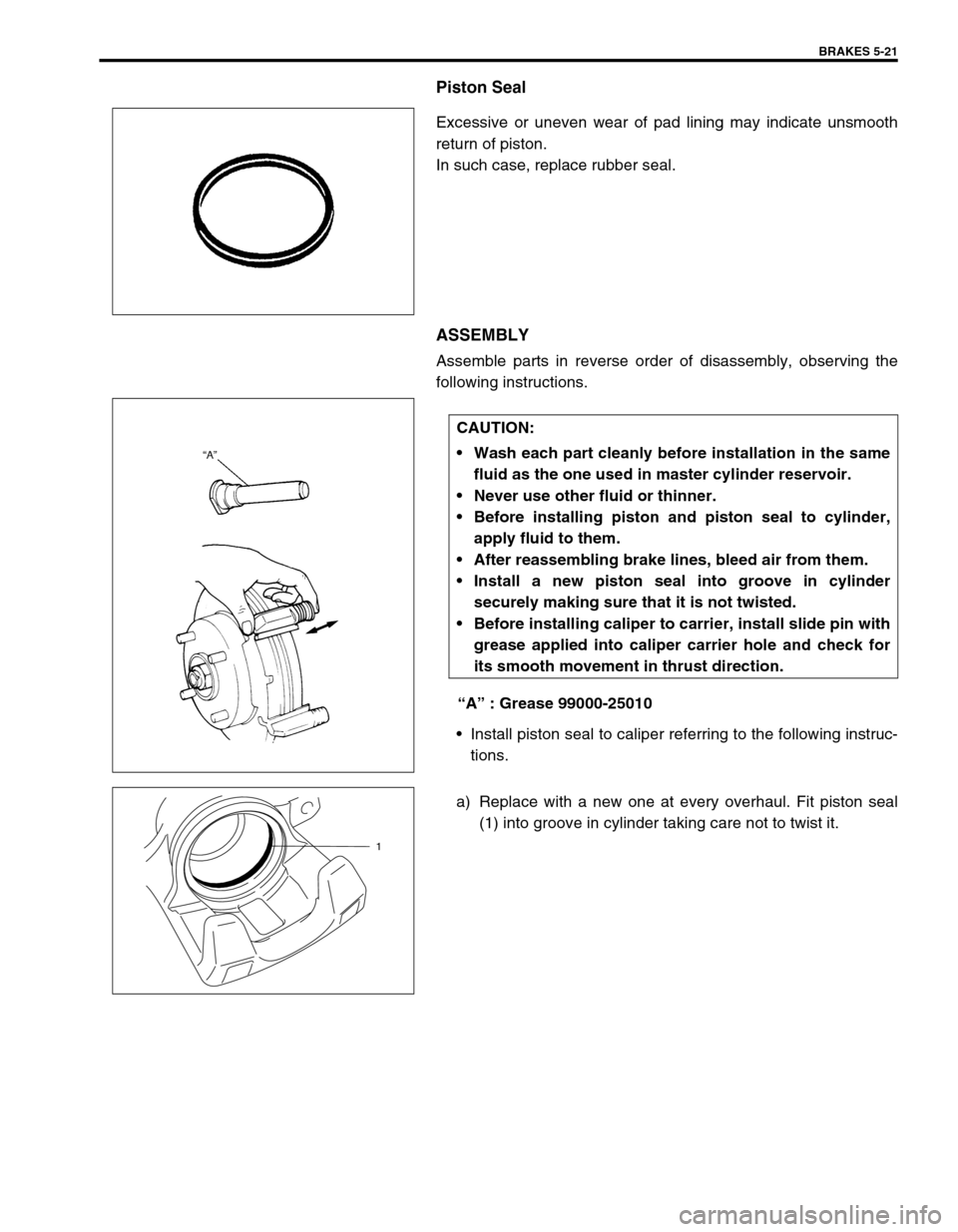

Piston Seal

Excessive or uneven wear of pad lining may indicate unsmooth

return of piston.

In such case, replace rubber seal.

ASSEMBLY

Assemble parts in reverse order of disassembly, observing the

following instructions.

“A” : Grease 99000-25010

Install piston seal to caliper referring to the following instruc-

tions.

a) Replace with a new one at every overhaul. Fit piston seal

(1) into groove in cylinder taking care not to twist it.

CAUTION:

Wash each part cleanly before installation in the same

fluid as the one used in master cylinder reservoir.

Never use other fluid or thinner.

Before installing piston and piston seal to cylinder,

apply fluid to them.

After reassembling brake lines, bleed air from them.

Install a new piston seal into groove in cylinder

securely making sure that it is not twisted.

Before installing caliper to carrier, install slide pin with

grease applied into caliper carrier hole and check for

its smooth movement in thrust direction.

1

Page 295 of 698

5-22 BRAKES

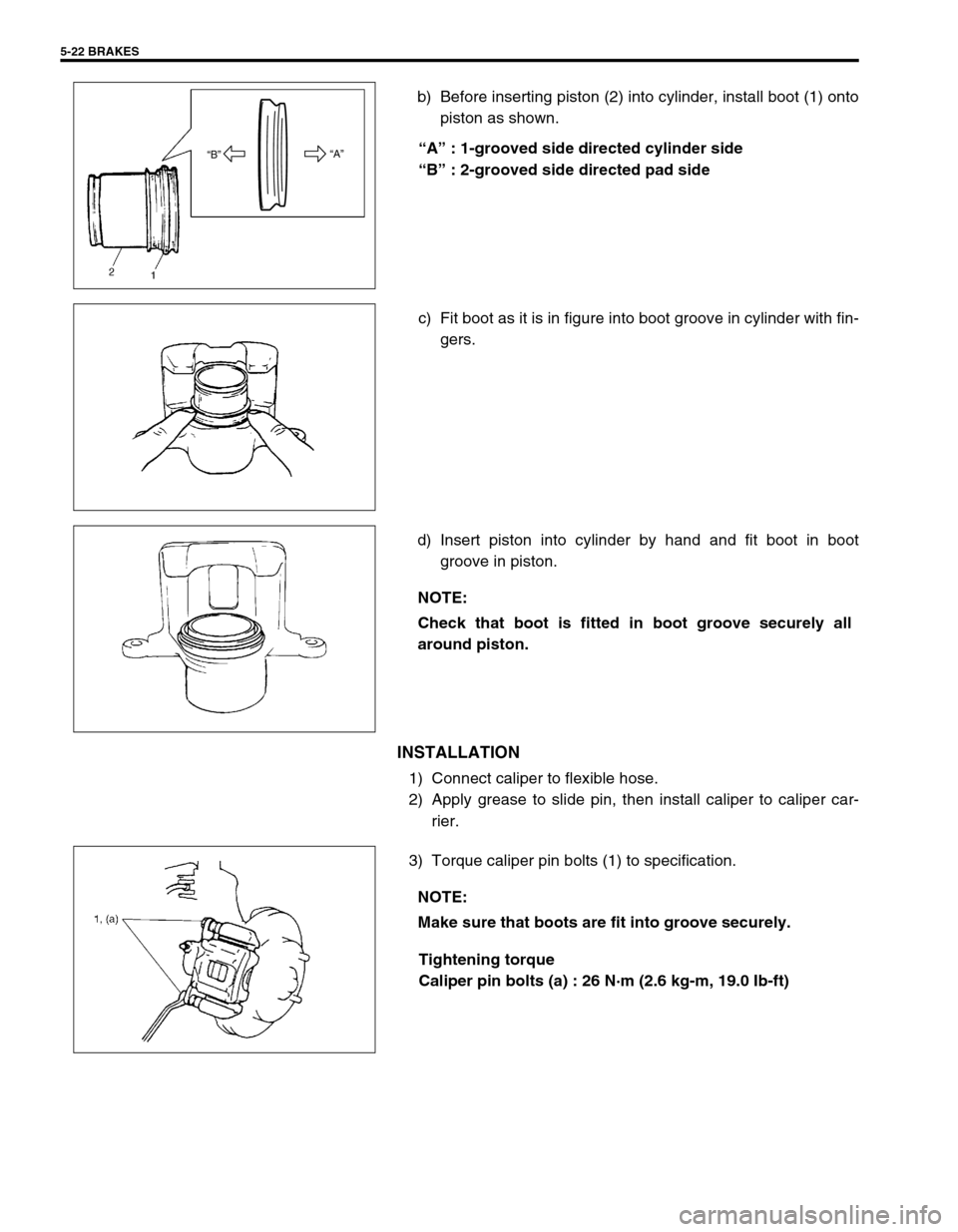

b) Before inserting piston (2) into cylinder, install boot (1) onto

piston as shown.

“A” : 1-grooved side directed cylinder side

“B” : 2-grooved side directed pad side

c) Fit boot as it is in figure into boot groove in cylinder with fin-

gers.

d) Insert piston into cylinder by hand and fit boot in boot

groove in piston.

INSTALLATION

1) Connect caliper to flexible hose.

2) Apply grease to slide pin, then install caliper to caliper car-

rier.

3) Torque caliper pin bolts (1) to specification.

Tightening torque

Caliper pin bolts (a) : 26 N·m (2.6 kg-m, 19.0 Ib-ft)

“A”

“B”

NOTE:

Check that boot is fitted in boot groove securely all

around piston.

NOTE:

Make sure that boots are fit into groove securely.

Page 296 of 698

BRAKES 5-23

4) Torque flexible hose joint bolt to specification.

Tightening torque

Flexible hose joint bolt (b) : 23 N·m (2.3 kg-m, 17.0 Ib-ft)

5) Install E-ring to strut securely.

6) Lower hoist.

7) Torque wheel nuts to specifications.

Tightening torque

Wheel nuts : 85 N·m (8.5 kg-m, 61.5 Ib-ft)

8) After completing installation, fill reservoir with brake fluid and

bleed air from brake system. Perform brake test and check

each installed part for oil leakage.

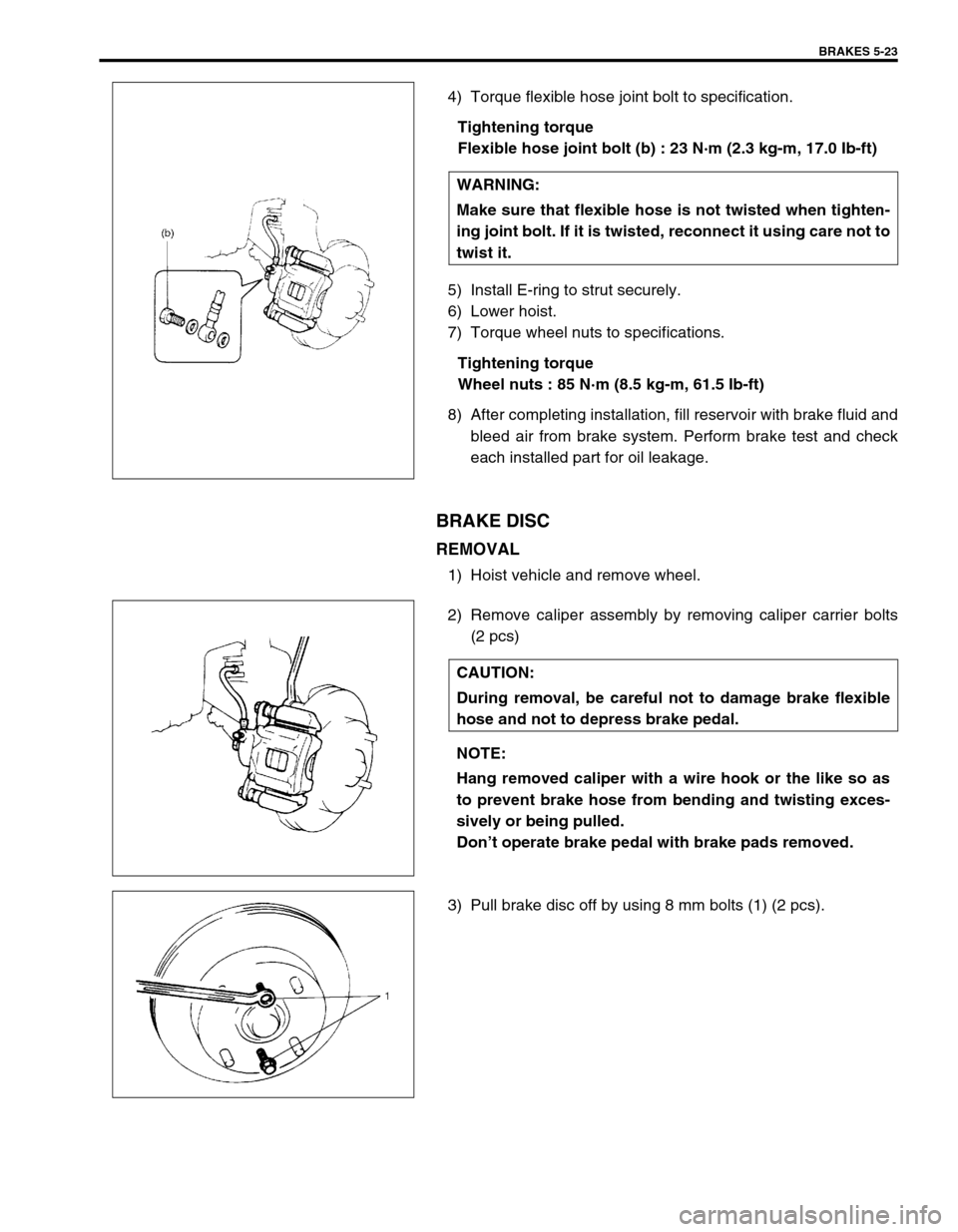

BRAKE DISC

REMOVAL

1) Hoist vehicle and remove wheel.

2) Remove caliper assembly by removing caliper carrier bolts

(2 pcs)

3) Pull brake disc off by using 8 mm bolts (1) (2 pcs).WARNING:

Make sure that flexible hose is not twisted when tighten-

ing joint bolt. If it is twisted, reconnect it using care not to

twist it.

CAUTION:

During removal, be careful not to damage brake flexible

hose and not to depress brake pedal.

NOTE:

Hang removed caliper with a wire hook or the like so as

to prevent brake hose from bending and twisting exces-

sively or being pulled.

Don’t operate brake pedal with brake pads removed.

Page 304 of 698

BRAKES 5-31

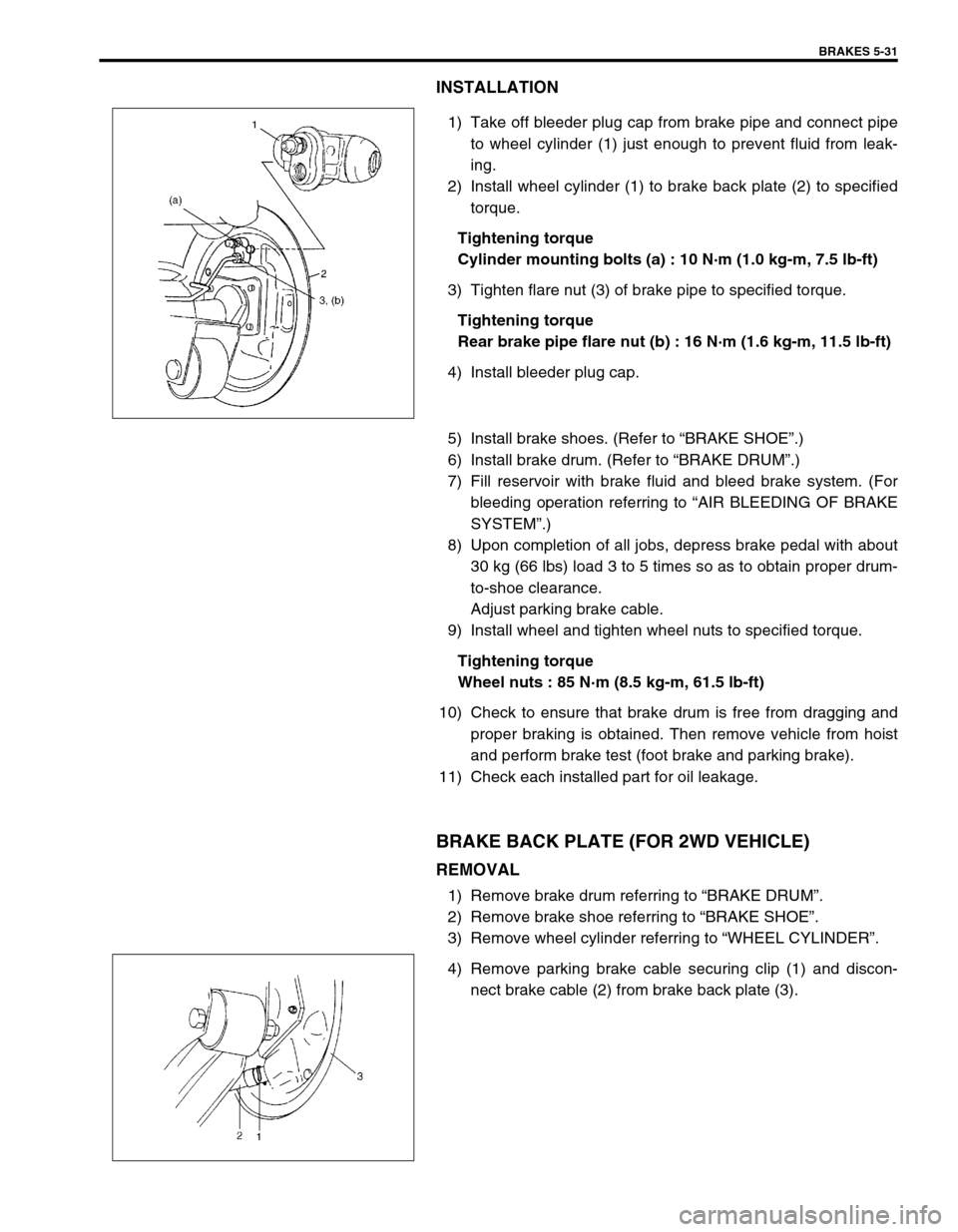

INSTALLATION

1) Take off bleeder plug cap from brake pipe and connect pipe

to wheel cylinder (1) just enough to prevent fluid from leak-

ing.

2) Install wheel cylinder (1) to brake back plate (2) to specified

torque.

Tightening torque

Cylinder mounting bolts (a) : 10 N·m (1.0 kg-m, 7.5 lb-ft)

3) Tighten flare nut (3) of brake pipe to specified torque.

Tightening torque

Rear brake pipe flare nut (b) : 16 N·m (1.6 kg-m, 11.5 lb-ft)

4) Install bleeder plug cap.

5) Install brake shoes. (Refer to “BRAKE SHOE”.)

6) Install brake drum. (Refer to “BRAKE DRUM”.)

7) Fill reservoir with brake fluid and bleed brake system. (For

bleeding operation referring to “AIR BLEEDING OF BRAKE

SYSTEM”.)

8) Upon completion of all jobs, depress brake pedal with about

30 kg (66 lbs) load 3 to 5 times so as to obtain proper drum-

to-shoe clearance.

Adjust parking brake cable.

9) Install wheel and tighten wheel nuts to specified torque.

Tightening torque

Wheel nuts : 85 N·m (8.5 kg-m, 61.5 lb-ft)

10) Check to ensure that brake drum is free from dragging and

proper braking is obtained. Then remove vehicle from hoist

and perform brake test (foot brake and parking brake).

11) Check each installed part for oil leakage.

BRAKE BACK PLATE (FOR 2WD VEHICLE)

REMOVAL

1) Remove brake drum referring to “BRAKE DRUM”.

2) Remove brake shoe referring to “BRAKE SHOE”.

3) Remove wheel cylinder referring to “WHEEL CYLINDER”.

4) Remove parking brake cable securing clip (1) and discon-

nect brake cable (2) from brake back plate (3).

Page 305 of 698

5-32 BRAKES

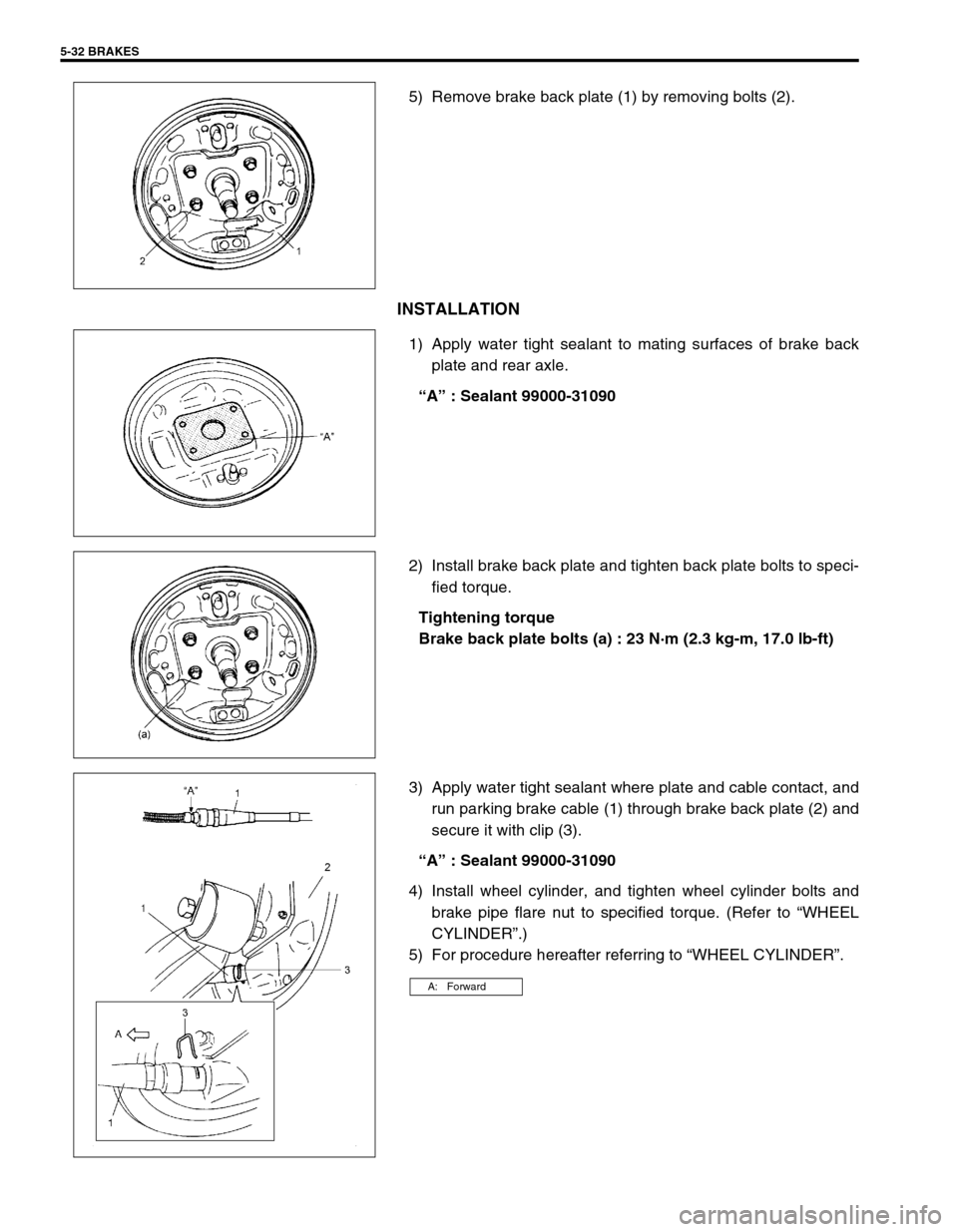

5) Remove brake back plate (1) by removing bolts (2).

INSTALLATION

1) Apply water tight sealant to mating surfaces of brake back

plate and rear axle.

“A” : Sealant 99000-31090

2) Install brake back plate and tighten back plate bolts to speci-

fied torque.

Tightening torque

Brake back plate bolts (a) : 23 N·m (2.3 kg-m, 17.0 lb-ft)

3) Apply water tight sealant where plate and cable contact, and

run parking brake cable (1) through brake back plate (2) and

secure it with clip (3).

“A” : Sealant 99000-31090

4) Install wheel cylinder, and tighten wheel cylinder bolts and

brake pipe flare nut to specified torque. (Refer to “WHEEL

CYLINDER”.)

5) For procedure hereafter referring to “WHEEL CYLINDER”.

A: Forward

Page 308 of 698

BRAKES 5-35

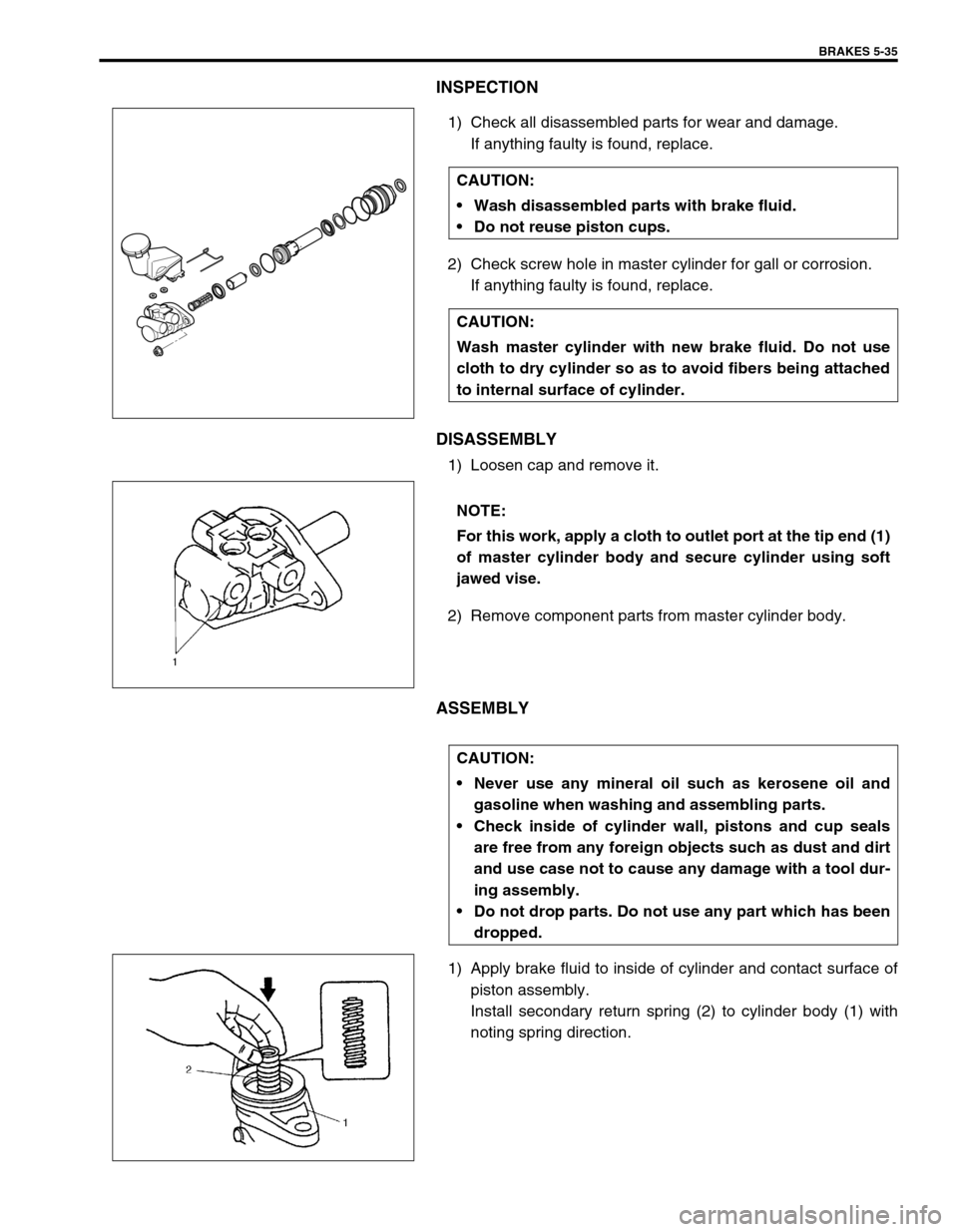

INSPECTION

1) Check all disassembled parts for wear and damage.

If anything faulty is found, replace.

2) Check screw hole in master cylinder for gall or corrosion.

If anything faulty is found, replace.

DISASSEMBLY

1) Loosen cap and remove it.

2) Remove component parts from master cylinder body.

ASSEMBLY

1) Apply brake fluid to inside of cylinder and contact surface of

piston assembly.

Install secondary return spring (2) to cylinder body (1) with

noting spring direction. CAUTION:

Wash disassembled parts with brake fluid.

Do not reuse piston cups.

CAUTION:

Wash master cylinder with new brake fluid. Do not use

cloth to dry cylinder so as to avoid fibers being attached

to internal surface of cylinder.

NOTE:

For this work, apply a cloth to outlet port at the tip end (1)

of master cylinder body and secure cylinder using soft

jawed vise.

CAUTION:

Never use any mineral oil such as kerosene oil and

gasoline when washing and assembling parts.

Check inside of cylinder wall, pistons and cup seals

are free from any foreign objects such as dust and dirt

and use case not to cause any damage with a tool dur-

ing assembly.

Do not drop parts. Do not use any part which has been

dropped.