engine oil SUZUKI SWIFT 2000 1.G RG413 Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 397 of 698

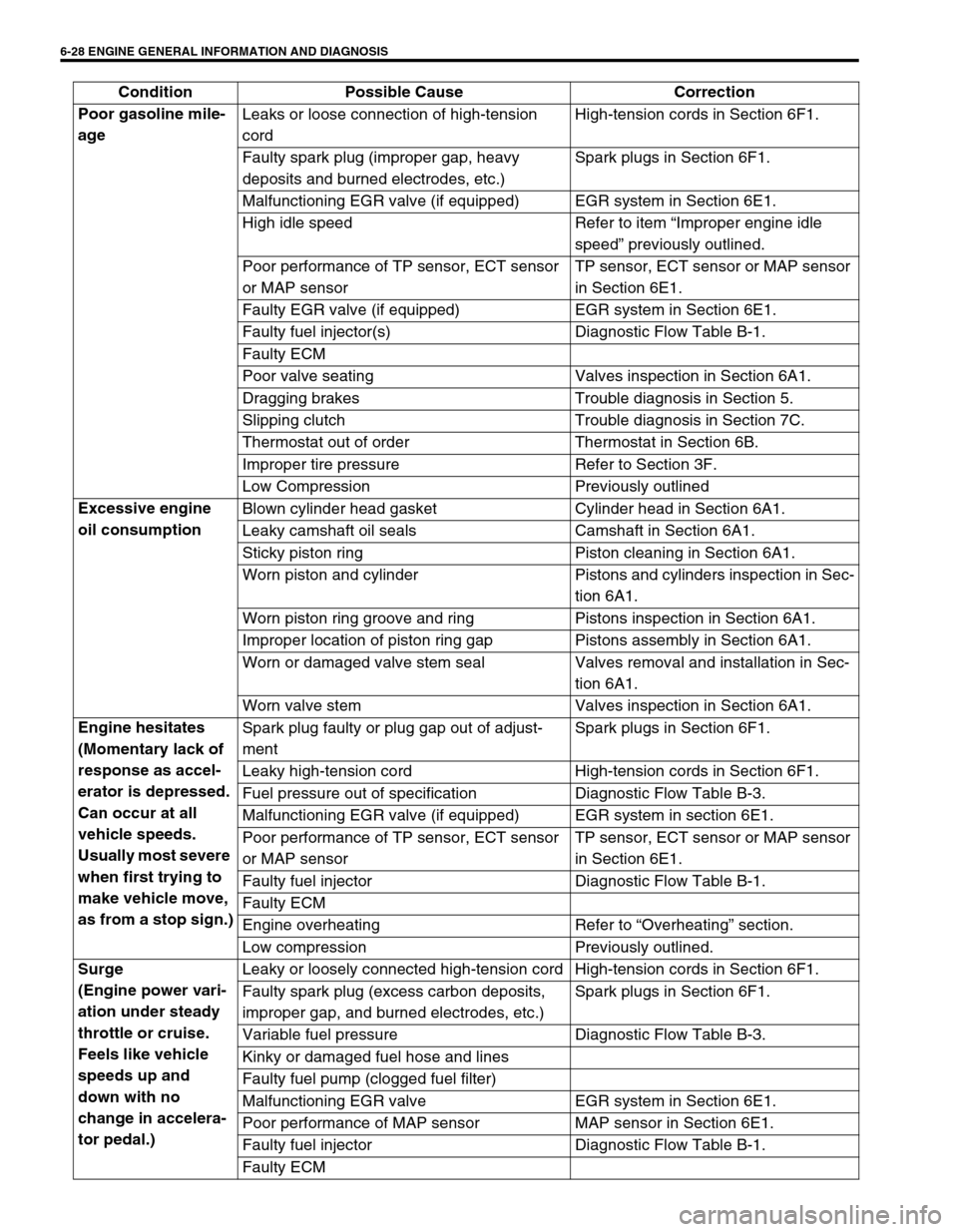

6-28 ENGINE GENERAL INFORMATION AND DIAGNOSIS

Poor gasoline mile-

age Leaks or loose connection of high-tension

cordHigh-tension cords in Section 6F1.

Faulty spark plug (improper gap, heavy

deposits and burned electrodes, etc.)Spark plugs in Section 6F1.

Malfunctioning EGR valve (if equipped) EGR system in Section 6E1.

High idle speed Refer to item “Improper engine idle

speed” previously outlined.

Poor performance of TP sensor, ECT sensor

or MAP sensorTP sensor, ECT sensor or MAP sensor

in Section 6E1.

Faulty EGR valve (if equipped) EGR system in Section 6E1.

Faulty fuel injector(s) Diagnostic Flow Table B-1.

Faulty ECM

Poor valve seating Valves inspection in Section 6A1.

Dragging brakes Trouble diagnosis in Section 5.

Slipping clutch Trouble diagnosis in Section 7C.

Thermostat out of order Thermostat in Section 6B.

Improper tire pressure Refer to Section 3F.

Low Compression Previously outlined

Excessive engine

oil consumption Blown cylinder head gasket Cylinder head in Section 6A1.

Leaky camshaft oil seals Camshaft in Section 6A1.

Sticky piston ring Piston cleaning in Section 6A1.

Worn piston and cylinder Pistons and cylinders inspection in Sec-

tion 6A1.

Worn piston ring groove and ring Pistons inspection in Section 6A1.

Improper location of piston ring gap Pistons assembly in Section 6A1.

Worn or damaged valve stem seal Valves removal and installation in Sec-

tion 6A1.

Worn valve stem Valves inspection in Section 6A1.

Engine hesitates

(Momentary lack of

response as accel-

erator is depressed.

Can occur at all

vehicle speeds.

Usually most severe

when first trying to

make vehicle move,

as from a stop sign.)Spark plug faulty or plug gap out of adjust-

mentSpark plugs in Section 6F1.

Leaky high-tension cord High-tension cords in Section 6F1.

Fuel pressure out of specification Diagnostic Flow Table B-3.

Malfunctioning EGR valve (if equipped) EGR system in section 6E1.

Poor performance of TP sensor, ECT sensor

or MAP sensorTP sensor, ECT sensor or MAP sensor

in Section 6E1.

Faulty fuel injector Diagnostic Flow Table B-1.

Faulty ECM

Engine overheating Refer to “Overheating” section.

Low compression Previously outlined.

Surge

(Engine power vari-

ation under steady

throttle or cruise.

Feels like vehicle

speeds up and

down with no

change in accelera-

tor pedal.)Leaky or loosely connected high-tension cord High-tension cords in Section 6F1.

Faulty spark plug (excess carbon deposits,

improper gap, and burned electrodes, etc.)Spark plugs in Section 6F1.

Variable fuel pressure Diagnostic Flow Table B-3.

Kinky or damaged fuel hose and lines

Faulty fuel pump (clogged fuel filter)

Malfunctioning EGR valve EGR system in Section 6E1.

Poor performance of MAP sensor MAP sensor in Section 6E1.

Faulty fuel injector Diagnostic Flow Table B-1.

Faulty ECM Condition Possible Cause Correction

Page 398 of 698

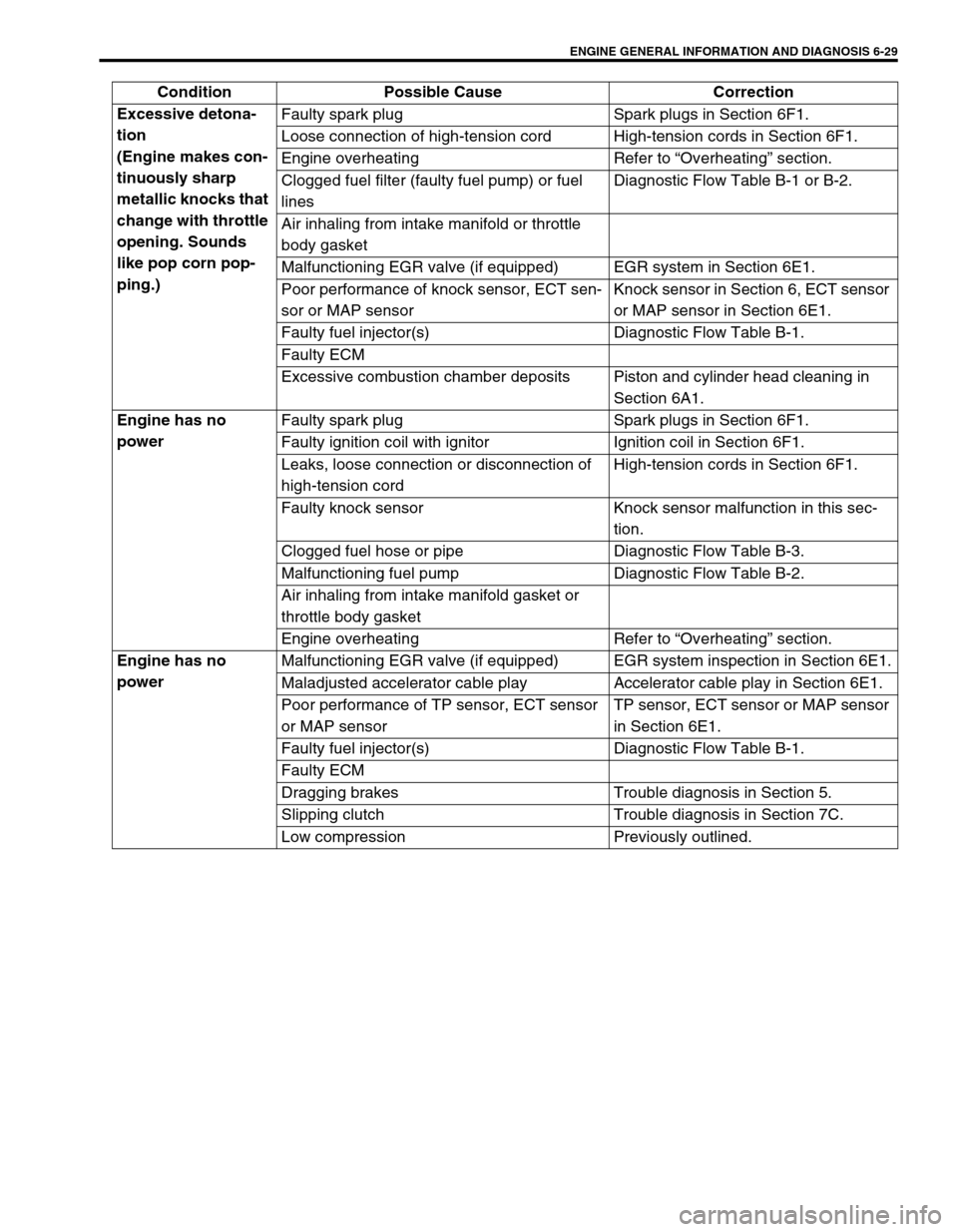

ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-29

Excessive detona-

tion

(Engine makes con-

tinuously sharp

metallic knocks that

change with throttle

opening. Sounds

like pop corn pop-

ping.)Faulty spark plug Spark plugs in Section 6F1.

Loose connection of high-tension cord High-tension cords in Section 6F1.

Engine overheating Refer to “Overheating” section.

Clogged fuel filter (faulty fuel pump) or fuel

linesDiagnostic Flow Table B-1 or B-2.

Air inhaling from intake manifold or throttle

body gasket

Malfunctioning EGR valve (if equipped) EGR system in Section 6E1.

Poor performance of knock sensor, ECT sen-

sor or MAP sensorKnock sensor in Section 6, ECT sensor

or MAP sensor in Section 6E1.

Faulty fuel injector(s) Diagnostic Flow Table B-1.

Faulty ECM

Excessive combustion chamber deposits Piston and cylinder head cleaning in

Section 6A1.

Engine has no

powerFaulty spark plug Spark plugs in Section 6F1.

Faulty ignition coil with ignitor Ignition coil in Section 6F1.

Leaks, loose connection or disconnection of

high-tension cordHigh-tension cords in Section 6F1.

Faulty knock sensor Knock sensor malfunction in this sec-

tion.

Clogged fuel hose or pipe Diagnostic Flow Table B-3.

Malfunctioning fuel pump Diagnostic Flow Table B-2.

Air inhaling from intake manifold gasket or

throttle body gasket

Engine overheating Refer to “Overheating” section.

Engine has no

powerMalfunctioning EGR valve (if equipped) EGR system inspection in Section 6E1.

Maladjusted accelerator cable play Accelerator cable play in Section 6E1.

Poor performance of TP sensor, ECT sensor

or MAP sensorTP sensor, ECT sensor or MAP sensor

in Section 6E1.

Faulty fuel injector(s) Diagnostic Flow Table B-1.

Faulty ECM

Dragging brakes Trouble diagnosis in Section 5.

Slipping clutch Trouble diagnosis in Section 7C.

Low compression Previously outlined. Condition Possible Cause Correction

Page 399 of 698

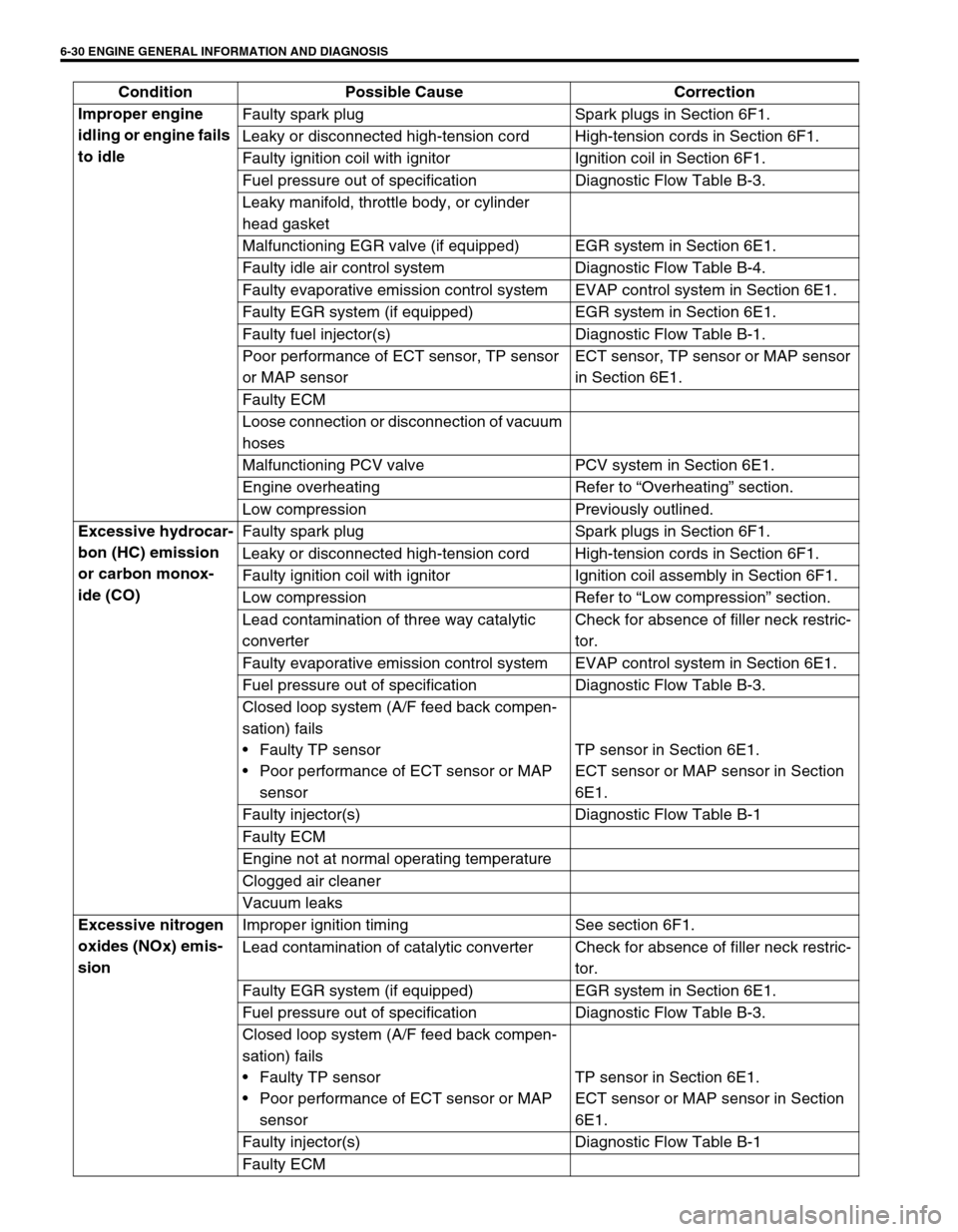

6-30 ENGINE GENERAL INFORMATION AND DIAGNOSIS

Improper engine

idling or engine fails

to idleFaulty spark plug Spark plugs in Section 6F1.

Leaky or disconnected high-tension cord High-tension cords in Section 6F1.

Faulty ignition coil with ignitor Ignition coil in Section 6F1.

Fuel pressure out of specification Diagnostic Flow Table B-3.

Leaky manifold, throttle body, or cylinder

head gasket

Malfunctioning EGR valve (if equipped) EGR system in Section 6E1.

Faulty idle air control system Diagnostic Flow Table B-4.

Faulty evaporative emission control system EVAP control system in Section 6E1.

Faulty EGR system (if equipped) EGR system in Section 6E1.

Faulty fuel injector(s) Diagnostic Flow Table B-1.

Poor performance of ECT sensor, TP sensor

or MAP sensorECT sensor, TP sensor or MAP sensor

in Section 6E1.

Faulty ECM

Loose connection or disconnection of vacuum

hoses

Malfunctioning PCV valve PCV system in Section 6E1.

Engine overheating Refer to “Overheating” section.

Low compression Previously outlined.

Excessive hydrocar-

bon (HC) emission

or carbon monox-

ide (CO)Faulty spark plug Spark plugs in Section 6F1.

Leaky or disconnected high-tension cord High-tension cords in Section 6F1.

Faulty ignition coil with ignitor Ignition coil assembly in Section 6F1.

Low compression Refer to “Low compression” section.

Lead contamination of three way catalytic

converterCheck for absence of filler neck restric-

tor.

Faulty evaporative emission control system EVAP control system in Section 6E1.

Fuel pressure out of specification Diagnostic Flow Table B-3.

Closed loop system (A/F feed back compen-

sation) fails

Faulty TP sensor

Poor performance of ECT sensor or MAP

sensorTP sensor in Section 6E1.

ECT sensor or MAP sensor in Section

6E1.

Faulty injector(s) Diagnostic Flow Table B-1

Faulty ECM

Engine not at normal operating temperature

Clogged air cleaner

Vacuum leaks

Excessive nitrogen

oxides (NOx) emis-

sionImproper ignition timing See section 6F1.

Lead contamination of catalytic converter Check for absence of filler neck restric-

tor.

Faulty EGR system (if equipped) EGR system in Section 6E1.

Fuel pressure out of specification Diagnostic Flow Table B-3.

Closed loop system (A/F feed back compen-

sation) fails

Faulty TP sensor

Poor performance of ECT sensor or MAP

sensorTP sensor in Section 6E1.

ECT sensor or MAP sensor in Section

6E1.

Faulty injector(s) Diagnostic Flow Table B-1

Faulty ECM Condition Possible Cause Correction

Page 406 of 698

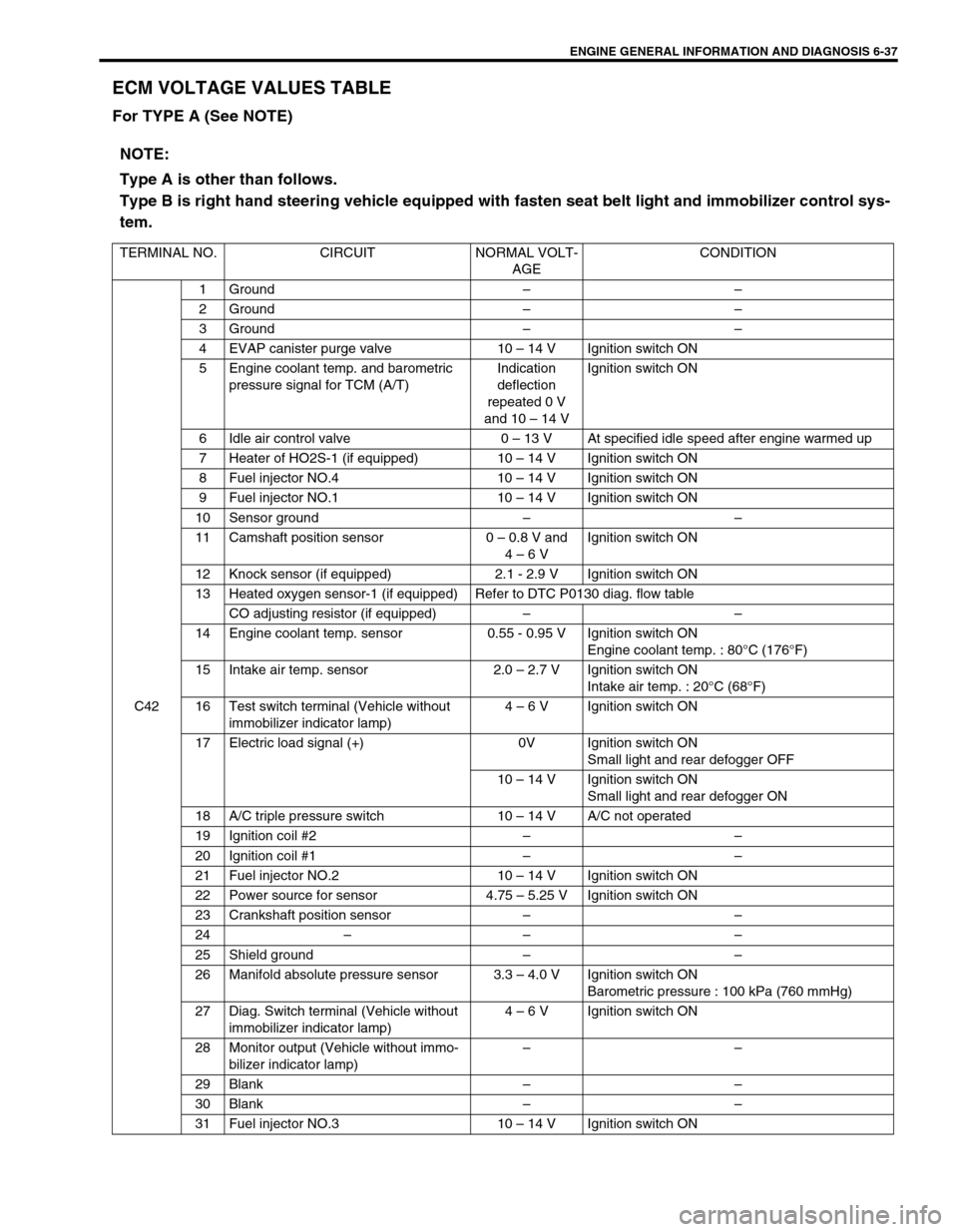

ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-37

ECM VOLTAGE VALUES TABLE

For TYPE A (See NOTE)

NOTE:

Type A is other than follows.

Type B is right hand steering vehicle equipped with fasten seat belt light and immobilizer control sys-

tem.

TERMINAL NO. CIRCUIT NORMAL VOLT-

AGECONDITION

C421 Ground––

2 Ground––

3 Ground––

4 EVAP canister purge valve 10 – 14 V Ignition switch ON

5 Engine coolant temp. and barometric

pressure signal for TCM (A/T)Indication

deflection

repeated 0 V

and 10 – 14 VIgnition switch ON

6 Idle air control valve 0 – 13 V At specified idle speed after engine warmed up

7 Heater of HO2S-1 (if equipped) 10 – 14 V Ignition switch ON

8 Fuel injector NO.4 10 – 14 V Ignition switch ON

9 Fuel injector NO.1 10 – 14 V Ignition switch ON

10 Sensor ground––

11 Camshaft position sensor 0 – 0.8 V and

4 – 6 VIgnition switch ON

12 Knock sensor (if equipped) 2.1 - 2.9 V Ignition switch ON

13 Heated oxygen sensor-1 (if equipped) Refer to DTC P0130 diag. flow table

CO adjusting resistor (if equipped)––

14 Engine coolant temp. sensor 0.55 - 0.95 V Ignition switch ON

Engine coolant temp. : 80°C (176°F)

15 Intake air temp. sensor 2.0 – 2.7 V Ignition switch ON

Intake air temp. : 20°C (68°F)

16 Test switch terminal (Vehicle without

immobilizer indicator lamp)4 – 6 V Ignition switch ON

17 Electric load signal (+) 0V Ignition switch ON

Small light and rear defogger OFF

10 – 14 V Ignition switch ON

Small light and rear defogger ON

18 A/C triple pressure switch 10 – 14 V A/C not operated

19 Ignition coil #2––

20 Ignition coil #1––

21 Fuel injector NO.2 10 – 14 V Ignition switch ON

22 Power source for sensor 4.75 – 5.25 V Ignition switch ON

23 Crankshaft position sensor––

24–– –

25 Shield ground––

26 Manifold absolute pressure sensor 3.3 – 4.0 V Ignition switch ON

Barometric pressure : 100 kPa (760 mmHg)

27 Diag. Switch terminal (Vehicle without

immobilizer indicator lamp)4 – 6 V Ignition switch ON

28 Monitor output (Vehicle without immo-

bilizer indicator lamp)––

29 Blank––

30 Blank––

31 Fuel injector NO.3 10 – 14 V Ignition switch ON

Page 407 of 698

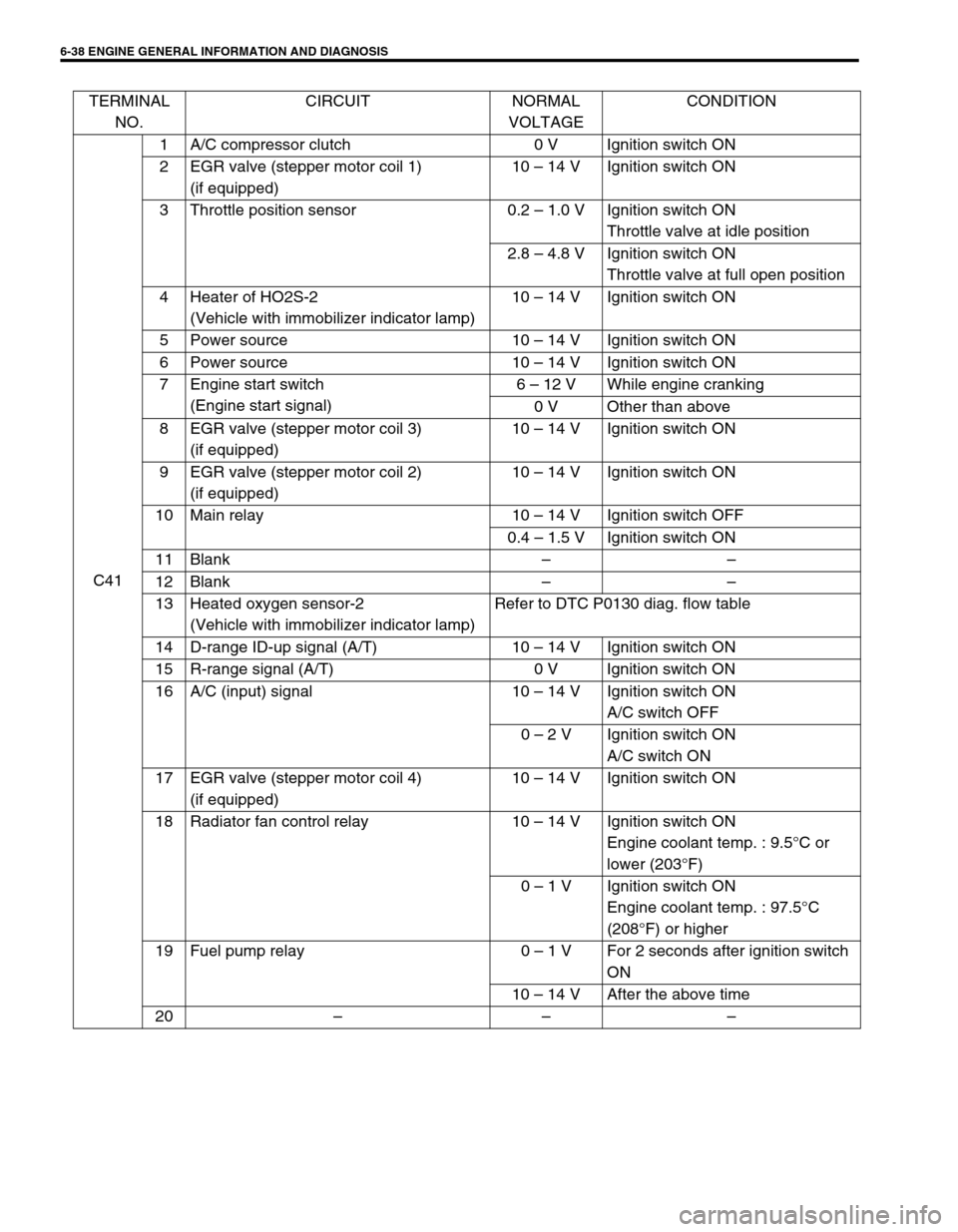

6-38 ENGINE GENERAL INFORMATION AND DIAGNOSIS

TERMINAL

NO.CIRCUIT NORMAL

VOLTAGECONDITION

C411 A/C compressor clutch 0 V Ignition switch ON

2 EGR valve (stepper motor coil 1)

(if equipped)10 – 14 V Ignition switch ON

3 Throttle position sensor 0.2 – 1.0 V Ignition switch ON

Throttle valve at idle position

2.8 – 4.8 V Ignition switch ON

Throttle valve at full open position

4 Heater of HO2S-2

(Vehicle with immobilizer indicator lamp)10 – 14 V Ignition switch ON

5 Power source 10 – 14 V Ignition switch ON

6 Power source 10 – 14 V Ignition switch ON

7 Engine start switch

(Engine start signal)6 – 12 V While engine cranking

0 V Other than above

8 EGR valve (stepper motor coil 3)

(if equipped)10 – 14 V Ignition switch ON

9 EGR valve (stepper motor coil 2)

(if equipped)10 – 14 V Ignition switch ON

10 Main relay 10 – 14 V Ignition switch OFF

0.4 – 1.5 V Ignition switch ON

11 Blank––

12 Blank––

13 Heated oxygen sensor-2

(Vehicle with immobilizer indicator lamp)Refer to DTC P0130 diag. flow table

14 D-range ID-up signal (A/T) 10 – 14 V Ignition switch ON

15 R-range signal (A/T) 0 V Ignition switch ON

16 A/C (input) signal 10 – 14 V Ignition switch ON

A/C switch OFF

0 – 2 V Ignition switch ON

A/C switch ON

17 EGR valve (stepper motor coil 4)

(if equipped)10 – 14 V Ignition switch ON

18 Radiator fan control relay 10 – 14 V Ignition switch ON

Engine coolant temp. : 9.5°C or

lower (203°F)

0 – 1 V Ignition switch ON

Engine coolant temp. : 97.5°C

(208°F) or higher

19 Fuel pump relay 0 – 1 V For 2 seconds after ignition switch

ON

10 – 14 V After the above time

20–––

Page 409 of 698

6-40 ENGINE GENERAL INFORMATION AND DIAGNOSIS

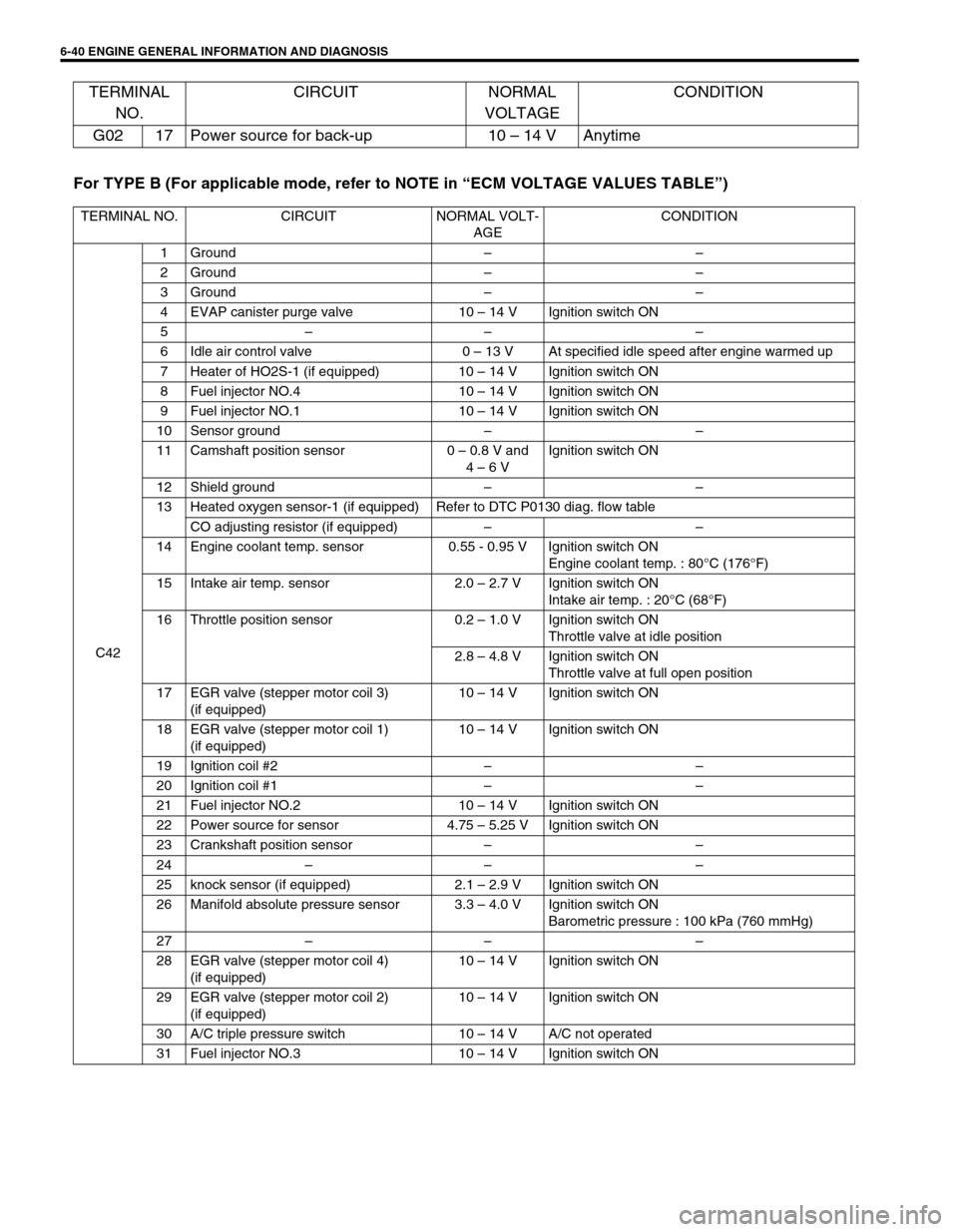

For TYPE B (For applicable mode, refer to NOTE in “ECM VOLTAGE VALUES TABLE”) G02 17 Power source for back-up 10 – 14 V Anytime

TERMINAL NO. CIRCUIT NORMAL VOLT-

AGECONDITION

C421Ground––

2Ground––

3Ground––

4 EVAP canister purge valve 10 – 14 V Ignition switch ON

5–– –

6 Idle air control valve 0 – 13 V At specified idle speed after engine warmed up

7 Heater of HO2S-1 (if equipped) 10 – 14 V Ignition switch ON

8 Fuel injector NO.4 10 – 14 V Ignition switch ON

9 Fuel injector NO.1 10 – 14 V Ignition switch ON

10 Sensor ground––

11 Camshaft position sensor 0 – 0.8 V and

4 – 6 VIgnition switch ON

12 Shield ground––

13 Heated oxygen sensor-1 (if equipped) Refer to DTC P0130 diag. flow table

CO adjusting resistor (if equipped)––

14 Engine coolant temp. sensor 0.55 - 0.95 V Ignition switch ON

Engine coolant temp. : 80°C (176°F)

15 Intake air temp. sensor 2.0 – 2.7 V Ignition switch ON

Intake air temp. : 20°C (68°F)

16 Throttle position sensor 0.2 – 1.0 V Ignition switch ON

Throttle valve at idle position

2.8 – 4.8 V Ignition switch ON

Throttle valve at full open position

17 EGR valve (stepper motor coil 3)

(if equipped)10 – 14 V Ignition switch ON

18 EGR valve (stepper motor coil 1)

(if equipped)10 – 14 V Ignition switch ON

19 Ignition coil #2––

20 Ignition coil #1––

21 Fuel injector NO.2 10 – 14 V Ignition switch ON

22 Power source for sensor 4.75 – 5.25 V Ignition switch ON

23 Crankshaft position sensor––

24–– –

25 knock sensor (if equipped) 2.1 – 2.9 V Ignition switch ON

26 Manifold absolute pressure sensor 3.3 – 4.0 V Ignition switch ON

Barometric pressure : 100 kPa (760 mmHg)

27–– –

28 EGR valve (stepper motor coil 4)

(if equipped)10 – 14 V Ignition switch ON

29 EGR valve (stepper motor coil 2)

(if equipped)10 – 14 V Ignition switch ON

30 A/C triple pressure switch 10 – 14 V A/C not operated

31 Fuel injector NO.3 10 – 14 V Ignition switch ON

TERMINAL

NO.CIRCUIT NORMAL

VOLTAGECONDITION

Page 412 of 698

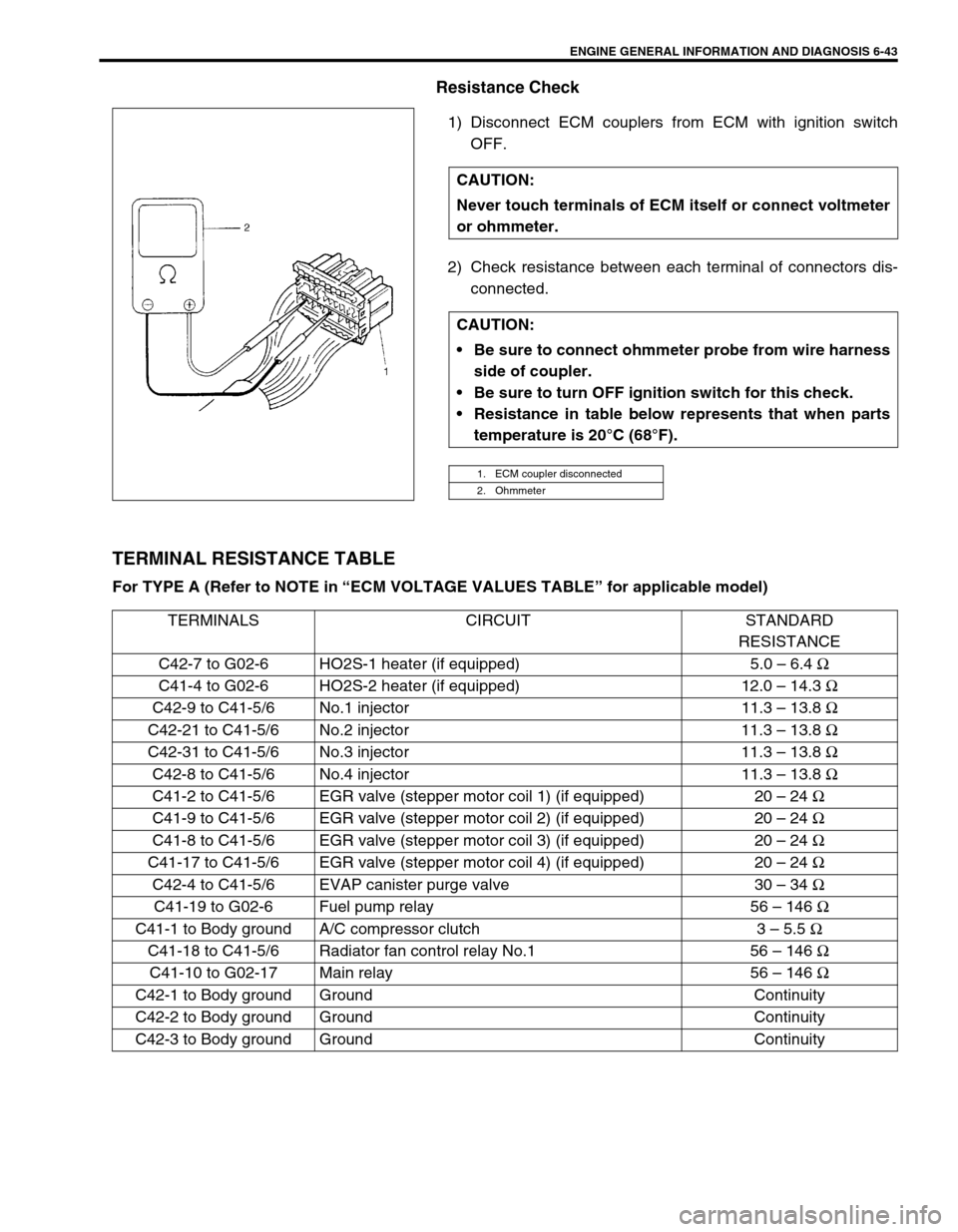

ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-43

Resistance Check

1) Disconnect ECM couplers from ECM with ignition switch

OFF.

2) Check resistance between each terminal of connectors dis-

connected.

TERMINAL RESISTANCE TABLE

For TYPE A (Refer to NOTE in “ECM VOLTAGE VALUES TABLE” for applicable model) CAUTION:

Never touch terminals of ECM itself or connect voltmeter

or ohmmeter.

CAUTION:

Be sure to connect ohmmeter probe from wire harness

side of coupler.

Be sure to turn OFF ignition switch for this check.

Resistance in table below represents that when parts

temperature is 20°C (68°F).

1. ECM coupler disconnected

2. Ohmmeter

TERMINALS CIRCUIT STANDARD

RESISTANCE

C42-7 to G02-6 HO2S-1 heater (if equipped) 5.0 – 6.4 Ω

C41-4 to G02-6 HO2S-2 heater (if equipped) 12.0 – 14.3 Ω

C42-9 to C41-5/6 No.1 injector 11.3 – 13.8 Ω

C42-21 to C41-5/6 No.2 injector 11.3 – 13.8 Ω

C42-31 to C41-5/6 No.3 injector 11.3 – 13.8 Ω

C42-8 to C41-5/6 No.4 injector 11.3 – 13.8 Ω

C41-2 to C41-5/6 EGR valve (stepper motor coil 1) (if equipped) 20 – 24 Ω

C41-9 to C41-5/6 EGR valve (stepper motor coil 2) (if equipped) 20 – 24 Ω

C41-8 to C41-5/6 EGR valve (stepper motor coil 3) (if equipped) 20 – 24 Ω

C41-17 to C41-5/6 EGR valve (stepper motor coil 4) (if equipped) 20 – 24 Ω

C42-4 to C41-5/6 EVAP canister purge valve 30 – 34 Ω

C41-19 to G02-6 Fuel pump relay 56 – 146 Ω

C41-1 to Body ground A/C compressor clutch 3 – 5.5 Ω

C41-18 to C41-5/6 Radiator fan control relay No.1 56 – 146 Ω

C41-10 to G02-17 Main relay 56 – 146 Ω

C42-1 to Body ground Ground Continuity

C42-2 to Body ground Ground Continuity

C42-3 to Body ground Ground Continuity

Page 413 of 698

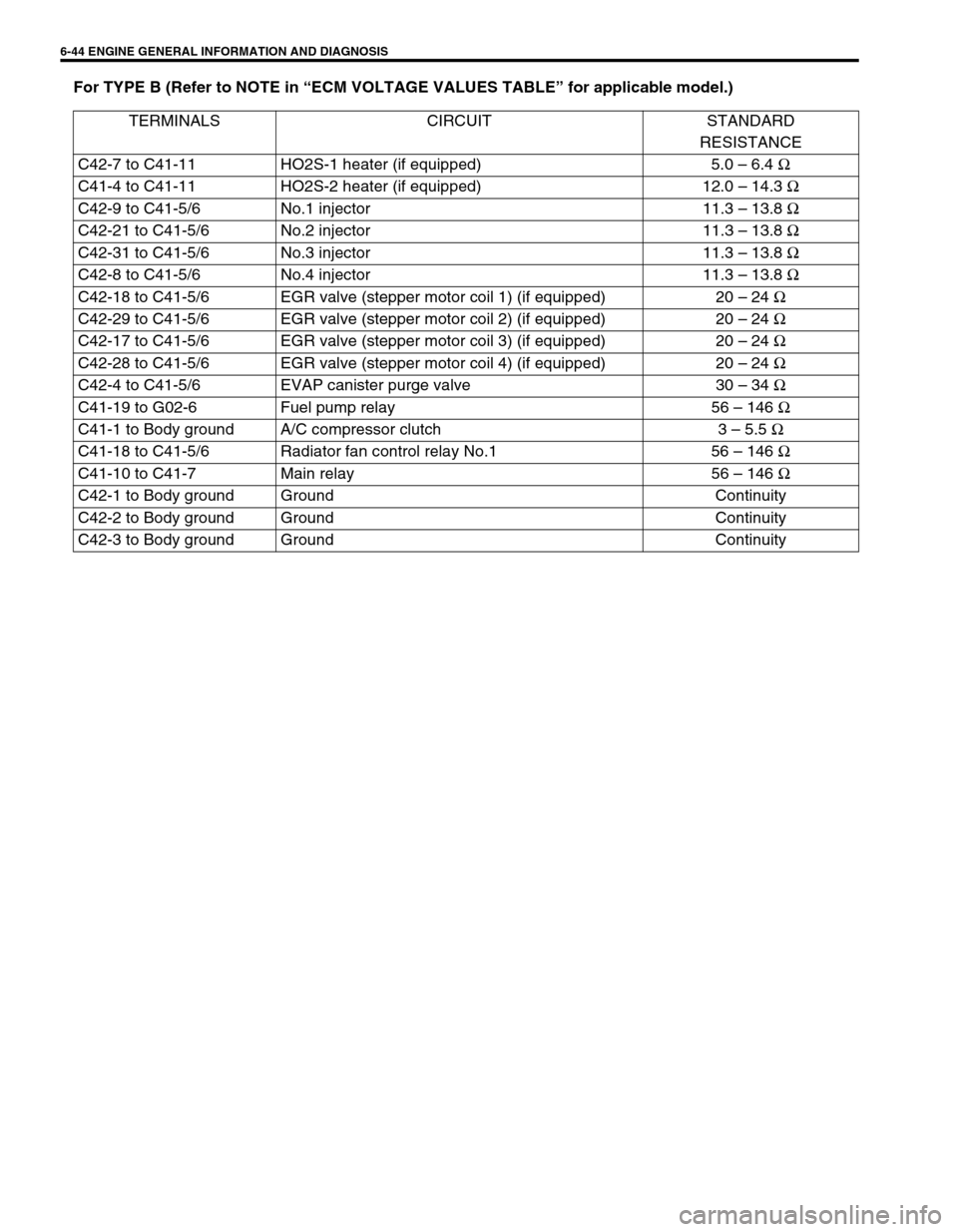

6-44 ENGINE GENERAL INFORMATION AND DIAGNOSIS

For TYPE B (Refer to NOTE in “ECM VOLTAGE VALUES TABLE” for applicable model.)

TERMINALS CIRCUIT STANDARD

RESISTANCE

C42-7 to C41-11 HO2S-1 heater (if equipped) 5.0 – 6.4 Ω

C41-4 to C41-11 HO2S-2 heater (if equipped) 12.0 – 14.3 Ω

C42-9 to C41-5/6 No.1 injector 11.3 – 13.8 Ω

C42-21 to C41-5/6 No.2 injector 11.3 – 13.8 Ω

C42-31 to C41-5/6 No.3 injector 11.3 – 13.8 Ω

C42-8 to C41-5/6 No.4 injector 11.3 – 13.8 Ω

C42-18 to C41-5/6 EGR valve (stepper motor coil 1) (if equipped) 20 – 24 Ω

C42-29 to C41-5/6 EGR valve (stepper motor coil 2) (if equipped) 20 – 24 Ω

C42-17 to C41-5/6 EGR valve (stepper motor coil 3) (if equipped) 20 – 24 Ω

C42-28 to C41-5/6 EGR valve (stepper motor coil 4) (if equipped) 20 – 24 Ω

C42-4 to C41-5/6 EVAP canister purge valve 30 – 34 Ω

C41-19 to G02-6 Fuel pump relay 56 – 146 Ω

C41-1 to Body ground A/C compressor clutch 3 – 5.5 Ω

C41-18 to C41-5/6 Radiator fan control relay No.1 56 – 146 Ω

C41-10 to C41-7 Main relay 56 – 146 Ω

C42-1 to Body ground Ground Continuity

C42-2 to Body ground Ground Continuity

C42-3 to Body ground Ground Continuity

Page 414 of 698

ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-45

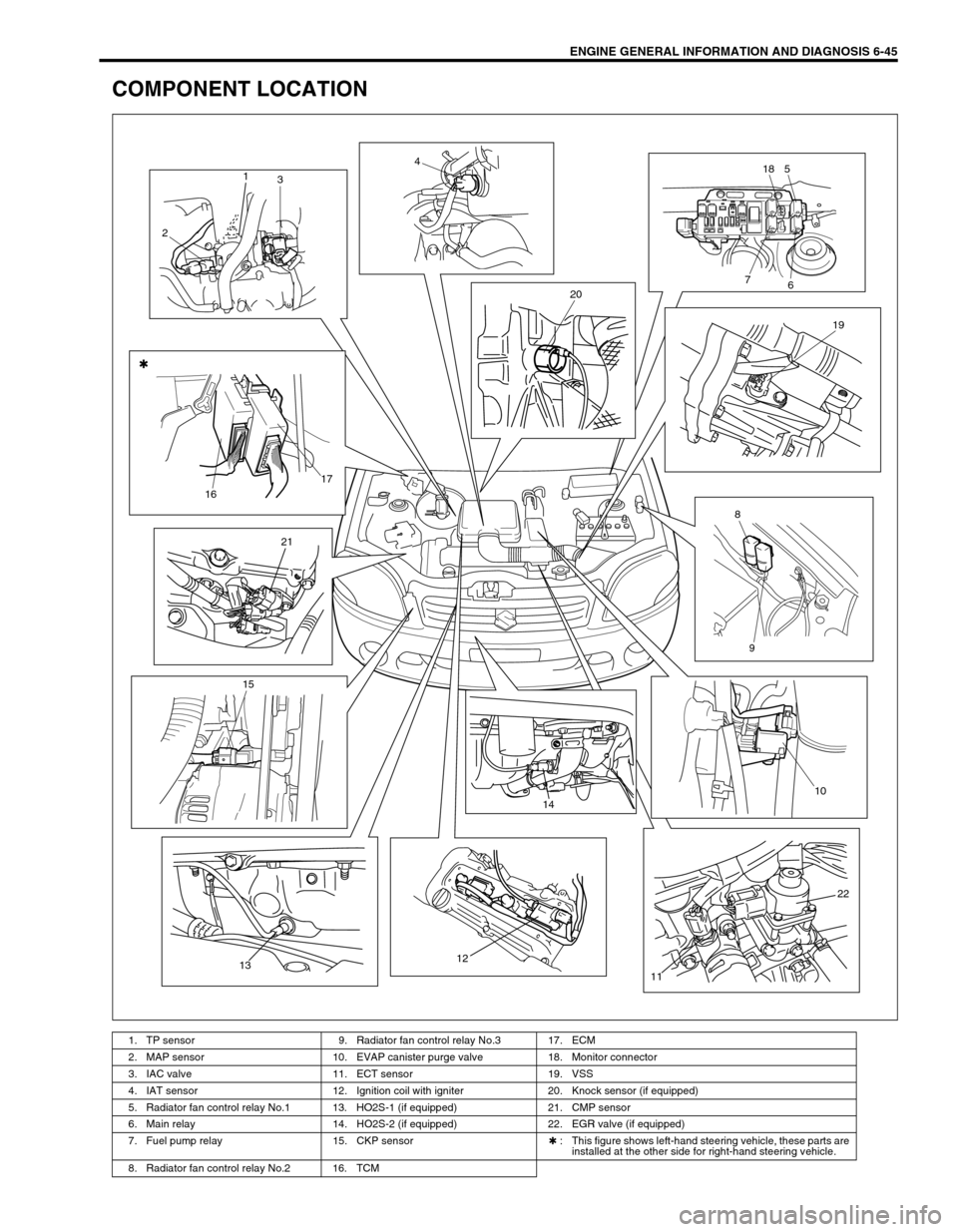

COMPONENT LOCATION

1. TP sensor 9. Radiator fan control relay No.3 17. ECM

2. MAP sensor 10. EVAP canister purge valve 18. Monitor connector

3. IAC valve 11. ECT sensor 19. VSS

4. IAT sensor 12. Ignition coil with igniter 20. Knock sensor (if equipped)

5. Radiator fan control relay No.1 13. HO2S-1 (if equipped) 21. CMP sensor

6. Main relay 14. HO2S-2 (if equipped) 22. EGR valve (if equipped)

7. Fuel pump relay 15. CKP sensor✱ : This figure shows left-hand steering vehicle, these parts are

installed at the other side for right-hand steering vehicle.

8. Radiator fan control relay No.2 16. TCM

1

3

24

518

6 7

20

19

8

9 1617

21

15

131214

10

22

11

Page 450 of 698

ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-81

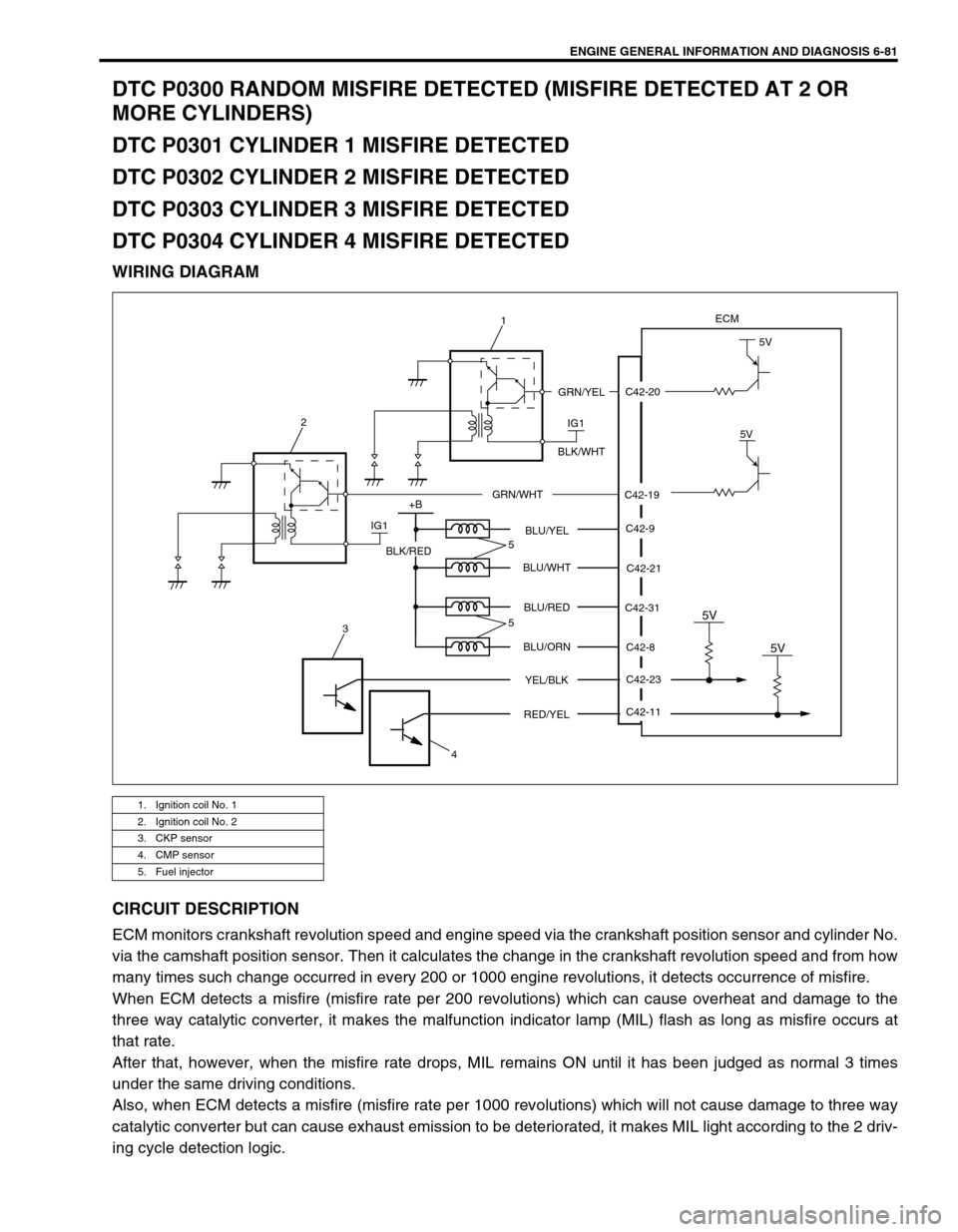

DTC P0300 RANDOM MISFIRE DETECTED (MISFIRE DETECTED AT 2 OR

MORE CYLINDERS)

DTC P0301 CYLINDER 1 MISFIRE DETECTED

DTC P0302 CYLINDER 2 MISFIRE DETECTED

DTC P0303 CYLINDER 3 MISFIRE DETECTED

DTC P0304 CYLINDER 4 MISFIRE DETECTED

WIRING DIAGRAM

CIRCUIT DESCRIPTION

ECM monitors crankshaft revolution speed and engine speed via the crankshaft position sensor and cylinder No.

via the camshaft position sensor. Then it calculates the change in the crankshaft revolution speed and from how

many times such change occurred in every 200 or 1000 engine revolutions, it detects occurrence of misfire.

When ECM detects a misfire (misfire rate per 200 revolutions) which can cause overheat and damage to the

three way catalytic converter, it makes the malfunction indicator lamp (MIL) flash as long as misfire occurs at

that rate.

After that, however, when the misfire rate drops, MIL remains ON until it has been judged as normal 3 times

under the same driving conditions.

Also, when ECM detects a misfire (misfire rate per 1000 revolutions) which will not cause damage to three way

catalytic converter but can cause exhaust emission to be deteriorated, it makes MIL light according to the 2 driv-

ing cycle detection logic.

1. Ignition coil No. 1

2. Ignition coil No. 2

3. CKP sensor

4. CMP sensor

5. Fuel injector

C42-20

C42-19

ECM

IG1

5V

5V

GRN/YEL

BLK/WHT

GRN/WHT

IG1 2

+B

C42-9

C42-21

C42-8

C42-23 C42-31 BLU/YEL

BLU/WHT

BLU/RED

BLU/ORN

YEL/BLK

5V

C42-11

RED/YEL

5V

BLK/RED

3

45

5

1