wheel bolts SUZUKI SWIFT 2000 1.G RG413 Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 206 of 698

FRONT SUSPENSION 3D-13

DISASSEMBLY

1) Uncaulk and remove dust cover (1).

2) Remove circlip.

3) Using hydraulic press (1) and special tool, remove wheel

bearing.

Special tool

(A) : 09913-75810

4) Remove wheel bearing outside inner race (1).

Special tool

(C) : 09913-61110

(D) : 09925-88210

5) Remove hub bolts (1).

CAUTION:

When installing wheel bearing, replace it with new one.

CAUTION:

Never remove bolt unless replacement is necessary.

Be sure to use a new bolt for replacement.

Page 225 of 698

3E-12 REAR SUSPENSION

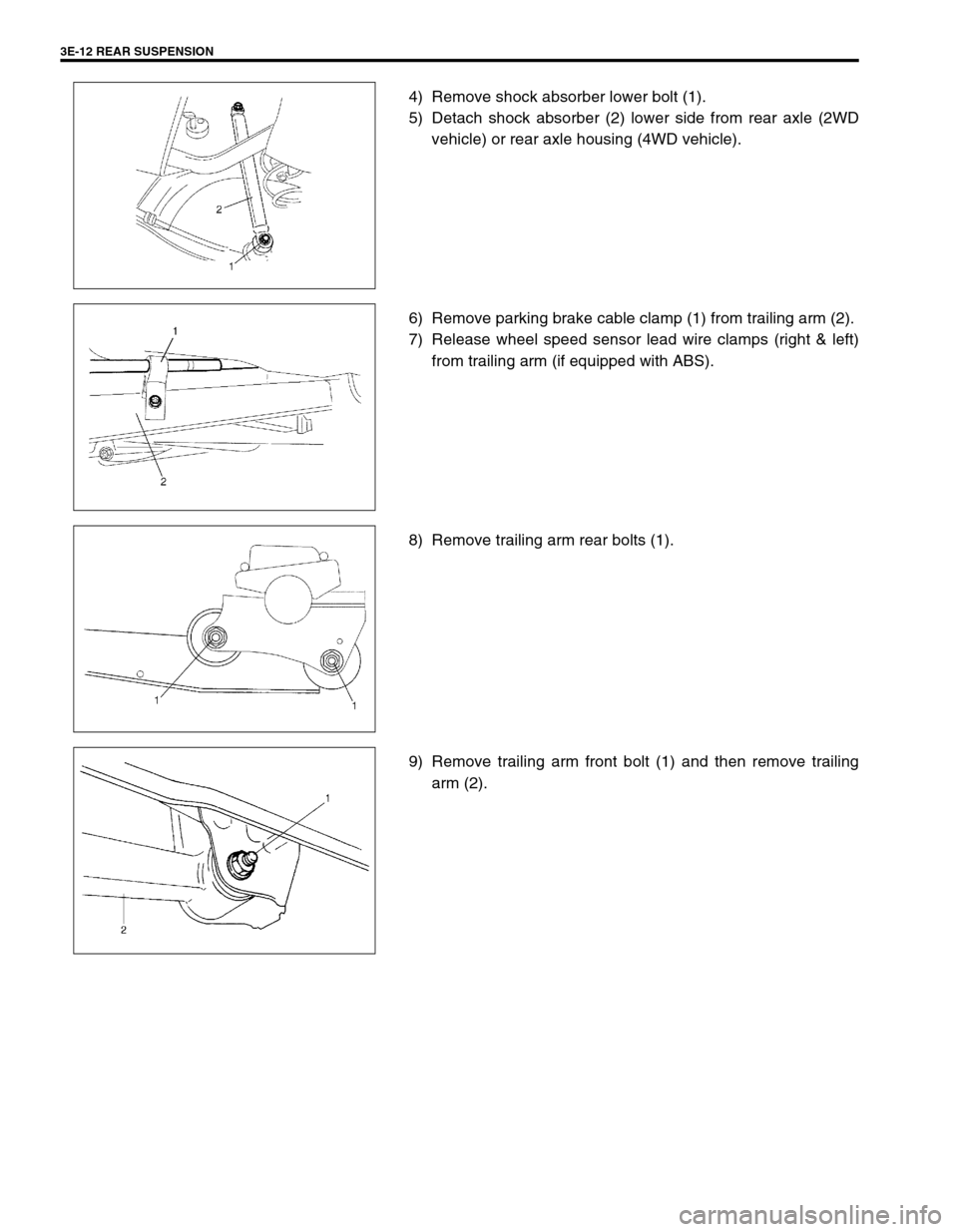

4) Remove shock absorber lower bolt (1).

5) Detach shock absorber (2) lower side from rear axle (2WD

vehicle) or rear axle housing (4WD vehicle).

6) Remove parking brake cable clamp (1) from trailing arm (2).

7) Release wheel speed sensor lead wire clamps (right & left)

from trailing arm (if equipped with ABS).

8) Remove trailing arm rear bolts (1).

9) Remove trailing arm front bolt (1) and then remove trailing

arm (2).

Page 226 of 698

REAR SUSPENSION 3E-13

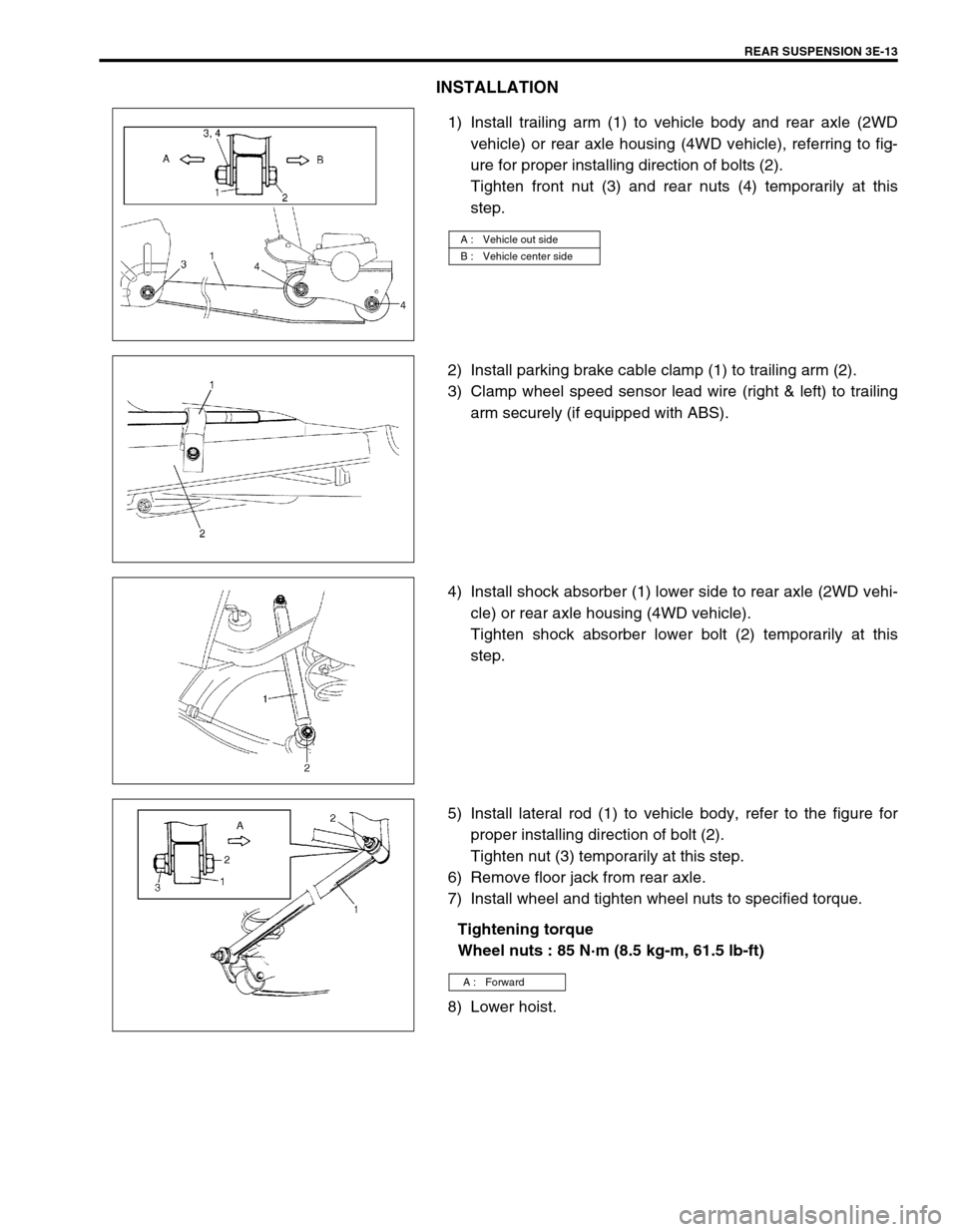

INSTALLATION

1) Install trailing arm (1) to vehicle body and rear axle (2WD

vehicle) or rear axle housing (4WD vehicle), referring to fig-

ure for proper installing direction of bolts (2).

Tighten front nut (3) and rear nuts (4) temporarily at this

step.

2) Install parking brake cable clamp (1) to trailing arm (2).

3) Clamp wheel speed sensor lead wire (right & left) to trailing

arm securely (if equipped with ABS).

4) Install shock absorber (1) lower side to rear axle (2WD vehi-

cle) or rear axle housing (4WD vehicle).

Tighten shock absorber lower bolt (2) temporarily at this

step.

5) Install lateral rod (1) to vehicle body, refer to the figure for

proper installing direction of bolt (2).

Tighten nut (3) temporarily at this step.

6) Remove floor jack from rear axle.

7) Install wheel and tighten wheel nuts to specified torque.

Tightening torque

Wheel nuts : 85 N·m (8.5 kg-m, 61.5 lb-ft)

8) Lower hoist.

A : Vehicle out side

B : Vehicle center side

A : Forward

Page 227 of 698

3E-14 REAR SUSPENSION

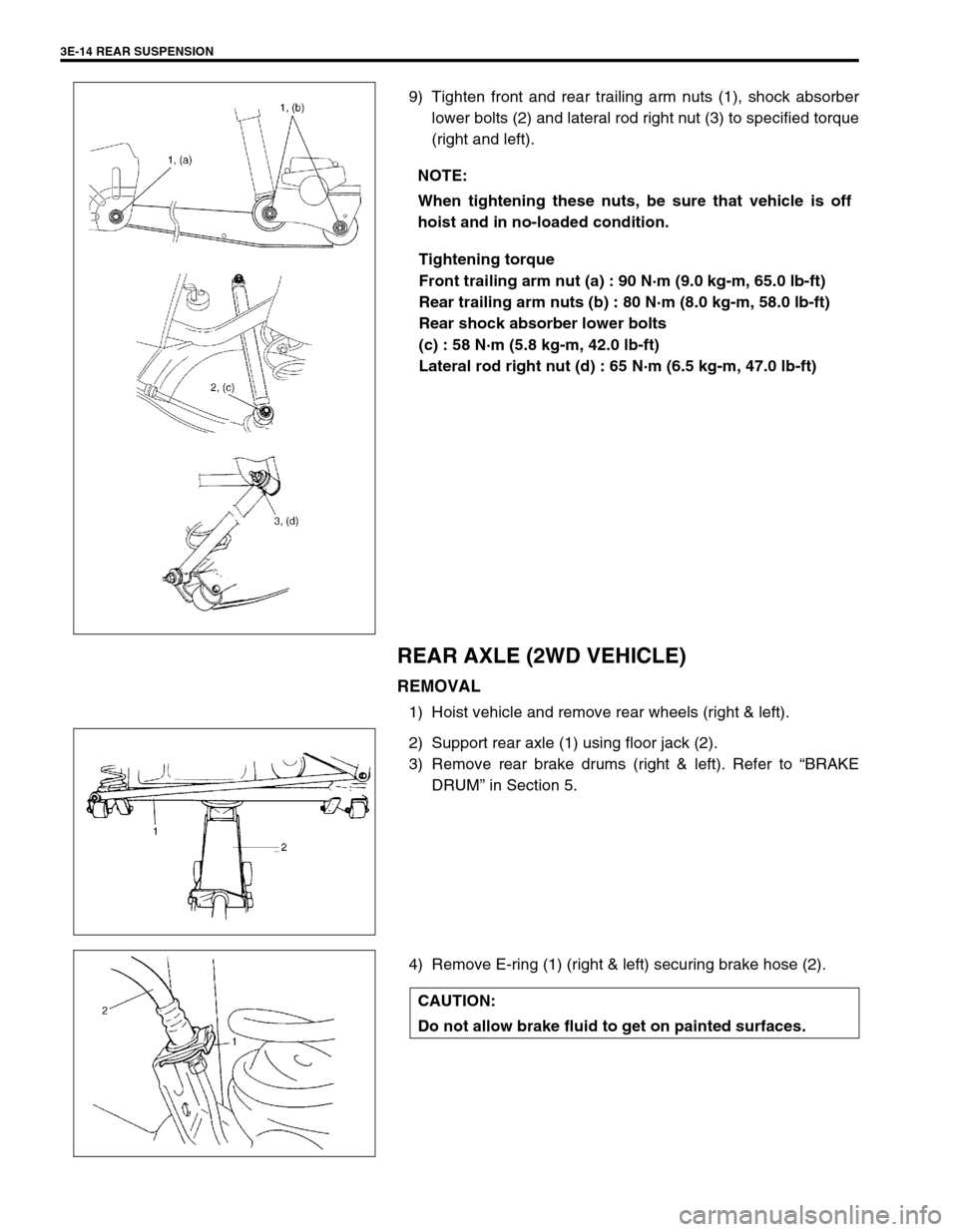

9) Tighten front and rear trailing arm nuts (1), shock absorber

lower bolts (2) and lateral rod right nut (3) to specified torque

(right and left).

Tightening torque

Front trailing arm nut (a) : 90 N·m (9.0 kg-m, 65.0 lb-ft)

Rear trailing arm nuts (b) : 80 N·m (8.0 kg-m, 58.0 lb-ft)

Rear shock absorber lower bolts

(c) : 58 N·m (5.8 kg-m, 42.0 lb-ft)

Lateral rod right nut (d) : 65 N·m (6.5 kg-m, 47.0 lb-ft)

REAR AXLE (2WD VEHICLE)

REMOVAL

1) Hoist vehicle and remove rear wheels (right & left).

2) Support rear axle (1) using floor jack (2).

3) Remove rear brake drums (right & left). Refer to “BRAKE

DRUM” in Section 5.

4) Remove E-ring (1) (right & left) securing brake hose (2).NOTE:

When tightening these nuts, be sure that vehicle is off

hoist and in no-loaded condition.

CAUTION:

Do not allow brake fluid to get on painted surfaces.

Page 232 of 698

REAR SUSPENSION 3E-19

15) Upon completion of all jobs, depress brake pedal with about

30 kg (66 Ibs) load three to five times so as to obtain proper

drum-to-shoe clearance.

Adjust parking brake cable. Refer to Section 5.

16) Install console box.

17) Lower hoist and bounce vehicle up and down several times

to stabilize suspension.

Be sure that vehicle is off hoist and in non loaded condition.

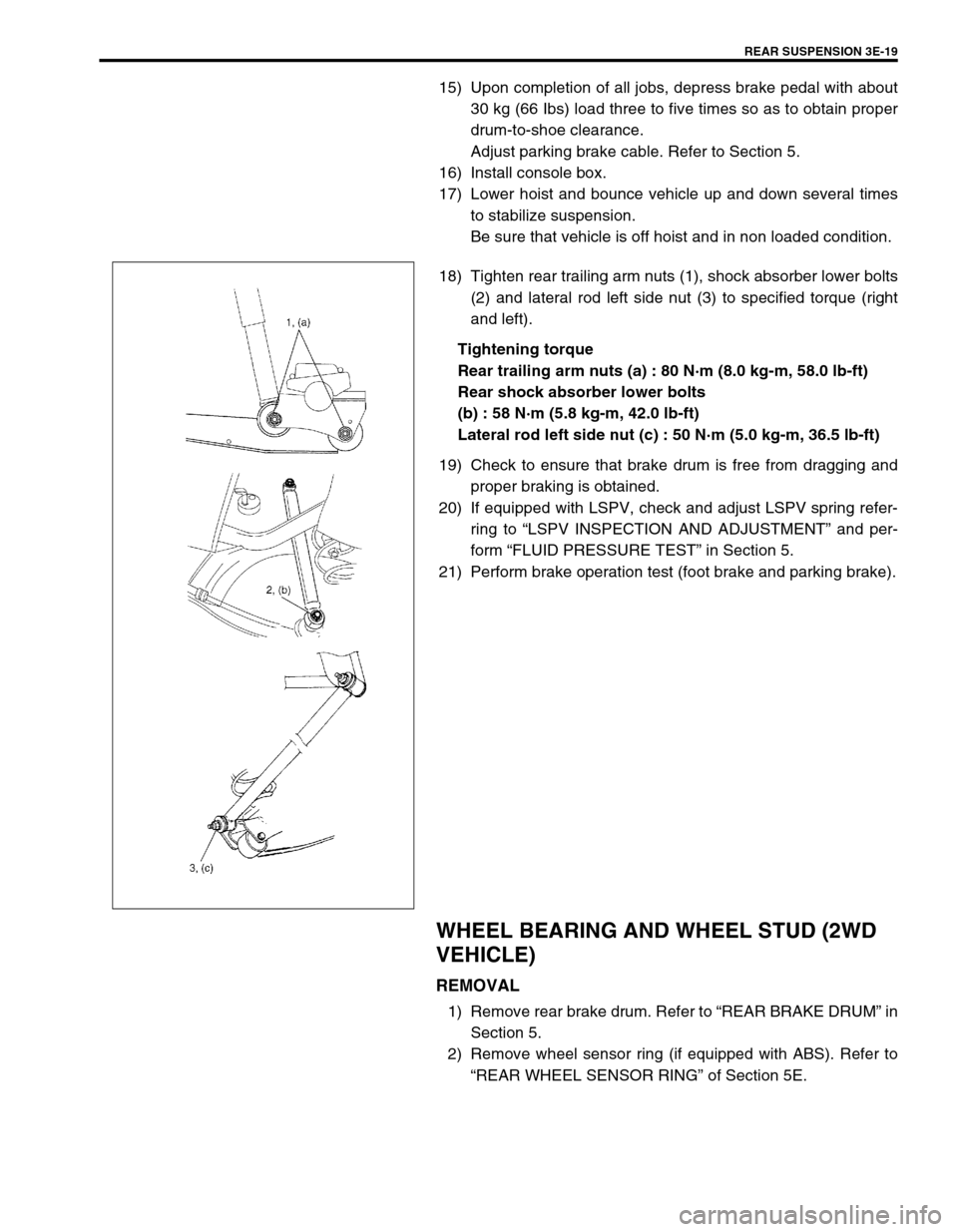

18) Tighten rear trailing arm nuts (1), shock absorber lower bolts

(2) and lateral rod left side nut (3) to specified torque (right

and left).

Tightening torque

Rear trailing arm nuts (a) : 80 N·m (8.0 kg-m, 58.0 lb-ft)

Rear shock absorber lower bolts

(b) : 58 N·m (5.8 kg-m, 42.0 lb-ft)

Lateral rod left side nut (c) : 50 N·m (5.0 kg-m, 36.5 lb-ft)

19) Check to ensure that brake drum is free from dragging and

proper braking is obtained.

20) If equipped with LSPV, check and adjust LSPV spring refer-

ring to “LSPV INSPECTION AND ADJUSTMENT” and per-

form “FLUID PRESSURE TEST” in Section 5.

21) Perform brake operation test (foot brake and parking brake).

WHEEL BEARING AND WHEEL STUD (2WD

VEHICLE)

REMOVAL

1) Remove rear brake drum. Refer to “REAR BRAKE DRUM” in

Section 5.

2) Remove wheel sensor ring (if equipped with ABS). Refer to

“REAR WHEEL SENSOR RING” of Section 5E.

Page 233 of 698

3E-20 REAR SUSPENSION

3) Remove bearing circlip (1) using special tool.

Special tool

(A) : 09900-06108

4) Remove wheel bearing using special tool and hydraulic

press (1).

Special tool

(A) : 09913-76010

5) Remove wheel stud bolts (1) using hydraulic press (2) and

general rod (3).

INSTALLATION

1) Insert new stud in drum hole and rotate it slowly to assure

serrations are aligned with those made by replaced bolt.

Page 235 of 698

3E-22 REAR SUSPENSION

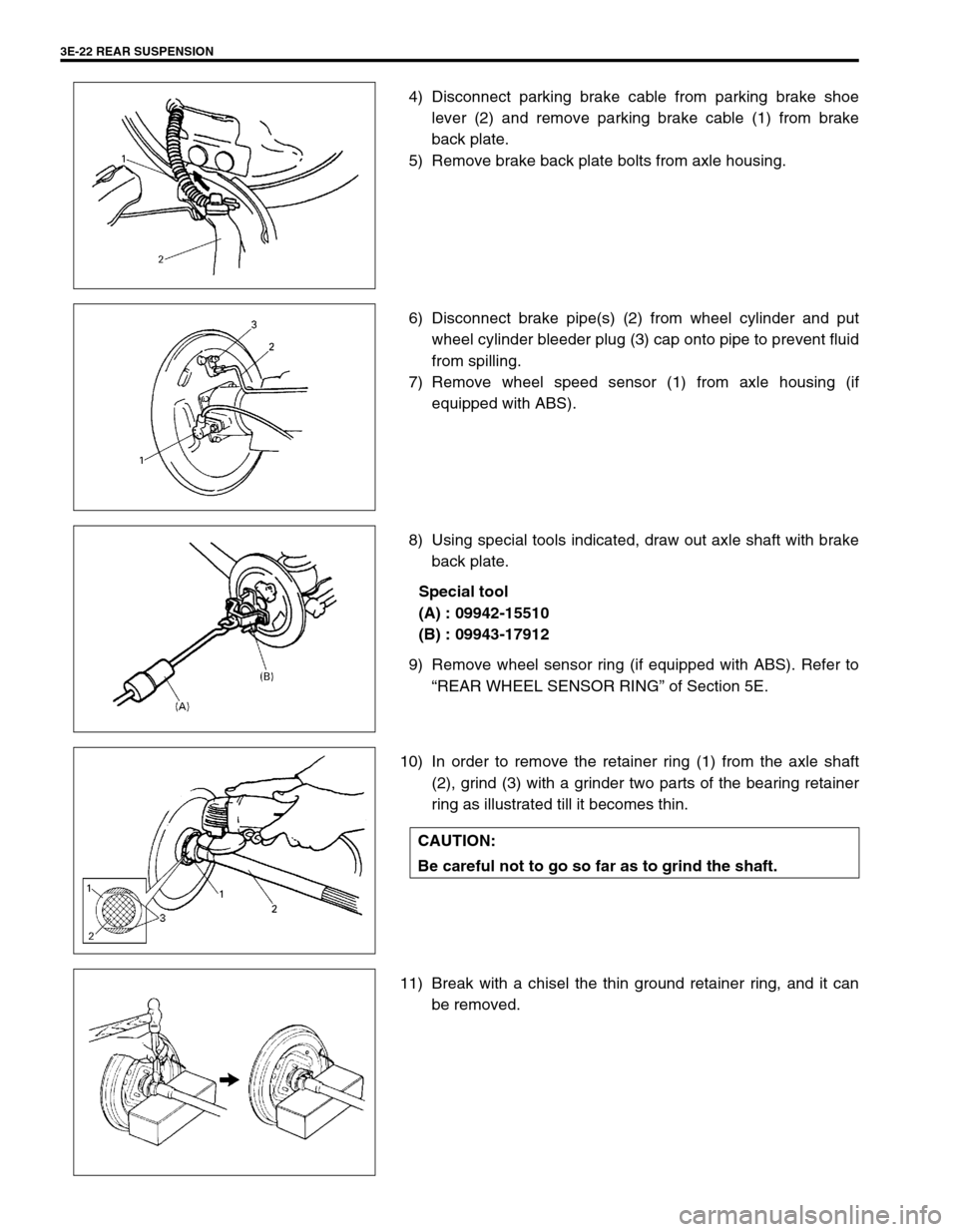

4) Disconnect parking brake cable from parking brake shoe

lever (2) and remove parking brake cable (1) from brake

back plate.

5) Remove brake back plate bolts from axle housing.

6) Disconnect brake pipe(s) (2) from wheel cylinder and put

wheel cylinder bleeder plug (3) cap onto pipe to prevent fluid

from spilling.

7) Remove wheel speed sensor (1) from axle housing (if

equipped with ABS).

8) Using special tools indicated, draw out axle shaft with brake

back plate.

Special tool

(A) : 09942-15510

(B) : 09943-17912

9) Remove wheel sensor ring (if equipped with ABS). Refer to

“REAR WHEEL SENSOR RING” of Section 5E.

10) In order to remove the retainer ring (1) from the axle shaft

(2), grind (3) with a grinder two parts of the bearing retainer

ring as illustrated till it becomes thin.

11) Break with a chisel the thin ground retainer ring, and it can

be removed.

CAUTION:

Be careful not to go so far as to grind the shaft.

Page 237 of 698

3E-24 REAR SUSPENSION

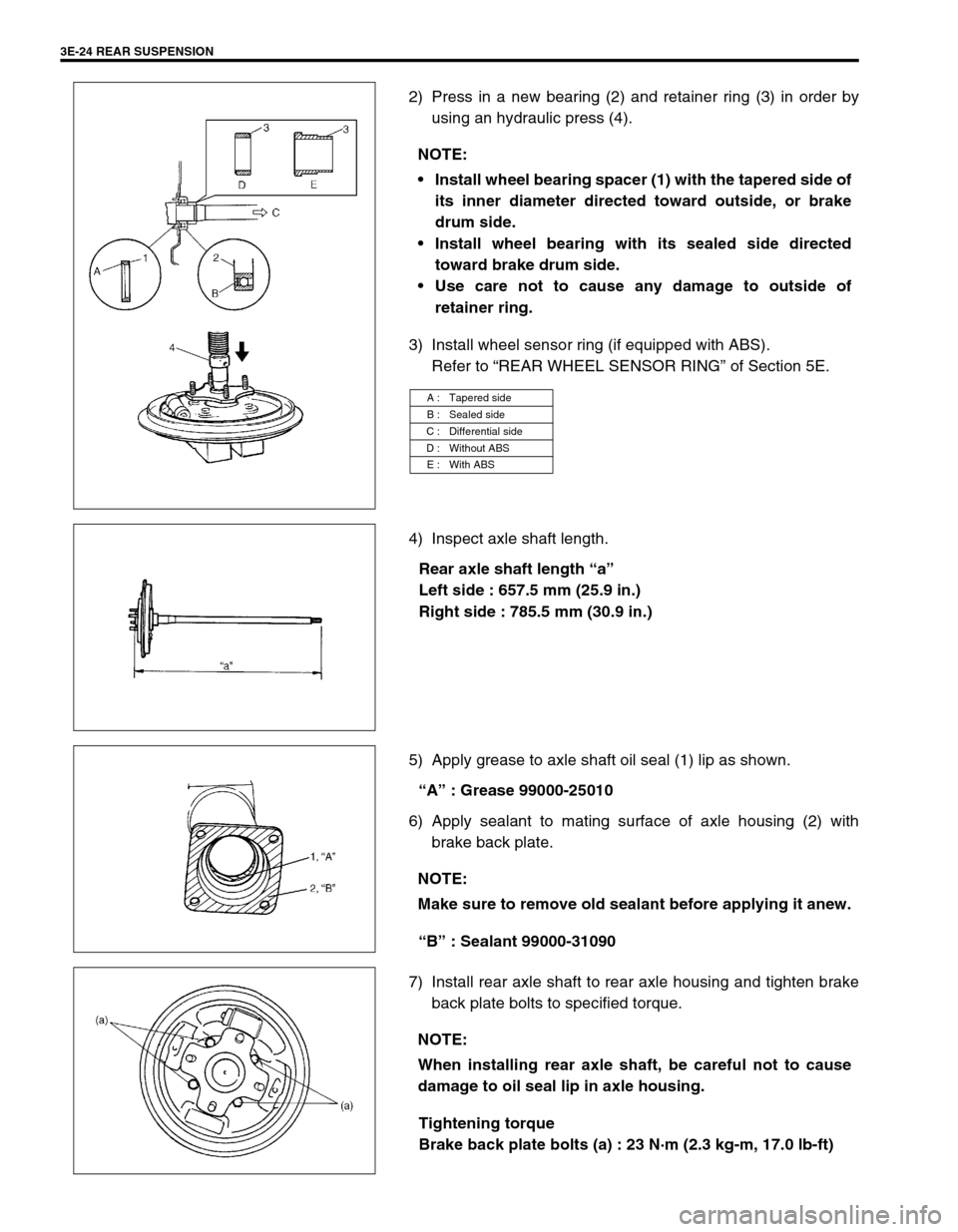

2) Press in a new bearing (2) and retainer ring (3) in order by

using an hydraulic press (4).

3) Install wheel sensor ring (if equipped with ABS).

Refer to “REAR WHEEL SENSOR RING” of Section 5E.

4) Inspect axle shaft length.

Rear axle shaft length “a”

Left side : 657.5 mm (25.9 in.)

Right side : 785.5 mm (30.9 in.)

5) Apply grease to axle shaft oil seal (1) lip as shown.

“A” : Grease 99000-25010

6) Apply sealant to mating surface of axle housing (2) with

brake back plate.

“B” : Sealant 99000-31090

7) Install rear axle shaft to rear axle housing and tighten brake

back plate bolts to specified torque.

Tightening torque

Brake back plate bolts (a) : 23 N·m (2.3 kg-m, 17.0 lb-ft) NOTE:

Install wheel bearing spacer (1) with the tapered side of

its inner diameter directed toward outside, or brake

drum side.

Install wheel bearing with its sealed side directed

toward brake drum side.

Use care not to cause any damage to outside of

retainer ring.

A : Tapered side

B : Sealed side

C : Differential side

D : Without ABS

E : With ABS

NOTE:

Make sure to remove old sealant before applying it anew.

NOTE:

When installing rear axle shaft, be careful not to cause

damage to oil seal lip in axle housing.

Page 242 of 698

REAR SUSPENSION 3E-29

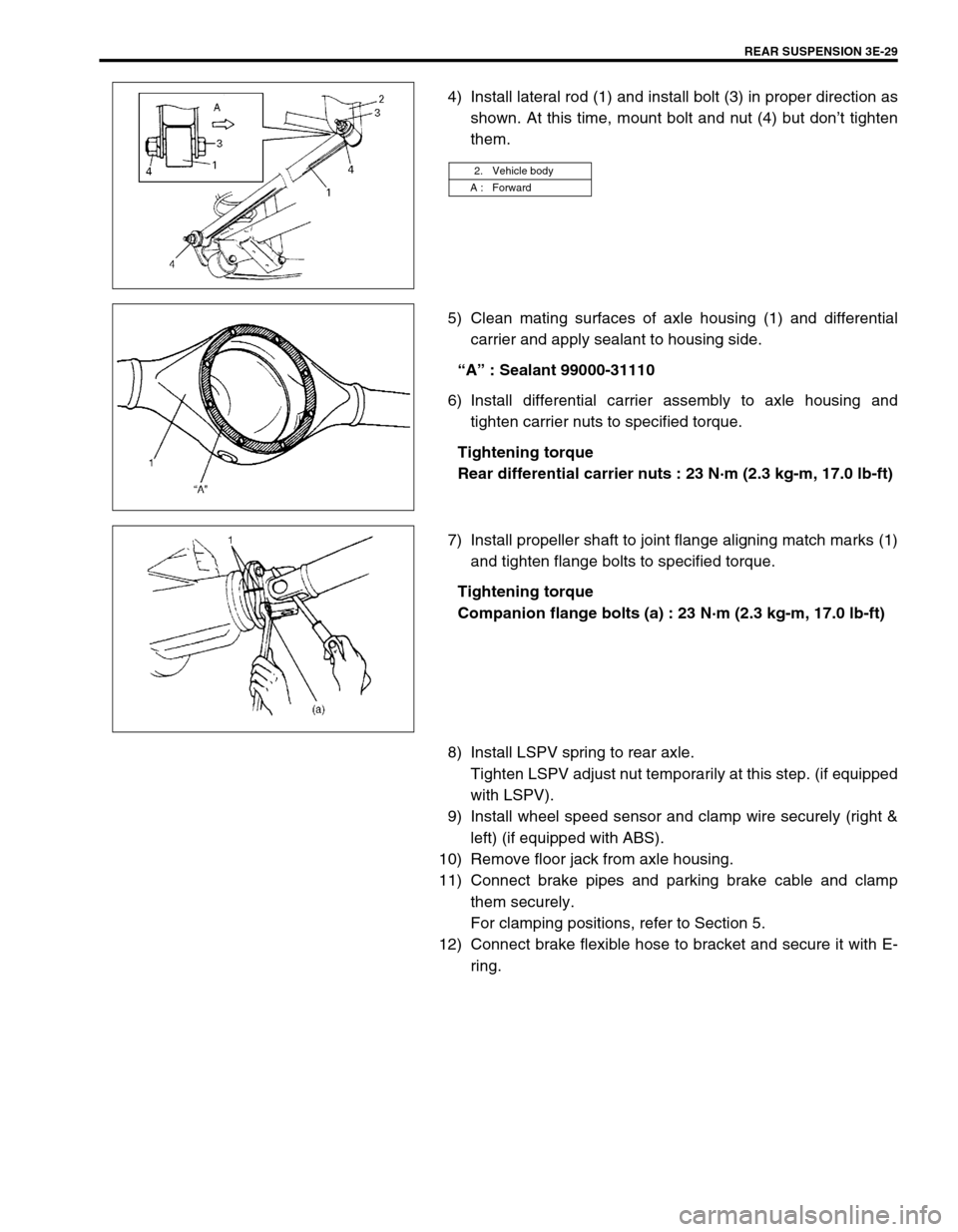

4) Install lateral rod (1) and install bolt (3) in proper direction as

shown. At this time, mount bolt and nut (4) but don’t tighten

them.

5) Clean mating surfaces of axle housing (1) and differential

carrier and apply sealant to housing side.

“A” : Sealant 99000-31110

6) Install differential carrier assembly to axle housing and

tighten carrier nuts to specified torque.

Tightening torque

Rear differential carrier nuts : 23 N·m (2.3 kg-m, 17.0 lb-ft)

7) Install propeller shaft to joint flange aligning match marks (1)

and tighten flange bolts to specified torque.

Tightening torque

Companion flange bolts (a) : 23 N·m (2.3 kg-m, 17.0 lb-ft)

8) Install LSPV spring to rear axle.

Tighten LSPV adjust nut temporarily at this step. (if equipped

with LSPV).

9) Install wheel speed sensor and clamp wire securely (right &

left) (if equipped with ABS).

10) Remove floor jack from axle housing.

11) Connect brake pipes and parking brake cable and clamp

them securely.

For clamping positions, refer to Section 5.

12) Connect brake flexible hose to bracket and secure it with E-

ring.

2. Vehicle body

A : Forward

Page 243 of 698

3E-30 REAR SUSPENSION

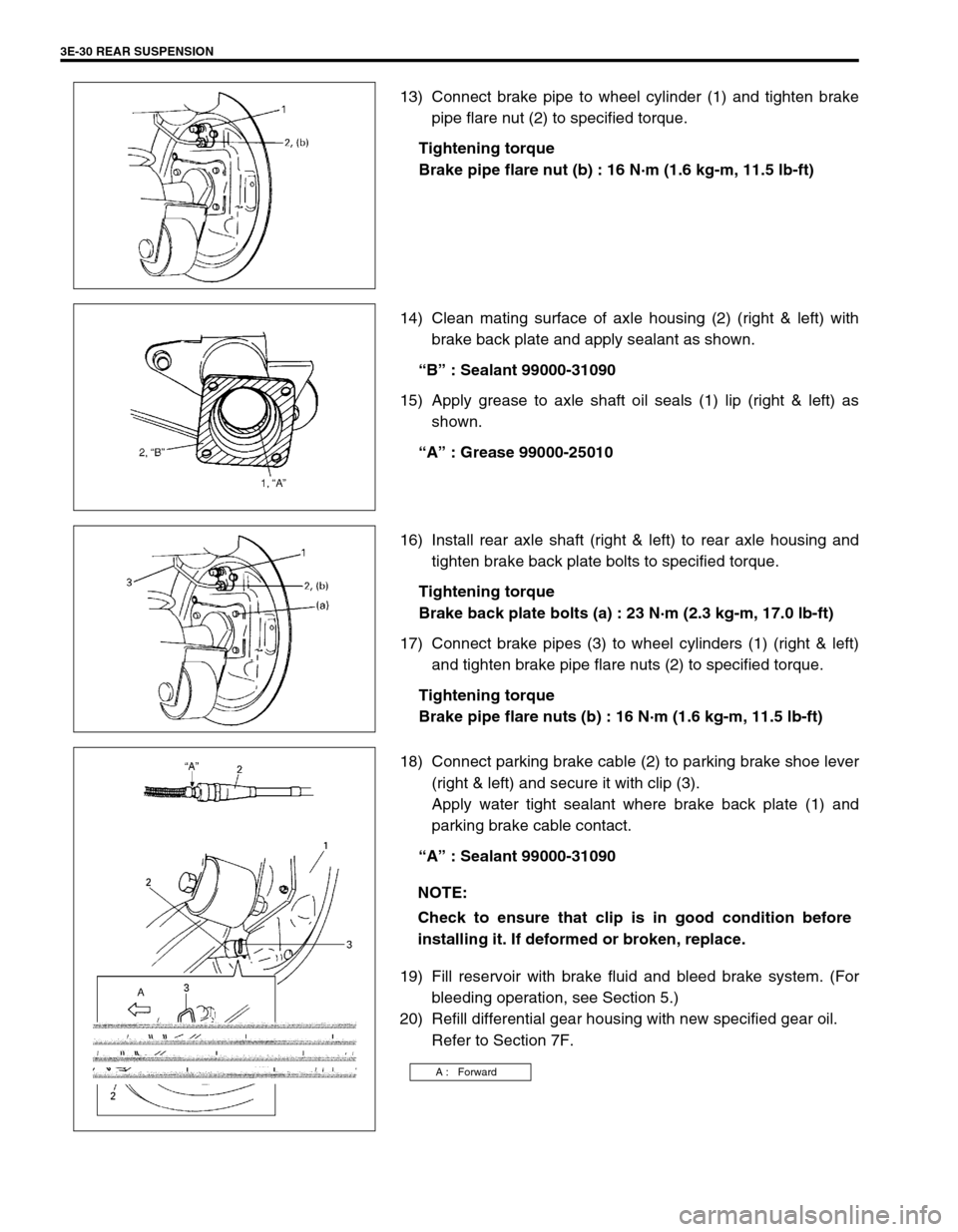

13) Connect brake pipe to wheel cylinder (1) and tighten brake

pipe flare nut (2) to specified torque.

Tightening torque

Brake pipe flare nut (b) : 16 N·m (1.6 kg-m, 11.5 lb-ft)

14) Clean mating surface of axle housing (2) (right & left) with

brake back plate and apply sealant as shown.

“B” : Sealant 99000-31090

15) Apply grease to axle shaft oil seals (1) lip (right & left) as

shown.

“A” : Grease 99000-25010

16) Install rear axle shaft (right & left) to rear axle housing and

tighten brake back plate bolts to specified torque.

Tightening torque

Brake back plate bolts (a) : 23 N·m (2.3 kg-m, 17.0 lb-ft)

17) Connect brake pipes (3) to wheel cylinders (1) (right & left)

and tighten brake pipe flare nuts (2) to specified torque.

Tightening torque

Brake pipe flare nuts (b) : 16 N·m (1.6 kg-m, 11.5 lb-ft)

18) Connect parking brake cable (2) to parking brake shoe lever

(right & left) and secure it with clip (3).

Apply water tight sealant where brake back plate (1) and

parking brake cable contact.

“A” : Sealant 99000-31090

19) Fill reservoir with brake fluid and bleed brake system. (For

bleeding operation, see Section 5.)

20) Refill differential gear housing with new specified gear oil.

Refer to Section 7F.

NOTE:

Check to ensure that clip is in good condition before

installing it. If deformed or broken, replace.

A : Forward