Electric power steering SUZUKI SWIFT 2000 1.G RG413 Service Owner's Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 170 of 698

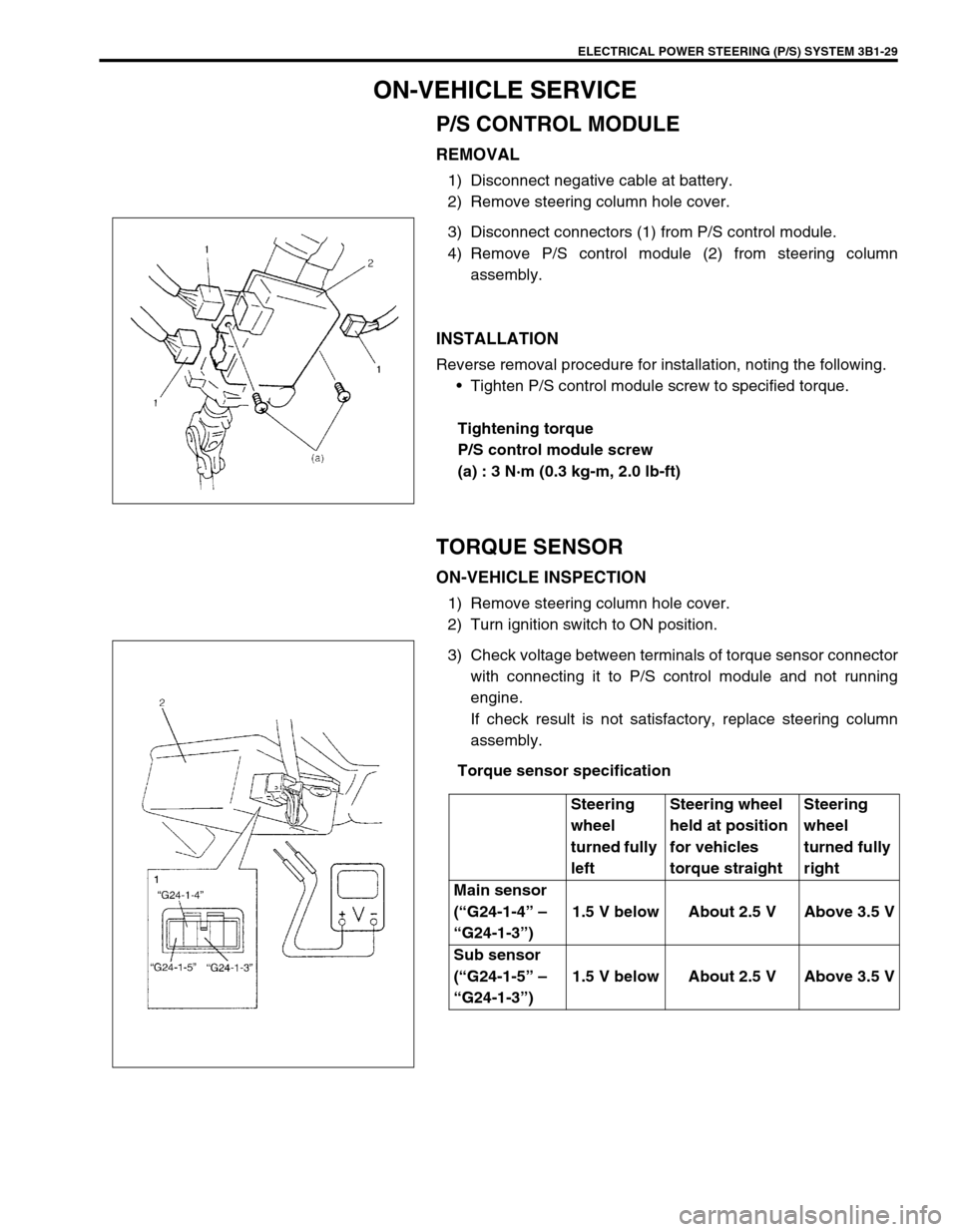

ELECTRICAL POWER STEERING (P/S) SYSTEM 3B1-29

ON-VEHICLE SERVICE

P/S CONTROL MODULE

REMOVAL

1) Disconnect negative cable at battery.

2) Remove steering column hole cover.

3) Disconnect connectors (1) from P/S control module.

4) Remove P/S control module (2) from steering column

assembly.

INSTALLATION

Reverse removal procedure for installation, noting the following.

Tighten P/S control module screw to specified torque.

Tightening torque

P/S control module screw

(a) : 3 N·m (0.3 kg-m, 2.0 lb-ft)

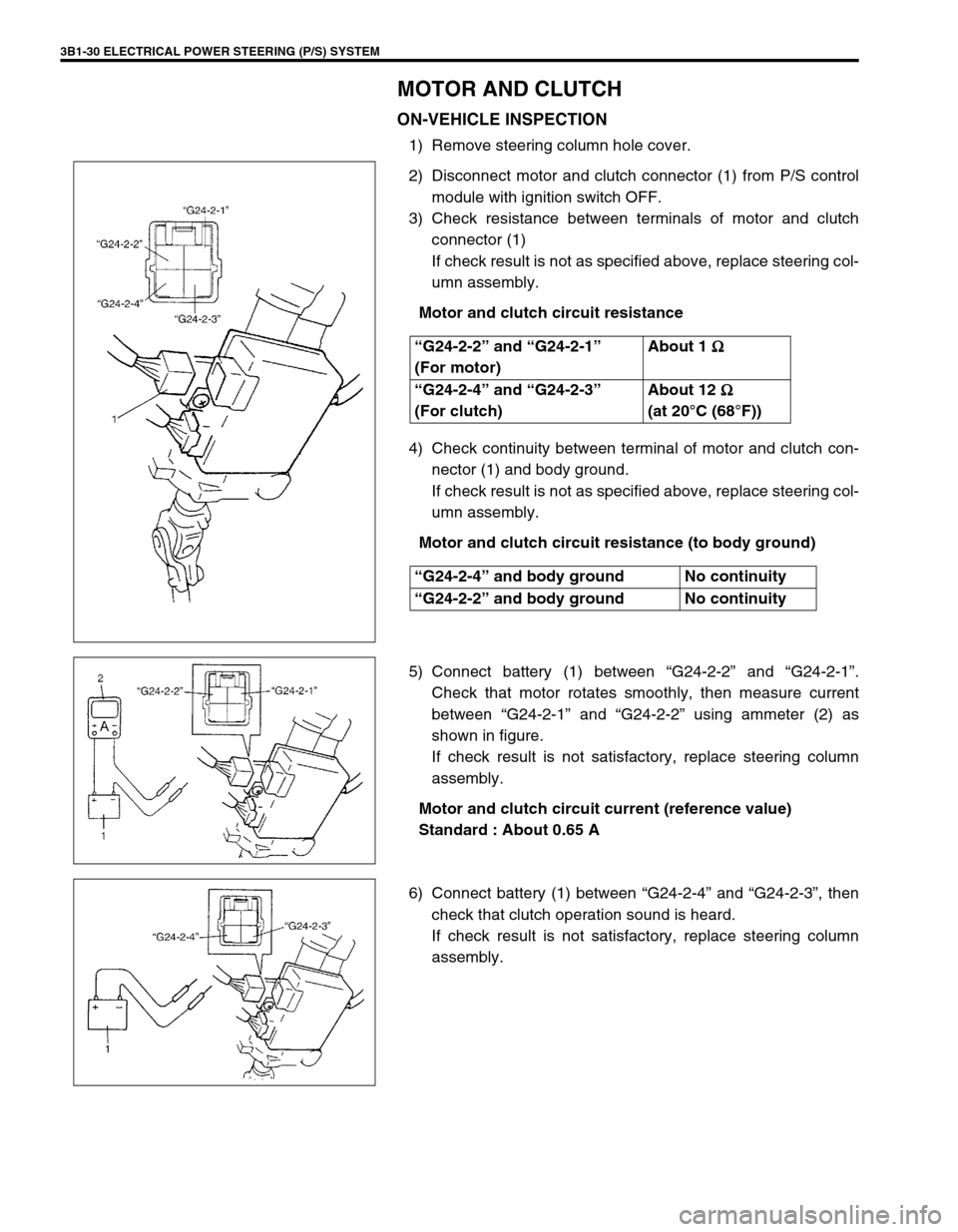

TORQUE SENSOR

ON-VEHICLE INSPECTION

1) Remove steering column hole cover.

2) Turn ignition switch to ON position.

3) Check voltage between terminals of torque sensor connector

with connecting it to P/S control module and not running

engine.

If check result is not satisfactory, replace steering column

assembly.

Torque sensor specification

Steering

wheel

turned fully

leftSteering wheel

held at position

for vehicles

torque straightSteering

wheel

turned fully

right

Main sensor

(“G24-1-4” –

“G24-1-3”)1.5 V below About 2.5 V Above 3.5 V

Sub sensor

(“G24-1-5” –

“G24-1-3”)1.5 V below About 2.5 V Above 3.5 V

Page 171 of 698

3B1-30 ELECTRICAL POWER STEERING (P/S) SYSTEM

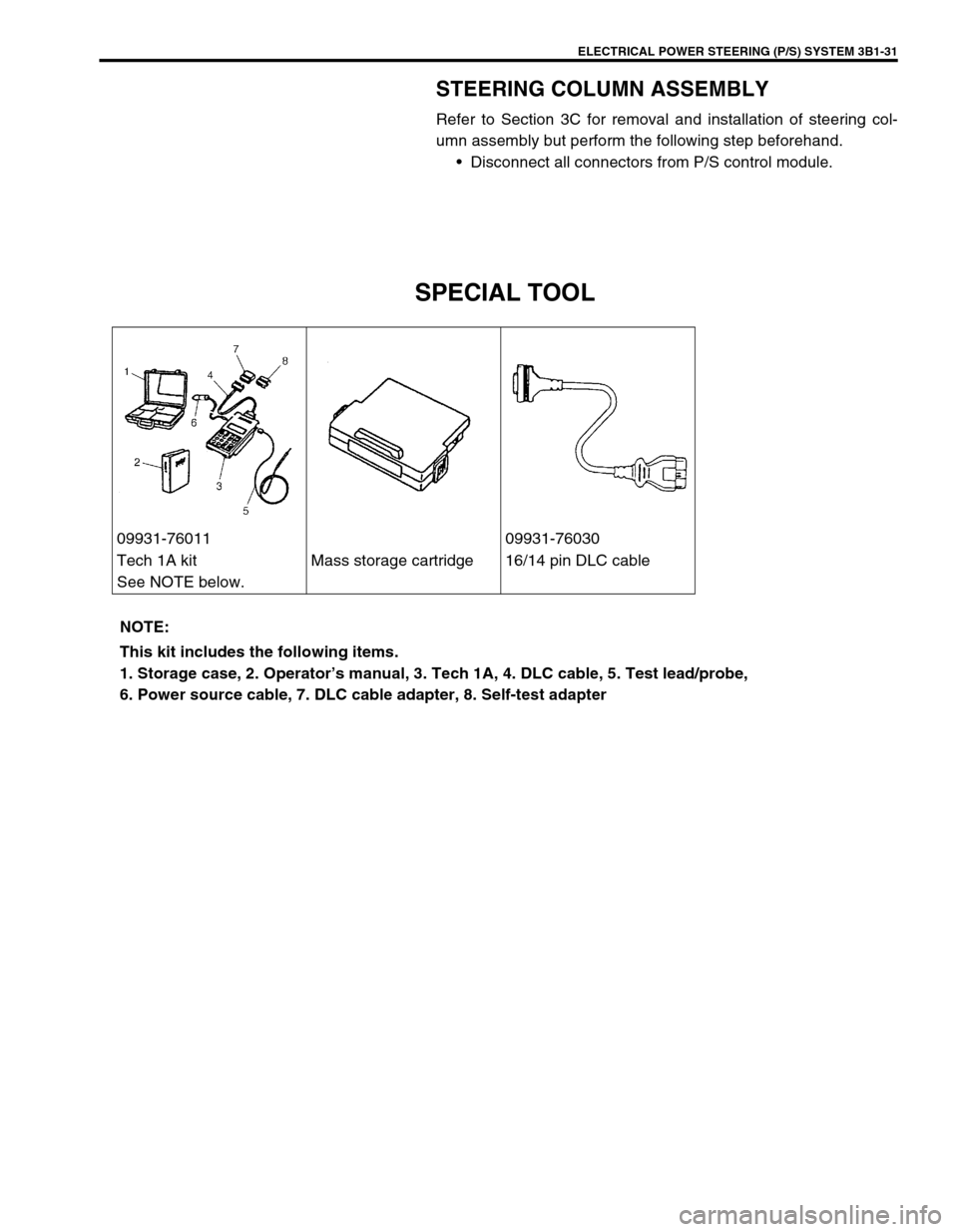

MOTOR AND CLUTCH

ON-VEHICLE INSPECTION

1) Remove steering column hole cover.

2) Disconnect motor and clutch connector (1) from P/S control

module with ignition switch OFF.

3) Check resistance between terminals of motor and clutch

connector (1)

If check result is not as specified above, replace steering col-

umn assembly.

Motor and clutch circuit resistance

4) Check continuity between terminal of motor and clutch con-

nector (1) and body ground.

If check result is not as specified above, replace steering col-

umn assembly.

Motor and clutch circuit resistance (to body ground)

5) Connect battery (1) between “G24-2-2” and “G24-2-1”.

Check that motor rotates smoothly, then measure current

between “G24-2-1” and “G24-2-2” using ammeter (2) as

shown in figure.

If check result is not satisfactory, replace steering column

assembly.

Motor and clutch circuit current (reference value)

Standard : About 0.65 A

6) Connect battery (1) between “G24-2-4” and “G24-2-3”, then

check that clutch operation sound is heard.

If check result is not satisfactory, replace steering column

assembly. “G24-2-2” and “G24-2-1”

(For motor)About 1

Ω

ΩΩ Ω

“G24-2-4” and “G24-2-3”

(For clutch)About 12

Ω

ΩΩ Ω

(at 20°C (68°F))

“G24-2-4” and body ground No continuity

“G24-2-2” and body ground No continuity

Page 172 of 698

ELECTRICAL POWER STEERING (P/S) SYSTEM 3B1-31

STEERING COLUMN ASSEMBLY

Refer to Section 3C for removal and installation of steering col-

umn assembly but perform the following step beforehand.

Disconnect all connectors from P/S control module.

SPECIAL TOOL

09931-76011 09931-76030

Tech 1A kit

See NOTE below.Mass storage cartridge 16/14 pin DLC cable

NOTE:

This kit includes the following items.

1. Storage case, 2. Operator’s manual, 3. Tech 1A, 4. DLC cable, 5. Test lead/probe,

6. Power source cable, 7. DLC cable adapter, 8. Self-test adapter

Page 173 of 698

3B1-32 ELECTRICAL POWER STEERING (P/S) SYSTEM

Page 406 of 698

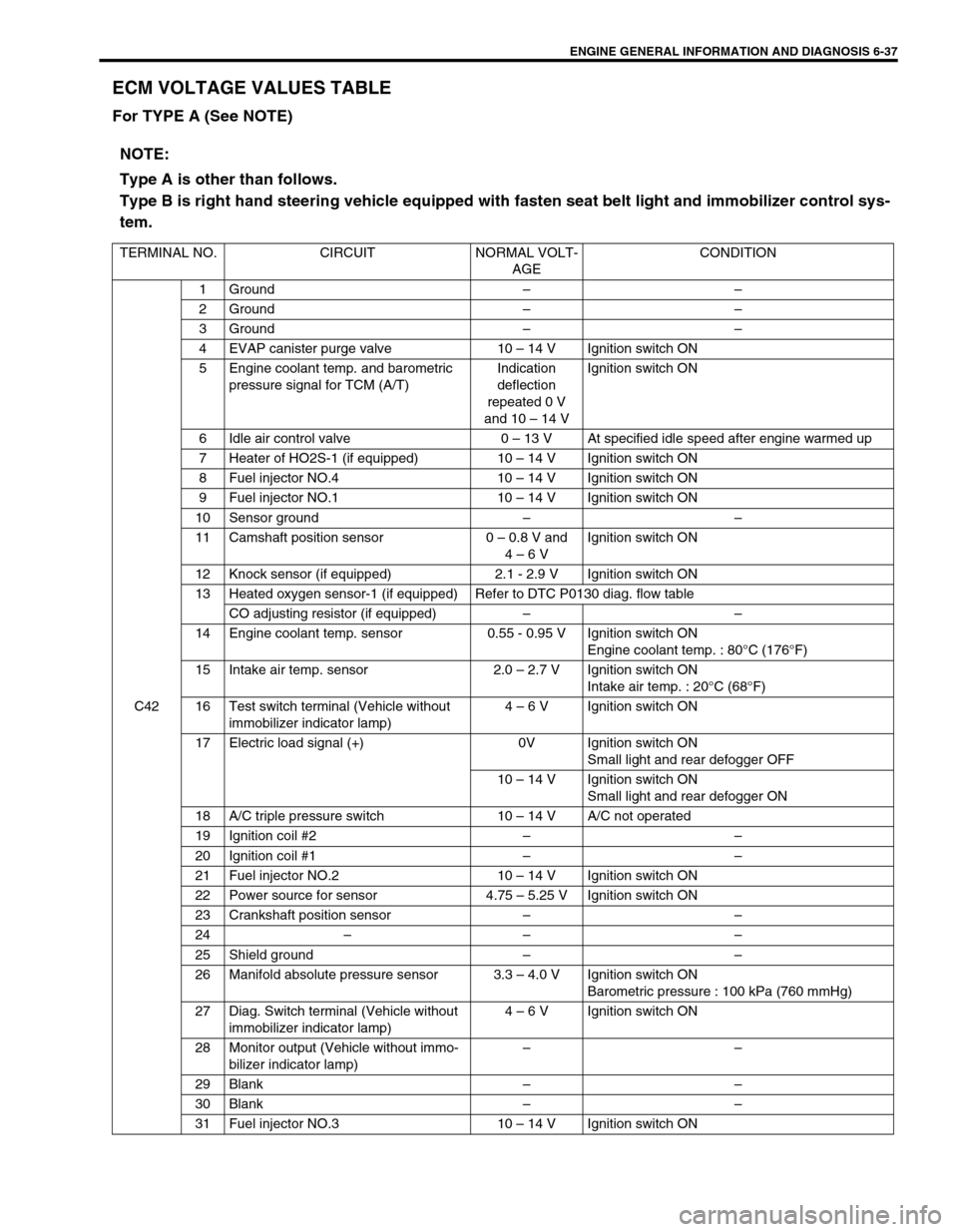

ENGINE GENERAL INFORMATION AND DIAGNOSIS 6-37

ECM VOLTAGE VALUES TABLE

For TYPE A (See NOTE)

NOTE:

Type A is other than follows.

Type B is right hand steering vehicle equipped with fasten seat belt light and immobilizer control sys-

tem.

TERMINAL NO. CIRCUIT NORMAL VOLT-

AGECONDITION

C421 Ground––

2 Ground––

3 Ground––

4 EVAP canister purge valve 10 – 14 V Ignition switch ON

5 Engine coolant temp. and barometric

pressure signal for TCM (A/T)Indication

deflection

repeated 0 V

and 10 – 14 VIgnition switch ON

6 Idle air control valve 0 – 13 V At specified idle speed after engine warmed up

7 Heater of HO2S-1 (if equipped) 10 – 14 V Ignition switch ON

8 Fuel injector NO.4 10 – 14 V Ignition switch ON

9 Fuel injector NO.1 10 – 14 V Ignition switch ON

10 Sensor ground––

11 Camshaft position sensor 0 – 0.8 V and

4 – 6 VIgnition switch ON

12 Knock sensor (if equipped) 2.1 - 2.9 V Ignition switch ON

13 Heated oxygen sensor-1 (if equipped) Refer to DTC P0130 diag. flow table

CO adjusting resistor (if equipped)––

14 Engine coolant temp. sensor 0.55 - 0.95 V Ignition switch ON

Engine coolant temp. : 80°C (176°F)

15 Intake air temp. sensor 2.0 – 2.7 V Ignition switch ON

Intake air temp. : 20°C (68°F)

16 Test switch terminal (Vehicle without

immobilizer indicator lamp)4 – 6 V Ignition switch ON

17 Electric load signal (+) 0V Ignition switch ON

Small light and rear defogger OFF

10 – 14 V Ignition switch ON

Small light and rear defogger ON

18 A/C triple pressure switch 10 – 14 V A/C not operated

19 Ignition coil #2––

20 Ignition coil #1––

21 Fuel injector NO.2 10 – 14 V Ignition switch ON

22 Power source for sensor 4.75 – 5.25 V Ignition switch ON

23 Crankshaft position sensor––

24–– –

25 Shield ground––

26 Manifold absolute pressure sensor 3.3 – 4.0 V Ignition switch ON

Barometric pressure : 100 kPa (760 mmHg)

27 Diag. Switch terminal (Vehicle without

immobilizer indicator lamp)4 – 6 V Ignition switch ON

28 Monitor output (Vehicle without immo-

bilizer indicator lamp)––

29 Blank––

30 Blank––

31 Fuel injector NO.3 10 – 14 V Ignition switch ON