ECU SUZUKI SWIFT 2000 1.G RG413 Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 643 of 698

6E1-22 ENGINE AND EMISSION CONTROL SYSTEM

6) Start engine and warm it up to normal operating tempera-

ture.

7) Measure fuel pressure at idling.

If measured pressure does not satisfy specification, refer to

“Diagnostic Flow Table B-3” in “Engine Diagnosis” section

and check each possibly defective part. Replace if found

defective.

8) After checking fuel pressure, remove fuel pressure gauge.

9) Remove special tools from fuel delivery pipe.

10) Connect fuel feed hose to fuel delivery pipe and clamp it

securely.

11) With engine “OFF” and ignition switch “ON”, check for fuel

leaks.

FUEL PUMP WITH PRESSURE REGULATOR

ON-VEHICLE INSPECTION

1) Remove filler cap and turn ON ignition switch. Then fuel

pump operating sound should be heard from fuel filler for

about 2 seconds and stop. Be sure to reinstall fuel filler cap

after checking.

If above check result is not satisfactory, advance to “Diag-

nostic Flow Table B-2”. CAUTION:

As fuel feed line is still under high fuel pressure, make

sure to release fuel pressure according to following pro-

cedures.

Place fuel container under joint.

Cover joint with rag and loosen joint nut slowly to

release fuel pressure gradually.

CAUTION:

When fuel filler cap is removed in any procedure, work

must be done in a well-ventilated area, keep away from

any open flames and without smoking.

NOTE:

The fuel pressure regulator is the one body with the fuel

pump assembly so individual inspection of it is impossi-

ble.

1. Fuel filler

2. Ignition switch

Page 644 of 698

ENGINE AND EMISSION CONTROL SYSTEM 6E1-23

2) Turn OFF ignition switch and leave over 10 minutes as it is.

3) Fuel pressure should be felt at fuel feed hose (1) for about 2

seconds after ignition switch ON.

If fuel pressure is not felt, advance to “Diagnostic Flow Table

B-3”.

REMOVAL

Remove fuel tank from body according to procedure described in

Section 6C and remove fuel pump from fuel tank.

INSPECTION

Check fuel pump filter for evidence of dirt and contamination. If

present, clean and check for presence of dirt in fuel tank.

INSTALLATION

1) Install fuel pump to its bracket.

2) Install fuel pump to fuel tank and then install fuel tank to

body according to procedure described in Section 6C.

FUEL INJECTOR

ON-VEHICLE INSPECTION

1) Using sound scope (1) or such, check operating sound of

injector (2) when engine is running or cranking.

Cycle of operating sound should vary according to engine

speed.

If no sound or an unusual sound is heard, check injector cir-

cuit (wire or connector) or injector (2).

2) Disconnect connector (1) from injector, connect ohmmeter

between terminals of injector and check resistance.

If resistance is out of specification, replace.

Resistance of fuel injector

: 11.3 – 13.8

Ω at 20°C (68°F)

3) Connect connector (1) to injector securely.

Page 648 of 698

ENGINE AND EMISSION CONTROL SYSTEM 6E1-27

ELECTRONIC CONTROL SYSTEM

ENGINE CONTROL MODULE (ECM)

REMOVAL

1) Disconnect battery negative cable at battery.

2) Disable air bag system, referring to “Disabling The Air Bag

System” in Section 10B if equipped.

3) Disconnect ECM (1) and TCM (2) (if equipped) connectors.

4) Remove bolt and nuts, remove ECM and TCM (if equipped).

INSTALLATION

Reverse removal procedure noting the following:

Connect connectors to ECM and TCM (if equipped) securely.

MANIFOLD ABSOLUTE PRESSURE SENSOR (MAP

SENSOR)

INSPECTION

Check MAP sensor referring to “MAP Sensor Individual Check” in

DTC P0105 (No.11) Flow Table. If malfunction is found, replace.CAUTION:

As ECM consists of precision parts, be careful not to

expose it to excessive shock.

2

1

Page 649 of 698

6E1-28 ENGINE AND EMISSION CONTROL SYSTEM

THROTTLE POSITION SENSOR (TP SENSOR)

INSPECTION

1) Disconnect negative cable at battery and connector from IAT

sensor.

2) Remove air cleaner assembly with air cleaner outlet hose

and disconnect TP sensor connector.

3) Using ohmmeter, check resistance between terminals under

each condition given in table below.

If check result is not satisfactory, replace TP sensor.

TP sensor resistance

4) Connect TP sensor connector securely.

5) Connect negative cable to battery.

REMOVAL

1) Disconnect battery negative cable at battery.

2) Remove throttle body from intake manifold referring to

“Throttle Body Removal” in this section.

3) Remove TP sensor from throttle body.

INSTALLATION

1) Install TP sensor (1) to throttle body.

Fit TP sensor to throttle body in such way that its holes (3)

are a little away from TP sensor screw holes (2) as shown in

left figure and turn TP sensor clockwise so that those holes

align (4).

Tightening torque

TP sensor screw (a) : 2.5 N·m (0.25 kg-m, 1.8 lb-ft)

2) Connect connector to TP sensor securely.

3) Connect battery negative cable to battery.TERMINALS RESISTANCE

Between 1 and

3 terminals4.0 – 6.0 k

Ω

Between 2 and

3 terminals20

Ω – 6.0 k

Ω, varying according to throt-

tle valve opening.

NOTE:

There should be more than 2 k

Ω resistance difference

between when throttle valve is at idle position and when

it is fully open.

1. Reference voltage terminal

2. Output voltage terminal

3. Ground terminal

Page 650 of 698

ENGINE AND EMISSION CONTROL SYSTEM 6E1-29

INTAKE AIR TEMPERATURE SENSOR (IAT SENSOR)

REMOVAL

1) Disconnect battery negative cable at battery.

2) Disconnect coupler (1) from IAT sensor.

3) Remove IAT sensor from air cleaner case (2).

INSPECTION

Immerse temperature sensing part of IAT sensor in water (or ice)

and measure resistance between sensor terminals while heating

water gradually.

If measured resistance does not show such characteristic as

shown in left figure, replace IAT sensor.

INSTALLATION

Reverse removal procedure noting the following.

Clean mating surfaces of IAT sensor and air cleaner case.

Connect IAT sensor connector (1) securely.

1

2

1

Page 651 of 698

6E1-30 ENGINE AND EMISSION CONTROL SYSTEM

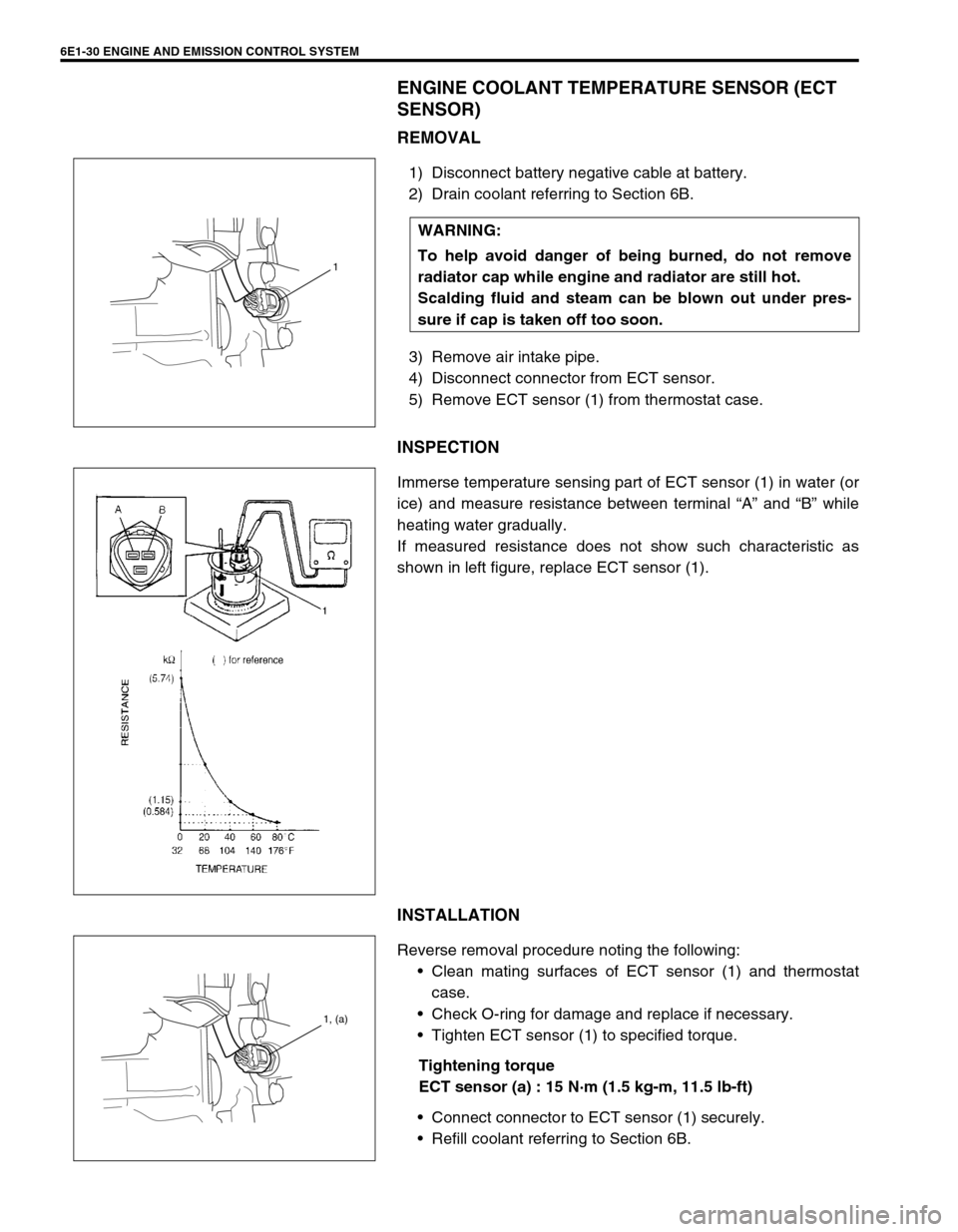

ENGINE COOLANT TEMPERATURE SENSOR (ECT

SENSOR)

REMOVAL

1) Disconnect battery negative cable at battery.

2) Drain coolant referring to Section 6B.

3) Remove air intake pipe.

4) Disconnect connector from ECT sensor.

5) Remove ECT sensor (1) from thermostat case.

INSPECTION

Immerse temperature sensing part of ECT sensor (1) in water (or

ice) and measure resistance between terminal “A” and “B” while

heating water gradually.

If measured resistance does not show such characteristic as

shown in left figure, replace ECT sensor (1).

INSTALLATION

Reverse removal procedure noting the following:

Clean mating surfaces of ECT sensor (1) and thermostat

case.

Check O-ring for damage and replace if necessary.

Tighten ECT sensor (1) to specified torque.

Tightening torque

ECT sensor (a) : 15 N·m (1.5 kg-m, 11.5 lb-ft)

Connect connector to ECT sensor (1) securely.

Refill coolant referring to Section 6B. WARNING:

To help avoid danger of being burned, do not remove

radiator cap while engine and radiator are still hot.

Scalding fluid and steam can be blown out under pres-

sure if cap is taken off too soon.

1

1, (a)

Page 652 of 698

ENGINE AND EMISSION CONTROL SYSTEM 6E1-31

HEATED OXYGEN SENSOR (HO2S-1 AND HO2S-2)

OXYGEN SENSOR HEATER INSPECTION

1) Disconnect sensor connector.

2) Using ohmmeter, measure resistance between terminals

“V

B” and “GND” of sensor connector.

If found faulty, replace oxygen sensor.

Resistance of oxygen sensor heater

HO2S-1 : 5.0 – 6.4

Ω at 20°C (68°F)

HO2S-2 : 11.7 – 14.3

Ω at 20°C (68°F)

3) Connect sensor connector securely.

REMOVAL

1) Disconnect negative cable at battery.

2) For HO2S-1, disconnect connector of heated oxygen sensor

and release its wire harness from clamps, then remove front

bumper and heat insulator panel.

3) For HO2S-2, disconnect connector of heated oxygen sensor

and release its wire harness from clamp and hoist vehicle.

4) Remove heated oxygen sensor (1) from exhaust manifold or

exhaust pipe.

INSTALLATION

Reverse removal procedure noting the following.

Tighten heated oxygen sensor (1) to specified torque.

Tightening torque

Heated oxygen sensor (a) : 45 N·m (4.5 kg-m, 32.5 lb-ft)

Connect connector of heated oxygen sensor (1) and clamp

wire harness securely.

After installing heated oxygen sensor (1), start engine and

check that no exhaust gas leakage exists. NOTE:

Temperature of sensor affects resistance value largely.

Make sure that sensor heater is at correct temperature.

1. Viewed from terminal side

WARNING:

To avoid danger of being burned, do not touch exhaust

system when system is hot. Oxygen sensor removal

should be performed when system is cool.

[A] : HO2S-1

[B] : HO2S-2

Page 653 of 698

6E1-32 ENGINE AND EMISSION CONTROL SYSTEM

CAMSHAFT POSITION SENSOR

INSPECTION

Check camshaft position sensor referring to DTC P0340 (No.15)

Diag. Flow Table in Section 6. If malfunction is found, replace.

REMOVAL

1) Disconnect negative cable at battery.

2) Disconnect connector from camshaft position sensor.

3) Remove camshaft position sensor from cylinder head.

INSTALLATION

1) Check that O-ring is free from damage.

2) Check that camshaft position sensor and signal rotor teeth

are free from any metal particles and damage.

3) Install camshaft position sensor to cylinder head.

Tightening torque

Camshaft position sensor bolt

(a) : 10 N·m (1.0 kg-m, 7.5 lb-ft)

4) Connect connector to it securely.

5) Connect negative cable to battery.

CRANKSHAFT POSITION SENSOR

INSPECTION

Check crankshaft position sensor referring to step 1 and 2 of DTC

P0335 (No.23) Flow Table. If malfunction is found, replace.

REMOVAL

1) Disconnect negative cable at battery.

2) Remove generator drive belt, loosen pivot bolt and move

generator outward.

3) Disconnect connector from crankshaft position sensor.

4) Remove crankshaft position sensor (1) from cylinder block.

INSTALLATION

1) Check to make sure that crankshaft position sensor and pul-

ley teeth are free from any metal particles and damage.

2) Install crankshaft position sensor to cylinder block.

3) Connect connector to it securely.

4) Adjust generator belt tension, refer to Section 6B.

5) Connect negative cable to battery.

Page 665 of 698

IGNITION SYSTEM (ELECTRONIC IGNITION SYSTEM 6F1-3

SYSTEM WIRING DIAGRAM

DIAGNOSIS

1. Ignition switch 7. No.1 spark plug

2. Main relay 8. No.2 spark plug

3. Ignition coil assembly for No.1 and No.4 spark plugs 9. No.3 spark plug

4. Ignition coil assembly for No.2 and No.3 spark plugs 10. No.4 spark plug

5. CMP sensor 11. Sensed information (MAP sensor, ECT sensor, IAT sensor, TP sensor, Knock sensor (if

equipped), VSS, Park/Neutral position signal, Electric load signal, Engine start signal, Test switch

terminal (Vehicle without immobilizer indicator lamp))

6. CKP sensor

Condition Possible Cause Correction

Engine cranks, but will

not start or hard to

start (No spark)Blown fuse for ignition coil Replace.

Loose connection or disconnection of lead wire

or high-tension cord(s)Connect securely.

Faulty high-tension cord(s) Replace.

Faulty spark plug(s) Adjust, clean or replace.

Faulty ignition coil Replace ignition coil assembly.

Faulty CKP sensor or CKP sensor plate Clean, tighten or replace.

Faulty ECM Replace.

Poor fuel economy or

engine performanceIncorrect ignition timing Check related sensors and CKP

sensor plate.

Faulty spark plug(s) or high-tension cord(s) Adjust, clean or replace.

Faulty ignition coil assembly Replace.

Faulty CKP sensor or CKP sensor plate Clean, tighten or replace.

Faulty ECM Replace.

Page 666 of 698

6F1-4 IGNITION SYSTEM (ELECTRONIC IGNITION SYSTEM)

IGNITION SYSTEM DIAGNOSTIC FLOW TABLE

Step Action Yes No

1Was “ENGINE DIAG. FLOW TABLE” in Section 6 per-

formed?Go to Step 2. Go to “ENGINE DIAG.

FLOW TABLE” in Sec-

tion 6.

2Ignition Spark Test

1) Check all spark plugs for condition and type refer-

ring to “Spark Plugs” section.

2) If OK, perform ignition spark test, referring to “Igni-

tion Spark Test” in this section.

Is spark emitted from all spark plugs?Go to Step 11. Go to Step 3.

3Diagnostic Trouble Code (DTC) Check Is DTC stored

in ECM?Go to applicable DTC

Diag. Flow Table in

Section 6.Go to Step 4.

4Electrical Connection Check

1) Check ignition coil assemblies and high-tension

cords for electrical connection.

Are they connected securely?Go to Step 5. Connect securely.

5High-tension Cords Check

1) Check high-tension cord for resistance referring to

“High-Tension Cords” in this section.

Is check result satisfactory?Go to Step 6. Replace high-tension

cord(s).

6Ignition Coil Assembly Power Supply and Ground Cir-

cuit Check

1) Check ignition coil assembly power supply and

ground circuits for open and short.

Are circuits in good condition?Go to Step 7. Repair or replace.

7Ignition Coil Assembly Check

1) Check ignition coil for resistance referring to “Igni-

tion Coil Assembly” in this section.

Is check result satisfactory?Go to Step 8. Replace ignition coil

assembly.

8Crankshaft Position (CKP) Sensor Check

1) Check crankshaft position sensor referring to Step

3 and 4 of “DTC P0335 (No.23) Diag. Flow Table”

in Section 6.

Is check result satisfactory?Go to Step 9. Tighten CKP sensor

bolt, replace CKP sen-

sor or CKP sensor

plate.

9Ignition Trigger Signal Circuit Check

1) Check ignition trigger signal wire for open, short

and poor connection.

Is circuit in good condition?Go to Step 10. Repair or replace.

10A Known-good Ignition Coil Assembly Substitution

1) Substitute a known-good ignition coil assembly

and then repeat Step 2.

Is check result of Step 2 satisfactory?Go to Step 11. Substitute a known-

good ECM and then

repeat Step 2.

11Ignition Timing Check

1) Check initial ignition timing and ignition timing

advance referring to “Ignition Timing” in this sec-

tion.

Is check result satisfactory?System is in good con-

dition.Check CKP sensor,

CKP sensor plate and

input signals related to

this system.