Electric system SUZUKI SWIFT 2000 1.G RG413 Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 666 of 698

6F1-4 IGNITION SYSTEM (ELECTRONIC IGNITION SYSTEM)

IGNITION SYSTEM DIAGNOSTIC FLOW TABLE

Step Action Yes No

1Was “ENGINE DIAG. FLOW TABLE” in Section 6 per-

formed?Go to Step 2. Go to “ENGINE DIAG.

FLOW TABLE” in Sec-

tion 6.

2Ignition Spark Test

1) Check all spark plugs for condition and type refer-

ring to “Spark Plugs” section.

2) If OK, perform ignition spark test, referring to “Igni-

tion Spark Test” in this section.

Is spark emitted from all spark plugs?Go to Step 11. Go to Step 3.

3Diagnostic Trouble Code (DTC) Check Is DTC stored

in ECM?Go to applicable DTC

Diag. Flow Table in

Section 6.Go to Step 4.

4Electrical Connection Check

1) Check ignition coil assemblies and high-tension

cords for electrical connection.

Are they connected securely?Go to Step 5. Connect securely.

5High-tension Cords Check

1) Check high-tension cord for resistance referring to

“High-Tension Cords” in this section.

Is check result satisfactory?Go to Step 6. Replace high-tension

cord(s).

6Ignition Coil Assembly Power Supply and Ground Cir-

cuit Check

1) Check ignition coil assembly power supply and

ground circuits for open and short.

Are circuits in good condition?Go to Step 7. Repair or replace.

7Ignition Coil Assembly Check

1) Check ignition coil for resistance referring to “Igni-

tion Coil Assembly” in this section.

Is check result satisfactory?Go to Step 8. Replace ignition coil

assembly.

8Crankshaft Position (CKP) Sensor Check

1) Check crankshaft position sensor referring to Step

3 and 4 of “DTC P0335 (No.23) Diag. Flow Table”

in Section 6.

Is check result satisfactory?Go to Step 9. Tighten CKP sensor

bolt, replace CKP sen-

sor or CKP sensor

plate.

9Ignition Trigger Signal Circuit Check

1) Check ignition trigger signal wire for open, short

and poor connection.

Is circuit in good condition?Go to Step 10. Repair or replace.

10A Known-good Ignition Coil Assembly Substitution

1) Substitute a known-good ignition coil assembly

and then repeat Step 2.

Is check result of Step 2 satisfactory?Go to Step 11. Substitute a known-

good ECM and then

repeat Step 2.

11Ignition Timing Check

1) Check initial ignition timing and ignition timing

advance referring to “Ignition Timing” in this sec-

tion.

Is check result satisfactory?System is in good con-

dition.Check CKP sensor,

CKP sensor plate and

input signals related to

this system.

Page 670 of 698

6F1-8 IGNITION SYSTEM (ELECTRONIC IGNITION SYSTEM)

IGNITION TIMING

INSPECTION

1) When using SUZUKI scan tool, connect SUZUKI scan tool to

DLC with ignition switch OFF.

Special tool

(A) : 09931-76011 (SUZUKI scan tool)

(B) : Mass storage cartridge

(C) : 09931-76030 (16/14 pin DLC cable)

2) Start engine and warm it up to normal operating tempera-

ture.

3) Make sure that all of electrical loads except ignition are

switched off.

4) Check to be sure that idle speed is within specification.

(Refer to Section 6E1)

5) Fix ignition timing to initial one as follows.

Select “MISC” mode on SUZUKI scan tool and fix ignition

timing to initial one.

If scan tool is not available (vehicle without immobilizer indi-

cator lamp), connect D and E terminals of monitor connector

(1) by using service wire so that ignition timing is fixed on ini-

tial one.

6) Using timing light (1), check that ignition timing is within

specification.

Initial ignition timing (test switch terminal grounded or

fixed with SUZUKI scan tool)

: 5

± 3° BTDC at idle speed

Ignition order

: 1-3-4-2 NOTE:

Ignition timing is not adjustable. If ignition timing is

out of specification, check system related parts.

Before starting engine, place transmission gear shift

lever in “Neutral” (shift selector lever to “P” range for

A/T model), and set parking brake.

(C)

(A)

(B)

D

E1

Page 682 of 698

6H-2 CHARGING SYSTEM

GENERAL DESCRIPTION

BATTERY

The battery has three major functions in the electrical system.

It is a source of electrical energy for cranking the engine.

It acts as a voltage stabilizer for the electrical system.

It can, for a limited time, provide energy when the electrical load exceeds the output of the generator.

CARRIER AND HOLD-DOWN

The battery carrier should be in good condition so that it will support the battery securely and keep it level.

Before installing the battery, the battery carrier and hold-down clamp should be clean and free from corrosion

and make certain there are no parts in carrier.

To prevent the battery from shaking in its carrier, the hold-down bolts should be tight enough but not over-tight-

ened.

ELECTROLYTE FREEZING

The freezing point of electrolyte depends on its specific gravity. Since freezing may ruin a battery, it should be

protected against freezing by keeping it in a fully charged condition. If a battery is frozen accidentally, it should

not be charged until it is warmed.

SULFATION

If the battery is allowed to stand for a long period in discharged condition, the lead sulfate becomes converted

into a hard, crystalline substance, which will not easily turn back to the active material again during the subse-

quent recharging. “Sulfation” means the result as well as the process of that reaction. Such a battery can be

revived by very slow charging and may be restored to usable condition but its capacity is lower than before.

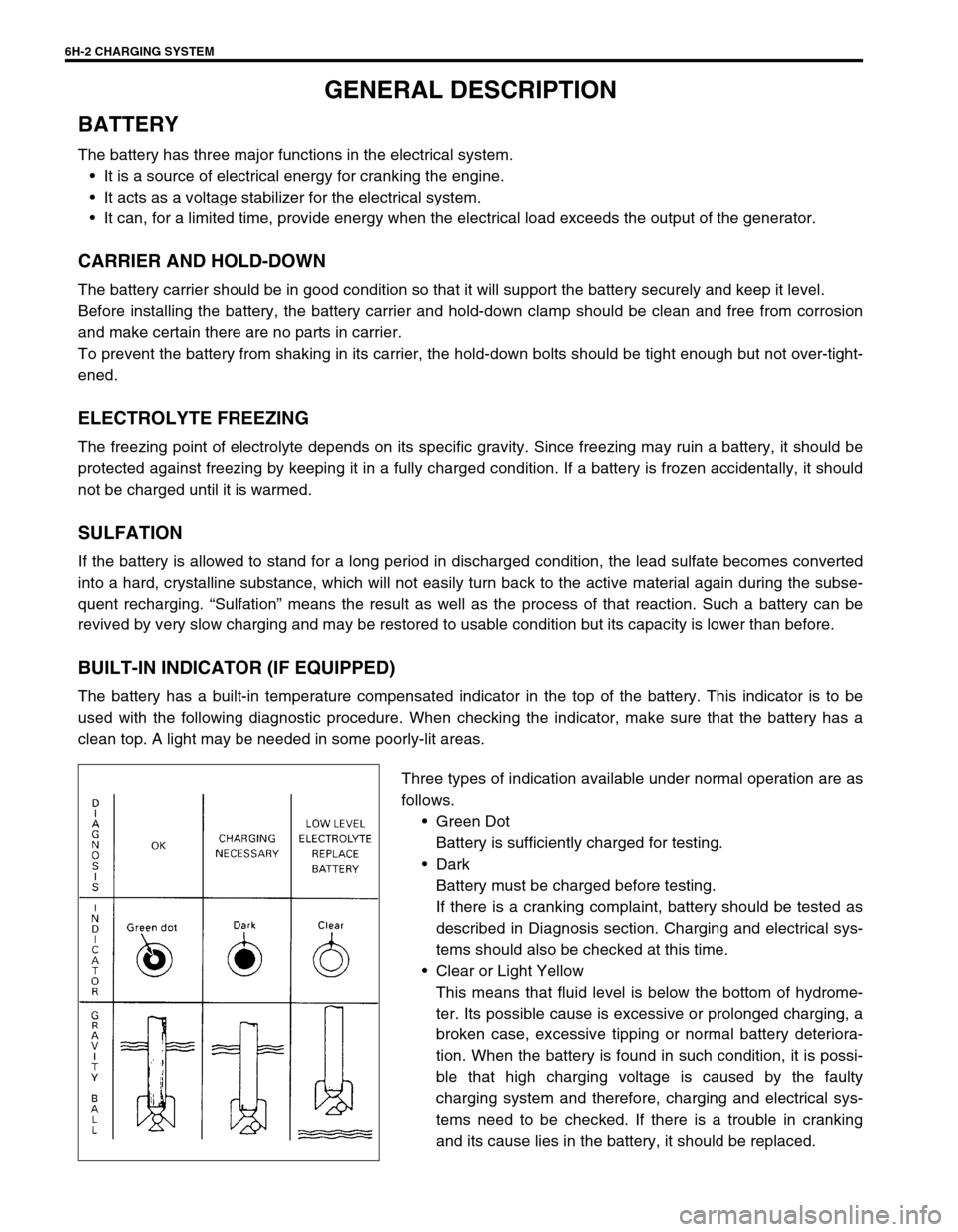

BUILT-IN INDICATOR (IF EQUIPPED)

The battery has a built-in temperature compensated indicator in the top of the battery. This indicator is to be

used with the following diagnostic procedure. When checking the indicator, make sure that the battery has a

clean top. A light may be needed in some poorly-lit areas.

Three types of indication available under normal operation are as

follows.

Green Dot

Battery is sufficiently charged for testing.

Dark

Battery must be charged before testing.

If there is a cranking complaint, battery should be tested as

described in Diagnosis section. Charging and electrical sys-

tems should also be checked at this time.

Clear or Light Yellow

This means that fluid level is below the bottom of hydrome-

ter. Its possible cause is excessive or prolonged charging, a

broken case, excessive tipping or normal battery deteriora-

tion. When the battery is found in such condition, it is possi-

ble that high charging voltage is caused by the faulty

charging system and therefore, charging and electrical sys-

tems need to be checked. If there is a trouble in cranking

and its cause lies in the battery, it should be replaced.

Page 683 of 698

CHARGING SYSTEM 6H-3

CARE OF BATTERY

1) The battery is a very reliable component, but needs periodical attentions.

Keep the battery carrier clean

Prevent rust formation on the terminal posts

Keep the electrolyte up to the upper level uniformly in all cells.

When keeping battery on vehicle over a long period of time, follow instructions given below.

–Weekly, start the engine and run it until it reaches normal operating temperature with engine speed of

2000 to 3000 rpm. Make sure all electric switches are off before storing the vehicle.

–Recharge the battery twice a month to prevent it from discharging excessively. This is especially impor-

tant when ambient temperature is low.

The battery discharges even when it is not used, while vehicles are being stored. Battery electrolyte can

freeze and battery case can crack at cold ambient condition if battery is not properly charged.

2) Keep the battery cable connections clean.

The cable connections, particularly at the positive (+) terminal post, tend to become corroded. The product

of corrosion, or rust, on the mating faces of conductors resists the flow of current.

Clean the terminals and fittings periodically to ensure good metal-to-metal contact, and grease the connec-

tions after each cleaning to protect them against rusting.

3) Be always in the know as to the state of charge of the battery. The simplest way to tell the state of charge is

to carry out a hydrometer test. The hydrometer is an instrument for measuring the specific gravity (S.G.) of

the battery electrolyte. The S.G. of the electrolyte is indicative of the state of charge. Refer to “DIAGNOSIS”

of BATTERY in this section. WARNING:

Never expose battery to open flame or electric spark because of battery generate gas which is flam-

mable and explosive.

Do not allow battery fluid to contact eyes, skin, fabrics, or painted surfaces as fluid is a corrosive

acid. Flush any contacted area with water immediately and thoroughly.

Batteries should always be kept out of reach of children.

Page 684 of 698

6H-4 CHARGING SYSTEM

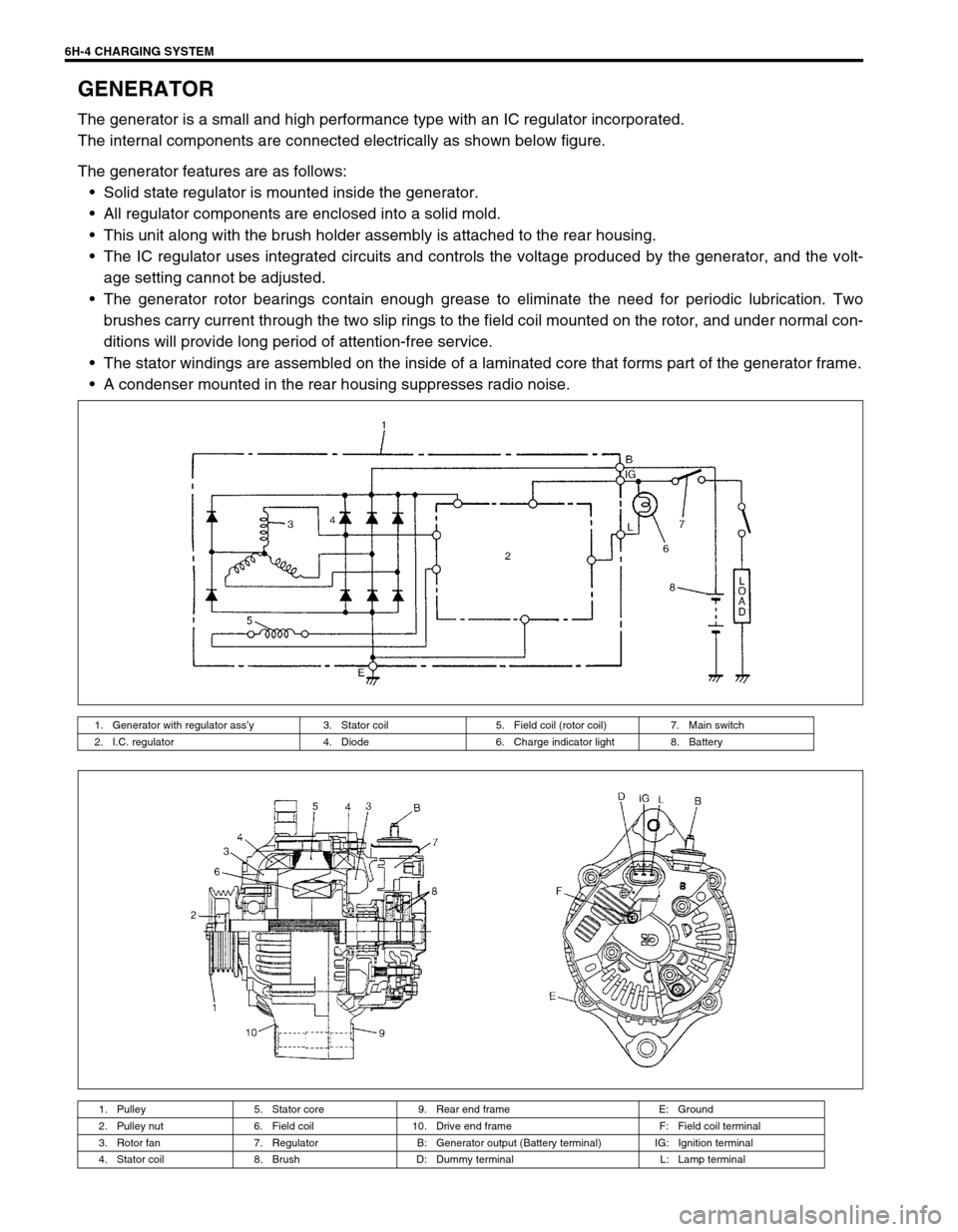

GENERATOR

The generator is a small and high performance type with an IC regulator incorporated.

The internal components are connected electrically as shown below figure.

The generator features are as follows:

Solid state regulator is mounted inside the generator.

All regulator components are enclosed into a solid mold.

This unit along with the brush holder assembly is attached to the rear housing.

The IC regulator uses integrated circuits and controls the voltage produced by the generator, and the volt-

age setting cannot be adjusted.

The generator rotor bearings contain enough grease to eliminate the need for periodic lubrication. Two

brushes carry current through the two slip rings to the field coil mounted on the rotor, and under normal con-

ditions will provide long period of attention-free service.

The stator windings are assembled on the inside of a laminated core that forms part of the generator frame.

A condenser mounted in the rear housing suppresses radio noise.

1. Generator with regulator ass’y 3. Stator coil 5. Field coil (rotor coil) 7. Main switch

2. I.C. regulator 4. Diode 6. Charge indicator light 8. Battery

1. Pulley 5. Stator core 9. Rear end frame E: Ground

2. Pulley nut 6. Field coil 10. Drive end frame F: Field coil terminal

3. Rotor fan 7. Regulator B: Generator output (Battery terminal) IG: Ignition terminal

4. Stator coil 8. Brush D: Dummy terminal L: Lamp terminal

Page 689 of 698

CHARGING SYSTEM 6H-9

ON-VEHICLE SERVICE

BATTERY

JUMP STARTING IN CASE OF EMERGENCY

WITH AUXILIARY (BOOSTER) BATTERY

Both booster and discharged battery should be treated carefully when using jumper cables. Follow procedure

outlined below, being careful not to cause sparks.

1) Set parking brake and place automatic transmission in PARK (NEUTRAL on manual transmission). Turn off

ignition, turn off lights and all other electrical loads.

2) Check electrolyte level. If it is below low level line, add distilled water.

3) Attach end of one jumper cable to positive terminal of booster battery and the other end of the same cable to

positive terminal of discharged battery. (Use 12-volt battery only to jump start engine).

4) Attach one end of the remaining negative cable to negative terminal of booster battery, and the other end to

a solid engine ground (such as exhaust manifold) at least 45 cm (18 in.) away from battery of vehicle being

started.

5) Start engine of vehicle with booster battery and turn off electrical accessories. Then Start engine of the vehi-

cle with discharged battery.

6) Disconnect jumper cables in the exact reverse order.

WITH CHARGING EQUIPMENT

CAUTION:

If vehicle is manual transmission model and has a catalytic converter, do not push or tow it to start.

Damage to its emission system and/or to other parts may result.

WARNING:

Departure from these conditions or procedure described below could result in:

–Serious personal injury (particularly to eyes) or property damage from such causes as battery

explosion, battery acid, or electrical burns.

–Damage to electronic components of either vehicle.

Remove rings, watches, and other jewelry. Wear approved eye protection.

Be careful so that metal tools or jumper cables do not contact positive battery terminal (or metal in

contact with it) and any other metal on vehicle, because a short circuit could occur.

WARNING:

Do not connect negative cable directly to negative terminal of dead battery.

CAUTION:

When jump starting engine with charging equipment, be sure equipment used is 12-volt and negative

ground. Do not use 24-volt charging equipment. Using such equipment can cause serious damage to

electrical system or electronic parts.