Electric power SUZUKI SWIFT 2000 1.G RG413 Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 3 of 698

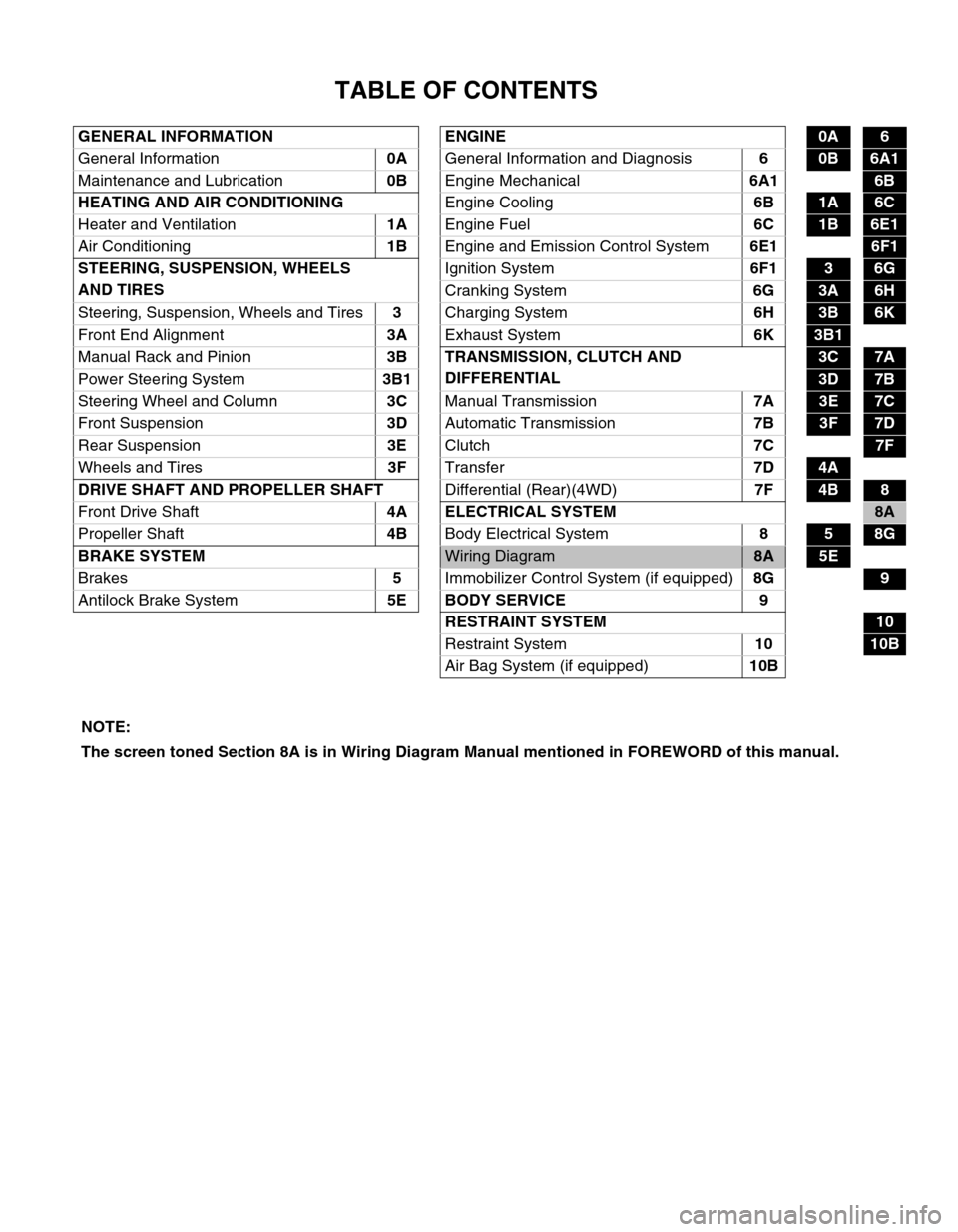

TABLE OF CONTENTS

GENERAL INFORMATION ENGINE0A6

General Information0A

General Information and Diagnosis6

0B6A1

Maintenance and Lubrication0B

Engine Mechanical6A1

6B

HEATING AND AIR CONDITIONING

Engine Cooling6B

1A6C

Heater and Ventilation1A

Engine Fuel6C

1B6E1

Air Conditioning1B

Engine and Emission Control System6E1

6F1

STEERING, SUSPENSION, WHEELS

AND TIRESIgnition System6F1

36G

Cranking System6G

3A6H

Steering, Suspension, Wheels and Tires3

Charging System6H

3B6K

Front End Alignment3A

Exhaust System6K

3B1 6B

Manual Rack and Pinion3B TRANSMISSION, CLUTCH AND

DIFFERENTIAL

3C7A

Power Steering System3B1

3D7B

Steering Wheel and Column3C

Manual Transmission7A

3E7C

Front Suspension3D

Automatic Transmission7B

3F7D

Rear Suspension3E

Clutch7C

7F

Wheels and Tires3F

Transfer7D

4A

DRIVE SHAFT AND PROPELLER SHAFT

Differential (Rear)(4WD)7F

4B8

Front Drive Shaft 4A ELECTRICAL SYSTEM

8A

Propeller Shaft4B

Body Electrical System8

58G

BRAKE SYSTEM

Wiring Diagram8A5E

Brakes5

Immobilizer Control System (if equipped)8G

9

Antilock Brake System5E BODY SERVICE 9

RESTRAINT SYSTEM

10

Restraint System10

10B

Air Bag System (if equipped)10B

NOTE:

The screen toned Section 8A is in Wiring Diagram Manual mentioned in FOREWORD of this manual.

Page 8 of 698

GENERAL INFORMATION 0A-5

Even when the accident was light enough not to cause air bags to activate, be sure to inspect sys-

tem parts and other related parts according to instructions under “REPAIR AND INSPECTION

REQUIRED AFTER AN ACCIDENT” in SECTION 10B.

When servicing parts other than air bag system, if shocks may be applied to air bag system compo-

nent parts, remove those parts beforehand.

When handling the air bag (inflator) modules (driver and passenger), seat belt pretensioners (driver

and passenger) or SDM, be careful not to drop it or apply an impact to it. If an excessive impact was

applied, never attempt disassembly or repair but replace it with a new one.

When grease, cleaning agent, oil, water, etc. has got onto air bag (inflator) modules (driver and pas-

senger) or seat belt pretensioners (drive and passenger), wipe off immediately with a dry cloth. WARNING:

SDM

For handling and storage of a SDM, select a place where the ambient temperature below 65°C

(150°F), without high humidity and away from electric noise.

During service procedures, be very careful when handling a Sensing and Diagnostic Module (SDM).

Never strike or jar the SDM.

Never power up the air bag system when the SDM is not rigidly attached to the vehicle. All SDM and

mounting bracket fasteners must be carefully torqued and the arrow must be pointing toward the

front of the vehicle to ensure proper operation of the air bag system.

The SDM could be activated when powered while not rigidly attached to the vehicle which could

cause deployment and result in personal injury.

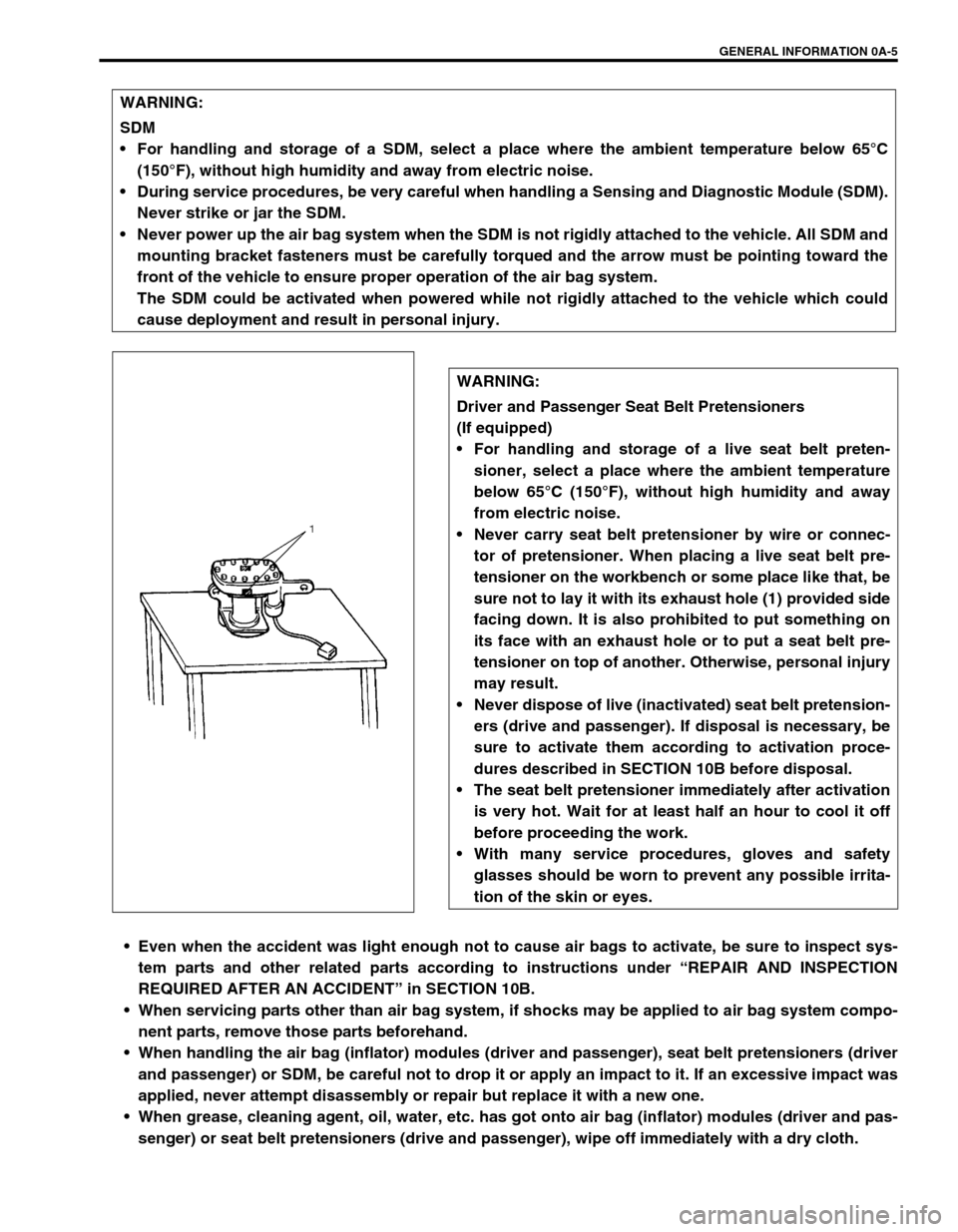

WARNING:

Driver and Passenger Seat Belt Pretensioners

(If equipped)

For handling and storage of a live seat belt preten-

sioner, select a place where the ambient temperature

below 65°C (150°F), without high humidity and away

from electric noise.

Never carry seat belt pretensioner by wire or connec-

tor of pretensioner. When placing a live seat belt pre-

tensioner on the workbench or some place like that, be

sure not to lay it with its exhaust hole (1) provided side

facing down. It is also prohibited to put something on

its face with an exhaust hole or to put a seat belt pre-

tensioner on top of another. Otherwise, personal injury

may result.

Never dispose of live (inactivated) seat belt pretension-

ers (drive and passenger). If disposal is necessary, be

sure to activate them according to activation proce-

dures described in SECTION 10B before disposal.

The seat belt pretensioner immediately after activation

is very hot. Wait for at least half an hour to cool it off

before proceeding the work.

With many service procedures, gloves and safety

glasses should be worn to prevent any possible irrita-

tion of the skin or eyes.

Page 9 of 698

0A-6 GENERAL INFORMATION

Air bag wire harness can be identified easily as it is covered with a yellow protection tube. Be very

careful when handling it.

When an open in air bag wire harness, damaged wire harness, connector or terminal is found,

replace wire harness, connectors and terminals as an assembly.

Do not apply power to the air bag system unless all components are connected or a diagnostic chart

requests it, as this will set a diagnostic trouble code.

Never use air bag system component parts from another vehicle.

When using electric welding, be sure to temporarily disable air bag system referring to “DISABLING

AIR BAG SYSTEM” in Section 10B.

Never expose air bag system component parts directly to hot air (drying or baking the vehicle after

painting) or flames.

WARNING/CAUTION labels are attached on each part of air bag system components. Be sure to fol-

low the instructions.

After vehicle is completely repaired, perform “AIR BAG DIAGNOSTIC SYSTEM CHECK” in SECTION

10B.

GENERAL PRECAUTIONS

The WARNING and CAUTION below describe some general precautions that you should observe when servic-

ing a vehicle. These general precautions apply to many of the service procedures described in this manual, and

they will not necessarily be repeated with each procedure to which they apply.

WARNING:

Whenever raising a vehicle for service, be sure to follow the instructions under “VEHICLE LIFTING

POINTS” in this section.

When it is necessary to do service work with the engine running, make sure that the parking brake

is set fully and the transmission is in Neutral (for manual transmission vehicles) or Park (for auto-

matic transmission vehicles), Keep hands, hair, clothing, tools, etc. away from the fan and belts

when the engine is running.

When it is necessary to run the engine indoors, make sure that the exhaust gas is forced outdoors.

Do not perform service work in areas where combustible materials can come in contact with a hot

exhaust system. When working with toxic or flammable materials (such as gasoline and refriger-

ant), make sure that the area you work in is well-ventilated.

To avoid getting burned, keep away from hot metal parts such as the radiator, exhaust manifold, tail

pipe, muffler, etc.

New and used engine oil can be hazardous. Children and pets may be harmed by swallowing new or

used oil. Keep new and used oil and used engine oil filters away from children and pets.

Continuous contact with used engine oil has been found to cause [skin] cancer in laboratory ani-

mals. Brief contact with used oil may irritate skin. To minimize your exposure to used engine oil,

wear a long-sleeve shirt and moisture-proof gloves (such as dish washing gloves) when changing

engine oil. If engine oil contacts your skin, wash thoroughly with soap and water. Launder any

clothing or rags if wet with oil, recycle or properly dispose of used oil and filters.

Make sure the bonnet is fully closed and latched before driving. If it is not, it can fly up unexpect-

edly during driving, obstructing your view and resulting in an accident.

Page 10 of 698

GENERAL INFORMATION 0A-7

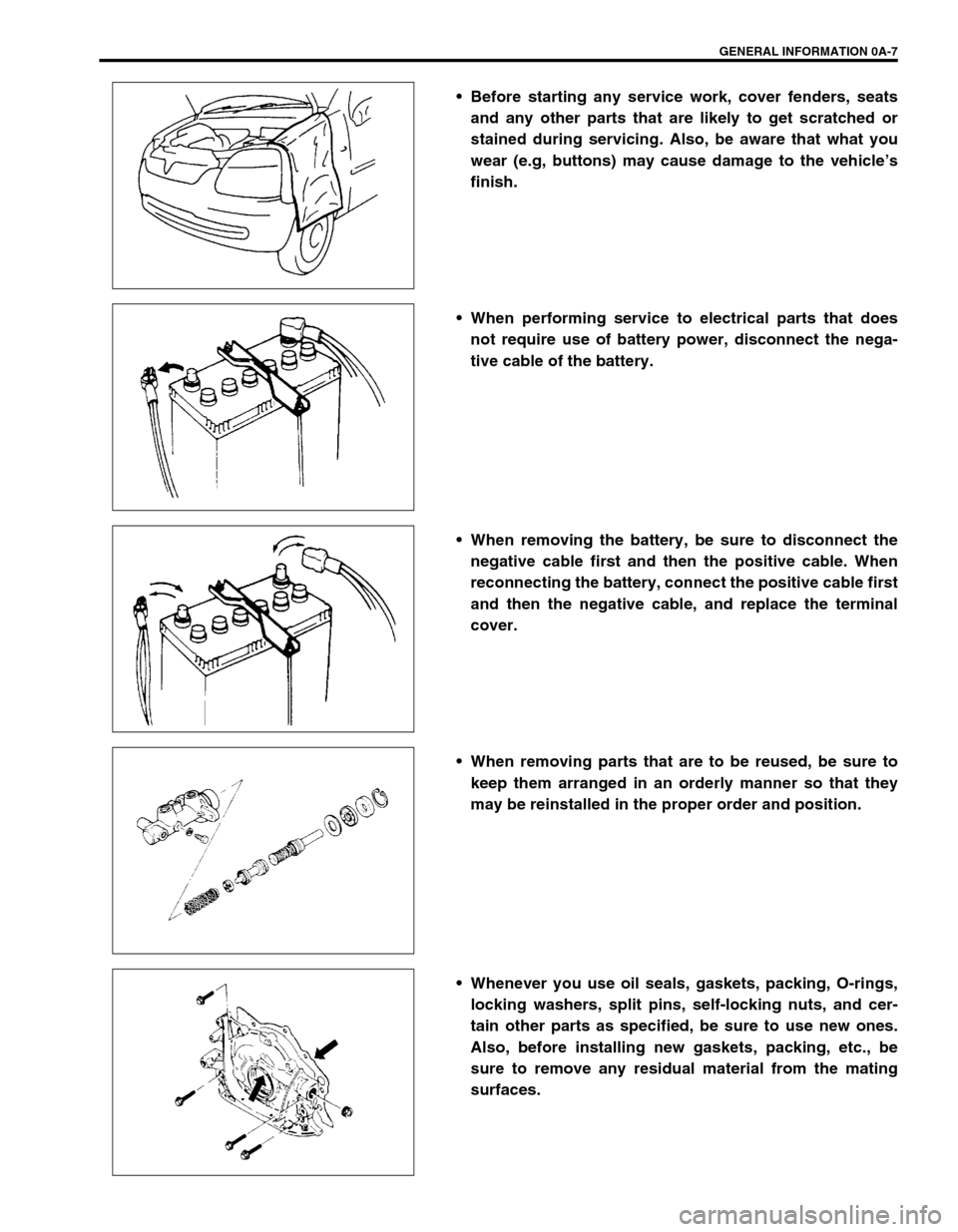

Before starting any service work, cover fenders, seats

and any other parts that are likely to get scratched or

stained during servicing. Also, be aware that what you

wear (e.g, buttons) may cause damage to the vehicle’s

finish.

When performing service to electrical parts that does

not require use of battery power, disconnect the nega-

tive cable of the battery.

When removing the battery, be sure to disconnect the

negative cable first and then the positive cable. When

reconnecting the battery, connect the positive cable first

and then the negative cable, and replace the terminal

cover.

When removing parts that are to be reused, be sure to

keep them arranged in an orderly manner so that they

may be reinstalled in the proper order and position.

Whenever you use oil seals, gaskets, packing, O-rings,

locking washers, split pins, self-locking nuts, and cer-

tain other parts as specified, be sure to use new ones.

Also, before installing new gaskets, packing, etc., be

sure to remove any residual material from the mating

surfaces.

Page 110 of 698

STEERING, SUSPENSION, WHEELS AND TIRES 3-1

6F1

6F2

6G

6H

6K

3

7A1

7B1

7C1

7D

7E

7F

8A

8B

8C

8D

8E

9

10

10A

10B

SECTION 3

STEERING, SUSPENSION, WHEELS AND TIRES

DIAGNOSIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

FRONT END ALIGNMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 3A

MANUAL RACK AND PINION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 3B

ELECTRICAL POWER STEERING (P/S) SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 3B1

STEERING WHEEL AND COLUMN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 3C

FRONT SUSPENSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 3D

REAR SUSPENSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 3E

WHEELS AND TIRES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 3F

CONTENTS

DIAGNOSIS ........................................................ 3-2

GENERAL DIAGNOSIS .................................. 3-2

DIAGNOSIS TABLE ........................................ 3-2

TIRE DIAGNOSIS ........................................... 3-5

IRREGULAR AND/OR PREMATURE

WEAR.......................................................... 3-5WEAR INDICATORS .................................. 3-5

RADIAL TIRE WADDLE.............................. 3-6

RADIAL TIRE LEAD.................................... 3-7

VIBRATION DIAGNOSIS................................ 3-7

Page 142 of 698

ELECTRICAL POWER STEERING (P/S) SYSTEM 3B1-1

6F1

6F2

6G

6H

6K

7A

7A1

3B1

7D

7E

7F

8A

8B

8C

8D

8E

9

10

10A

10B

SECTION 3B1

ELECTRICAL POWER STEERING (P/S) SYSTEM

CONTENTS

GENERAL DESCRIPTION .............................3B1-2

SYSTEM COMPONENTS ........................... 3B1-2

WIRING DIAGRAM ..................................... 3B1-3

DIAGNOSIS ....................................................3B1-4

ON-BOARD DIAGNOSTIC SYSTEM .......... 3B1-4

PRECAUTIONS IN DIAGNOSING

TROUBLES ................................................. 3B1-4

SYSTEM CHECK FLOW TABLE ................ 3B1-5

MALFUNCTION INDICATOR LAMP

(“EPS” WARNING LAMP) CHECK.............. 3B1-7

DTC CHECK ............................................... 3B1-8

DTC CLEARANCE ...................................... 3B1-9

SERIAL DATA LINK CIRCUIT CHECK ..... 3B1-10

DTC TABLE .............................................. 3B1-11

TABLE A - MALFUNCTION INDICATOR

LAMP DOES NOT COME ON AT

IGNITION SWITCH ON BUT LEAVING

ENGINE OFF ............................................ 3B1-13

TABLE B - MALFUNCTION INDICATOR

LAMP FLASHES AT IGNITION SWITCH

ON ............................................................. 3B1-15

TABLE C - MALFUNCTION INDICATOR

LAMP DOES NOT FLASH, JUST

REMAINS ON OR JUST REMAINS OFF

EVEN WITH DIAGNOSIS SWITCH

TERMINAL GROUNDED .......................... 3B1-15

DTC C1111 (DTC No.11) TORQUE

SENSOR MAIN CIRCUIT FAILURE ......... 3B1-16

DTC C1113 (DTC No.13) TORQUE

SENSOR MAIN AND SUB CIRCUIT

FAILURE ................................................... 3B1-16DTC C1115 (DTC No.15) TORQUE

SENSOR SUB CIRCUIT FAILURE........... 3B1-16

DTC C1114 (DTC No.14) TORQUE

SENSOR 5V POWER SUPPLY CIRCUIT

FAILURE ................................................... 3B1-17

DTC C1116 (DTC No.16) TORQUE

SENSOR 8V POWER SUPPLY CIRCUIT

FAILURE ................................................... 3B1-18

DTC C1121/C1123/C1124

(DTC No.21/23/24) VSS CIRCUIT

FAILURE ................................................... 3B1-19

DTC C1122 (DTC No.22) ENGINE

SPEED SIGNAL CIRCUIT FAILURE ........ 3B1-20

DTC C1141/C1142/C1143/C1144/C1145

(DTC No.41/42/43/44/45) MOTOR

CIRCUIT FAILURE ................................... 3B1-21

DTC C1151 (DTC No.51) CLUTCH

CIRCUIT FAILURE ................................... 3B1-22

DTC C1153(DTC No.53) P/S CONTROL

MODULE POWER SUPPLY CIRCUIT

FAILURE ................................................... 3B1-24

DTC C1152/C1154/C1155

(DTC No.52/54/55) P/S CONTROL

MODULE FAILURE .................................. 3B1-24

TROUBLE DIAGNOSIS (FOR TROUBLE

NOT INDICATED BY ON BOARD

DIAGNOSTIC SYSTEM)........................... 3B1-25

INSPECTION OF P/S CONTROL

MODULE AND ITS CIRCUITS ................. 3B1-26

STEERING WHEEL PLAY

INSPECTION ............................................ 3B1-28 WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System :

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

Page 143 of 698

3B1-2 ELECTRICAL POWER STEERING (P/S) SYSTEM

STEERING FORCE INSPECTION ........... 3B1-28

ON-VEHICLE SERVICE ............................... 3B1-29

P/S CONTROL MODULE ......................... 3B1-29

TORQUE SENSOR .................................. 3B1-29MOTOR AND CLUTCH ............................ 3B1-30

STEERING COLUMN ASSEMBLY .......... 3B1-31

SPECIAL TOOL ........................................... 3B1-31

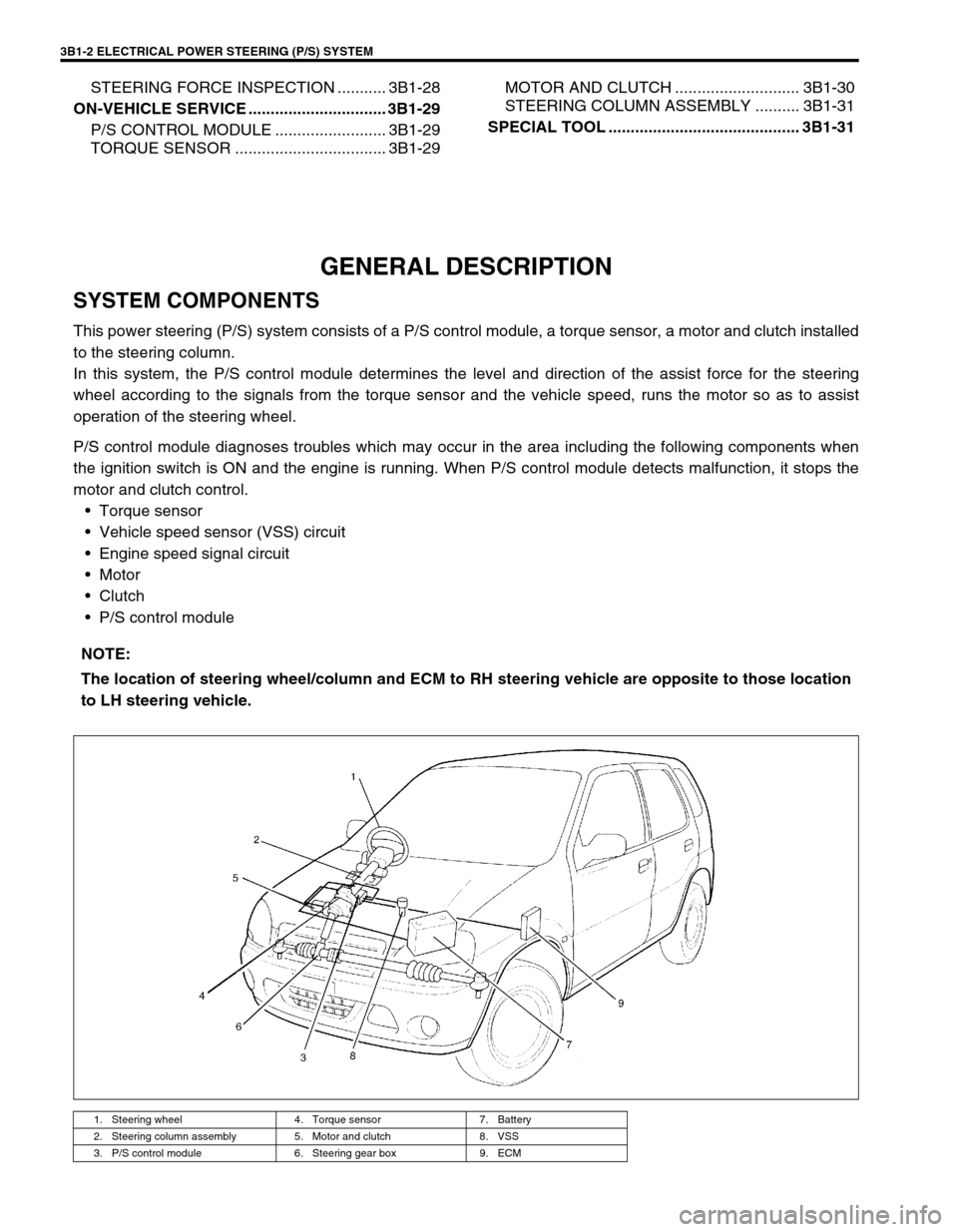

GENERAL DESCRIPTION

SYSTEM COMPONENTS

This power steering (P/S) system consists of a P/S control module, a torque sensor, a motor and clutch installed

to the steering column.

In this system, the P/S control module determines the level and direction of the assist force for the steering

wheel according to the signals from the torque sensor and the vehicle speed, runs the motor so as to assist

operation of the steering wheel.

P/S control module diagnoses troubles which may occur in the area including the following components when

the ignition switch is ON and the engine is running. When P/S control module detects malfunction, it stops the

motor and clutch control.

Torque sensor

Vehicle speed sensor (VSS) circuit

Engine speed signal circuit

Motor

Clutch

P/S control module

NOTE:

The location of steering wheel/column and ECM to RH steering vehicle are opposite to those location

to LH steering vehicle.

1. Steering wheel 4. Torque sensor 7. Battery

2. Steering column assembly 5. Motor and clutch 8. VSS

3. P/S control module 6. Steering gear box 9. ECM

Page 144 of 698

ELECTRICAL POWER STEERING (P/S) SYSTEM 3B1-3

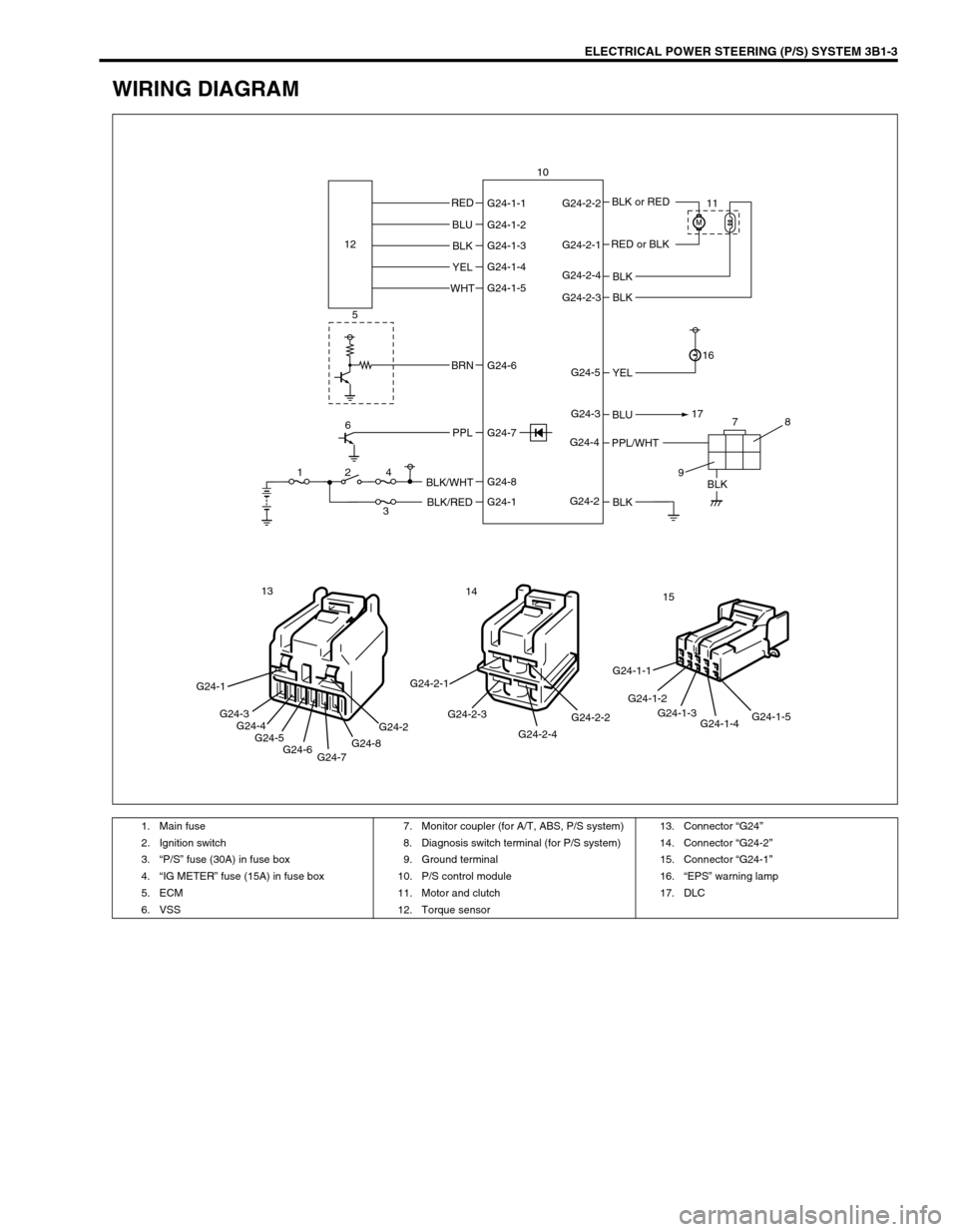

WIRING DIAGRAM

BLK RED

BLK

BLK

BLU

BLK YEL BLU

BLK

YEL

WHT

BRN

PPLBLK/WHT

BLK/RED

PPL/WHTBLK or RED

RED or BLK G24-1-1 G24-2-2

G24-2-1

G24-2-4

G24-2-3

G24-5

G24-3

G24-4

G24-2 G24-1-2

G24-1-3

G24-1-4

G24-1-5

G24-6

G24-8

G24-1 G24-7 12

5

6

124

378

9171611 10

G24-1

G24-3

G24-4

G24-5

G24-6

G24-7G24-8G24-2

13

G24-2-2

G24-2-4 G24-2-3 G24-2-1

14

G24-1-5

G24-1-4 G24-1-3 G24-1-2 G24-1-115

1. Main fuse 7. Monitor coupler (for A/T, ABS, P/S system) 13. Connector “G24”

2. Ignition switch 8. Diagnosis switch terminal (for P/S system) 14. Connector “G24-2”

3.“P/S” fuse (30A) in fuse box 9. Ground terminal 15. Connector “G24-1”

4.“IG METER” fuse (15A) in fuse box 10. P/S control module 16.“EPS” warning lamp

5. ECM 11. Motor and clutch 17. DLC

6. VSS 12. Torque sensor

Page 145 of 698

3B1-4 ELECTRICAL POWER STEERING (P/S) SYSTEM

DIAGNOSIS

The P/S system in this vehicle is controlled by P/S control module. P/S control module has an on-board diagnos-

tic system which detects a malfunction in this system.

When diagnosing troubles, be sure to have full understanding of the outline of “ON-BOARD DIAGNOSTIC SYS-

TEM” and each item in “PRECAUTION IN DIAGNOSING TROUBLE” and execute diagnosis according to “SYS-

TEM CHECK FLOW TABLE”.

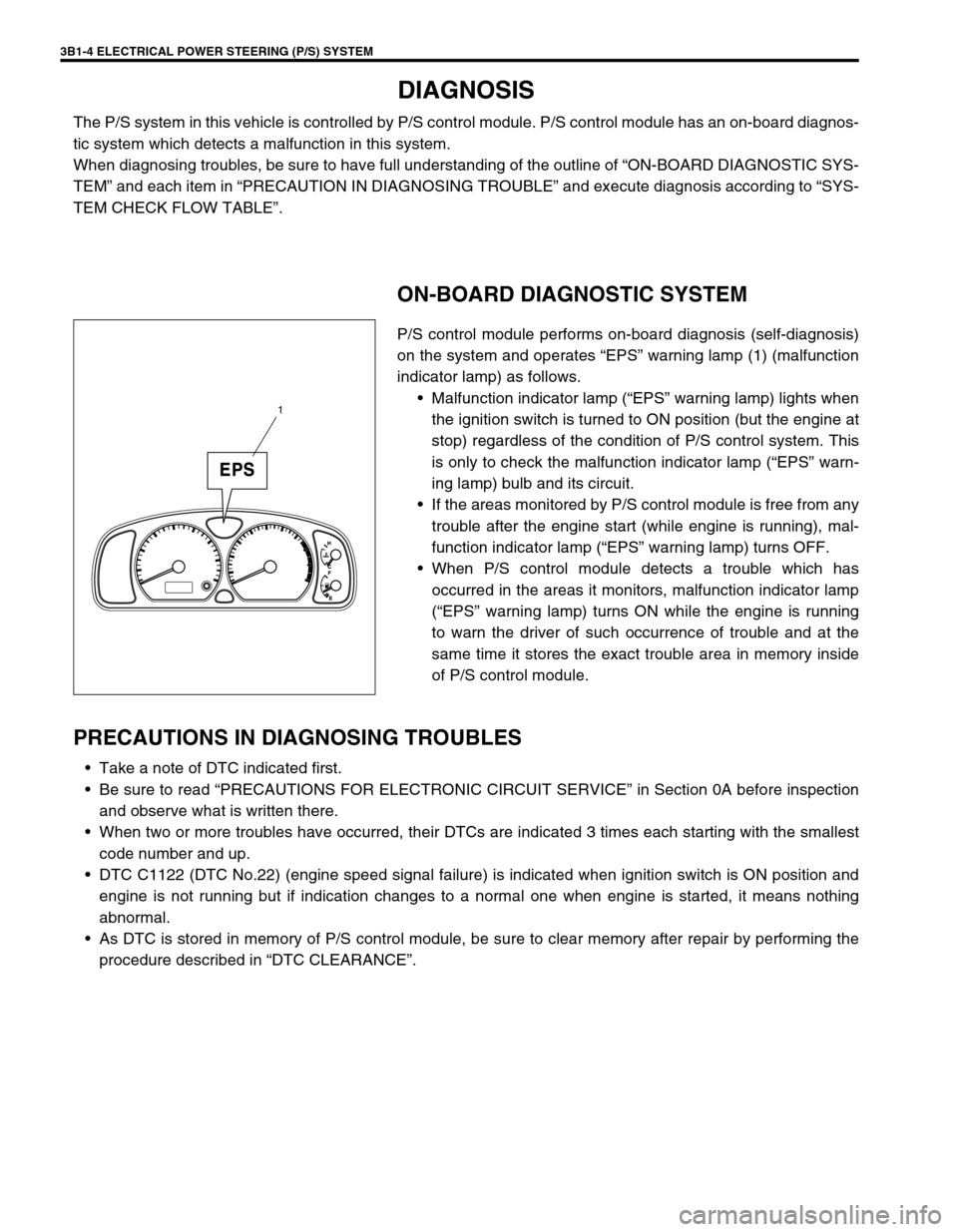

ON-BOARD DIAGNOSTIC SYSTEM

P/S control module performs on-board diagnosis (self-diagnosis)

on the system and operates “EPS” warning lamp (1) (malfunction

indicator lamp) as follows.

Malfunction indicator lamp (“EPS” warning lamp) lights when

the ignition switch is turned to ON position (but the engine at

stop) regardless of the condition of P/S control system. This

is only to check the malfunction indicator lamp (“EPS” warn-

ing lamp) bulb and its circuit.

If the areas monitored by P/S control module is free from any

trouble after the engine start (while engine is running), mal-

function indicator lamp (“EPS” warning lamp) turns OFF.

When P/S control module detects a trouble which has

occurred in the areas it monitors, malfunction indicator lamp

(“EPS” warning lamp) turns ON while the engine is running

to warn the driver of such occurrence of trouble and at the

same time it stores the exact trouble area in memory inside

of P/S control module.

PRECAUTIONS IN DIAGNOSING TROUBLES

Take a note of DTC indicated first.

Be sure to read “PRECAUTIONS FOR ELECTRONIC CIRCUIT SERVICE” in Section 0A before inspection

and observe what is written there.

When two or more troubles have occurred, their DTCs are indicated 3 times each starting with the smallest

code number and up.

DTC C1122 (DTC No.22) (engine speed signal failure) is indicated when ignition switch is ON position and

engine is not running but if indication changes to a normal one when engine is started, it means nothing

abnormal.

As DTC is stored in memory of P/S control module, be sure to clear memory after repair by performing the

procedure described in “DTC CLEARANCE”.

1

Page 146 of 698

ELECTRICAL POWER STEERING (P/S) SYSTEM 3B1-5

SYSTEM CHECK FLOW TABLE

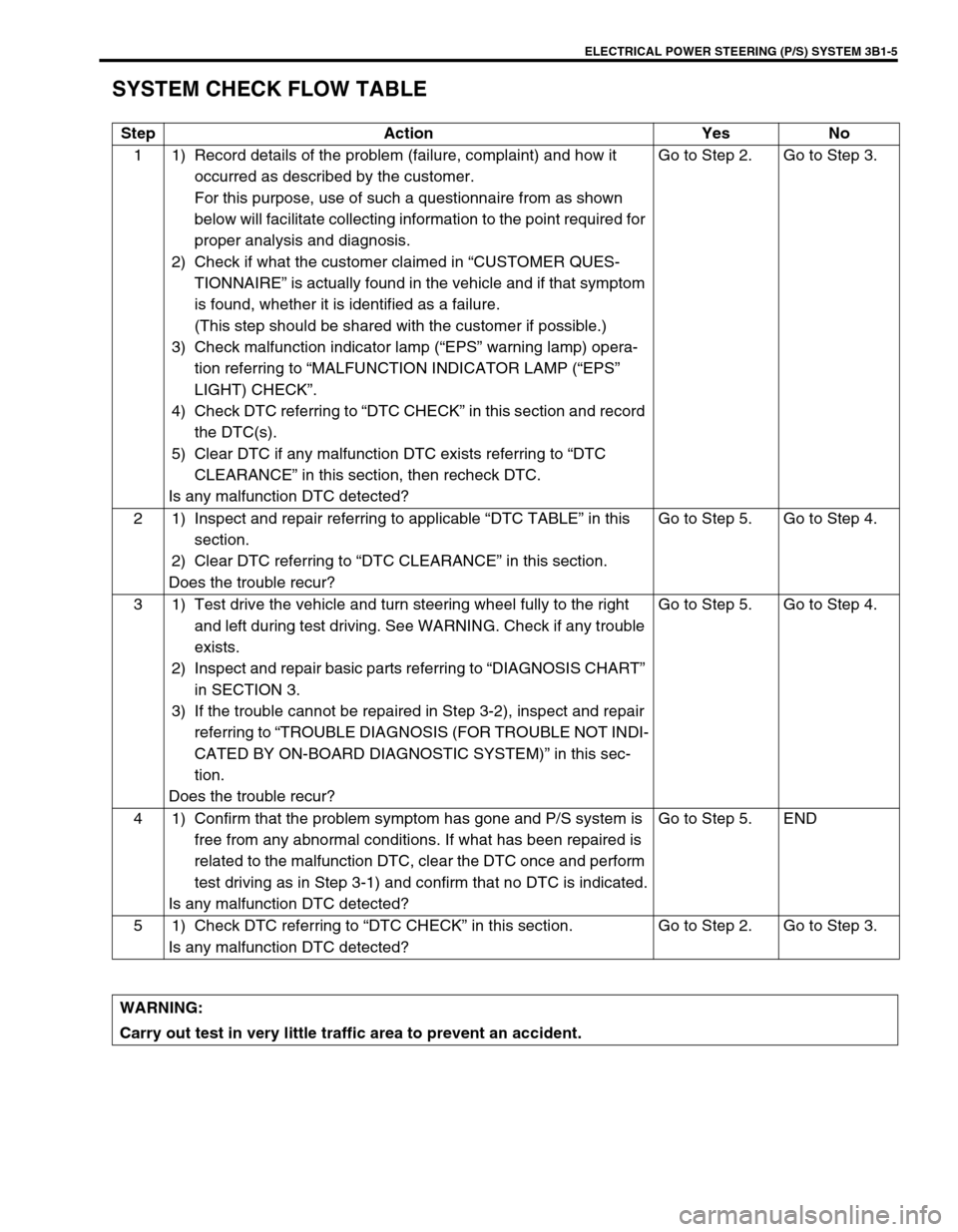

Step Action Yes No

1 1) Record details of the problem (failure, complaint) and how it

occurred as described by the customer.

For this purpose, use of such a questionnaire from as shown

below will facilitate collecting information to the point required for

proper analysis and diagnosis.

2) Check if what the customer claimed in “CUSTOMER QUES-

TIONNAIRE” is actually found in the vehicle and if that symptom

is found, whether it is identified as a failure.

(This step should be shared with the customer if possible.)

3) Check malfunction indicator lamp (“EPS” warning lamp) opera-

tion referring to “MALFUNCTION INDICATOR LAMP (“EPS”

LIGHT) CHECK”.

4) Check DTC referring to “DTC CHECK” in this section and record

the DTC(s).

5) Clear DTC if any malfunction DTC exists referring to “DTC

CLEARANCE” in this section, then recheck DTC.

Is any malfunction DTC detected?Go to Step 2. Go to Step 3.

2 1) Inspect and repair referring to applicable “DTC TABLE” in this

section.

2) Clear DTC referring to “DTC CLEARANCE” in this section.

Does the trouble recur?Go to Step 5. Go to Step 4.

3 1) Test drive the vehicle and turn steering wheel fully to the right

and left during test driving. See WARNING. Check if any trouble

exists.

2) Inspect and repair basic parts referring to “DIAGNOSIS CHART”

in SECTION 3.

3) If the trouble cannot be repaired in Step 3-2), inspect and repair

referring to “TROUBLE DIAGNOSIS (FOR TROUBLE NOT INDI-

CATED BY ON-BOARD DIAGNOSTIC SYSTEM)” in this sec-

tion.

Does the trouble recur?Go to Step 5. Go to Step 4.

4 1) Confirm that the problem symptom has gone and P/S system is

free from any abnormal conditions. If what has been repaired is

related to the malfunction DTC, clear the DTC once and perform

test driving as in Step 3-1) and confirm that no DTC is indicated.

Is any malfunction DTC detected?Go to Step 5. END

5 1) Check DTC referring to “DTC CHECK” in this section.

Is any malfunction DTC detected?Go to Step 2. Go to Step 3.

WARNING:

Carry out test in very little traffic area to prevent an accident.