temperature SUZUKI SWIFT 2000 1.G RG413 Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 1 of 698

IMPORTANT

WARNING/CAUTION/NOTE

Please read this manual and follow its instructions carefully. To emphasize special information, the words

WARNING, CAUTION

and NOTE

have special meanings. Pay special attention to the messages highlighted by

these signal words.

WARNING:

Indicates a potential hazard that could result in death or injury.

CAUTION:

Indicates a potential hazard that could result in vehicle damage.

NOTE:

Indicates special information to make maintenance easier or instructions clearer.

WARNING:

This service manual is intended for authorized Suzuki dealers and qualified service mechanics only.

Inexperienced mechanics or mechanics without the proper tools and equipment may not be able to

properly perform the services described in this manual.

Improper repair may result in injury to the mechanic and may render the vehicle unsafe for the driver

and passengers.

WARNING:

For vehicles equipped with a Supplemental Restraint (Air Bag) System:

• Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

If the air bag system and another vehicle system both need repair, Suzuki recommends that the air

bag system be repaired first, to help avoid unintended air bag system activation.

Do not modify the steering wheel, instrument panel or any other air bag system component (on or

around air bag system components or wiring). Modifications can adversely affect air bag system

performance and lead to injury.

If the vehicle will be exposed to temperatures over 93°C (200°F) (for example, during a paint baking

process), remove the air bag system components (air bag (inflator) modules, SDM and/or seat belt

with pretensioner) beforehand to avoid component damage or unintended activation.

Page 6 of 698

GENERAL INFORMATION 0A-3

PRECAUTIONS

PRECAUTION FOR VEHICLES EQUIPPED

WITH A SUPPLEMENTAL RESTRAINT

(AIR BAG) SYSTEM

DIAGNOSIS

When troubleshooting air bag system, be sure to follow

“DIAGNOSIS” in SECTION 10B. Bypassing these proce-

dures may result in extended diagnostic time, incorrect diag-

nosis, and incorrect parts replacement.

Never use electrical test equipment other than that specified

in this manual. WARNING:

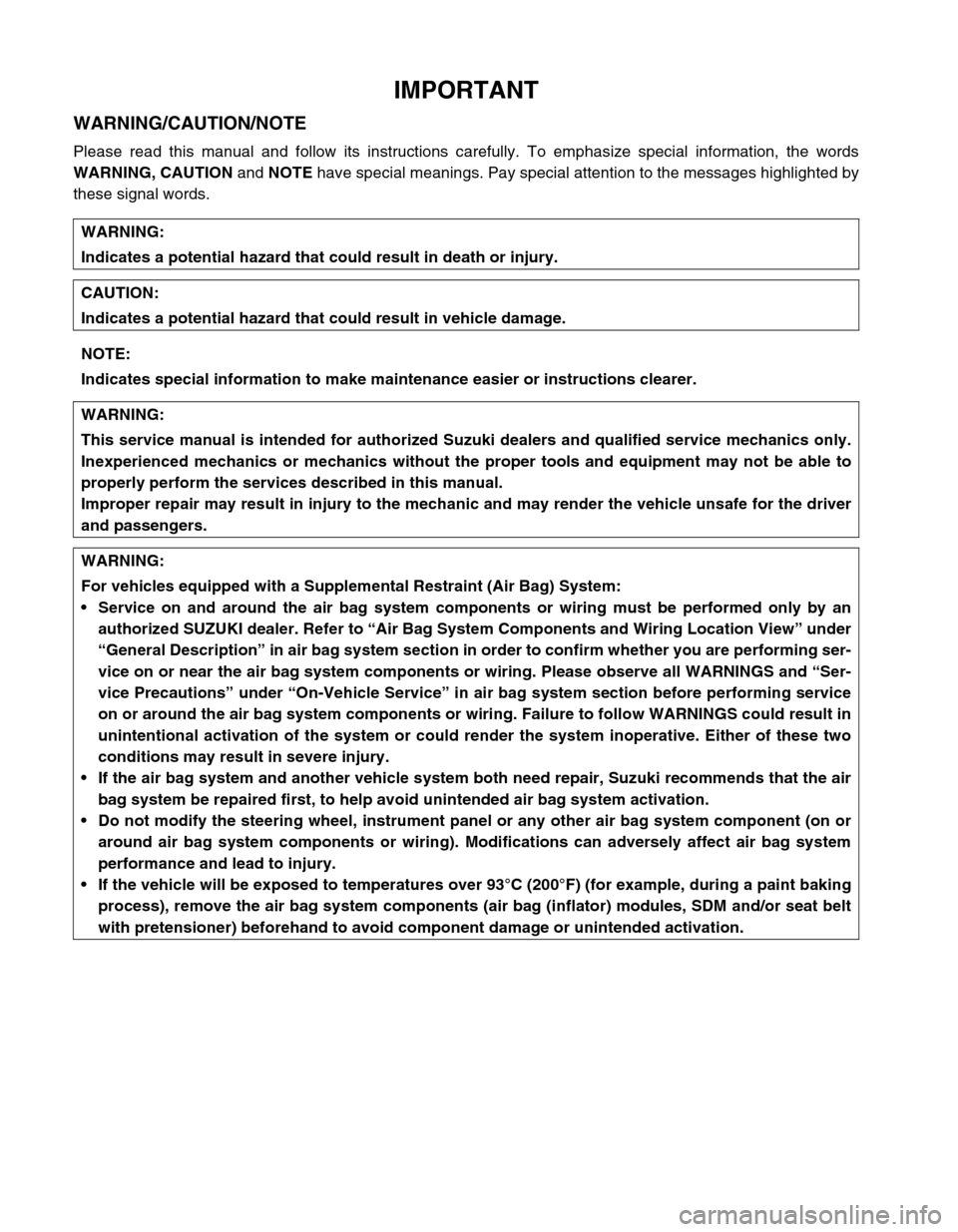

The configuration of air bag system parts are as shown

in the figure. When it is necessary to service (remove,

reinstall and inspect) these parts, be sure to follow

procedures described in SECTION 10B. Failure to fol-

low proper procedures could result in possible air bag

system activation, personal injury, damage to parts or

air bag system being unable to activate when neces-

sary.

If the air bag system and another vehicle system both

need repair, SUZUKI recommends that the air bag sys-

tem be repaired first, to help avoid unintended air bag

system activation.

Do not modify the steering wheel, dashboard, or any

other air bag system components. Modifications can

adversely affect air bag system performance and lead

to injury.

If the vehicle will be exposed to temperatures over

93°C (200°F) (for example, during a paint baking pro-

cess), remove the air bag system components before-

hand to avoid component damage or unintended air

bag system activation.

1. Air bag wire harness 4. Seat belt pretensioner

2. Passenger air bag (inflator) module 5. Contact coil

3. SDM 6. Driver air bag (inflator) module

3

4

4

6

1

52

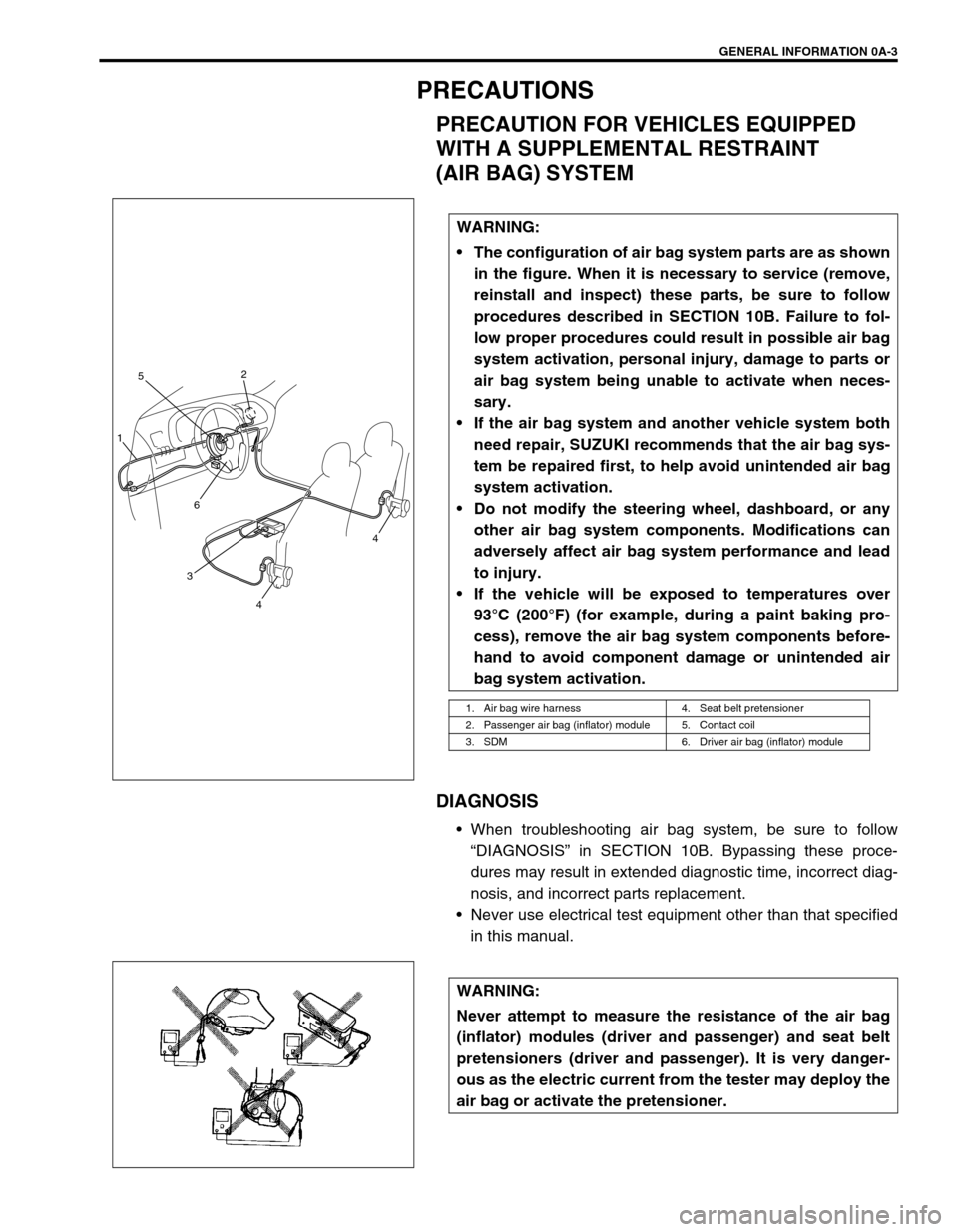

WARNING:

Never attempt to measure the resistance of the air bag

(inflator) modules (driver and passenger) and seat belt

pretensioners (driver and passenger). It is very danger-

ous as the electric current from the tester may deploy the

air bag or activate the pretensioner.

Page 7 of 698

0A-4 GENERAL INFORMATION

SERVICING AND HANDLING

WARNING:

Many of service procedures require disconnection of

“AIR BAG” fuse and all air bag (inflator) module(s) from

initiator circuit to avoid an accidental deployment.

Driver and Passenger Air Bag (Inflator) Modules

For handling and storage of a live air bag (inflator)

module, select a place where the ambient temperature

below 65°C (150°F), without high humidity and away

from electric noise.

When carrying a live air bag (inflator) module, make

sure the bag opening is pointed away from you. In

case of an accidental deployment, the bag will then

deploy with minimal chance of injury. Never carry the

air bag (inflator) module by the wires or connector on

the underside of the module. When placing a live air

bag (inflator) module on a bench or other surface,

always face the bag up, away from the surface. As the

live passenger air bag (inflator) module must be placed

with its bag (trim cover) facing up, place it on the work-

bench with a slit or use the workbench vise to hold it

securely at its lower mounting bracket. This is neces-

sary so that a free space is provided to allow the air

bag to expand in the unlikely event of accidental

deployment. Otherwise, personal injury may result.

Never dispose of live (undeployed) air bag (inflator)

modules (driver and passenger). If disposal is neces-

sary, be sure to deploy them according to deployment

procedures described in SECTION 10B before dis-

posal.

The air bag (inflator) module immediately after deploy-

ment is very hot. Wait for at least half an hour to cool it

off before proceeding the work.

After an air bag (inflator) module has been deployed,

the surface of the air bag may contain a powdery resi-

due. This powder consists primarily of cornstarch

(used to lubricate the bag as it inflates) and by-prod-

ucts of the chemical reaction. As with many service

procedures, gloves and safety glasses should be

worn.

[A] : ALWAYS CARRY AIR BAG (INFLATOR) MODULE WITH TRIM COVER (AIR BAG

OPENING) AWAY FROM BODY.

[B] : ALWAYS PLACE AIR BAG (INFLATOR) MODULE ON WORKBENCH WITH TRIM

COVER (AIR BAG OPENING) UP, AWAY FROM LOOSE OBJECTS.

1. Slit on workbench

2. Workbench vise

3. Lower mounting bracket

Page 8 of 698

GENERAL INFORMATION 0A-5

Even when the accident was light enough not to cause air bags to activate, be sure to inspect sys-

tem parts and other related parts according to instructions under “REPAIR AND INSPECTION

REQUIRED AFTER AN ACCIDENT” in SECTION 10B.

When servicing parts other than air bag system, if shocks may be applied to air bag system compo-

nent parts, remove those parts beforehand.

When handling the air bag (inflator) modules (driver and passenger), seat belt pretensioners (driver

and passenger) or SDM, be careful not to drop it or apply an impact to it. If an excessive impact was

applied, never attempt disassembly or repair but replace it with a new one.

When grease, cleaning agent, oil, water, etc. has got onto air bag (inflator) modules (driver and pas-

senger) or seat belt pretensioners (drive and passenger), wipe off immediately with a dry cloth. WARNING:

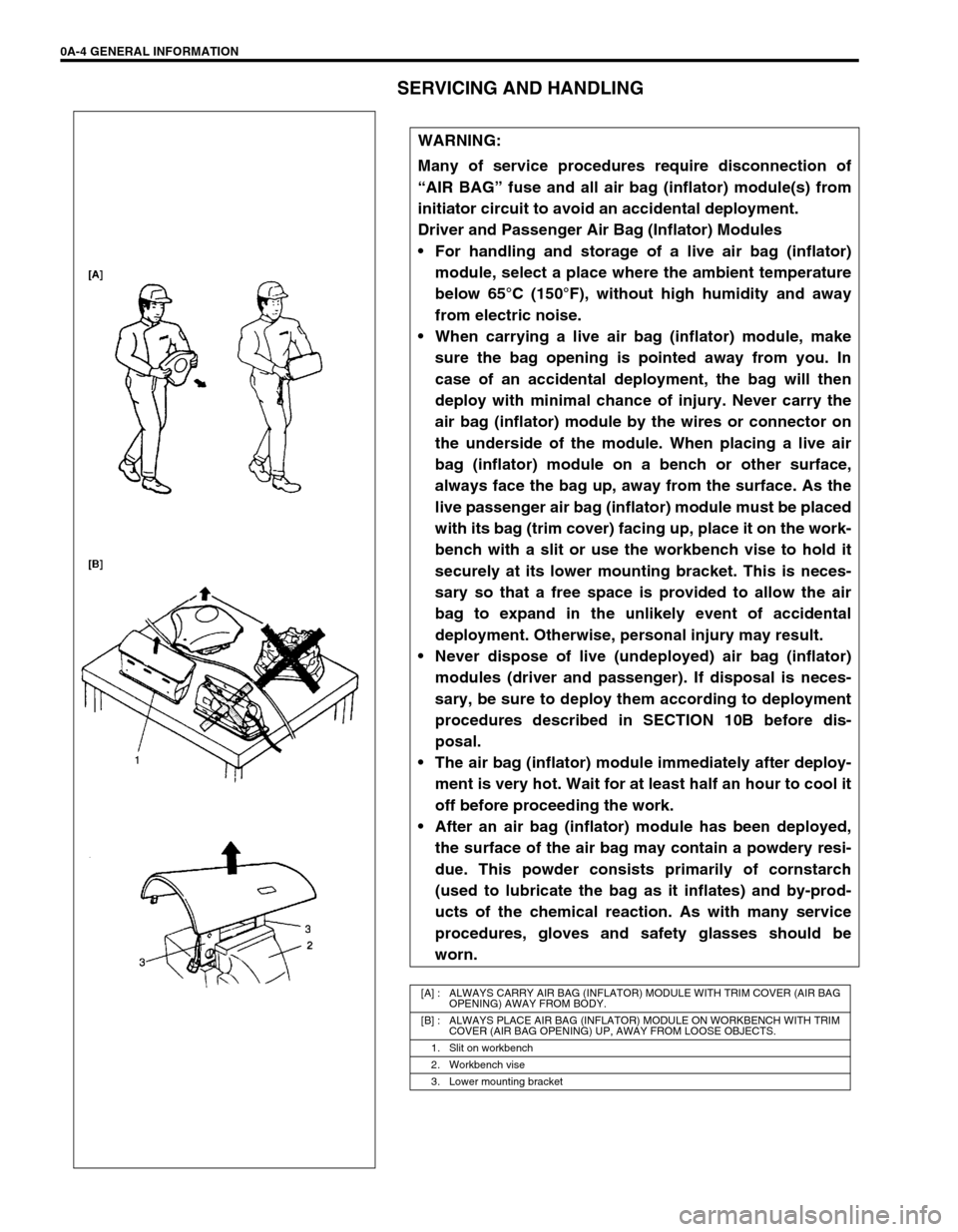

SDM

For handling and storage of a SDM, select a place where the ambient temperature below 65°C

(150°F), without high humidity and away from electric noise.

During service procedures, be very careful when handling a Sensing and Diagnostic Module (SDM).

Never strike or jar the SDM.

Never power up the air bag system when the SDM is not rigidly attached to the vehicle. All SDM and

mounting bracket fasteners must be carefully torqued and the arrow must be pointing toward the

front of the vehicle to ensure proper operation of the air bag system.

The SDM could be activated when powered while not rigidly attached to the vehicle which could

cause deployment and result in personal injury.

WARNING:

Driver and Passenger Seat Belt Pretensioners

(If equipped)

For handling and storage of a live seat belt preten-

sioner, select a place where the ambient temperature

below 65°C (150°F), without high humidity and away

from electric noise.

Never carry seat belt pretensioner by wire or connec-

tor of pretensioner. When placing a live seat belt pre-

tensioner on the workbench or some place like that, be

sure not to lay it with its exhaust hole (1) provided side

facing down. It is also prohibited to put something on

its face with an exhaust hole or to put a seat belt pre-

tensioner on top of another. Otherwise, personal injury

may result.

Never dispose of live (inactivated) seat belt pretension-

ers (drive and passenger). If disposal is necessary, be

sure to activate them according to activation proce-

dures described in SECTION 10B before disposal.

The seat belt pretensioner immediately after activation

is very hot. Wait for at least half an hour to cool it off

before proceeding the work.

With many service procedures, gloves and safety

glasses should be worn to prevent any possible irrita-

tion of the skin or eyes.

Page 25 of 698

0A-22 GENERAL INFORMATION

ABBREVIATIONS AND SYMBOLS MAY BE USED IN THIS MANUAL

ABBREVIATIONS

AABS Anti-lock Brake System

EEFE Heater Early Fuel Evaporation Heater

(Positive Temperature Coefficient,

PTC Heater) ATDC After Top Dead Center

API American Petroleum Institute

ATF Automatic Transmission Fluid EPS Electronic Power Steering

ALR Automatic Locking Retractor EVAP Evaporative Emission

AC Alternating Current EVAP Canister Evaporative Emission Canister

(Charcoal Canister)

A/T Automatic TransmissionF

4WD 4 Wheel Drive

A/C Air Conditioning

GGEN Generator

ABDC After Bottom Dead Center GND Ground

A/F Air Fuel Mixture Ratio

HHC Hydrocarbons

A-ELR Automatic-Emergency Locking

RetractorHO2S Heated Oxygen Sensor

IIAC Valve Idle Air Control Valve (Idle Speed

Control Solenoid Valve ISC Sole-

noid Valve)

BB+ Battery Positive Voltage

BTDC Before Top Dead Center

BBDC Before Bottom Dead Center IAT Sensor Intake Air Temperature Sensor

(Air temperature Sensor, ATS)

CCKT Circuit

CKP sensor Crankshaft Position Sensor ICM Immobilizer Control Module

CMP sensor Camshaft Position Sensor IG Ignition

CO Carbon Monoxide ISC Actuator Idle Speed Control Actuator

CPP switch Clutch Pedal Position Switch

(Clutch Switch, Clutch Start

Switch)LLH Left Hand

LSPV Load Sensing Proportioning Valve

CPU Central Processing Unit

MMAF Sensor Mass Air Flow Sensor (Air Flow

Sensor, AFS, Air Flow Meter,

AFM) CRS Child Restraint System

DDC Direct Current

DLC Data Link Connector (Assembly

Line Diag. Link, ALDL, Serial Data

Link, SDL)MAP Sensor Manifold Absolute Pressure Sen-

sor (Pressure Sensor, PS)

Max Maximum

DOHC Double Over Head Camshaft MFI Multiport Fuel Injection

(Multipoint Fuel Injection)

DOJ Double Offset Joint

DRL Daytime Running Light MIN Minimum

DTC Diagnostic Trouble Code (Diag-

nostic Code)MIL Malfunction Indicator Lamp

(“SERVICE ENGINE SOON”

Light)

EEBCM Electronic Brake Control Module,

ABS Control Module M/T Manual Transmission

EBD Electronic Brake Force Distribu-

tionNNOx Nitrogen Oxides

ECM Engine Control Module

OOBD On-Board Diagnostic System

(Self-Diagnosis Function)

ECT sensor Engine Coolant Temperature Sen-

sor (Water Temp. Sensor, WTS)

O/D Overdrive

EGR Exhaust Gas Recirculation OHC Over Head Camshaft

EGRT sensor EGR Temperature Sensor (Recir-

culated Exhaust Gas Temp. Sen-

sor, REGTS)O2S Oxygen Sensor

PPNP Park/Neutral Position

P/S Power Steering

Page 37 of 698

0B-8 MAINTENANCE AND LUBRICATION

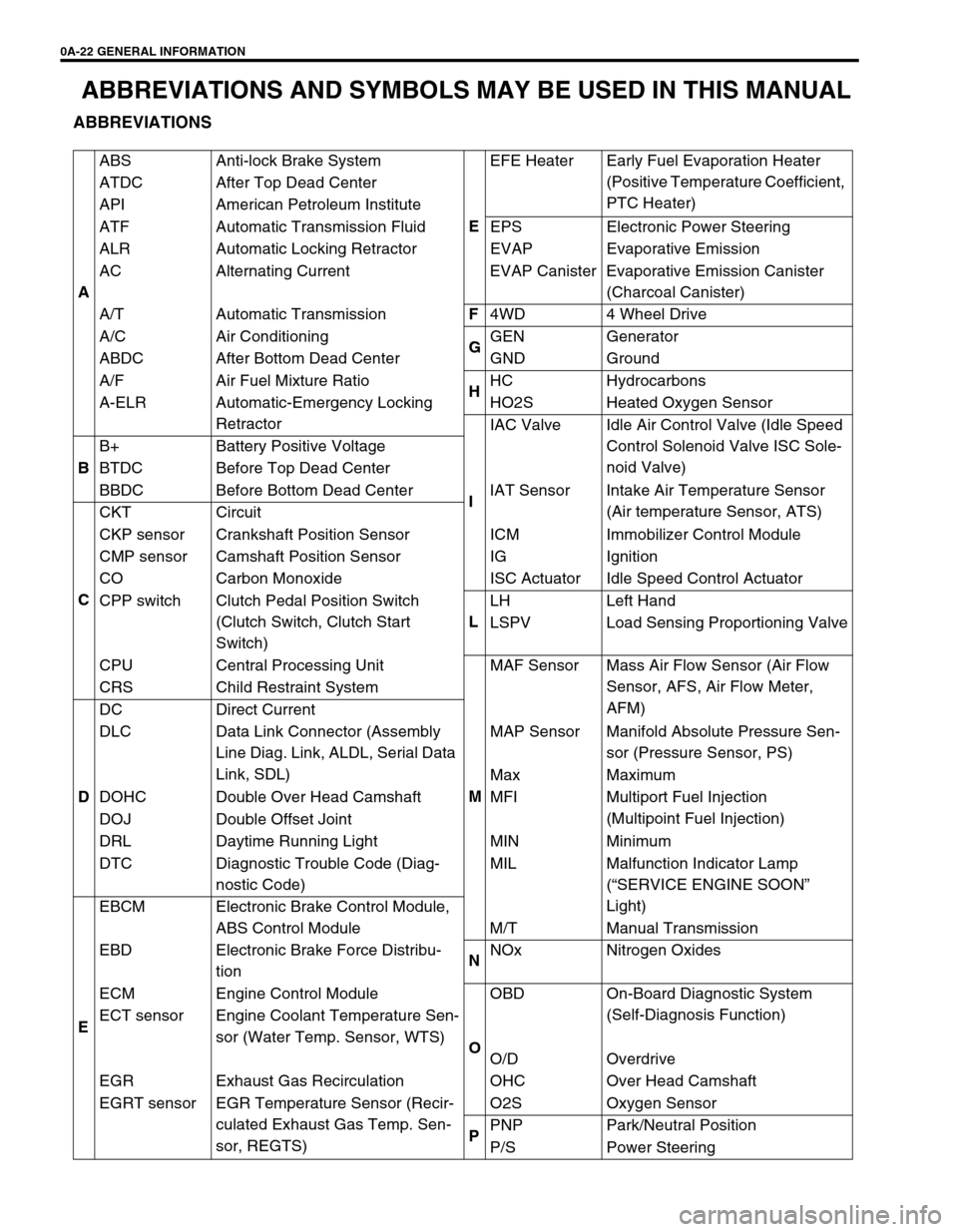

6) Replenish oil until oil level is brought to FULL level mark on

dipstick. (oil pan and oil filter capacity). The filler inlet is at

the top of the cylinder head cover.

It is recommended to use engine oil of SE, SF, SG, SH or SJ

grade. Select the appropriate oil viscosity according to the

proper engine oil viscosity chart [A].

Engine oil specification

7) Check oil filter and drain plug for oil leakage.

8) Start engine and run it for 3 minutes. Stop it and wait 5 min-

utes before checking oil level. Add oil, as necessary, to bring

oil level to FULL level mark on dipstick.

ENGINE COOLANT

REPLACEMENT

NOTE:

For ambient temperature between –20°C (–4°F) and 30°C

(86°F), it is highly recommended to use SAE 10W – 30 oil.

Oil pan capacity About 3.6 liters (7.6/6.3 US/lmp pt.)

Oil filter capacity About 0.2 liter (0.4/0.3 US/lmp pt.)

Others About 0.3 liter (0.6/0.5 US/lmp pt.)

Total About 4.1 liters (8.7/7.2 US/lmp pt.)

NOTE:

Engine oil capacity is specified. However, note that the

amount of oil required when actually changing oil may

somewhat differ from the data in the table depending on

various conditions (temperature, viscosity, etc.)

1. Full level mark (hole)

2. Low level mark (hole)

WARNING:

To help avoid danger of being burned, do not remove

radiator cap while engine and radiator are still hot. Scald-

ing fluid and steam can be blown out under pressure if

cap is taken off too soon.

Page 38 of 698

MAINTENANCE AND LUBRICATION 0B-9

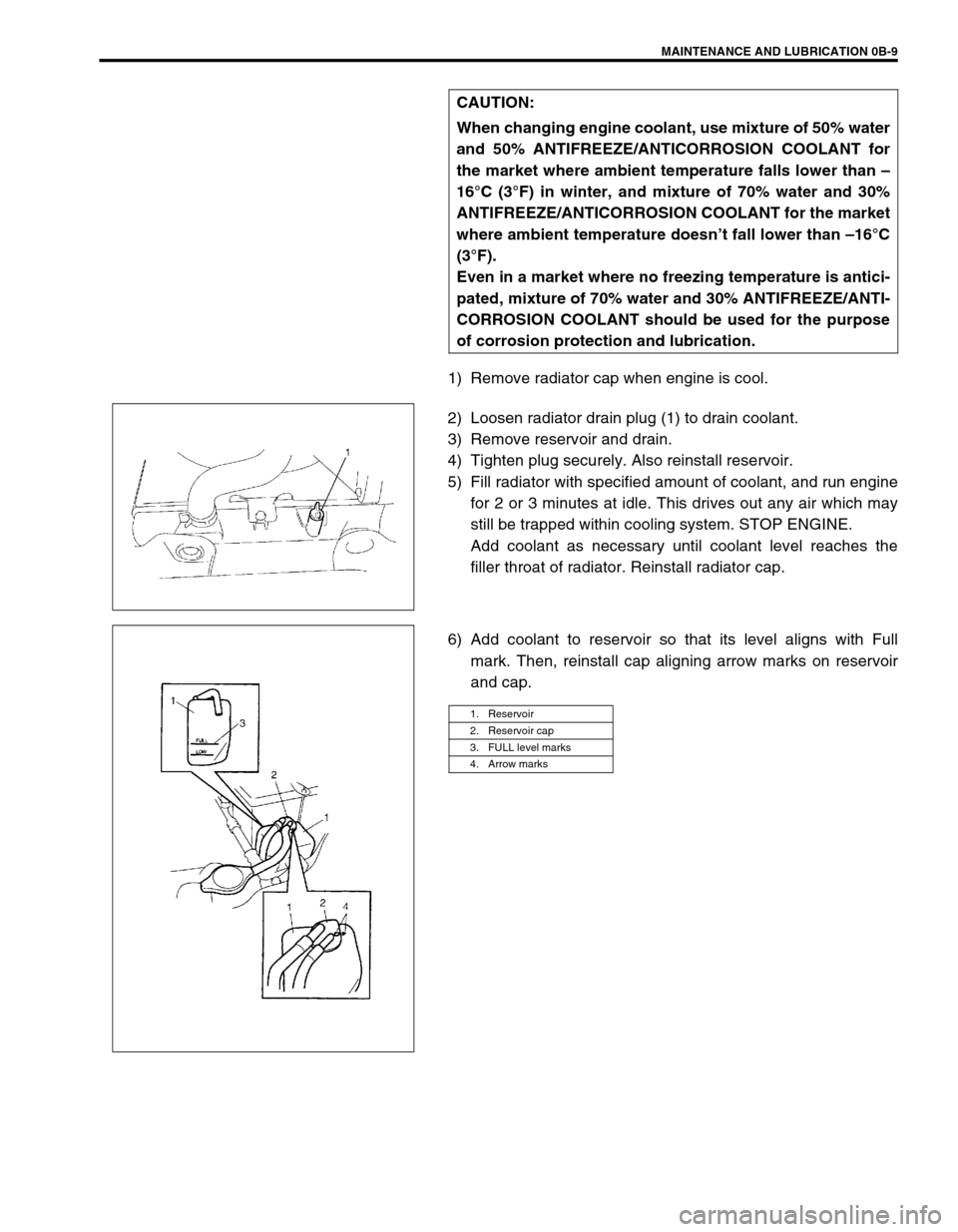

1) Remove radiator cap when engine is cool.

2) Loosen radiator drain plug (1) to drain coolant.

3) Remove reservoir and drain.

4) Tighten plug securely. Also reinstall reservoir.

5) Fill radiator with specified amount of coolant, and run engine

for 2 or 3 minutes at idle. This drives out any air which may

still be trapped within cooling system. STOP ENGINE.

Add coolant as necessary until coolant level reaches the

filler throat of radiator. Reinstall radiator cap.

6) Add coolant to reservoir so that its level aligns with Full

mark. Then, reinstall cap aligning arrow marks on reservoir

and cap. CAUTION:

When changing engine coolant, use mixture of 50% water

and 50% ANTIFREEZE/ANTICORROSION COOLANT for

the market where ambient temperature falls lower than –

16°C (3°F) in winter, and mixture of 70% water and 30%

ANTIFREEZE/ANTICORROSION COOLANT for the market

where ambient temperature doesn’t fall lower than –16°C

(3°F).

Even in a market where no freezing temperature is antici-

pated, mixture of 70% water and 30% ANTIFREEZE/ANTI-

CORROSION COOLANT should be used for the purpose

of corrosion protection and lubrication.

1. Reservoir

2. Reservoir cap

3. FULL level marks

4. Arrow marks

Page 50 of 698

MAINTENANCE AND LUBRICATION 0B-21

STEERING

Check to ensure that steering wheel is free from instability, or abnormally heavy feeling.

Check that the vehicle does not wander or pull to one side.

ENGINE

Check that engine responds readily at all speeds.

Check that engine is free from abnormal noise and abnormal vibration.

BODY, WHEELS AND POWER TRANSMITTING SYSTEM

Check that body, wheels and power transmitting system are free from abnormal noise and abnormal vibration or

any other abnormal condition.

METERS AND GAUGE

Check that speedometer, odometer, fuel meter, temperature gauge, etc. are operating accurately.

LIGHTS

Check that all lights operate properly.

WINDSHIELD DEFROSTER

Periodically check that air comes out from defroster outlet when operating heater or air conditioning.

Set mode control lever to defroster position and fan switch lever to “HI” position for this check.

RECOMMENDED FLUIDS AND LUBRICANTS

Engine oil SE, SF, SG, SH or SJ grade (Refer to “ENGINE OIL AND OIL FILTER”

in this section for engine oil viscosity.)

Engine coolant

(Ethylene glycol base coolant)“Antifreeze/Anticorrosion coolant”

Brake fluid DOT 3

Manual transmission oil Refer to “M/T OIL CHANGE” in Section 7A.

Transfer oil (4WD) Refer to “TRANSFER OIL CHANGE” in Section 7D.

Differential oil (4WD) Refer to “DIFFERENTIAL OIL CHANGE” in Section 7F.

Automatic transmission fluid

An equivalent of DEXRON

®-III

Door hinges Engine oil or water resistance chassis grease

Hood latch assembly Engine oil or water resistance chassis grease

Key lock cylinder Spray lubricant

Page 54 of 698

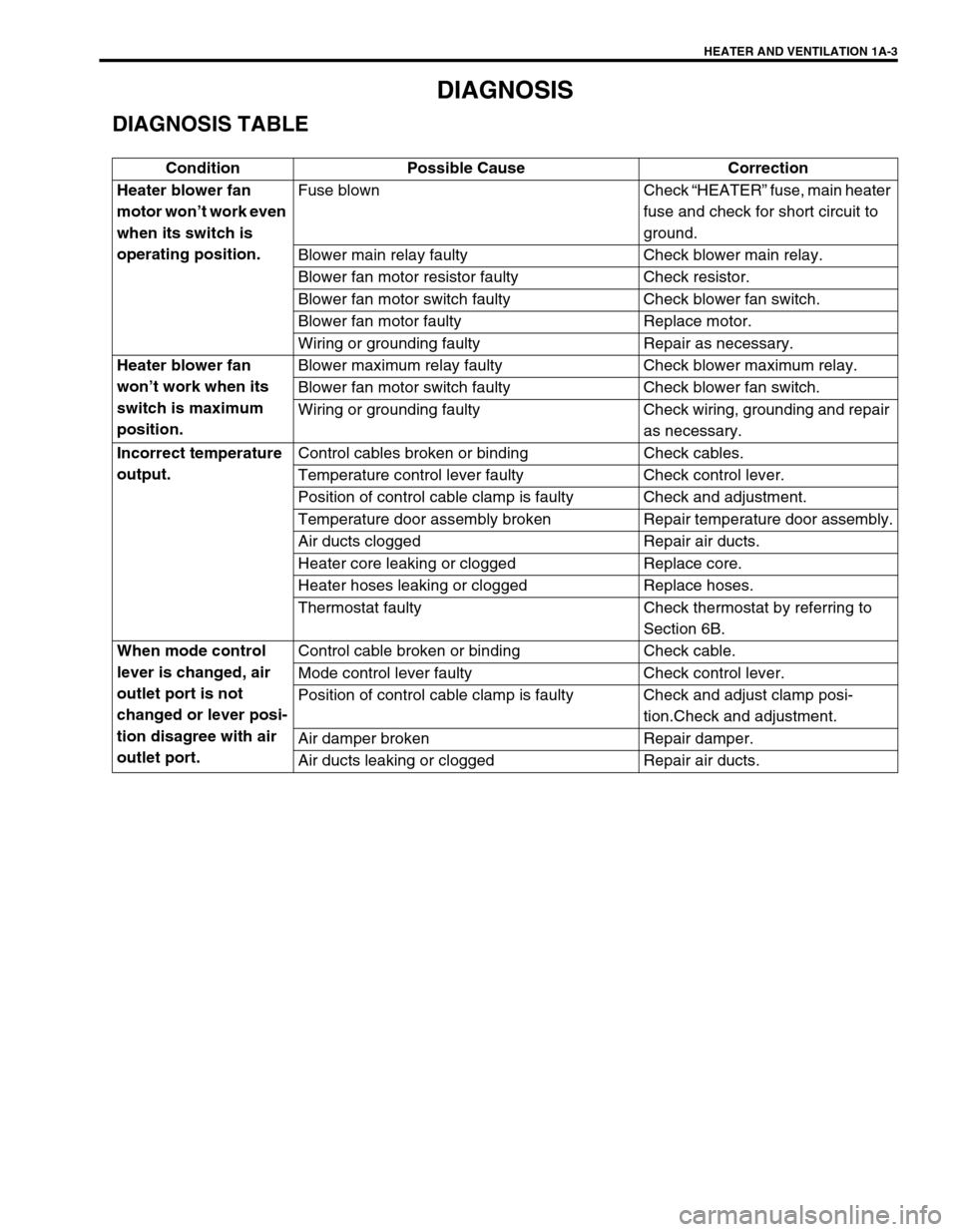

HEATER AND VENTILATION 1A-3

DIAGNOSIS

DIAGNOSIS TABLE

Condition Possible Cause Correction

Heater blower fan

motor won’t work even

when its switch is

operating position.Fuse blown Check “HEATER” fuse, main heater

fuse and check for short circuit to

ground.

Blower main relay faulty Check blower main relay.

Blower fan motor resistor faulty Check resistor.

Blower fan motor switch faulty Check blower fan switch.

Blower fan motor faulty Replace motor.

Wiring or grounding faulty Repair as necessary.

Heater blower fan

won’t work when its

switch is maximum

position.Blower maximum relay faulty Check blower maximum relay.

Blower fan motor switch faulty Check blower fan switch.

Wiring or grounding faulty Check wiring, grounding and repair

as necessary.

Incorrect temperature

output.Control cables broken or binding Check cables.

Temperature control lever faulty Check control lever.

Position of control cable clamp is faulty Check and adjustment.

Temperature door assembly broken Repair temperature door assembly.

Air ducts clogged Repair air ducts.

Heater core leaking or clogged Replace core.

Heater hoses leaking or clogged Replace hoses.

Thermostat faulty Check thermostat by referring to

Section 6B.

When mode control

lever is changed, air

outlet port is not

changed or lever posi-

tion disagree with air

outlet port.Control cable broken or binding Check cable.

Mode control lever faulty Check control lever.

Position of control cable clamp is faulty Check and adjust clamp posi-

tion.Check and adjustment.

Air damper broken Repair damper.

Air ducts leaking or clogged Repair air ducts.

Page 56 of 698

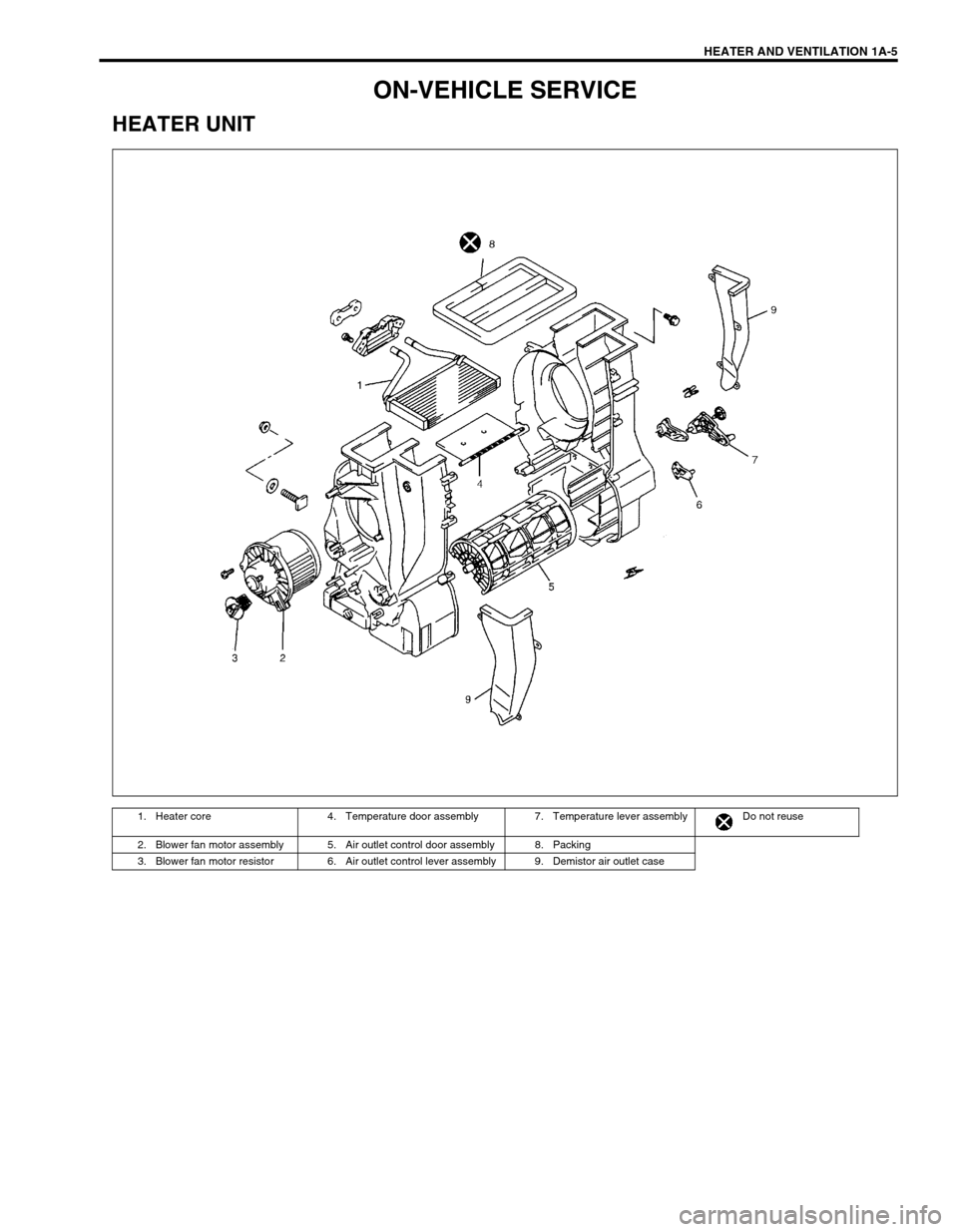

HEATER AND VENTILATION 1A-5

ON-VEHICLE SERVICE

HEATER UNIT

1. Heater core 4. Temperature door assembly 7. Temperature lever assembly Do not reuse

2. Blower fan motor assembly 5. Air outlet control door assembly 8. Packing

3. Blower fan motor resistor 6. Air outlet control lever assembly 9. Demistor air outlet case