temperature SUZUKI SWIFT 2000 1.G RG413 Service Manual PDF

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 698, PDF Size: 16.01 MB

Page 687 of 698

CHARGING SYSTEM 6H-7

UNDERCHARGED BATTERY

This condition, as evidenced by slow cranking or indicator clear

with red dot can be caused by one or more of the following condi-

tions even though indicator lamp may be operating normal.

Following procedure also applies to cars with voltmeter and

ammeter.

Make sure that undercharged condition has not been caused

by accessories left on for extended period of time.

Check drive belt for proper tension.

If battery defect is suspected, refer to BATTERY section.

Inspect wiring for defects. Check all connections for tight-

ness and cleanliness, battery cable connections at battery,

starting motor and ignition ground cable.

NO-LOAD CHECK

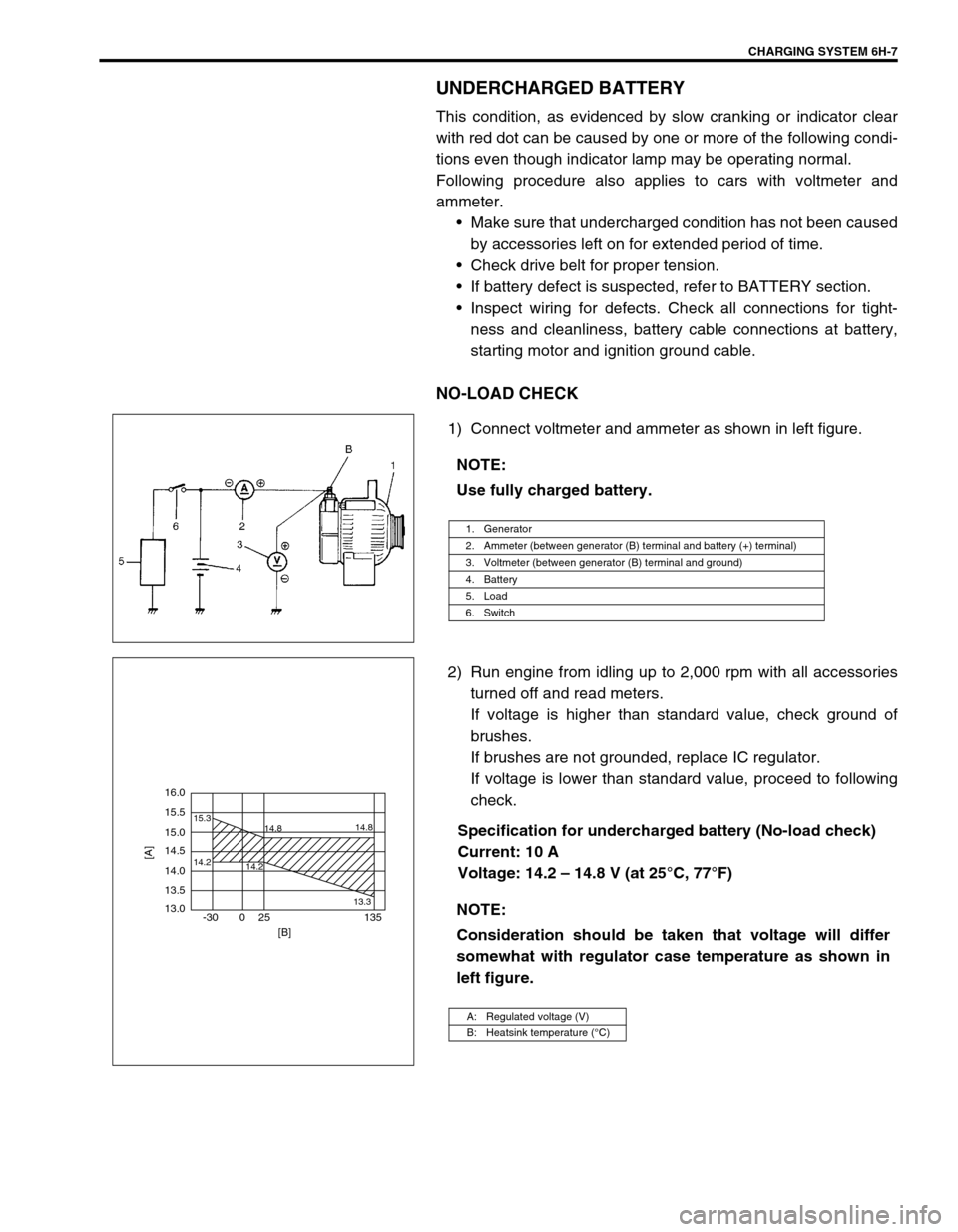

1) Connect voltmeter and ammeter as shown in left figure.

2) Run engine from idling up to 2,000 rpm with all accessories

turned off and read meters.

If voltage is higher than standard value, check ground of

brushes.

If brushes are not grounded, replace IC regulator.

If voltage is lower than standard value, proceed to following

check.

Specification for undercharged battery (No-load check)

Current: 10 A

Voltage: 14.2 – 14.8 V (at 25°C, 77°F) NOTE:

Use fully charged battery.

1. Generator

2. Ammeter (between generator (B) terminal and battery (+) terminal)

3. Voltmeter (between generator (B) terminal and ground)

4. Battery

5. Load

6. Switch

NOTE:

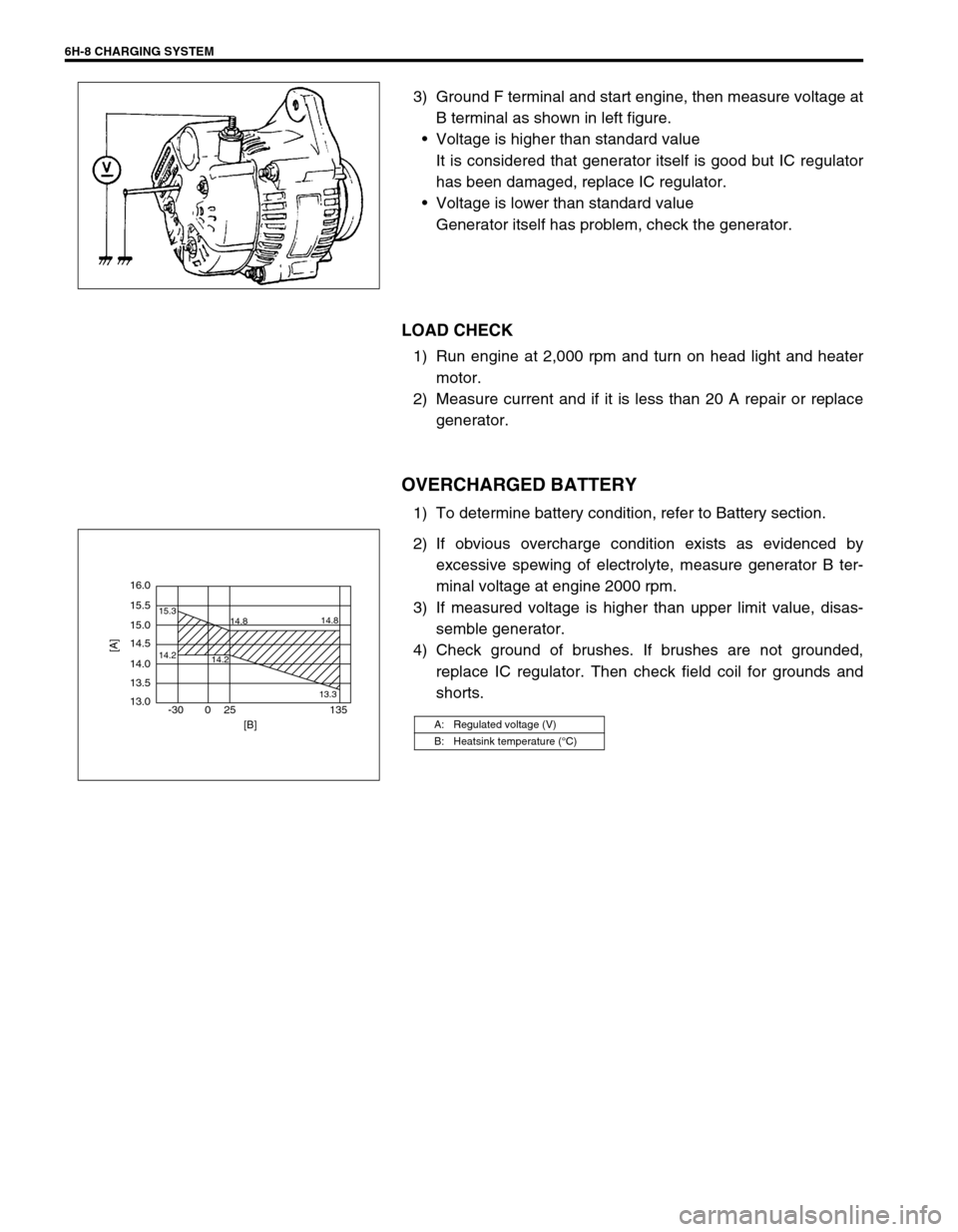

Consideration should be taken that voltage will differ

somewhat with regulator case temperature as shown in

left figure.

A: Regulated voltage (V)

B: Heatsink temperature (°C)

16.0

15.5

14.2 15.3

14.8

14.2

13.314.8

15.0

14.5

14.0

13.5

13.0

-30 0 25 135

[A]

[B]

Page 688 of 698

6H-8 CHARGING SYSTEM

3) Ground F terminal and start engine, then measure voltage at

B terminal as shown in left figure.

Voltage is higher than standard value

It is considered that generator itself is good but IC regulator

has been damaged, replace IC regulator.

Voltage is lower than standard value

Generator itself has problem, check the generator.

LOAD CHECK

1) Run engine at 2,000 rpm and turn on head light and heater

motor.

2) Measure current and if it is less than 20 A repair or replace

generator.

OVERCHARGED BATTERY

1) To determine battery condition, refer to Battery section.

2) If obvious overcharge condition exists as evidenced by

excessive spewing of electrolyte, measure generator B ter-

minal voltage at engine 2000 rpm.

3) If measured voltage is higher than upper limit value, disas-

semble generator.

4) Check ground of brushes. If brushes are not grounded,

replace IC regulator. Then check field coil for grounds and

shorts.

A: Regulated voltage (V)

B: Heatsink temperature (°C)

16.0

15.5

14.2 15.3

14.8

14.2

13.314.8

15.0

14.5

14.0

13.5

13.0

-30 0 25 135

[A]

[B]

Page 694 of 698

6H-14 CHARGING SYSTEM

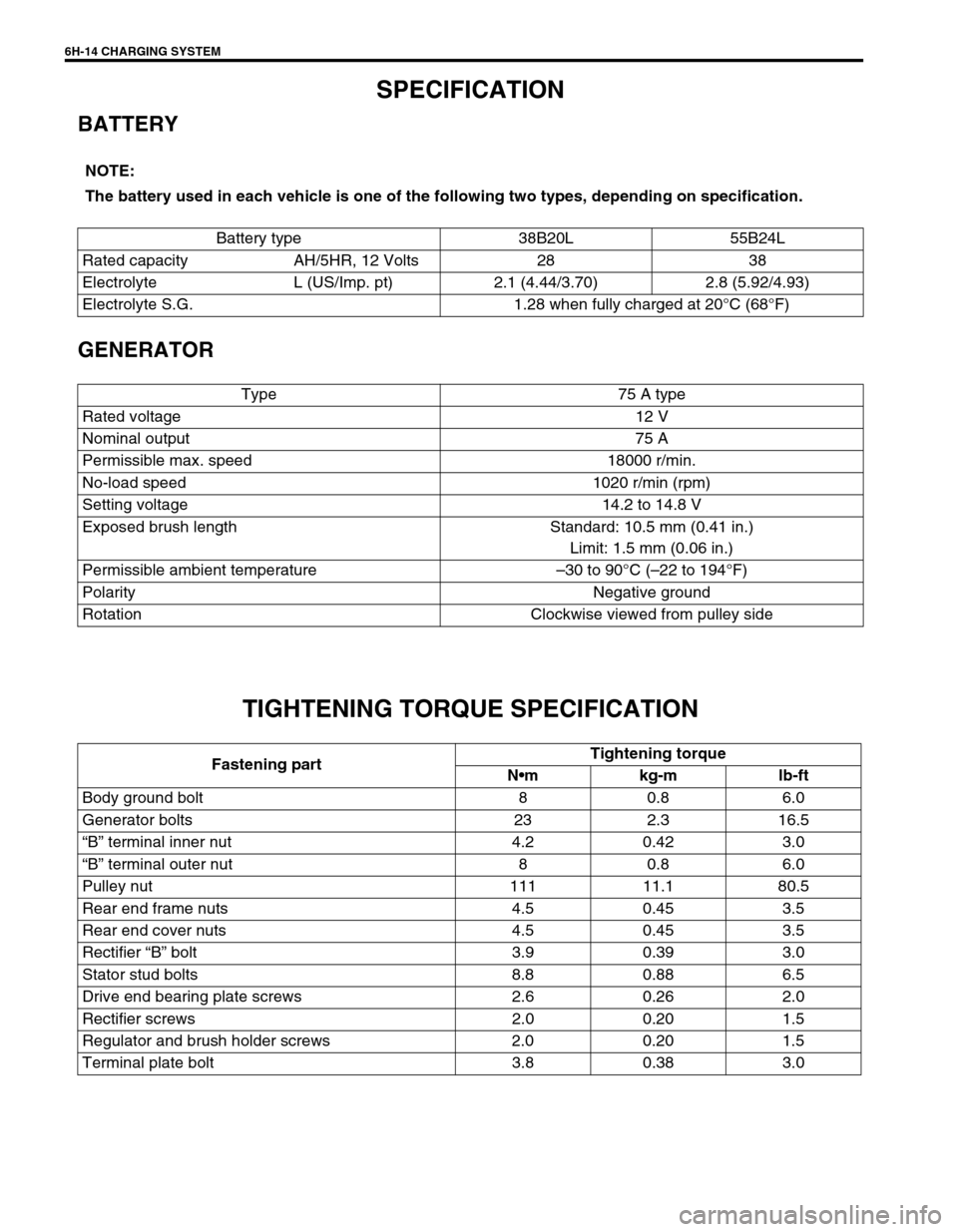

SPECIFICATION

BATTERY

GENERATOR

TIGHTENING TORQUE SPECIFICATION

NOTE:

The battery used in each vehicle is one of the following two types, depending on specification.

Battery type 38B20L 55B24L

Rated capacity AH/5HR, 12 Volts 28 38

Electrolyte L (US/Imp. pt) 2.1 (4.44/3.70) 2.8 (5.92/4.93)

Electrolyte S.G. 1.28 when fully charged at 20°C (68°F)

Type 75 A type

Rated voltage 12 V

Nominal output 75 A

Permissible max. speed 18000 r/min.

No-load speed 1020 r/min (rpm)

Setting voltage 14.2 to 14.8 V

Exposed brush length Standard: 10.5 mm (0.41 in.)

Limit: 1.5 mm (0.06 in.)

Permissible ambient temperature–30 to 90°C (–22 to 194°F)

Polarity Negative ground

Rotation Clockwise viewed from pulley side

Fastening partTightening torque

Nm kg-m lb-ft

Body ground bolt 8 0.8 6.0

Generator bolts 23 2.3 16.5

“B” terminal inner nut 4.2 0.42 3.0

“B” terminal outer nut 8 0.8 6.0

Pulley nut 111 11.1 80.5

Rear end frame nuts 4.5 0.45 3.5

Rear end cover nuts 4.5 0.45 3.5

Rectifier “B” bolt 3.9 0.39 3.0

Stator stud bolts 8.8 0.88 6.5

Drive end bearing plate screws 2.6 0.26 2.0

Rectifier screws 2.0 0.20 1.5

Regulator and brush holder screws 2.0 0.20 1.5

Terminal plate bolt 3.8 0.38 3.0