torque SUZUKI SWIFT 2000 1.G Transmission Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 447, PDF Size: 10.54 MB

Page 370 of 447

10-4 RESTRAINT SYSTEM

ON-VEHICLE SERVICE

SERVICE PRECAUTIONS

SERVICE AND DIAGNOSIS

Before servicing or replacing seat belts, refer to following precautionary items.

Seat belts should be normal relative to strap retractor and buckle portions.

Keep sharp edges and damaging objects away from belts.

Avoid bending or damaging any portion of belt buckle or latch plate.

Do not bleach or dye belt webbing. (Use only mild soap and lukewarm water to clean it.)

When installing a seat belt anchor bolt, it should be tightened by hand at first to prevent cross-threading and

then to specified torque.

Do not attempt any repairs on retractor mechanisms or retractor covers. Replace defective assemblies with

new replacement parts.

Keep belts dry and clean at all times.

If there exist any parts in question, replace such parts.

Replace belts whose webbing is cut or otherwise damaged.

Do not put anything into trim panel opening which seat belt webbing passes through.

For Seat Belt with Pretensioner

Refer to “SERVICE AND DIAGNOSIS” of “SERVICE PRECAUTIONS” under “ON-VEHICLE SERVICE” in Sec-

tion 10B.

DISABLING AIR BAG SYSTEM

Refer to “DISABLING AIR BAG SYSTEM” of “SERVICE PRECAUTIONS” under “ON-VEHICLE SERVICE” in

Section 10B.

ENABLING AIR BAG SYSTEM

Refer to “ENABLING AIR BAG SYSTEM” of “SERVICE PRECAUTIONS” under “ON-VEHICLE SERVICE” in

Section 10B.

HANDLING AND STORAGE

Refer to “HANDLING AND STORAGE” of “SERVICE PRECAUTIONS” under “ON-VEHICLE SERVICE” in Sec-

tion 10B.

DISPOSAL

Refer to “DISPOSAL” of “SERVICE PRECAUTIONS” under “ON-VEHICLE SERVICE” in Section 10B. WARNING:

If replacing seat belt is necessary, replace buckle and ELR (or webbing) together as a set. This is for

the reason of ensuring locking of tongue plate with buckle.

If these parts are replaced individually, such a locking condition may become unreliable. For this rea-

son, SUZUKI will supply only the spare buckle and ELR (or webbing) in a set part.

WARNING:

When performing service on or around air bag system components or air bag system wiring, disable

the air bag system. Refer to “DISABLING AIR BAG SYSTEM” of “SERVICE PRECAUTIONS” under

“ON-VEHICLE SERVICE” in Section 10B.

Failure to follow procedures could result in possible air bag activation, personal injury or unneeded

air bag system repairs.

Page 371 of 447

RESTRAINT SYSTEM 10-5

FRONT SEAT BELT

WARNING:

Never attempt to disassemble or repair the seat belt pretensioner (retractor assembly). If any abnor-

mality is found, be sure to replace it with new one as an assembly.

Be sure to read “SERVICE PRECAUTIONS”, before starting to work and observe every precaution

during work. Neglecting them may result in personal injury or unactivation of the seat belt preten-

sioner when necessary.

1. Upper anchor 4. BuckleTightening torque

2. Lower anchor 5. Yellow connector (for seat belt pretensioner) (if equipped)

3. Retractor assembly 6. Retractor assembly upper mounting bolt

: After tightening lower bolt, tightening upper bolt

Page 372 of 447

10-6 RESTRAINT SYSTEM

REMOVAL

1) Disconnect negative battery cable at battery.

2) Disable air bag system. Refer to “DISABLING AIR BAG SYSTEM” of “SERVICE PRECAUTIONS” under

“ON-VEHICLE SERVICE” in Section 10B.

3) Remove center pillar lower trim.

4) Disconnect Yellow connector for seat belt pretensioner.

a) Release locking of lock lever.

b) After unlocked, disconnect to connector.

5) Remove front seat belts from the vehicle.

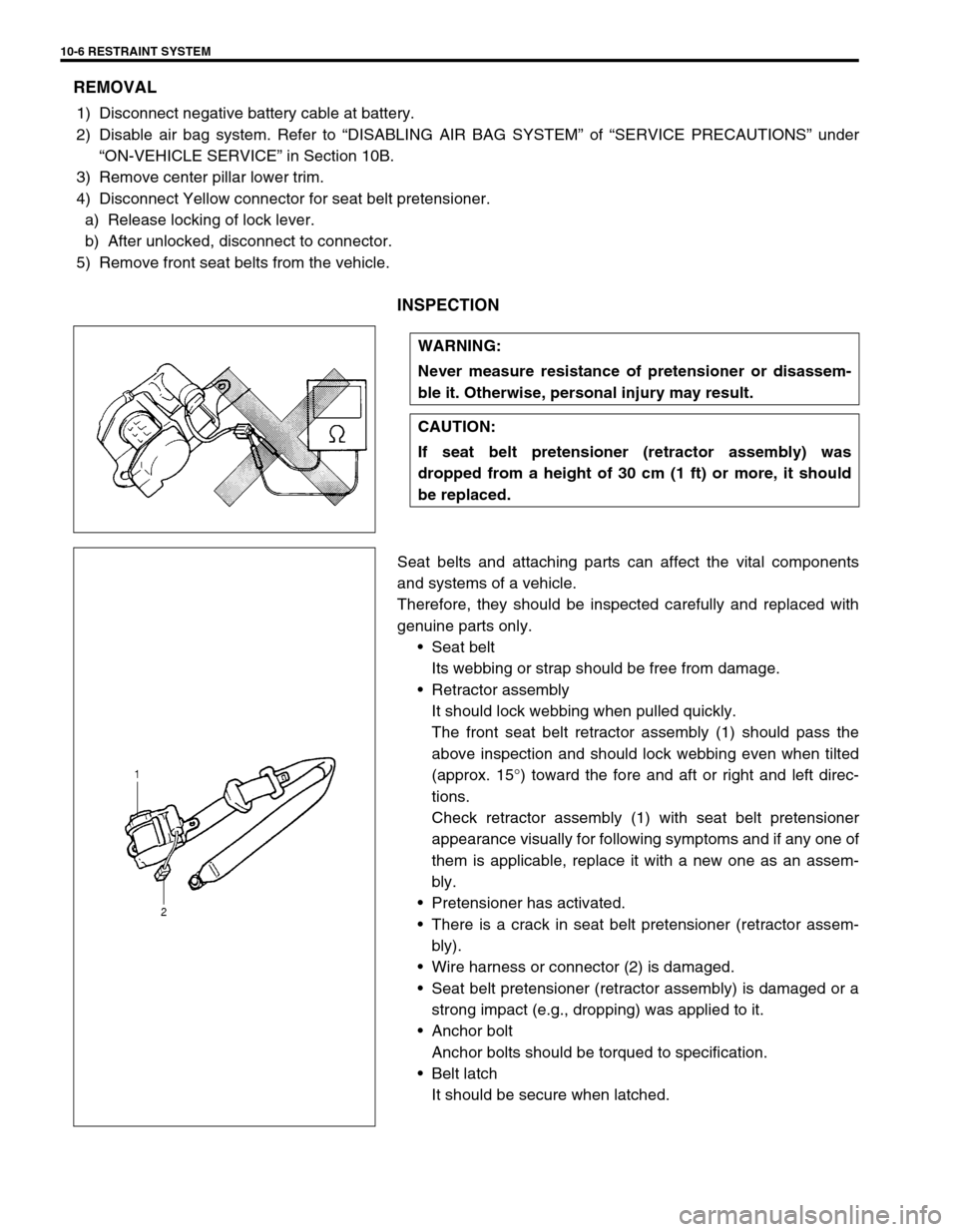

INSPECTION

Seat belts and attaching parts can affect the vital components

and systems of a vehicle.

Therefore, they should be inspected carefully and replaced with

genuine parts only.

Seat belt

Its webbing or strap should be free from damage.

Retractor assembly

It should lock webbing when pulled quickly.

The front seat belt retractor assembly (1) should pass the

above inspection and should lock webbing even when tilted

(approx. 15°) toward the fore and aft or right and left direc-

tions.

Check retractor assembly (1) with seat belt pretensioner

appearance visually for following symptoms and if any one of

them is applicable, replace it with a new one as an assem-

bly.

Pretensioner has activated.

There is a crack in seat belt pretensioner (retractor assem-

bly).

Wire harness or connector (2) is damaged.

Seat belt pretensioner (retractor assembly) is damaged or a

strong impact (e.g., dropping) was applied to it.

Anchor bolt

Anchor bolts should be torqued to specification.

Belt latch

It should be secure when latched. WARNING:

Never measure resistance of pretensioner or disassem-

ble it. Otherwise, personal injury may result.

CAUTION:

If seat belt pretensioner (retractor assembly) was

dropped from a height of 30 cm (1 ft) or more, it should

be replaced.

Page 374 of 447

10-8 RESTRAINT SYSTEM

REAR SEAT BELT

REMOVAL

Remove rear seat belts as shown in figure.

INSPECTION

Check the rear seat belt in the same way as “INSPECTION” of “FRONT SEAT BELT”.

INSTALLATION

Install the rear seat belt observing the same precautions as “INSTALLATION” of “FRONT SEAT BELT”. WARNING:

Be sure to read “SERVICE PRECAUTIONS” before starting to work and observe every precaution dur-

ing work.

1. Upper anchor 4. Buckle

2. Lower anchor Tightening torque

3. Retractor assembly

Page 375 of 447

AIR BAG SYSTEM 10B-1

6F1

6F2

6G

6H

6K

7A

7A1

7B1

7C1

7D

7E

7F

8A

8B

8C

8D

8E

9

10

10B

SECTION 10B

AIR BAG SYSTEM

CONTENTS

GENERAL DESCRIPTION .............................10B-3

SYSTEM COMPONENTS AND WIRING

LOCATION VIEW AND CONNECTORS..... 10B-4

SYSTEM WIRING DIAGRAM ..................... 10B-5

DIAGNOSIS ....................................................10B-6

DIAGNOSTIC TROUBLE CODE (DTC) ...... 10B-6

USE OF SPECIAL TOOL ............................ 10B-6

INTERMITTENTS AND POOR

CONNECTIONS .......................................... 10B-8

AIR BAG DIAGNOSTIC SYSTEM CHECK . 10B-9

AIR BAG DIAGNOSTIC SYSTEM

CHECK FLOW TABLE .............................. 10B-10

DTC CHECK ............................................. 10B-11

DTC CLEARANCE .................................... 10B-12

DTC TABLE .............................................. 10B-13

TABLE A - “AIR BAG” WARNING LAMP

COMES ON STEADY ............................... 10B-15

TABLE B - “AIR BAG” WARNING LAMP

DOES NOT COME ON ............................. 10B-15

TABLE C - “AIR BAG” WARNING LAMP

FLASHES .................................................. 10B-15

TABLE D - “AIR BAG” WARNING LAMP

CANNOT INDICATE FLASHING

PATTERN OF DTC ................................... 10B-15TABLE E - SDM CANNOT COMMUNICATE

THROUGH THE SERIAL DATA

CIRCUIT ................................................... 10B-21

DTC B1015 - PASSENGER AIR BAG

INITIATOR CIRCUIT RESISTANCE

HIGH ......................................................... 10B-23

DTC B1016 - PASSENGER AIR BAG

INITIATOR CIRCUIT RESISTANCE

LOW .......................................................... 10B-23

DTC B1018 - PASSENGER AIR BAG

INITIATOR CIRCUIT SHORT TO

GROUND .................................................. 10B-23

DTC B1019 - PASSENGER AIR BAG

INITIATOR CIRCUIT SHORT TO

POWER CIRCUIT ..................................... 10B-23

DTC B1021 – DRIVER AIR BAG

INITIATOR CIRCUIT RESISTANCE

HIGH ......................................................... 10B-29

DTC B1022 – DRIVER AIR BAG

INITIATOR CIRCUIT RESISTANCE

LOW .......................................................... 10B-29

DTC B1024 – DRIVER AIR BAG

INITIATOR CIRCUIT SHORT TO

GROUND .................................................. 10B-29 WARNING:

Service on or around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Please observe all WARNINGS and “Service Precautions” under “On-

Vehicle Service” in this section before performing service on or around the air bag system compo-

nents or wiring. Failure to follow WARNINGS could result in unintended activation of the system or

could render the system inoperative. Either of these two conditions may result in severe injury.

The procedures in this section must be followed in the order listed to disable the air bag system

temporarily and prevent false diagnostic trouble codes from setting. Failure to follow procedures

could result in possible activation of the air bag system, personal injury or otherwise unneeded air

bag system repairs.

CAUTION:

When fasteners are removed, always reinstall them at the same location from which they were

removed. If a fastener needs to be replaced, use the correct part number fastener for that application.

If the correct part number fastener is not available, a fastener of equal size and strength (or stronger)

may be used. Fasteners that are not reused, and those requiring thread-locking compound, will be

called out. The correct torque value must be used when installing fasteners that require it. If the above

conditions are not followed, parts or system damage could result.

Page 409 of 447

AIR BAG SYSTEM 10B-35

Fig. for STEP 1 and 2

Fig. for STEP 2

Fig. for STEP 3

Tightening torque

(A) : 09932-76010

(B) : 09932-75010

BASE OF

COLUMN

“Q01”

NOTE:

Upon completion of inspection and repair work, perform following items.

Reconnect all air bag system components, ensure all components are properly mounted.

Clear diagnostic trouble codes (Refer to DTC CLEARANCE), if any.

Repeat AIR BAG DIAGNOSTIC SYSTEM CHECK to confirm that the trouble has been corrected.

Page 422 of 447

10B-48 AIR BAG SYSTEM

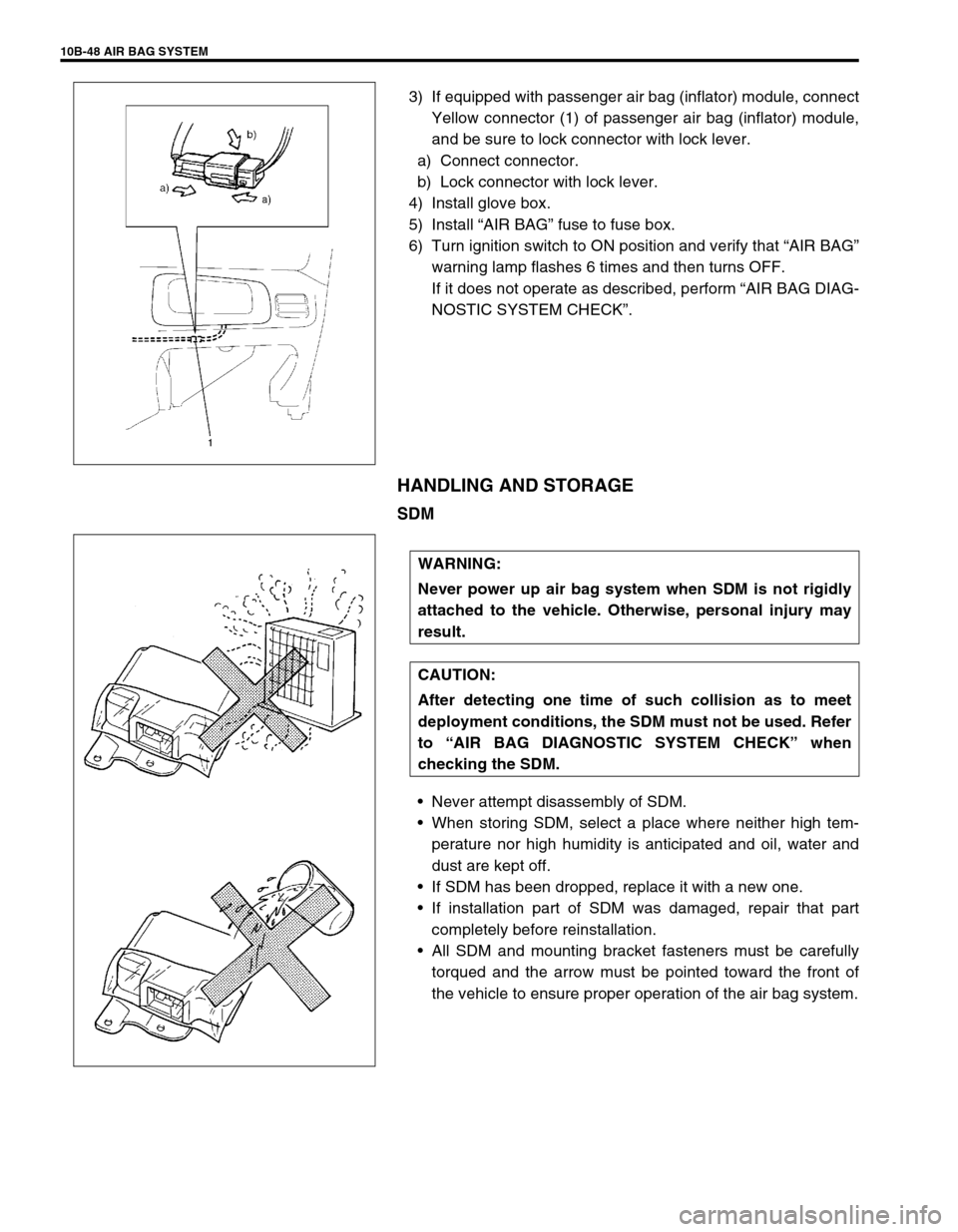

3) If equipped with passenger air bag (inflator) module, connect

Yellow connector (1) of passenger air bag (inflator) module,

and be sure to lock connector with lock lever.

a) Connect connector.

b) Lock connector with lock lever.

4) Install glove box.

5) Install “AIR BAG” fuse to fuse box.

6) Turn ignition switch to ON position and verify that “AIR BAG”

warning lamp flashes 6 times and then turns OFF.

If it does not operate as described, perform “AIR BAG DIAG-

NOSTIC SYSTEM CHECK”.

HANDLING AND STORAGE

SDM

Never attempt disassembly of SDM.

When storing SDM, select a place where neither high tem-

perature nor high humidity is anticipated and oil, water and

dust are kept off.

If SDM has been dropped, replace it with a new one.

If installation part of SDM was damaged, repair that part

completely before reinstallation.

All SDM and mounting bracket fasteners must be carefully

torqued and the arrow must be pointed toward the front of

the vehicle to ensure proper operation of the air bag system.

WARNING:

Never power up air bag system when SDM is not rigidly

attached to the vehicle. Otherwise, personal injury may

result.

CAUTION:

After detecting one time of such collision as to meet

deployment conditions, the SDM must not be used. Refer

to “AIR BAG DIAGNOSTIC SYSTEM CHECK” when

checking the SDM.

Page 431 of 447

AIR BAG SYSTEM 10B-57

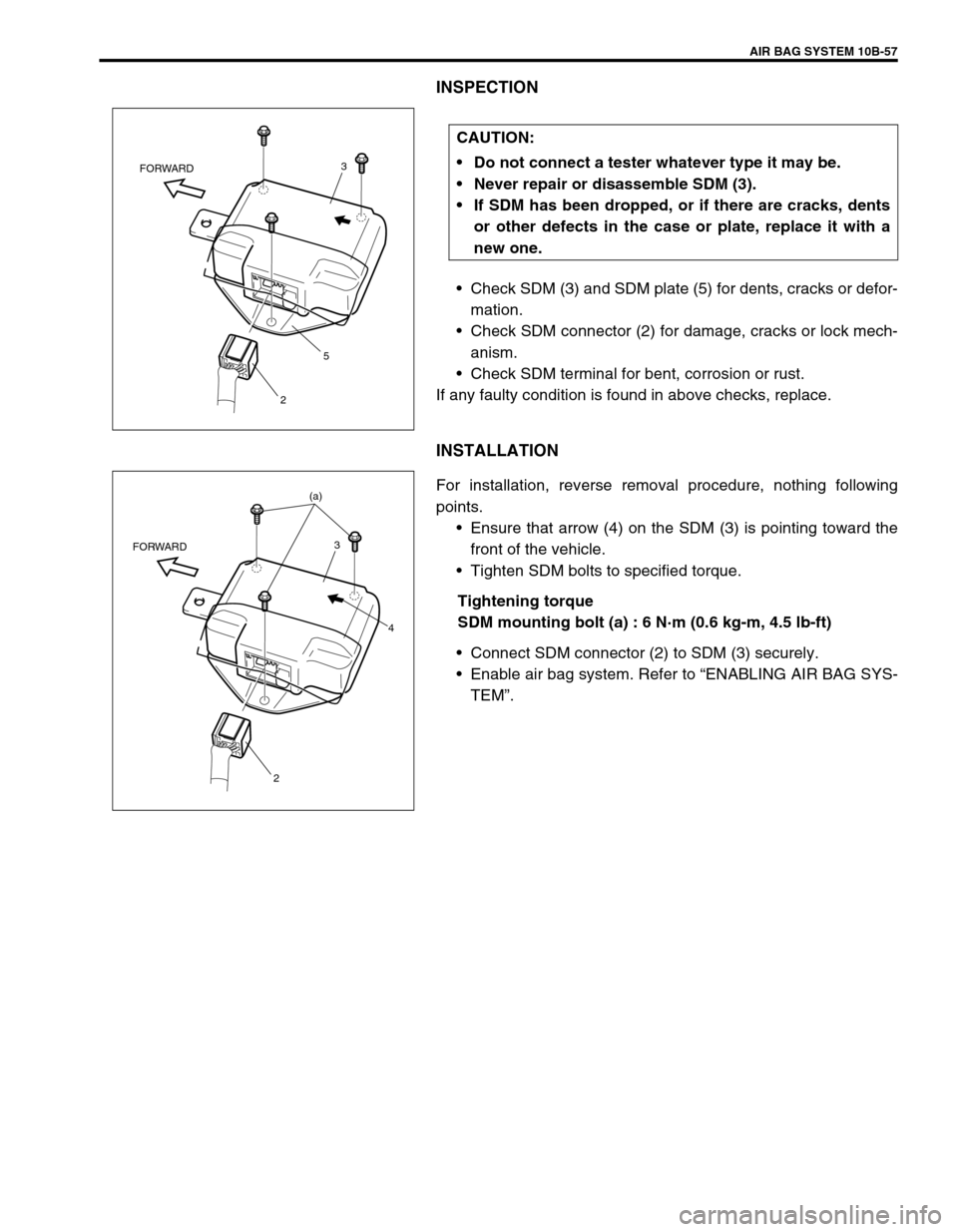

INSPECTION

Check SDM (3) and SDM plate (5) for dents, cracks or defor-

mation.

Check SDM connector (2) for damage, cracks or lock mech-

anism.

Check SDM terminal for bent, corrosion or rust.

If any faulty condition is found in above checks, replace.

INSTALLATION

For installation, reverse removal procedure, nothing following

points.

Ensure that arrow (4) on the SDM (3) is pointing toward the

front of the vehicle.

Tighten SDM bolts to specified torque.

Tightening torque

SDM mounting bolt (a) : 6 N·m (0.6 kg-m, 4.5 lb-ft)

Connect SDM connector (2) to SDM (3) securely.

Enable air bag system. Refer to “ENABLING AIR BAG SYS-

TEM”. CAUTION:

Do not connect a tester whatever type it may be.

Never repair or disassemble SDM (3).

If SDM has been dropped, or if there are cracks, dents

or other defects in the case or plate, replace it with a

new one.

3

5

2 FORWARD

(a)

3

4

2 FORWARD

Page 433 of 447

AIR BAG SYSTEM 10B-59

INSTALLATION

1) Install passenger air bag (inflator) module (1) to instrument

panel (2).

2) Tighten passenger air bag (inflator) module attaching bolts

to specified torque.

Tightening torque

Passenger air bag (inflator) module mounting bolt

(a) : 23 N·m (2.3 kg-m, 16.5 lb-ft)

3) Connect negative cable to battery.

4) Enable air bag system. Refer to “ENABLING AIR BAG SYS-

TEM”.

DRIVER AIR BAG (INFLATOR) MODULE

Refer to “DRIVER AIR BAG (INFLATOR) MODULE” in SECTION

3C for removal, inspection and installation.

CONTACT COIL AND COMBINATION SWITCH

ASSEMBLY

Refer to “CONTACT COIL AND COMBINATION SWITCH

ASSEMBLY” in SECTION 3C for removal, inspection and installa-

tion.

SEAT BELT PRETENSIONER (IF EQUIPPED)

Refer to “FRONT SEAT BELT WITH PRETENSIONER” in SEC-

TION 10 for removal, inspection and installation.

1

2

(a)