torque SUZUKI SWIFT 2000 1.G Transmission Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 447, PDF Size: 10.54 MB

Page 178 of 447

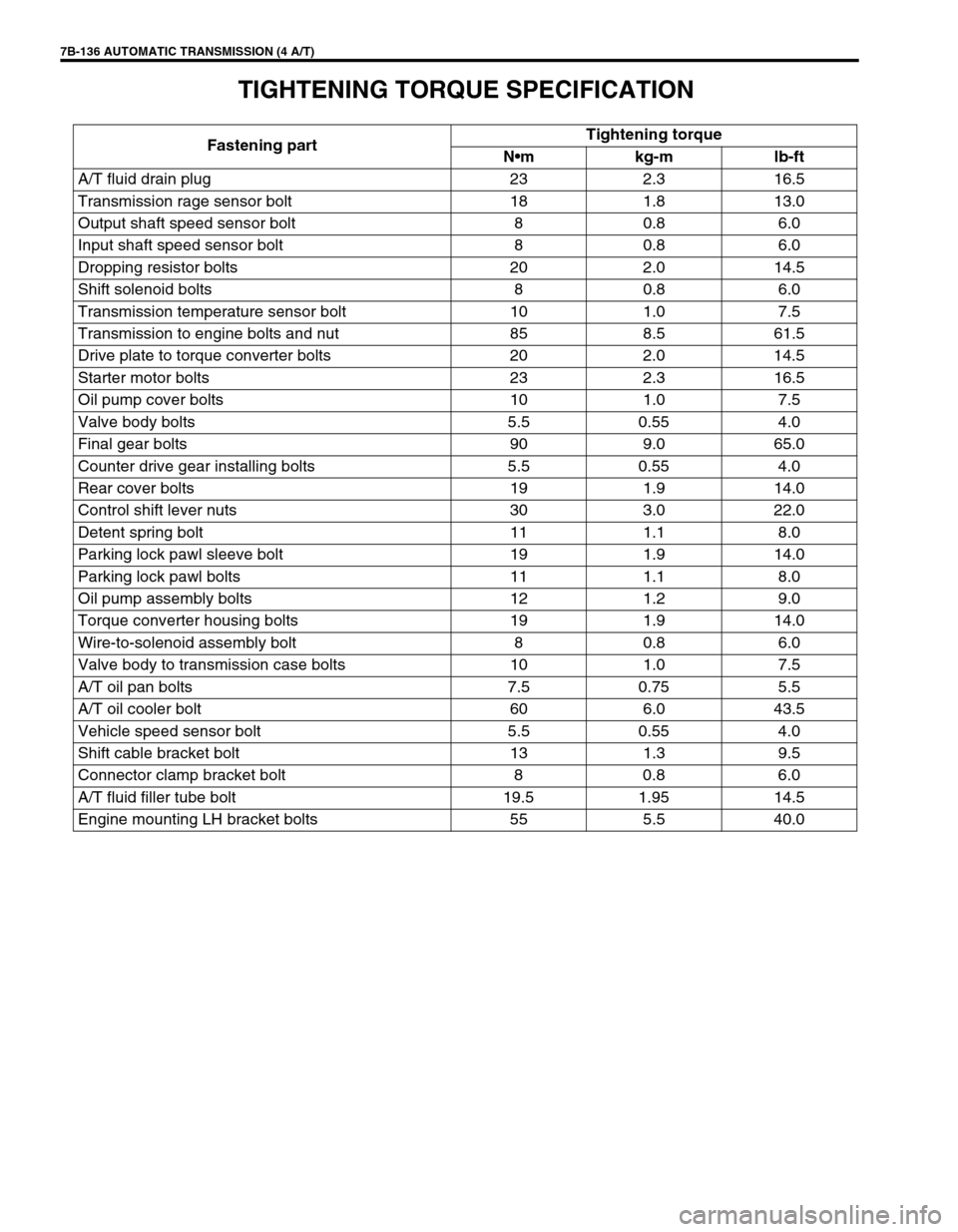

7B-136 AUTOMATIC TRANSMISSION (4 A/T)

TIGHTENING TORQUE SPECIFICATION

Fastening partTightening torque

Nm kg-m lb-ft

A/T fluid drain plug 23 2.3 16.5

Transmission rage sensor bolt 18 1.8 13.0

Output shaft speed sensor bolt 8 0.8 6.0

Input shaft speed sensor bolt 8 0.8 6.0

Dropping resistor bolts 20 2.0 14.5

Shift solenoid bolts 8 0.8 6.0

Transmission temperature sensor bolt 10 1.0 7.5

Transmission to engine bolts and nut 85 8.5 61.5

Drive plate to torque converter bolts 20 2.0 14.5

Starter motor bolts 23 2.3 16.5

Oil pump cover bolts 10 1.0 7.5

Valve body bolts 5.5 0.55 4.0

Final gear bolts 90 9.0 65.0

Counter drive gear installing bolts 5.5 0.55 4.0

Rear cover bolts 19 1.9 14.0

Control shift lever nuts 30 3.0 22.0

Detent spring bolt 11 1.1 8.0

Parking lock pawl sleeve bolt 19 1.9 14.0

Parking lock pawl bolts 11 1.1 8.0

Oil pump assembly bolts 12 1.2 9.0

Torque converter housing bolts 19 1.9 14.0

Wire-to-solenoid assembly bolt 8 0.8 6.0

Valve body to transmission case bolts 10 1.0 7.5

A/T oil pan bolts 7.5 0.75 5.5

A/T oil cooler bolt 60 6.0 43.5

Vehicle speed sensor bolt 5.5 0.55 4.0

Shift cable bracket bolt 13 1.3 9.5

Connector clamp bracket bolt 8 0.8 6.0

A/T fluid filler tube bolt 19.5 1.95 14.5

Engine mounting LH bracket bolts 55 5.5 40.0

Page 181 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-139

REQUIRED SERVICE MATERIAL

NOTE:

This kit includes the following items.

1. Storage case, 2. Operator’s manual, 3. SUZUKI scan tool (Tech-1A), 4. DLC cable,

5. Test lead / probe, 6. Power source cable, 7. DLC cable adaptor, 8. Self-test adaptor

MaterialRecommended SUZUKI product

(Part Number)Use

Automatic transmission fluid

An equivalent of DEXRON

®-III or

DEXRONR

®-IIEAutomatic transmission

Parts lubrication when installing

Sealant SUZUKI BOND No. 1215

(99000-31110)Case housing star-shaped recess

bolts

(3 pcs only)

Lithium grease SUZUKI SUPER GREASE C

(99000-25030)Retaining parts in place when

assembling

Oil seal lips

D-rings

O-rings

SUZUKI SUPER GREASE A

(99000-25010)Cable ends

Converter center cup

Thread lock cement THREAD LOCK 1322

(99000-32110)Final gear bolts

Torque converter housing bolts

Page 183 of 447

CLUTCH 7C-1

6F1

6F2

6G

6H

6K

7A1

7B1

7C1

7D

7E

7C

8A

8B

8C

8D

8E

9

10

10A

10B

SECTION 7C

CLUTCH

CONTENTS

GENERAL DESCRIPTION .............................. 7C-2

DIAGNOSIS ..................................................... 7C-3

ON-VEHICLE SERVICE .................................. 7C-4

CLUTCH CABLE .......................................... 7C-4

CLUTCH PEDAL AND CLUTCH PEDAL

BRACKET .................................................... 7C-6

CLUTCH PEDAL HEIGHT ....................... 7C-7

CLUTCH PEDAL FREE TRAVEL ............ 7C-7UNIT REPAIR OVERHAUL ............................. 7C-8

CLUTCH COVER, CLUTCH DISC AND

FLYWHEEL.................................................. 7C-8

CLUTCH RELEASE SYSTEM ................... 7C-11

TIGHTENING TORQUE SPECIFICATION.... 7C-14

REQUIRED SERVICE MATERIAL................ 7C-14

SPECIAL TOOL ............................................ 7C-14

WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System:

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

Page 186 of 447

7C-4 CLUTCH

ON-VEHICLE SERVICE

CLUTCH CABLE

REMOVAL

1) Disconnect negative cable at battery.

2) Remove clutch cable joint nut (1).

3) Remove joint pin (2) from clutch release lever (3).

4) Disconnect cable hook (1) from clutch pedal (4).

5) Remove clutch cable (3) from bracket (5) by turning cable

cap (2) about 90° as shown.

1. Clutch cable 6. Pedal bracket

2. Release lever 7. Adjusting bolt

3. Joint pin

: Apply grease 99000-25010 to joint pin.8. Lock nut

4. Joint nut 9. Clutch cable hook

: Apply grease 99000-25010 to cable hook.

5. Clutch pedal Tightening torque

Page 188 of 447

7C-6 CLUTCH

CLUTCH PEDAL AND CLUTCH PEDAL BRACKET

1. Clutch cable hook

: Apply grease 99000-25010 to cable

hook.7. Pedal spring

: Apply grease 99000-25010 to inside surface

of spring.13. Adjusting bolt cap

2. Clutch pedal bracket 8. Pedal shaft spacer

: Apply grease 99000-25010 to outside sur-

face of spacer.14. Adjusting bolt

3. Bolt 9. Pedal shaft 15. Lock nut

4.

Nut10.

Clutch pedalTightening torque

5. Pedal shaft nut 11. Pedal pad

6. Pedal bush 12. Pedal return cushion

Page 190 of 447

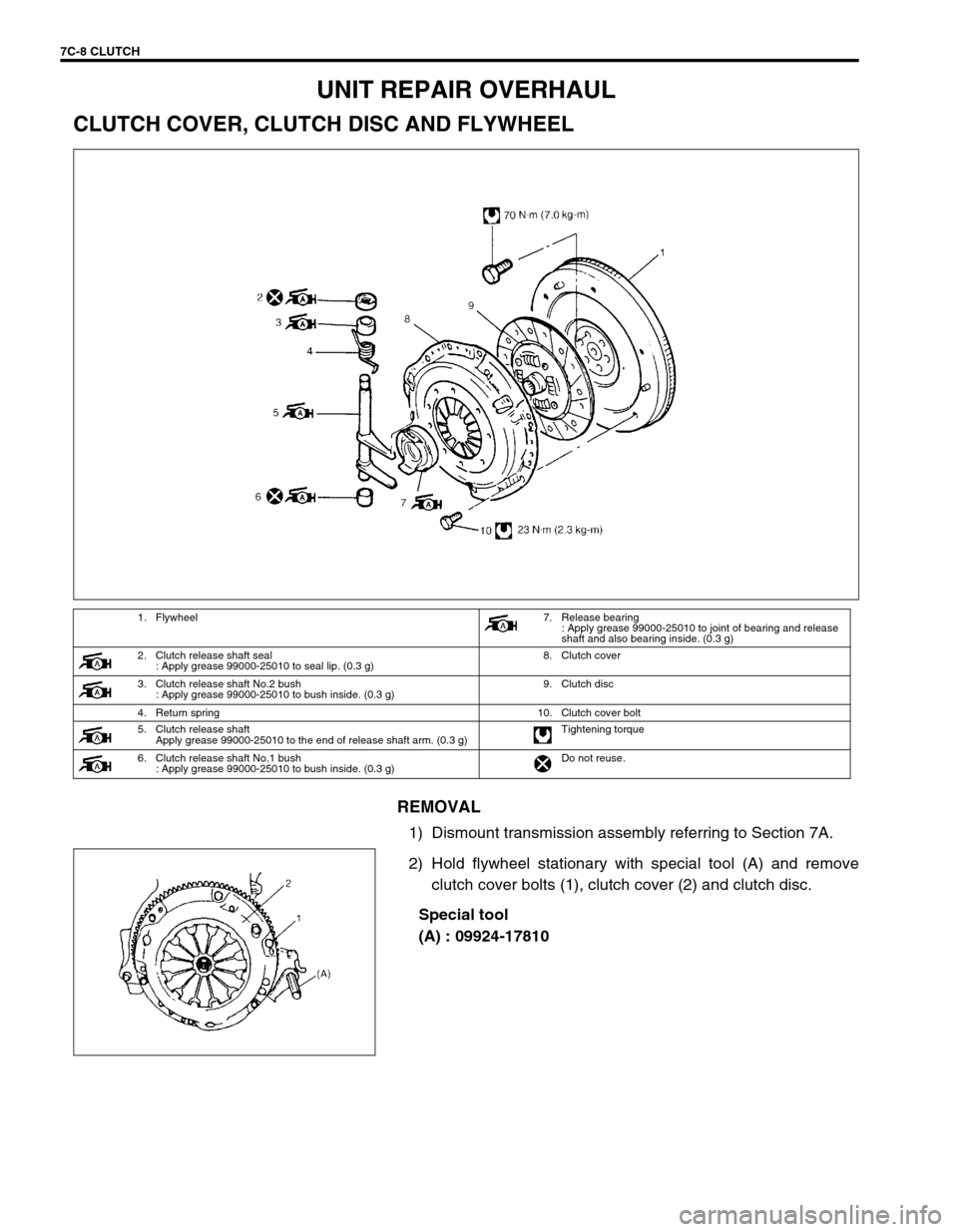

7C-8 CLUTCH

UNIT REPAIR OVERHAUL

CLUTCH COVER, CLUTCH DISC AND FLYWHEEL

REMOVAL

1) Dismount transmission assembly referring to Section 7A.

2) Hold flywheel stationary with special tool (A) and remove

clutch cover bolts (1), clutch cover (2) and clutch disc.

Special tool

(A) : 09924-17810

1. Flywheel7. Release bearing

: Apply grease 99000-25010 to joint of bearing and release

shaft and also bearing inside. (0.3 g)

2. Clutch release shaft seal

: Apply grease 99000-25010 to seal lip. (0.3 g)8. Clutch cover

3. Clutch release shaft No.2 bush

: Apply grease 99000-25010 to bush inside. (0.3 g)9. Clutch disc

4. Return spring 10. Clutch cover bolt

5. Clutch release shaft

Apply grease 99000-25010 to the end of release shaft arm. (0.3 g)Tightening torque

6. Clutch release shaft No.1 bush

: Apply grease 99000-25010 to bush inside. (0.3 g)Do not reuse.

Page 192 of 447

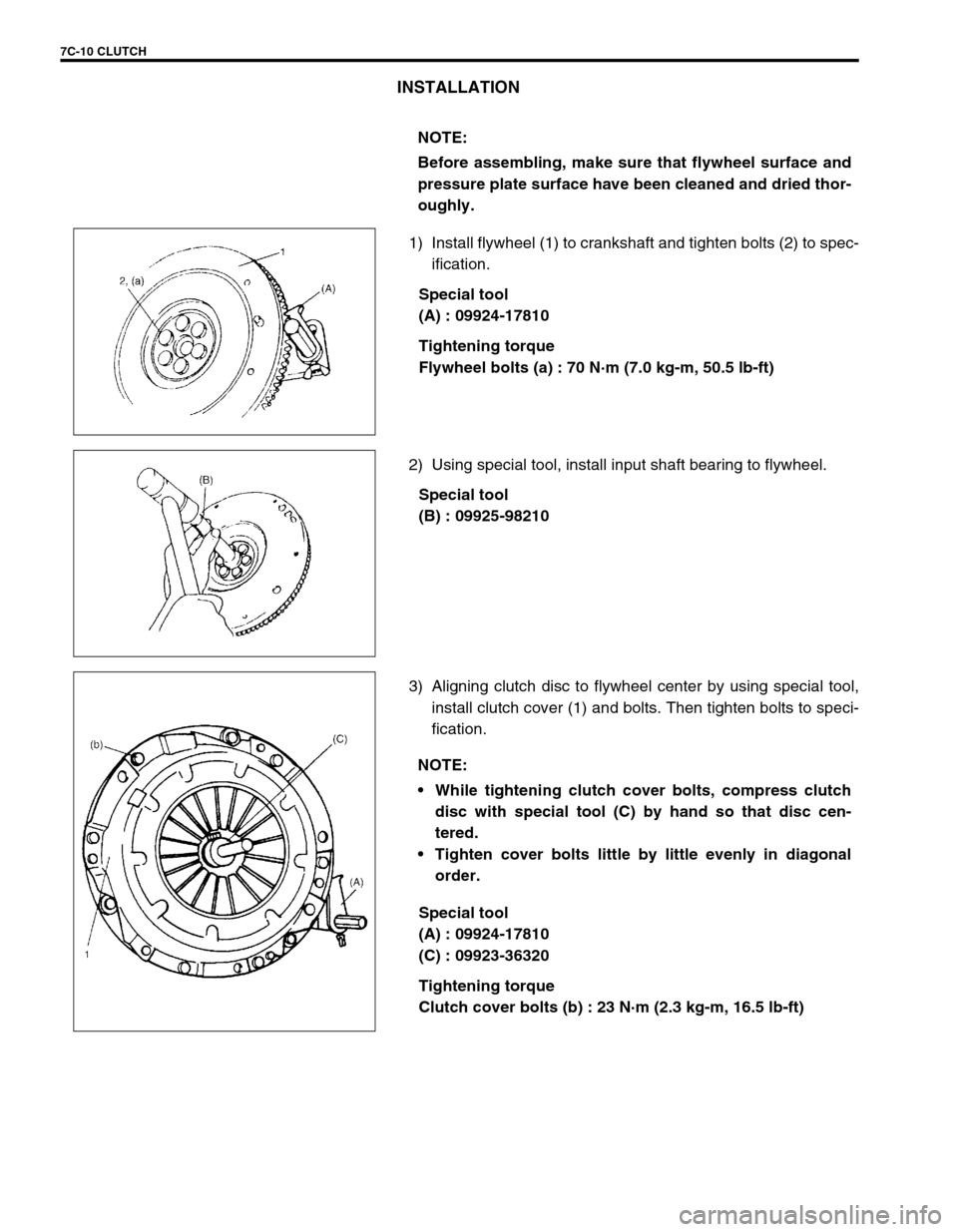

7C-10 CLUTCH

INSTALLATION

1) Install flywheel (1) to crankshaft and tighten bolts (2) to spec-

ification.

Special tool

(A) : 09924-17810

Tightening torque

Flywheel bolts (a) : 70 N·m (7.0 kg-m, 50.5 lb-ft)

2) Using special tool, install input shaft bearing to flywheel.

Special tool

(B) : 09925-98210

3) Aligning clutch disc to flywheel center by using special tool,

install clutch cover (1) and bolts. Then tighten bolts to speci-

fication.

Special tool

(A) : 09924-17810

(C) : 09923-36320

Tightening torque

Clutch cover bolts (b) : 23 N·m (2.3 kg-m, 16.5 lb-ft) NOTE:

Before assembling, make sure that flywheel surface and

pressure plate surface have been cleaned and dried thor-

oughly.

NOTE:

While tightening clutch cover bolts, compress clutch

disc with special tool (C) by hand so that disc cen-

tered.

Tighten cover bolts little by little evenly in diagonal

order.

Page 195 of 447

CLUTCH 7C-13

3) Apply grease to No.2 bush (1) inside and press-fit it by using

the same special tool as in removal.

“A” : Grease 99000-25010

Special tool

(C) : 09922-46010

4) Coat grease to shaft seal (2) lip and then install it till it is flush

with case surface. Use special tool for this installation and

face seal lip downward (inside).

“A” : Grease 99000-25010

Special tool

(D) : 09925-98221

5) Caulk seal at A by using caulking tool and hammer.

6) Hook return spring.

7) Apply grease to release bearing (1) inside and release shaft

arm (2), then set bearing.

“A” : Grease 99000-25010

8) Apply small amount of grease to input shaft (3) spline (0.3 g)

and front end (0.15 g) as well.

“B” : Grease 99000-25210

9) Set release lever to release shaft aligning their punch marks

(1), then tighten bolt.

Tightening torque

Release lever bolt (a) : 23 N·m (2.3 kg-m, 16.5 lb-ft)

Page 196 of 447

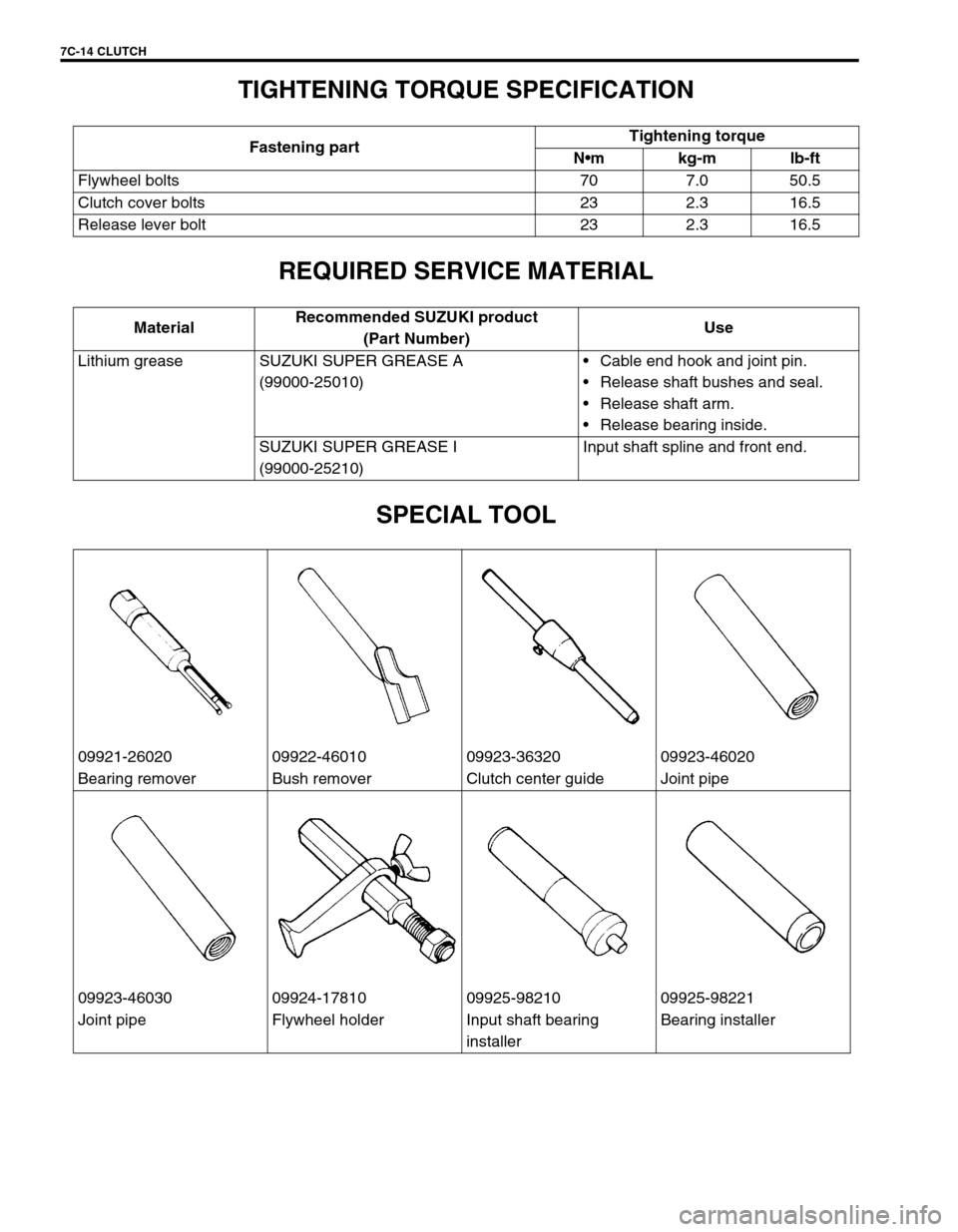

7C-14 CLUTCH

TIGHTENING TORQUE SPECIFICATION

REQUIRED SERVICE MATERIAL

SPECIAL TOOL

Fastening partTightening torque

Nm kg-m lb-ft

Flywheel bolts 70 7.0 50.5

Clutch cover bolts 23 2.3 16.5

Release lever bolt 23 2.3 16.5

MaterialRecommended SUZUKI product

(Part Number)Use

Lithium grease SUZUKI SUPER GREASE A

(99000-25010)Cable end hook and joint pin.

Release shaft bushes and seal.

Release shaft arm.

Release bearing inside.

SUZUKI SUPER GREASE I

(99000-25210)Input shaft spline and front end.

09921-26020 09922-46010 09923-36320 09923-46020

Bearing remover Bush remover Clutch center guide Joint pipe

09923-46030 09924-17810 09925-98210 09925-98221

Joint pipe Flywheel holder Input shaft bearing

installerBearing installer

Page 199 of 447

TRANSFER 7D-1

6F1

6F2

6G

6H

6K

7A

7A1

7B1

7C1

7E

7F

7D

8A

8B

8C

8D

8E

9

10

10A

10B

SECTION 7D

TRANSFER

CONTENTS

GENERAL DESCRIPTION ...............................7D-2

DIAGNOSIS ......................................................7D-2

ON-VEHICLE SERVICE ...................................7D-3

UNIT REPAIR OVERHAUL ..............................7D-4

UNIT DISMOUNTING ...................................7D-5

UNIT DISASSEMBLY ...................................7D-6

TRANSFER ASSEMBLY...........................7D-6

REDUCTION DRIVEN GEAR ...................7D-7

INTERMEDIATE SHAFT ...........................7D-8

TRANSFER OUTPUT RETAINER ............7D-9

COMPONENT INSPECTION ......................7D-10

UNIT ASSEMBLY .......................................7D-10REDUCTION DRIVEN GEAR ................. 7D-10

BEVEL GEAR SHIM ............................... 7D-11

TRANSFER OUTPUT RETAINER .......... 7D-12

RIGHT CASE .......................................... 7D-16

LEFT CASE............................................. 7D-17

TRANSFER ASSEMBLY ........................ 7D-17

BEVEL GEAR BACK LASH .................... 7D-18

UNIT INSTALLATION ................................. 7D-20

TIGHTENING TORQUE SPECIFICATION..... 7D-22

REQUIRED SERVICE MATERIAL................. 7D-22

SPECIAL TOOL ............................................. 7D-22