differential SUZUKI SWIFT 2000 1.G Transmission Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 447, PDF Size: 10.54 MB

Page 20 of 447

7A-20 MANUAL TRANSMISSION

11) Tapping input shaft end with plastic hammer, push it out as

assembly from case a little, then take out input shaft assem-

bly (1), counter shaft assembly (2), high speed gear shift

shaft (3) and low speed gear shift shaft (4) all at once.

12) Remove counter shaft left bearing cup from left case.

13) Remove differential side left oil seal also from left case.

RIGHT CASE

1) Remove differential gear assembly (1) from right case (2).

2) Remove bolt and then pull out VSS (3).

3) If input shaft right bearing has been left in right case, pull it

out by using special tools.

Remove input shaft oil seal (1) by using special tools.

Special tool

(A) : 09930-30104

(B) : 09923-74510

4) Also pull out countershaft right bearing cup (2) by using spe-

cial tools.

Special tool

09941-64511

09923-30104

Page 21 of 447

MANUAL TRANSMISSION 7A-21

SUB ASSEMBLY SERVICE

RIGHT CASE

1) Install input shaft oil seal (1) facing its spring side upward.

Use special tool and hammer for installation and apply

grease to oil seal lip.

“B” : Grease 99000-25010

Special tool

(A) : 09951-76010

2) Install countershaft right bearing cup (2) by using special

tools and hammer.

Special tool

(B) : 09924-74510

(C) : 09925-68210

LEFT CASE

1) If input oil gutter has been removed, install it with bolt to

which thread lock cement have been applied.

“A” : Thread lock cement 99000-32110

Tightening torque

Oil gutter bolt (a) : 10 N·m (1.0 kg-m, 7.5 lb-ft)

2) Install differential side left oil seal (1) facing its spring side

inward until it becomes flush with case surface by using spe-

cial tool with hammer, and then apply grease to its lip.

“B” : Grease 99000-25010

Special tool

(A) : 09913-75510

3) Install counter shaft left bearing cup into case bore by tap-

ping it with plastic hammer lightly. NOTE:

Before installation, wash each part and apply specified

gear oil to sliding faces of bearing and gear.

Page 30 of 447

7A-30 MANUAL TRANSMISSION

2) Insert each gear shift shaft into case and check that it moves

smoothly. If it doesn’t, correct by using oilstone, reamer or

the like.

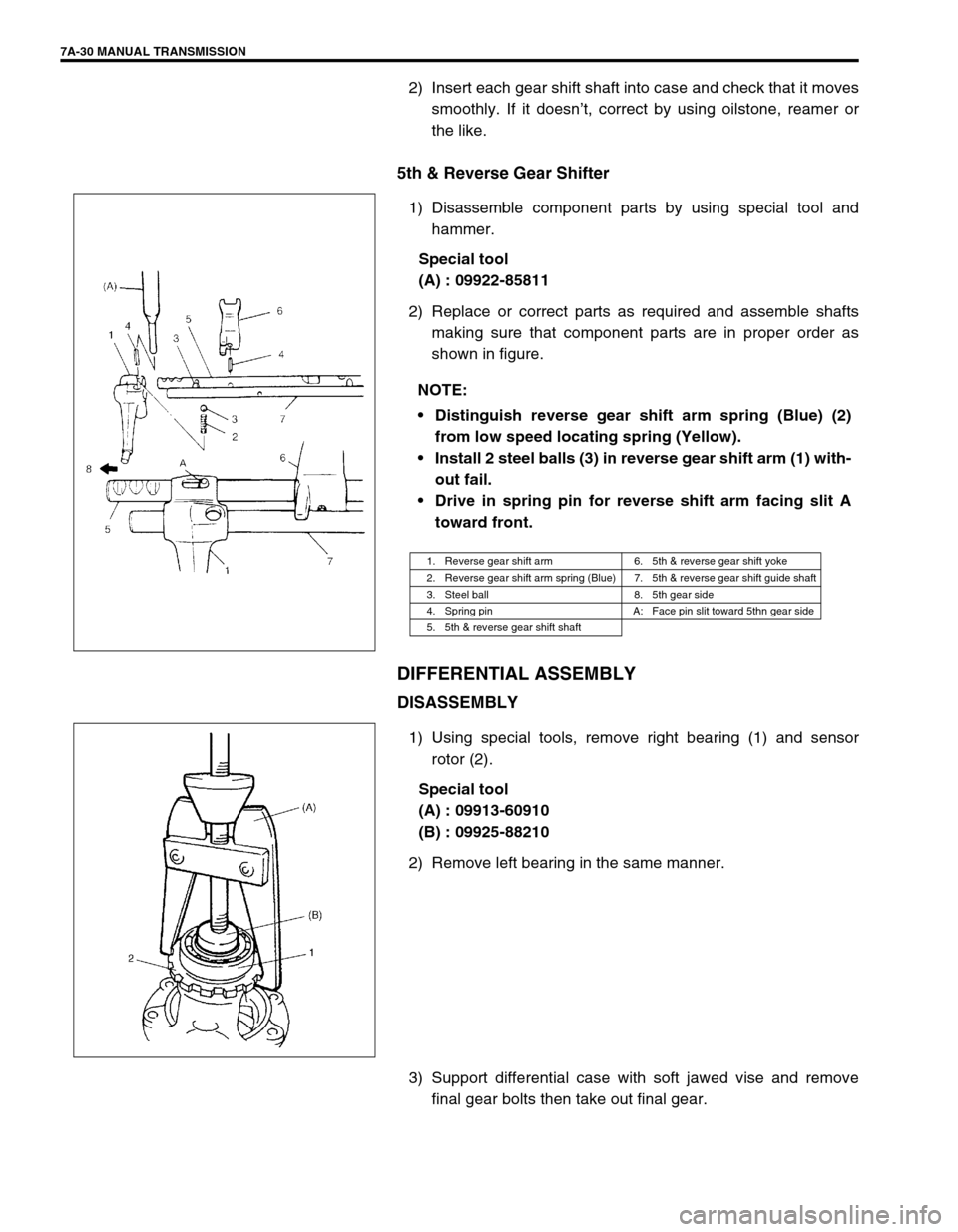

5th & Reverse Gear Shifter

1) Disassemble component parts by using special tool and

hammer.

Special tool

(A) : 09922-85811

2) Replace or correct parts as required and assemble shafts

making sure that component parts are in proper order as

shown in figure.

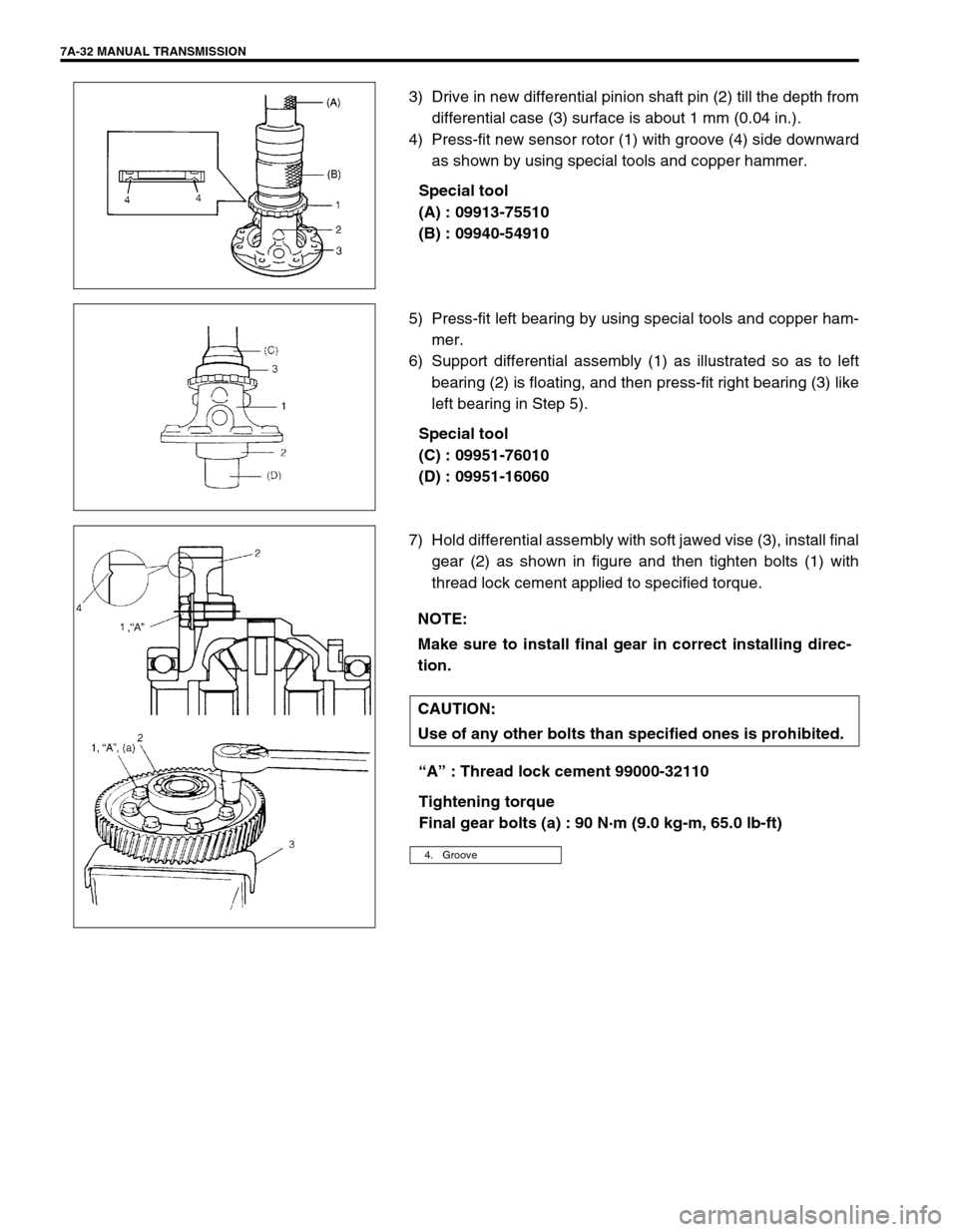

DIFFERENTIAL ASSEMBLY

DISASSEMBLY

1) Using special tools, remove right bearing (1) and sensor

rotor (2).

Special tool

(A) : 09913-60910

(B) : 09925-88210

2) Remove left bearing in the same manner.

3) Support differential case with soft jawed vise and remove

final gear bolts then take out final gear. NOTE:

Distinguish reverse gear shift arm spring (Blue) (2)

from low speed locating spring (Yellow).

Install 2 steel balls (3) in reverse gear shift arm (1) with-

out fail.

Drive in spring pin for reverse shift arm facing slit A

toward front.

1. Reverse gear shift arm 6. 5th & reverse gear shift yoke

2. Reverse gear shift arm spring (Blue) 7. 5th & reverse gear shift guide shaft

3. Steel ball 8. 5th gear side

4. Spring pin A: Face pin slit toward 5thn gear side

5. 5th & reverse gear shift shaft

Page 31 of 447

MANUAL TRANSMISSION 7A-31

4) Using special tool and hammer, drive out differential pinion

shaft pin and then disassemble component parts.

Special tool

(C) : 09922-85811

ADJUSTMENT AND REASSEMBLY

Judging from abnormality noted before disassembly and what is

found through visual check of component parts after disassembly,

prepare replacing parts and proceed to reassembly. Make sure

that all parts are clean.

1) Assemble differential gear and measure thrust play of differ-

ential gear as follows.

Differential gear thrust play

: 0.03 – 0.31 mm (0.001 – 0.012 in.)

Left side

Hold differential assembly with soft jawed vise and apply

measuring tip of dial gauge to top surface of gear.

Using 2 screwdrivers (1), move gear (2) up and down and

read movement of dial gauge pointer.

Special tool

(A) : 09900-20606

(B) : 09900-20701

Right side

Using similar procedure to the above, set dial gauge tip to

gear (1) shoulder.

Move gear up and down by hand and read dial gauge.

Special tool

(A) : 09900-20606

(B) : 09900-20701

2) If thrust play is out of specification, select suitable thrust

washer from among the following available size, install it and

check again that specified gear play is obtained.

Available thrust washer thickness

0.9, 0.95, 1.0, 1.05, 1.1, 1.15 and 1.2 mm

(0.035, 0.037, 0.039, 0.041, 0.043, 0.045, and 0.047 in.)

1. Differential case

2. Differential gear

3. Differential pinion shaft

Page 32 of 447

7A-32 MANUAL TRANSMISSION

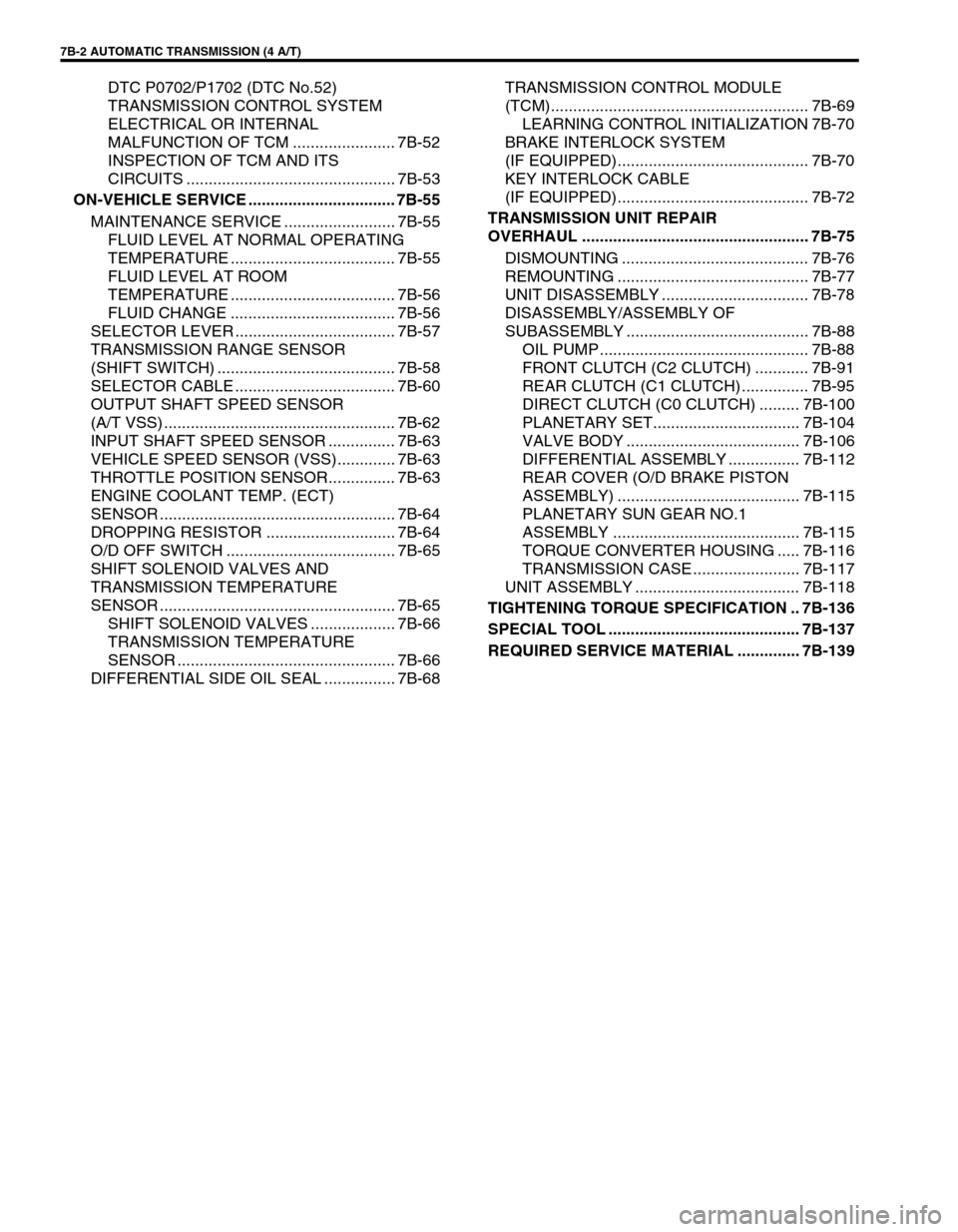

3) Drive in new differential pinion shaft pin (2) till the depth from

differential case (3) surface is about 1 mm (0.04 in.).

4) Press-fit new sensor rotor (1) with groove (4) side downward

as shown by using special tools and copper hammer.

Special tool

(A) : 09913-75510

(B) : 09940-54910

5) Press-fit left bearing by using special tools and copper ham-

mer.

6) Support differential assembly (1) as illustrated so as to left

bearing (2) is floating, and then press-fit right bearing (3) like

left bearing in Step 5).

Special tool

(C) : 09951-76010

(D) : 09951-16060

7) Hold differential assembly with soft jawed vise (3), install final

gear (2) as shown in figure and then tighten bolts (1) with

thread lock cement applied to specified torque.

“A” : Thread lock cement 99000-32110

Tightening torque

Final gear bolts (a) : 90 N·m (9.0 kg-m, 65.0 lb-ft)

NOTE:

Make sure to install final gear in correct installing direc-

tion.

CAUTION:

Use of any other bolts than specified ones is prohibited.

4. Groove

Page 33 of 447

MANUAL TRANSMISSION 7A-33

UNIT ASSEMBLY

DIFFERENTIAL TO LEFT CASE

ASSEMBLY

1) Install differential assembly (1) into right case (2).

2) Insert VSS (3) with grease applied to its O-ring, then tighten

it with bolt.

Grease 99000-25010

3) Join input shaft (5), countershaft (4), low speed gear shift

shaft (2) and high speed gear shift shaft (3) assemblies all

together, then install them into right case (1).

4) Install 5th & reverse gear shift shaft (1) with 5th & reverse

gear shift guide shaft (2) into right case (5). Reverse gear

shift arm (4) has to be joined with reverse gear shift lever (3)

at the same time.

5) Place reverse gear shift lever, fasten it with bolts after apply-

ing thread lock cement.

“A” : Thread lock cement 99000-32110

Tightening torque

Revers gear shift lever bolts

(a) : 23 N·m (2.3 kg-m, 17.0 lb-ft)

Distance between lever end and shaft bore

“a” : 5 mm (0.2 in.)

CAUTION:

Take care not to damage oil seal lip by input shaft, or oil

leakage may take place.

NOTE:

Input shaft right bearing on shaft can be installed into

right case by tapping shaft with plastic hammer.

Check to make sure that counter shaft is engaged with

final gear while installing.

NOTE:

When installing reverse gear shift lever, set it as the

following specification.

Page 44 of 447

7B-2 AUTOMATIC TRANSMISSION (4 A/T)

DTC P0702/P1702 (DTC No.52)

TRANSMISSION CONTROL SYSTEM

ELECTRICAL OR INTERNAL

MALFUNCTION OF TCM ....................... 7B-52

INSPECTION OF TCM AND ITS

CIRCUITS ............................................... 7B-53

ON-VEHICLE SERVICE ................................. 7B-55

MAINTENANCE SERVICE ......................... 7B-55

FLUID LEVEL AT NORMAL OPERATING

TEMPERATURE ..................................... 7B-55

FLUID LEVEL AT ROOM

TEMPERATURE ..................................... 7B-56

FLUID CHANGE ..................................... 7B-56

SELECTOR LEVER .................................... 7B-57

TRANSMISSION RANGE SENSOR

(SHIFT SWITCH) ........................................ 7B-58

SELECTOR CABLE .................................... 7B-60

OUTPUT SHAFT SPEED SENSOR

(A/T VSS) .................................................... 7B-62

INPUT SHAFT SPEED SENSOR ............... 7B-63

VEHICLE SPEED SENSOR (VSS)............. 7B-63

THROTTLE POSITION SENSOR............... 7B-63

ENGINE COOLANT TEMP. (ECT)

SENSOR ..................................................... 7B-64

DROPPING RESISTOR ............................. 7B-64

O/D OFF SWITCH ...................................... 7B-65

SHIFT SOLENOID VALVES AND

TRANSMISSION TEMPERATURE

SENSOR ..................................................... 7B-65

SHIFT SOLENOID VALVES ................... 7B-66

TRANSMISSION TEMPERATURE

SENSOR ................................................. 7B-66

DIFFERENTIAL SIDE OIL SEAL ................ 7B-68TRANSMISSION CONTROL MODULE

(TCM).......................................................... 7B-69

LEARNING CONTROL INITIALIZATION 7B-70

BRAKE INTERLOCK SYSTEM

(IF EQUIPPED)........................................... 7B-70

KEY INTERLOCK CABLE

(IF EQUIPPED)........................................... 7B-72

TRANSMISSION UNIT REPAIR

OVERHAUL ................................................... 7B-75

DISMOUNTING .......................................... 7B-76

REMOUNTING ........................................... 7B-77

UNIT DISASSEMBLY ................................. 7B-78

DISASSEMBLY/ASSEMBLY OF

SUBASSEMBLY ......................................... 7B-88

OIL PUMP ............................................... 7B-88

FRONT CLUTCH (C2 CLUTCH) ............ 7B-91

REAR CLUTCH (C1 CLUTCH) ............... 7B-95

DIRECT CLUTCH (C0 CLUTCH) ......... 7B-100

PLANETARY SET................................. 7B-104

VALVE BODY ....................................... 7B-106

DIFFERENTIAL ASSEMBLY ................ 7B-112

REAR COVER (O/D BRAKE PISTON

ASSEMBLY) ......................................... 7B-115

PLANETARY SUN GEAR NO.1

ASSEMBLY .......................................... 7B-115

TORQUE CONVERTER HOUSING ..... 7B-116

TRANSMISSION CASE ........................ 7B-117

UNIT ASSEMBLY ..................................... 7B-118

TIGHTENING TORQUE SPECIFICATION .. 7B-136

SPECIAL TOOL ........................................... 7B-137

REQUIRED SERVICE MATERIAL .............. 7B-139

Page 45 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-3

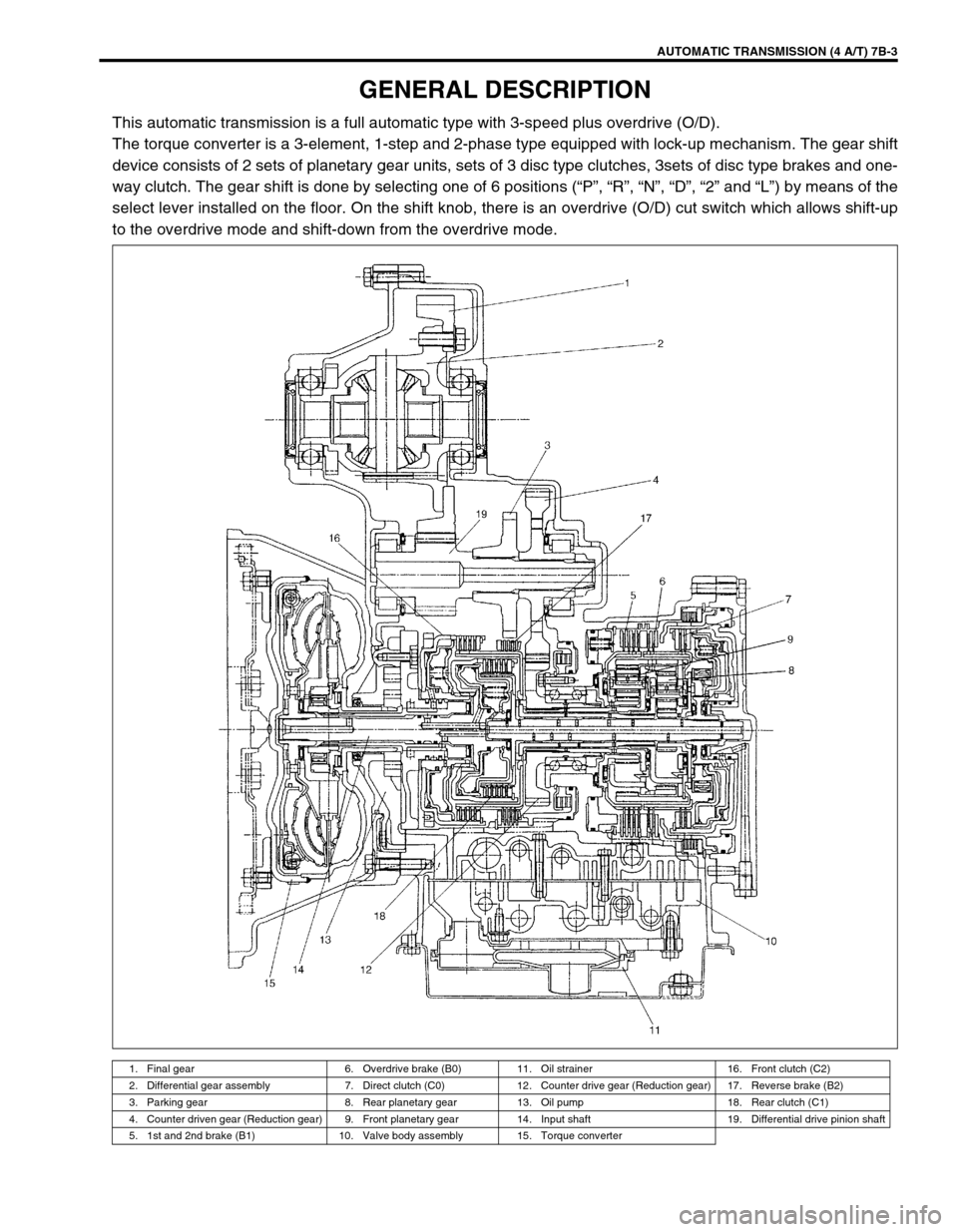

GENERAL DESCRIPTION

This automatic transmission is a full automatic type with 3-speed plus overdrive (O/D).

The torque converter is a 3-element, 1-step and 2-phase type equipped with lock-up mechanism. The gear shift

device consists of 2 sets of planetary gear units, sets of 3 disc type clutches, 3sets of disc type brakes and one-

way clutch. The gear shift is done by selecting one of 6 positions (“P”, “R”, “N”, “D”, “2” and “L”) by means of the

select lever installed on the floor. On the shift knob, there is an overdrive (O/D) cut switch which allows shift-up

to the overdrive mode and shift-down from the overdrive mode.

1. Final gear 6. Overdrive brake (B0) 11. Oil strainer 16. Front clutch (C2)

2. Differential gear assembly 7. Direct clutch (C0) 12. Counter drive gear (Reduction gear) 17. Reverse brake (B2)

3. Parking gear 8. Rear planetary gear 13. Oil pump 18. Rear clutch (C1)

4. Counter driven gear (Reduction gear) 9. Front planetary gear 14. Input shaft 19. Differential drive pinion shaft

5. 1st and 2nd brake (B1) 10. Valve body assembly 15. Torque converter

Page 46 of 447

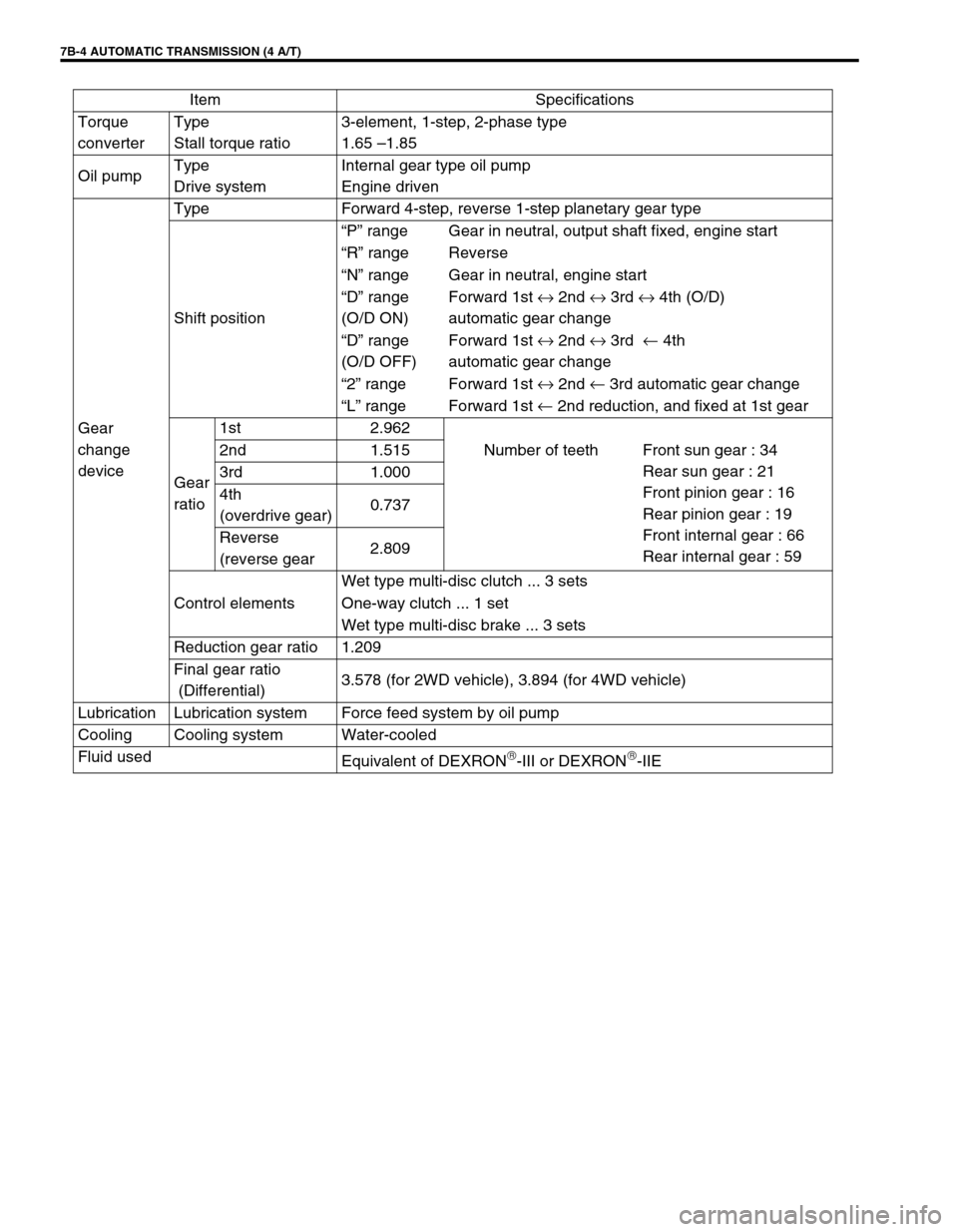

7B-4 AUTOMATIC TRANSMISSION (4 A/T)

Item Specifications

Torque

converterType

Stall torque ratio3-element, 1-step, 2-phase type

1.65 –1.85

Oil pumpType

Drive systemInternal gear type oil pump

Engine driven

Gear

change

deviceType Forward 4-step, reverse 1-step planetary gear type

Shift position“P” range Gear in neutral, output shaft fixed, engine start

“R” range Reverse

“N” range Gear in neutral, engine start

“D” range

(O/D ON)Forward 1st ↔

2nd ↔

3rd ↔

4th (O/D)

automatic gear change

“D” range

(O/D OFF)Forward 1st ↔

2nd ↔

3rd ←

4th

automatic gear change

“2” range Forward 1st ↔

2nd ←

3rd automatic gear change

“L” range Forward 1st ←

2nd reduction, and fixed at 1st gear

Gear

ratio1st 2.962

2nd 1.515 Number of teeth Front sun gear : 34

Rear sun gear : 21

Front pinion gear : 16

Rear pinion gear : 19

Front internal gear : 66

Rear internal gear : 59 3rd 1.000

4th

(overdrive gear)0.737

Reverse

(reverse gear2.809

Control elementsWet type multi-disc clutch ... 3 sets

One-way clutch ... 1 set

Wet type multi-disc brake ... 3 sets

Reduction gear ratio 1.209

Final gear ratio

(Differential)3.578 (for 2WD vehicle), 3.894 (for 4WD vehicle)

Lubrication Lubrication system Force feed system by oil pump

Cooling Cooling system Water-cooled

Fluid used

Equivalent of DEXRON

-III or DEXRON-IIE

Page 110 of 447

7B-68 AUTOMATIC TRANSMISSION (4 A/T)

DIFFERENTIAL SIDE OIL SEAL

REPLACEMENT

1) Lift up vehicle and drain transmission oil.

2) Remove drive shaft joints from differential gear of transmis-

sion.

Refer to Section 4 for procedure to disconnect drive shaft

joints.

For differential side oil seal removal, it is not necessary to

remove drive shafts from steering knuckle.

For 4WD vehicle, remove transfer referring to Section 7D.

3) Remove differential side oil seal (1) by using flat end rod or

like.

4) Install new differential side oil seal by using special tool.

Special tool

(A) : 09940-53111

(B) : 09913-75510

5) Install drive shaft referring to Section 4.

6) Refill A/T fluid referring to “FLUID CHANGE” in this section. NOTE:

For oil seal installation, press-fit oil seal so that transmis-

sion case end face is flush with oil seal end face.

2. Steering gear box

3. A/T oil pan

4. Torque converter hous-

ing

5. Transmission case