engine oil SUZUKI SWIFT 2000 1.G Transmission Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 447, PDF Size: 10.54 MB

Page 120 of 447

7B-78 AUTOMATIC TRANSMISSION (4 A/T)

UNIT DISASSEMBLY

1) Remove torque converter (1).

2) Remove engine mounting LH bracket.

3) Remove oil cooler (1) and battery ground cable (2) (if still

attached). CAUTION:

Thoroughly clean transmission exterior before over-

hauling it.

Keep working table, tools and hands clean while over-

hauling.

Use special care to handle aluminum parts so as not to

damage them.

Do not expose removed parts to dust. Keep them

always clean.

Page 178 of 447

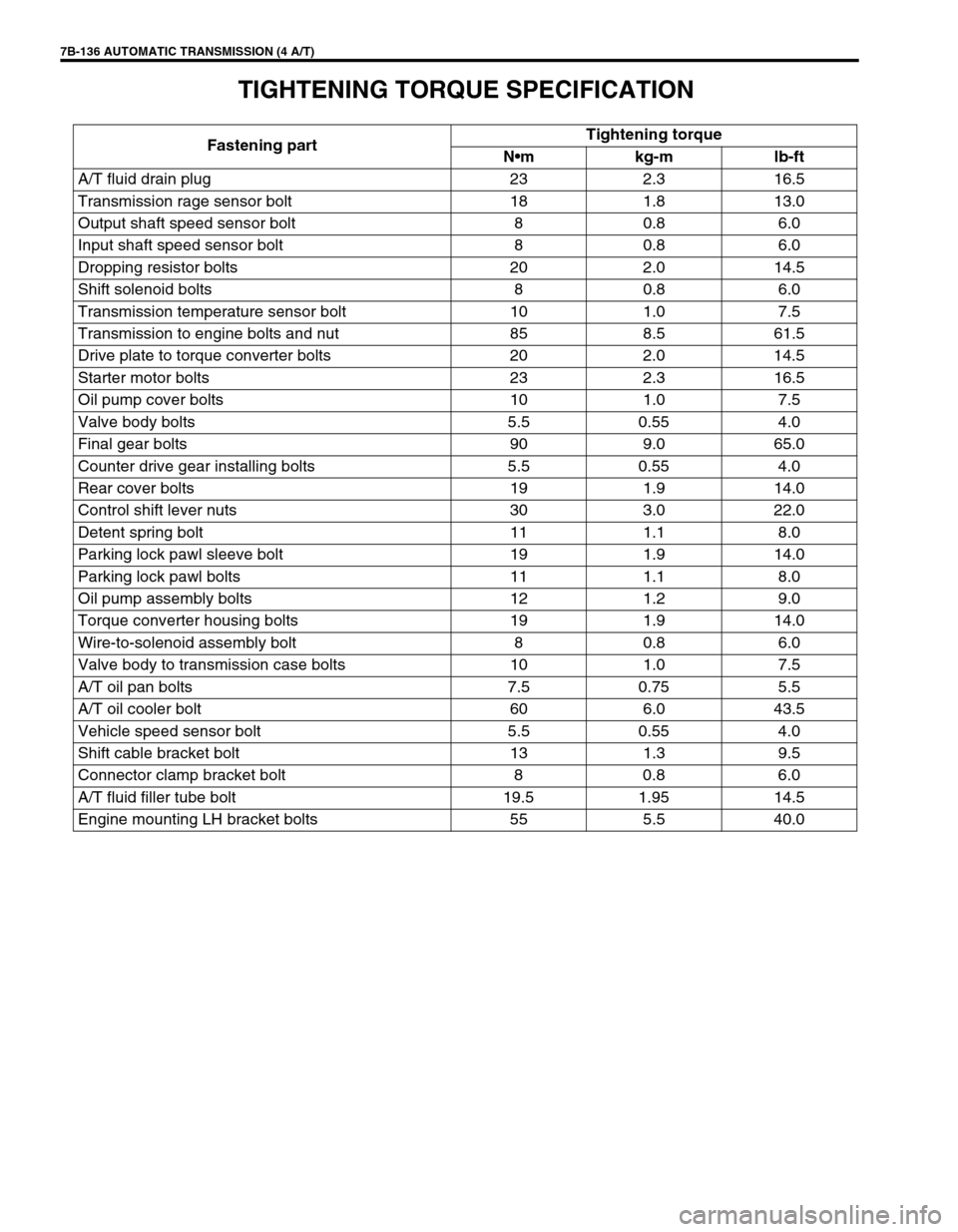

7B-136 AUTOMATIC TRANSMISSION (4 A/T)

TIGHTENING TORQUE SPECIFICATION

Fastening partTightening torque

Nm kg-m lb-ft

A/T fluid drain plug 23 2.3 16.5

Transmission rage sensor bolt 18 1.8 13.0

Output shaft speed sensor bolt 8 0.8 6.0

Input shaft speed sensor bolt 8 0.8 6.0

Dropping resistor bolts 20 2.0 14.5

Shift solenoid bolts 8 0.8 6.0

Transmission temperature sensor bolt 10 1.0 7.5

Transmission to engine bolts and nut 85 8.5 61.5

Drive plate to torque converter bolts 20 2.0 14.5

Starter motor bolts 23 2.3 16.5

Oil pump cover bolts 10 1.0 7.5

Valve body bolts 5.5 0.55 4.0

Final gear bolts 90 9.0 65.0

Counter drive gear installing bolts 5.5 0.55 4.0

Rear cover bolts 19 1.9 14.0

Control shift lever nuts 30 3.0 22.0

Detent spring bolt 11 1.1 8.0

Parking lock pawl sleeve bolt 19 1.9 14.0

Parking lock pawl bolts 11 1.1 8.0

Oil pump assembly bolts 12 1.2 9.0

Torque converter housing bolts 19 1.9 14.0

Wire-to-solenoid assembly bolt 8 0.8 6.0

Valve body to transmission case bolts 10 1.0 7.5

A/T oil pan bolts 7.5 0.75 5.5

A/T oil cooler bolt 60 6.0 43.5

Vehicle speed sensor bolt 5.5 0.55 4.0

Shift cable bracket bolt 13 1.3 9.5

Connector clamp bracket bolt 8 0.8 6.0

A/T fluid filler tube bolt 19.5 1.95 14.5

Engine mounting LH bracket bolts 55 5.5 40.0

Page 185 of 447

CLUTCH 7C-3

DIAGNOSIS

Condition Possible Cause Correction

Slipping

Improper clutch pedal free travel Adjust free travel.

Worn or oily clutch disc facing Replace disc.

Warped disc, pressure plate or flywheel surface Replace disc, clutch cover or

flywheel.

Weakened diaphragm spring Replace clutch cover.

Rusted clutch cable Replace cable.

Dragging clutch

Improper clutch pedal free travel Adjust free travel.

Weakened diaphragm spring, or worn spring tip Replace clutch cover.

Rusted input shaft splines Lubricate.

Damaged or worn splines of transmission input shaft Replace input shaft.

Excessively wobbly clutch disc Replace disc.

Clutch facings broken or dirty with oil Replace disc.

Clutch vibration

Glazed (glass-like) clutch facings Repair or replace disc.

Clutch facings dirty with oil Replace disc.

Release bearing slides unsmoothly on input shaft

bearing retainerLubricate or replace input

shaft bearing retainer.

Wobbly clutch disc, or poor facing contact Replace disc.

Weakened torsion springs in clutch disc Replace disc.

Clutch disc rivets loose Replace disc.

Distorted pressure plate or flywheel surface Replace clutch cover or fly-

wheel.

Weakened engine mounting or loosened engine

mounting bolt or nutRetighten or replace mount-

ing.

Noisy clutch

Worn or broken release bearing Replace release bearing.

Input shaft front bearing worn down Replace input shaft bearing.

Excessive rattle of clutch disc hub Replace disc.

Cracked clutch disc Replace disc.

Pressure plate and diaphragm spring rattling Replace clutch cover.

Grabbing clutch

Clutch disc facings soaked with oil Replace disc.

Clutch disc facings excessively worn Replace disc.

Rivet heads showing out of facing Replace disc.

Weakened torsion springs Replace disc.

Page 201 of 447

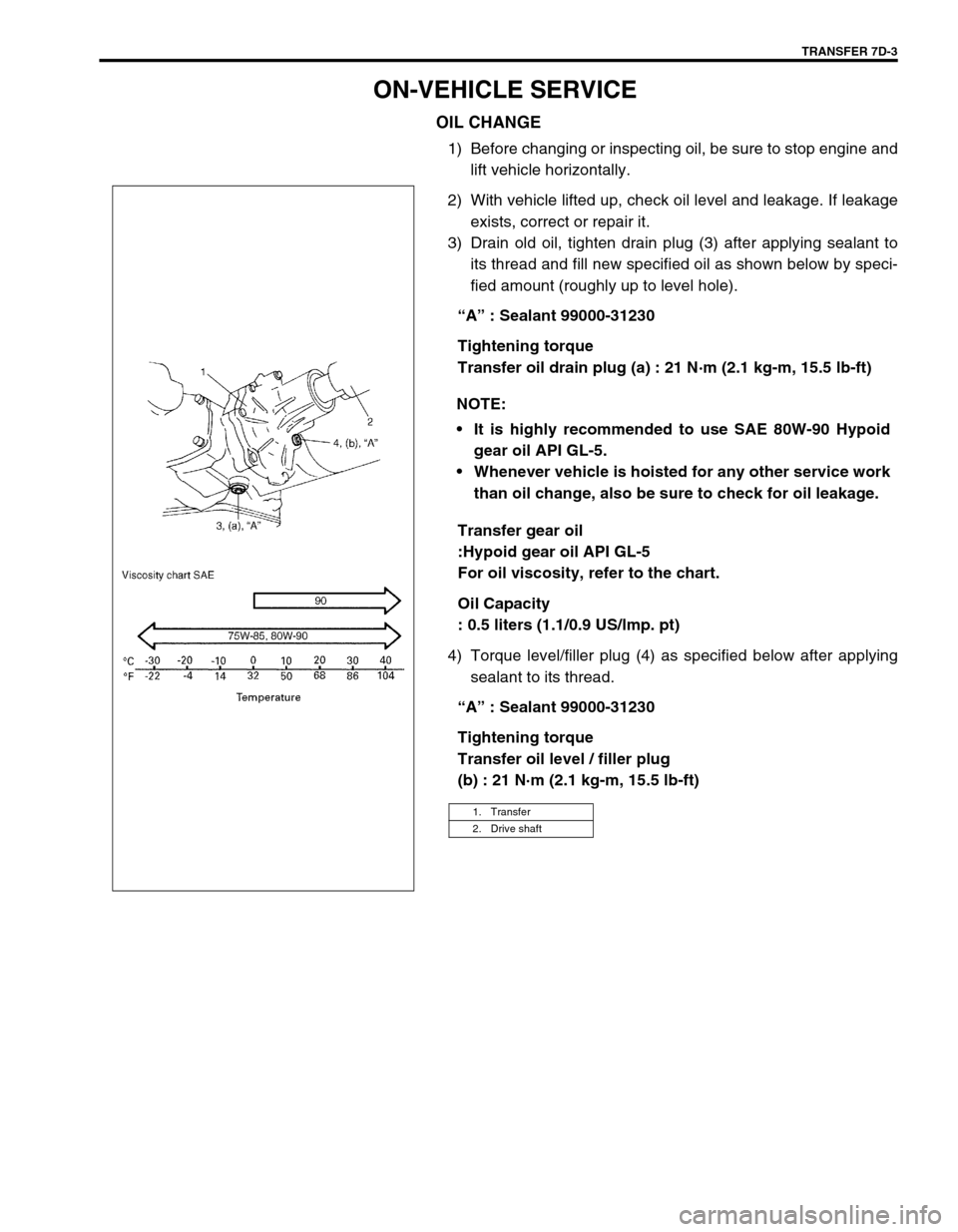

TRANSFER 7D-3

ON-VEHICLE SERVICE

OIL CHANGE

1) Before changing or inspecting oil, be sure to stop engine and

lift vehicle horizontally.

2) With vehicle lifted up, check oil level and leakage. If leakage

exists, correct or repair it.

3) Drain old oil, tighten drain plug (3) after applying sealant to

its thread and fill new specified oil as shown below by speci-

fied amount (roughly up to level hole).

“A” : Sealant 99000-31230

Tightening torque

Transfer oil drain plug (a) : 21 N·m (2.1 kg-m, 15.5 lb-ft)

Transfer gear oil

:Hypoid gear oil API GL-5

For oil viscosity, refer to the chart.

Oil Capacity

: 0.5 liters (1.1/0.9 US/lmp. pt)

4) Torque level/filler plug (4) as specified below after applying

sealant to its thread.

“A” : Sealant 99000-31230

Tightening torque

Transfer oil level / filler plug

(b) : 21 N·m (2.1 kg-m, 15.5 lb-ft) NOTE:

It is highly recommended to use SAE 80W-90 Hypoid

gear oil API GL-5.

Whenever vehicle is hoisted for any other service work

than oil change, also be sure to check for oil leakage.

1. Transfer

2. Drive shaft

Page 226 of 447

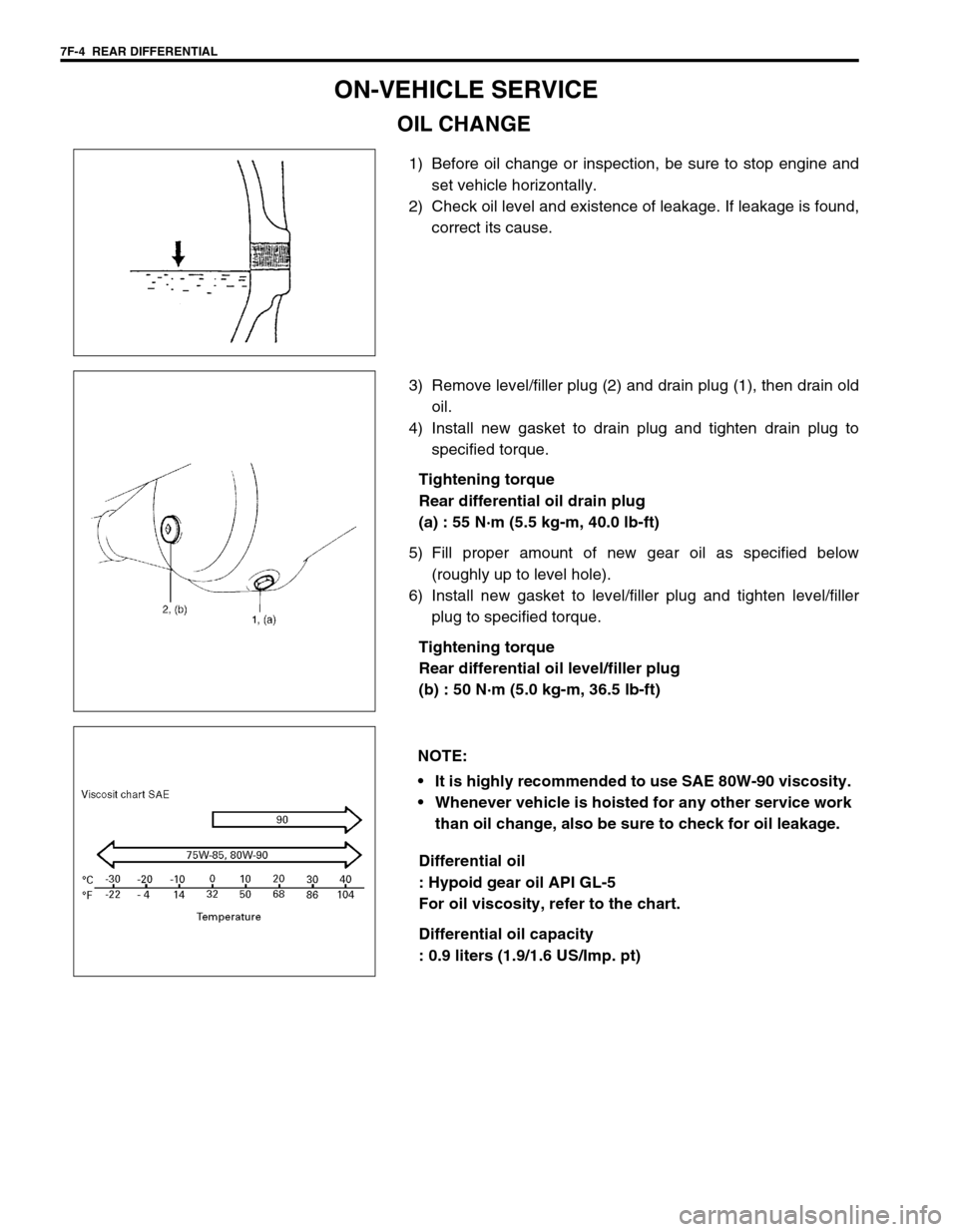

7F-4 REAR DIFFERENTIAL

ON-VEHICLE SERVICE

OIL CHANGE

1) Before oil change or inspection, be sure to stop engine and

set vehicle horizontally.

2) Check oil level and existence of leakage. If leakage is found,

correct its cause.

3) Remove level/filler plug (2) and drain plug (1), then drain old

oil.

4) Install new gasket to drain plug and tighten drain plug to

specified torque.

Tightening torque

Rear differential oil drain plug

(a) : 55 N·m (5.5 kg-m, 40.0 lb-ft)

5) Fill proper amount of new gear oil as specified below

(roughly up to level hole).

6) Install new gasket to level/filler plug and tighten level/filler

plug to specified torque.

Tightening torque

Rear differential oil level/filler plug

(b) : 50 N·m (5.0 kg-m, 36.5 lb-ft)

Differential oil

: Hypoid gear oil API GL-5

For oil viscosity, refer to the chart.

Differential oil capacity

: 0.9 liters (1.9/1.6 US/Imp. pt)

NOTE:

It is highly recommended to use SAE 80W-90 viscosity.

Whenever vehicle is hoisted for any other service work

than oil change, also be sure to check for oil leakage.

Page 245 of 447

BODY ELECTRICAL SYSTEM 8-1

6F1

6F2

6G

6H

6K

7A

7A1

7B1

7C1

7D

7E

7F

8A

8

8D

8E

9

10

10A

10B

SECTION 8

BODY ELECTRICAL SYSTEM

CONTENTS

DIAGNOSIS ........................................................ 8-3

HEADLIGHT .................................................... 8-3

HEADLIGHTS WITH LEVELING SYSTEM

(IF EQUIPPED) ............................................... 8-3

TURN SIGNAL AND HAZARD WARNING

LIGHT .............................................................. 8-3

CLEARANCE, TAIL AND LICENSE

PLATE LIGHT ................................................. 8-4

BACK-UP LIGHT ............................................. 8-4

BRAKE LIGHT ................................................ 8-4

FRONT FOG LIGHT (IF EQUIPPED) ............. 8-4

REAR FOG LIGHT (IF EQUIPPED) ................ 8-4

SPEEDOMETER AND VSS ............................ 8-5

FUEL METER AND FUEL LEVEL SENSOR

(GAUGE UNIT) ............................................... 8-5

ENGINE COOLANT TEMPERATURE (ECT)

METER AND ECT SENSOR ........................... 8-5

OIL PRESSURE WARNING LIGHT ................ 8-5

BRAKE AND PARKING BRAKE WARNING

LIGHT .............................................................. 8-6

REAR WINDOW DEFOGGER ........................ 8-6

WIPERS AND WASHERS .............................. 8-6

FRONT WIPER AND WASHER .................. 8-6

REAR WIPER AND WASHER (IF

EQUIPPED)................................................. 8-6

POWER WINDOW CONTROL SYSTEM

(IF EQUIPPED) ............................................... 8-7

CIGARETTE LIGHTER ................................... 8-7

POWER DOOR LOCK CONTROL SYSTEM

(IF EQUIPPED) ............................................... 8-7

KEYLESS ENTRY SYSTEM (IF

EQUIPPED) .................................................... 8-7POWER DOOR MIRROR CONTROL

SYSTEM (IF EQUIPPED) ............................... 8-8

INTERIOR LIGHT ........................................... 8-8

HORN ............................................................. 8-8

IGNITION KEY REMAINDER (IF EQUIPPED)

AND LIGHT REMAINDER WARNING

BUZZER.......................................................... 8-8

SEAT BELT WARNING LIGHT (IF

EQUIPPED) .................................................... 8-8

FRONT SEAT HEATER (IF EQUIPPED) ....... 8-9

ON-VEHICLE SERVICE ..................................... 8-9

CAUTIONS IN SERVICING ............................ 8-9

HEADLIGHT ................................................... 8-9

HEADLIGHT SWITCH ................................ 8-9

HEADLIGHT ASSEMBLY ......................... 8-10

HEADLIGHT BULB ................................... 8-10

HEADLIGHT AIMING ADJUSTMENT

WITH SCREEN ......................................... 8-11

HEADLIGHT LEVELING SWITCH (IF

EQUIPPED) .............................................. 8-12

TURN SIGNAL AND HAZARD WARNING

LIGHTS ......................................................... 8-12

TURN SIGNAL LIGHT SWITCH ............... 8-12

REMOVAL AND INSTALLATION ............. 8-12

TURN SIGNAL AND HAZARD RELAY ..... 8-13

HAZARD SWITCH .................................... 8-13

FRONT FOG LIGHTS (IF EQUIPPED)......... 8-13

FRONT FOG LIGHT SWITCH .................. 8-13

REAR FOG LIGHT (IF EQUIPPED) ............. 8-14

REAR FOG LIGHT SWITCH..................... 8-14

IGNITION SWITCH ....................................... 8-14

COMBINATION METER ............................... 8-15 WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System :

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

Page 246 of 447

8-2 BODY ELECTRICAL SYSTEM

CIRCUIT.................................................... 8-15

FUEL METER AND FUEL LEVEL

SENSOR (GAUGE UNIT) ............................. 8-16

FUEL LEVEL METER ............................... 8-16

FUEL LEVEL SENSOR (GAUGE UNIT) ... 8-17

SPEED METER AND VSS ........................... 8-17

VSS ........................................................... 8-17

ENGINE COOLANT TEMPERATURE (ECT)

METER AND SENSOR................................. 8-17

ENGINE COOLANT TEMPERATURE

(ECT) METER ........................................... 8-17

ECT SENSOR ........................................... 8-18

OIL PRESSURE WARNING LIGHT ............. 8-18

OIL PRESSURE SWITCH ........................ 8-18

BRAKE FLUID LEVEL AND PARKING

BRAKE WARNING LIGHT ............................ 8-18

BRAKE FLUID LEVEL SWITCH ............... 8-18

PARKING BRAKE SWITCH...................... 8-19

REAR WINDOW DEFOGGER...................... 8-19

DEFOGGER SWITCH .............................. 8-19

DEFOGGER WIRE ................................... 8-19

WIPERS AND WASHERS ............................ 8-21

COMPONENTS ........................................ 8-21

FRONT WIPER AND WASHER

SWITCH .................................................... 8-21

FRONT WIPER MOTOR........................... 8-23

WASHER TANK AND WASHER

PUMP ........................................................ 8-24

REAR WIPER AND WASHER SWITCH

(IF EQUIPPED) ......................................... 8-25REAR WIPER MOTOR .............................. 8-25

IGNITION KEY REMAINDER (IF EQUIPPED)

AND LIGHT REMAINDER WARNING

BUZZER ........................................................ 8-25

POWER WINDOW CONTROL SYSTEM

(IF EQUIPPED).............................................. 8-26

POWER WINDOW MAIN SWITCH ........... 8-26

POWER WINDOW SUB SWITCH ............. 8-27

DOOR SWITCH ............................................. 8-27

STOP LAMP (BRAKE) SWITCH ................... 8-27

POWER DOOR LOCK SYSTEM (IF

EQUIPPED) ................................................... 8-28

DOOR LOCK CONTROLLER .................... 8-28

DRIVER’S DOOR KNOB SWITCH ............ 8-28

DOOR LOCK ACTUATOR......................... 8-29

KEYLESS ENTRY SYSTEM (IF

EQUIPPED) ................................................... 8-29

DOOR LOCK CONTROLLER .................... 8-29

DOOR LOCK ACTUATOR......................... 8-29

RECEIVER................................................. 8-30

TRANSMITTER ......................................... 8-30

POWER DOOR MIRROR CONTROL

SYSTEM (IF EQUIPPED) .............................. 8-31

MIRROR SWITCH ..................................... 8-31

DOOR MIRROR ACTUATOR .................... 8-32

FRONT SEAT HEATER (IF EQUIPPED) ...... 8-32

SEAT HEATER SWITCH (DRIVER AND

PASSENGER SIDE) .................................. 8-32

SEAT HEATER WIRE................................ 8-33

Page 249 of 447

BODY ELECTRICAL SYSTEM 8-5

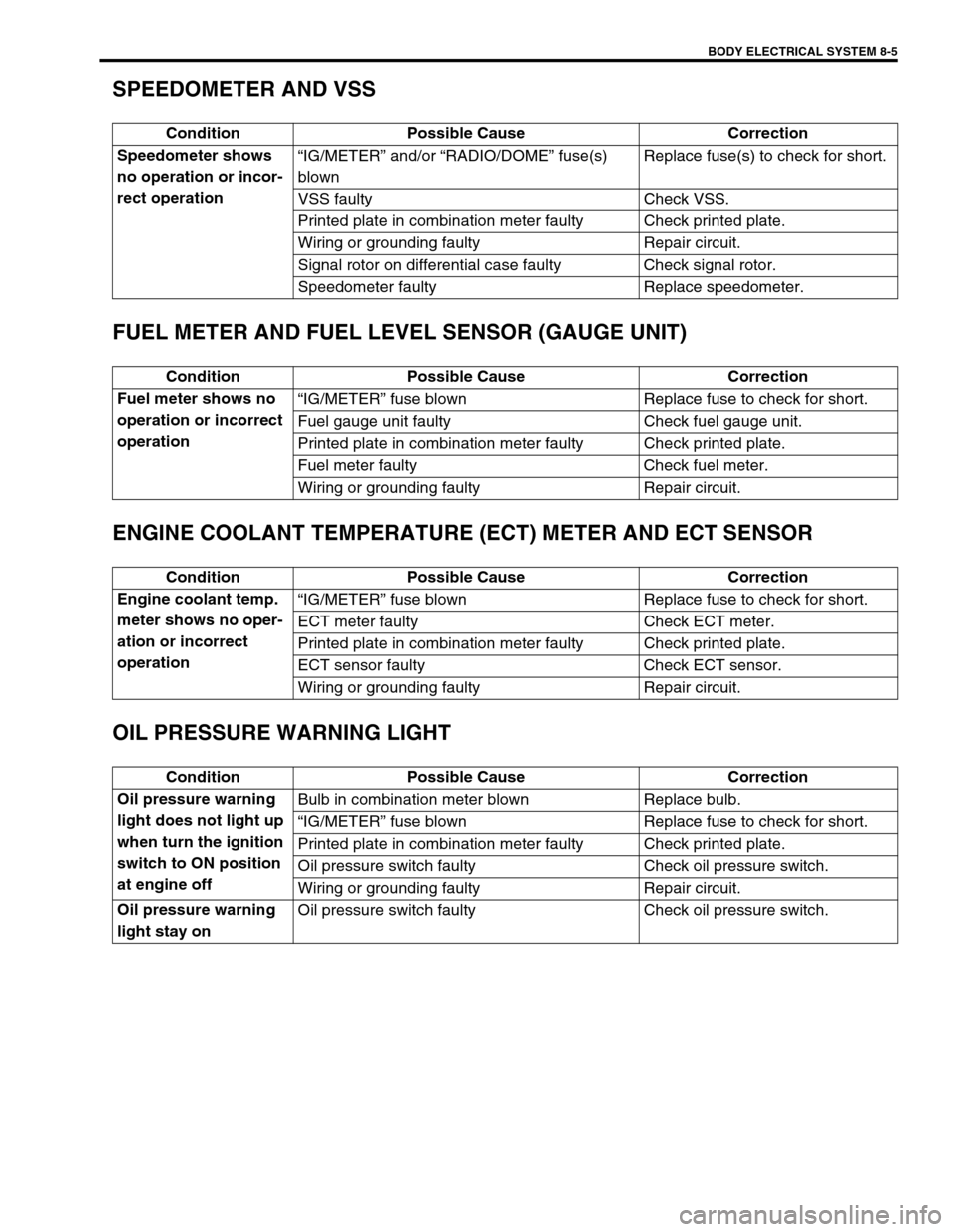

SPEEDOMETER AND VSS

FUEL METER AND FUEL LEVEL SENSOR (GAUGE UNIT)

ENGINE COOLANT TEMPERATURE (ECT) METER AND ECT SENSOR

OIL PRESSURE WARNING LIGHT

Condition Possible Cause Correction

Speedometer shows

no operation or incor-

rect operation“IG/METER” and/or “RADIO/DOME” fuse(s)

blownReplace fuse(s) to check for short.

VSS faulty Check VSS.

Printed plate in combination meter faulty Check printed plate.

Wiring or grounding faulty Repair circuit.

Signal rotor on differential case faulty Check signal rotor.

Speedometer faulty Replace speedometer.

Condition Possible Cause Correction

Fuel meter shows no

operation or incorrect

operation“IG/METER” fuse blown Replace fuse to check for short.

Fuel gauge unit faulty Check fuel gauge unit.

Printed plate in combination meter faulty Check printed plate.

Fuel meter faulty Check fuel meter.

Wiring or grounding faulty Repair circuit.

Condition Possible Cause Correction

Engine coolant temp.

meter shows no oper-

ation or incorrect

operation“IG/METER” fuse blown Replace fuse to check for short.

ECT meter faulty Check ECT meter.

Printed plate in combination meter faulty Check printed plate.

ECT sensor faulty Check ECT sensor.

Wiring or grounding faulty Repair circuit.

Condition Possible Cause Correction

Oil pressure warning

light does not light up

when turn the ignition

switch to ON position

at engine offBulb in combination meter blown Replace bulb.

“IG/METER” fuse blown Replace fuse to check for short.

Printed plate in combination meter faulty Check printed plate.

Oil pressure switch faulty Check oil pressure switch.

Wiring or grounding faulty Repair circuit.

Oil pressure warning

light stay onOil pressure switch faulty Check oil pressure switch.

Page 259 of 447

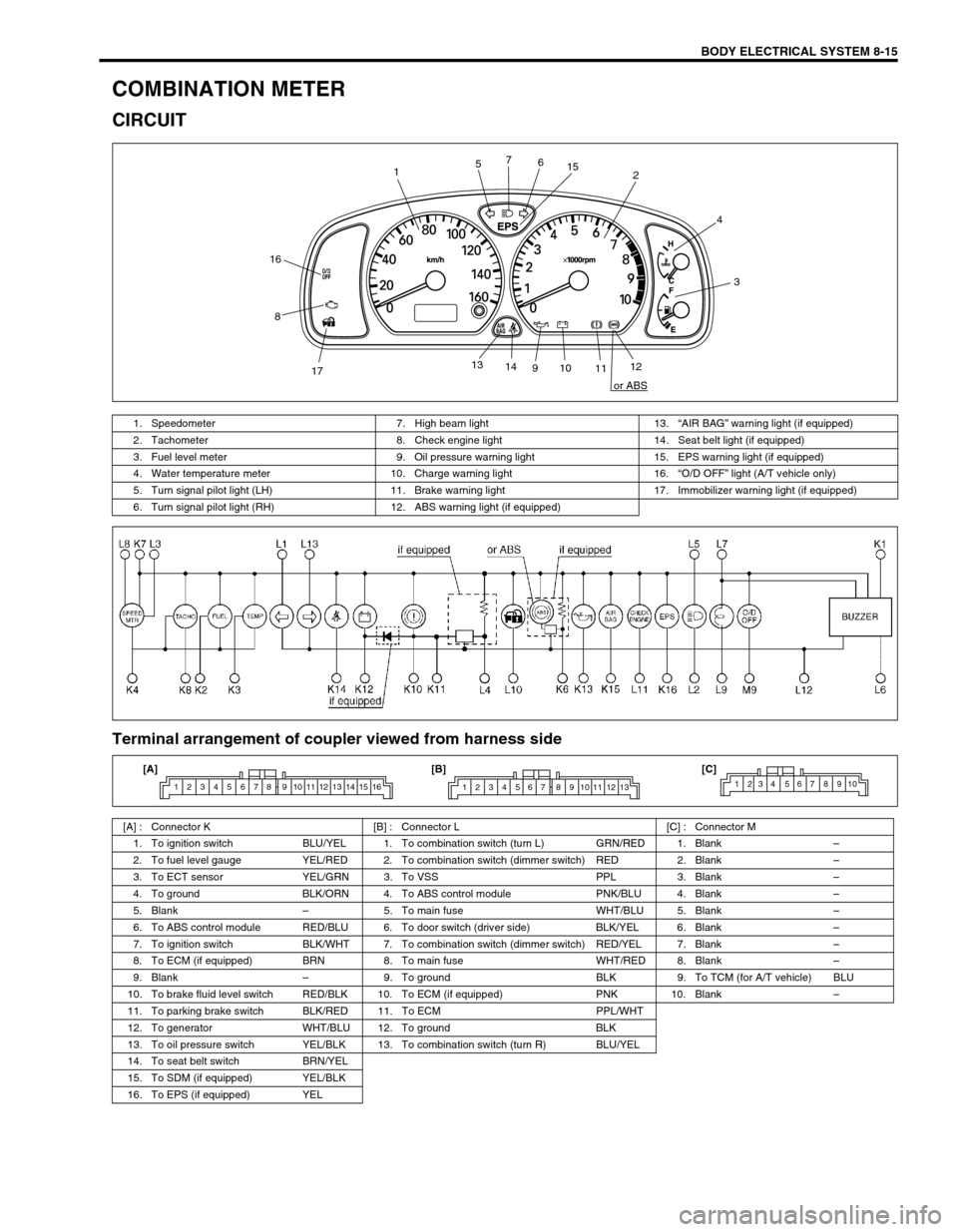

BODY ELECTRICAL SYSTEM 8-15

COMBINATION METER

CIRCUIT

Terminal arrangement of coupler viewed from harness side

12

3 4

56 7

8

910

1112 13

14

1715

16

or ABS

1. Speedometer 7. High beam light 13.“AIR BAG” warning light (if equipped)

2. Tachometer 8. Check engine light 14. Seat belt light (if equipped)

3. Fuel level meter 9. Oil pressure warning light 15. EPS warning light (if equipped)

4. Water temperature meter 10. Charge warning light 16.“O/D OFF” light (A/T vehicle only)

5. Turn signal pilot light (LH) 11. Brake warning light 17. Immobilizer warning light (if equipped)

6. Turn signal pilot light (RH) 12. ABS warning light (if equipped)

[A] : Connector K [B] : Connector L [C] : Connector M

1. To ignition switch BLU/YEL 1. To combination switch (turn L) GRN/RED 1. Blank–

2. To fuel level gauge YEL/RED 2. To combination switch (dimmer switch) RED 2. Blank–

3. To ECT sensor YEL/GRN 3. To VSS PPL 3. Blank–

4. To ground BLK/ORN 4. To ABS control module PNK/BLU 4. Blank–

5. Blank–5. To main fuse WHT/BLU 5. Blank–

6. To ABS control module RED/BLU 6. To door switch (driver side) BLK/YEL 6. Blank–

7. To ignition switch BLK/WHT 7. To combination switch (dimmer switch) RED/YEL 7. Blank–

8. To ECM (if equipped) BRN 8. To main fuse WHT/RED 8. Blank–

9. Blank–9. To ground BLK 9. To TCM (for A/T vehicle) BLU

10. To brake fluid level switch RED/BLK 10. To ECM (if equipped) PNK 10. Blank–

11. To parking brake switch BLK/RED 11. To ECM PPL/WHT

12. To generator WHT/BLU 12. To ground BLK

13. To oil pressure switch YEL/BLK 13. To combination switch (turn R) BLU/YEL

14. To seat belt switch BRN/YEL

15. To SDM (if equipped) YEL/BLK

16. To EPS (if equipped) YEL

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 161 2 3 4 5 6 7 8 9 10 11 12 131234 567 8910[A] [B] [C]

Page 262 of 447

8-18 BODY ELECTRICAL SYSTEM

ECT SENSOR

REMOVAL, INSTALLATION AND INSPECTION

Refer to “ECT SENSOR” in Section 6E1.

OIL PRESSURE WARNING LIGHT

OIL PRESSURE SWITCH

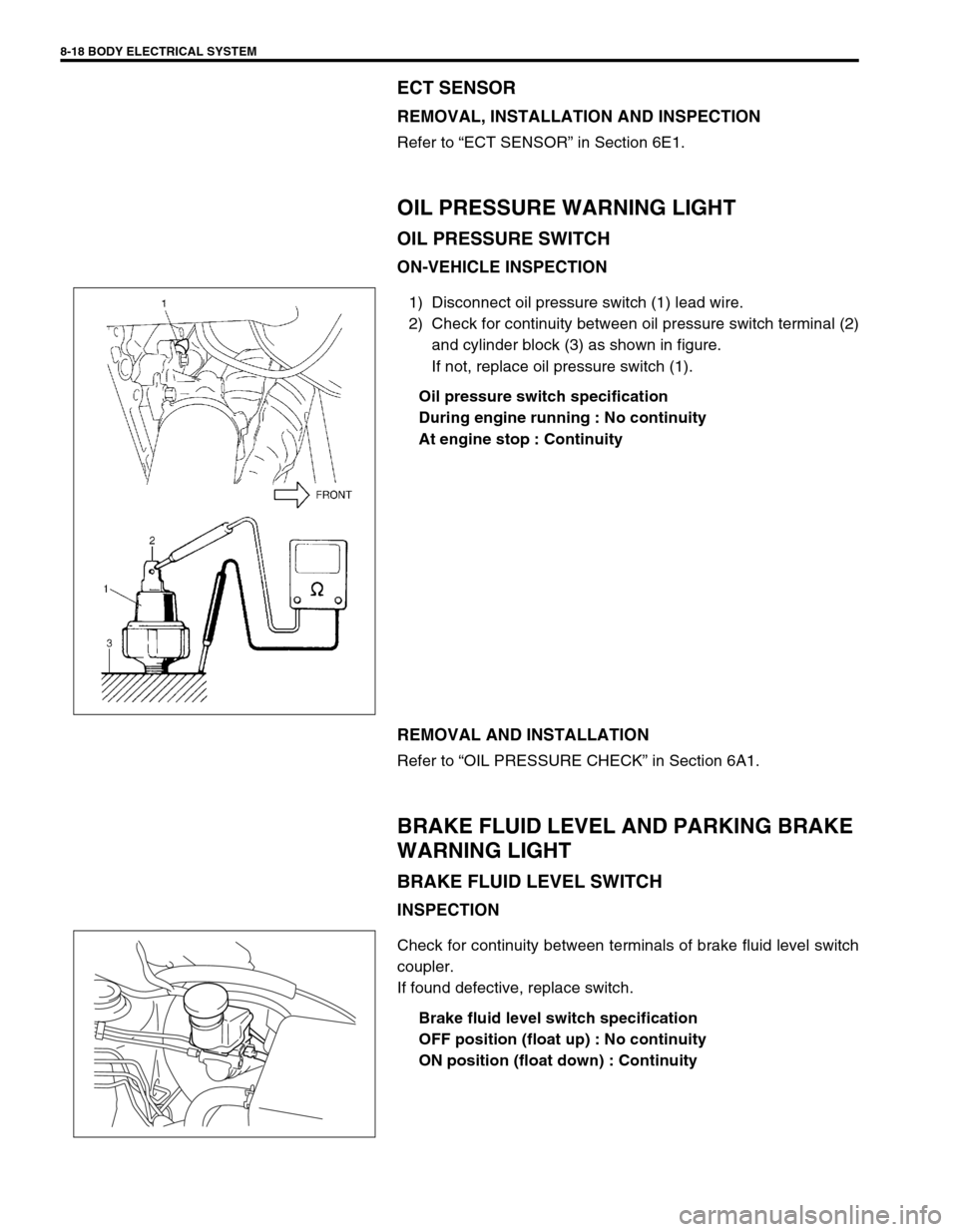

ON-VEHICLE INSPECTION

1) Disconnect oil pressure switch (1) lead wire.

2) Check for continuity between oil pressure switch terminal (2)

and cylinder block (3) as shown in figure.

If not, replace oil pressure switch (1).

Oil pressure switch specification

During engine running : No continuity

At engine stop : Continuity

REMOVAL AND INSTALLATION

Refer to “OIL PRESSURE CHECK” in Section 6A1.

BRAKE FLUID LEVEL AND PARKING BRAKE

WARNING LIGHT

BRAKE FLUID LEVEL SWITCH

INSPECTION

Check for continuity between terminals of brake fluid level switch

coupler.

If found defective, replace switch.

Brake fluid level switch specification

OFF position (float up) : No continuity

ON position (float down) : Continuity