belt SUZUKI SWIFT 2000 1.G Transmission Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 447, PDF Size: 10.54 MB

Page 245 of 447

BODY ELECTRICAL SYSTEM 8-1

6F1

6F2

6G

6H

6K

7A

7A1

7B1

7C1

7D

7E

7F

8A

8

8D

8E

9

10

10A

10B

SECTION 8

BODY ELECTRICAL SYSTEM

CONTENTS

DIAGNOSIS ........................................................ 8-3

HEADLIGHT .................................................... 8-3

HEADLIGHTS WITH LEVELING SYSTEM

(IF EQUIPPED) ............................................... 8-3

TURN SIGNAL AND HAZARD WARNING

LIGHT .............................................................. 8-3

CLEARANCE, TAIL AND LICENSE

PLATE LIGHT ................................................. 8-4

BACK-UP LIGHT ............................................. 8-4

BRAKE LIGHT ................................................ 8-4

FRONT FOG LIGHT (IF EQUIPPED) ............. 8-4

REAR FOG LIGHT (IF EQUIPPED) ................ 8-4

SPEEDOMETER AND VSS ............................ 8-5

FUEL METER AND FUEL LEVEL SENSOR

(GAUGE UNIT) ............................................... 8-5

ENGINE COOLANT TEMPERATURE (ECT)

METER AND ECT SENSOR ........................... 8-5

OIL PRESSURE WARNING LIGHT ................ 8-5

BRAKE AND PARKING BRAKE WARNING

LIGHT .............................................................. 8-6

REAR WINDOW DEFOGGER ........................ 8-6

WIPERS AND WASHERS .............................. 8-6

FRONT WIPER AND WASHER .................. 8-6

REAR WIPER AND WASHER (IF

EQUIPPED)................................................. 8-6

POWER WINDOW CONTROL SYSTEM

(IF EQUIPPED) ............................................... 8-7

CIGARETTE LIGHTER ................................... 8-7

POWER DOOR LOCK CONTROL SYSTEM

(IF EQUIPPED) ............................................... 8-7

KEYLESS ENTRY SYSTEM (IF

EQUIPPED) .................................................... 8-7POWER DOOR MIRROR CONTROL

SYSTEM (IF EQUIPPED) ............................... 8-8

INTERIOR LIGHT ........................................... 8-8

HORN ............................................................. 8-8

IGNITION KEY REMAINDER (IF EQUIPPED)

AND LIGHT REMAINDER WARNING

BUZZER.......................................................... 8-8

SEAT BELT WARNING LIGHT (IF

EQUIPPED) .................................................... 8-8

FRONT SEAT HEATER (IF EQUIPPED) ....... 8-9

ON-VEHICLE SERVICE ..................................... 8-9

CAUTIONS IN SERVICING ............................ 8-9

HEADLIGHT ................................................... 8-9

HEADLIGHT SWITCH ................................ 8-9

HEADLIGHT ASSEMBLY ......................... 8-10

HEADLIGHT BULB ................................... 8-10

HEADLIGHT AIMING ADJUSTMENT

WITH SCREEN ......................................... 8-11

HEADLIGHT LEVELING SWITCH (IF

EQUIPPED) .............................................. 8-12

TURN SIGNAL AND HAZARD WARNING

LIGHTS ......................................................... 8-12

TURN SIGNAL LIGHT SWITCH ............... 8-12

REMOVAL AND INSTALLATION ............. 8-12

TURN SIGNAL AND HAZARD RELAY ..... 8-13

HAZARD SWITCH .................................... 8-13

FRONT FOG LIGHTS (IF EQUIPPED)......... 8-13

FRONT FOG LIGHT SWITCH .................. 8-13

REAR FOG LIGHT (IF EQUIPPED) ............. 8-14

REAR FOG LIGHT SWITCH..................... 8-14

IGNITION SWITCH ....................................... 8-14

COMBINATION METER ............................... 8-15 WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System :

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

Page 252 of 447

8-8 BODY ELECTRICAL SYSTEM

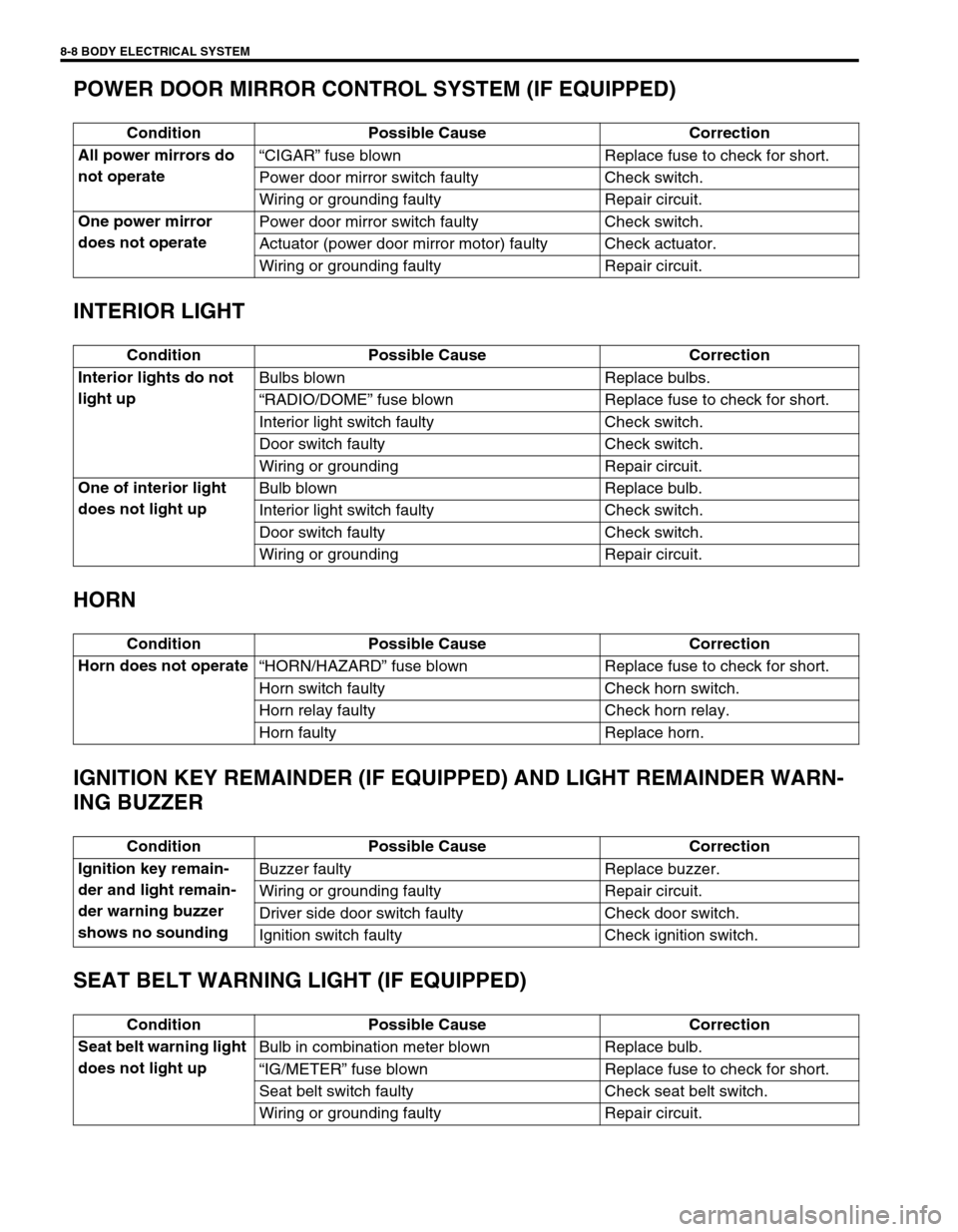

POWER DOOR MIRROR CONTROL SYSTEM (IF EQUIPPED)

INTERIOR LIGHT

HORN

IGNITION KEY REMAINDER (IF EQUIPPED) AND LIGHT REMAINDER WARN-

ING BUZZER

SEAT BELT WARNING LIGHT (IF EQUIPPED)

Condition Possible Cause Correction

All power mirrors do

not operate“CIGAR” fuse blown Replace fuse to check for short.

Power door mirror switch faulty Check switch.

Wiring or grounding faulty Repair circuit.

One power mirror

does not operatePower door mirror switch faulty Check switch.

Actuator (power door mirror motor) faulty Check actuator.

Wiring or grounding faulty Repair circuit.

Condition Possible Cause Correction

Interior lights do not

light upBulbs blown Replace bulbs.

“RADIO/DOME” fuse blown Replace fuse to check for short.

Interior light switch faulty Check switch.

Door switch faulty Check switch.

Wiring or grounding Repair circuit.

One of interior light

does not light upBulb blown Replace bulb.

Interior light switch faulty Check switch.

Door switch faulty Check switch.

Wiring or grounding Repair circuit.

Condition Possible Cause Correction

Horn does not operate

“HORN/HAZARD” fuse blown Replace fuse to check for short.

Horn switch faulty Check horn switch.

Horn relay faulty Check horn relay.

Horn faulty Replace horn.

Condition Possible Cause Correction

Ignition key remain-

der and light remain-

der warning buzzer

shows no soundingBuzzer faulty Replace buzzer.

Wiring or grounding faulty Repair circuit.

Driver side door switch faulty Check door switch.

Ignition switch faulty Check ignition switch.

Condition Possible Cause Correction

Seat belt warning light

does not light upBulb in combination meter blown Replace bulb.

“IG/METER” fuse blown Replace fuse to check for short.

Seat belt switch faulty Check seat belt switch.

Wiring or grounding faulty Repair circuit.

Page 259 of 447

BODY ELECTRICAL SYSTEM 8-15

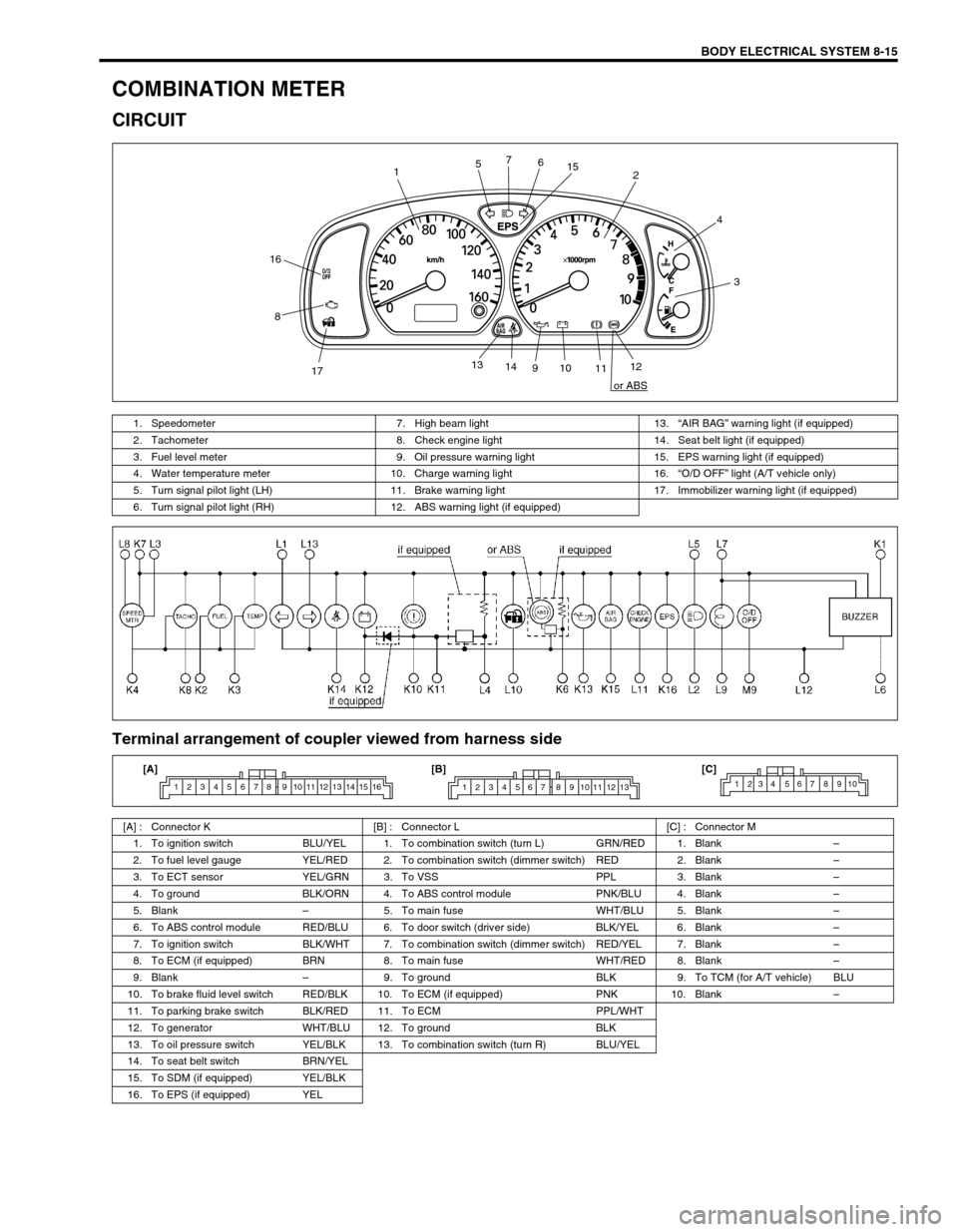

COMBINATION METER

CIRCUIT

Terminal arrangement of coupler viewed from harness side

12

3 4

56 7

8

910

1112 13

14

1715

16

or ABS

1. Speedometer 7. High beam light 13.“AIR BAG” warning light (if equipped)

2. Tachometer 8. Check engine light 14. Seat belt light (if equipped)

3. Fuel level meter 9. Oil pressure warning light 15. EPS warning light (if equipped)

4. Water temperature meter 10. Charge warning light 16.“O/D OFF” light (A/T vehicle only)

5. Turn signal pilot light (LH) 11. Brake warning light 17. Immobilizer warning light (if equipped)

6. Turn signal pilot light (RH) 12. ABS warning light (if equipped)

[A] : Connector K [B] : Connector L [C] : Connector M

1. To ignition switch BLU/YEL 1. To combination switch (turn L) GRN/RED 1. Blank–

2. To fuel level gauge YEL/RED 2. To combination switch (dimmer switch) RED 2. Blank–

3. To ECT sensor YEL/GRN 3. To VSS PPL 3. Blank–

4. To ground BLK/ORN 4. To ABS control module PNK/BLU 4. Blank–

5. Blank–5. To main fuse WHT/BLU 5. Blank–

6. To ABS control module RED/BLU 6. To door switch (driver side) BLK/YEL 6. Blank–

7. To ignition switch BLK/WHT 7. To combination switch (dimmer switch) RED/YEL 7. Blank–

8. To ECM (if equipped) BRN 8. To main fuse WHT/RED 8. Blank–

9. Blank–9. To ground BLK 9. To TCM (for A/T vehicle) BLU

10. To brake fluid level switch RED/BLK 10. To ECM (if equipped) PNK 10. Blank–

11. To parking brake switch BLK/RED 11. To ECM PPL/WHT

12. To generator WHT/BLU 12. To ground BLK

13. To oil pressure switch YEL/BLK 13. To combination switch (turn R) BLU/YEL

14. To seat belt switch BRN/YEL

15. To SDM (if equipped) YEL/BLK

16. To EPS (if equipped) YEL

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 161 2 3 4 5 6 7 8 9 10 11 12 131234 567 8910[A] [B] [C]

Page 351 of 447

BODY SERVICE 9-47

IGNITION SWITCH LOCK CYLINDER

REMOVAL AND INSTALLATION

Refer to “STEERING LOCK ASSEMBLY (IGNITION SWITCH)” in

Section 3C.

ELECTRICAL DIAGNOSIS

For ignition switch electrical troubleshooting, refer to “IGNITION

SWITCH” in Section 8.

EXTERIOR AND INTERIOR TRIM

FLOOR CARPET

REMOVAL

1) Remove front seats and rear seat cushion.

2) Remove seat belt lower anchor bolt.

3) Remove dash side trims, front side sill scuffs, center pillar inner lower trims, quarter inner trims and rear side

sill scuffs.

4) Remove parking brake lever cover and console box.

5) Remove floor carpet.

INSTALLATION

Reverse removal sequence to install front floor carpet, noting the following instruction.

For tightening torque of seat belt anchor bolt, refer to “FRONT SEAT BELT” in Section 10.

1. Floor carpet

2. Dash panel silencer

3. Silencer seat

Page 367 of 447

RESTRAINT SYSTEM 10-1

6F1

6F2

6G

6H

6K

7A

7A1

7B1

7C1

7D

7E

7F

8A

8B

8C

8D

8E

9

10

10A

10B

SECTION 10

RESTRAINT SYSTEM

CONTENTS

GENERAL DESCRIPTION .............................. 10-2

SYSTEM SPECIFICATION .......................... 10-3

SEAT BELT PRETENSIONER

(IF EQUIPPED) ............................................ 10-3

DIAGNOSIS ..................................................... 10-3

INSPECTION AND REPAIR REQUIRED

AFTER ACCIDENT ...................................... 10-3

ON-VEHICLE SERVICE .................................. 10-4SERVICE PRECAUTIONS .......................... 10-4

SERVICE AND DIAGNOSIS .................... 10-4

DISABLING AIR BAG SYSTEM............... 10-4

ENABLING AIR BAG SYSTEM................ 10-4

HANDLING AND STORAGE ................... 10-4

DISPOSAL ............................................... 10-4

FRONT SEAT BELT .................................... 10-5

REAR SEAT BELT....................................... 10-8

WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System with seat belt pretensioner:

Service on or around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Please observe all WARNINGS and “Service Precautions” under “On-

Vehicle Service” in air bag system section before performing service on or around the air bag sys-

tem components or wiring. Failure to follow WARNINGS could result in unintentional activation of

the system or could render the system inoperative. Either of these two conditions may result in

severe injury.

The procedures in this section must be followed in the order listed to disable the air bag system

temporarily and prevent false diagnostic trouble codes from setting. Failure to follow procedures

could result in possible activation of the air bag system, personal injury or otherwise unneeded air

bag system repairs.

CAUTION:

When fasteners are removed, always reinstall them at the same location from which they were

removed. If a fastener needs to be replaced, use the correct part number fastener for that application.

If the correct part number fastener is not available, a fastener of equal size and strength (or stronger)

may be used. Fasteners that are not reused, and those requiring thread-locking compound, will be

called out. The correct torque value must be used when installing fasteners that require it. If the above

procedures are not followed, parts or system damage could result.

Page 368 of 447

10-2 RESTRAINT SYSTEM

GENERAL DESCRIPTION

Seat Belt with ELR

The seat belt with emergency locking retractor (ELR) is designed so that it locks immediately (to prevent the

webbing from being pulled out of the retractor any further) when any of the following items is detected as

exceeding each set value;

speed at which the webbing is pulled out of the retractor,

acceleration or deceleration of the vehicle speed, and

inclination.

Seat Belt with A-ELR

The automatic and emergency locking retractor (A-ELR) works as an Emergency Locking Retractor (ELR) till its

webbing is pulled all the way out and then on as an Automatic Locking Retractor (ALR) till it is retracted fully.

ALR: Automatically locks when the webbing is pulled out from the retractor and allowed to retract even a little.

Then the webbing can not be pulled out any further, unless it is wound all the way back into the retractor, which

releases the lock and allows the webbing to be pulled out.

Seat Belt with ELR and Pretensioner

The seat belt with ELR and a pretensioner has a pretensioner mechanism which operates in linkage with the air

bag in addition to the above described ELR. The pretensioner takes up the sag of the seat belt in occurrence of

a front collision with an impact larger than a certain set value, thereby enhancing restraint performance.

1. Front seat belt 4. Passenger air bag (if equipped)

2. Rear seat belt 5. Label (for seat belt with pretensioner)

3. Driver air bag (if equipped) 6. Rear center seat belt

Page 369 of 447

RESTRAINT SYSTEM 10-3

Driver and Front Passenger Air Bags and Seat Belt Pretensioners

With the air bag system which includes air bags for both the driver’s and passenger’s sides as well as the seat

belt pretensioners, the pretensioner takes up the sag of the seat belt, the driver air bag (inflator) module is

deployed from the center of the steering column and the passenger air bag (inflator) module from the top of the

instrument panel in front of the front passenger seat in occurrence of a front collision with an impact larger than

a certain set value to supplement protection offered by the driver and front passenger seat belts.

SYSTEM SPECIFICATION

SEAT BELT PRETENSIONER (IF EQUIPPED)

Some seat belts of the driver and front passenger seats are provided with a pretensioner as an optional function

unit. The pretensioner is incorporated in retractor assembly and controlled by SDM as one of air bag system

components. It will be activated at the same time as the air bag when an impact at the front of vehicle exceeds

the specified value.

When servicing seat belt (retractor assembly) with pretensioner, be sure to observe all WARNINGS and CAU-

TIONS in this section and “SERVICE PRECAUTIONS” of “ON-VEHICLE SERVICE” in Section 10B

DIAGNOSIS

For diagnosis of air bag system (including in seat belt pretensioner), refer to Section 10B.

INSPECTION AND REPAIR REQUIRED AFTER ACCIDENT

After an accident, whether the seat belt pretensioner has been activated or not, be sure to perform checks and

repairs described on “REPAIRS AND INSPECTIONS REQUIRED AFTER ACCIDENT” under “DIAGNOSIS” in

Section 10B.Type 1 Type 2 Type 3

Front

seatSeat belt with ELRDriver air bag

Seat belt with ELR and

pretensionerDriver and front passenger air bags

Seat belt wit ELR and pretensioner

Rear

seatSeat belt with A-ELR

(right and left)

Seat belt (center)Seat belt with A-ELR

(right and left)

Seat belt (center)Seat belt with A-ELR (right and left)

Seat belt (center)

CAUTION:

Do not reuse the seat belt pretensioner (retractor assembly) that has operated but replace it with a

new one as an assembly. For checking procedure of its operation, refer to “SERVICE PRECAUTIONS”

of “ON-VEHICLE SERVICE” in Section 10B.

Page 370 of 447

10-4 RESTRAINT SYSTEM

ON-VEHICLE SERVICE

SERVICE PRECAUTIONS

SERVICE AND DIAGNOSIS

Before servicing or replacing seat belts, refer to following precautionary items.

Seat belts should be normal relative to strap retractor and buckle portions.

Keep sharp edges and damaging objects away from belts.

Avoid bending or damaging any portion of belt buckle or latch plate.

Do not bleach or dye belt webbing. (Use only mild soap and lukewarm water to clean it.)

When installing a seat belt anchor bolt, it should be tightened by hand at first to prevent cross-threading and

then to specified torque.

Do not attempt any repairs on retractor mechanisms or retractor covers. Replace defective assemblies with

new replacement parts.

Keep belts dry and clean at all times.

If there exist any parts in question, replace such parts.

Replace belts whose webbing is cut or otherwise damaged.

Do not put anything into trim panel opening which seat belt webbing passes through.

For Seat Belt with Pretensioner

Refer to “SERVICE AND DIAGNOSIS” of “SERVICE PRECAUTIONS” under “ON-VEHICLE SERVICE” in Sec-

tion 10B.

DISABLING AIR BAG SYSTEM

Refer to “DISABLING AIR BAG SYSTEM” of “SERVICE PRECAUTIONS” under “ON-VEHICLE SERVICE” in

Section 10B.

ENABLING AIR BAG SYSTEM

Refer to “ENABLING AIR BAG SYSTEM” of “SERVICE PRECAUTIONS” under “ON-VEHICLE SERVICE” in

Section 10B.

HANDLING AND STORAGE

Refer to “HANDLING AND STORAGE” of “SERVICE PRECAUTIONS” under “ON-VEHICLE SERVICE” in Sec-

tion 10B.

DISPOSAL

Refer to “DISPOSAL” of “SERVICE PRECAUTIONS” under “ON-VEHICLE SERVICE” in Section 10B. WARNING:

If replacing seat belt is necessary, replace buckle and ELR (or webbing) together as a set. This is for

the reason of ensuring locking of tongue plate with buckle.

If these parts are replaced individually, such a locking condition may become unreliable. For this rea-

son, SUZUKI will supply only the spare buckle and ELR (or webbing) in a set part.

WARNING:

When performing service on or around air bag system components or air bag system wiring, disable

the air bag system. Refer to “DISABLING AIR BAG SYSTEM” of “SERVICE PRECAUTIONS” under

“ON-VEHICLE SERVICE” in Section 10B.

Failure to follow procedures could result in possible air bag activation, personal injury or unneeded

air bag system repairs.

Page 371 of 447

RESTRAINT SYSTEM 10-5

FRONT SEAT BELT

WARNING:

Never attempt to disassemble or repair the seat belt pretensioner (retractor assembly). If any abnor-

mality is found, be sure to replace it with new one as an assembly.

Be sure to read “SERVICE PRECAUTIONS”, before starting to work and observe every precaution

during work. Neglecting them may result in personal injury or unactivation of the seat belt preten-

sioner when necessary.

1. Upper anchor 4. BuckleTightening torque

2. Lower anchor 5. Yellow connector (for seat belt pretensioner) (if equipped)

3. Retractor assembly 6. Retractor assembly upper mounting bolt

: After tightening lower bolt, tightening upper bolt

Page 372 of 447

10-6 RESTRAINT SYSTEM

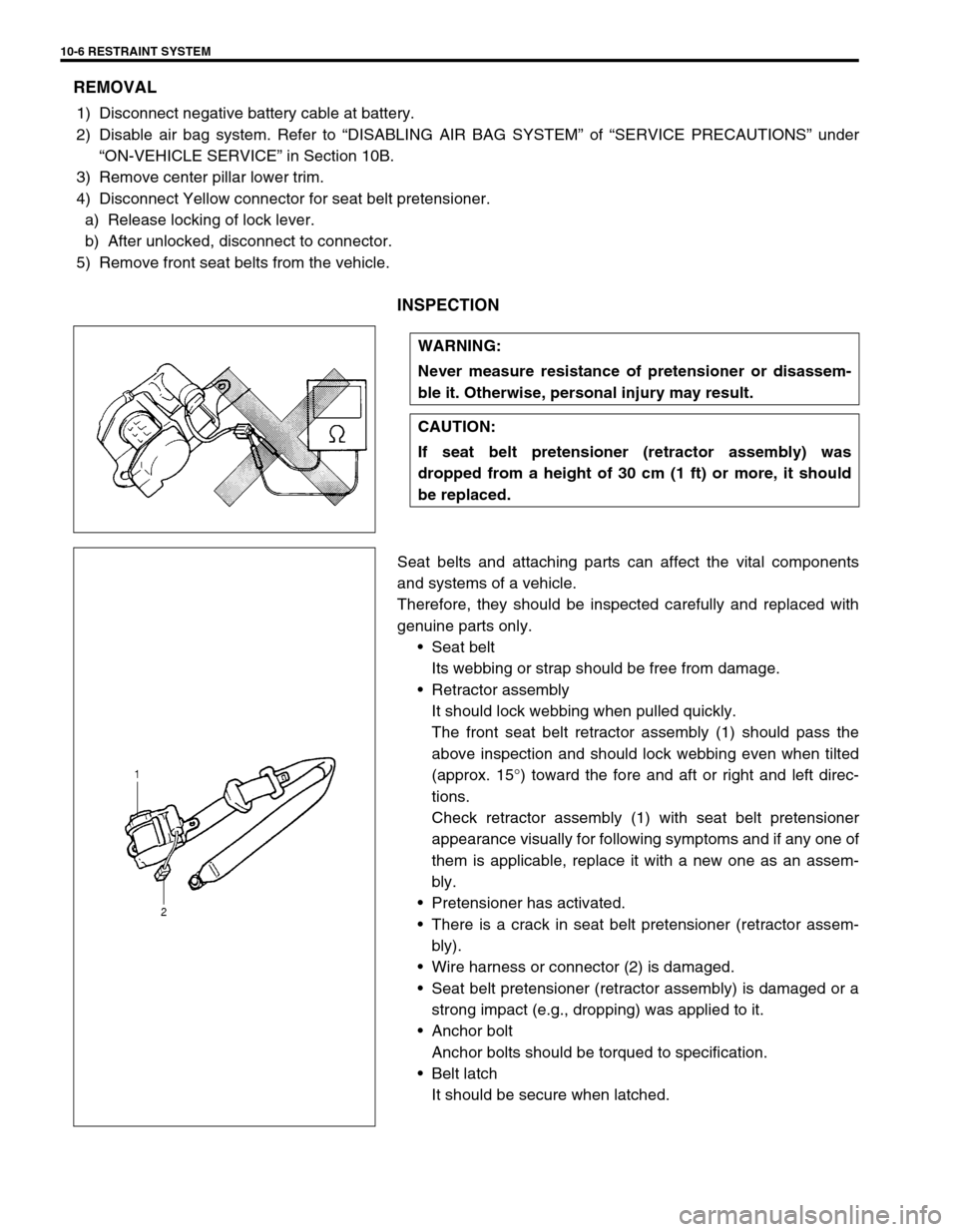

REMOVAL

1) Disconnect negative battery cable at battery.

2) Disable air bag system. Refer to “DISABLING AIR BAG SYSTEM” of “SERVICE PRECAUTIONS” under

“ON-VEHICLE SERVICE” in Section 10B.

3) Remove center pillar lower trim.

4) Disconnect Yellow connector for seat belt pretensioner.

a) Release locking of lock lever.

b) After unlocked, disconnect to connector.

5) Remove front seat belts from the vehicle.

INSPECTION

Seat belts and attaching parts can affect the vital components

and systems of a vehicle.

Therefore, they should be inspected carefully and replaced with

genuine parts only.

Seat belt

Its webbing or strap should be free from damage.

Retractor assembly

It should lock webbing when pulled quickly.

The front seat belt retractor assembly (1) should pass the

above inspection and should lock webbing even when tilted

(approx. 15°) toward the fore and aft or right and left direc-

tions.

Check retractor assembly (1) with seat belt pretensioner

appearance visually for following symptoms and if any one of

them is applicable, replace it with a new one as an assem-

bly.

Pretensioner has activated.

There is a crack in seat belt pretensioner (retractor assem-

bly).

Wire harness or connector (2) is damaged.

Seat belt pretensioner (retractor assembly) is damaged or a

strong impact (e.g., dropping) was applied to it.

Anchor bolt

Anchor bolts should be torqued to specification.

Belt latch

It should be secure when latched. WARNING:

Never measure resistance of pretensioner or disassem-

ble it. Otherwise, personal injury may result.

CAUTION:

If seat belt pretensioner (retractor assembly) was

dropped from a height of 30 cm (1 ft) or more, it should

be replaced.