rear brake SUZUKI SWIFT 2000 1.G Transmission Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 447, PDF Size: 10.54 MB

Page 124 of 447

7B-82 AUTOMATIC TRANSMISSION (4 A/T)

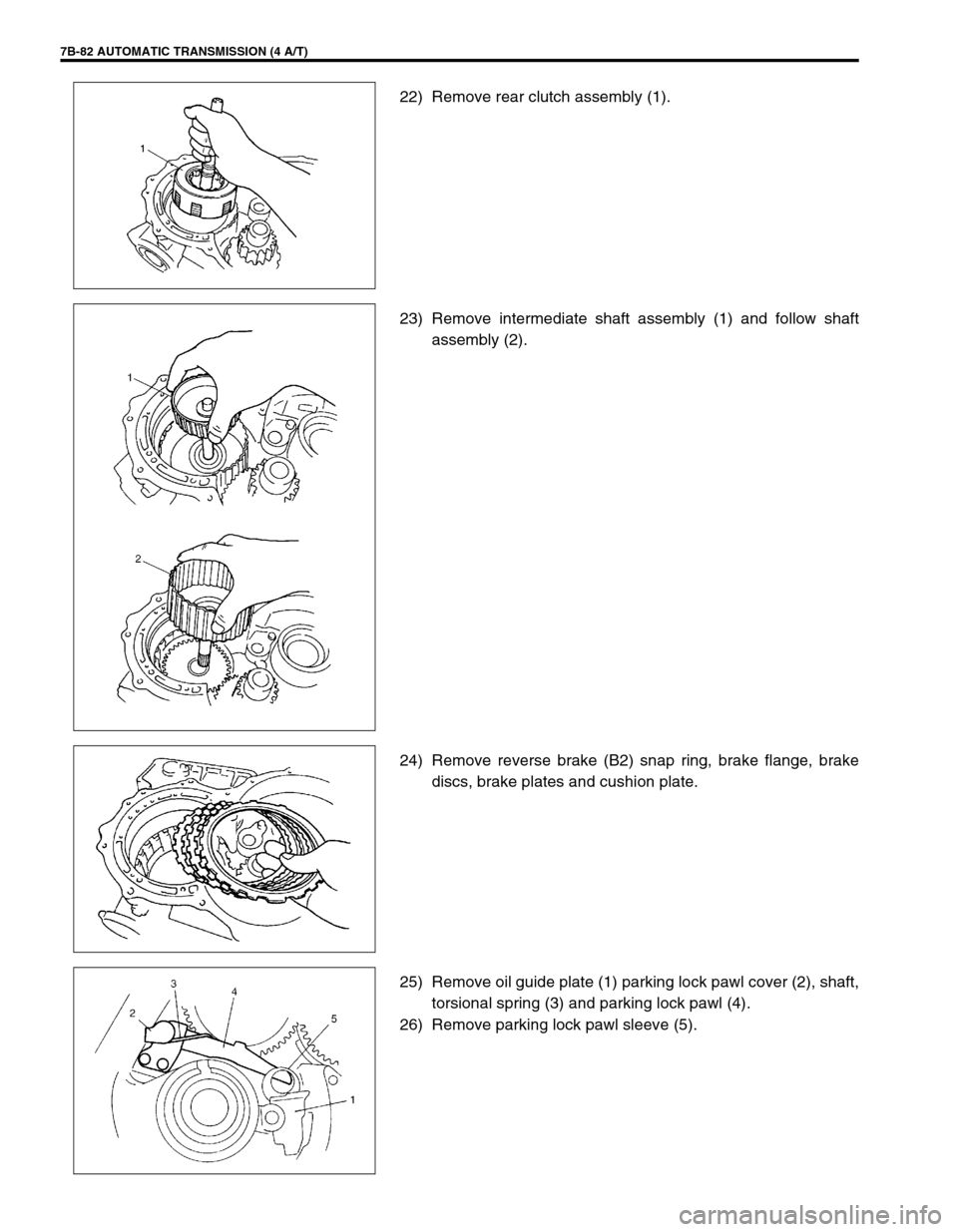

22) Remove rear clutch assembly (1).

23) Remove intermediate shaft assembly (1) and follow shaft

assembly (2).

24) Remove reverse brake (B2) snap ring, brake flange, brake

discs, brake plates and cushion plate.

25) Remove oil guide plate (1) parking lock pawl cover (2), shaft,

torsional spring (3) and parking lock pawl (4).

26) Remove parking lock pawl sleeve (5).

Page 126 of 447

7B-84 AUTOMATIC TRANSMISSION (4 A/T)

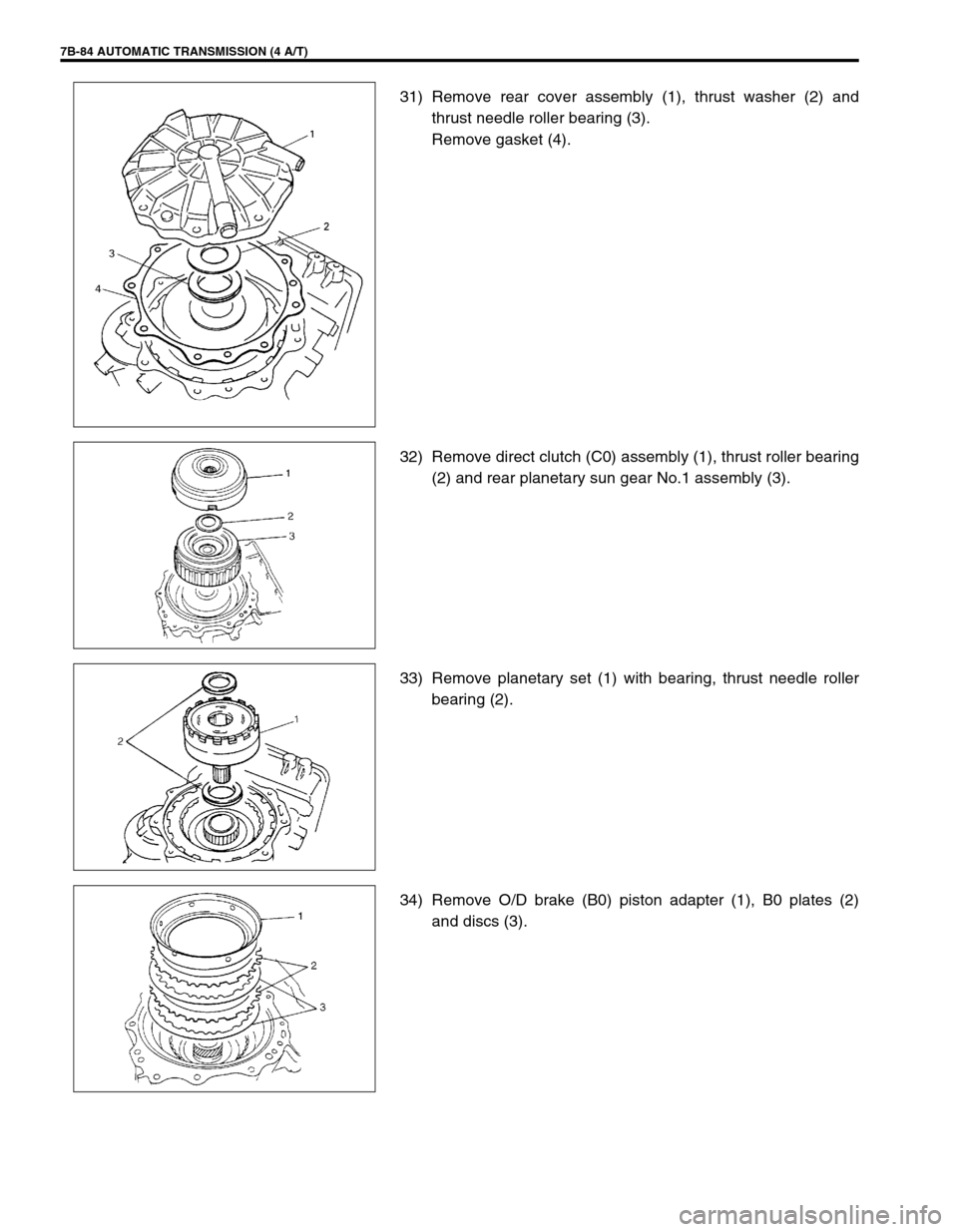

31) Remove rear cover assembly (1), thrust washer (2) and

thrust needle roller bearing (3).

Remove gasket (4).

32) Remove direct clutch (C0) assembly (1), thrust roller bearing

(2) and rear planetary sun gear No.1 assembly (3).

33) Remove planetary set (1) with bearing, thrust needle roller

bearing (2).

34) Remove O/D brake (B0) piston adapter (1), B0 plates (2)

and discs (3).

Page 157 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-115

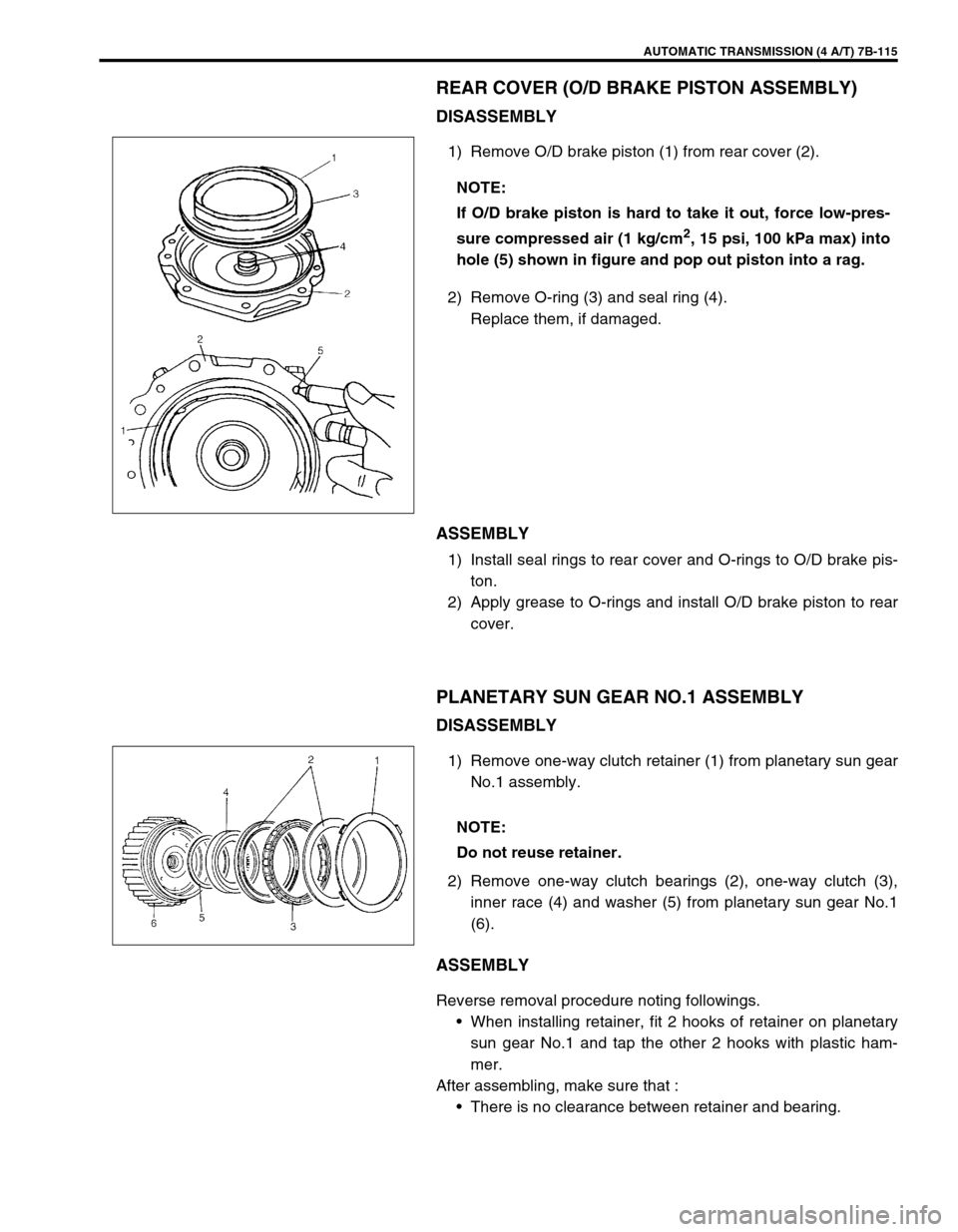

REAR COVER (O/D BRAKE PISTON ASSEMBLY)

DISASSEMBLY

1) Remove O/D brake piston (1) from rear cover (2).

2) Remove O-ring (3) and seal ring (4).

Replace them, if damaged.

ASSEMBLY

1) Install seal rings to rear cover and O-rings to O/D brake pis-

ton.

2) Apply grease to O-rings and install O/D brake piston to rear

cover.

PLANETARY SUN GEAR NO.1 ASSEMBLY

DISASSEMBLY

1) Remove one-way clutch retainer (1) from planetary sun gear

No.1 assembly.

2) Remove one-way clutch bearings (2), one-way clutch (3),

inner race (4) and washer (5) from planetary sun gear No.1

(6).

ASSEMBLY

Reverse removal procedure noting followings.

When installing retainer, fit 2 hooks of retainer on planetary

sun gear No.1 and tap the other 2 hooks with plastic ham-

mer.

After assembling, make sure that :

There is no clearance between retainer and bearing. NOTE:

If O/D brake piston is hard to take it out, force low-pres-

sure compressed air (1 kg/cm

2, 15 psi, 100 kPa max) into

hole (5) shown in figure and pop out piston into a rag.

NOTE:

Do not reuse retainer.

Page 163 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-121

12) Measure 1st & 2nd brake (B1) stroke and clearance in fol-

lowing manner.

Set the dial gauge (1) to 1st & 2nd brake (B1) piston as

shown. Blow compressed air into hole (4) shown in figure.

Then measure the difference as the compressed air is blown

in.

1st & 2nd brake (B1) piston stroke

Standard : 1.79 – 2.01 mm (0.0705 – 0.0791 in.)

Set the dial gauge (1) on the top-most brake disc (5).

Blow compressed air into the hole (4) shown in figure.

Measure the difference. Call this value (A).

If the measured value (s) is (are) out of specification, replace

brake discs, plates and flange.

1st & 2nd brake (B1) disc clearance

Standard : 1.31 – 1.96 mm (0.0516 – 0.0772 in.)

\

13) Install O/D brake (B0) return spring seat (4), return spring (3)

and then retainer (2).

14) While compressing retainer (2), install snap ring (1).

2. Tip of dial gauge on B1 brake piston

3. Air gun

CAUTION:

Position return spring (3) to be centered so that rear

cover not be caught.

Page 165 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-123

19) Measure the clearance of O/D brake (B0) in the following

manner.

Blow compressed air into hole (4) shown in figure to activate

1st & 2nd brake (B1) piston, then measure the distance

between the top of O/D brake (B0) plate and the transmis-

sion case – rear cover mating surface.

Call this value (A).

((A) = The value on vernier caliper – width of straight edge )

Measure the distance from top of O/D brake (B0) piston (on

rear cover) to rear cover – transmission case mating surface.

Call this value (B).

Clearance = (A) – (B) + 0.4

O/D brake (B0) clearance

Standard : 0.80 – 1.40 mm (0.0315 – 0.0551 in.)

20) If the obtained value is out of standard value, replace brake

disc and plate.

21) Install O/D brake piston adapter (1) thrust needle roller bear-

ing (2) and direct clutch (C0) assembly (3).

1. Straight edge

2. Vernier caliper

3. Rear cover assembly (with B0 piston)

5. Air gun

6. O/D brake piston adapter

Page 170 of 447

7B-128 AUTOMATIC TRANSMISSION (4 A/T)

38) Install follow shaft (1) to transmission case.

Turn it right and left to match the reverse brake (B2) discs

and the spline of follow shaft.

39) Install thrust needle roller bearing (1) to intermediate shaft

(2).

40) Install intermediate shaft (1) to transmission case.

41) Install rear clutch assembly (1) by turning it right and left to

match the clutch disc of rear clutch assembly and the spline

of intermediate shaft.

42) Install thrust bearing race (2).

“A” : Grease 99000-25030

43) Install front clutch assembly (1) by turning it right and left to

match the clutch of disc clutch assembly and the spline of

follow shaft. NOTE:

When installing follow shaft, do not let the thrust washer

fall off from follow shaft.

Page 228 of 447

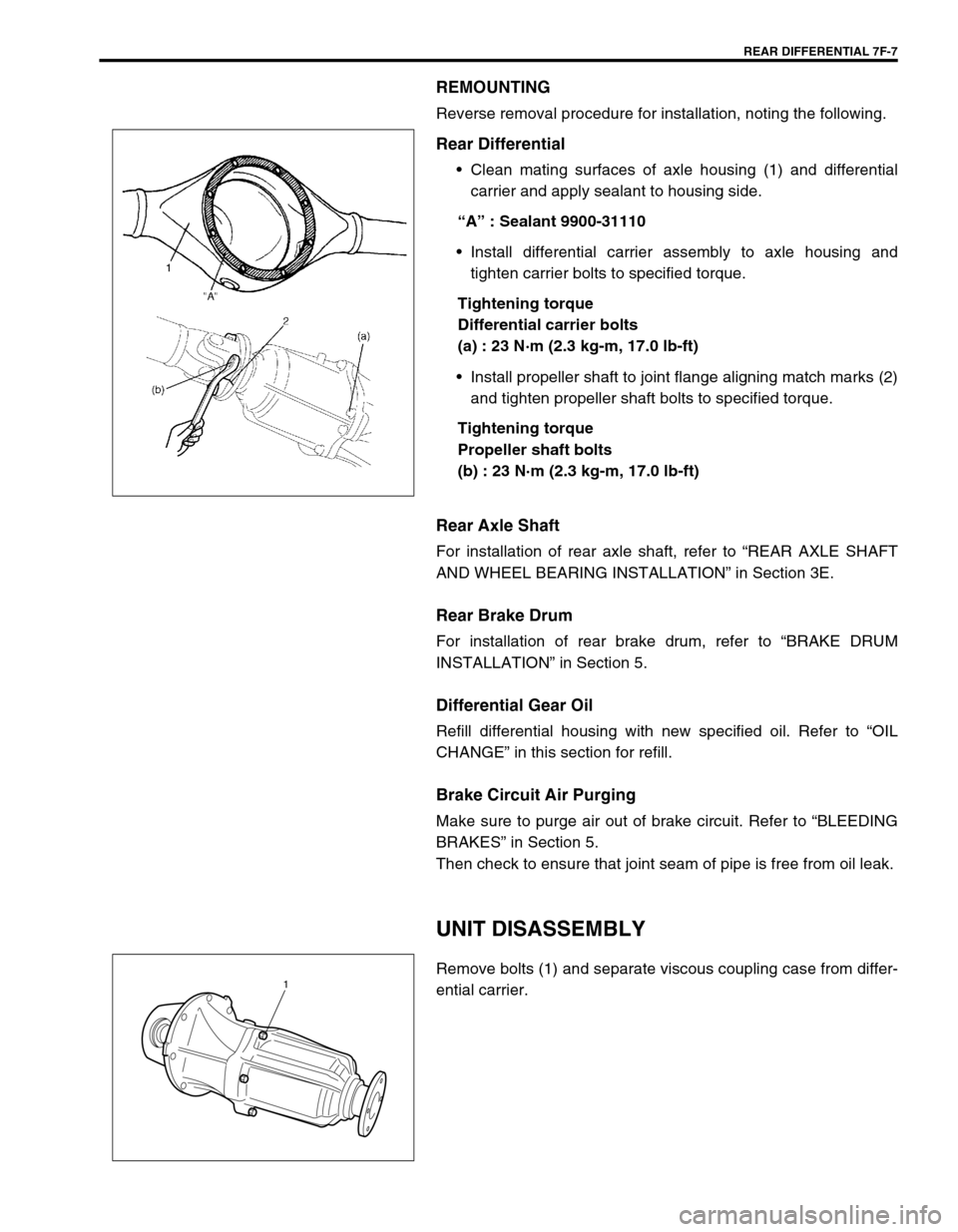

7F-6 REAR DIFFERENTIAL

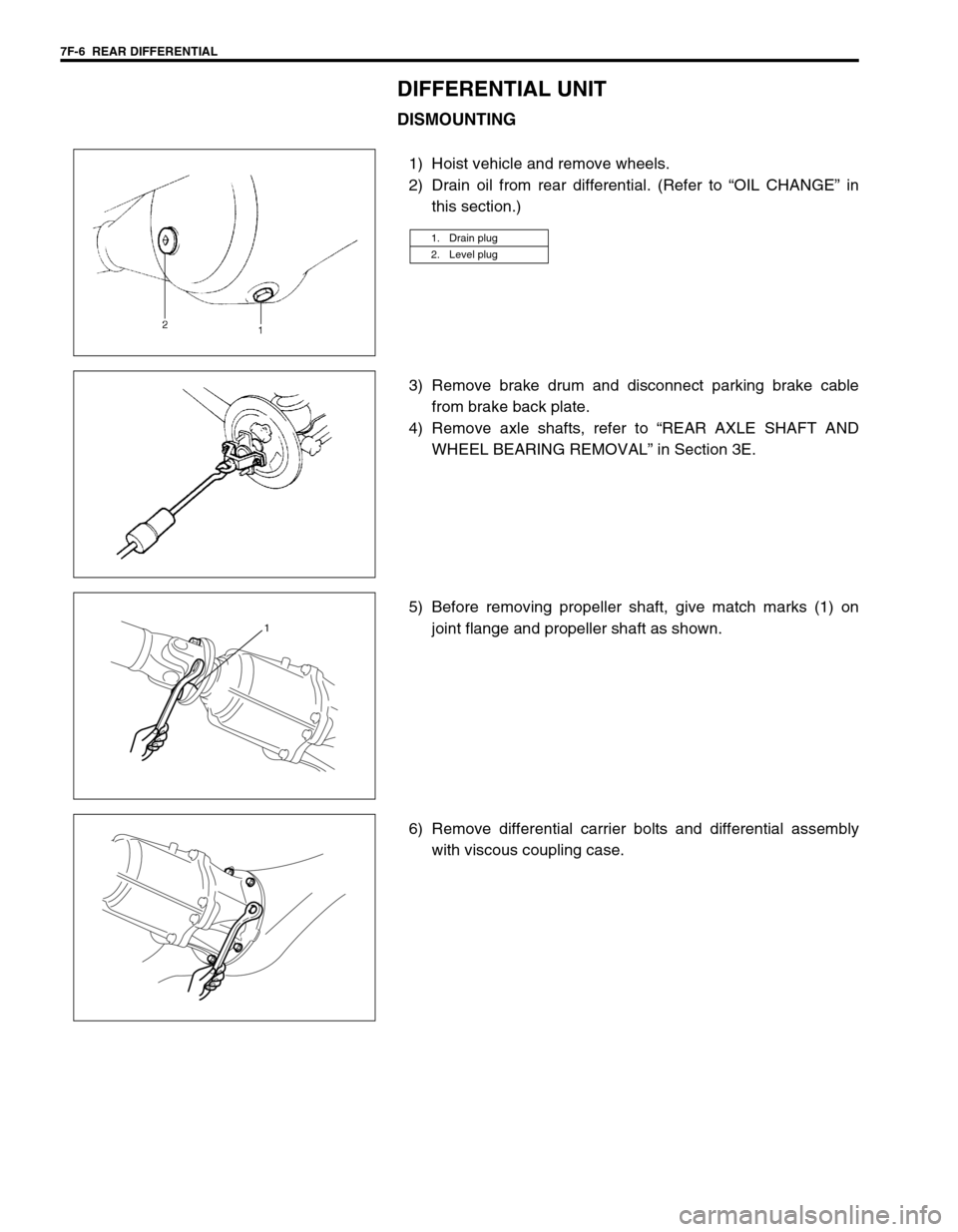

DIFFERENTIAL UNIT

DISMOUNTING

1) Hoist vehicle and remove wheels.

2) Drain oil from rear differential. (Refer to “OIL CHANGE” in

this section.)

3) Remove brake drum and disconnect parking brake cable

from brake back plate.

4) Remove axle shafts, refer to “REAR AXLE SHAFT AND

WHEEL BEARING REMOVAL” in Section 3E.

5) Before removing propeller shaft, give match marks (1) on

joint flange and propeller shaft as shown.

6) Remove differential carrier bolts and differential assembly

with viscous coupling case.

1. Drain plug

2. Level plug

1

Page 229 of 447

REAR DIFFERENTIAL 7F-7

REMOUNTING

Reverse removal procedure for installation, noting the following.

Rear Differential

Clean mating surfaces of axle housing (1) and differential

carrier and apply sealant to housing side.

“A” : Sealant 9900-31110

Install differential carrier assembly to axle housing and

tighten carrier bolts to specified torque.

Tightening torque

Differential carrier bolts

(a) : 23 N·m (2.3 kg-m, 17.0 lb-ft)

Install propeller shaft to joint flange aligning match marks (2)

and tighten propeller shaft bolts to specified torque.

Tightening torque

Propeller shaft bolts

(b) : 23 N·m (2.3 kg-m, 17.0 lb-ft)

Rear Axle Shaft

For installation of rear axle shaft, refer to “REAR AXLE SHAFT

AND WHEEL BEARING INSTALLATION” in Section 3E.

Rear Brake Drum

For installation of rear brake drum, refer to “BRAKE DRUM

INSTALLATION” in Section 5.

Differential Gear Oil

Refill differential housing with new specified oil. Refer to “OIL

CHANGE” in this section for refill.

Brake Circuit Air Purging

Make sure to purge air out of brake circuit. Refer to “BLEEDING

BRAKES” in Section 5.

Then check to ensure that joint seam of pipe is free from oil leak.

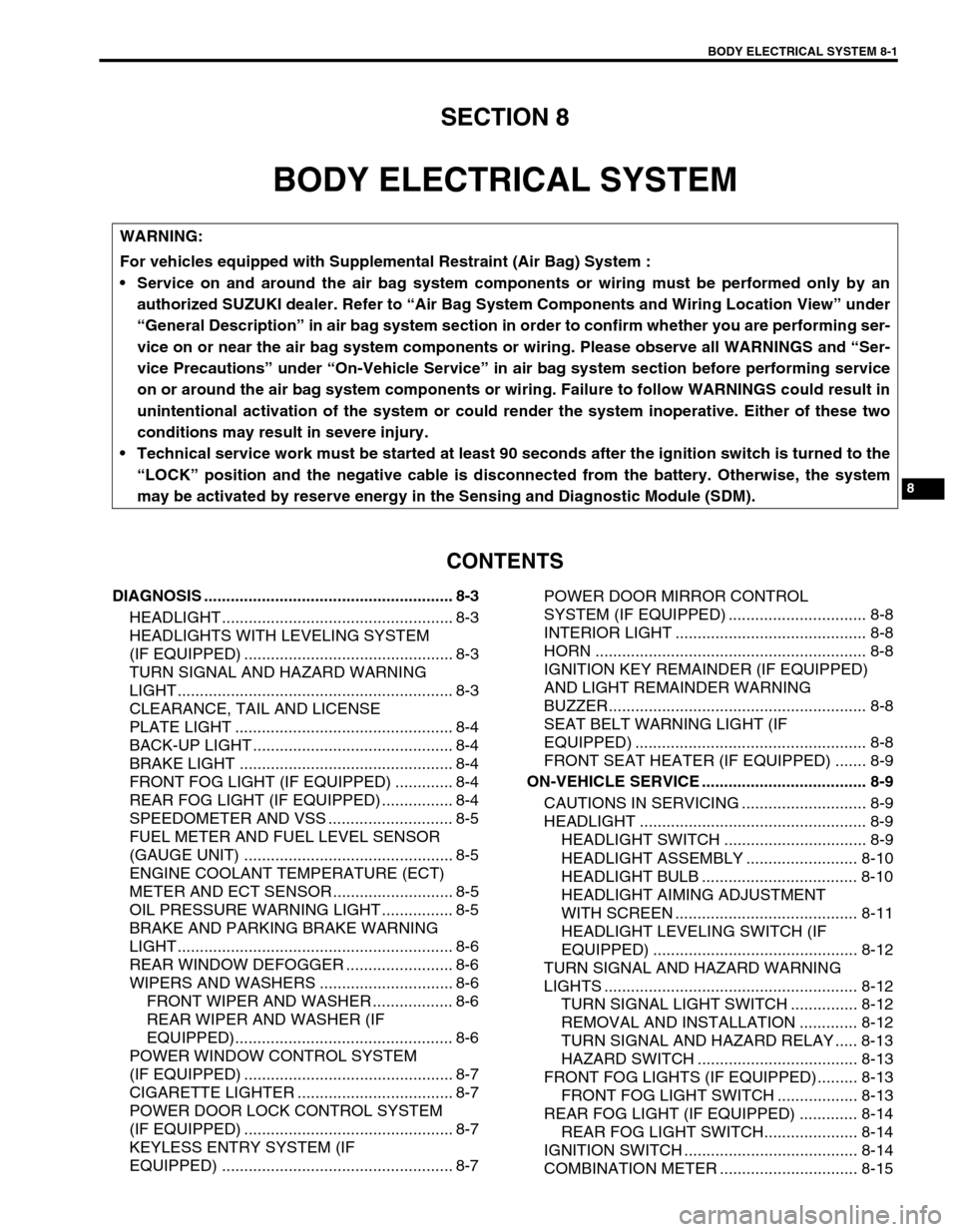

UNIT DISASSEMBLY

Remove bolts (1) and separate viscous coupling case from differ-

ential carrier.1

Page 245 of 447

BODY ELECTRICAL SYSTEM 8-1

6F1

6F2

6G

6H

6K

7A

7A1

7B1

7C1

7D

7E

7F

8A

8

8D

8E

9

10

10A

10B

SECTION 8

BODY ELECTRICAL SYSTEM

CONTENTS

DIAGNOSIS ........................................................ 8-3

HEADLIGHT .................................................... 8-3

HEADLIGHTS WITH LEVELING SYSTEM

(IF EQUIPPED) ............................................... 8-3

TURN SIGNAL AND HAZARD WARNING

LIGHT .............................................................. 8-3

CLEARANCE, TAIL AND LICENSE

PLATE LIGHT ................................................. 8-4

BACK-UP LIGHT ............................................. 8-4

BRAKE LIGHT ................................................ 8-4

FRONT FOG LIGHT (IF EQUIPPED) ............. 8-4

REAR FOG LIGHT (IF EQUIPPED) ................ 8-4

SPEEDOMETER AND VSS ............................ 8-5

FUEL METER AND FUEL LEVEL SENSOR

(GAUGE UNIT) ............................................... 8-5

ENGINE COOLANT TEMPERATURE (ECT)

METER AND ECT SENSOR ........................... 8-5

OIL PRESSURE WARNING LIGHT ................ 8-5

BRAKE AND PARKING BRAKE WARNING

LIGHT .............................................................. 8-6

REAR WINDOW DEFOGGER ........................ 8-6

WIPERS AND WASHERS .............................. 8-6

FRONT WIPER AND WASHER .................. 8-6

REAR WIPER AND WASHER (IF

EQUIPPED)................................................. 8-6

POWER WINDOW CONTROL SYSTEM

(IF EQUIPPED) ............................................... 8-7

CIGARETTE LIGHTER ................................... 8-7

POWER DOOR LOCK CONTROL SYSTEM

(IF EQUIPPED) ............................................... 8-7

KEYLESS ENTRY SYSTEM (IF

EQUIPPED) .................................................... 8-7POWER DOOR MIRROR CONTROL

SYSTEM (IF EQUIPPED) ............................... 8-8

INTERIOR LIGHT ........................................... 8-8

HORN ............................................................. 8-8

IGNITION KEY REMAINDER (IF EQUIPPED)

AND LIGHT REMAINDER WARNING

BUZZER.......................................................... 8-8

SEAT BELT WARNING LIGHT (IF

EQUIPPED) .................................................... 8-8

FRONT SEAT HEATER (IF EQUIPPED) ....... 8-9

ON-VEHICLE SERVICE ..................................... 8-9

CAUTIONS IN SERVICING ............................ 8-9

HEADLIGHT ................................................... 8-9

HEADLIGHT SWITCH ................................ 8-9

HEADLIGHT ASSEMBLY ......................... 8-10

HEADLIGHT BULB ................................... 8-10

HEADLIGHT AIMING ADJUSTMENT

WITH SCREEN ......................................... 8-11

HEADLIGHT LEVELING SWITCH (IF

EQUIPPED) .............................................. 8-12

TURN SIGNAL AND HAZARD WARNING

LIGHTS ......................................................... 8-12

TURN SIGNAL LIGHT SWITCH ............... 8-12

REMOVAL AND INSTALLATION ............. 8-12

TURN SIGNAL AND HAZARD RELAY ..... 8-13

HAZARD SWITCH .................................... 8-13

FRONT FOG LIGHTS (IF EQUIPPED)......... 8-13

FRONT FOG LIGHT SWITCH .................. 8-13

REAR FOG LIGHT (IF EQUIPPED) ............. 8-14

REAR FOG LIGHT SWITCH..................... 8-14

IGNITION SWITCH ....................................... 8-14

COMBINATION METER ............................... 8-15 WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System :

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

Page 246 of 447

8-2 BODY ELECTRICAL SYSTEM

CIRCUIT.................................................... 8-15

FUEL METER AND FUEL LEVEL

SENSOR (GAUGE UNIT) ............................. 8-16

FUEL LEVEL METER ............................... 8-16

FUEL LEVEL SENSOR (GAUGE UNIT) ... 8-17

SPEED METER AND VSS ........................... 8-17

VSS ........................................................... 8-17

ENGINE COOLANT TEMPERATURE (ECT)

METER AND SENSOR................................. 8-17

ENGINE COOLANT TEMPERATURE

(ECT) METER ........................................... 8-17

ECT SENSOR ........................................... 8-18

OIL PRESSURE WARNING LIGHT ............. 8-18

OIL PRESSURE SWITCH ........................ 8-18

BRAKE FLUID LEVEL AND PARKING

BRAKE WARNING LIGHT ............................ 8-18

BRAKE FLUID LEVEL SWITCH ............... 8-18

PARKING BRAKE SWITCH...................... 8-19

REAR WINDOW DEFOGGER...................... 8-19

DEFOGGER SWITCH .............................. 8-19

DEFOGGER WIRE ................................... 8-19

WIPERS AND WASHERS ............................ 8-21

COMPONENTS ........................................ 8-21

FRONT WIPER AND WASHER

SWITCH .................................................... 8-21

FRONT WIPER MOTOR........................... 8-23

WASHER TANK AND WASHER

PUMP ........................................................ 8-24

REAR WIPER AND WASHER SWITCH

(IF EQUIPPED) ......................................... 8-25REAR WIPER MOTOR .............................. 8-25

IGNITION KEY REMAINDER (IF EQUIPPED)

AND LIGHT REMAINDER WARNING

BUZZER ........................................................ 8-25

POWER WINDOW CONTROL SYSTEM

(IF EQUIPPED).............................................. 8-26

POWER WINDOW MAIN SWITCH ........... 8-26

POWER WINDOW SUB SWITCH ............. 8-27

DOOR SWITCH ............................................. 8-27

STOP LAMP (BRAKE) SWITCH ................... 8-27

POWER DOOR LOCK SYSTEM (IF

EQUIPPED) ................................................... 8-28

DOOR LOCK CONTROLLER .................... 8-28

DRIVER’S DOOR KNOB SWITCH ............ 8-28

DOOR LOCK ACTUATOR......................... 8-29

KEYLESS ENTRY SYSTEM (IF

EQUIPPED) ................................................... 8-29

DOOR LOCK CONTROLLER .................... 8-29

DOOR LOCK ACTUATOR......................... 8-29

RECEIVER................................................. 8-30

TRANSMITTER ......................................... 8-30

POWER DOOR MIRROR CONTROL

SYSTEM (IF EQUIPPED) .............................. 8-31

MIRROR SWITCH ..................................... 8-31

DOOR MIRROR ACTUATOR .................... 8-32

FRONT SEAT HEATER (IF EQUIPPED) ...... 8-32

SEAT HEATER SWITCH (DRIVER AND

PASSENGER SIDE) .................................. 8-32

SEAT HEATER WIRE................................ 8-33