window SUZUKI SWIFT 2000 1.G Transmission Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 447, PDF Size: 10.54 MB

Page 308 of 447

9-4 BODY SERVICE

8) Remove outer weather-strip (1).

Lower window all the way down. Then, use a tape-wrapped

putty knife to pry off outer weather-strip.

9) Remove bottom channel attaching screws (1).

10) When removing door glass (2), turn door glass 90° counter-

clockwise to remove it.

INSTALLATION

Reverse removal procedure to install door glass noting the follow-

ing instructions.

If there is deformity for glass run, replace new one.

Tighten bottom channel attaching screws. Tighten rear

screw first, and then tighten front screw.

Glass fitted position of bottom channel (1) is as shown in fig-

ure.

Glass fitted position of bottom channel “a”

3-door model : 335.5 - 338.5 mm (13.21 - 13.33 in.)

5-door model : 90.8 - 93.8 mm (3.57 - 3.69 in.) NOTE:

When removed outer weather-strip (1) from door panel

(2), be careful not to deformation for outer weather-strip

(1).

12

2

2

1

Page 309 of 447

BODY SERVICE 9-5

Adjust equalizer (1) of window regular so that measurement

“a” and “b” are equal.

Secure door sealing cover (1) with adhesive (2).

Install door window regulator handle (1) so that it has a 45°

±12.5° angle when glass is fully closed as shown in figure

1 “a”“b”

1

2

A : Front

Page 310 of 447

9-6 BODY SERVICE

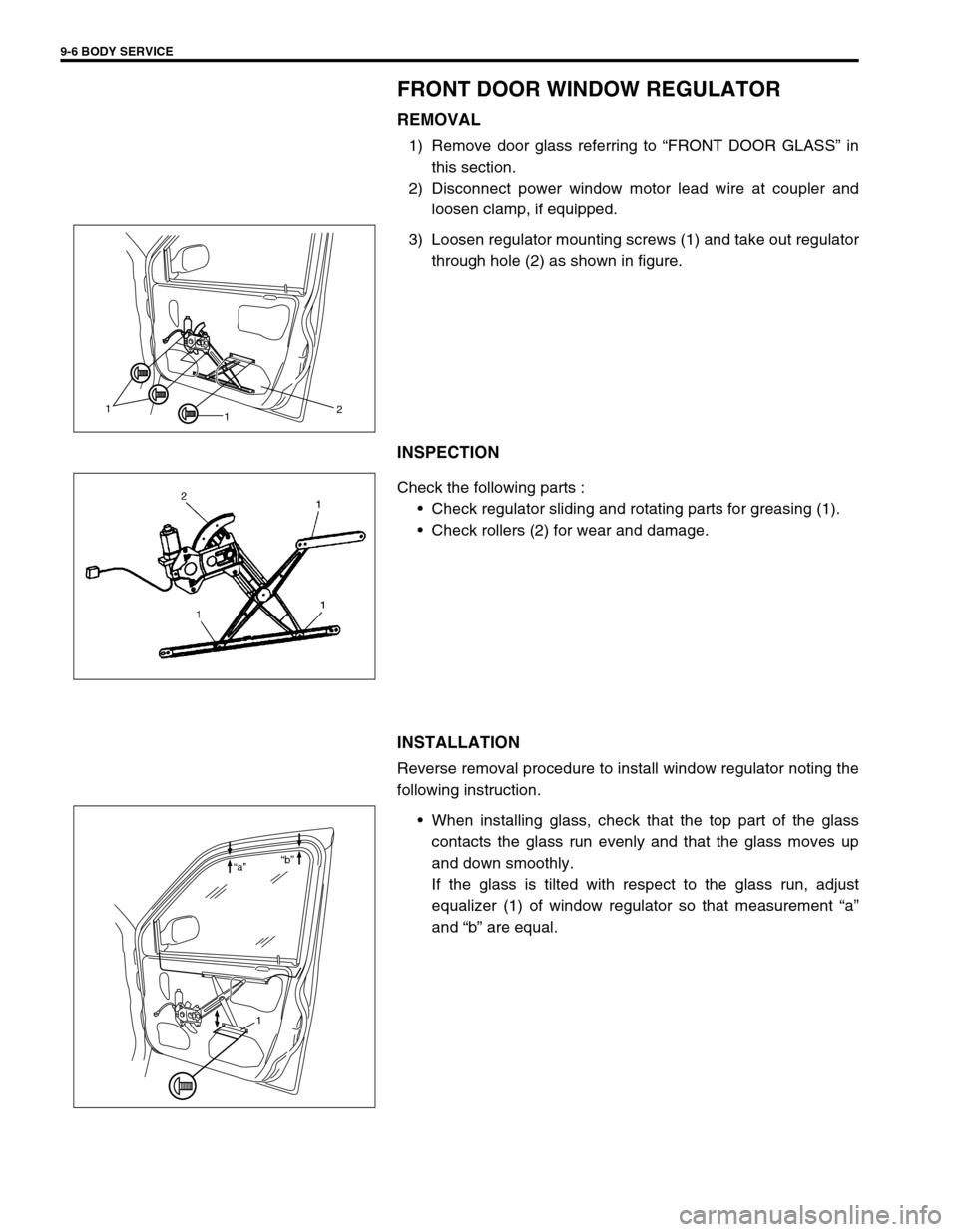

FRONT DOOR WINDOW REGULATOR

REMOVAL

1) Remove door glass referring to “FRONT DOOR GLASS” in

this section.

2) Disconnect power window motor lead wire at coupler and

loosen clamp, if equipped.

3) Loosen regulator mounting screws (1) and take out regulator

through hole (2) as shown in figure.

INSPECTION

Check the following parts :

Check regulator sliding and rotating parts for greasing (1).

Check rollers (2) for wear and damage.

INSTALLATION

Reverse removal procedure to install window regulator noting the

following instruction.

When installing glass, check that the top part of the glass

contacts the glass run evenly and that the glass moves up

and down smoothly.

If the glass is tilted with respect to the glass run, adjust

equalizer (1) of window regulator so that measurement “a”

and “b” are equal.

1

12

1 “a”“b”

Page 312 of 447

9-8 BODY SERVICE

REAR DOOR GLASS (IF EQUIPPED)

1. Door glass 7. Window regulator handle 13. Glass bottom rubber

2. Window regulator assembly

: Apply lithium grease 99000-25010 to moving section.8. Rear door outer weather-strip 14. Door inside pull handle case

3. Glass run 9. Rear door inside pull handle bracket [A] : Without power window model

4. Door trim 10. Rear door inner garnish [B] : With power window model

5. Door sealing cover 11. Rear door outer garnish

6. Door sash 12. Glass bottom channel

Page 313 of 447

BODY SERVICE 9-9

REMOVAL

1) Remove window regulator handle (1) (if equipped).

For its removal, pull off snap by using a cloth (2) as shown in

figure.

2) Remove inside handle bezel (1).

3) Remove door inside pull handle case fitting screw.

4) Remove rear door inner garnish.

5) Remove door trim (1).

With inside handle bezel (2) tilted as shown in figure, turn

door trim 90° counterclockwise to remove it.

And disconnect power window switch lead wire at coupler (if

equipped).

6) Remove door inside pull handle bracket.

7) Remove door sealing cover (1).

2

1

1

Page 314 of 447

9-10 BODY SERVICE

8) Remove rear door outer garnish (1).

9) Remove outer weather-strip (2).

Lower window all the way down. Then, use a tape-wrapped

putty knife (or screwdriver) to pry off outer weather-strip.

10) Detach rear part of glass run (1) from sash (2) and remove

sash (2) by removing 2 screws (3).

11) Loosen window regulator mounting screws (5).

12) When removing door glass (4), turn door glass 90° counter-

clockwise to remove it.

INSTALLATION

Reverse removal procedure to install door glass noting the follow-

ing instructions.

If there is deformity for glass run, replace new one.

Tighten bottom channel attaching screws. Tighten rear

screw first, and then tighten front screw.

Glass fitted position of bottom channel (1) is as shown in fig-

ure.

Glass fitted position of bottom channel

“a” : 201.9 - 204.9 mm (7.95 - 8.07 in.)

Secure door sealing cover (1) with adhesive (2). NOTE:

When removed outer weather-strip (2) from door panel

(3), be careful not to deformation for outer weather-strip

(2).

2 3

1

4

1

23

5

4

1

2

Page 315 of 447

BODY SERVICE 9-11

Install door window regulator handle (1) so that it has a 45°

±12.5° angle when glass is fully closed.

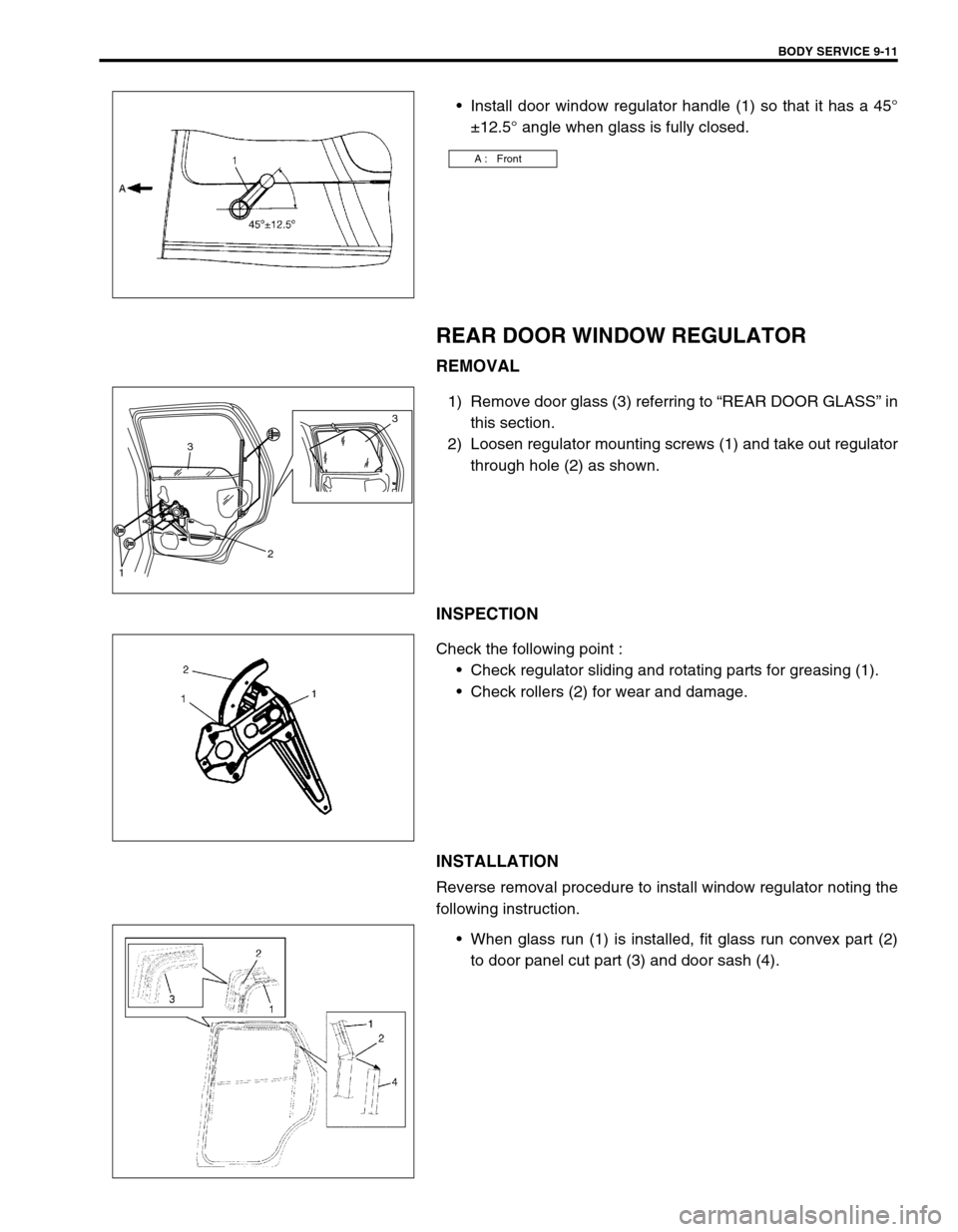

REAR DOOR WINDOW REGULATOR

REMOVAL

1) Remove door glass (3) referring to “REAR DOOR GLASS” in

this section.

2) Loosen regulator mounting screws (1) and take out regulator

through hole (2) as shown.

INSPECTION

Check the following point :

Check regulator sliding and rotating parts for greasing (1).

Check rollers (2) for wear and damage.

INSTALLATION

Reverse removal procedure to install window regulator noting the

following instruction.

When glass run (1) is installed, fit glass run convex part (2)

to door panel cut part (3) and door sash (4).

A : Front

3

3

2

1

Page 316 of 447

9-12 BODY SERVICE

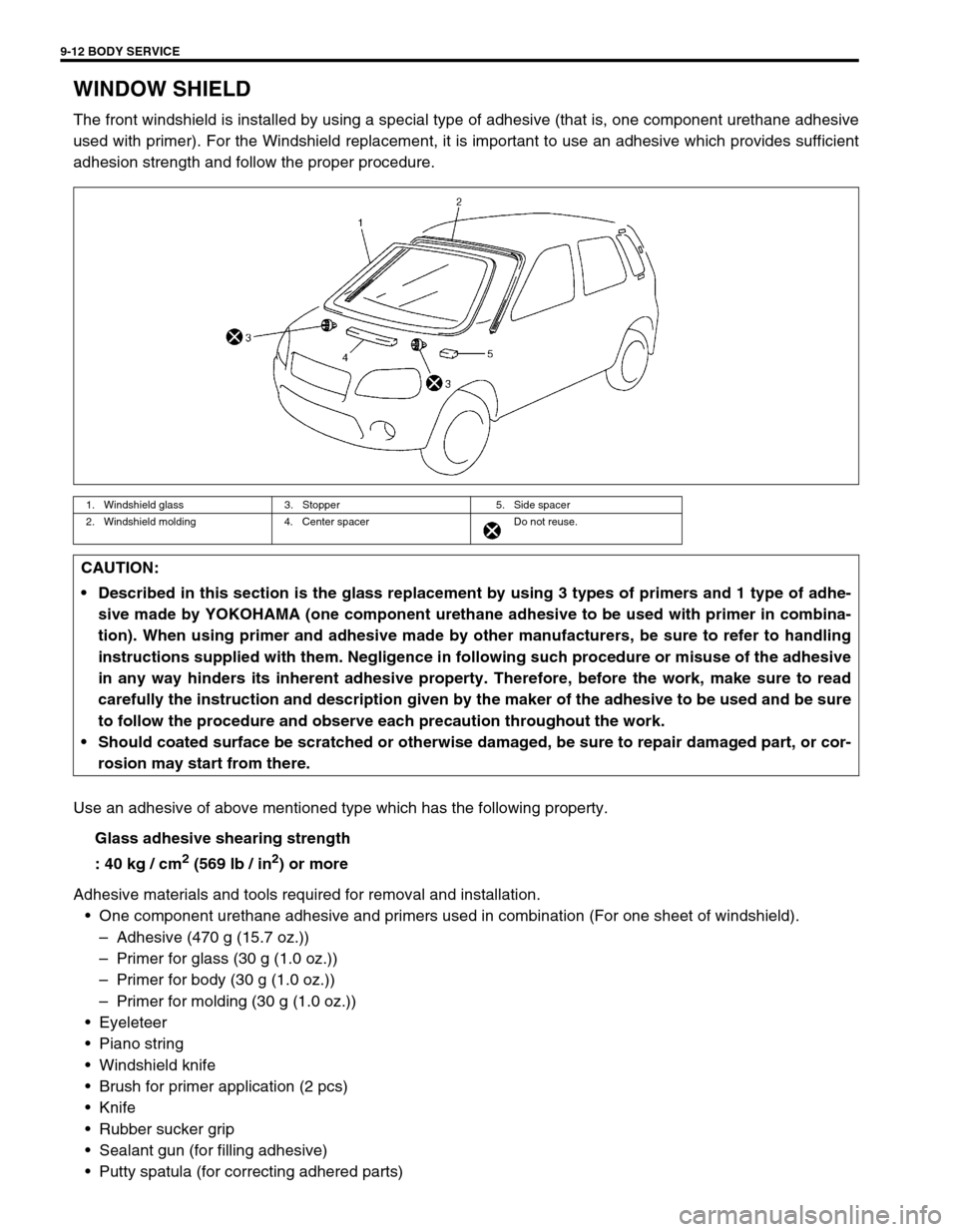

WINDOW SHIELD

The front windshield is installed by using a special type of adhesive (that is, one component urethane adhesive

used with primer). For the Windshield replacement, it is important to use an adhesive which provides sufficient

adhesion strength and follow the proper procedure.

Use an adhesive of above mentioned type which has the following property.

Glass adhesive shearing strength

: 40 kg / cm

2 (569 lb / in2) or more

Adhesive materials and tools required for removal and installation.

One component urethane adhesive and primers used in combination (For one sheet of windshield).

–Adhesive (470 g (15.7 oz.))

–Primer for glass (30 g (1.0 oz.))

–Primer for body (30 g (1.0 oz.))

–Primer for molding (30 g (1.0 oz.))

Eyeleteer

Piano string

Windshield knife

Brush for primer application (2 pcs)

Knife

Rubber sucker grip

Sealant gun (for filling adhesive)

Putty spatula (for correcting adhered parts)

1. Windshield glass 3. Stopper 5. Side spacer

2. Windshield molding 4. Center spacer Do not reuse.

CAUTION:

Described in this section is the glass replacement by using 3 types of primers and 1 type of adhe-

sive made by YOKOHAMA (one component urethane adhesive to be used with primer in combina-

tion). When using primer and adhesive made by other manufacturers, be sure to refer to handling

instructions supplied with them. Negligence in following such procedure or misuse of the adhesive

in any way hinders its inherent adhesive property. Therefore, before the work, make sure to read

carefully the instruction and description given by the maker of the adhesive to be used and be sure

to follow the procedure and observe each precaution throughout the work.

Should coated surface be scratched or otherwise damaged, be sure to repair damaged part, or cor-

rosion may start from there.

Page 321 of 447

BODY SERVICE 9-17

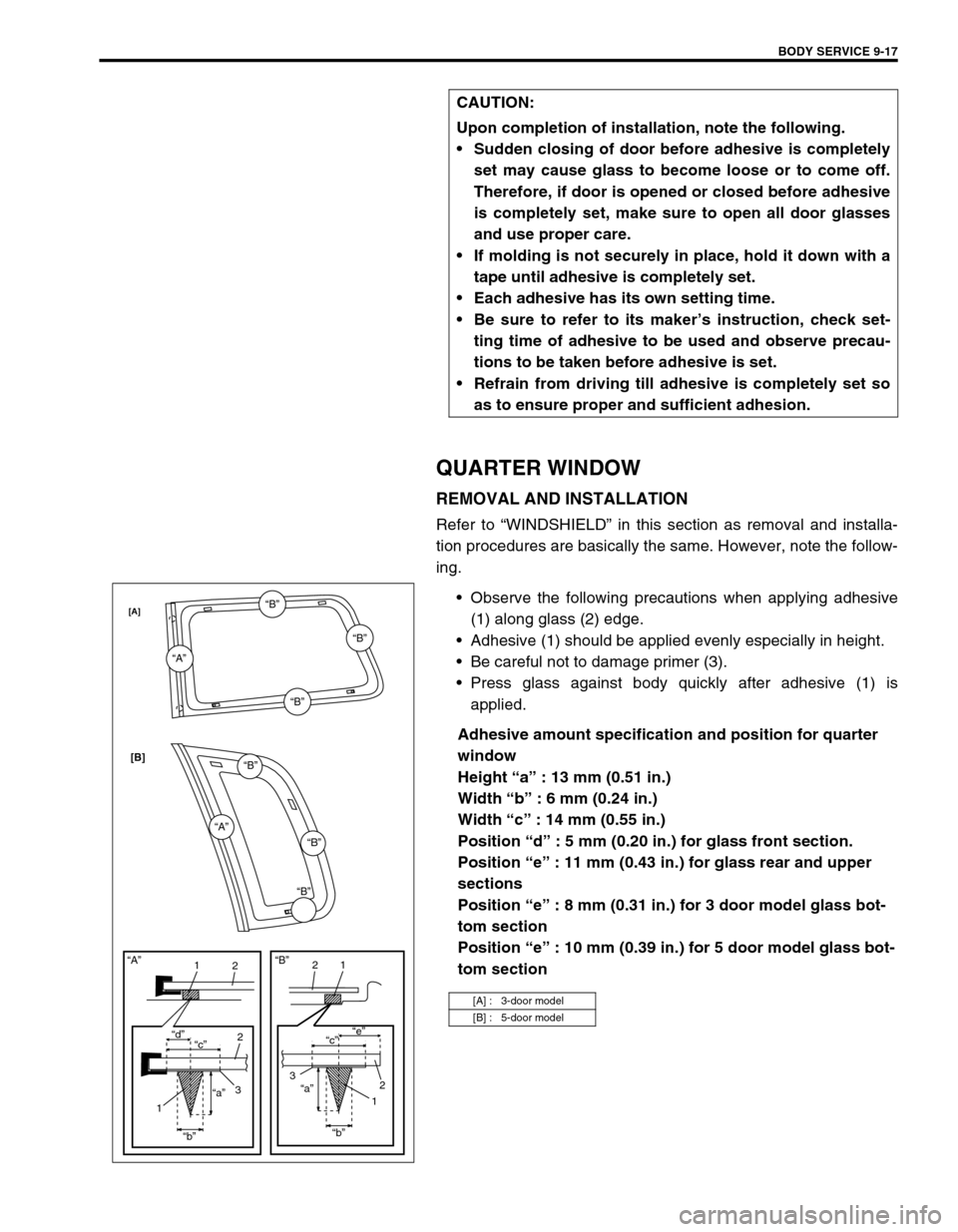

QUARTER WINDOW

REMOVAL AND INSTALLATION

Refer to “WINDSHIELD” in this section as removal and installa-

tion procedures are basically the same. However, note the follow-

ing.

Observe the following precautions when applying adhesive

(1) along glass (2) edge.

Adhesive (1) should be applied evenly especially in height.

Be careful not to damage primer (3).

Press glass against body quickly after adhesive (1) is

applied.

Adhesive amount specification and position for quarter

window

Height “a” : 13 mm (0.51 in.)

Width “b” : 6 mm (0.24 in.)

Width “c” : 14 mm (0.55 in.)

Position “d” : 5 mm (0.20 in.) for glass front section.

Position “e” : 11 mm (0.43 in.) for glass rear and upper

sections

Position “e” : 8 mm (0.31 in.) for 3 door model glass bot-

tom section

Position “e” : 10 mm (0.39 in.) for 5 door model glass bot-

tom section CAUTION:

Upon completion of installation, note the following.

Sudden closing of door before adhesive is completely

set may cause glass to become loose or to come off.

Therefore, if door is opened or closed before adhesive

is completely set, make sure to open all door glasses

and use proper care.

If molding is not securely in place, hold it down with a

tape until adhesive is completely set.

Each adhesive has its own setting time.

Be sure to refer to its maker’s instruction, check set-

ting time of adhesive to be used and observe precau-

tions to be taken before adhesive is set.

Refrain from driving till adhesive is completely set so

as to ensure proper and sufficient adhesion.

[A] : 3-door model

[B] : 5-door model

“A”

“A”“B”

“B”

“B”

“B”

“B”“B”

11

22

2

33 “d”

“c”“c”“e”

“a”“a”

“b”“b”

11

2 “A”“B”

[A]

[B]

Page 327 of 447

BODY SERVICE 9-23

BACK DOOR ASSEMBLY

REMOVAL

1) Remove back door trim (1).

2) Remove related section of head lining and quarter trim.

3) Disconnect back door harness connectors (2) and washer

hose (3).

4) Remove wire harness connectors inside back door.

5) Remove back door balancer (4) (first at its door side and next

at its body side).

6) Remove door hinge nuts (5) and remove back door assembly

(6).

1. Back door panel assembly 4. Back door balancer unit

2. Back door window glass 5. Back door trim

3. Back door hinge

: Apply lithium grease 99000-25010 to door hinge moving section

: Apply sealant 99000-31110 to contact face6. Weather strip