window SUZUKI SWIFT 2000 1.G Transmission Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 447, PDF Size: 10.54 MB

Page 245 of 447

BODY ELECTRICAL SYSTEM 8-1

6F1

6F2

6G

6H

6K

7A

7A1

7B1

7C1

7D

7E

7F

8A

8

8D

8E

9

10

10A

10B

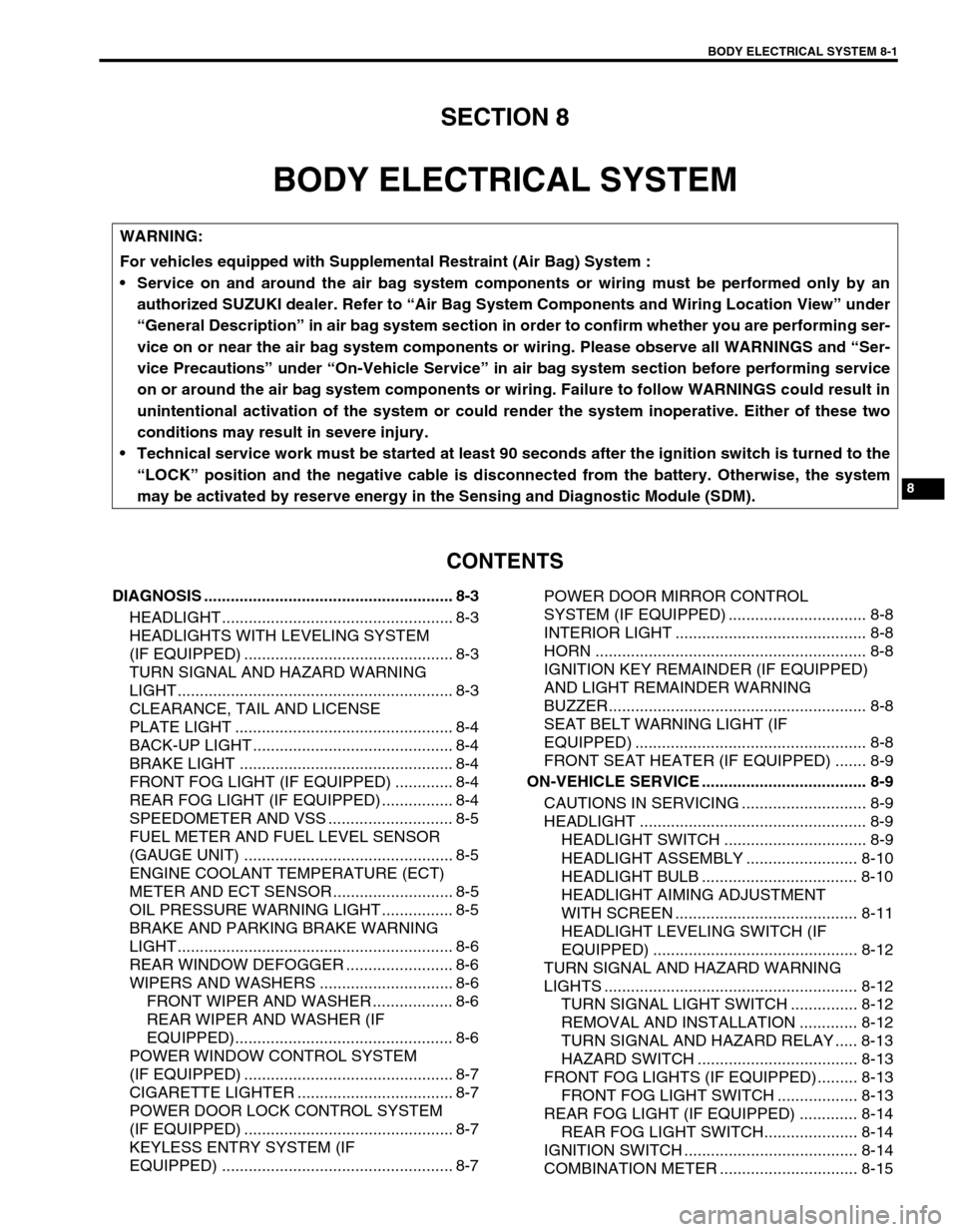

SECTION 8

BODY ELECTRICAL SYSTEM

CONTENTS

DIAGNOSIS ........................................................ 8-3

HEADLIGHT .................................................... 8-3

HEADLIGHTS WITH LEVELING SYSTEM

(IF EQUIPPED) ............................................... 8-3

TURN SIGNAL AND HAZARD WARNING

LIGHT .............................................................. 8-3

CLEARANCE, TAIL AND LICENSE

PLATE LIGHT ................................................. 8-4

BACK-UP LIGHT ............................................. 8-4

BRAKE LIGHT ................................................ 8-4

FRONT FOG LIGHT (IF EQUIPPED) ............. 8-4

REAR FOG LIGHT (IF EQUIPPED) ................ 8-4

SPEEDOMETER AND VSS ............................ 8-5

FUEL METER AND FUEL LEVEL SENSOR

(GAUGE UNIT) ............................................... 8-5

ENGINE COOLANT TEMPERATURE (ECT)

METER AND ECT SENSOR ........................... 8-5

OIL PRESSURE WARNING LIGHT ................ 8-5

BRAKE AND PARKING BRAKE WARNING

LIGHT .............................................................. 8-6

REAR WINDOW DEFOGGER ........................ 8-6

WIPERS AND WASHERS .............................. 8-6

FRONT WIPER AND WASHER .................. 8-6

REAR WIPER AND WASHER (IF

EQUIPPED)................................................. 8-6

POWER WINDOW CONTROL SYSTEM

(IF EQUIPPED) ............................................... 8-7

CIGARETTE LIGHTER ................................... 8-7

POWER DOOR LOCK CONTROL SYSTEM

(IF EQUIPPED) ............................................... 8-7

KEYLESS ENTRY SYSTEM (IF

EQUIPPED) .................................................... 8-7POWER DOOR MIRROR CONTROL

SYSTEM (IF EQUIPPED) ............................... 8-8

INTERIOR LIGHT ........................................... 8-8

HORN ............................................................. 8-8

IGNITION KEY REMAINDER (IF EQUIPPED)

AND LIGHT REMAINDER WARNING

BUZZER.......................................................... 8-8

SEAT BELT WARNING LIGHT (IF

EQUIPPED) .................................................... 8-8

FRONT SEAT HEATER (IF EQUIPPED) ....... 8-9

ON-VEHICLE SERVICE ..................................... 8-9

CAUTIONS IN SERVICING ............................ 8-9

HEADLIGHT ................................................... 8-9

HEADLIGHT SWITCH ................................ 8-9

HEADLIGHT ASSEMBLY ......................... 8-10

HEADLIGHT BULB ................................... 8-10

HEADLIGHT AIMING ADJUSTMENT

WITH SCREEN ......................................... 8-11

HEADLIGHT LEVELING SWITCH (IF

EQUIPPED) .............................................. 8-12

TURN SIGNAL AND HAZARD WARNING

LIGHTS ......................................................... 8-12

TURN SIGNAL LIGHT SWITCH ............... 8-12

REMOVAL AND INSTALLATION ............. 8-12

TURN SIGNAL AND HAZARD RELAY ..... 8-13

HAZARD SWITCH .................................... 8-13

FRONT FOG LIGHTS (IF EQUIPPED)......... 8-13

FRONT FOG LIGHT SWITCH .................. 8-13

REAR FOG LIGHT (IF EQUIPPED) ............. 8-14

REAR FOG LIGHT SWITCH..................... 8-14

IGNITION SWITCH ....................................... 8-14

COMBINATION METER ............................... 8-15 WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System :

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

Page 246 of 447

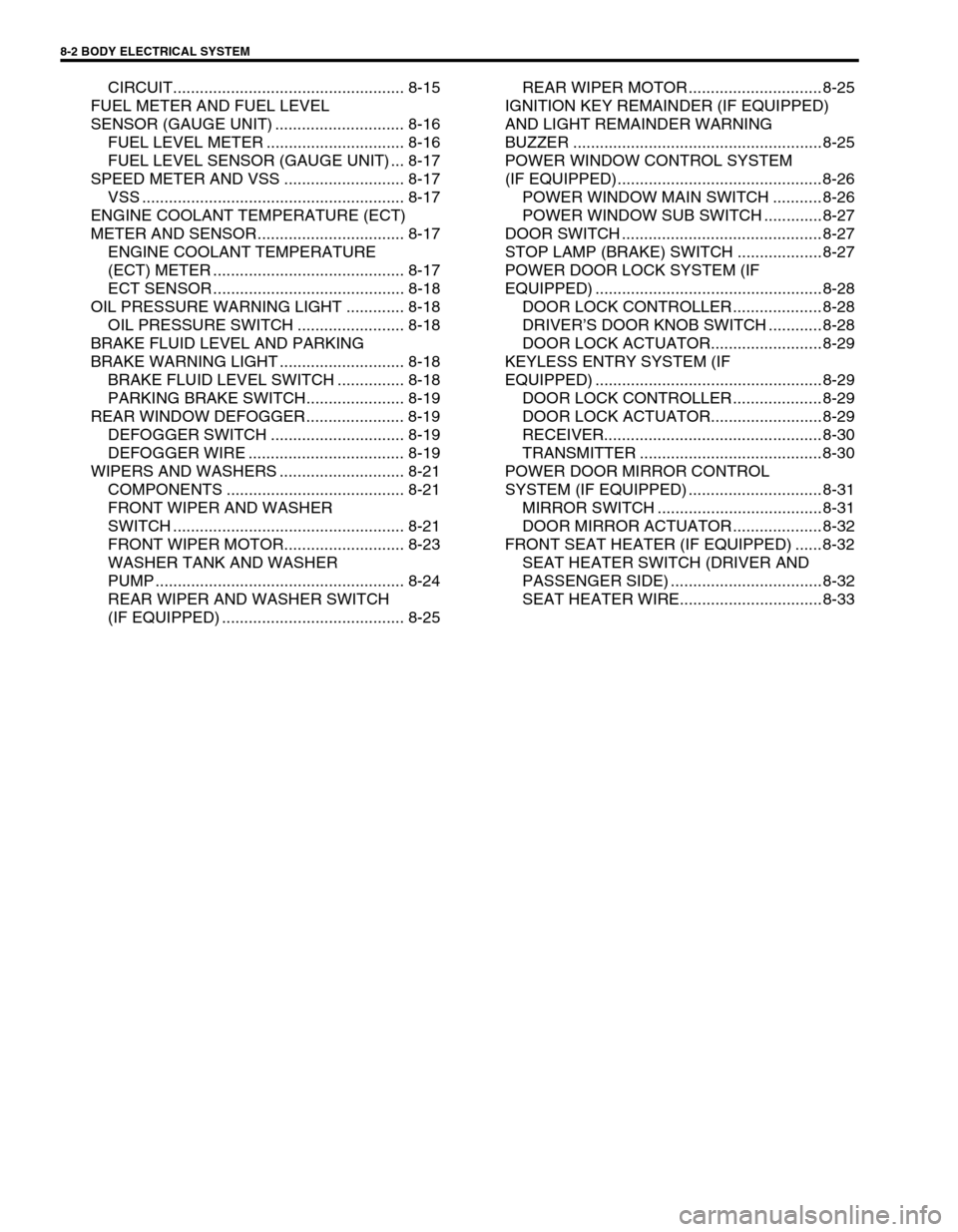

8-2 BODY ELECTRICAL SYSTEM

CIRCUIT.................................................... 8-15

FUEL METER AND FUEL LEVEL

SENSOR (GAUGE UNIT) ............................. 8-16

FUEL LEVEL METER ............................... 8-16

FUEL LEVEL SENSOR (GAUGE UNIT) ... 8-17

SPEED METER AND VSS ........................... 8-17

VSS ........................................................... 8-17

ENGINE COOLANT TEMPERATURE (ECT)

METER AND SENSOR................................. 8-17

ENGINE COOLANT TEMPERATURE

(ECT) METER ........................................... 8-17

ECT SENSOR ........................................... 8-18

OIL PRESSURE WARNING LIGHT ............. 8-18

OIL PRESSURE SWITCH ........................ 8-18

BRAKE FLUID LEVEL AND PARKING

BRAKE WARNING LIGHT ............................ 8-18

BRAKE FLUID LEVEL SWITCH ............... 8-18

PARKING BRAKE SWITCH...................... 8-19

REAR WINDOW DEFOGGER...................... 8-19

DEFOGGER SWITCH .............................. 8-19

DEFOGGER WIRE ................................... 8-19

WIPERS AND WASHERS ............................ 8-21

COMPONENTS ........................................ 8-21

FRONT WIPER AND WASHER

SWITCH .................................................... 8-21

FRONT WIPER MOTOR........................... 8-23

WASHER TANK AND WASHER

PUMP ........................................................ 8-24

REAR WIPER AND WASHER SWITCH

(IF EQUIPPED) ......................................... 8-25REAR WIPER MOTOR .............................. 8-25

IGNITION KEY REMAINDER (IF EQUIPPED)

AND LIGHT REMAINDER WARNING

BUZZER ........................................................ 8-25

POWER WINDOW CONTROL SYSTEM

(IF EQUIPPED).............................................. 8-26

POWER WINDOW MAIN SWITCH ........... 8-26

POWER WINDOW SUB SWITCH ............. 8-27

DOOR SWITCH ............................................. 8-27

STOP LAMP (BRAKE) SWITCH ................... 8-27

POWER DOOR LOCK SYSTEM (IF

EQUIPPED) ................................................... 8-28

DOOR LOCK CONTROLLER .................... 8-28

DRIVER’S DOOR KNOB SWITCH ............ 8-28

DOOR LOCK ACTUATOR......................... 8-29

KEYLESS ENTRY SYSTEM (IF

EQUIPPED) ................................................... 8-29

DOOR LOCK CONTROLLER .................... 8-29

DOOR LOCK ACTUATOR......................... 8-29

RECEIVER................................................. 8-30

TRANSMITTER ......................................... 8-30

POWER DOOR MIRROR CONTROL

SYSTEM (IF EQUIPPED) .............................. 8-31

MIRROR SWITCH ..................................... 8-31

DOOR MIRROR ACTUATOR .................... 8-32

FRONT SEAT HEATER (IF EQUIPPED) ...... 8-32

SEAT HEATER SWITCH (DRIVER AND

PASSENGER SIDE) .................................. 8-32

SEAT HEATER WIRE................................ 8-33

Page 250 of 447

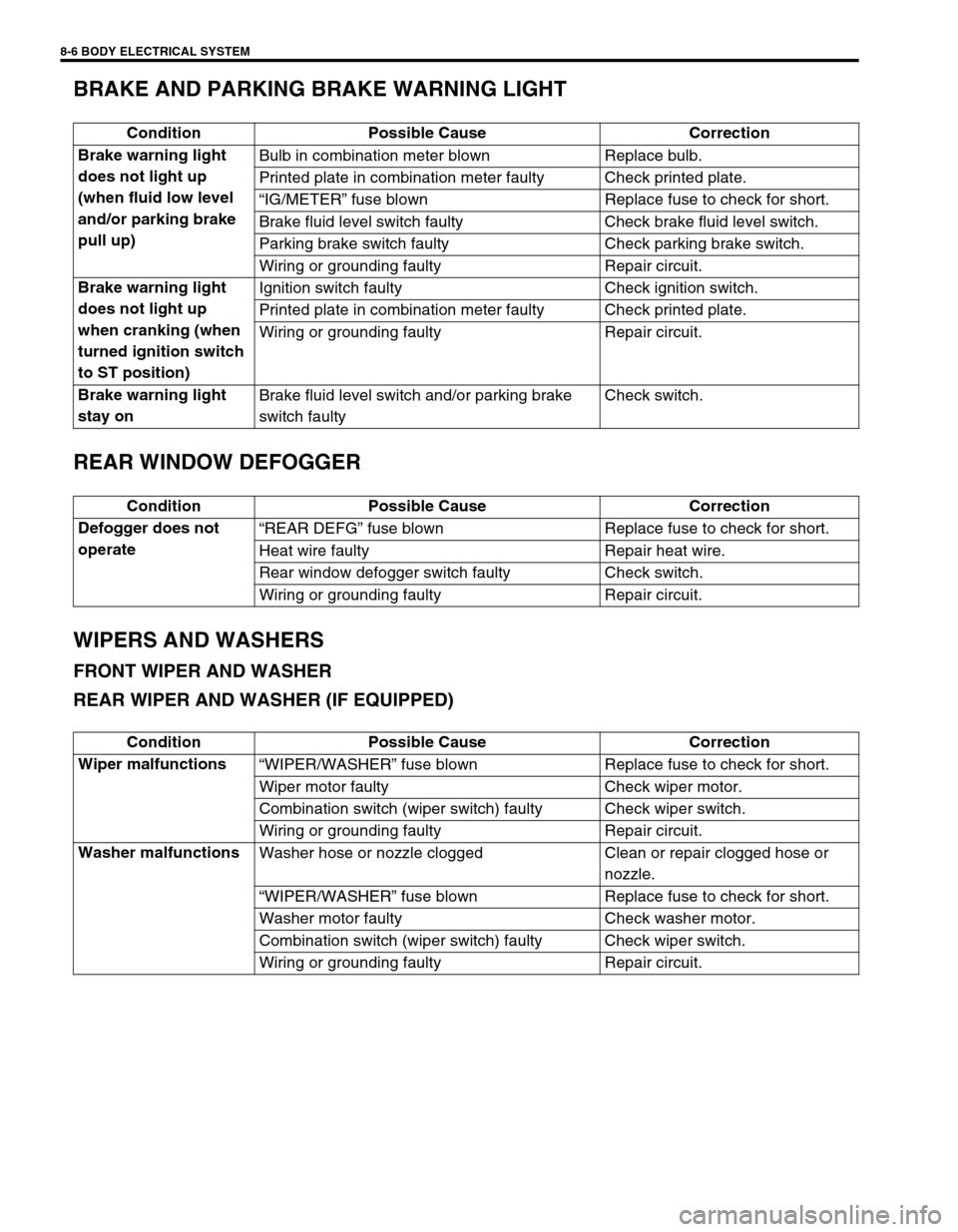

8-6 BODY ELECTRICAL SYSTEM

BRAKE AND PARKING BRAKE WARNING LIGHT

REAR WINDOW DEFOGGER

WIPERS AND WASHERS

FRONT WIPER AND WASHER

REAR WIPER AND WASHER (IF EQUIPPED)

Condition Possible Cause Correction

Brake warning light

does not light up

(when fluid low level

and/or parking brake

pull up)Bulb in combination meter blown Replace bulb.

Printed plate in combination meter faulty Check printed plate.

“IG/METER” fuse blown Replace fuse to check for short.

Brake fluid level switch faulty Check brake fluid level switch.

Parking brake switch faulty Check parking brake switch.

Wiring or grounding faulty Repair circuit.

Brake warning light

does not light up

when cranking (when

turned ignition switch

to ST position)Ignition switch faulty Check ignition switch.

Printed plate in combination meter faulty Check printed plate.

Wiring or grounding faulty Repair circuit.

Brake warning light

stay onBrake fluid level switch and/or parking brake

switch faultyCheck switch.

Condition Possible Cause Correction

Defogger does not

operate“REAR DEFG” fuse blown Replace fuse to check for short.

Heat wire faulty Repair heat wire.

Rear window defogger switch faulty Check switch.

Wiring or grounding faulty Repair circuit.

Condition Possible Cause Correction

Wiper malfunctions

“WIPER/WASHER” fuse blown Replace fuse to check for short.

Wiper motor faulty Check wiper motor.

Combination switch (wiper switch) faulty Check wiper switch.

Wiring or grounding faulty Repair circuit.

Washer malfunctions

Washer hose or nozzle clogged Clean or repair clogged hose or

nozzle.

“WIPER/WASHER” fuse blown Replace fuse to check for short.

Washer motor faulty Check washer motor.

Combination switch (wiper switch) faulty Check wiper switch.

Wiring or grounding faulty Repair circuit.

Page 251 of 447

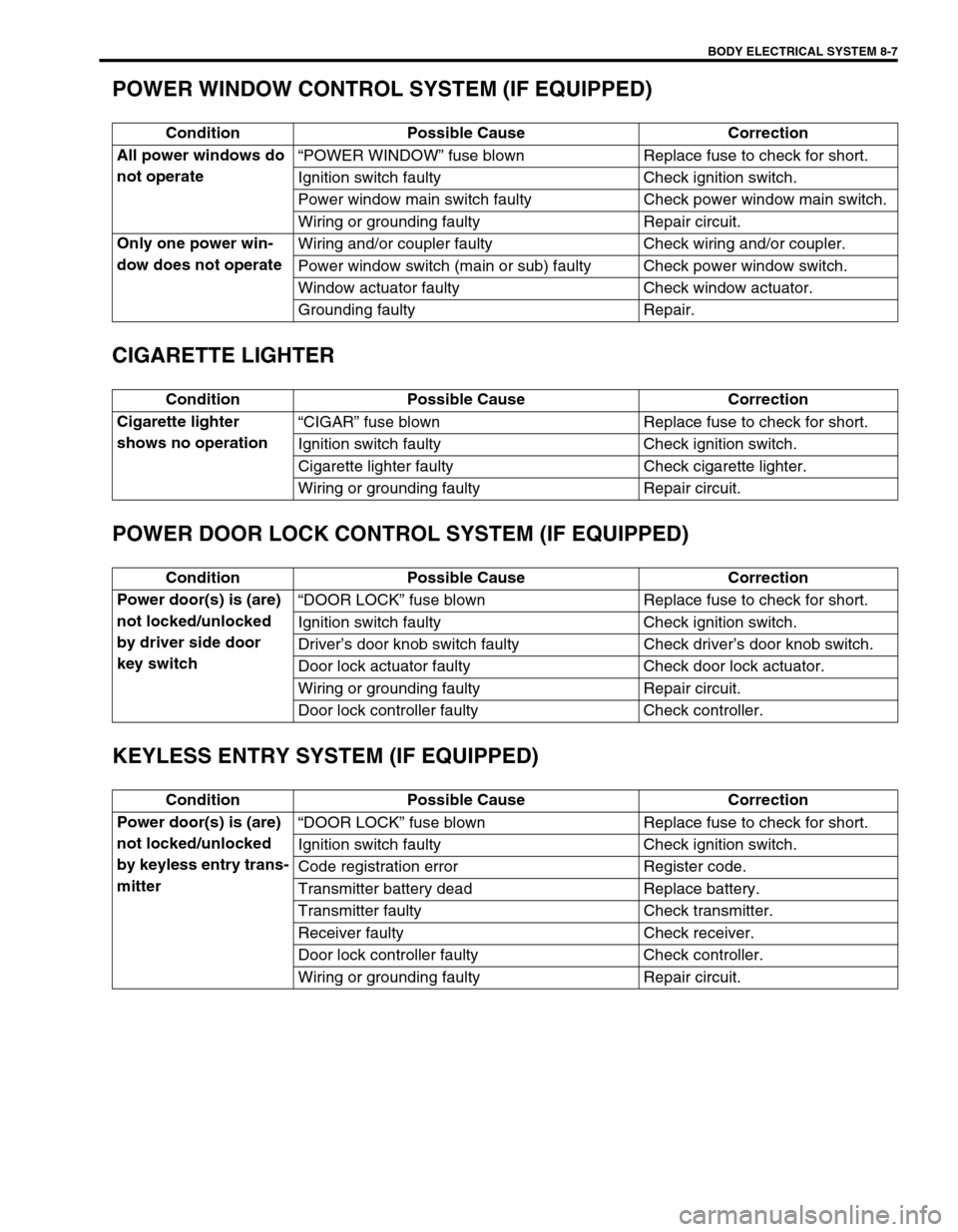

BODY ELECTRICAL SYSTEM 8-7

POWER WINDOW CONTROL SYSTEM (IF EQUIPPED)

CIGARETTE LIGHTER

POWER DOOR LOCK CONTROL SYSTEM (IF EQUIPPED)

KEYLESS ENTRY SYSTEM (IF EQUIPPED)

Condition Possible Cause Correction

All power windows do

not operate“POWER WINDOW” fuse blown Replace fuse to check for short.

Ignition switch faulty Check ignition switch.

Power window main switch faulty Check power window main switch.

Wiring or grounding faulty Repair circuit.

Only one power win-

dow does not operateWiring and/or coupler faulty Check wiring and/or coupler.

Power window switch (main or sub) faulty Check power window switch.

Window actuator faulty Check window actuator.

Grounding faulty Repair.

Condition Possible Cause Correction

Cigarette lighter

shows no operation“CIGAR” fuse blown Replace fuse to check for short.

Ignition switch faulty Check ignition switch.

Cigarette lighter faulty Check cigarette lighter.

Wiring or grounding faulty Repair circuit.

Condition Possible Cause Correction

Power door(s) is (are)

not locked/unlocked

by driver side door

key switch“DOOR LOCK” fuse blown Replace fuse to check for short.

Ignition switch faulty Check ignition switch.

Driver’s door knob switch faulty Check driver’s door knob switch.

Door lock actuator faulty Check door lock actuator.

Wiring or grounding faulty Repair circuit.

Door lock controller faulty Check controller.

Condition Possible Cause Correction

Power door(s) is (are)

not locked/unlocked

by keyless entry trans-

mitter“DOOR LOCK” fuse blown Replace fuse to check for short.

Ignition switch faulty Check ignition switch.

Code registration error Register code.

Transmitter battery dead Replace battery.

Transmitter faulty Check transmitter.

Receiver faulty Check receiver.

Door lock controller faulty Check controller.

Wiring or grounding faulty Repair circuit.

Page 263 of 447

BODY ELECTRICAL SYSTEM 8-19

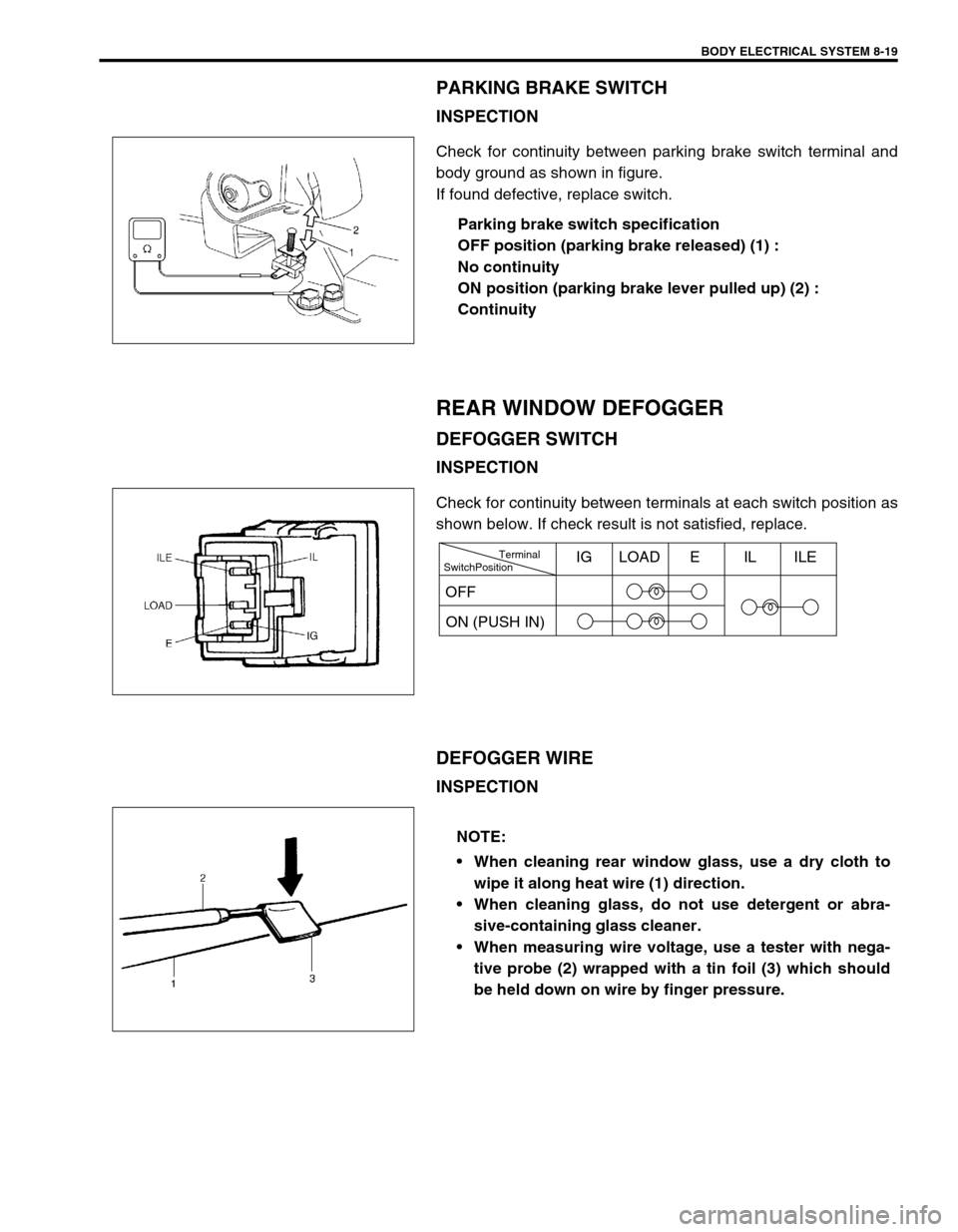

PARKING BRAKE SWITCH

INSPECTION

Check for continuity between parking brake switch terminal and

body ground as shown in figure.

If found defective, replace switch.

Parking brake switch specification

OFF position (parking brake released) (1) :

No continuity

ON position (parking brake lever pulled up) (2) :

Continuity

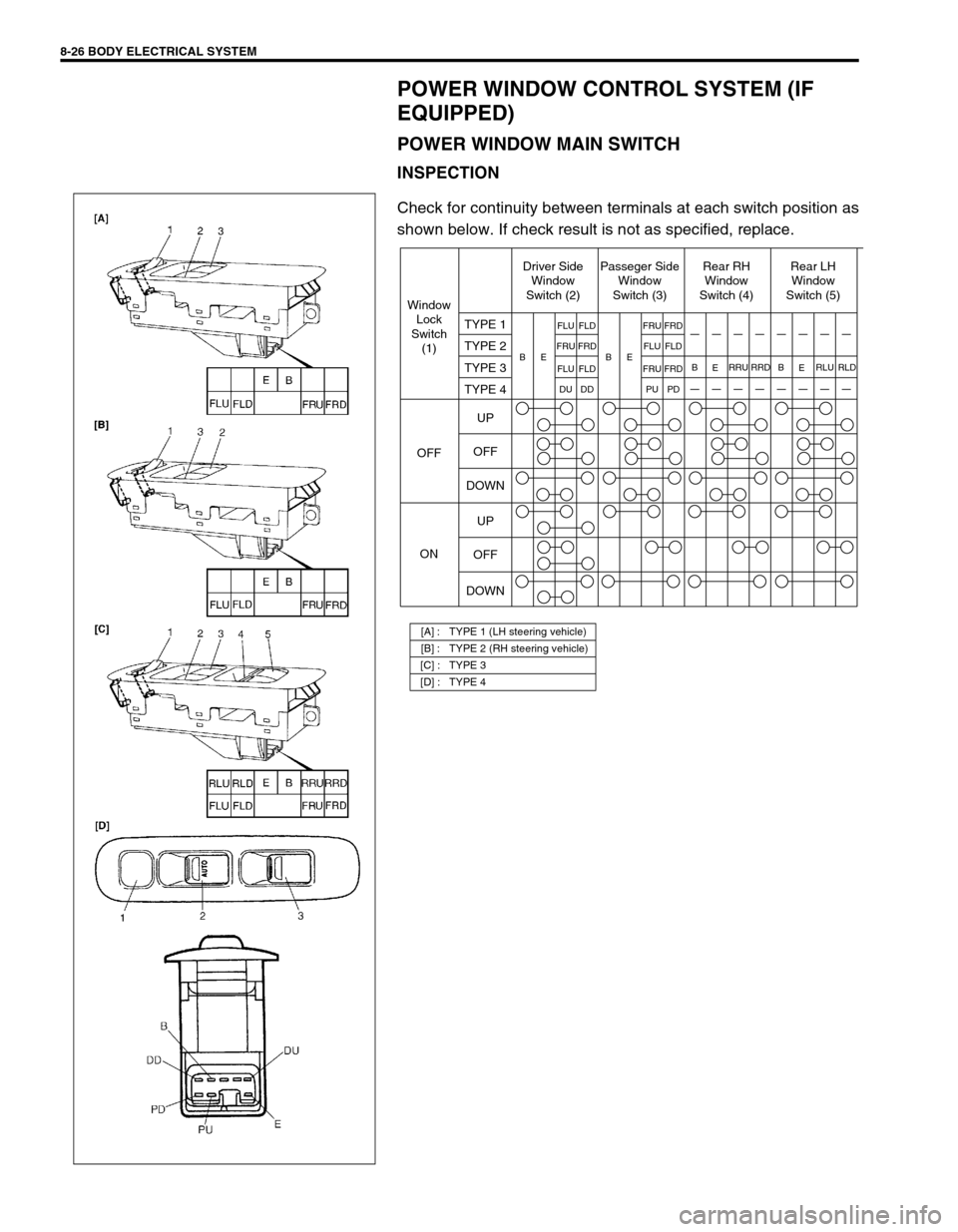

REAR WINDOW DEFOGGER

DEFOGGER SWITCH

INSPECTION

Check for continuity between terminals at each switch position as

shown below. If check result is not satisfied, replace.

DEFOGGER WIRE

INSPECTION

SwitchPositionTerminal

ON (PUSH IN)IG LOAD E IL ILE

OFF

NOTE:

When cleaning rear window glass, use a dry cloth to

wipe it along heat wire (1) direction.

When cleaning glass, do not use detergent or abra-

sive-containing glass cleaner.

When measuring wire voltage, use a tester with nega-

tive probe (2) wrapped with a tin foil (3) which should

be held down on wire by finger pressure.

Page 270 of 447

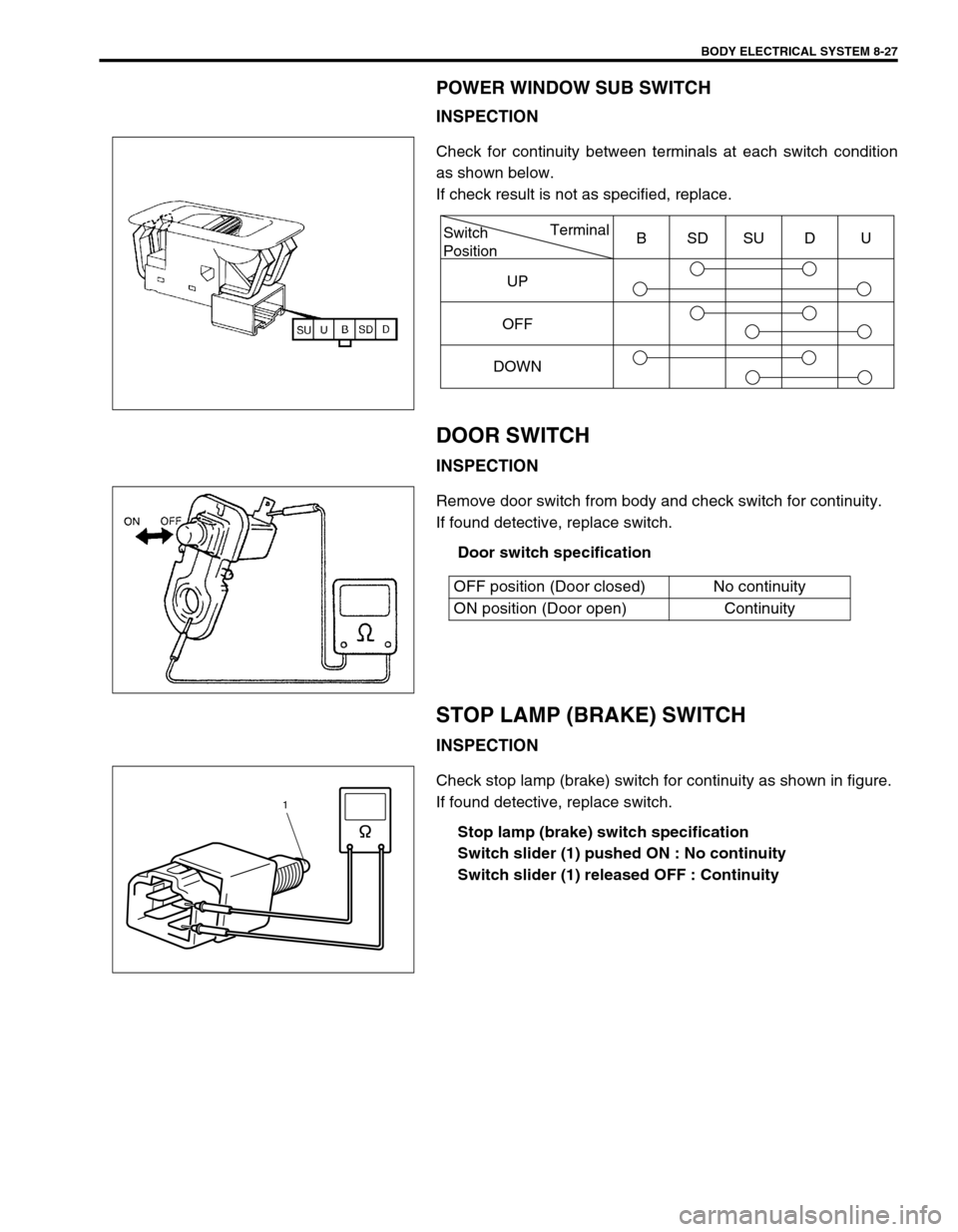

8-26 BODY ELECTRICAL SYSTEM

POWER WINDOW CONTROL SYSTEM (IF

EQUIPPED)

POWER WINDOW MAIN SWITCH

INSPECTION

Check for continuity between terminals at each switch position as

shown below. If check result is not as specified, replace.

[A] : TYPE 1 (LH steering vehicle)

[B] : TYPE 2 (RH steering vehicle)

[C] : TYPE 3

[D] : TYPE 4

Window

Lock

Switch

(1)Driver Side

Window

Switch (2)Passeger Side

Window

Switch (3)Rear RH

Window

Switch (4)Rear LH

Window

Switch (5)

OFF

ONTYPE 1

TYPE 2

TYPE 3

TYPE 4

UP

OFF

DOWN

UP

OFF

DOWN

B

B EBE

E FLU

FRU

FLU

DUFLD

FRD

FLD

DDFRU

RRU RRD B

ERLU RLD FLU

FRU

PUFRD

FLD

FRD

PD

Page 271 of 447

BODY ELECTRICAL SYSTEM 8-27

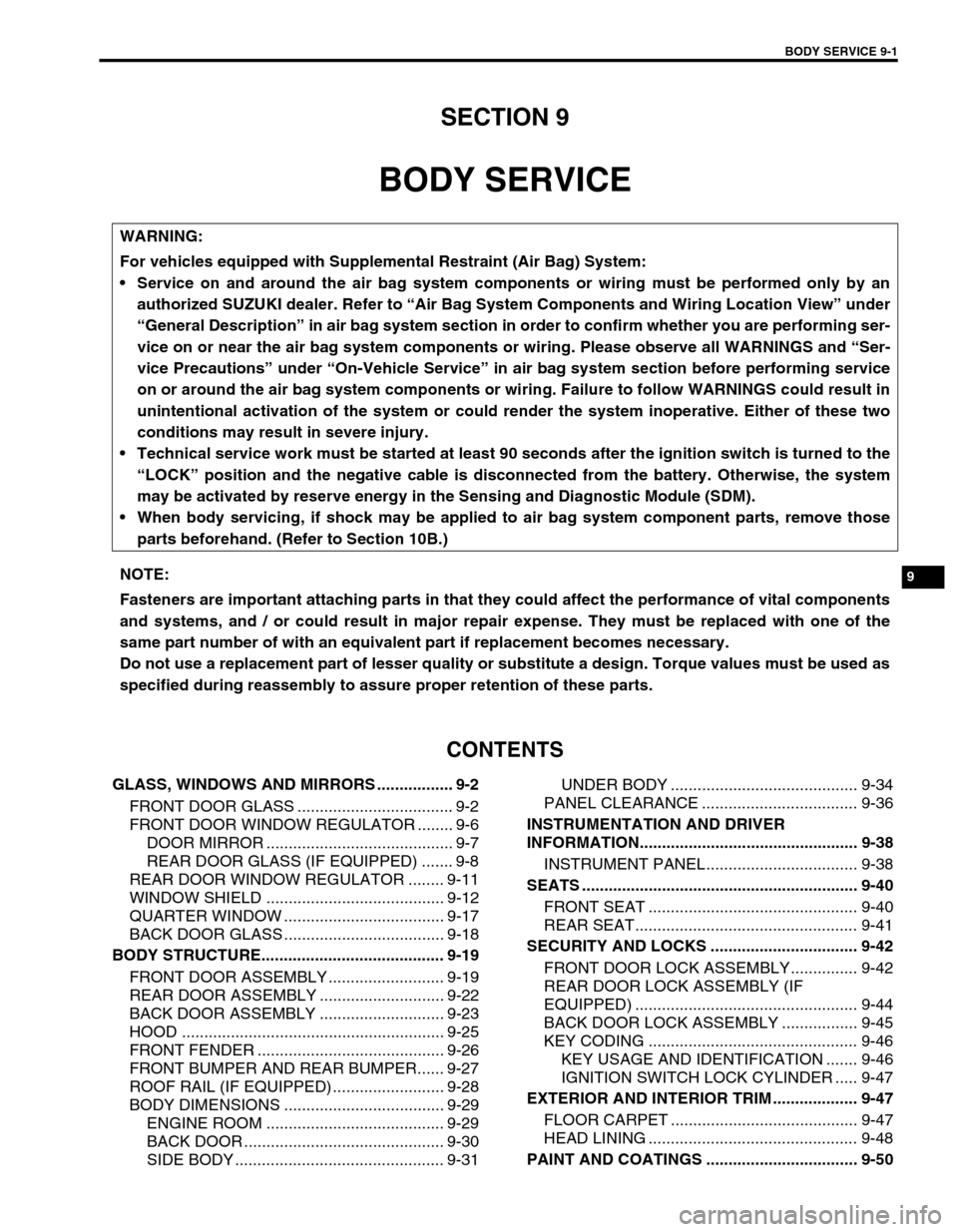

POWER WINDOW SUB SWITCH

INSPECTION

Check for continuity between terminals at each switch condition

as shown below.

If check result is not as specified, replace.

DOOR SWITCH

INSPECTION

Remove door switch from body and check switch for continuity.

If found detective, replace switch.

Door switch specification

STOP LAMP (BRAKE) SWITCH

INSPECTION

Check stop lamp (brake) switch for continuity as shown in figure.

If found detective, replace switch.

Stop lamp (brake) switch specification

Switch slider (1) pushed ON : No continuity

Switch slider (1) released OFF : Continuity

Terminal

Switch

Position

UPBSDSUD U

OFF

DOWN

OFF position (Door closed) No continuity

ON position (Door open) Continuity

1

Page 305 of 447

BODY SERVICE 9-1

6F1

6F2

6G

6H

6K

7A

7A1

7B1

7C1

7D

7E

7F

8A

8B

8C

8D

8E

9

10

10A

10B

SECTION 9

BODY SERVICE

CONTENTS

GLASS, WINDOWS AND MIRRORS ................. 9-2

FRONT DOOR GLASS ................................... 9-2

FRONT DOOR WINDOW REGULATOR ........ 9-6

DOOR MIRROR .......................................... 9-7

REAR DOOR GLASS (IF EQUIPPED) ....... 9-8

REAR DOOR WINDOW REGULATOR ........ 9-11

WINDOW SHIELD ........................................ 9-12

QUARTER WINDOW .................................... 9-17

BACK DOOR GLASS .................................... 9-18

BODY STRUCTURE......................................... 9-19

FRONT DOOR ASSEMBLY .......................... 9-19

REAR DOOR ASSEMBLY ............................ 9-22

BACK DOOR ASSEMBLY ............................ 9-23

HOOD ........................................................... 9-25

FRONT FENDER .......................................... 9-26

FRONT BUMPER AND REAR BUMPER...... 9-27

ROOF RAIL (IF EQUIPPED) ......................... 9-28

BODY DIMENSIONS .................................... 9-29

ENGINE ROOM ........................................ 9-29

BACK DOOR ............................................. 9-30

SIDE BODY ............................................... 9-31UNDER BODY .......................................... 9-34

PANEL CLEARANCE ................................... 9-36

INSTRUMENTATION AND DRIVER

INFORMATION................................................. 9-38

INSTRUMENT PANEL .................................. 9-38

SEATS .............................................................. 9-40

FRONT SEAT ............................................... 9-40

REAR SEAT.................................................. 9-41

SECURITY AND LOCKS ................................. 9-42

FRONT DOOR LOCK ASSEMBLY............... 9-42

REAR DOOR LOCK ASSEMBLY (IF

EQUIPPED) .................................................. 9-44

BACK DOOR LOCK ASSEMBLY ................. 9-45

KEY CODING ............................................... 9-46

KEY USAGE AND IDENTIFICATION ....... 9-46

IGNITION SWITCH LOCK CYLINDER ..... 9-47

EXTERIOR AND INTERIOR TRIM ................... 9-47

FLOOR CARPET .......................................... 9-47

HEAD LINING ............................................... 9-48

PAINT AND COATINGS .................................. 9-50 WARNING:

For vehicles equipped with Supplemental Restraint (Air Bag) System:

Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

Technical service work must be started at least 90 seconds after the ignition switch is turned to the

“LOCK” position and the negative cable is disconnected from the battery. Otherwise, the system

may be activated by reserve energy in the Sensing and Diagnostic Module (SDM).

When body servicing, if shock may be applied to air bag system component parts, remove those

parts beforehand. (Refer to Section 10B.)

NOTE:

Fasteners are important attaching parts in that they could affect the performance of vital components

and systems, and / or could result in major repair expense. They must be replaced with one of the

same part number of with an equivalent part if replacement becomes necessary.

Do not use a replacement part of lesser quality or substitute a design. Torque values must be used as

specified during reassembly to assure proper retention of these parts.

Page 306 of 447

9-2 BODY SERVICE

ANTI-CORROSION TREATMENT ............... 9-50

SEALANT APPLICATION AREAS................ 9-51

UNDER COATING APPLICATION AREAS .. 9-58

ANTI-CORROSION COMPOUND

APPLICATION AREA ................................... 9-60REQUIRED SERVICE MATERIAL ................... 9-61

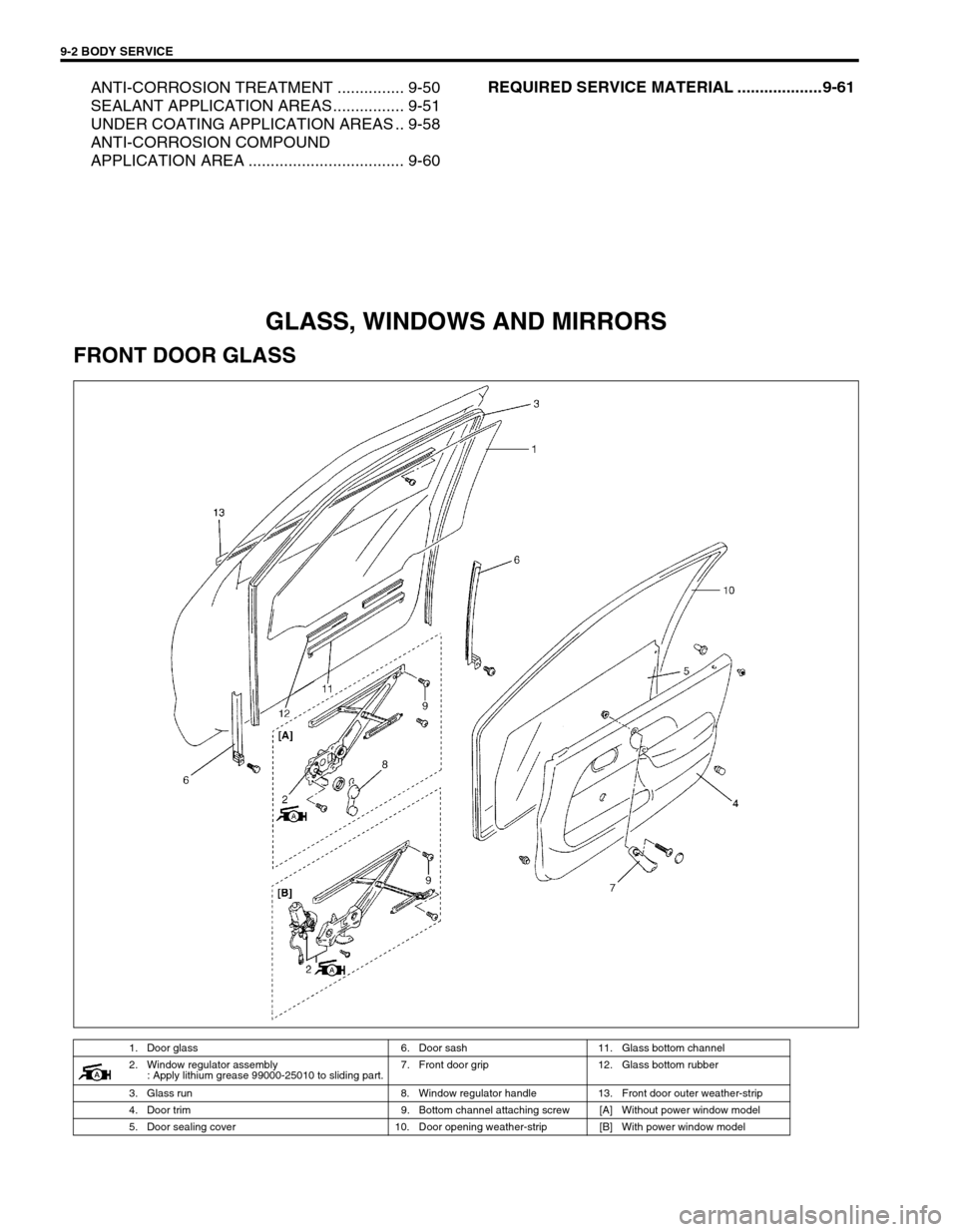

GLASS, WINDOWS AND MIRRORS

FRONT DOOR GLASS

1. Door glass 6. Door sash 11. Glass bottom channel

2. Window regulator assembly

: Apply lithium grease 99000-25010 to sliding part.7. Front door grip 12. Glass bottom rubber

3. Glass run 8. Window regulator handle 13. Front door outer weather-strip

4. Door trim 9. Bottom channel attaching screw [A] Without power window model

5. Door sealing cover 10. Door opening weather-strip [B] With power window model

Page 307 of 447

BODY SERVICE 9-3

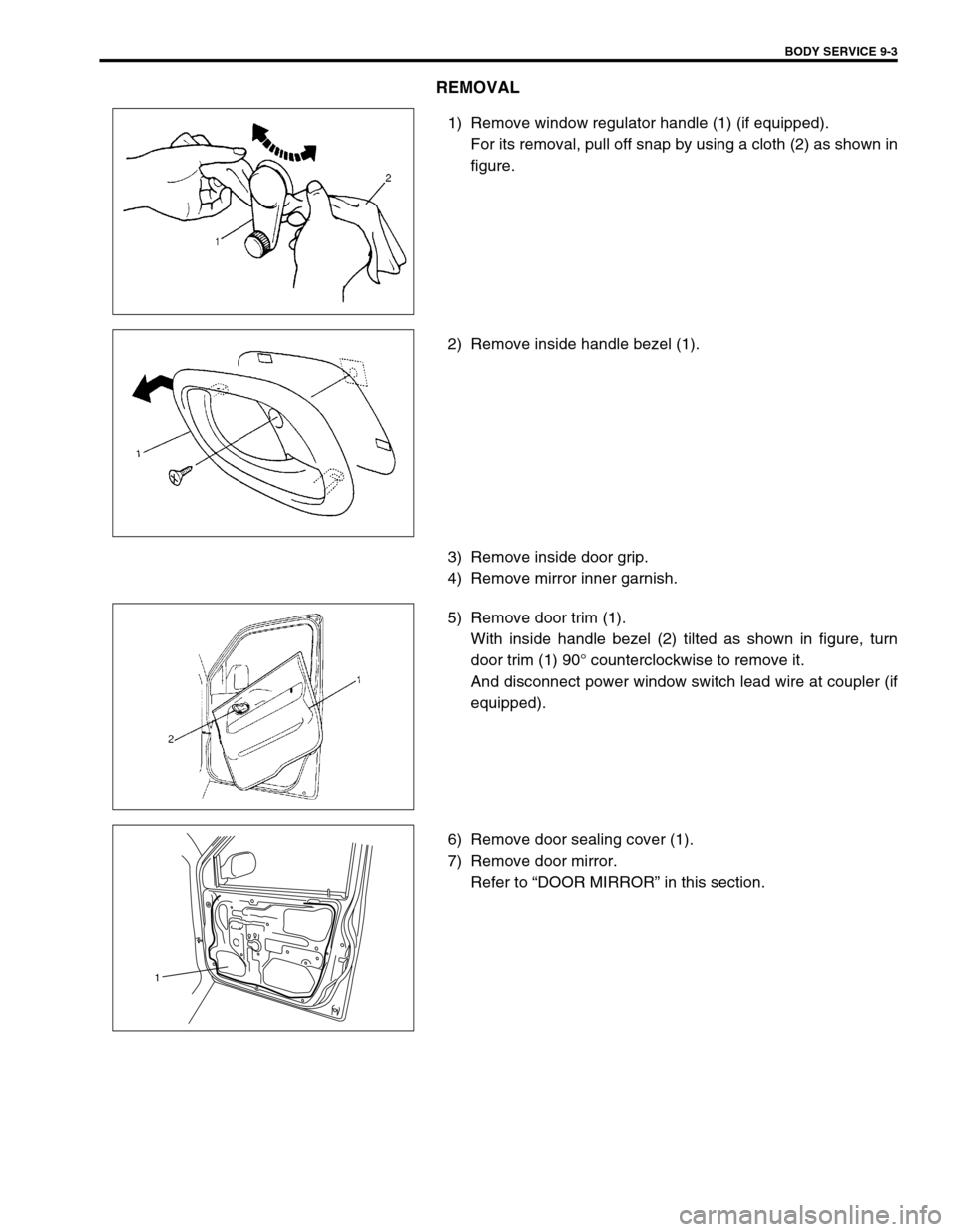

REMOVAL

1) Remove window regulator handle (1) (if equipped).

For its removal, pull off snap by using a cloth (2) as shown in

figure.

2) Remove inside handle bezel (1).

3) Remove inside door grip.

4) Remove mirror inner garnish.

5) Remove door trim (1).

With inside handle bezel (2) tilted as shown in figure, turn

door trim (1) 90° counterclockwise to remove it.

And disconnect power window switch lead wire at coupler (if

equipped).

6) Remove door sealing cover (1).

7) Remove door mirror.

Refer to “DOOR MIRROR” in this section.

1