Meter SUZUKI SWIFT 2000 1.G Transmission Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 447, PDF Size: 10.54 MB

Page 246 of 447

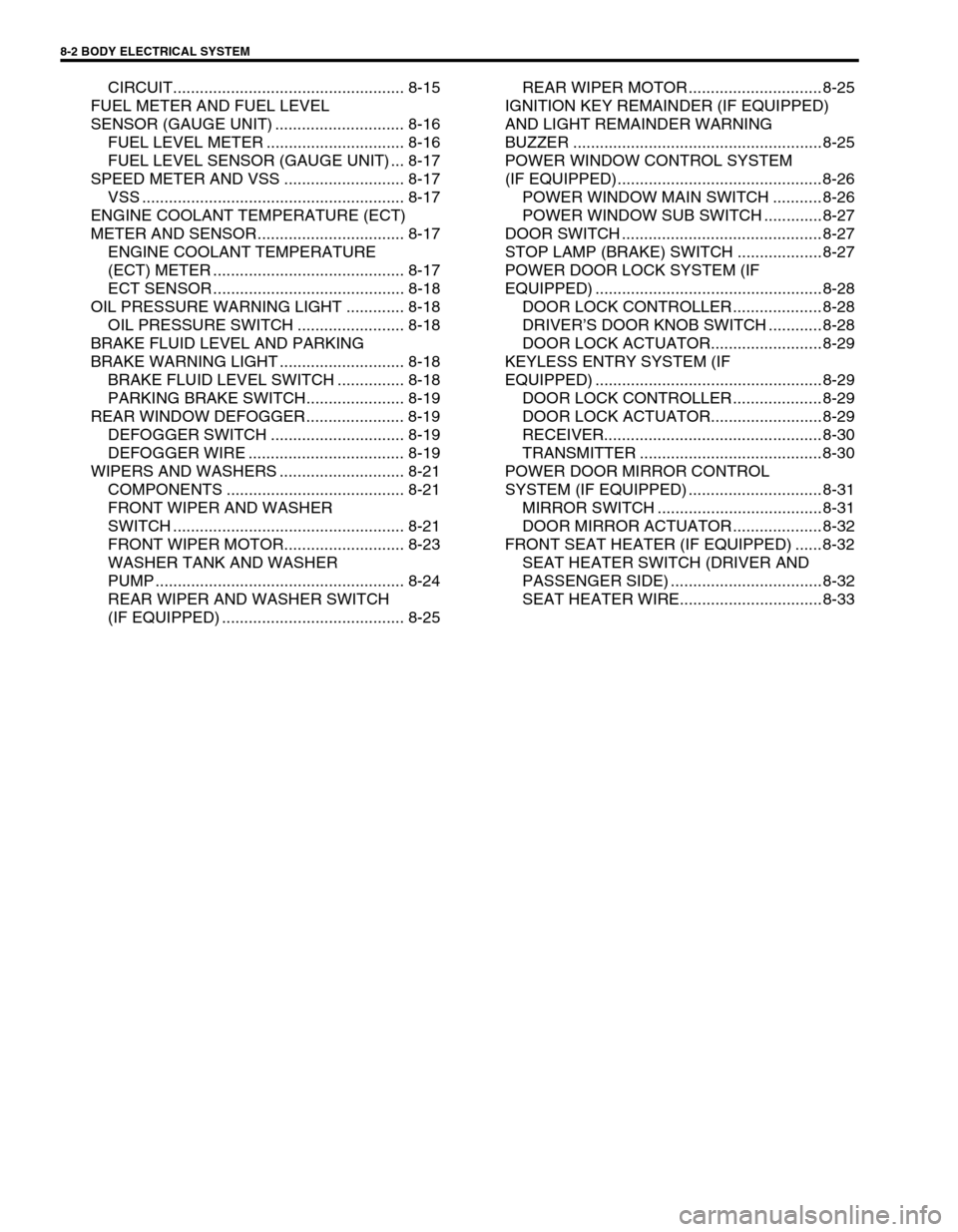

8-2 BODY ELECTRICAL SYSTEM

CIRCUIT.................................................... 8-15

FUEL METER AND FUEL LEVEL

SENSOR (GAUGE UNIT) ............................. 8-16

FUEL LEVEL METER ............................... 8-16

FUEL LEVEL SENSOR (GAUGE UNIT) ... 8-17

SPEED METER AND VSS ........................... 8-17

VSS ........................................................... 8-17

ENGINE COOLANT TEMPERATURE (ECT)

METER AND SENSOR................................. 8-17

ENGINE COOLANT TEMPERATURE

(ECT) METER ........................................... 8-17

ECT SENSOR ........................................... 8-18

OIL PRESSURE WARNING LIGHT ............. 8-18

OIL PRESSURE SWITCH ........................ 8-18

BRAKE FLUID LEVEL AND PARKING

BRAKE WARNING LIGHT ............................ 8-18

BRAKE FLUID LEVEL SWITCH ............... 8-18

PARKING BRAKE SWITCH...................... 8-19

REAR WINDOW DEFOGGER...................... 8-19

DEFOGGER SWITCH .............................. 8-19

DEFOGGER WIRE ................................... 8-19

WIPERS AND WASHERS ............................ 8-21

COMPONENTS ........................................ 8-21

FRONT WIPER AND WASHER

SWITCH .................................................... 8-21

FRONT WIPER MOTOR........................... 8-23

WASHER TANK AND WASHER

PUMP ........................................................ 8-24

REAR WIPER AND WASHER SWITCH

(IF EQUIPPED) ......................................... 8-25REAR WIPER MOTOR .............................. 8-25

IGNITION KEY REMAINDER (IF EQUIPPED)

AND LIGHT REMAINDER WARNING

BUZZER ........................................................ 8-25

POWER WINDOW CONTROL SYSTEM

(IF EQUIPPED).............................................. 8-26

POWER WINDOW MAIN SWITCH ........... 8-26

POWER WINDOW SUB SWITCH ............. 8-27

DOOR SWITCH ............................................. 8-27

STOP LAMP (BRAKE) SWITCH ................... 8-27

POWER DOOR LOCK SYSTEM (IF

EQUIPPED) ................................................... 8-28

DOOR LOCK CONTROLLER .................... 8-28

DRIVER’S DOOR KNOB SWITCH ............ 8-28

DOOR LOCK ACTUATOR......................... 8-29

KEYLESS ENTRY SYSTEM (IF

EQUIPPED) ................................................... 8-29

DOOR LOCK CONTROLLER .................... 8-29

DOOR LOCK ACTUATOR......................... 8-29

RECEIVER................................................. 8-30

TRANSMITTER ......................................... 8-30

POWER DOOR MIRROR CONTROL

SYSTEM (IF EQUIPPED) .............................. 8-31

MIRROR SWITCH ..................................... 8-31

DOOR MIRROR ACTUATOR .................... 8-32

FRONT SEAT HEATER (IF EQUIPPED) ...... 8-32

SEAT HEATER SWITCH (DRIVER AND

PASSENGER SIDE) .................................. 8-32

SEAT HEATER WIRE................................ 8-33

Page 249 of 447

BODY ELECTRICAL SYSTEM 8-5

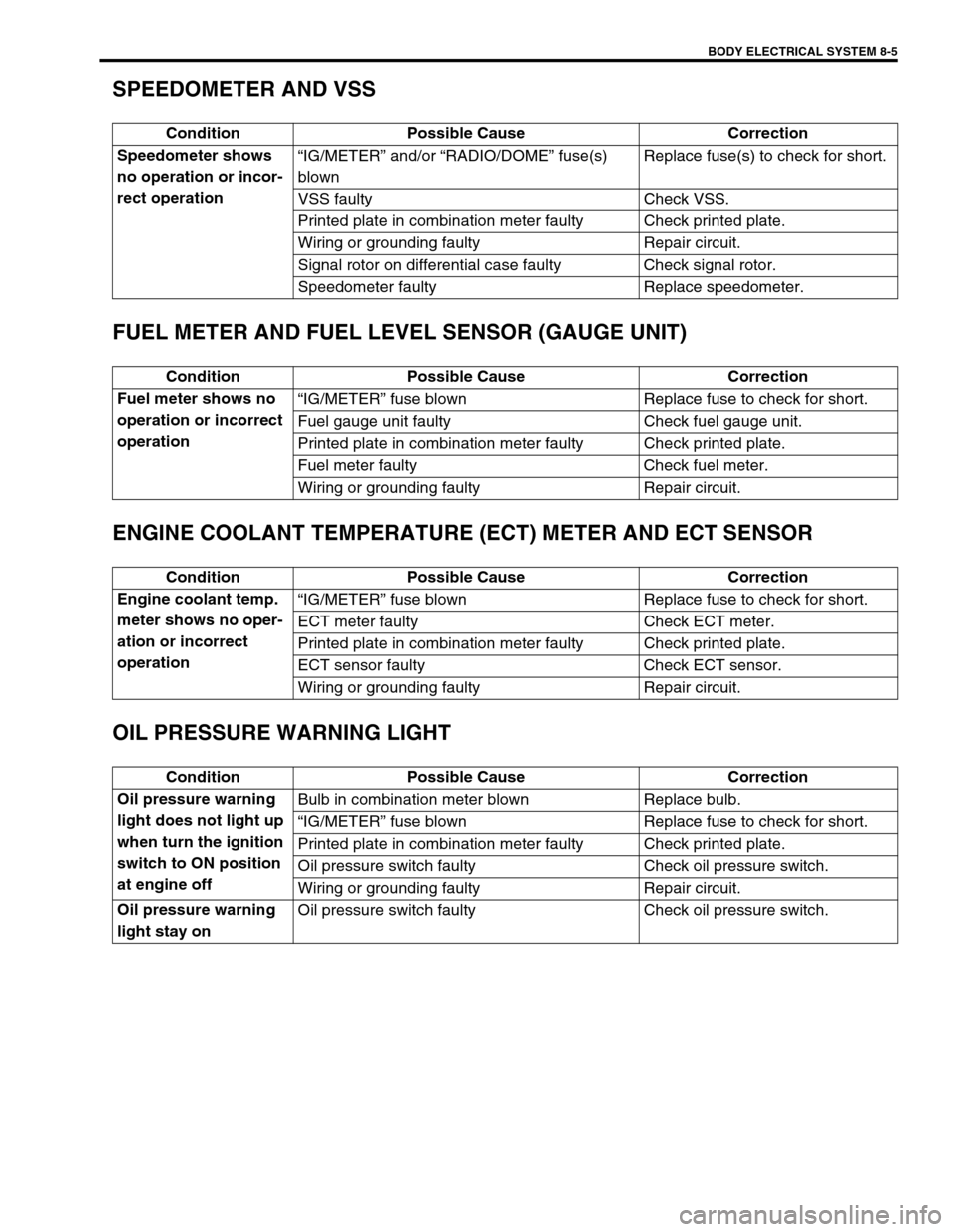

SPEEDOMETER AND VSS

FUEL METER AND FUEL LEVEL SENSOR (GAUGE UNIT)

ENGINE COOLANT TEMPERATURE (ECT) METER AND ECT SENSOR

OIL PRESSURE WARNING LIGHT

Condition Possible Cause Correction

Speedometer shows

no operation or incor-

rect operation“IG/METER” and/or “RADIO/DOME” fuse(s)

blownReplace fuse(s) to check for short.

VSS faulty Check VSS.

Printed plate in combination meter faulty Check printed plate.

Wiring or grounding faulty Repair circuit.

Signal rotor on differential case faulty Check signal rotor.

Speedometer faulty Replace speedometer.

Condition Possible Cause Correction

Fuel meter shows no

operation or incorrect

operation“IG/METER” fuse blown Replace fuse to check for short.

Fuel gauge unit faulty Check fuel gauge unit.

Printed plate in combination meter faulty Check printed plate.

Fuel meter faulty Check fuel meter.

Wiring or grounding faulty Repair circuit.

Condition Possible Cause Correction

Engine coolant temp.

meter shows no oper-

ation or incorrect

operation“IG/METER” fuse blown Replace fuse to check for short.

ECT meter faulty Check ECT meter.

Printed plate in combination meter faulty Check printed plate.

ECT sensor faulty Check ECT sensor.

Wiring or grounding faulty Repair circuit.

Condition Possible Cause Correction

Oil pressure warning

light does not light up

when turn the ignition

switch to ON position

at engine offBulb in combination meter blown Replace bulb.

“IG/METER” fuse blown Replace fuse to check for short.

Printed plate in combination meter faulty Check printed plate.

Oil pressure switch faulty Check oil pressure switch.

Wiring or grounding faulty Repair circuit.

Oil pressure warning

light stay onOil pressure switch faulty Check oil pressure switch.

Page 250 of 447

8-6 BODY ELECTRICAL SYSTEM

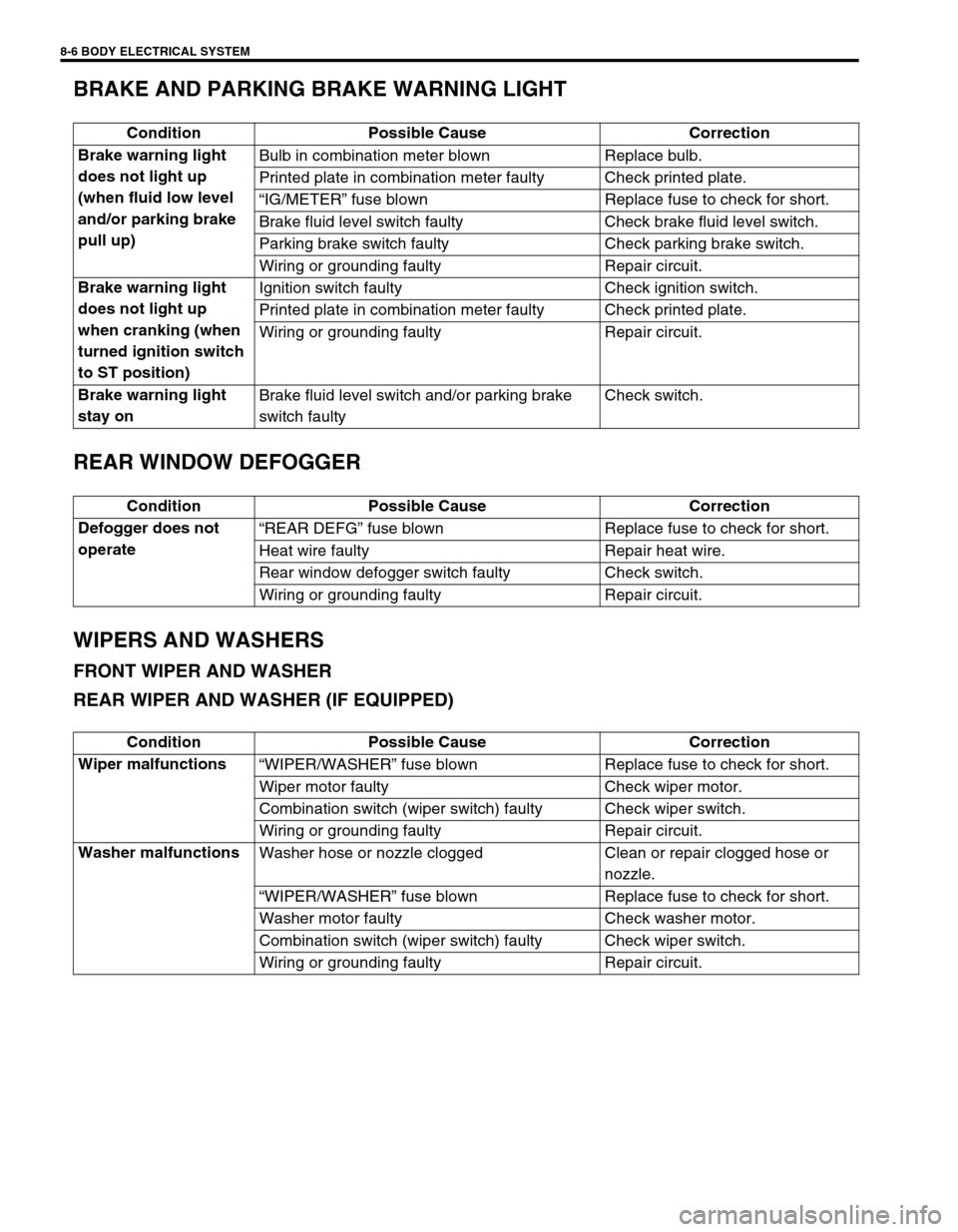

BRAKE AND PARKING BRAKE WARNING LIGHT

REAR WINDOW DEFOGGER

WIPERS AND WASHERS

FRONT WIPER AND WASHER

REAR WIPER AND WASHER (IF EQUIPPED)

Condition Possible Cause Correction

Brake warning light

does not light up

(when fluid low level

and/or parking brake

pull up)Bulb in combination meter blown Replace bulb.

Printed plate in combination meter faulty Check printed plate.

“IG/METER” fuse blown Replace fuse to check for short.

Brake fluid level switch faulty Check brake fluid level switch.

Parking brake switch faulty Check parking brake switch.

Wiring or grounding faulty Repair circuit.

Brake warning light

does not light up

when cranking (when

turned ignition switch

to ST position)Ignition switch faulty Check ignition switch.

Printed plate in combination meter faulty Check printed plate.

Wiring or grounding faulty Repair circuit.

Brake warning light

stay onBrake fluid level switch and/or parking brake

switch faultyCheck switch.

Condition Possible Cause Correction

Defogger does not

operate“REAR DEFG” fuse blown Replace fuse to check for short.

Heat wire faulty Repair heat wire.

Rear window defogger switch faulty Check switch.

Wiring or grounding faulty Repair circuit.

Condition Possible Cause Correction

Wiper malfunctions

“WIPER/WASHER” fuse blown Replace fuse to check for short.

Wiper motor faulty Check wiper motor.

Combination switch (wiper switch) faulty Check wiper switch.

Wiring or grounding faulty Repair circuit.

Washer malfunctions

Washer hose or nozzle clogged Clean or repair clogged hose or

nozzle.

“WIPER/WASHER” fuse blown Replace fuse to check for short.

Washer motor faulty Check washer motor.

Combination switch (wiper switch) faulty Check wiper switch.

Wiring or grounding faulty Repair circuit.

Page 252 of 447

8-8 BODY ELECTRICAL SYSTEM

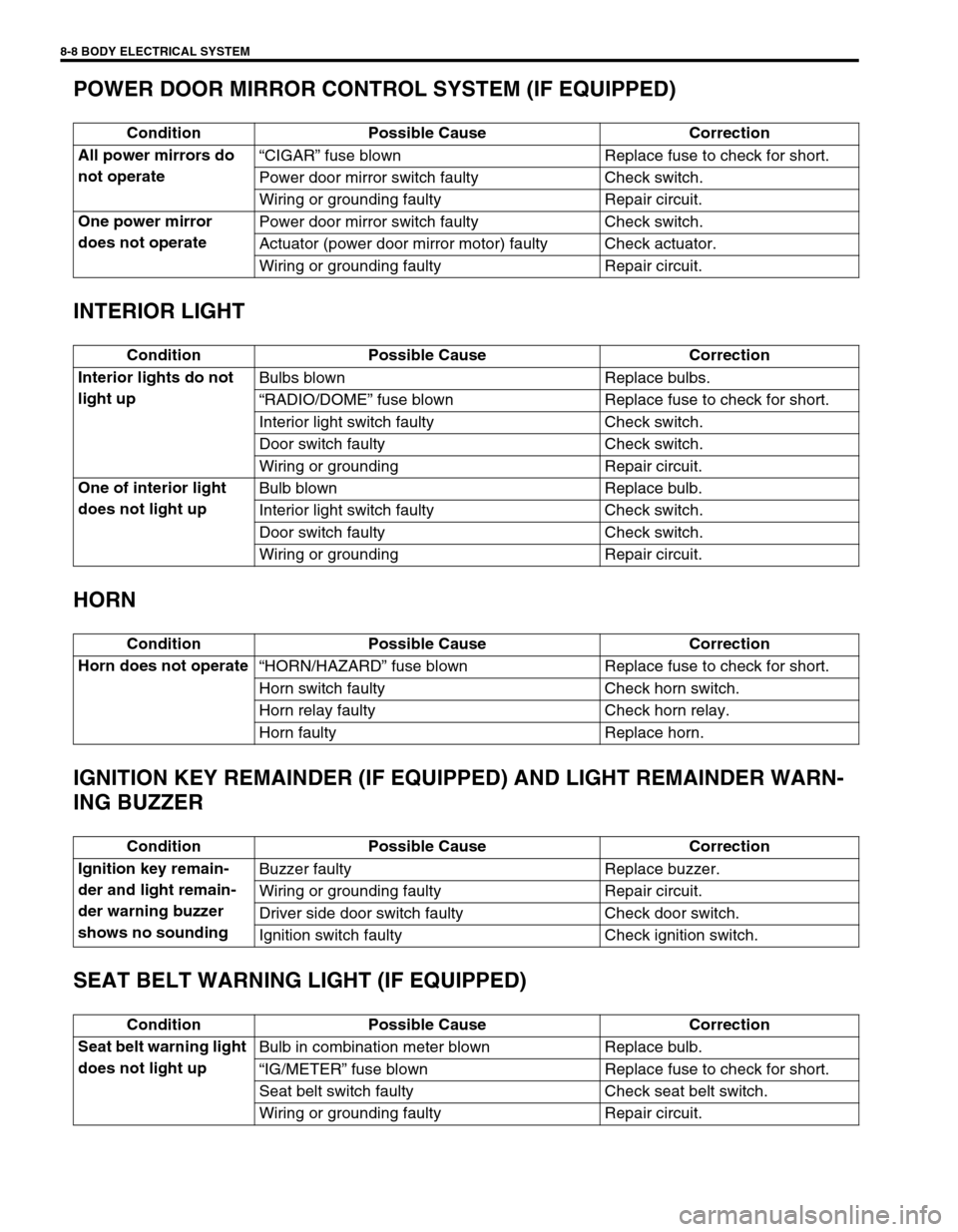

POWER DOOR MIRROR CONTROL SYSTEM (IF EQUIPPED)

INTERIOR LIGHT

HORN

IGNITION KEY REMAINDER (IF EQUIPPED) AND LIGHT REMAINDER WARN-

ING BUZZER

SEAT BELT WARNING LIGHT (IF EQUIPPED)

Condition Possible Cause Correction

All power mirrors do

not operate“CIGAR” fuse blown Replace fuse to check for short.

Power door mirror switch faulty Check switch.

Wiring or grounding faulty Repair circuit.

One power mirror

does not operatePower door mirror switch faulty Check switch.

Actuator (power door mirror motor) faulty Check actuator.

Wiring or grounding faulty Repair circuit.

Condition Possible Cause Correction

Interior lights do not

light upBulbs blown Replace bulbs.

“RADIO/DOME” fuse blown Replace fuse to check for short.

Interior light switch faulty Check switch.

Door switch faulty Check switch.

Wiring or grounding Repair circuit.

One of interior light

does not light upBulb blown Replace bulb.

Interior light switch faulty Check switch.

Door switch faulty Check switch.

Wiring or grounding Repair circuit.

Condition Possible Cause Correction

Horn does not operate

“HORN/HAZARD” fuse blown Replace fuse to check for short.

Horn switch faulty Check horn switch.

Horn relay faulty Check horn relay.

Horn faulty Replace horn.

Condition Possible Cause Correction

Ignition key remain-

der and light remain-

der warning buzzer

shows no soundingBuzzer faulty Replace buzzer.

Wiring or grounding faulty Repair circuit.

Driver side door switch faulty Check door switch.

Ignition switch faulty Check ignition switch.

Condition Possible Cause Correction

Seat belt warning light

does not light upBulb in combination meter blown Replace bulb.

“IG/METER” fuse blown Replace fuse to check for short.

Seat belt switch faulty Check seat belt switch.

Wiring or grounding faulty Repair circuit.

Page 259 of 447

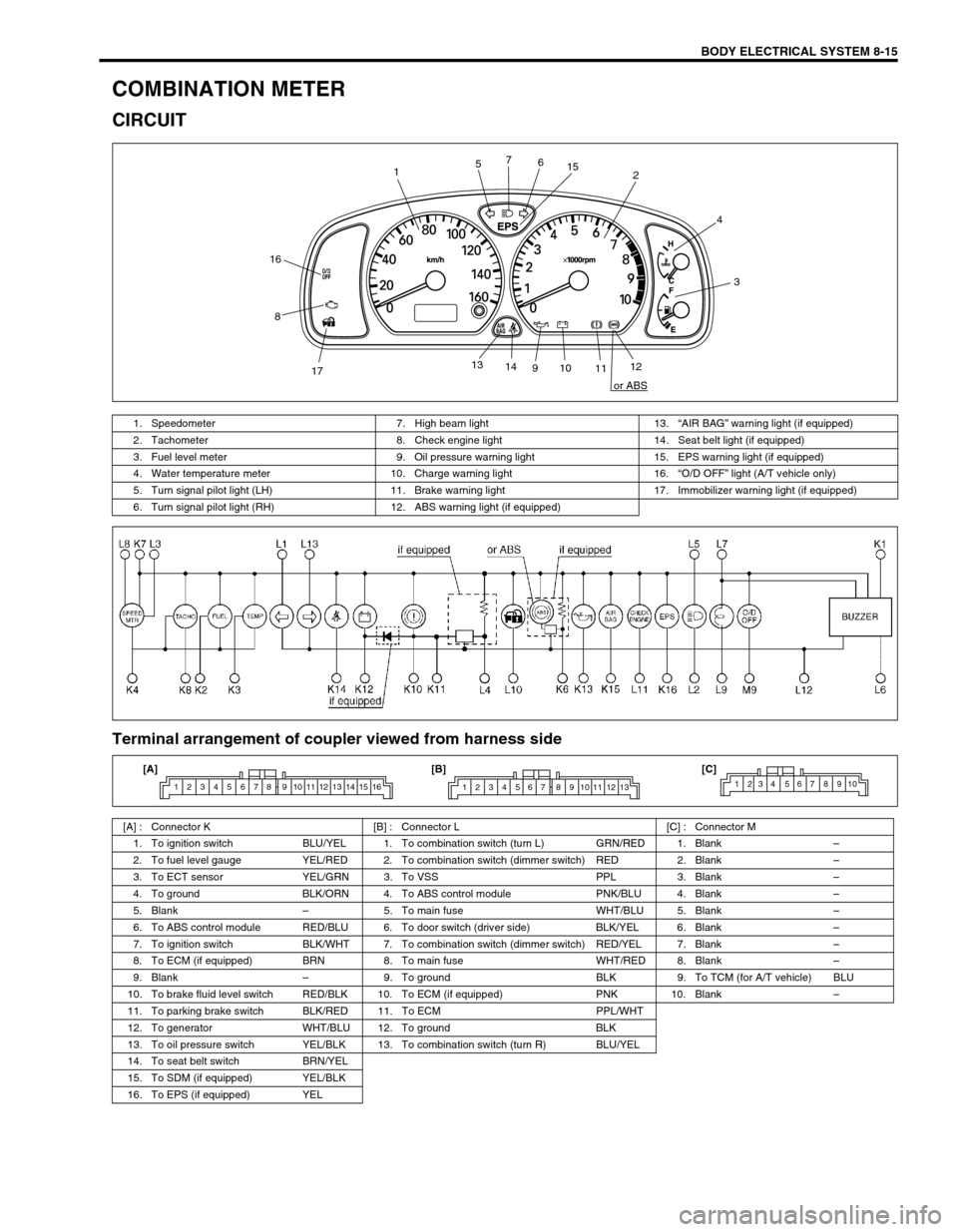

BODY ELECTRICAL SYSTEM 8-15

COMBINATION METER

CIRCUIT

Terminal arrangement of coupler viewed from harness side

12

3 4

56 7

8

910

1112 13

14

1715

16

or ABS

1. Speedometer 7. High beam light 13.“AIR BAG” warning light (if equipped)

2. Tachometer 8. Check engine light 14. Seat belt light (if equipped)

3. Fuel level meter 9. Oil pressure warning light 15. EPS warning light (if equipped)

4. Water temperature meter 10. Charge warning light 16.“O/D OFF” light (A/T vehicle only)

5. Turn signal pilot light (LH) 11. Brake warning light 17. Immobilizer warning light (if equipped)

6. Turn signal pilot light (RH) 12. ABS warning light (if equipped)

[A] : Connector K [B] : Connector L [C] : Connector M

1. To ignition switch BLU/YEL 1. To combination switch (turn L) GRN/RED 1. Blank–

2. To fuel level gauge YEL/RED 2. To combination switch (dimmer switch) RED 2. Blank–

3. To ECT sensor YEL/GRN 3. To VSS PPL 3. Blank–

4. To ground BLK/ORN 4. To ABS control module PNK/BLU 4. Blank–

5. Blank–5. To main fuse WHT/BLU 5. Blank–

6. To ABS control module RED/BLU 6. To door switch (driver side) BLK/YEL 6. Blank–

7. To ignition switch BLK/WHT 7. To combination switch (dimmer switch) RED/YEL 7. Blank–

8. To ECM (if equipped) BRN 8. To main fuse WHT/RED 8. Blank–

9. Blank–9. To ground BLK 9. To TCM (for A/T vehicle) BLU

10. To brake fluid level switch RED/BLK 10. To ECM (if equipped) PNK 10. Blank–

11. To parking brake switch BLK/RED 11. To ECM PPL/WHT

12. To generator WHT/BLU 12. To ground BLK

13. To oil pressure switch YEL/BLK 13. To combination switch (turn R) BLU/YEL

14. To seat belt switch BRN/YEL

15. To SDM (if equipped) YEL/BLK

16. To EPS (if equipped) YEL

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 161 2 3 4 5 6 7 8 9 10 11 12 131234 567 8910[A] [B] [C]

Page 260 of 447

8-16 BODY ELECTRICAL SYSTEM

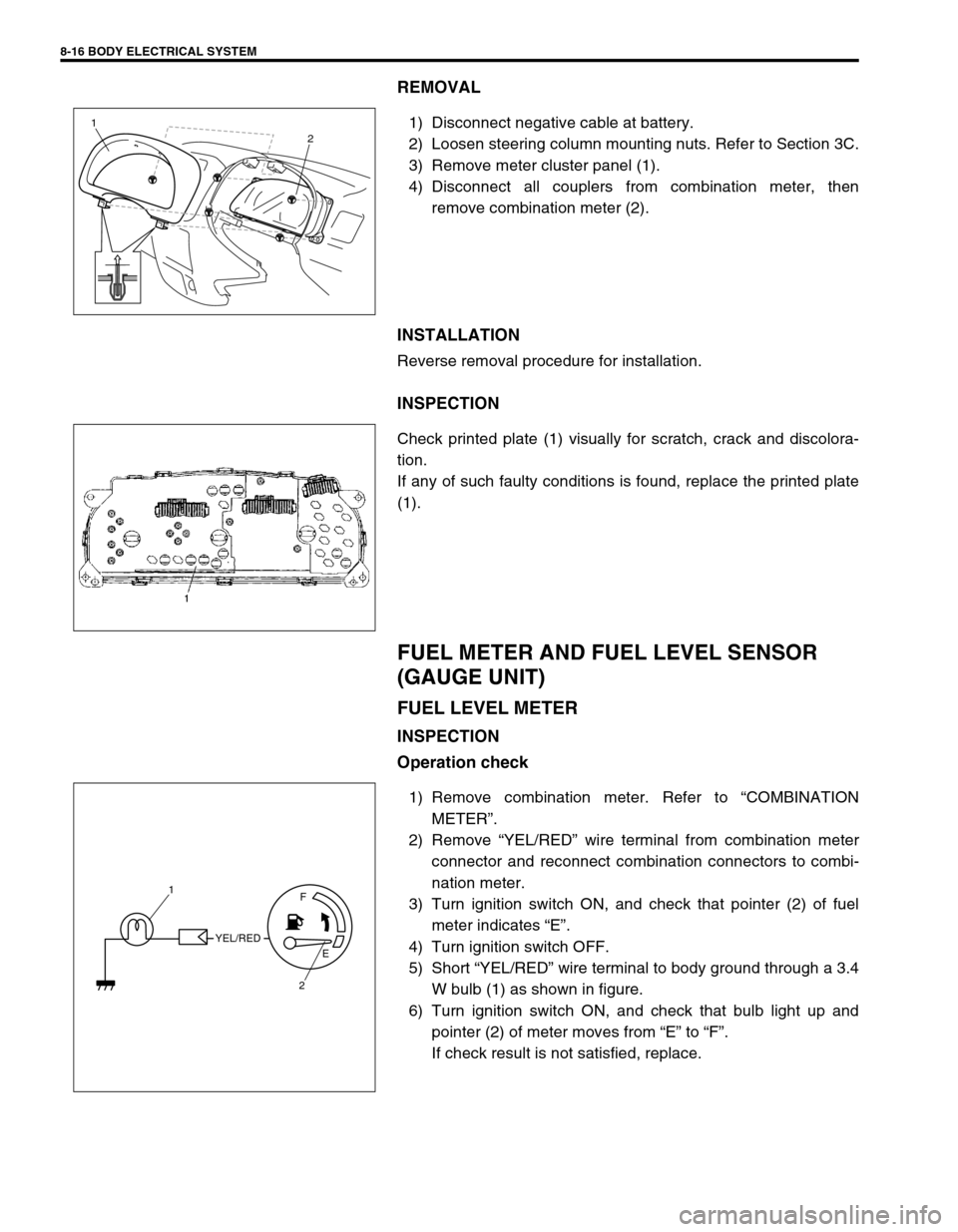

REMOVAL

1) Disconnect negative cable at battery.

2) Loosen steering column mounting nuts. Refer to Section 3C.

3) Remove meter cluster panel (1).

4) Disconnect all couplers from combination meter, then

remove combination meter (2).

INSTALLATION

Reverse removal procedure for installation.

INSPECTION

Check printed plate (1) visually for scratch, crack and discolora-

tion.

If any of such faulty conditions is found, replace the printed plate

(1).

FUEL METER AND FUEL LEVEL SENSOR

(GAUGE UNIT)

FUEL LEVEL METER

INSPECTION

Operation check

1) Remove combination meter. Refer to “COMBINATION

METER”.

2) Remove “YEL/RED” wire terminal from combination meter

connector and reconnect combination connectors to combi-

nation meter.

3) Turn ignition switch ON, and check that pointer (2) of fuel

meter indicates “E”.

4) Turn ignition switch OFF.

5) Short “YEL/RED” wire terminal to body ground through a 3.4

W bulb (1) as shown in figure.

6) Turn ignition switch ON, and check that bulb light up and

pointer (2) of meter moves from “E” to “F”.

If check result is not satisfied, replace.

1

2

YEL/REDF

E

2 1

Page 261 of 447

BODY ELECTRICAL SYSTEM 8-17

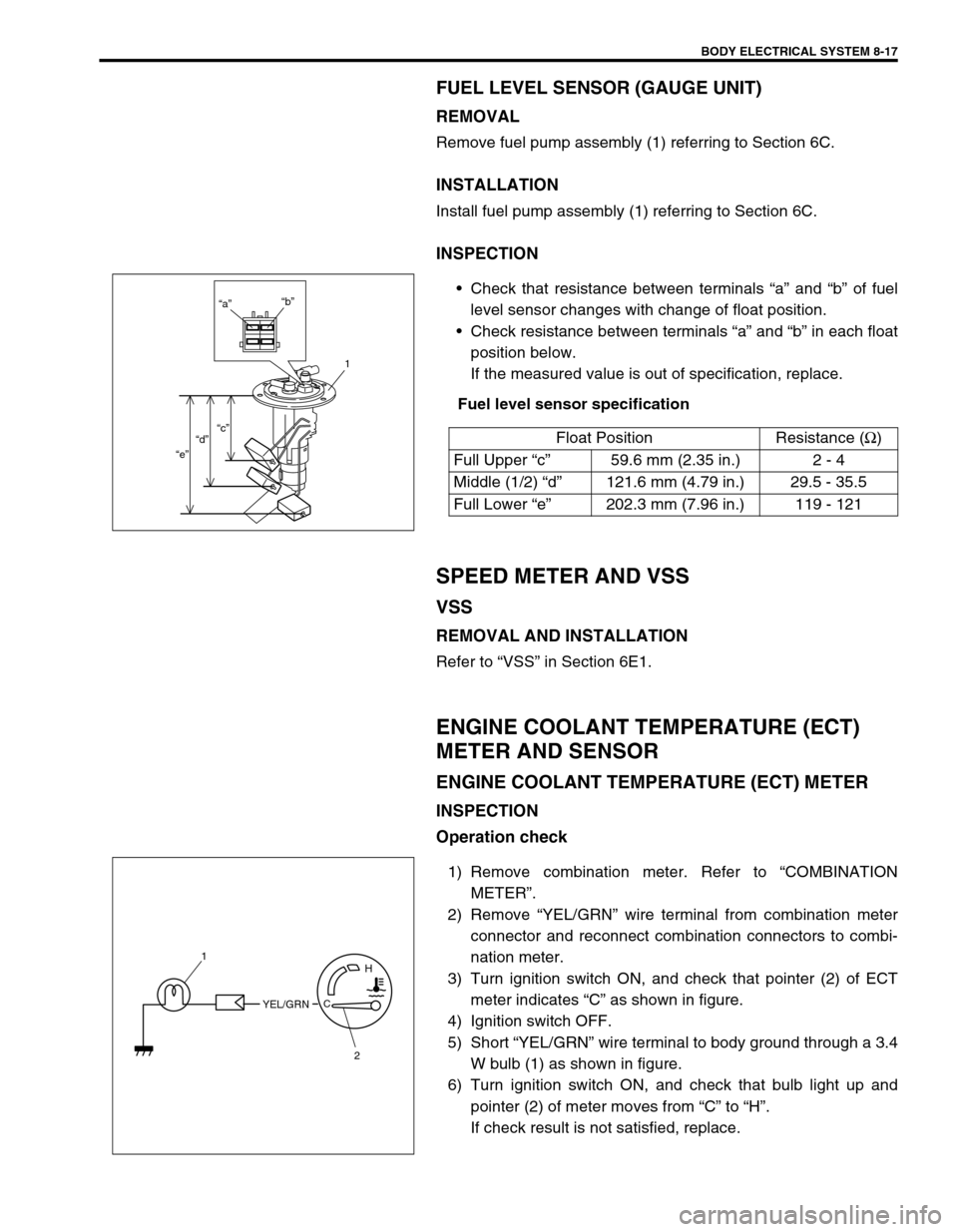

FUEL LEVEL SENSOR (GAUGE UNIT)

REMOVAL

Remove fuel pump assembly (1) referring to Section 6C.

INSTALLATION

Install fuel pump assembly (1) referring to Section 6C.

INSPECTION

Check that resistance between terminals “a” and “b” of fuel

level sensor changes with change of float position.

Check resistance between terminals “a” and “b” in each float

position below.

If the measured value is out of specification, replace.

Fuel level sensor specification

SPEED METER AND VSS

VSS

REMOVAL AND INSTALLATION

Refer to “VSS” in Section 6E1.

ENGINE COOLANT TEMPERATURE (ECT)

METER AND SENSOR

ENGINE COOLANT TEMPERATURE (ECT) METER

INSPECTION

Operation check

1) Remove combination meter. Refer to “COMBINATION

METER”.

2) Remove “YEL/GRN” wire terminal from combination meter

connector and reconnect combination connectors to combi-

nation meter.

3) Turn ignition switch ON, and check that pointer (2) of ECT

meter indicates “C” as shown in figure.

4) Ignition switch OFF.

5) Short “YEL/GRN” wire terminal to body ground through a 3.4

W bulb (1) as shown in figure.

6) Turn ignition switch ON, and check that bulb light up and

pointer (2) of meter moves from “C” to “H”.

If check result is not satisfied, replace.Float Position Resistance (Ω

)

Full Upper “c”59.6 mm (2.35 in.) 2 - 4

Middle (1/2) “d”121.6 mm (4.79 in.) 29.5 - 35.5

Full Lower “e”202.3 mm (7.96 in.) 119 - 121

“a”“b”

1

“c”

“d”

“e”

YEL/GRNC

H1

2

Page 264 of 447

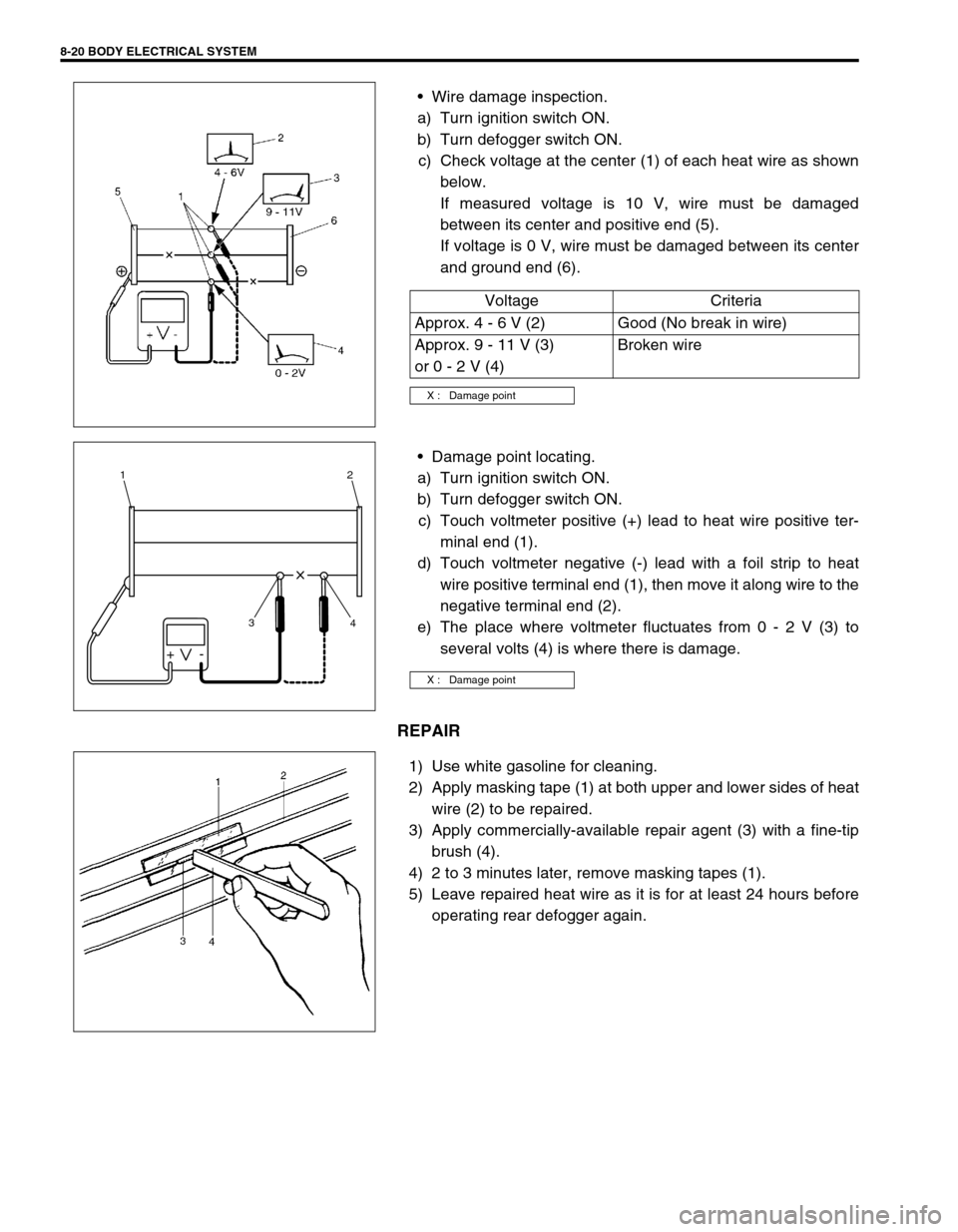

8-20 BODY ELECTRICAL SYSTEM

Wire damage inspection.

a) Turn ignition switch ON.

b) Turn defogger switch ON.

c) Check voltage at the center (1) of each heat wire as shown

below.

If measured voltage is 10 V, wire must be damaged

between its center and positive end (5).

If voltage is 0 V, wire must be damaged between its center

and ground end (6).

Damage point locating.

a) Turn ignition switch ON.

b) Turn defogger switch ON.

c) Touch voltmeter positive (+) lead to heat wire positive ter-

minal end (1).

d) Touch voltmeter negative (-) lead with a foil strip to heat

wire positive terminal end (1), then move it along wire to the

negative terminal end (2).

e) The place where voltmeter fluctuates from 0 - 2 V (3) to

several volts (4) is where there is damage.

REPAIR

1) Use white gasoline for cleaning.

2) Apply masking tape (1) at both upper and lower sides of heat

wire (2) to be repaired.

3) Apply commercially-available repair agent (3) with a fine-tip

brush (4).

4) 2 to 3 minutes later, remove masking tapes (1).

5) Leave repaired heat wire as it is for at least 24 hours before

operating rear defogger again.Voltage Criteria

Approx. 4 - 6 V (2) Good (No break in wire)

Approx. 9 - 11 V (3)

or 0 - 2 V (4)Broken wire

X : Damage point

X : Damage point

+-

3 12

4

Page 266 of 447

8-22 BODY ELECTRICAL SYSTEM

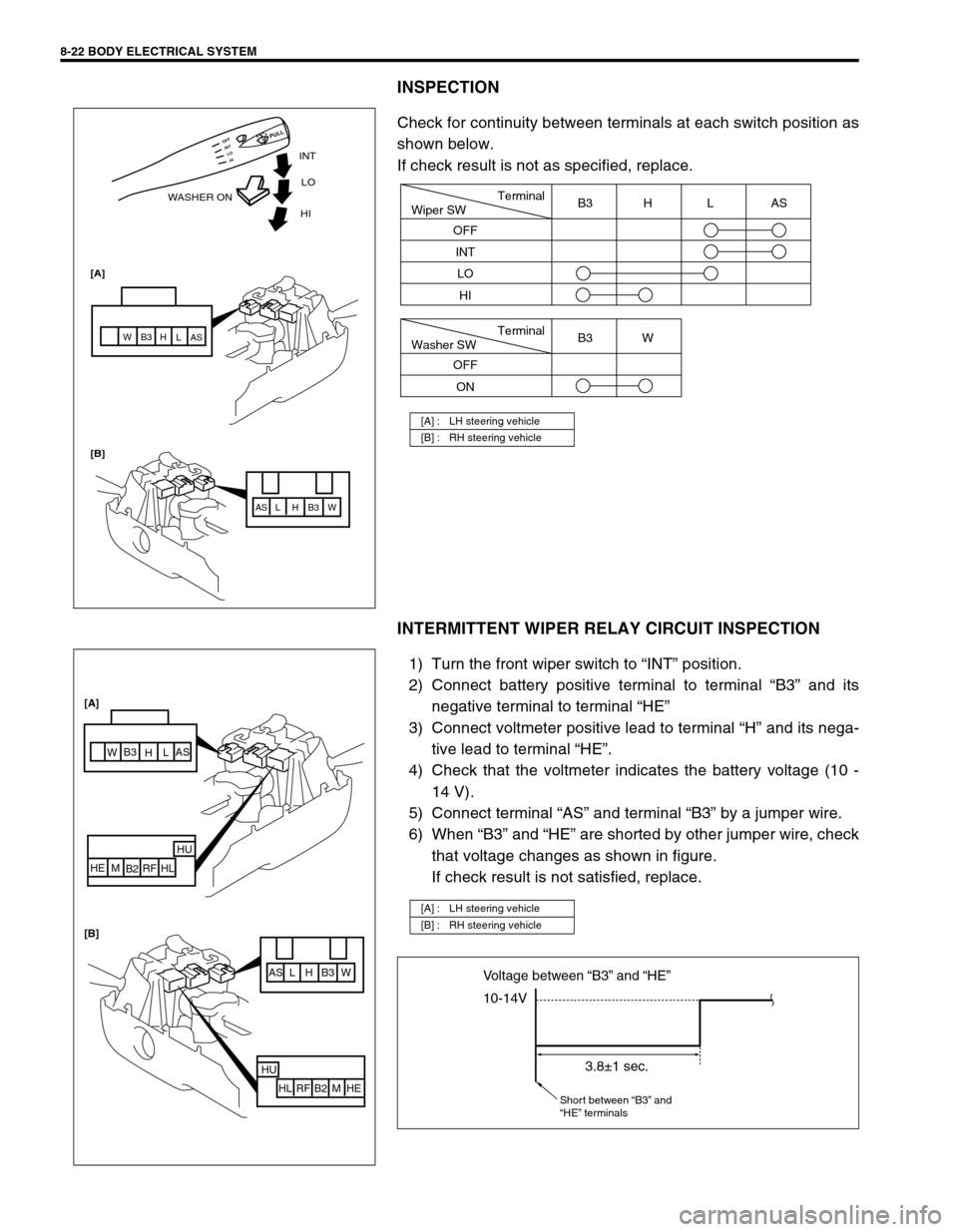

INSPECTION

Check for continuity between terminals at each switch position as

shown below.

If check result is not as specified, replace.

INTERMITTENT WIPER RELAY CIRCUIT INSPECTION

1) Turn the front wiper switch to “INT” position.

2) Connect battery positive terminal to terminal “B3” and its

negative terminal to terminal “HE”

3) Connect voltmeter positive lead to terminal “H” and its nega-

tive lead to terminal “HE”.

4) Check that the voltmeter indicates the battery voltage (10 -

14 V).

5) Connect terminal “AS” and terminal “B3” by a jumper wire.

6) When “B3” and “HE” are shorted by other jumper wire, check

that voltage changes as shown in figure.

If check result is not satisfied, replace.

[A] : LH steering vehicle

[B] : RH steering vehicle

INT

WASHER ONLO

[A]

[B]HI

AS AS

L L

H H

B3 B3

W W

HI LO INT OFF

PULL

Terminal

Wiper SW

OFF

INT

LOB3 H L AS

HI

Terminal

Washer SW

OFF

ONB3 W

[A] : LH steering vehicle

[B] : RH steering vehicle

AS L H B3 W

HU

HL RF B2 M HE

AS

L

H B3

W

HU

HL RF

B2 M HE [A]

[B]

10-14V Voltage between “B3” and “HE”

3.8±1 sec.

Short between “B3” and

“HE” terminals

Page 267 of 447

BODY ELECTRICAL SYSTEM 8-23

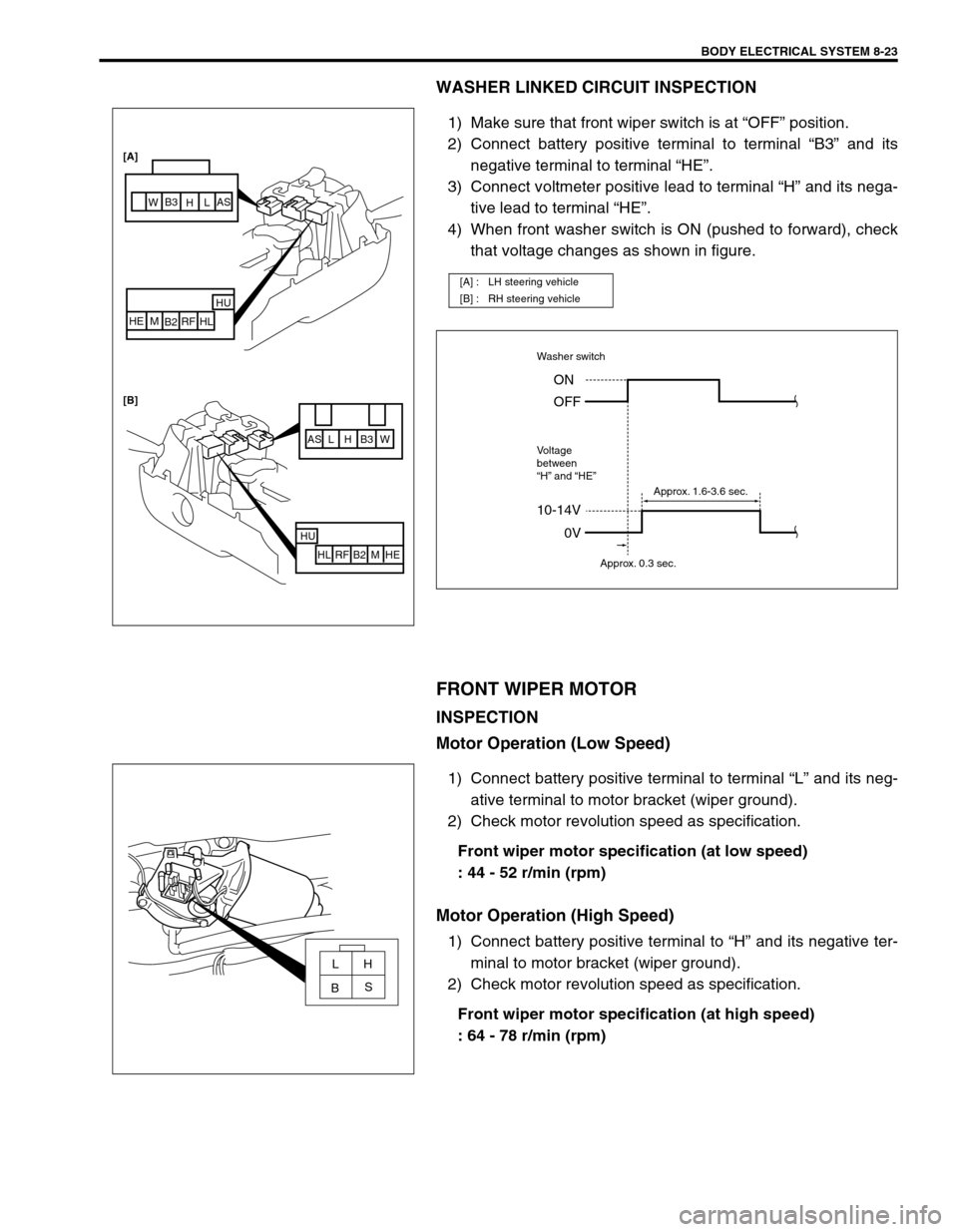

WASHER LINKED CIRCUIT INSPECTION

1) Make sure that front wiper switch is at “OFF” position.

2) Connect battery positive terminal to terminal “B3” and its

negative terminal to terminal “HE”.

3) Connect voltmeter positive lead to terminal “H” and its nega-

tive lead to terminal “HE”.

4) When front washer switch is ON (pushed to forward), check

that voltage changes as shown in figure.

FRONT WIPER MOTOR

INSPECTION

Motor Operation (Low Speed)

1) Connect battery positive terminal to terminal “L” and its neg-

ative terminal to motor bracket (wiper ground).

2) Check motor revolution speed as specification.

Front wiper motor specification (at low speed)

: 44 - 52 r/min (rpm)

Motor Operation (High Speed)

1) Connect battery positive terminal to “H” and its negative ter-

minal to motor bracket (wiper ground).

2) Check motor revolution speed as specification.

Front wiper motor specification (at high speed)

: 64 - 78 r/min (rpm)

[A] : LH steering vehicle

[B] : RH steering vehicle

AS L H B3 W

HU

HL RF B2 M HE

HU

HL RF

B2 M HE [A]

[B]

AS

L

H B3

W

10-14V

Washer switch

Voltage

between

“H” and “HE”

0V ON

OFF

Approx. 0.3 sec.Approx. 1.6-3.6 sec.

LH

S

B