immobilizer SUZUKI SWIFT 2000 1.G Transmission Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 447, PDF Size: 10.54 MB

Page 297 of 447

IMMOBILIZER CONTROL SYSTEM 8G-19

Fig. 1 for Step 1

Fig. 2 for Step 2NOTE:

After replacing with a known-good ECM, register ECM/Immobilizer Control Module code in ECM by

performing procedure described in “PROCEDURE AFTER ECM REPLACEMENT” in this section.

After replacing with a known-good Immobilizer Control Module, register ECM/Immobilizer Control

Module code in ECM and Transponder code and ECM/Immobilizer Control Module code in Immobi-

lizer Control Module by performing procedure described in “PROCEDURE AFTER IMMOBILIZER

CONTROL MODULE REPLACEMENT” in the section.

2. Connect to serial data link terminal (G02-7) of ECM coupler disconnected

Page 298 of 447

8G-20 IMMOBILIZER CONTROL SYSTEM

INSPECTION OF ECM, IMMOBILIZER CON-

TROL MODULE AND ITS CIRCUIT

ECM, Immobilizer Control Module and its circuit can be checked

at ECM wiring couplers and Immobilizer Control Module wiring

coupler by measuring voltage. Described here is only inspection

of Immobilizer Control Module. For inspection of ECM, refer to

“ENGINE & EMISSION CONTROL INPUT/OUTPUT TABLE” in

Section 6E1.

Voltage Check

1) Remove Immobilizer Control Module from steering lock

assembly with ignition switch OFF, referring to “REMOVAL”

of “IMMOBILIZER CONTROL MODULE” in this section.

2) Connect Immobilizer Control Module coupler to Immobilizer

Control Module.

3) Check voltage at each terminal of coupler connected.CAUTION:

Immobilizer Control Module cannot be checked by itself.

It is strictly prohibited to connect voltmeter or ohmmeter

to Immobilizer Control Module with coupler disconnected

from it.

NOTE:

As each terminal voltage is affected by the battery volt-

age, confirm that it is 11V or more when ignition switch is

ON.

1. Immobilizer Control Module

2. Immobilizer Control Module coupler

3. Body ground

TERMINAL CIRCUIT NOMAL VOLTAGE CONDITION

G06-1 Ground––

G06-2Data link connector

(Serial data terminal)4 – 5V Ignition switch ON

G06-3 Ignition signal10 – 14V Ignition switch ON

0 – 0.8V Ignition switch OFF

G06-4 Power source 10 – 14V Ignition switch ON

Page 299 of 447

IMMOBILIZER CONTROL SYSTEM 8G-21

ON-VEHICLE SERVICE

PRECAUTIONS IN HANDLING IMMOBILIZER

CONTROL SYSTEM

Don’t turn ON ignition switch with ignition key for immobilizer

control system put together with another one or placed quite

close to another one. Or the system may detect abnormal

condition and prevent engine from starting.

Do not turn ON ignition switch by using ignition key with any

type of metal wound around its grip or in contact with it. Or

the system may detect abnormal condition and prevent

engine from starting.

Do not leave ignition key where high temperature is antici-

pated.High temperature will cause transponder in ignition

key to be abnormal or damaged.

Page 300 of 447

8G-22 IMMOBILIZER CONTROL SYSTEM

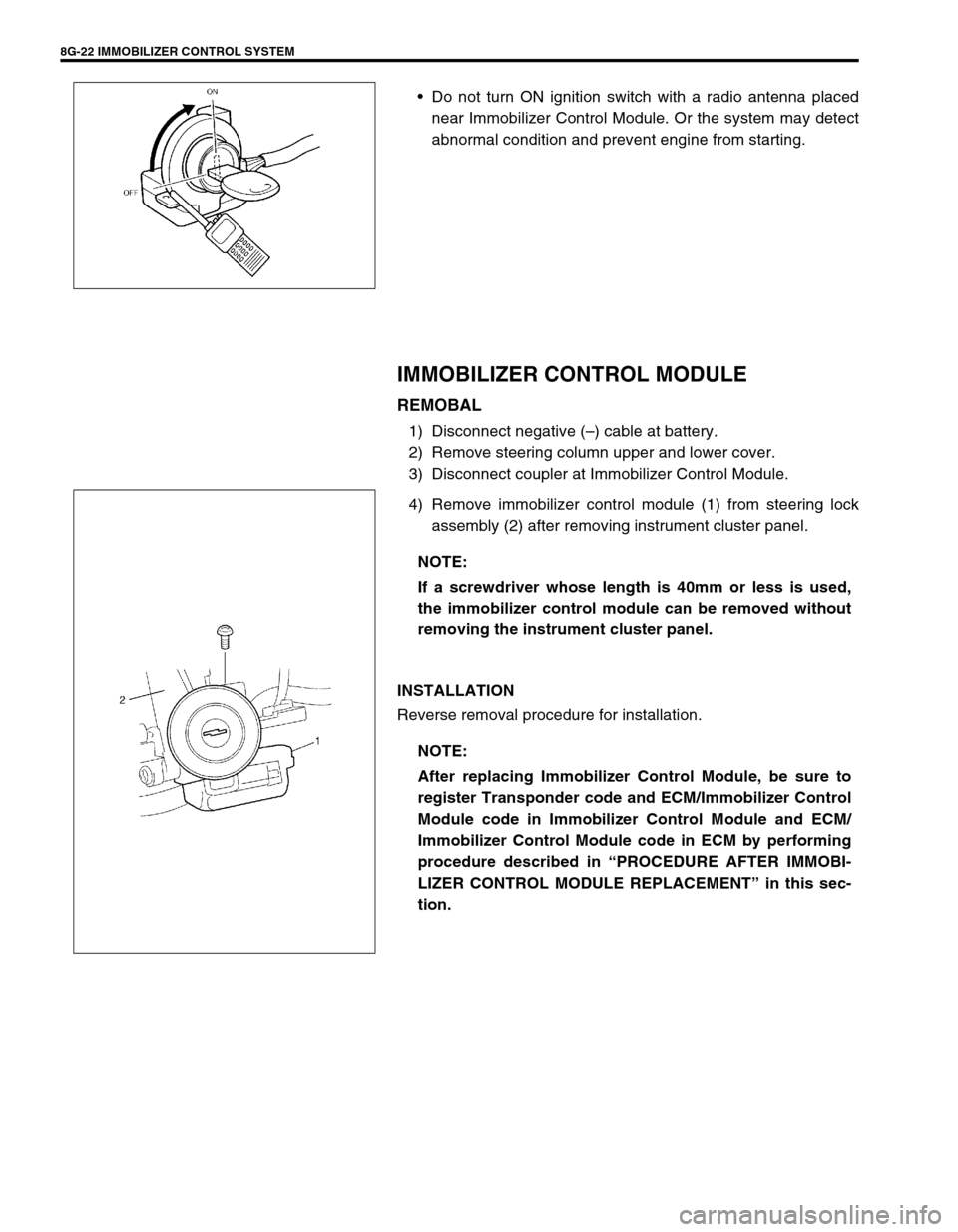

Do not turn ON ignition switch with a radio antenna placed

near Immobilizer Control Module. Or the system may detect

abnormal condition and prevent engine from starting.

IMMOBILIZER CONTROL MODULE

REMOBAL

1) Disconnect negative (–) cable at battery.

2) Remove steering column upper and lower cover.

3) Disconnect coupler at Immobilizer Control Module.

4) Remove immobilizer control module (1) from steering lock

assembly (2) after removing instrument cluster panel.

INSTALLATION

Reverse removal procedure for installation.

NOTE:

If a screwdriver whose length is 40mm or less is used,

the immobilizer control module can be removed without

removing the instrument cluster panel.

NOTE:

After replacing Immobilizer Control Module, be sure to

register Transponder code and ECM/Immobilizer Control

Module code in Immobilizer Control Module and ECM/

Immobilizer Control Module code in ECM by performing

procedure described in “PROCEDURE AFTER IMMOBI-

LIZER CONTROL MODULE REPLACEMENT” in this sec-

tion.

Page 301 of 447

IMMOBILIZER CONTROL SYSTEM 8G-23

HOW TO REGISTER IGNITION KEY

Register the ignition key with a built-in transponder in Immobilizer

Control Module by using the following procedure.

1) Prepare SUZUKI scan tool and cartridge for immobilizer con-

trol system.

2) With ignition switch OFF, connect SUZUKI scan tool to data

link connector (DLC) (1) located on underside of instrument

panel at driver’s seat side.

(A) : 09931-76011 (SUZUKI scan tool)

(B) : Immobilizer cartridge

(C) : 09931-76030 (16/14 pin DLC cable)

3) Prepare ignition key with a built-in transponder (1). And then

turn ignition switch ON by using it.

4) Number of Transponder codes for ignition key with a built-in

transponder that can be registered in Immobilizer Control

Module is limited to 4. If needed, clear all Transponder

codes for ignition key with a built-in transponder that have

been registered in Immobilizer Control Module by executing

the “CLR. TRANS COD (CLEAR TP CODE)” command in

the SELECT MODE menu by using SUZUKI scan tool. CAUTION:

When registering the ignition key including a transpon-

der into the immobilizer control module by using Suzuki

scan tool, confirm that the knob color of the ignition key

to be registered for the vehicle is dark gray. The ignition

key with wrong knob color cannot be registered.

NOTE:

For operation procedure of SUZUKI scan tool, refer to

SUZUKI scan tool operator’s manual.

1

(C)(A)

(B)

NOTE:

When “CLR. TRANS COD (CLEAR TP CODE)” command

is executed with the immobilizer indicator lamp ON, it

remains ON even after execution of that command is

over. It will start flashing when the ignition switch is

turned OFF once and then turned ON after some sec-

onds.

Page 302 of 447

8G-24 IMMOBILIZER CONTROL SYSTEM

5) Using SUZUKI scan tool, register Transponder code in

Immobilizer Control Module by executing “ENT. TRANS

COD (ENT. TP CODE)” command in SELECT MODE menu.

6) Make sure that immobilizer indicator lamp lights when igni-

tion switch is turned OFF once and then ON.

7) If any other Transponder code for ignition key with a built-in

transponder needs to be registered, repeat above steps 3),

5) and 6).

PROCEDURE AFTER IMMOBILIZER CONTROL MODULE

REPLACEMENT

When Immobilizer Control Module was replaced, including when replaced because rechecking by using a

known-good Immobilizer Control Module was necessary during trouble diagnosis, register Transponder code

and ECM/Immobilizer Control Module code in Immobilizer Control Module and ECM/Immobilizer Control Module

code in ECM by performing following procedure.

1) Perform steps 1) and 2) described in “How To Register Ignition Key”.

2) Prepare ignition key with a built-in transponder. And then turn ignition switch ON by using it.

3) Using SUZUKI scan tool, clear all transponder codes registered in Immobilizer Control Module by executing

“CLR. TRANS COD (CLEAR TP CODE)” command in SELECT MODE menu.

4) Using SUZUKI scan tool, register Transponder code in Immobilizer Control Module by executing “ENT.

TRANS COD (ENT. TP CODE)” command in SELECT MODE menu.

5) Using SUZUKI scan tool, register ECM/Immobilizer Control Module code in both Immobilizer Control Module

and ECM by executing “RECORD ECU (RECORD ECM/PCM/ICM)” command in SELECT MODE menu.

6) Make sure that immobilizer indicator lamp lights when ignition switch is turned OFF once and then ON.

7) If any other Transponder code for ignition key with a built-in transponder needs to be registered, repeat

above steps 2), 4) and 6).NOTE:

Up to 4 Transponder codes for ignition key with a built-

in transponder can be registered.

It is not possible to register the same Transponder

code for ignition key with a built-in transponder as the

one already registered in Immobilizer Control Module.

CAUTION:

When registering the ignition key including a transponder into the immobilizer control module by

using Suzuki scan tool, confirm that the knob color of the ignition key to be registered for the vehicle

is dark gray. The ignition key with wrong knob color cannot be registered.

NOTE:

When “CLR. TRANS COD (CLEAR TP CODE)” command is executed with the immobilizer indicator

lamp ON, it remains ON even after execution of that command is over. It will start flashing when the

ignition switch is turned OFF once and then turned ON after some seconds.

Page 303 of 447

IMMOBILIZER CONTROL SYSTEM 8G-25

PROCEDURE AFTER ECM REPLACEMENT

When ECM was replaced, including when replaced because rechecking by using a known-good ECM was nec-

essary during trouble diagnosis, register ECM/Immobilizer Control Module code in ECM by performing following

procedure.

1) Perform steps 1) and 2) described in “How To Register Ignition Key”. And then turn ignition switch ON.

2) Using SUZUKI scan tool, register ECM/Immobilizer Control Module code in ECM by executing “RECORD

ECU (RECORD ECM/lCM)” command in SELECT MODE menu.

3) Make sure that malfunction indicator lamp lights when ignition switch is turned OFF once and then ON.

SPECIAL TOOL

NOTE:

Up to 4 Transponder codes for ignition key with a built-in transponder can be registered.

It is not possible to register the same Transponder code for ignition key with a built-in transponder

as the one already registered in Immobilizer Control Module.

NOTE:

For operation procedure of SUZUKI scan tool, refer to SUZUKI scan tool operator’s manual.

09931-76011 09931-76030

Tech 1A kit

See NOTE below.Immobilizer cartridge of

version 1.1 or more16/14 pin DLC cable Mass storage cartridge of

version 1.5 or more

NOTE:

This kit includs the following items.

1. Storage case, 2. Operator’s manual, 3. Tech 1A, 4. DLC cable, 5. Test lead/probe,

6. Power source cable, 7. DLC cable adaptor, 8. Self-test adaptor

Page 304 of 447

8G-26 IMMOBILIZER CONTROL SYSTEM

Page 395 of 447

AIR BAG SYSTEM 10B-21

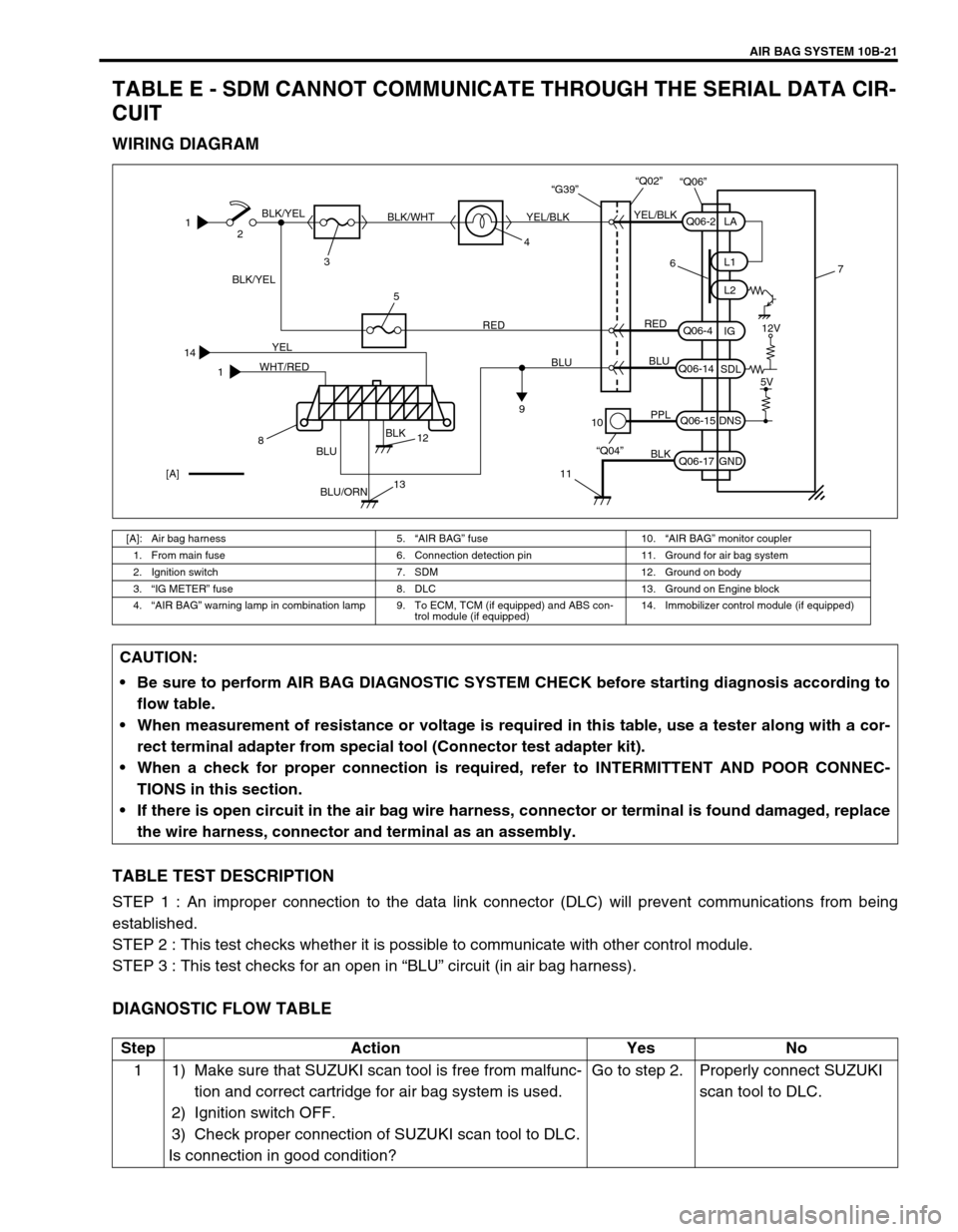

TABLE E - SDM CANNOT COMMUNICATE THROUGH THE SERIAL DATA CIR-

CUIT

WIRING DIAGRAM

TABLE TEST DESCRIPTION

STEP 1 : An improper connection to the data link connector (DLC) will prevent communications from being

established.

STEP 2 : This test checks whether it is possible to communicate with other control module.

STEP 3 : This test checks for an open in “BLU” circuit (in air bag harness).

DIAGNOSTIC FLOW TABLE

[A]: Air bag harness 5.“AIR BAG” fuse 10.“AIR BAG” monitor coupler

1. From main fuse 6. Connection detection pin 11. Ground for air bag system

2. Ignition switch 7. SDM 12. Ground on body

3.“IG METER” fuse 8. DLC 13. Ground on Engine block

4.“AIR BAG” warning lamp in combination lamp 9. To ECM, TCM (if equipped) and ABS con-

trol module (if equipped)14. Immobilizer control module (if equipped)

1

14

12

34 BLK/YEL

BLK/YEL

YELBLK/WHT

BLK

BLU/ORNYEL/BLKYEL/BLK

6

RED

WHT/REDRED

BLU

BLU

BLU

5

9

10

11

PPL

BLK

“Q04”“Q06”

Q06-2

Q06-4

Q06-14

Q06-15

Q06-17L1

L2

IG

SDL

DNS

GNDLA

7

[A]

12V

5V

“G39”“Q02”

812

13

CAUTION:

Be sure to perform AIR BAG DIAGNOSTIC SYSTEM CHECK before starting diagnosis according to

flow table.

When measurement of resistance or voltage is required in this table, use a tester along with a cor-

rect terminal adapter from special tool (Connector test adapter kit).

When a check for proper connection is required, refer to INTERMITTENT AND POOR CONNEC-

TIONS in this section.

If there is open circuit in the air bag wire harness, connector or terminal is found damaged, replace

the wire harness, connector and terminal as an assembly.

Step Action Yes No

1 1) Make sure that SUZUKI scan tool is free from malfunc-

tion and correct cartridge for air bag system is used.

2) Ignition switch OFF.

3) Check proper connection of SUZUKI scan tool to DLC.

Is connection in good condition?Go to step 2. Properly connect SUZUKI

scan tool to DLC.