lock SUZUKI SWIFT 2000 1.G Transmission Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2000, Model line: SWIFT, Model: SUZUKI SWIFT 2000 1.GPages: 447, PDF Size: 10.54 MB

Page 50 of 447

7B-8 AUTOMATIC TRANSMISSION (4 A/T)

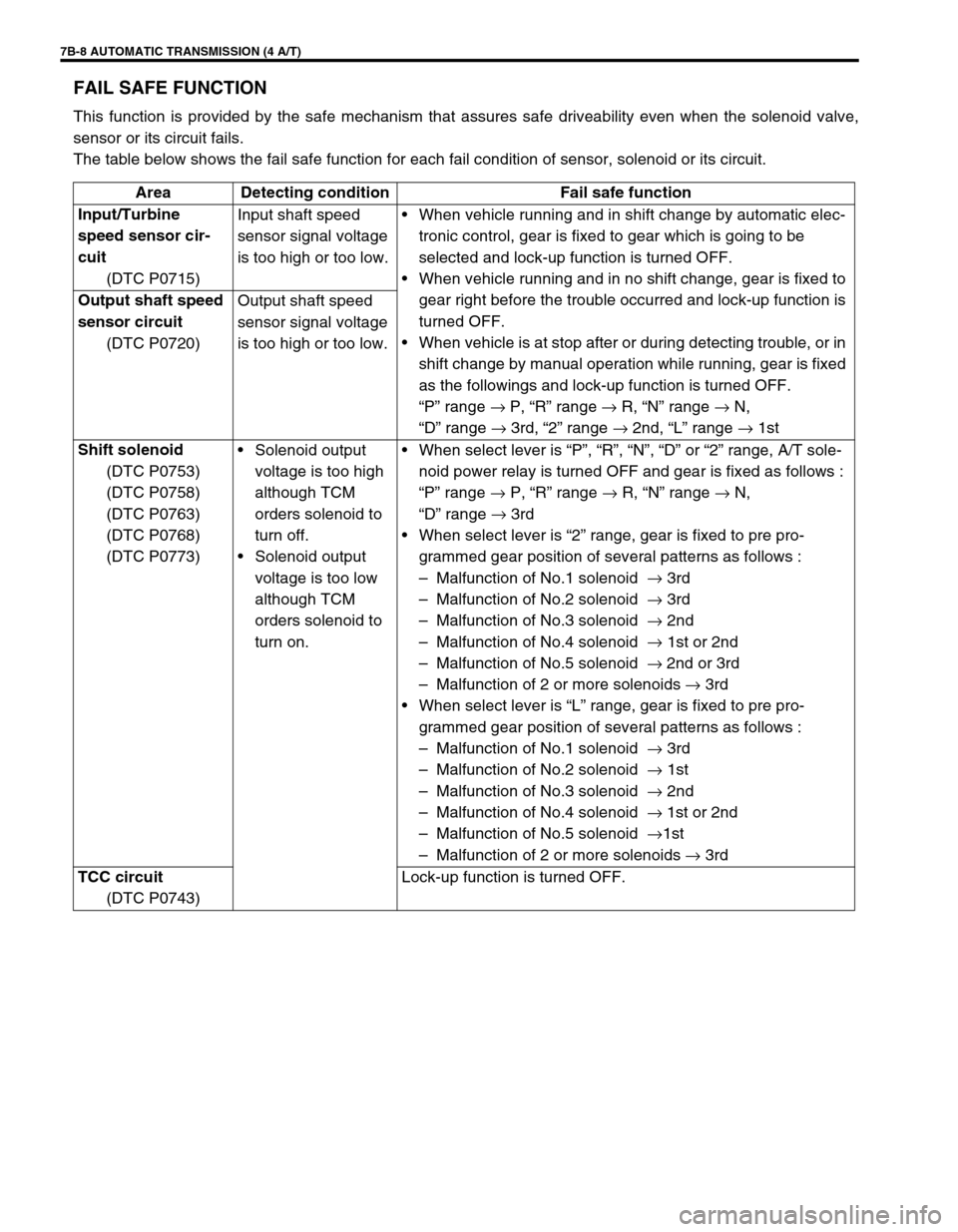

FAIL SAFE FUNCTION

This function is provided by the safe mechanism that assures safe driveability even when the solenoid valve,

sensor or its circuit fails.

The table below shows the fail safe function for each fail condition of sensor, solenoid or its circuit.

Area Detecting condition Fail safe function

Input/Turbine

speed sensor cir-

cuit

(DTC P0715)Input shaft speed

sensor signal voltage

is too high or too low.When vehicle running and in shift change by automatic elec-

tronic control, gear is fixed to gear which is going to be

selected and lock-up function is turned OFF.

When vehicle running and in no shift change, gear is fixed to

gear right before the trouble occurred and lock-up function is

turned OFF.

When vehicle is at stop after or during detecting trouble, or in

shift change by manual operation while running, gear is fixed

as the followings and lock-up function is turned OFF.

“P” range →

P, “R” range →

R, “N” range →

N,

“D” range →

3rd, “2” range →

2nd, “L” range →

1st Output shaft speed

sensor circuit

(DTC P0720)Output shaft speed

sensor signal voltage

is too high or too low.

Shift solenoid

(DTC P0753)

(DTC P0758)

(DTC P0763)

(DTC P0768)

(DTC P0773)Solenoid output

voltage is too high

although TCM

orders solenoid to

turn off.

Solenoid output

voltage is too low

although TCM

orders solenoid to

turn on.When select lever is “P”, “R”, “N”, “D” or “2” range, A/T sole-

noid power relay is turned OFF and gear is fixed as follows :

“P” range →

P, “R” range →

R, “N” range →

N,

“D” range →

3rd

When select lever is “2” range, gear is fixed to pre pro-

grammed gear position of several patterns as follows :

–Malfunction of No.1 solenoid →

3rd

–Malfunction of No.2 solenoid →

3rd

–Malfunction of No.3 solenoid →

2nd

–Malfunction of No.4 solenoid →

1st or 2nd

–Malfunction of No.5 solenoid →

2nd or 3rd

–Malfunction of 2 or more solenoids →

3rd

When select lever is “L” range, gear is fixed to pre pro-

grammed gear position of several patterns as follows :

–Malfunction of No.1 solenoid →

3rd

–Malfunction of No.2 solenoid →

1st

–Malfunction of No.3 solenoid →

2nd

–Malfunction of No.4 solenoid →

1st or 2nd

–Malfunction of No.5 solenoid →

1st

–Malfunction of 2 or more solenoids →

3rd

TCC circuit

(DTC P0743)Lock-up function is turned OFF.

Page 51 of 447

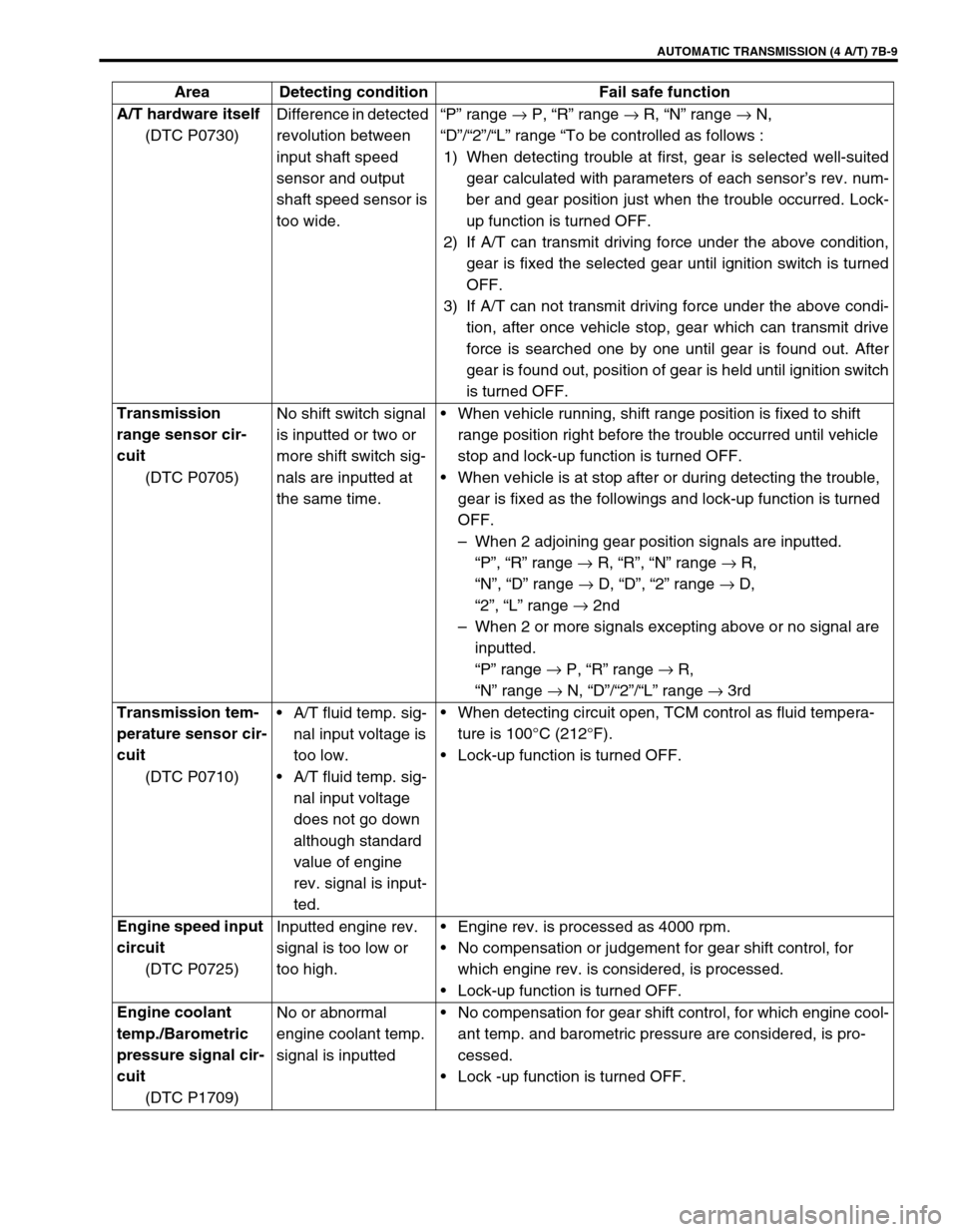

AUTOMATIC TRANSMISSION (4 A/T) 7B-9

A/T hardware itself

(DTC P0730)Difference in detected

revolution between

input shaft speed

sensor and output

shaft speed sensor is

too wide.“P” range →

P, “R” range →

R, “N” range →

N,

“D”/“2”/“L” range “To be controlled as follows :

1) When detecting trouble at first, gear is selected well-suited

gear calculated with parameters of each sensor’s rev. num-

ber and gear position just when the trouble occurred. Lock-

up function is turned OFF.

2) If A/T can transmit driving force under the above condition,

gear is fixed the selected gear until ignition switch is turned

OFF.

3) If A/T can not transmit driving force under the above condi-

tion, after once vehicle stop, gear which can transmit drive

force is searched one by one until gear is found out. After

gear is found out, position of gear is held until ignition switch

is turned OFF.

Transmission

range sensor cir-

cuit

(DTC P0705)No shift switch signal

is inputted or two or

more shift switch sig-

nals are inputted at

the same time.When vehicle running, shift range position is fixed to shift

range position right before the trouble occurred until vehicle

stop and lock-up function is turned OFF.

When vehicle is at stop after or during detecting the trouble,

gear is fixed as the followings and lock-up function is turned

OFF.

–When 2 adjoining gear position signals are inputted.

“P”, “R” range →

R, “R”, “N” range →

R,

“N”, “D” range →

D, “D”, “2” range →

D,

“2”, “L” range →

2nd

–When 2 or more signals excepting above or no signal are

inputted.

“P” range →

P, “R” range →

R,

“N” range →

N, “D”/“2”/“L” range →

3rd

Transmission tem-

perature sensor cir-

cuit

(DTC P0710)A/T fluid temp. sig-

nal input voltage is

too low.

A/T fluid temp. sig-

nal input voltage

does not go down

although standard

value of engine

rev. signal is input-

ted.When detecting circuit open, TCM control as fluid tempera-

ture is 100°C (212°F).

Lock-up function is turned OFF.

Engine speed input

circuit

(DTC P0725)Inputted engine rev.

signal is too low or

too high.Engine rev. is processed as 4000 rpm.

No compensation or judgement for gear shift control, for

which engine rev. is considered, is processed.

Lock-up function is turned OFF.

Engine coolant

temp./Barometric

pressure signal cir-

cuit

(DTC P1709)No or abnormal

engine coolant temp.

signal is inputtedNo compensation for gear shift control, for which engine cool-

ant temp. and barometric pressure are considered, is pro-

cessed.

Lock -up function is turned OFF. Area Detecting condition Fail safe function

Page 52 of 447

7B-10 AUTOMATIC TRANSMISSION (4 A/T)

CHANGE MECHANISM

The same select pattern shift lever is used as the floor type and

frequently used “N” and “D” ranges are made selectable freely. Throttle position

signal circuit

(DTC P1700)No or abnormal throt-

tle opening signal is

inputtedScheduling of automatic gear shift is performed as throttle

valve opening is 0%.

Control of automatic gear shift (i.e. control of oil pressure) is

performed as throttle valve opening is 100%.

Coast down shifting is performed when brake is applied and

engine rev. is less than 1,500 rpm.

Lock-up function is turned OFF.

Transmission con-

trol system electri-

cal

(DTC P0702)Solenoid power sup-

ply relay output volt-

age is too high

although TCM orders

relay to turn off or

relay output voltage is

too low although TCM

orders relay to turn

on.When relay shorted, the gear is fixed as the followings and

lock-up function is turned OFF.

“P” range →

P, “R” range →

R, “N” range →

N,

“D” range →

3rd, “2” range →

2nd, “L” range →

1st

When relay open, power supply to all solenoids is cut and the

gear is fixed as the followings. Lock-up function is turned

OFF.

“P” range →

P, “R” range →

R, “N” range →

N,

“D”/“2”/“L” range →

3rd

Internal malfunc-

tion of TCM

(DTC P1702)Incorrect calculations

of checking TCM pro-

grammed data indi-

cated.Power supply to all solenoid is cut and the gear is fixed as fol-

lows :

“P” range P, “R” range R, “N” range N,

“D”/“2”/“L” range “3rd Area Detecting condition Fail safe function

Page 53 of 447

![SUZUKI SWIFT 2000 1.G Transmission Service Owners Manual AUTOMATIC TRANSMISSION (4 A/T) 7B-11

AUTOMATIC GEAR SHIFT DIAGRAM

Automatic shift schedule as a result of shift control is shown below.

[For 2WD model]

Gear Shift Diagram

TCC Lock-up Diagram

Shift

Thr SUZUKI SWIFT 2000 1.G Transmission Service Owners Manual AUTOMATIC TRANSMISSION (4 A/T) 7B-11

AUTOMATIC GEAR SHIFT DIAGRAM

Automatic shift schedule as a result of shift control is shown below.

[For 2WD model]

Gear Shift Diagram

TCC Lock-up Diagram

Shift

Thr](/img/20/7605/w960_7605-52.png)

AUTOMATIC TRANSMISSION (4 A/T) 7B-11

AUTOMATIC GEAR SHIFT DIAGRAM

Automatic shift schedule as a result of shift control is shown below.

[For 2WD model]

Gear Shift Diagram

TCC Lock-up Diagram

Shift

Throttle opening 1→

22→

33→

44→

33→

22→

1

Full throttle 44 98 - 135 87 35

Closed throttle 13 26 43 34 9 9

Page 54 of 447

![SUZUKI SWIFT 2000 1.G Transmission Service Owners Manual 7B-12 AUTOMATIC TRANSMISSION (4 A/T)

[For 4WD model]

Gear Shift Diagram

TCC Lock-up Diagram

Shift

Throttle opening 1→

22→

33→

44→

33→

22→

1

Full throttle 40 90 143 124 80 32

Closed throttl SUZUKI SWIFT 2000 1.G Transmission Service Owners Manual 7B-12 AUTOMATIC TRANSMISSION (4 A/T)

[For 4WD model]

Gear Shift Diagram

TCC Lock-up Diagram

Shift

Throttle opening 1→

22→

33→

44→

33→

22→

1

Full throttle 40 90 143 124 80 32

Closed throttl](/img/20/7605/w960_7605-53.png)

7B-12 AUTOMATIC TRANSMISSION (4 A/T)

[For 4WD model]

Gear Shift Diagram

TCC Lock-up Diagram

Shift

Throttle opening 1→

22→

33→

44→

33→

22→

1

Full throttle 40 90 143 124 80 32

Closed throttle 12 24 40 31 9 9

Page 60 of 447

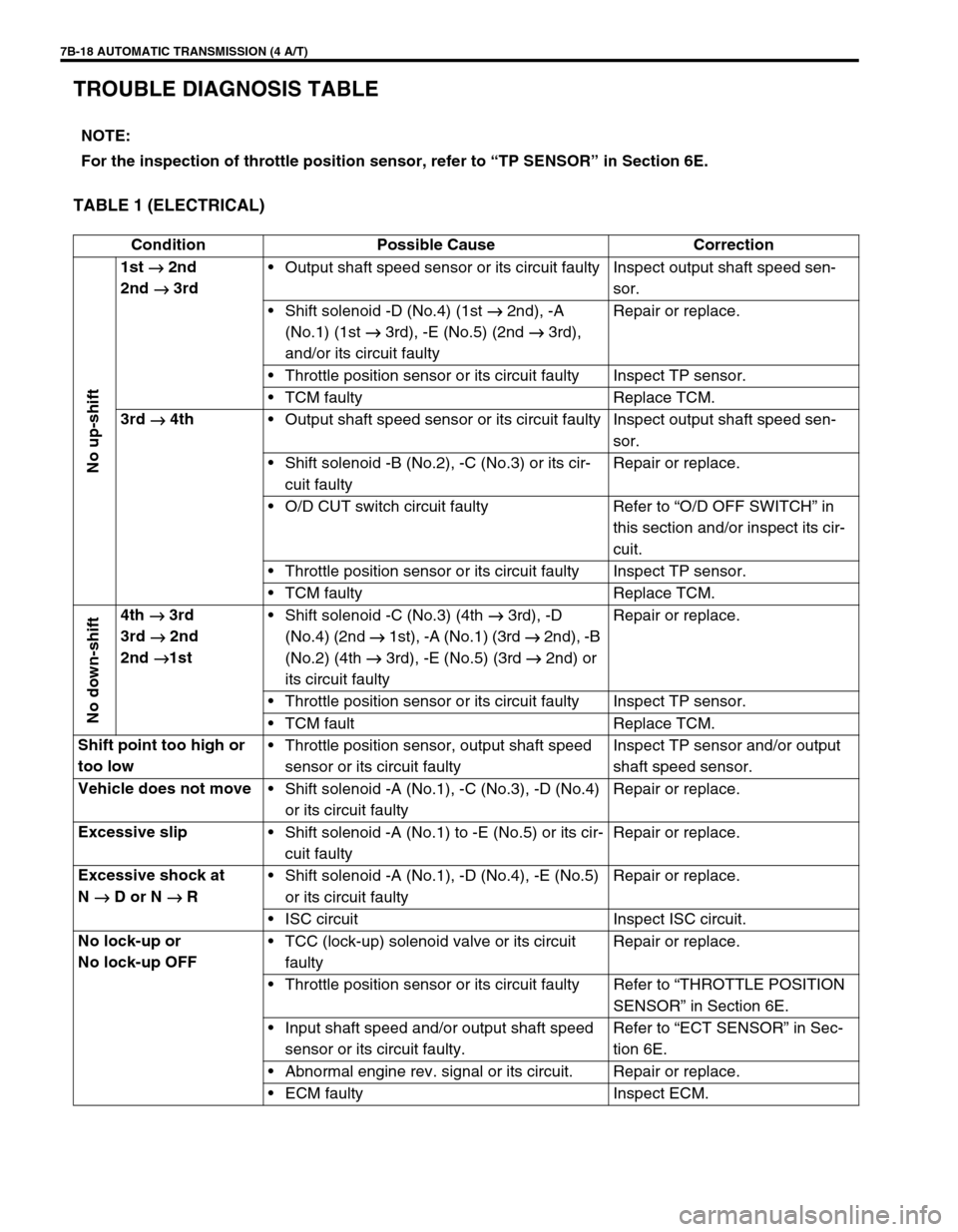

7B-18 AUTOMATIC TRANSMISSION (4 A/T)

TROUBLE DIAGNOSIS TABLE

TABLE 1 (ELECTRICAL)

NOTE:

For the inspection of throttle position sensor, refer to “TP SENSOR” in Section 6E.

Condition Possible Cause Correction

No up-shift

1st

→

→→ → 2nd

2nd

→

→→ → 3rdOutput shaft speed sensor or its circuit faulty Inspect output shaft speed sen-

sor.

Shift solenoid -D (No.4) (1st →

→→ →

2nd), -A

(No.1) (1st →

→→ →

3rd), -E (No.5) (2nd →

→→ →

3rd),

and/or its circuit faultyRepair or replace.

Throttle position sensor or its circuit faulty Inspect TP sensor.

TCM faulty Replace TCM.

3rd

→

→→ → 4th

Output shaft speed sensor or its circuit faulty Inspect output shaft speed sen-

sor.

Shift solenoid -B (No.2), -C (No.3) or its cir-

cuit faultyRepair or replace.

O/D CUT switch circuit faulty Refer to “O/D OFF SWITCH” in

this section and/or inspect its cir-

cuit.

Throttle position sensor or its circuit faulty Inspect TP sensor.

TCM faulty Replace TCM.

No down-shift

4th

→

→→ → 3rd

3rd

→

→→ → 2nd

2nd

→

→→ →1stShift solenoid -C (No.3) (4th →

→→ →

3rd), -D

(No.4) (2nd →

→→ →

1st), -A (No.1) (3rd →

→→ →

2nd), -B

(No.2) (4th →

→→ →

3rd), -E (No.5) (3rd →

→→ →

2nd) or

its circuit faultyRepair or replace.

Throttle position sensor or its circuit faulty Inspect TP sensor.

TCM fault Replace TCM.

Shift point too high or

too lowThrottle position sensor, output shaft speed

sensor or its circuit faultyInspect TP sensor and/or output

shaft speed sensor.

Vehicle does not move

Shift solenoid -A (No.1), -C (No.3), -D (No.4)

or its circuit faultyRepair or replace.

Excessive slip

Shift solenoid -A (No.1) to -E (No.5) or its cir-

cuit faultyRepair or replace.

Excessive shock at

N

→

→→ → D or N

→

→→ → RShift solenoid -A (No.1), -D (No.4), -E (No.5)

or its circuit faultyRepair or replace.

ISC circuit Inspect ISC circuit.

No lock-up or

No lock-up OFFTCC (lock-up) solenoid valve or its circuit

faultyRepair or replace.

Throttle position sensor or its circuit faulty Refer to “THROTTLE POSITION

SENSOR” in Section 6E.

Input shaft speed and/or output shaft speed

sensor or its circuit faulty.Refer to “ECT SENSOR” in Sec-

tion 6E.

Abnormal engine rev. signal or its circuit. Repair or replace.

ECM faulty Inspect ECM.

Page 61 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-19

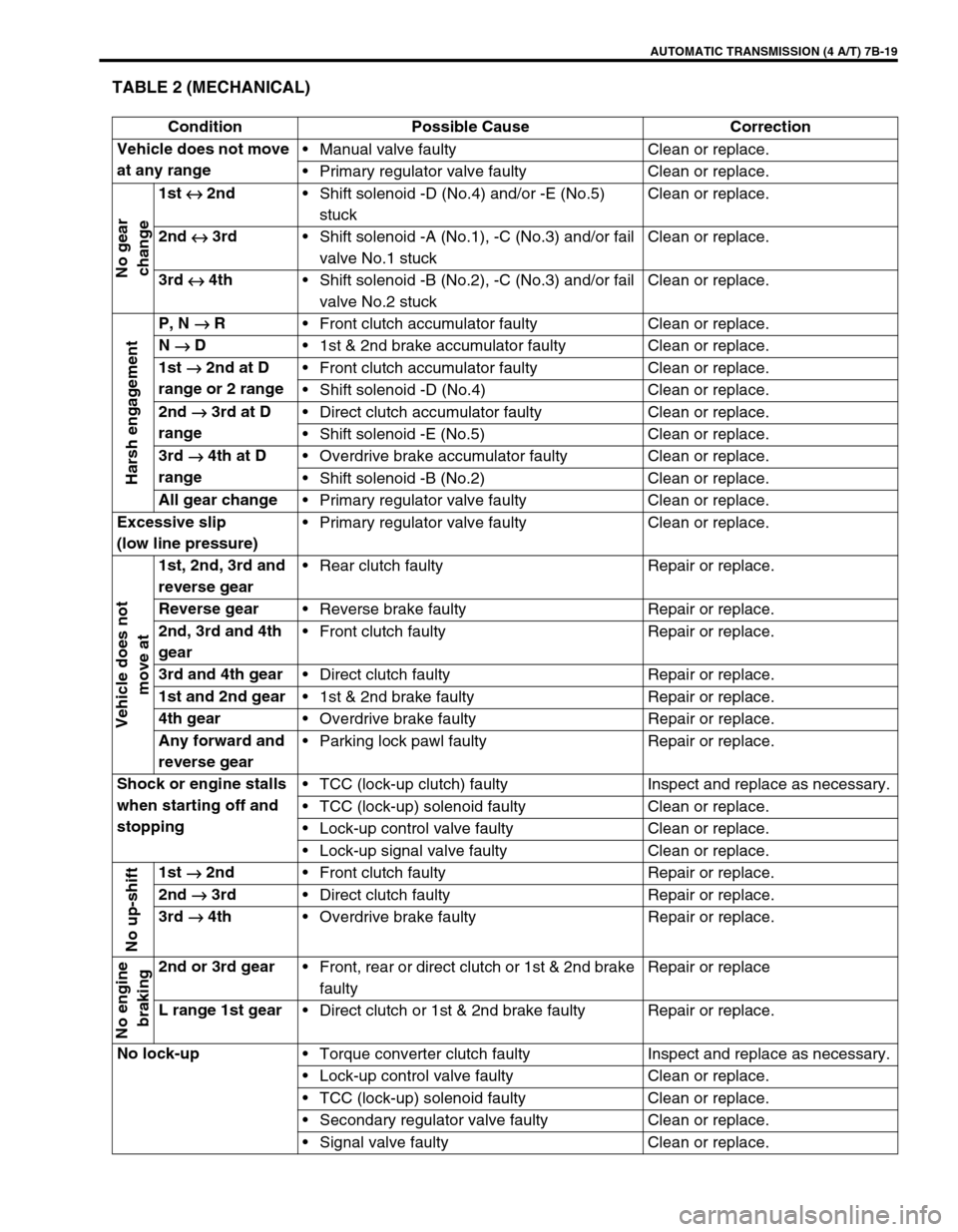

TABLE 2 (MECHANICAL)

Condition Possible Cause Correction

Vehicle does not move

at any rangeManual valve faulty Clean or replace.

Primary regulator valve faulty Clean or replace.

No gear

change

1st

↔

↔↔ ↔ 2nd

Shift solenoid -D (No.4) and/or -E (No.5)

stuck Clean or replace.

2nd

↔

↔↔ ↔ 3rd

Shift solenoid -A (No.1), -C (No.3) and/or fail

valve No.1 stuckClean or replace.

3rd

↔

↔↔ ↔ 4th

Shift solenoid -B (No.2), -C (No.3) and/or fail

valve No.2 stuckClean or replace.

Harsh engagement

P, N

→

→→ → R

Front clutch accumulator faulty Clean or replace.

N

→

→→ → D

1st & 2nd brake accumulator faulty Clean or replace.

1st

→

→→ → 2nd at D

range or 2 rangeFront clutch accumulator faulty Clean or replace.

Shift solenoid -D (No.4) Clean or replace.

2nd

→

→→ → 3rd at D

rangeDirect clutch accumulator faulty Clean or replace.

Shift solenoid -E (No.5) Clean or replace.

3rd

→

→→ → 4th at D

rangeOverdrive brake accumulator faulty Clean or replace.

Shift solenoid -B (No.2) Clean or replace.

All gear change

Primary regulator valve faulty Clean or replace.

Excessive slip

(low line pressure)Primary regulator valve faulty Clean or replace.

Vehicle does not

move at

1st, 2nd, 3rd and

reverse gearRear clutch faulty Repair or replace.

Reverse gear

Reverse brake faulty Repair or replace.

2nd, 3rd and 4th

gearFront clutch faulty Repair or replace.

3rd and 4th gear

Direct clutch faulty Repair or replace.

1st and 2nd gear

1st & 2nd brake faulty Repair or replace.

4th gear

Overdrive brake faulty Repair or replace.

Any forward and

reverse gearParking lock pawl faulty Repair or replace.

Shock or engine stalls

when starting off and

stoppingTCC (lock-up clutch) faulty Inspect and replace as necessary.

TCC (lock-up) solenoid faulty Clean or replace.

Lock-up control valve faulty Clean or replace.

Lock-up signal valve faulty Clean or replace.

No up-shift

1st

→

→→ → 2nd

Front clutch faulty Repair or replace.

2nd

→

→→ → 3rd

Direct clutch faulty Repair or replace.

3rd

→

→→ → 4th

Overdrive brake faulty Repair or replace.

No engine

braking

2nd or 3rd gear

Front, rear or direct clutch or 1st & 2nd brake

faultyRepair or replace

L range 1st gear

Direct clutch or 1st & 2nd brake faulty Repair or replace.

No lock-up

Torque converter clutch faulty Inspect and replace as necessary.

Lock-up control valve faulty Clean or replace.

TCC (lock-up) solenoid faulty Clean or replace.

Secondary regulator valve faulty Clean or replace.

Signal valve faulty Clean or replace.

Page 62 of 447

7B-20 AUTOMATIC TRANSMISSION (4 A/T)

STALL TEST

This test is to check overall performance of automatic transmis-

sion and engine by measuring stall speed at “D” and “R” ranges.

Be sure to perform this test only when transmission fluid is at nor-

mal operating temperature and its level is between FULL and

LOW marks.

1) Apply parking brake and block wheels.

2) Install tachometer.

3) Start engine with select lever shifted to “P”.

4) Depress brake pedal fully.

5) Shift select lever to “D” and depress accelerator pedal fully

while watching tachometer. Read engine rpm quickly when it

has become constant (stall speed).

6) Release accelerator pedal immediately after stall speed is

checked.

7) In the same way, check stall speed in “R” range.

8) Stall speed should be within following specification.

Stall speed

: 2,750 – 3,150 r/min CAUTION:

Do not run engine at stall more than 5 seconds contin-

uously, for fluid temperature may rise excessively

high.

After performing stall test, be sure to leave engine run-

ning at idle for longer than 30 seconds before another

stall test.

Test result Possible cause

Lower than

standard levelLack of engine output

Defective torque converter

Higher than

standard level

in “D” rangeLow line pressure

Malfunctioning 1st & 2nd brake

Malfunctioning rear clutch

Malfunctioning stator one-way clutch

Higher than

standard level

in “R” rangeLow line pressure

Malfunctioning rear clutch

Malfunctioning reverse brake

Malfunctioning stator one-way clutch

Malfunctioning direct clutch

Page 65 of 447

AUTOMATIC TRANSMISSION (4 A/T) 7B-23

ENGINE BRAKE TEST

1) While driving vehicle in 3rd gear of “D” range, shift select lever down to “2” range and check if engine brake

operates.

2) In the same way as in Step 1), check engine brake for operation when select lever is shifted down to “L”

range.

3) Engine brake should operate in above test.

“P” RANGE TEST

1) Stop vehicle on a slope, shift select lever to “P” range and at the same time apply parking brake.

2) After stopping engine, depress brake pedal and release parking brake.

3) Then, release brake pedal gradually and check that vehicle remains stationary.

4) Depress brake pedal and shift select lever to “N” range.

5) Then, release brake pedal gradually and check that vehicle moves.WARNING:

Before test, make sure that there is no vehicle behind so as to pre-

vent rear-end collision.

Test result Possible cause

Fails to operate when shifted down to “2”

rangeDefective shift switch

1st & 2nd brake defective

Direct clutch defective

Fails to operate when shifted down to “L”

range

WARNING:

Before test, check to make sure no one is around vehicle or

down on a slope and keep watchful for safety during test.

Test result Possible cause

Vehicle moves at “P” range or

remains stationary at “N” rangeDefective parking lock pawl or

spring

Page 70 of 447

7B-28 AUTOMATIC TRANSMISSION (4 A/T)

DTC TABLE

DTC NO.

“O/D OFF” Lamp

Flashing Pattern of DTC

(Not using scan tool)DETECTING ITEMSMIL

Using

scan toolNot using

scan toolVehicle

equipped

with

immobi-

lizer indi-

cator lampVehicle

equipped

without

immobi-

lizer indi-

cator lamp

–12 Normal––

P0715 14Input/Turbine speed sensor circuit

malfunction1 driving

cycleNot

applicable

P0730 18 Incorrect gear ratio2 driving

cyclesNot

applicable

P075321

Shift solenoid-A (No.1) electrical1 driving

cycleNot

applicable

22

P075823

Shift solenoid-B (No.2) electrical1 driving

cycleNot

applicable

24

P0763 43 Shift solenoid-C (No.3) electrical1 driving

cycleNot

applicable

P0768 45 Shift solenoid-D (No.4) electrical1 driving

cycleNot

applicable

P0773 48 Shift solenoid-E (No.5) electrical1 driving

cycleNot

applicable

P074325

Torque converter clutch (lock-up)

system electrical1 driving

cycleNot

applicable

26