Pistons SUZUKI SWIFT 2005 2.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 339 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-54

Main Bearings, Crankshaft and Cylinder Block

Removal and Installation

S7RS0B1406036

Removal1) Remove engine assembly from vehicle referring to “Engine Assembly Removal and Installation”.

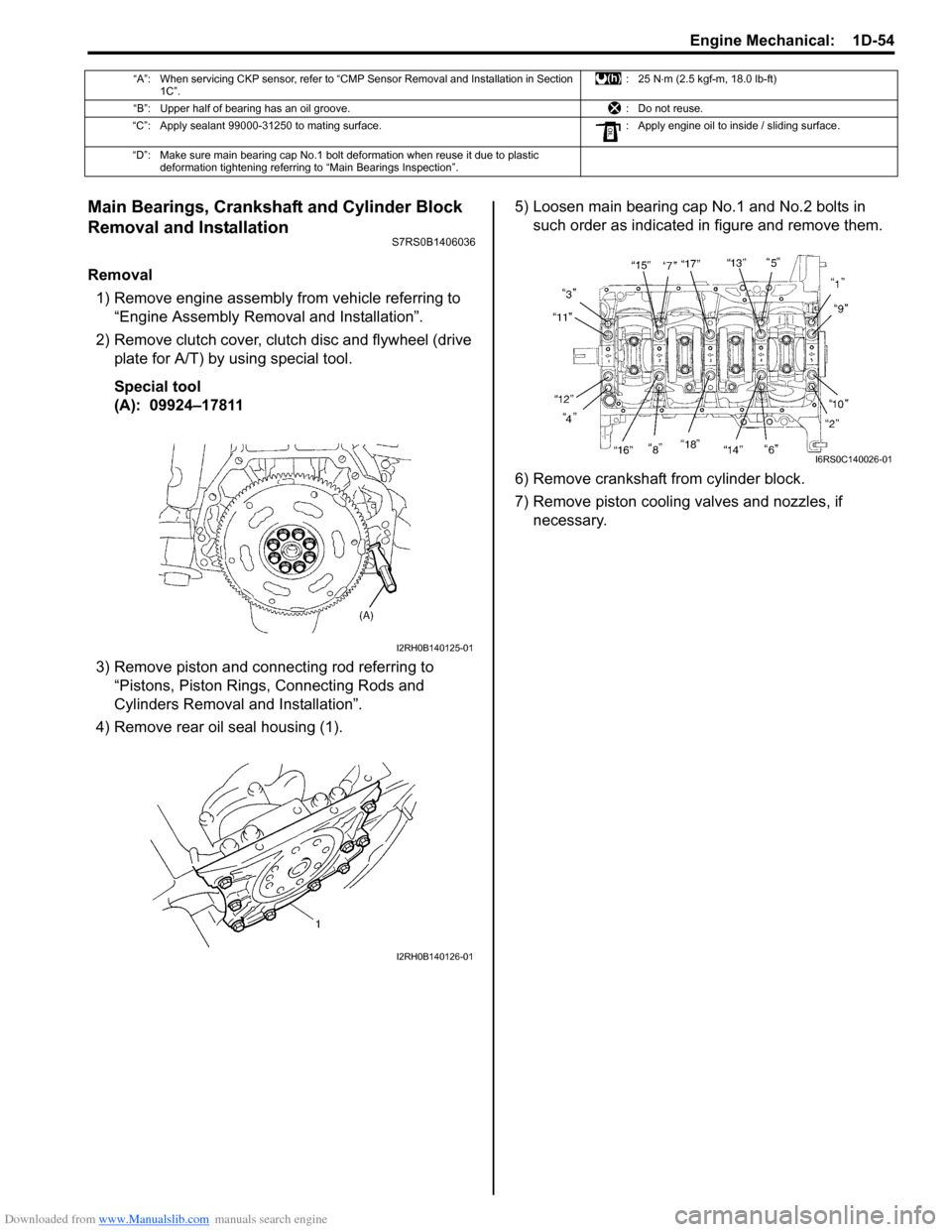

2) Remove clutch cover, clut ch disc and flywheel (drive

plate for A/T) by using special tool.

Special tool

(A): 09924–17811

3) Remove piston and connecting rod referring to “Pistons, Piston Rings, Connecting Rods and

Cylinders Removal and Installation”.

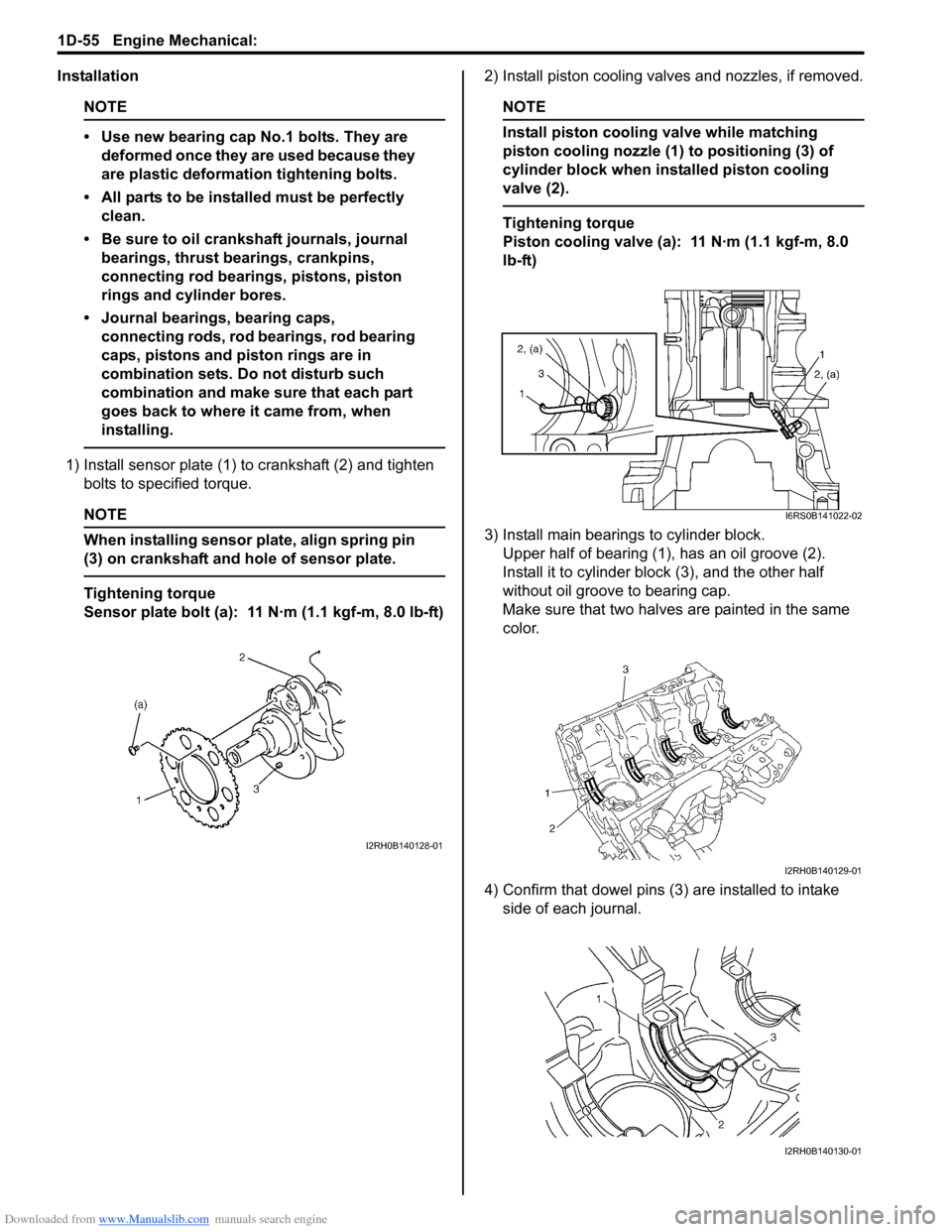

4) Remove rear oil seal housing (1). 5) Loosen main bearing cap No.1 and No.2 bolts in

such order as indicated in figure and remove them.

6) Remove crankshaft from cylinder block.

7) Remove piston cooling valves and nozzles, if necessary.

“A”: When servicing CKP sensor, refer to “CMP Sensor Removal and Installation in Section 1C”. :25 N

⋅m (2.5 kgf-m, 18.0 lb-ft)

“B”: Upper half of bearing has an oil groove. : Do not reuse.

“C”: Apply sealant 99000-31250 to mating surface. : Apply engine oil to inside / sliding surface.

“D”: Make sure main bearing cap No.1 bolt deformation when reuse it due to plastic deformation tightening referring to “Main Bearings Inspection”.

I2RH0B140125-01

I2RH0B140126-01

I6RS0C140026-01

Page 340 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-55 Engine Mechanical:

Installation

NOTE

• Use new bearing cap No.1 bolts. They are deformed once they are used because they

are plastic deformation tightening bolts.

• All parts to be insta lled must be perfectly

clean.

• Be sure to oil crankshaft journals, journal bearings, thrust bearings, crankpins,

connecting rod bearings, pistons, piston

rings and cylinder bores.

• Journal bearings, bearing caps, connecting rods, rod bearings, rod bearing

caps, pistons and piston rings are in

combination sets. Do not disturb such

combination and make sure that each part

goes back to where it came from, when

installing.

1) Install sensor plate (1) to crankshaft (2) and tighten bolts to spec ified torque.

NOTE

When installing sensor plate, align spring pin

(3) on crankshaft and hole of sensor plate.

Tightening torque

Sensor plate bolt (a): 11 N·m (1.1 kgf-m, 8.0 lb-ft) 2) Install piston cooling valves and nozzles, if removed.

NOTE

Install piston cooling valve while matching

piston cooling nozzle (1) to positioning (3) of

cylinder block when installed piston cooling

valve (2).

Tightening torque

Piston cooling valve (a): 11 N·m (1.1 kgf-m, 8.0

lb-ft)

3) Install main bearings to cylinder block. Upper half of bearing (1), has an oil groove (2).

Install it to cylinder block (3), and the other half

without oil groove to bearing cap.

Make sure that two halves are painted in the same

color.

4) Confirm that dowel pins (3 ) are installed to intake

side of each journal.

I2RH0B140128-01

I6RS0B141022-02

I2RH0B140129-01

I2RH0B140130-01

Page 342 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-57 Engine Mechanical:

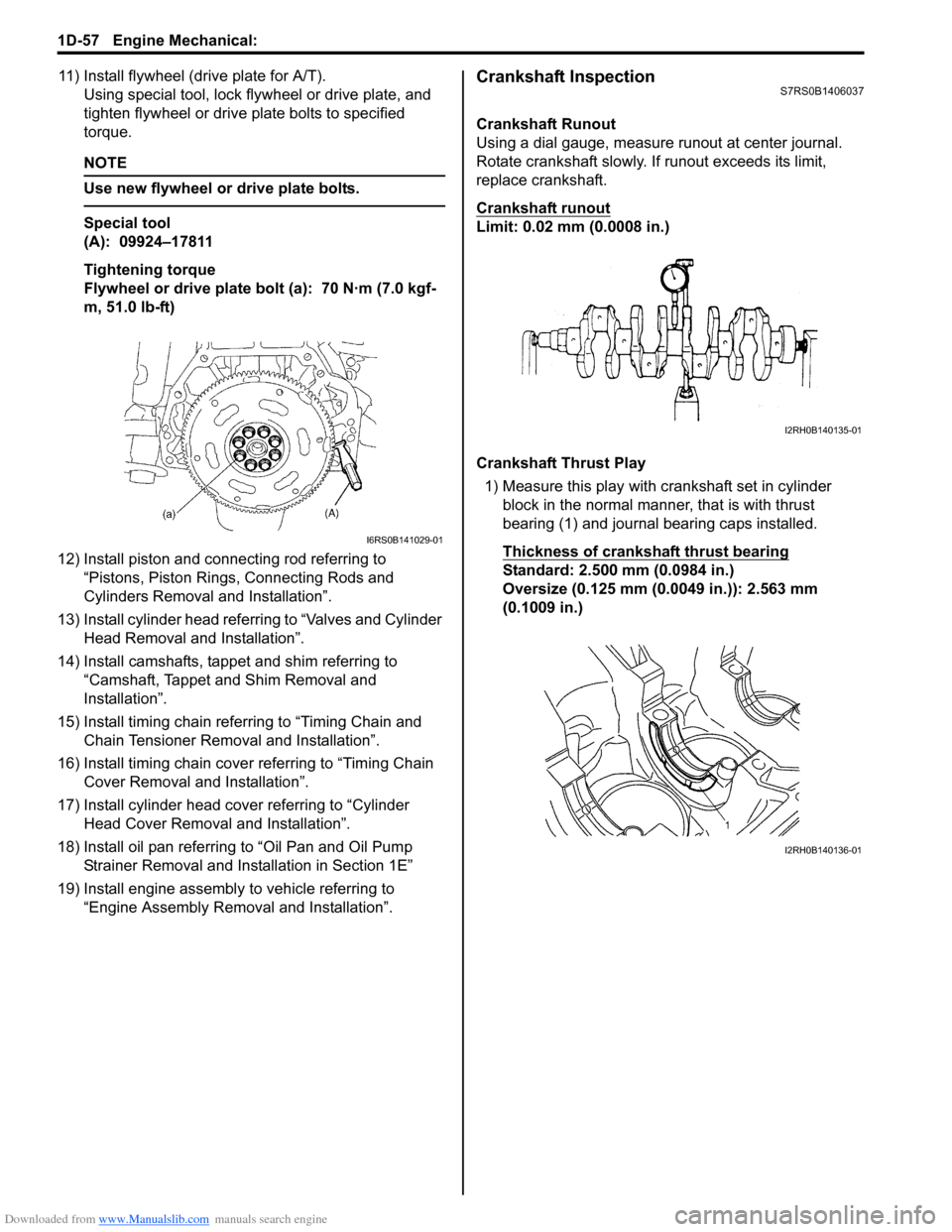

11) Install flywheel (drive plate for A/T).Using special tool, lock flyw heel or drive plate, and

tighten flywheel or drive plate bolts to specified

torque.

NOTE

Use new flywheel or drive plate bolts.

Special tool

(A): 09924–17811

Tightening torque

Flywheel or drive plate bolt (a): 70 N·m (7.0 kgf-

m, 51.0 lb-ft)

12) Install piston and connecting rod referring to “Pistons, Piston Rings, Connecting Rods and

Cylinders Removal and Installation”.

13) Install cylinder head referring to “Valves and Cylinder Head Removal and Installation”.

14) Install camshafts, tappet and shim referring to “Camshaft, Tappet and Shim Removal and

Installation”.

15) Install timing chain referring to “Timing Chain and Chain Tensioner Removal and Installation”.

16) Install timing chain cover referring to “Timing Chain Cover Removal and Installation”.

17) Install cylinder head cover referring to “Cylinder Head Cover Removal and Installation”.

18) Install oil pan referring to “Oil Pan and Oil Pump

Strainer Removal and Installation in Section 1E”

19) Install engine assembly to vehicle referring to “Engine Assembly Removal and Installation”.

Crankshaft InspectionS7RS0B1406037

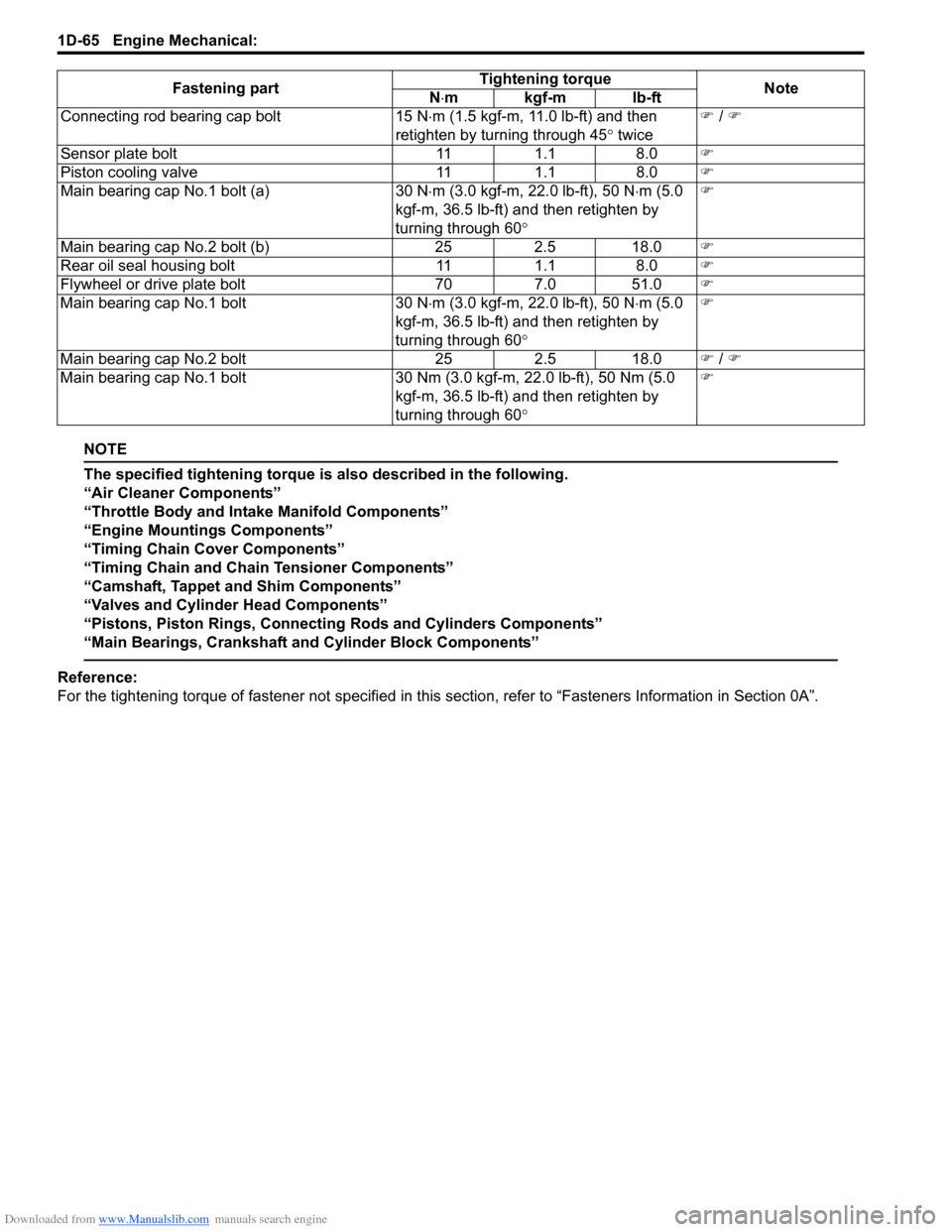

Crankshaft Runout

Using a dial gauge, measure runout at center journal.

Rotate crankshaft slowly. If runout exceeds its limit,

replace crankshaft.

Crankshaft runout

Limit: 0.02 mm (0.0008 in.)

Crankshaft Thrust Play

1) Measure this play with crankshaft set in cylinder block in the normal manner, that is with thrust

bearing (1) and journal bearing caps installed.

Thickness of crankshaft thrust bearing

Standard: 2.500 mm (0.0984 in.)

Oversize (0.125 mm (0.0049 in.)): 2.563 mm

(0.1009 in.)

I6RS0B141029-01

I2RH0B140135-01

I2RH0B140136-01

Page 350 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-65 Engine Mechanical:

NOTE

The specified tightening torque is also described in the following.

“Air Cleaner Components”

“Throttle Body and Intake Manifold Components”

“Engine Mountings Components”

“Timing Chain Cover Components”

“Timing Chain and Chain Tensioner Components”

“Camshaft, Tappet and Shim Components”

“Valves and Cylinder Head Components”

“Pistons, Piston Rings, Connecting Rods and Cylinders Components”

“Main Bearings, Crankshaft and Cylinder Block Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Connecting rod bearing cap bolt

15 N⋅m (1.5 kgf-m, 11.0 lb-ft) and then

retighten by turning through 45 ° twice �)

/ �)

Sensor plate bolt 111.1 8.0 �)

Piston cooling valve 111.1 8.0 �)

Main bearing cap No.1 bolt (a) 30 N⋅m (3.0 kgf-m, 22.0 lb-ft), 50 N ⋅m (5.0

kgf-m, 36.5 lb-ft) and then retighten by

turning through 60 ° �)

Main bearing cap No.2 bolt (b) 252.5 18.0 �)

Rear oil seal housing bolt 111.1 8.0 �)

Flywheel or drive plate bolt 707.0 51.0 �)

Main bearing cap No.1 bolt 30 N⋅m (3.0 kgf-m, 22.0 lb-ft), 50 N ⋅m (5.0

kgf-m, 36.5 lb-ft) and then retighten by

turning through 60 ° �)

Main bearing cap No.2 bolt 252.5 18.0 �) / �)

Main bearing cap No.1 bolt 30 Nm (3.0 kgf-m, 22.0 lb-ft), 50 Nm (5.0

kgf-m, 36.5 lb-ft) and then retighten by

turning through 60 ° �)

Fastening part

Tightening torque

Note

N ⋅mkgf-mlb-ft

Page 351 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-66

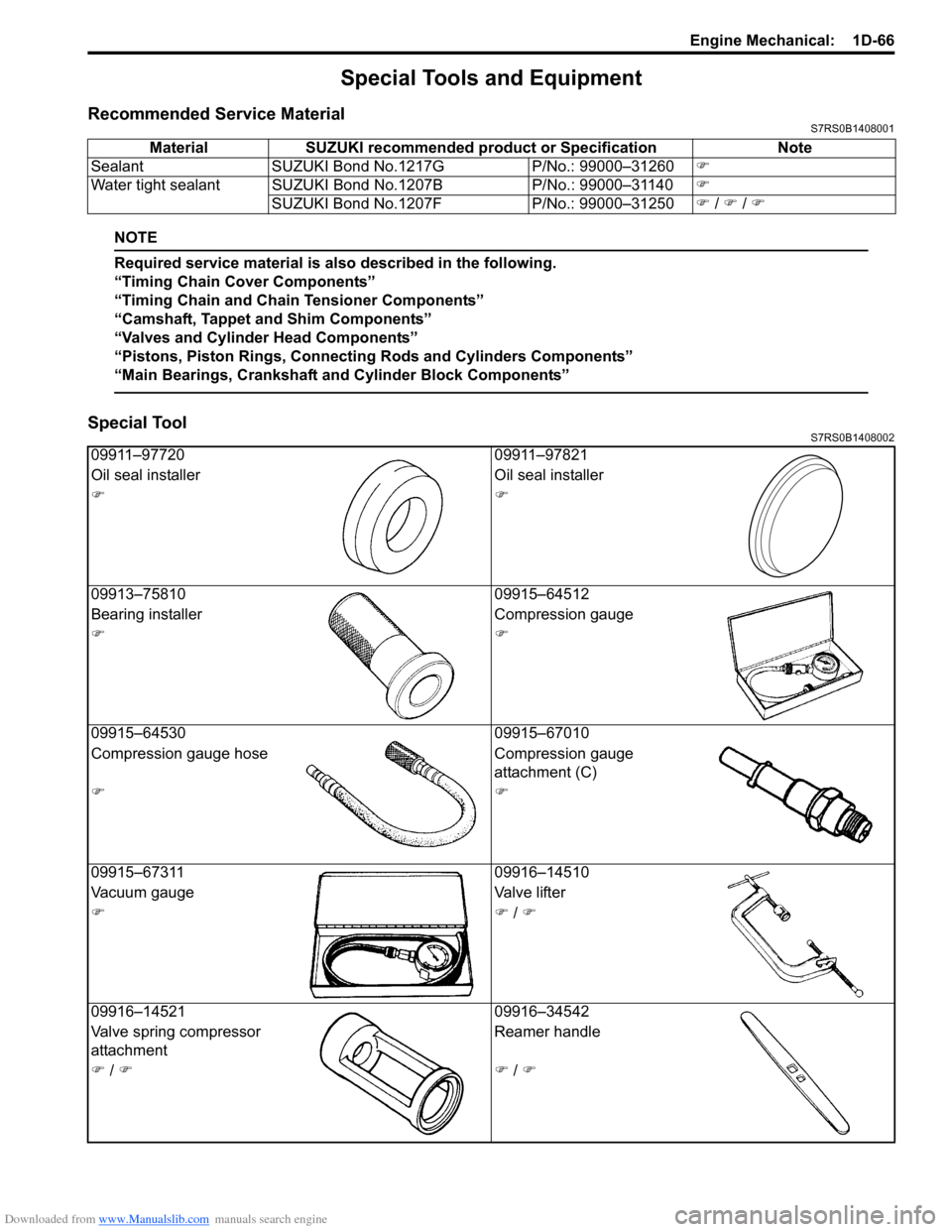

Special Tools and Equipment

Recommended Service MaterialS7RS0B1408001

NOTE

Required service material is also described in the following.

“Timing Chain Cover Components”

“Timing Chain and Chain Tensioner Components”

“Camshaft, Tappet and Shim Components”

“Valves and Cylinder Head Components”

“Pistons, Piston Rings, Connecting Rods and Cylinders Components”

“Main Bearings, Crankshaft and Cylinder Block Components”

Special ToolS7RS0B1408002

Material SUZUKI recommended product or Specification Note

Sealant SUZUKI Bond No.1217G P/No.: 99000–31260�)

Water tight sealant SUZUKI Bond No.1207B P/No.: 99000–31140�)

SUZUKI Bond No.1207F P/No.: 99000–31250�) / �) / �)

09911–97720 09911–97821

Oil seal installer Oil seal installer

�)�)

09913–75810 09915–64512

Bearing installer Compression gauge

�)�)

09915–64530 09915–67010

Compression gauge hose Compression gauge

attachment (C)

�)�)

09915–67311 09916–14510

Vacuum gauge Valve lifter

�)�) / �)

09916–14521 09916–34542

Valve spring compressor

attachment Reamer handle

�) / �)�) / �)

Page 499 of 1496

Downloaded from www.Manualslib.com manuals search engine Brake Control System and Diagnosis: 4A-1

Brakes

Brake Control System and Diagnosis

Precautions

Precautions on BrakeS7RS0B4100001

Air Bag Warning

Refer to “Air Bag System Service Warning in Section 00”.

Brakes Diagnosis Note

Refer to “Brakes Diagnosis Note”.

General Description

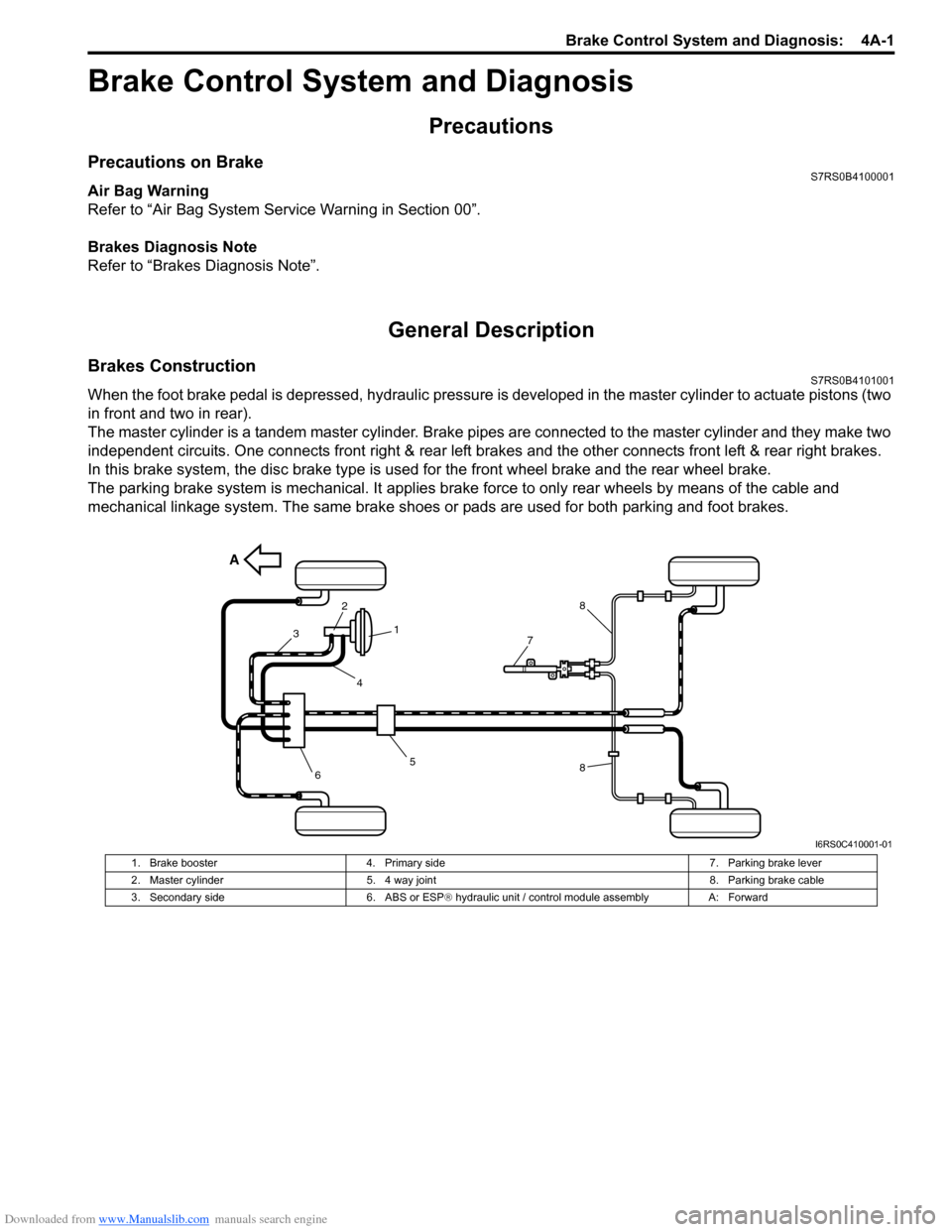

Brakes ConstructionS7RS0B4101001

When the foot brake pedal is depressed, hydraulic pressure is developed in the master cylinder to actuate pistons (two

in front and two in rear).

The master cylinder is a tandem master cylinder. Brake pipes are connected to the master cylinder and they make two

independent circuits. One connects front right & rear left brakes and the other connects front left & rear right brakes.

In this brake system, the disc brake type is used for the front wheel brake and the rear wheel brake.

The parking brake system is mechanical. It applies brake force to only rear wheels by means of the cable and

mechanical linkage system. The same brake shoes or pads are used for both parking and foot brakes.

A

5

3

2

1

4

8

8

6

7

I6RS0C410001-01

1. Brake booster 4. Primary side 7. Parking brake lever

2. Master cylinder 5. 4 way joint 8. Parking brake cable

3. Secondary side 6. ABS or ESP® hydraulic unit / control module assembly A: Forward

Page 503 of 1496

Downloaded from www.Manualslib.com manuals search engine Brake Control System and Diagnosis: 4A-5

If deterioration of rubber is evident, disassemble all

hydraulic parts and wash with alcohol. Dry these parts

with compressed air before assembly to keep alcohol out

of the system. Replace all rubber parts in the system,

including hoses. Also, when working on the brake

mechanisms, check for fluid on the linings.

If excessive fluid is found, replace the pads. If master cylinder piston seals

are satisfactory, check for

leakage or excessive heat co nditions. If leakage is not

found, drain fluid, flush with brake fluid, refill and bleed

system.

The system must be flushed if there is any doubt as to

the grade of fluid in the system or if fluid has been used

which contained parts that have been subjected to

contaminated fluid.

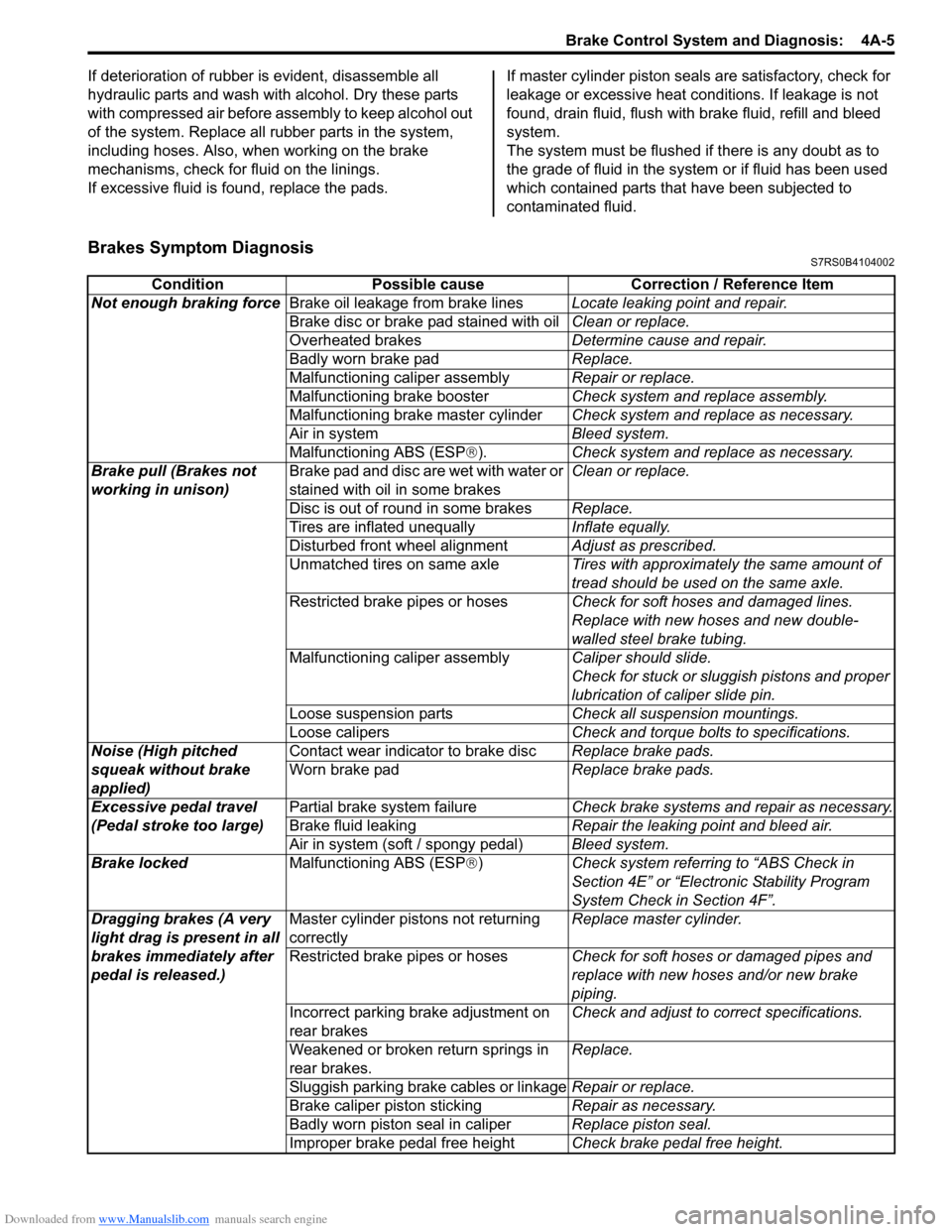

Brakes Symptom DiagnosisS7RS0B4104002

Condition Possible cause Correction / Reference Item

Not enough braking force Brake oil leakage from brake lines Locate leaking point and repair.

Brake disc or brake pad stained with oil Clean or replace.

Overheated brakes Determine cause and repair.

Badly worn brake pad Replace.

Malfunctioning caliper assembly Repair or replace.

Malfunctioning brake booster Check system and replace assembly.

Malfunctioning brake master cylinder Check system and replace as necessary.

Air in system Bleed system.

Malfunctioning ABS (ESP ®). Check system and replace as necessary.

Brake pull (Brakes not

working in unison) Brake pad and disc are wet with water or

stained with oil in some brakes Clean or replace.

Disc is out of round in some brakes Replace.

Tires are inflated unequally Inflate equally.

Disturbed front wheel alignment Adjust as prescribed.

Unmatched tires on same axle Tires with approximately the same amount of

tread should be used on the same axle.

Restricted brake pipes or hoses Check for soft hoses and damaged lines.

Replace with new hoses and new double-

walled steel brake tubing.

Malfunctioning caliper assembly Caliper should slide.

Check for stuck or sluggish pistons and proper

lubrication of caliper slide pin.

Loose suspension parts Check all suspension mountings.

Loose calipers Check and torque bolts to specifications.

Noise (High pitched

squeak without brake

applied) Contact wear indicator to brake disc

Replace brake pads.

Worn brake pad Replace brake pads.

Excessive pedal travel

(Pedal stroke too large) Partial brake system failure

Check brake systems and repair as necessary.

Brake fluid leaking Repair the leaking point and bleed air.

Air in system (soft / spongy pedal) Bleed system.

Brake locked Malfunctioning ABS (ESP®) Check system referri ng to “ABS Check in

Section 4E” or “Electronic Stability Program

System Check in Section 4F”.

Dragging brakes (A very

light drag is present in all

brakes immediately after

pedal is released.) Master cylinder pistons not returning

correctly

Replace master cylinder.

Restricted brake pipes or hoses Check for soft hoses or damaged pipes and

replace with new hoses and/or new brake

piping.

Incorrect parking brake adjustment on

rear brakes Check and adjust to correct specifications.

Weakened or broken return springs in

rear brakes. Replace.

Sluggish parking brake cables or linkage Repair or replace.

Brake caliper piston sticking Repair as necessary.

Badly worn piston seal in caliper Replace piston seal.

Improper brake pedal free height Check brake pedal free height.

Page 512 of 1496

Downloaded from www.Manualslib.com manuals search engine 4A-14 Brake Control System and Diagnosis:

6) Fill reservoir with specified fluid.

7) After completing the work, bleed air from brake and clutch system referring to “Air Bleeding of Brake

System” and “Air Bleeding of Clutch System in

Section 5C” (M/T model).

8) Install cowl top panel referring to “Cowl Top Components in Section 9K”.

9) Install windshield wiper referring to “Windshield

Wiper Removal and Insta llation in Section 9D”.

10) Perform brake test and check each installed part for fluid leakage.

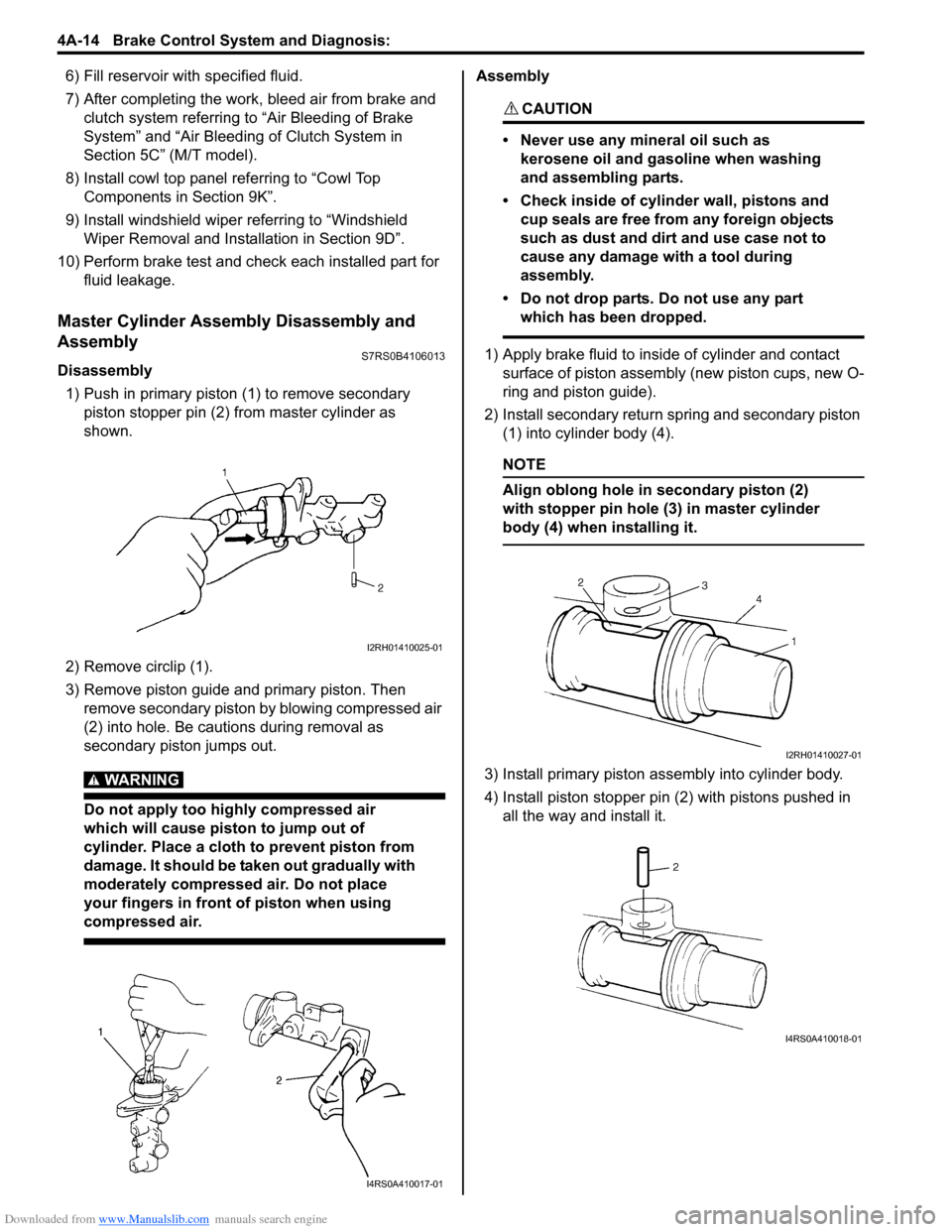

Master Cylinder Assembly Disassembly and

Assembly

S7RS0B4106013

Disassembly

1) Push in primary piston (1) to remove secondary

piston stopper pin (2) from master cylinder as

shown.

2) Remove circlip (1).

3) Remove piston guide and primary piston. Then remove secondary piston by blowing compressed air

(2) into hole. Be cautions during removal as

secondary piston jumps out.

WARNING!

Do not apply too highly compressed air

which will cause piston to jump out of

cylinder. Place a cloth to prevent piston from

damage. It should be taken out gradually with

moderately compressed air. Do not place

your fingers in front of piston when using

compressed air.

Assembly

CAUTION!

• Never use any mineral oil such as kerosene oil and gasoline when washing

and assembling parts.

• Check inside of cylinder wall, pistons and cup seals are free from any foreign objects

such as dust and dirt and use case not to

cause any damage with a tool during

assembly.

• Do not drop parts. Do not use any part which has been dropped.

1) Apply brake fluid to inside of cylinder and contact surface of piston assembly (new piston cups, new O-

ring and piston guide).

2) Install secondary return spring and secondary piston (1) into cylinder body (4).

NOTE

Align oblong hole in secondary piston (2)

with stopper pin hole (3) in master cylinder

body (4) when installing it.

3) Install primary piston assembly into cylinder body.

4) Install piston stopper pin (2) with pistons pushed in all the way and install it.

I2RH01410025-01

I4RS0A410017-01

I2RH01410027-01

I4RS0A410018-01

Page 756 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-112 Automatic Transmission/Transaxle:

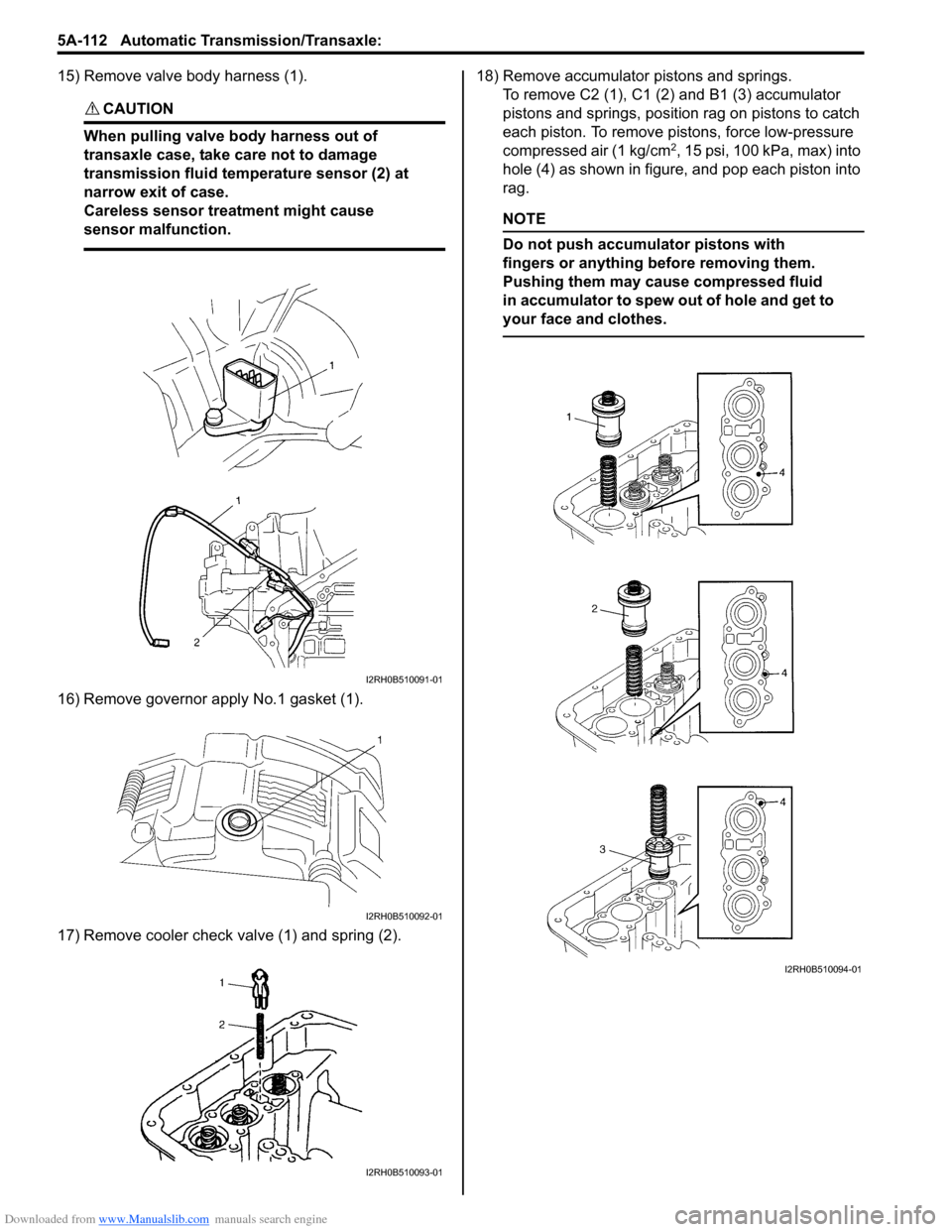

15) Remove valve body harness (1).

CAUTION!

When pulling valve body harness out of

transaxle case, take care not to damage

transmission fluid temperature sensor (2) at

narrow exit of case.

Careless sensor treatment might cause

sensor malfunction.

16) Remove governor apply No.1 gasket (1).

17) Remove cooler check valve (1) and spring (2).18) Remove accumulator pistons and springs.

To remove C2 (1), C1 (2) and B1 (3) accumulator

pistons and springs, position rag on pistons to catch

each piston. To remove pistons, force low-pressure

compressed air (1 kg/cm

2, 15 psi, 100 kPa, max) into

hole (4) as shown in figure, and pop each piston into

rag.

NOTE

Do not push accumulator pistons with

fingers or anything before removing them.

Pushing them may cause compressed fluid

in accumulator to spew out of hole and get to

your face and clothes.

I2RH0B510091-01

I2RH0B510092-01

I2RH0B510093-01

I2RH0B510094-01

Page 806 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-162 Automatic Transmission/Transaxle:

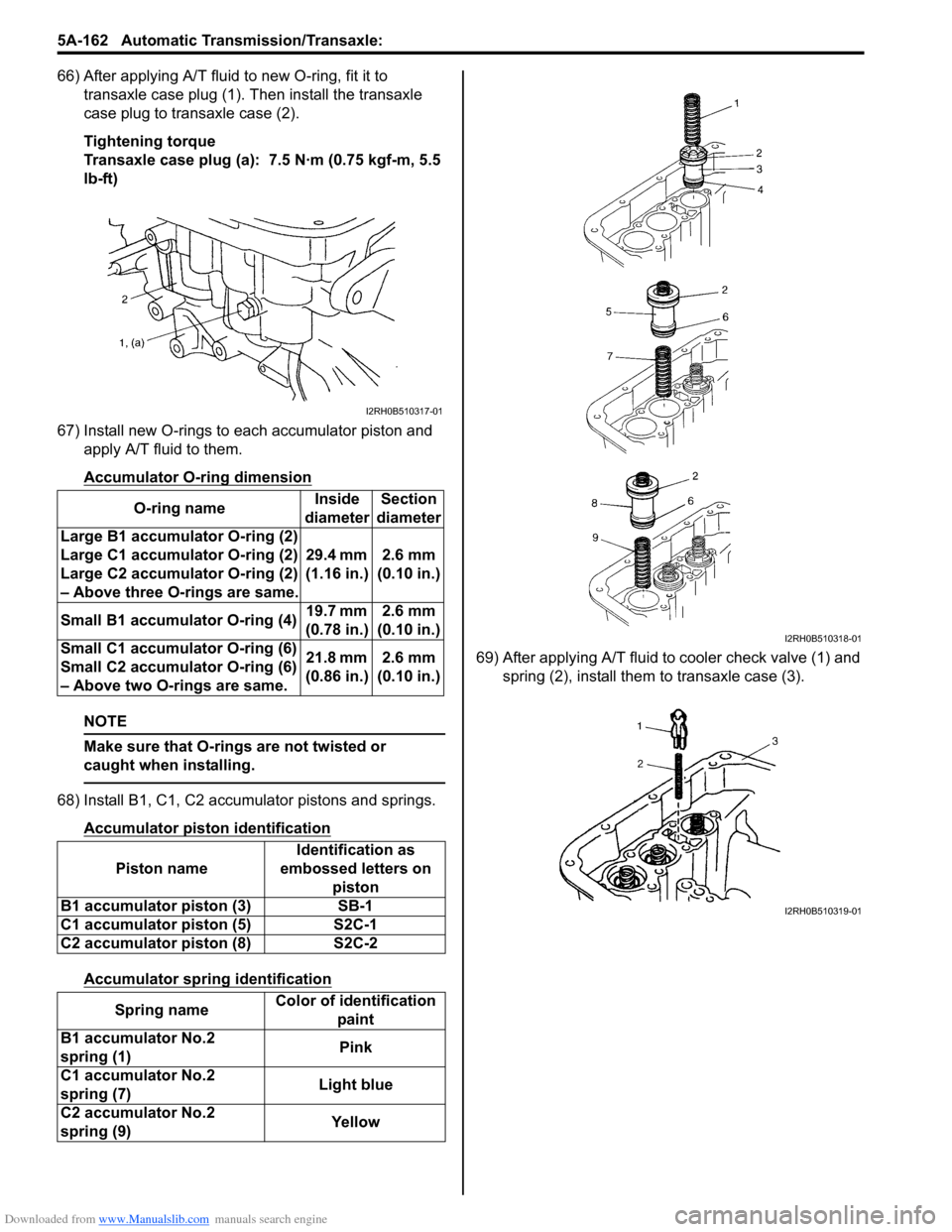

66) After applying A/T fluid to new O-ring, fit it to transaxle case plug (1). Then install the transaxle

case plug to transaxle case (2).

Tightening torque

Transaxle case plug (a): 7.5 N·m (0.75 kgf-m, 5.5

lb-ft)

67) Install new O-rings to each accumulator piston and apply A/T fluid to them.

Accumulator O-ri ng dimension

NOTE

Make sure that O-rings are not twisted or

caught when installing.

68) Install B1, C1, C2 accumulator pistons and springs.

Accumulator piston identification

Accumulator spring identification

69) After applying A/T fluid to cooler check valve (1) and

spring (2), install them to transaxle case (3).

O-ring name

Inside

diameter Section

diameter

Large B1 accumula tor O-ring (2)

Large C1 accumula tor O-ring (2)

Large C2 accumula tor O-ring (2)

– Above three O-rings are same. 29.4 mm

(1.16 in.) 2.6 mm

(0.10 in.)

Small B1 accumulator O-ring (4) 19.7 mm

(0.78 in.) 2.6 mm

(0.10 in.)

Small C1 accumulator O-ring (6)

Small C2 accumulator O-ring (6)

– Above two O-rings are same. 21.8 mm

(0.86 in.) 2.6 mm

(0.10 in.)

Piston name Identification as

embossed letters on piston

B1 accumulator piston (3) SB-1

C1 accumulator piston (5) S2C-1

C2 accumulator piston (8) S2C-2

Spring name Color of identification

paint

B1 accumulator No.2

spring (1) Pink

C1 accumulator No.2

spring (7) Light blue

C2 accumulator No.2

spring (9) Yellow

I2RH0B510317-01

I2RH0B510318-01

I2RH0B510319-01