connecting rod SUZUKI SWIFT 2005 2.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 335 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-50

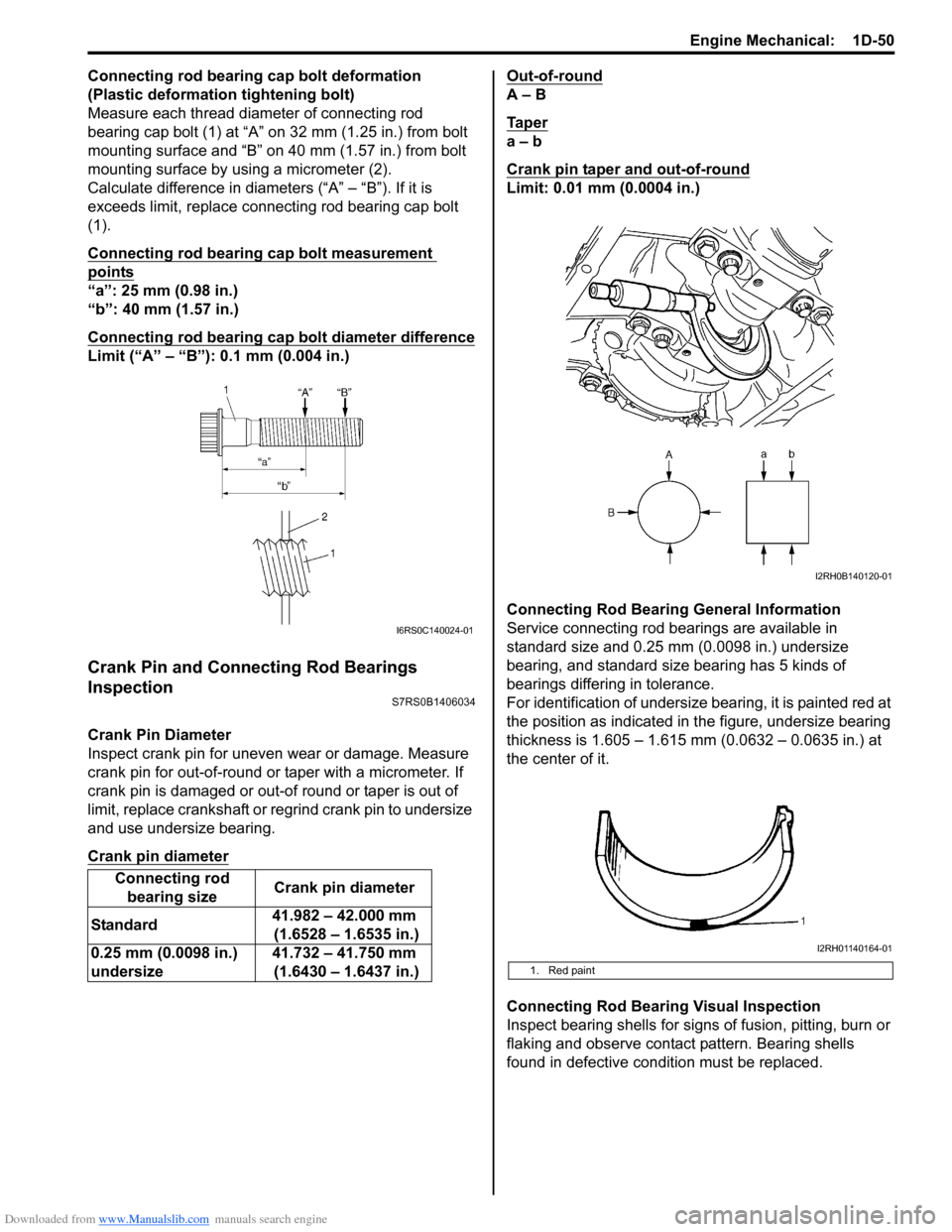

Connecting rod bearing cap bolt deformation

(Plastic deformation tightening bolt)

Measure each thread diameter of connecting rod

bearing cap bolt (1) at “A” on 32 mm (1.25 in.) from bolt

mounting surface and “B” on 40 mm (1.57 in.) from bolt

mounting surface by using a micrometer (2).

Calculate difference in diameters (“A” – “B”). If it is

exceeds limit, replace connecting rod bearing cap bolt

(1).

Connecting rod bearing cap bolt measurement

points

“a”: 25 mm (0.98 in.)

“b”: 40 mm (1.57 in.)

Connecting rod bearing cap bolt diameter difference

Limit (“A” – “B”): 0.1 mm (0.004 in.)

Crank Pin and Connecting Rod Bearings

Inspection

S7RS0B1406034

Crank Pin Diameter

Inspect crank pin for uneven wear or damage. Measure

crank pin for out-of-round or taper with a micrometer. If

crank pin is damaged or out-of round or taper is out of

limit, replace crankshaft or regrind crank pin to undersize

and use undersize bearing.

Crank pin diameter

Out-of-round

A – B

Ta p e r

a – b

Crank pin taper and out-of-round

Limit: 0.01 mm (0.0004 in.)

Connecting Rod Bearing General Information

Service connecting rod be arings are available in

standard size and 0.25 mm (0.0098 in.) undersize

bearing, and standard size bearing has 5 kinds of

bearings differing in tolerance.

For identification of undersize bearing, it is painted red at

the position as indicated in the figure, undersize bearing

thickness is 1.605 – 1.615 mm (0.0632 – 0.0635 in.) at

the center of it.

Connecting Rod Bearing Visual Inspection

Inspect bearing shells for signs of fusion, pitting, burn or

flaking and observe contact pattern. Bearing shells

found in defective condition must be replaced.

Connecting rod

bearing size Crank pin diameter

Standard 41.982 – 42.000 mm

(1.6528 – 1.6535 in.)

0.25 mm (0.0098 in.)

undersize 41.732 – 41.750 mm

(1.6430 – 1.6437 in.)

I6RS0C140024-01

1. Red paint

I2RH0B140120-01

I2RH01140164-01

Page 336 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-51 Engine Mechanical:

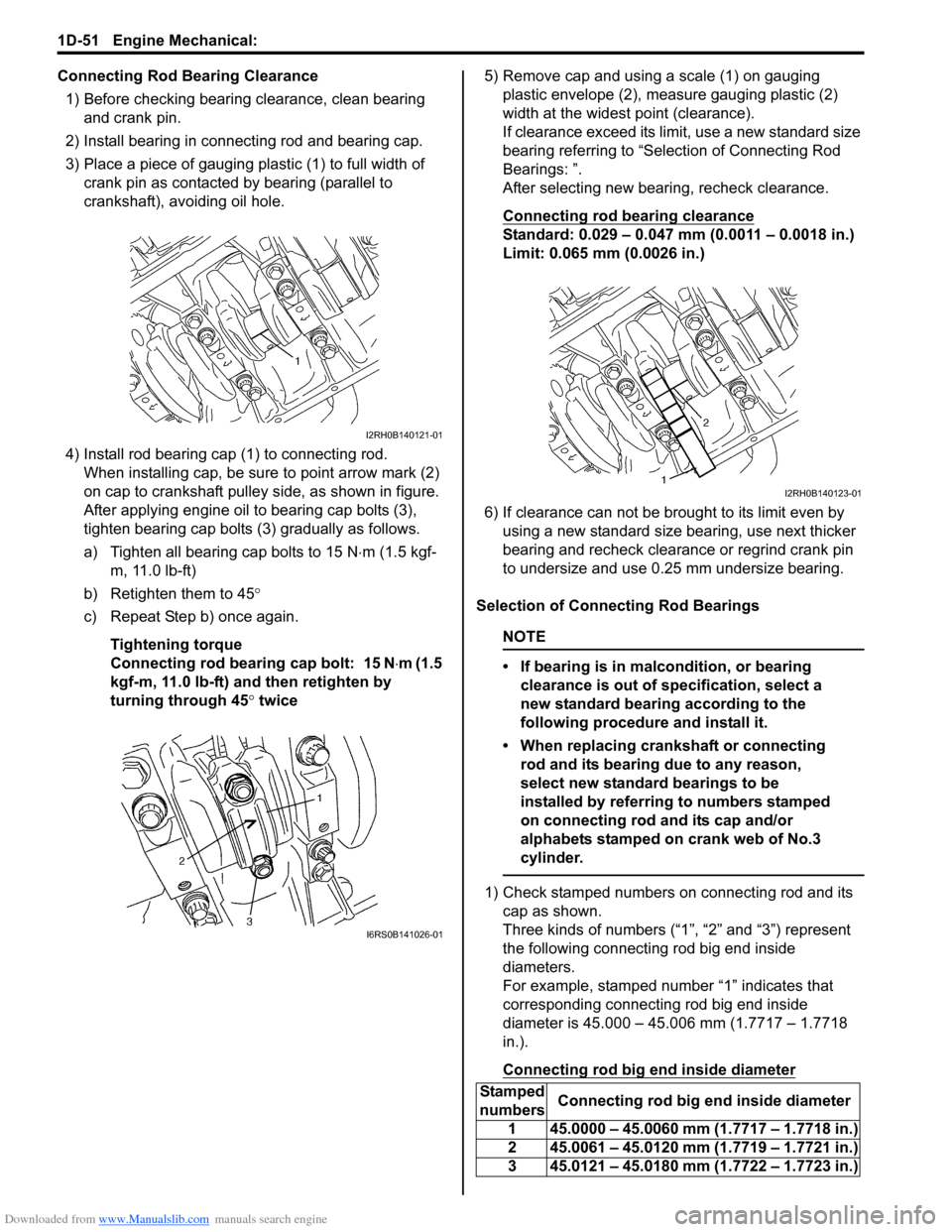

Connecting Rod Bearing Clearance1) Before checking bearing clearance, clean bearing and crank pin.

2) Install bearing in connecting rod and bearing cap.

3) Place a piece of gauging plastic (1) to full width of crank pin as contacted by bearing (parallel to

crankshaft), avoiding oil hole.

4) Install rod bearing cap (1) to connecting rod. When installing cap, be sure to point arrow mark (2)

on cap to crankshaft pulley side, as shown in figure.

After applying engine oil to bearing cap bolts (3),

tighten bearing cap bolts (3) gradually as follows.

a) Tighten all bearing cap bolts to 15 N ⋅m (1.5 kgf-

m, 11.0 lb-ft)

b) Retighten them to 45°

c) Repeat Step b) once again.

Tightening torque

Connecting rod bearing cap bolt: 15 N ⋅m (1.5

kgf-m, 11.0 lb-ft) and then retighten by

turning through 45 ° twice 5) Remove cap and using a scale (1) on gauging

plastic envelope (2), measure gauging plastic (2)

width at the widest point (clearance).

If clearance exceed its limit, use a new standard size

bearing referring to “Selection of Connecting Rod

Bearings: ”.

After selecting new bearing, recheck clearance.

Connecting rod bearing clearance

Standard: 0.029 – 0.047 mm (0.0011 – 0.0018 in.)

Limit: 0.065 mm (0.0026 in.)

6) If clearance can not be brought to its limit even by using a new standard size bearing, use next thicker

bearing and recheck clearance or regrind crank pin

to undersize and use 0.25 mm undersize bearing.

Selection of Connecting Rod Bearings

NOTE

• If bearing is in malcondition, or bearing clearance is out of specification, select a

new standard bearing according to the

following procedure and install it.

• When replacing crankshaft or connecting rod and its bearing due to any reason,

select new standard bearings to be

installed by referring to numbers stamped

on connecting rod and its cap and/or

alphabets stamped on crank web of No.3

cylinder.

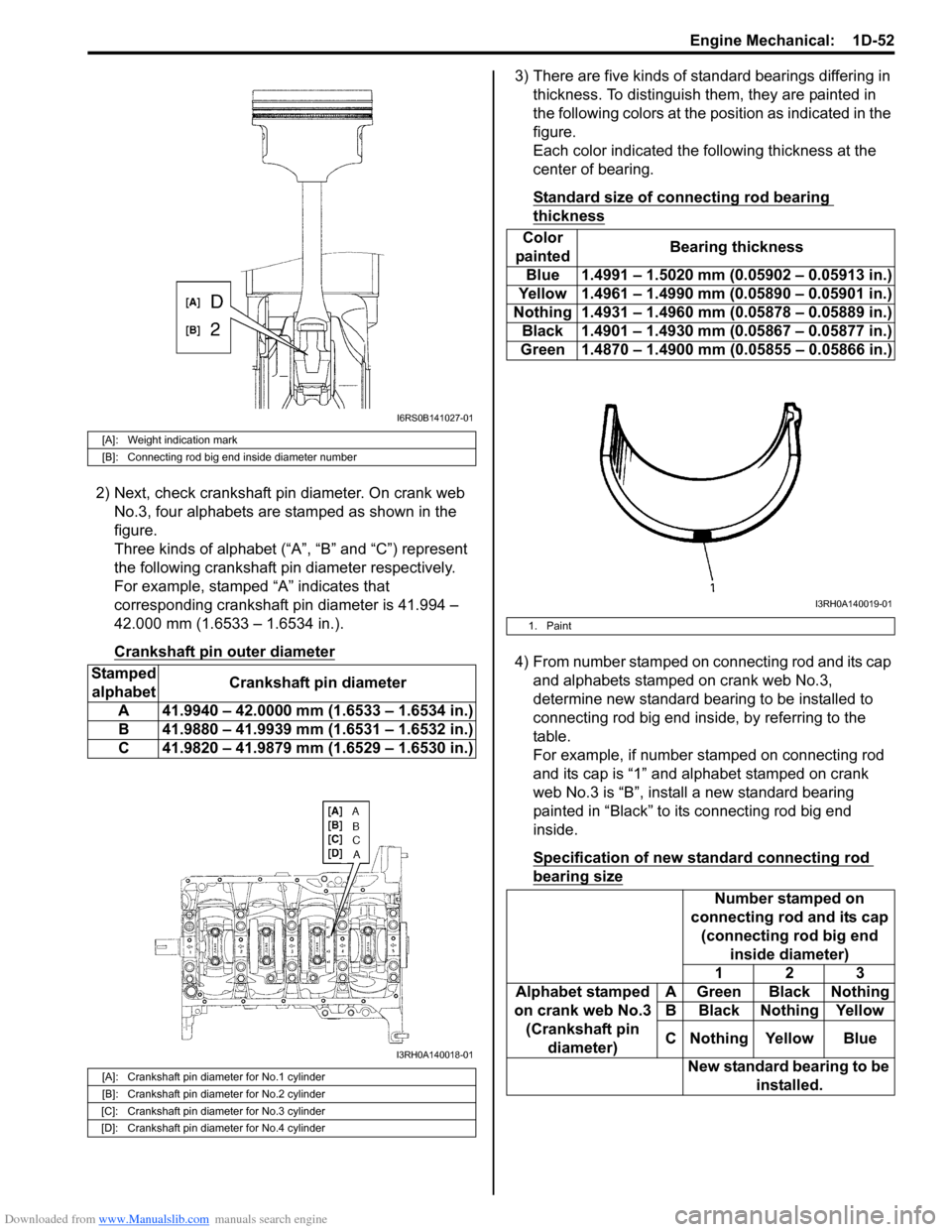

1) Check stamped numbers on connecting rod and its cap as shown.

Three kinds of numbers (“1”, “2” and “3”) represent

the following connecting rod big end inside

diameters.

For example, stamped number “1” indicates that

corresponding connecting rod big end inside

diameter is 45.000 – 45.006 mm (1.7717 – 1.7718

in.).

Connecting rod big end inside diameter

I2RH0B140121-01

I6RS0B141026-01

Stamped

numbers Connecting rod big end inside diameter

1 45.0000 – 45.0060 mm (1.7717 – 1.7718 in.)

2 45.0061 – 45.0120 mm (1.7719 – 1.7721 in.)

3 45.0121 – 45.0180 mm (1.7722 – 1.7723 in.)

I2RH0B140123-01

Page 337 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-52

2) Next, check crankshaft pin diameter. On crank web No.3, four alphabets are stamped as shown in the

figure.

Three kinds of alphabet (“A”, “B” and “C”) represent

the following crankshaft pin diameter respectively.

For example, stamped “A” indicates that

corresponding crankshaft pin diameter is 41.994 –

42.000 mm (1.6533 – 1.6534 in.).

Crankshaft pin outer diameter

3) There are five kinds of standard bearings differing in thickness. To distinguish them, they are painted in

the following colors at the position as indicated in the

figure.

Each color indicated the following thickness at the

center of bearing.

Standard size of connecting rod bearing

thickness

4) From number stamped on connecting rod and its cap and alphabets stamped on crank web No.3,

determine new standard bearing to be installed to

connecting rod big end inside, by referring to the

table.

For example, if number stamped on connecting rod

and its cap is “1” and alphabet stamped on crank

web No.3 is “B”, install a new standard bearing

painted in “Black” to its connecting rod big end

inside.

Specification of new standard connecting rod

bearing size

[A]: Weight indication mark

[B]: Connecting rod big end inside diameter number

Stamped alphabet Crankshaft pin diameter

A 41.9940 – 42.0000 mm (1.6533 – 1.6534 in.)

B 41.9880 – 41.9939 mm (1.6531 – 1.6532 in.)

C 41.9820 – 41.9879 mm (1.6529 – 1.6530 in.)

[A]: Crankshaft pin diameter for No.1 cylinder

[B]: Crankshaft pin diameter for No.2 cylinder

[C]: Crankshaft pin diameter for No.3 cylinder

[D]: Crankshaft pin diameter for No.4 cylinder

I6RS0B141027-01

I3RH0A140018-01

Color

painted Bearing thickness

Blue 1.4991 – 1.5020 mm (0.05902 – 0.05913 in.)

Yellow 1.4961 – 1.4990 mm (0.05890 – 0.05901 in.)

Nothing 1.4931 – 1.4960 mm (0.05878 – 0.05889 in.) Black 1.4901 – 1.4930 mm (0.05867 – 0.05877 in.)

Green 1.4870 – 1.4900 mm (0.05855 – 0.05866 in.)

1. Paint

Number stamped on

connecting rod and its cap (connecting rod big end inside diameter)

123

Alphabet stamped

on crank web No.3 (Crankshaft pin diameter) A Green Black Nothing

B Black Nothing Yellow

C Nothing Yellow Blue

New standard bearing to be installed.

I3RH0A140019-01

Page 339 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-54

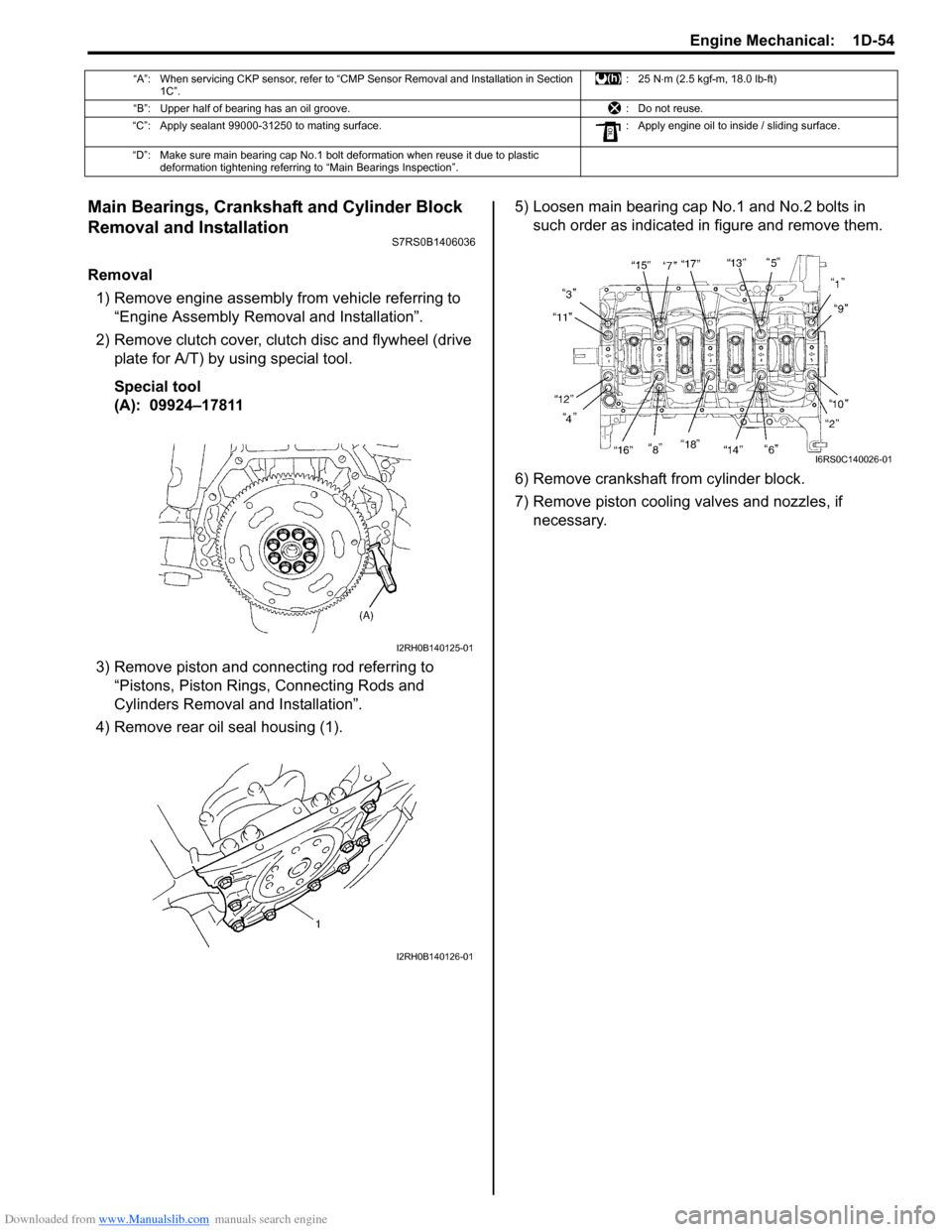

Main Bearings, Crankshaft and Cylinder Block

Removal and Installation

S7RS0B1406036

Removal1) Remove engine assembly from vehicle referring to “Engine Assembly Removal and Installation”.

2) Remove clutch cover, clut ch disc and flywheel (drive

plate for A/T) by using special tool.

Special tool

(A): 09924–17811

3) Remove piston and connecting rod referring to “Pistons, Piston Rings, Connecting Rods and

Cylinders Removal and Installation”.

4) Remove rear oil seal housing (1). 5) Loosen main bearing cap No.1 and No.2 bolts in

such order as indicated in figure and remove them.

6) Remove crankshaft from cylinder block.

7) Remove piston cooling valves and nozzles, if necessary.

“A”: When servicing CKP sensor, refer to “CMP Sensor Removal and Installation in Section 1C”. :25 N

⋅m (2.5 kgf-m, 18.0 lb-ft)

“B”: Upper half of bearing has an oil groove. : Do not reuse.

“C”: Apply sealant 99000-31250 to mating surface. : Apply engine oil to inside / sliding surface.

“D”: Make sure main bearing cap No.1 bolt deformation when reuse it due to plastic deformation tightening referring to “Main Bearings Inspection”.

I2RH0B140125-01

I2RH0B140126-01

I6RS0C140026-01

Page 340 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-55 Engine Mechanical:

Installation

NOTE

• Use new bearing cap No.1 bolts. They are deformed once they are used because they

are plastic deformation tightening bolts.

• All parts to be insta lled must be perfectly

clean.

• Be sure to oil crankshaft journals, journal bearings, thrust bearings, crankpins,

connecting rod bearings, pistons, piston

rings and cylinder bores.

• Journal bearings, bearing caps, connecting rods, rod bearings, rod bearing

caps, pistons and piston rings are in

combination sets. Do not disturb such

combination and make sure that each part

goes back to where it came from, when

installing.

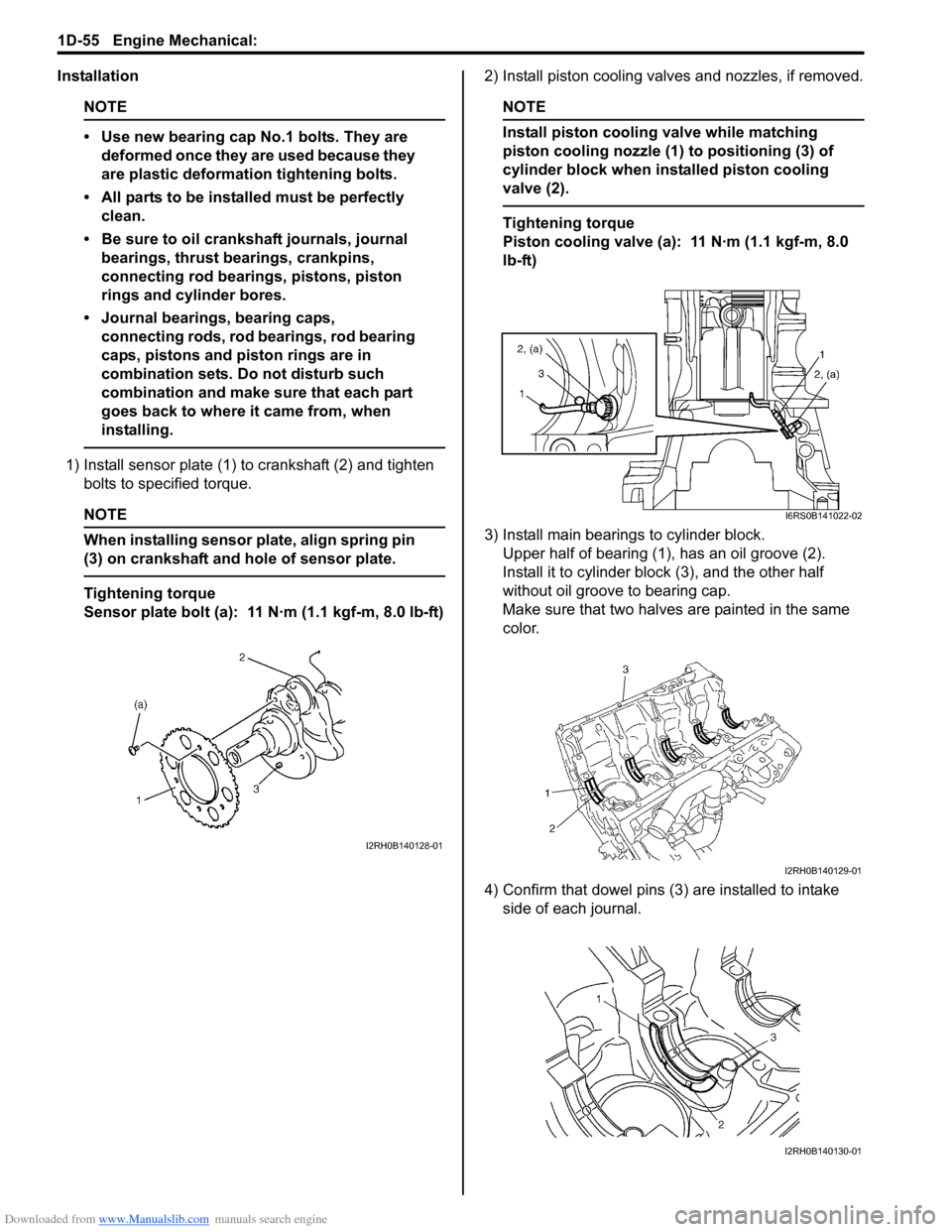

1) Install sensor plate (1) to crankshaft (2) and tighten bolts to spec ified torque.

NOTE

When installing sensor plate, align spring pin

(3) on crankshaft and hole of sensor plate.

Tightening torque

Sensor plate bolt (a): 11 N·m (1.1 kgf-m, 8.0 lb-ft) 2) Install piston cooling valves and nozzles, if removed.

NOTE

Install piston cooling valve while matching

piston cooling nozzle (1) to positioning (3) of

cylinder block when installed piston cooling

valve (2).

Tightening torque

Piston cooling valve (a): 11 N·m (1.1 kgf-m, 8.0

lb-ft)

3) Install main bearings to cylinder block. Upper half of bearing (1), has an oil groove (2).

Install it to cylinder block (3), and the other half

without oil groove to bearing cap.

Make sure that two halves are painted in the same

color.

4) Confirm that dowel pins (3 ) are installed to intake

side of each journal.

I2RH0B140128-01

I6RS0B141022-02

I2RH0B140129-01

I2RH0B140130-01

Page 342 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-57 Engine Mechanical:

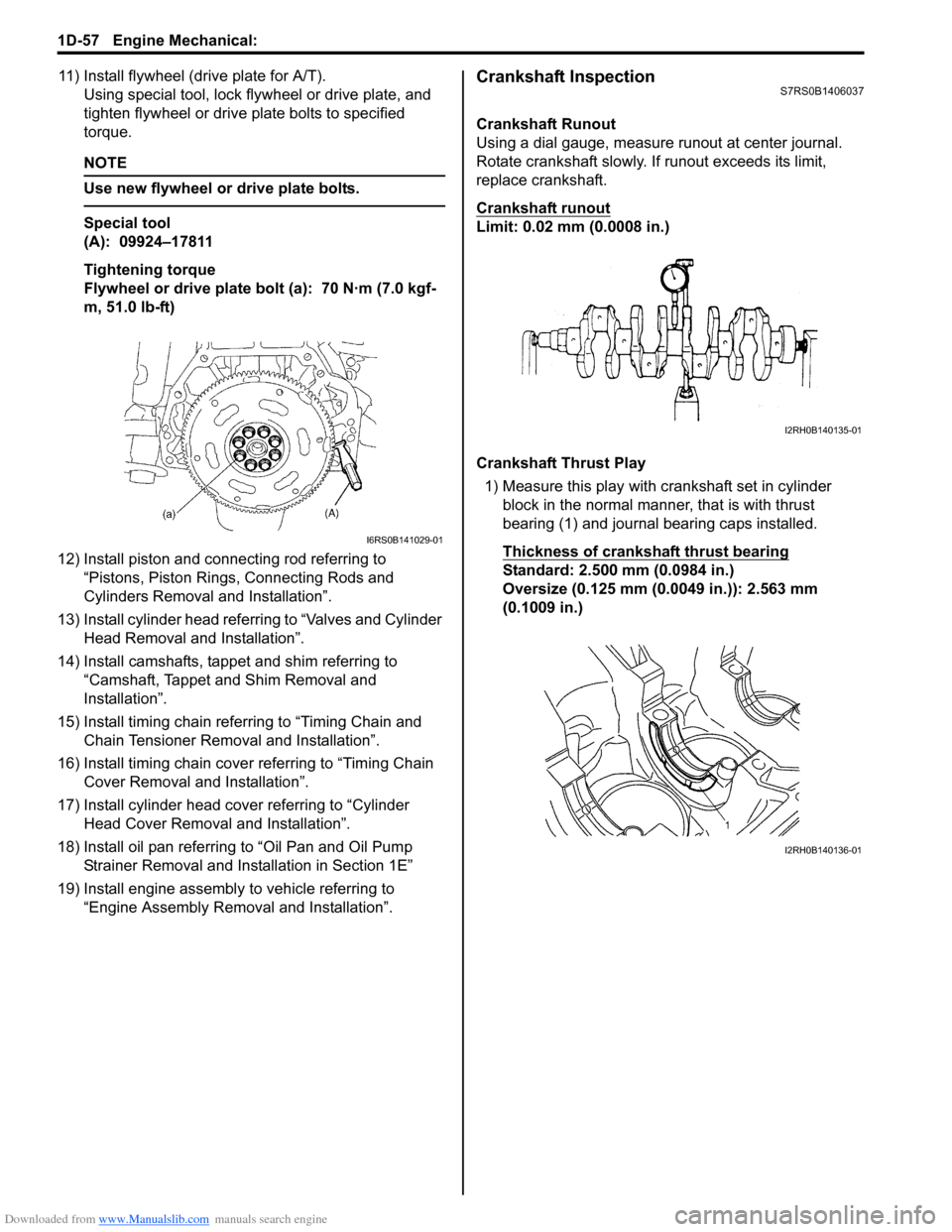

11) Install flywheel (drive plate for A/T).Using special tool, lock flyw heel or drive plate, and

tighten flywheel or drive plate bolts to specified

torque.

NOTE

Use new flywheel or drive plate bolts.

Special tool

(A): 09924–17811

Tightening torque

Flywheel or drive plate bolt (a): 70 N·m (7.0 kgf-

m, 51.0 lb-ft)

12) Install piston and connecting rod referring to “Pistons, Piston Rings, Connecting Rods and

Cylinders Removal and Installation”.

13) Install cylinder head referring to “Valves and Cylinder Head Removal and Installation”.

14) Install camshafts, tappet and shim referring to “Camshaft, Tappet and Shim Removal and

Installation”.

15) Install timing chain referring to “Timing Chain and Chain Tensioner Removal and Installation”.

16) Install timing chain cover referring to “Timing Chain Cover Removal and Installation”.

17) Install cylinder head cover referring to “Cylinder Head Cover Removal and Installation”.

18) Install oil pan referring to “Oil Pan and Oil Pump

Strainer Removal and Installation in Section 1E”

19) Install engine assembly to vehicle referring to “Engine Assembly Removal and Installation”.

Crankshaft InspectionS7RS0B1406037

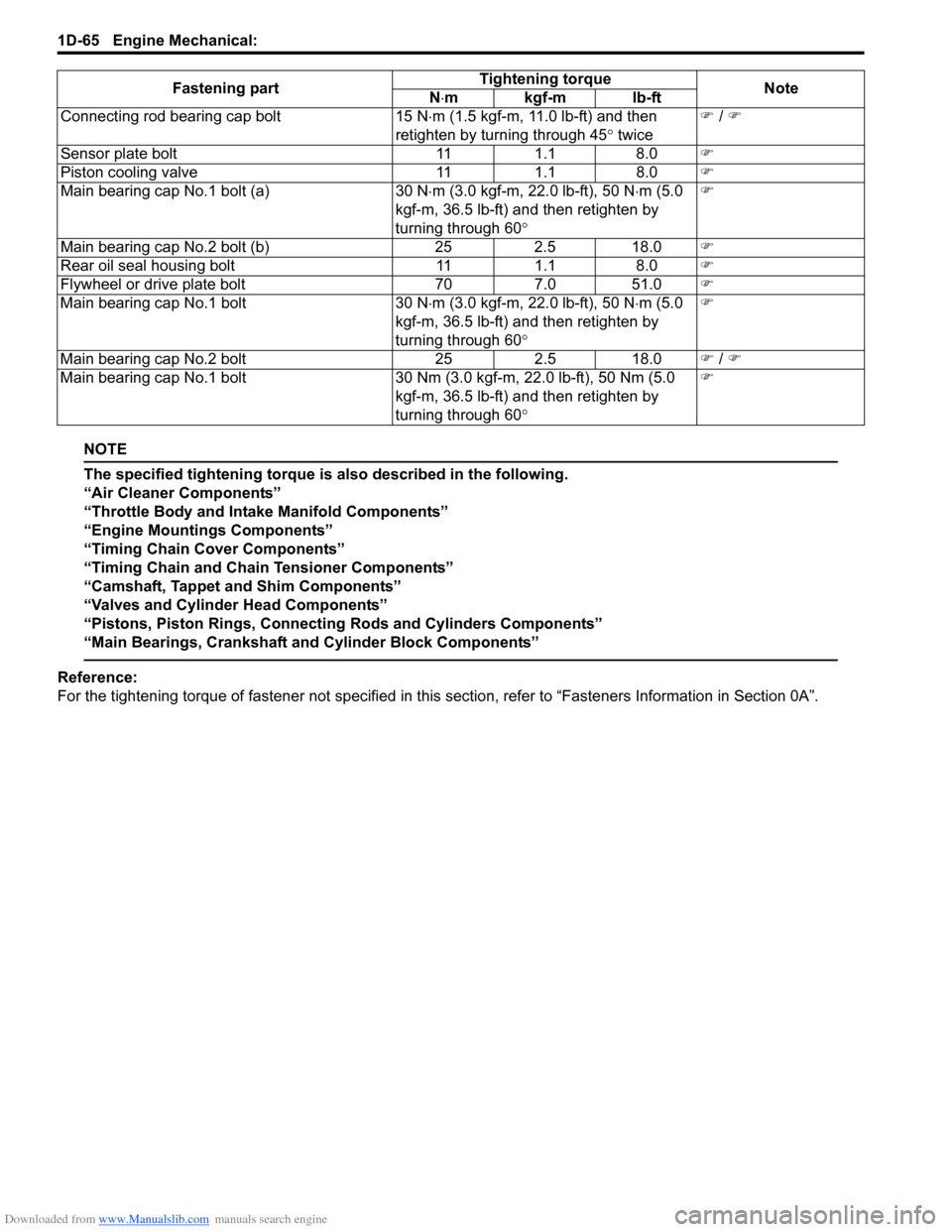

Crankshaft Runout

Using a dial gauge, measure runout at center journal.

Rotate crankshaft slowly. If runout exceeds its limit,

replace crankshaft.

Crankshaft runout

Limit: 0.02 mm (0.0008 in.)

Crankshaft Thrust Play

1) Measure this play with crankshaft set in cylinder block in the normal manner, that is with thrust

bearing (1) and journal bearing caps installed.

Thickness of crankshaft thrust bearing

Standard: 2.500 mm (0.0984 in.)

Oversize (0.125 mm (0.0049 in.)): 2.563 mm

(0.1009 in.)

I6RS0B141029-01

I2RH0B140135-01

I2RH0B140136-01

Page 350 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-65 Engine Mechanical:

NOTE

The specified tightening torque is also described in the following.

“Air Cleaner Components”

“Throttle Body and Intake Manifold Components”

“Engine Mountings Components”

“Timing Chain Cover Components”

“Timing Chain and Chain Tensioner Components”

“Camshaft, Tappet and Shim Components”

“Valves and Cylinder Head Components”

“Pistons, Piston Rings, Connecting Rods and Cylinders Components”

“Main Bearings, Crankshaft and Cylinder Block Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Connecting rod bearing cap bolt

15 N⋅m (1.5 kgf-m, 11.0 lb-ft) and then

retighten by turning through 45 ° twice �)

/ �)

Sensor plate bolt 111.1 8.0 �)

Piston cooling valve 111.1 8.0 �)

Main bearing cap No.1 bolt (a) 30 N⋅m (3.0 kgf-m, 22.0 lb-ft), 50 N ⋅m (5.0

kgf-m, 36.5 lb-ft) and then retighten by

turning through 60 ° �)

Main bearing cap No.2 bolt (b) 252.5 18.0 �)

Rear oil seal housing bolt 111.1 8.0 �)

Flywheel or drive plate bolt 707.0 51.0 �)

Main bearing cap No.1 bolt 30 N⋅m (3.0 kgf-m, 22.0 lb-ft), 50 N ⋅m (5.0

kgf-m, 36.5 lb-ft) and then retighten by

turning through 60 ° �)

Main bearing cap No.2 bolt 252.5 18.0 �) / �)

Main bearing cap No.1 bolt 30 Nm (3.0 kgf-m, 22.0 lb-ft), 50 Nm (5.0

kgf-m, 36.5 lb-ft) and then retighten by

turning through 60 ° �)

Fastening part

Tightening torque

Note

N ⋅mkgf-mlb-ft

Page 351 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-66

Special Tools and Equipment

Recommended Service MaterialS7RS0B1408001

NOTE

Required service material is also described in the following.

“Timing Chain Cover Components”

“Timing Chain and Chain Tensioner Components”

“Camshaft, Tappet and Shim Components”

“Valves and Cylinder Head Components”

“Pistons, Piston Rings, Connecting Rods and Cylinders Components”

“Main Bearings, Crankshaft and Cylinder Block Components”

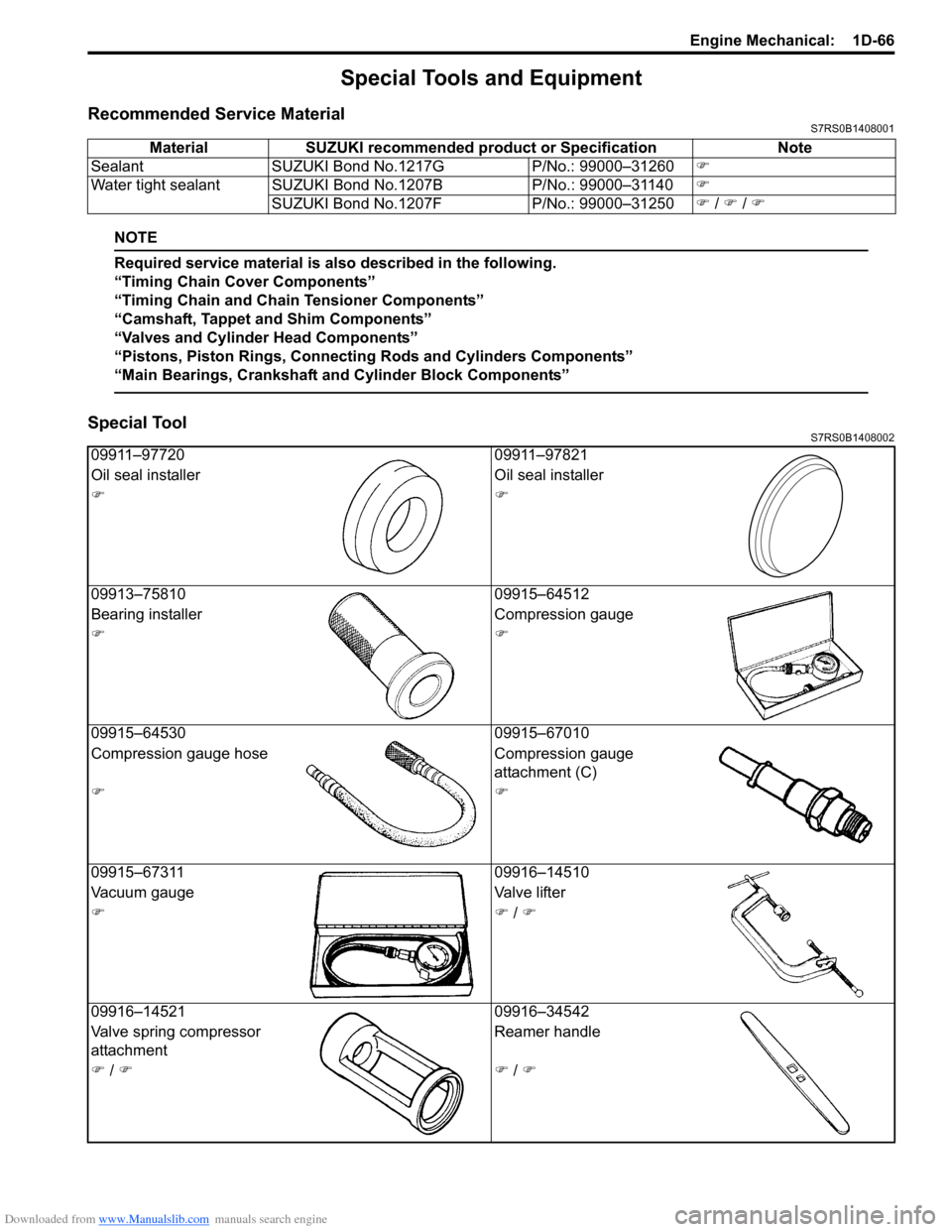

Special ToolS7RS0B1408002

Material SUZUKI recommended product or Specification Note

Sealant SUZUKI Bond No.1217G P/No.: 99000–31260�)

Water tight sealant SUZUKI Bond No.1207B P/No.: 99000–31140�)

SUZUKI Bond No.1207F P/No.: 99000–31250�) / �) / �)

09911–97720 09911–97821

Oil seal installer Oil seal installer

�)�)

09913–75810 09915–64512

Bearing installer Compression gauge

�)�)

09915–64530 09915–67010

Compression gauge hose Compression gauge

attachment (C)

�)�)

09915–67311 09916–14510

Vacuum gauge Valve lifter

�)�) / �)

09916–14521 09916–34542

Valve spring compressor

attachment Reamer handle

�) / �)�) / �)

Page 353 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Lubrication System: 1E-1

Engine

Engine Lubrication System

General Description

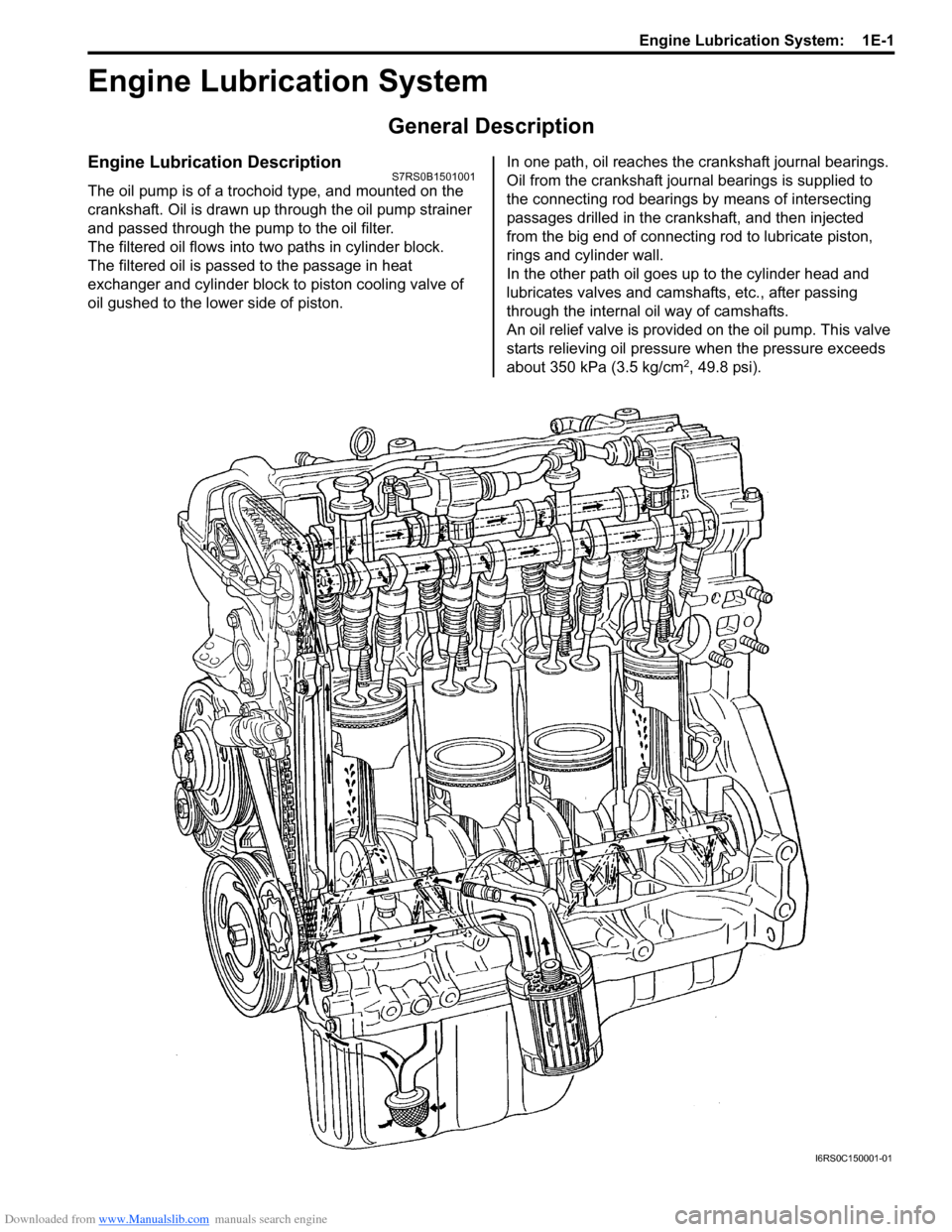

Engine Lubrication DescriptionS7RS0B1501001

The oil pump is of a trochoid type, and mounted on the

crankshaft. Oil is drawn up through the oil pump strainer

and passed through the pump to the oil filter.

The filtered oil flows into two paths in cylinder block.

The filtered oil is passed to the passage in heat

exchanger and cylinder block to piston cooling valve of

oil gushed to the lower side of piston. In one path, oil reaches the crankshaft journal bearings.

Oil from the crankshaft journal bearings is supplied to

the connecting rod bearings by means of intersecting

passages drilled in the cran

kshaft, and then injected

from the big end of connecting rod to lubricate piston,

rings and cylinder wall.

In the other path oil goes up to the cylinder head and

lubricates valves and camshafts, etc., after passing

through the internal oil way of camshafts.

An oil relief valve is provided on the oil pump. This valve

starts relieving oil pressure when the pressure exceeds

about 350 kPa (3.5 kg/cm

2, 49.8 psi).

I6RS0C150001-01

Page 386 of 1496

Downloaded from www.Manualslib.com manuals search engine 1G-11 Fuel System:

Fuel Tank Inlet Valve Removal and InstallationS7RS0B1706011

WARNING!

Before starting the following procedure, be

sure to observe “Precautions on Fuel System

Service” in order to reduce the risk or fire

and personal injury.

Removal1) Remove fuel filler cap.

2) Insert hose of a hand oper ated pump into fuel filler

hose (1) and drain fuel in space “A” as shown in

figure.

CAUTION!

Do not force pump hose into fuel tank, or

pump hose may damage to fuel tank inlet

valve (2).

3) Hoist vehicle, and remove clamp (2) and fuel filler

hose (1) from fuel tank. 4) Remove fuel tank inlet valve (1) using flat head rod

(2) or the like.

CAUTION!

Be careful not to damage fuel tank inlet valve

(1) with flat head rod (2) or the like.

Installation

1) Install fuel tank inlet valve (1) to fuel tank.

2) Install fuel filler hose (1) to fuel tank and secure it

with clamp (2).

For proper installation, refer to “Fuel Hose

Disconnecting and Reconnecting”.

3) Lower vehicle and install fuel filler cap.

IYSQ01170010-01

1

2

I4RS0A170007-01

I6RS0C170007-01

I2RH0B170018-01

1

2

I4RS0A170007-01