connecting rod SUZUKI SWIFT 2005 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 11 of 1496

Downloaded from www.Manualslib.com manuals search engine Precautions: 00-6

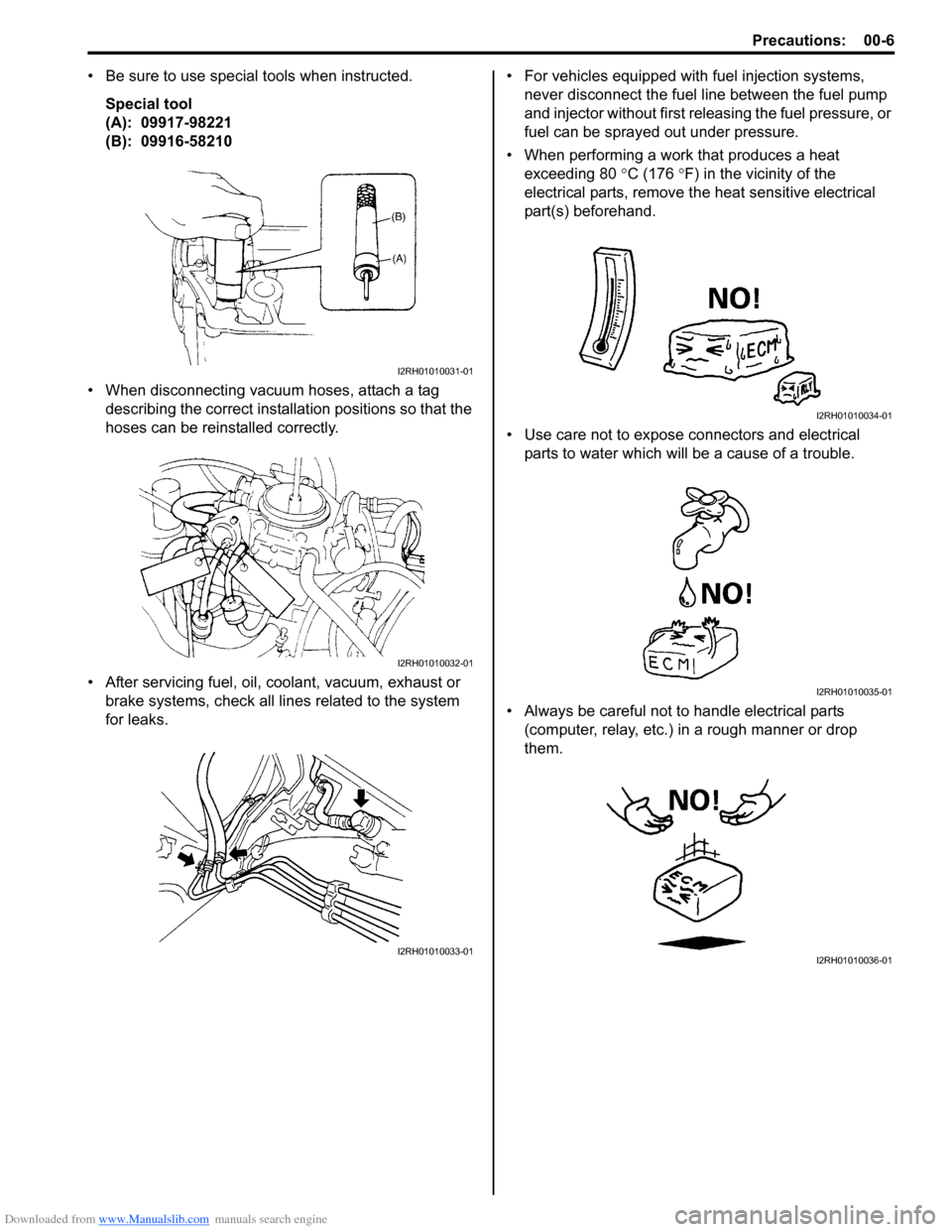

• Be sure to use special tools when instructed.Special tool

(A): 09917-98221

(B): 09916-58210

• When disconnecting vacuum hoses, attach a tag describing the correct installation positions so that the

hoses can be reinstalled correctly.

• After servicing fuel, oil, coolant, vacuum, exhaust or brake systems, check all lin es related to the system

for leaks. • For vehicles equipped with fuel injection systems,

never disconnect the fuel line between the fuel pump

and injector without first releasing the fuel pressure, or

fuel can be sprayed out under pressure.

• When performing a work that produces a heat exceeding 80 °C (176 ° F) in the vicinity of the

electrical parts, remove t he heat sensitive electrical

part(s) beforehand.

• Use care not to expose connectors and electrical parts to water which will be a cause of a trouble.

• Always be careful not to handle electrical parts (computer, relay, etc.) in a rough manner or drop

them.

I2RH01010031-01

I2RH01010032-01

I2RH01010033-01

I2RH01010034-01

I2RH01010035-01

I2RH01010036-01

Page 47 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 1-iii

EVAP Canister Purge Valve and Its Circuit

Inspection.......................................................... 1B-2

Vacuum Passage Inspection .............................. 1B-3

Vacuum Hose and Purge Valve Chamber Inspection.......................................................... 1B-3

EVAP Canister Purge Valve Inspection .............. 1B-3

EVAP Canister Inspection ... ................................ 1B-4

EGR Valve Removal and Installation .................. 1B-4

EGR Valve Inspection ......................................... 1B-4

PCV Hose Inspection .......................................... 1B-4

PCV Valve Inspection ......................................... 1B-5

Special Tools and Equipmen t ............................. 1B-5

Special Tool ........................................................ 1B-5

Engine Electrical Devices .. ..................... 1C-1

Repair Instructions .............................................. 1C-1

ECM Removal and Installation ............................ 1C-1

MAP Sensor Inspection ...................................... 1C-2

Electric Throttle Body Assembly On-Vehicle

Inspection.......................................................... 1C-2

Electric Throttle Body System Calibration ........... 1C-5

APP Sensor Assembly On-V ehicle Inspection .... 1C-5

APP Sensor Assembly Removal and Installation ......................................................... 1C-5

APP Sensor Assembly Inspection ...................... 1C-6

ECT Sensor Removal and In stallation ................ 1C-6

ECT Sensor Inspection ....................................... 1C-7

HO2S-1 and HO2S-2 Heater On-Vehicle Inspection.......................................................... 1C-7

HO2S-1 and HO2S-2 Removal and Installation ......................................................... 1C-7

CMP Sensor Removal and In stallation ............... 1C-8

Camshaft Position (CMP) Se nsor Inspection ...... 1C-8

CKP Sensor Removal and Installation ................ 1C-9

CKP Sensor Inspection ....................................... 1C-9

Knock Sensor Removal and Installation ........... 1C-10

Main Relay, Fuel Pump Relay and Starting

Motor Control Relay Inspection....................... 1C-10

MAF and IAT Sensor On-Vehicle Inspection .... 1C-11

MAF and IAT Sensor Removal and Installation ....................................................... 1C-11

MAF and IAT Sensor Inspection ....................... 1C-12

Electric Load Current Sensor On-Vehicle Inspection........................................................ 1C-12

Specifications ..................................................... 1C-13

Tightening Torque Specifications ...................... 1C-13

Engine Mechanical ......... ......................... 1D-1

General Description ............................................. 1D-1

Engine Construction Description ......................... 1D-1

Camshaft Position Control (VVT Variable Valve Timing) System Description .................... 1D-2

Diagnostic Information and Procedures ............ 1D-4 Compression Check ............................................ 1D-4

Engine Vacuum Check ....................................... 1D-5

Valve Lash (Clearance) Inspection ..................... 1D-6

Repair Instructions .............................................. 1D-9 Air Cleaner Components ..................................... 1D-9

Air Cleaner Element Removal and Installation .... 1D-9 Air Cleaner Element Ins

pection and Cleaning ..1D-10

Cylinder Head Co ver Removal and

Installation .......................................................1D-10

Throttle Body and Intake Manifold

Components ....................................................1D-12

Throttle Body On-Vehicle Inspection.................1D-13

Electric Throttle Body Assembly Removal and Installation .......................................................1D-13

Throttle Body Cleaning......................................1D-14

Intake Manifold Removal and Installation .........1D-14

Engine Mountings Components ........................1D-16

Engine Assembly Removal and Installation ......1D-17

Timing Chain Cover Components .....................1D-20

Timing Chain Cover Removal and Installation ..1D-21

Timing Chain Cover Inspection .........................1D-23

Oil Control Valve Removal and Installation .......1D-23

Oil Control Valve Inspection ..............................1D-24

Timing Chain and Chain Tensioner Components ....................................................1D-24

Timing Chain and Chain Tensioner Removal and Installation ................................................1D-25

Timing Chain and Chain Tensioner Inspection ..1D-27

Camshaft, Tappet and Shim Components ........1D-28

Camshaft, Tappet and Shim Removal and Installation .......................................................1D-29

Camshaft, Tappet and Shim Inspection ............1D-31

Valves and Cylinder Head Components ...........1D-34

Valves and Cylinder Head Removal and

Installation .......................................................1D-35

Valves and Cylinder Head Disassembly and Assembly.........................................................1D-37

Valves and Valve Guides Inspection.................1D-40

Cylinder Head Inspection . .................................1D-42

Valve Spring Inspection ....................................1D-43

Pistons, Piston Rings , Connecting Rods and

Cylinders Components ....................................1D-44

Pistons, Piston Rings , Connecting Rods and

Cylinders Removal and Installation .................1D-45

Pistons, Piston Rings , Connecting Rods and

Cylinders Disassembly and Assembly ............1D-46

Cylinders, Pistons and Piston Rings Inspection ........................................................1D-47

Piston Pins and Connecting Rods Inspection ...1D-49

Crank Pin and Connecting Rod Bearings Inspection ........................................................1D-50

Main Bearings, Cran kshaft and Cylinder

Block Components ..........................................1D-53

Main Bearings, Cran kshaft and Cylinder

Block Removal and Installa tion .......................1D-54

Crankshaft Inspection .......................................1D-57

Main Bearings Inspection . .................................1D-59

Sensor Plate Inspection ....................................1D-63

Rear Oil Seal Inspection ...................................1D-63

Flywheel Inspection...........................................1D-63

Cylinder Block Inspection ..................................1D-63

Specifications .................... .................................1D-64

Tightening Torque Specifications ......................1D-64

Special Tools and Equipmen t ...........................1D-66

Recommended Service Material .......................1D-66

Special Tool ......................................................1D-66

Page 52 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-2 Engine General Information and Diagnosis:

• Be sure to read “Precautions for Electrical Circuit Service in Section 00” befo re inspection and observe

what is written there.

• ECM replacement: When substituting a known-good ECM, check for the

following conditions. Neglec ting this check may cause

damage to a known-good ECM.

– Resistance value of all relays, actuators is as specified respectively.

– MAP sensor, A/C refrigerant pressure sensor and TP sensor are in good condition and none of power

circuits of these sensors is shorted to ground.

• Communication of ECM, BCM, ABS/ESP ® control

module, combination meter, keyless start control

module, steering angle sensor (ESP ® model) and

TCM (A/T model), is esta blished by CAN (Controller

Area Network). (For more detail of CAN

communication for ECM, refer to “CAN

Communication System Description”). Therefore,

handle CAN communication line with care referring to

“Precaution for CAN Communication System in

Section 00”.

• Immobilizer transponder code registration after

replacing ECM

When ECM is replaced with new one or with another

one, make sure to register immobilizer transponder

code to ECM correctly according to “Procedure after

ECM Replacement in Section 10C”.Precautions of ECM Circuit InspectionS7RS0B1100003

• ECM connectors are waterproofed. Each terminal of the ECM connectors is sealed up with the grommet.

Therefore, when measuring ci rcuit voltage, resistance

and/or pulse signal at ECM connector, do not insert

the tester’s probe into th e sealed terminal at the

harness side. When measuring circuit voltage,

resistance and/or pulse signal at ECM connector,

connect the special tool to the ECM connectors. And,

insert the tester’s probe into the special tool’s

connectors at the harness side, and then measure

voltage, resistance and/or pulse signal. Or, ECM and

its circuits may be damaged by water.

• Wire colors of the special tool’s connectors are different from the ones of the ECM connectors.

However, the circuit arrangement of the special tool’s

connectors is same as the one of the ECM

connectors. Therefore, measure circuit voltage and

resistance by identifying the terminal location subject

to the measurement.

Precautions of Electric Throttle Body System

Calibration

S7RS0B1100004

After performing one of works described below, it is

necessary to re-register the completely closed throttle

valve reference position stored in memory of ECM. (For

detailed information, refer to “Description of Electric

Throttle Body System Calibration”.) For the procedure to

register such data in ECM, refer to “Electric Throttle

Body System Calibration in Section 1C”.

• To shut off backup power of ECM for such purposes of battery replacement or “DOME” fuse removal

• To erase DTCs P0122, P01 23, P0222, P0223, P2101,

P2102, P2103, P2111, P2112, P2113, P2119, P2123,

P2127, P2128, P2135 and/or P2138

• To replace ECM

• To replace throttle body and/or accelerator pedal position (APP) sensor assembly

General Description

Statement on Cleanliness and CareS7RS0B1101001

An automobile engine is a combination of many

machined, honed, polished and lapped surfaces with

tolerances that are measured in the thousands of an

millimeter (ten thous ands of an inch).

Accordingly, when any internal engine parts are

serviced, care and cleanliness are important.

It should be understood that proper cleaning and

protection of machined surfaces and friction areas is part

of the repair procedure. This is considered standard

shop practice even if not specifically stated.

• A liberal coating of engine oil should be applied to friction areas during assembly to protect and lubricate

the surfaces on initial operation. • Whenever valve train components, pistons, piston

rings, connecting rods, rod bearings, and crankshaft

journal bearings are removed for service, they should

be retained in order.

At the time of installation, they should be installed in

the same locations and with the same mating

surfaces as when removed.

• Battery cables should be disconnected before any major work is performed on the engine.

Failure to disconnect cables may result in damage to

wire harness or other electrical parts.

Page 92 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-42 Engine General Information and Diagnosis:

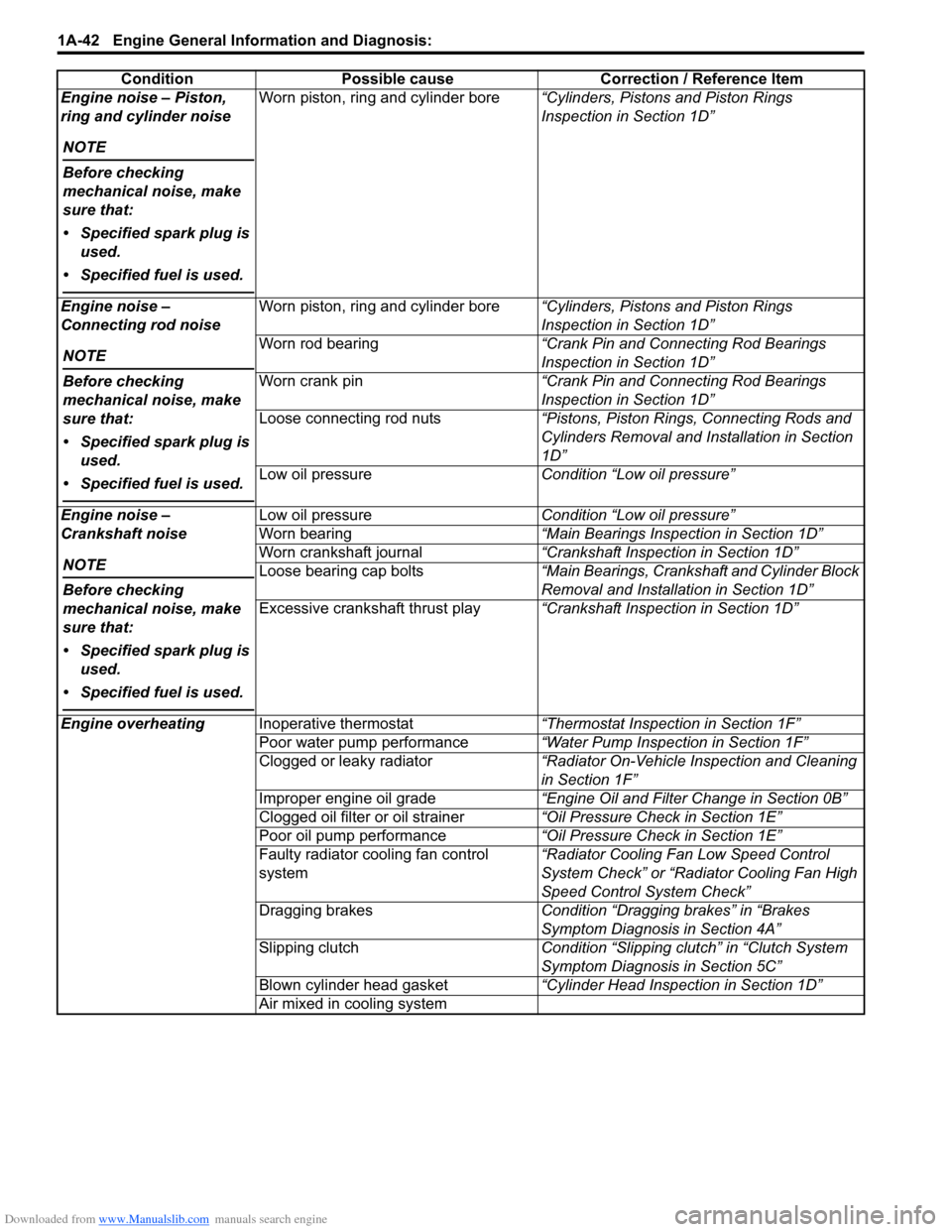

Engine noise – Piston,

ring and cylinder noise

NOTE

Before checking

mechanical noise, make

sure that:

• Specified spark plug is used.

• Specified fuel is used.

Worn piston, ring and cylinder bore “Cylinders, Pistons and Piston Rings

Inspection in Section 1D”

Engine noise –

Connecting rod noise

NOTE

Before checking

mechanical noise, make

sure that:

• Specified spark plug is used.

• Specified fuel is used.

Worn piston, ring and cylinder bore “Cylinders, Pistons and Piston Rings

Inspection in Section 1D”

Worn rod bearing “Crank Pin and Connecting Rod Bearings

Inspection in Section 1D”

Worn crank pin “Crank Pin and Connecting Rod Bearings

Inspection in Section 1D”

Loose connecting rod nuts “Pistons, Piston Rings, Connecting Rods and

Cylinders Removal and Installation in Section

1D”

Low oil pressure Condition “Low oil pressure”

Engine noise –

Crankshaft noise

NOTE

Before checking

mechanical noise, make

sure that:

• Specified spark plug is used.

• Specified fuel is used.

Low oil pressure Condition “Low oil pressure”

Worn bearing “Main Bearings Inspection in Section 1D”

Worn crankshaft journal “Crankshaft Inspection in Section 1D”

Loose bearing cap bolts “Main Bearings, Crankshaft and Cylinder Block

Removal and Installation in Section 1D”

Excessive crankshaft thrust play “Crankshaft Inspection in Section 1D”

Engine overheating Inoperative thermostat “Thermostat Inspection in Section 1F”

Poor water pump performance “Water Pump Inspection in Section 1F”

Clogged or leaky radiator “Radiator On-Vehicle Inspection and Cleaning

in Section 1F”

Improper engine oil grade “Engine Oil and Filter Change in Section 0B”

Clogged oil filter or oil strainer “Oil Pressure Check in Section 1E”

Poor oil pump performance “Oil Pressure Check in Section 1E”

Faulty radiator cooling fan control

system “Radiator Cooling Fan Low Speed Control

System Check” or “Rad

iator Cooling Fan High

Speed Control System Check”

Dragging brakes Condition “Dragging brakes” in “Brakes

Symptom Diagnosis in Section 4A”

Slipping clutch Condition “Slipping clutch” in “Clutch System

Symptom Diagnosis in Section 5C”

Blown cylinder head gasket “Cylinder Head Inspection in Section 1D”

Air mixed in cooling system

Condition Possible cause Correction / Reference Item

Page 93 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-43

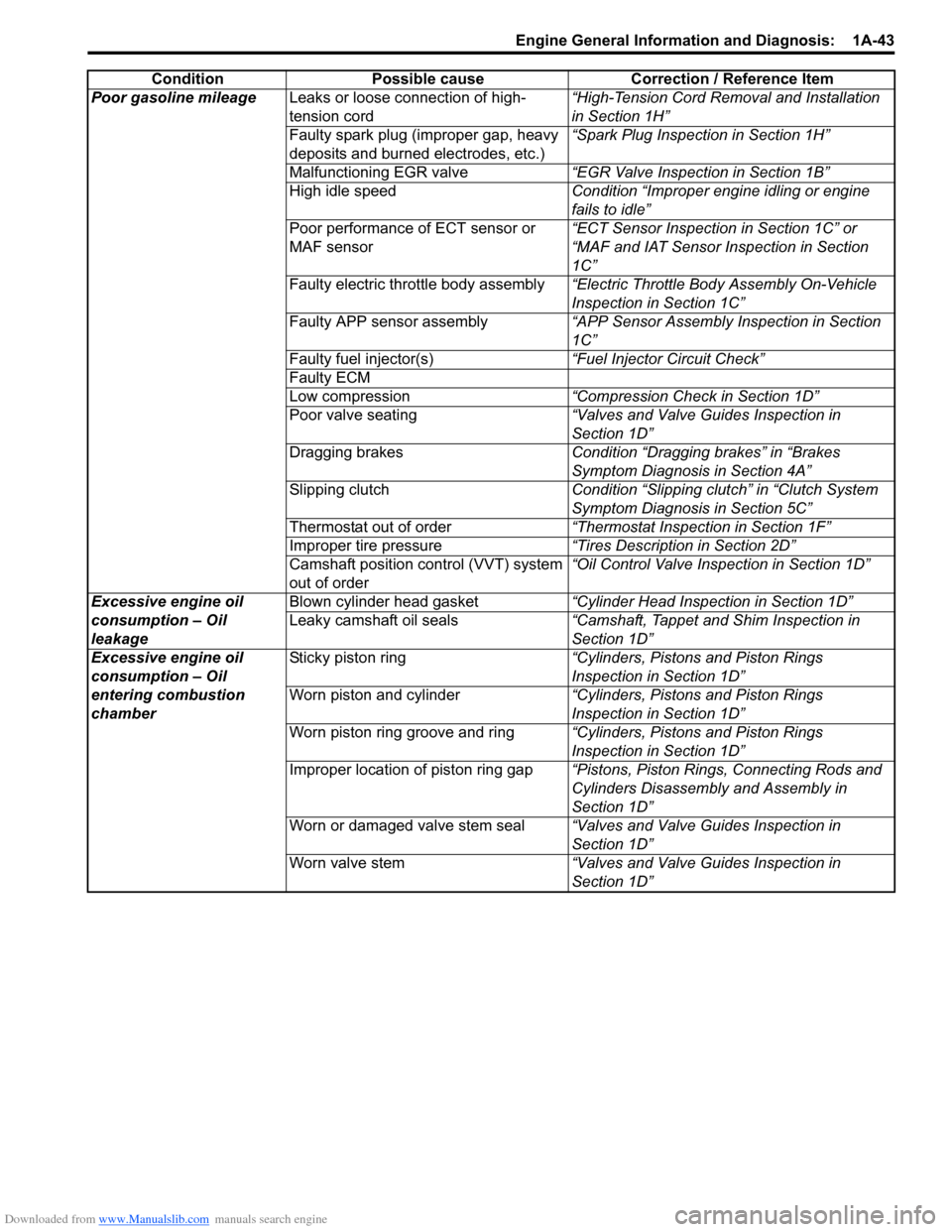

Poor gasoline mileageLeaks or loose connection of high-

tension cord “High-Tension Cord Removal and Installation

in Section 1H”

Faulty spark plug (improper gap, heavy

deposits and burned electrodes, etc.) “Spark Plug Inspection in Section 1H”

Malfunctioning EGR valve “EGR Valve Inspection in Section 1B”

High idle speed Condition “Improper engine idling or engine

fails to idle”

Poor performance of ECT sensor or

MAF sensor “ECT Sensor Inspection in Section 1C” or

“MAF and IAT Sensor Inspection in Section

1C”

Faulty electric throttle body assembly “Electric Throttle Body Assembly On-Vehicle

Inspection in Section 1C”

Faulty APP sensor assembly “APP Sensor Assembly Inspection in Section

1C”

Faulty fuel injector(s) “Fuel Injector Circuit Check”

Faulty ECM

Low compression “Compression Check in Section 1D”

Poor valve seating “Valves and Valve Guides Inspection in

Section 1D”

Dragging brakes Condition “Dragging brakes” in “Brakes

Symptom Diagnosis in Section 4A”

Slipping clutch Condition “Slipping clutch” in “Clutch System

Symptom Diagnosis in Section 5C”

Thermostat out of order “Thermostat Inspection in Section 1F”

Improper tire pressure “Tires Description in Section 2D”

Camshaft position control (VVT) system

out of order “Oil Control Valve Inspection in Section 1D”

Excessive engine oil

consumption – Oil

leakage Blown cylinder head gasket

“Cylinder Head Inspection in Section 1D”

Leaky camshaft oil seals “Camshaft, Tappet and Shim Inspection in

Section 1D”

Excessive engine oil

consumption – Oil

entering combustion

chamber Sticky piston ring

“Cylinders, Pistons and Piston Rings

Inspection in Section 1D”

Worn piston and cylinder “Cylinders, Pistons and Piston Rings

Inspection in Section 1D”

Worn piston ring groove and ring “Cylinders, Pistons and Piston Rings

Inspection in Section 1D”

Improper location of piston ring gap “Pistons, Piston Rings, Connecting Rods and

Cylinders Disassembly and Assembly in

Section 1D”

Worn or damaged valve stem seal “Valves and Valve Guides Inspection in

Section 1D”

Worn valve stem “Valves and Valve Guides Inspection in

Section 1D”

Condition Possible cause Correction / Reference Item

Page 94 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-44 Engine General Information and Diagnosis:

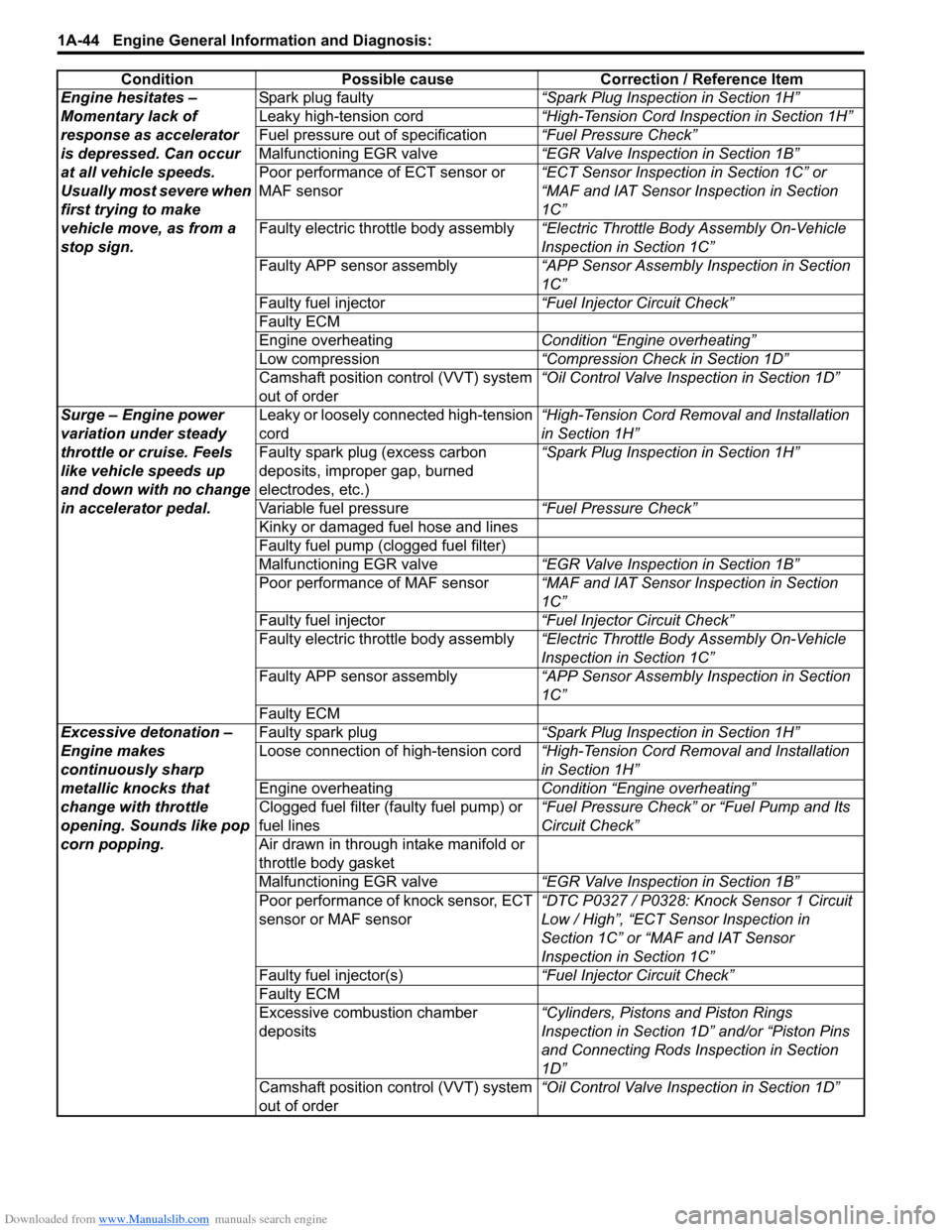

Engine hesitates –

Momentary lack of

response as accelerator

is depressed. Can occur

at all vehicle speeds.

Usually most severe when

first trying to make

vehicle move, as from a

stop sign.Spark plug faulty

“Spark Plug Inspection in Section 1H”

Leaky high-tension cord “High-Tension Cord Inspection in Section 1H”

Fuel pressure out of specification “Fuel Pressure Check”

Malfunctioning EGR valve “EGR Valve Inspection in Section 1B”

Poor performance of ECT sensor or

MAF sensor “ECT Sensor Inspection in Section 1C” or

“MAF and IAT Sensor Inspection in Section

1C”

Faulty electric throttle body assembly “Electric Throttle Body Assembly On-Vehicle

Inspection in Section 1C”

Faulty APP sensor assembly “APP Sensor Assembly Inspection in Section

1C”

Faulty fuel injector “Fuel Injector Circuit Check”

Faulty ECM

Engine overheating Condition “Engine overheating”

Low compression “Compression Check in Section 1D”

Camshaft position control (VVT) system

out of order “Oil Control Valve Inspection in Section 1D”

Surge – Engine power

variation under steady

throttle or cruise. Feels

like vehicle speeds up

and down with no change

in accelerator pedal. Leaky or loosely connected high-tension

cord

“High-Tension Cord Removal and Installation

in Section 1H”

Faulty spark plug (excess carbon

deposits, improper gap, burned

electrodes, etc.) “Spark Plug Inspection in Section 1H”

Variable fuel pressure “Fuel Pressure Check”

Kinky or damaged fuel hose and lines

Faulty fuel pump (clogged fuel filter)

Malfunctioning EGR valve “EGR Valve Inspection in Section 1B”

Poor performance of MAF sensor “MAF and IAT Sensor Inspection in Section

1C”

Faulty fuel injector “Fuel Injector Circuit Check”

Faulty electric throttle body assembly “Electric Throttle Body Assembly On-Vehicle

Inspection in Section 1C”

Faulty APP sensor assembly “APP Sensor Assembly Inspection in Section

1C”

Faulty ECM

Excessive detonation –

Engine makes

continuously sharp

metallic knocks that

change with throttle

opening. Sounds like pop

corn popping. Faulty spark plug

“Spark Plug Inspection in Section 1H”

Loose connection of high-tension cord “High-Tension Cord Removal and Installation

in Section 1H”

Engine overheating Condition “Engine overheating”

Clogged fuel filter (faulty fuel pump) or

fuel lines “Fuel Pressure Check” or “Fuel Pump and Its

Circuit Check”

Air drawn in through intake manifold or

throttle body gasket

Malfunctioning EGR valve “EGR Valve Inspection in Section 1B”

Poor performance of knock sensor, ECT

sensor or MAF sensor “DTC P0327 / P0328: Knock Sensor 1 Circuit

Low / High”, “ECT Sensor Inspection in

Section 1C” or “MAF and IAT Sensor

Inspection in Section 1C”

Faulty fuel injector(s) “Fuel Injector Circuit Check”

Faulty ECM

Excessive combustion chamber

deposits “Cylinders, Pistons and Piston Rings

Inspection in Section 1D” and/or “Piston Pins

and Connecting Rods In

spection in Section

1D”

Camshaft position control (VVT) system

out of order “Oil Control Valve Inspection in Section 1D”

Condition Possible cause Correction / Reference Item

Page 329 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-44

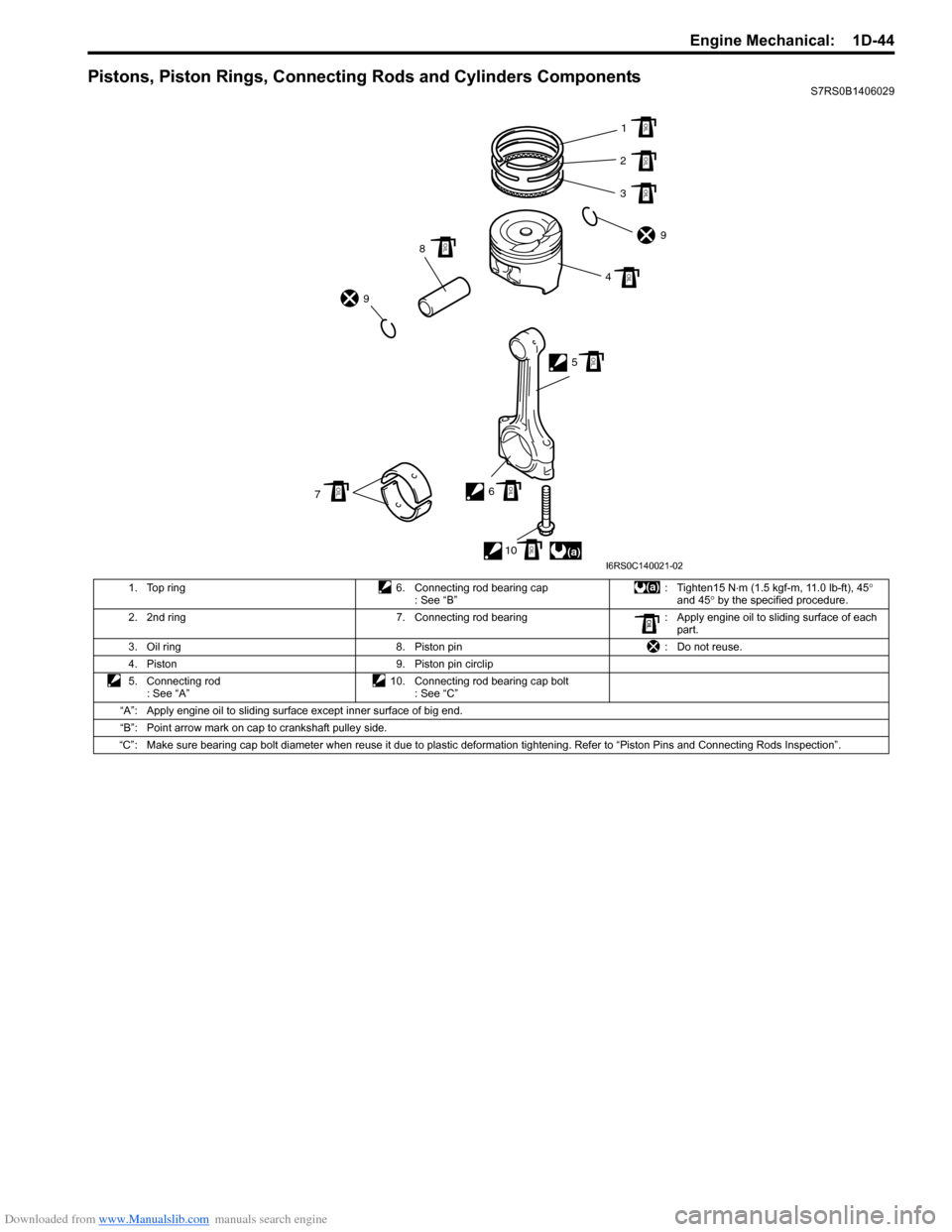

Pistons, Piston Rings, Connecting Rods and Cylinders ComponentsS7RS0B1406029

1. Top ring 6. Connecting rod bearing cap : See “B”: Tighten15 N

⋅m (1.5 kgf-m, 11.0 lb-ft), 45 °

and 45 ° by the specified procedure.

2. 2nd ring 7. Connecting rod bearing : Apply engine oil to sliding surface of each

part.

3. Oil ring 8. Piston pin : Do not reuse.

4. Piston 9. Piston pin circlip

5. Connecting rod : See “A” 10. Connecting rod bearing cap bolt

: See “C”

“A”: Apply engine oil to sliding surface except inner surface of big end.

“B”: Point arrow mark on cap to crankshaft pulley side.

“C”: Make sure bearing cap bolt diameter when reuse it due to plastic deformation tightening. Refer to “Piston Pins and Connecti ng Rods Inspection”.

(a)1

2

3

9

4

5

6 10

7 8

9

OIL

OIL

OIL

OIL

OIL

OIL

OIL

OIL

OIL

I6RS0C140021-02

Page 330 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-45 Engine Mechanical:

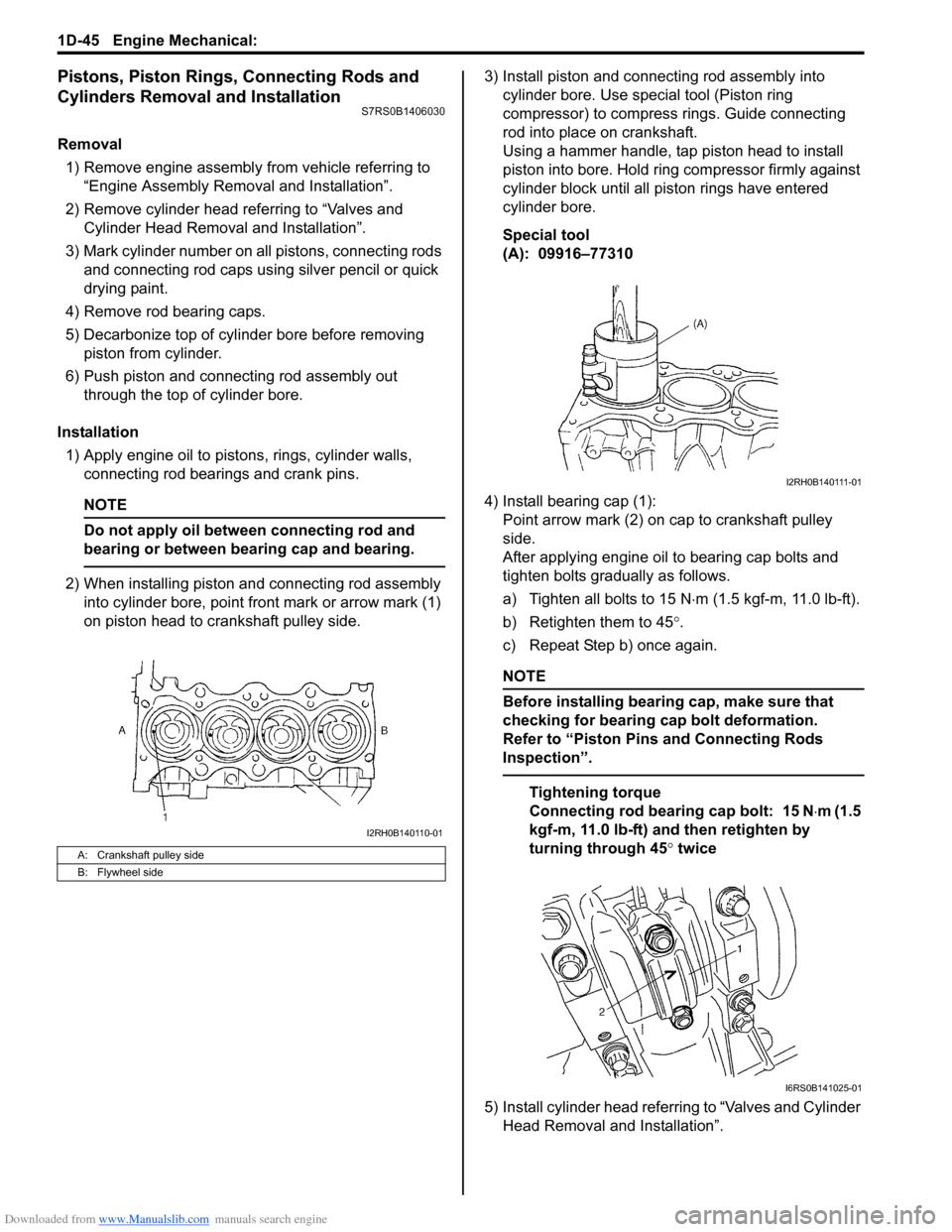

Pistons, Piston Rings, Connecting Rods and

Cylinders Removal and Installation

S7RS0B1406030

Removal1) Remove engine assembly from vehicle referring to “Engine Assembly Removal and Installation”.

2) Remove cylinder head referring to “Valves and Cylinder Head Removal and Installation”.

3) Mark cylinder number on all pistons, connecting rods

and connecting rod caps using silver pencil or quick

drying paint.

4) Remove rod bearing caps.

5) Decarbonize top of cylinder bore before removing piston from cylinder.

6) Push piston and connecting rod assembly out through the top of cylinder bore.

Installation 1) Apply engine oil to pistons, rings, cylinder walls, connecting rod bearings and crank pins.

NOTE

Do not apply oil between connecting rod and

bearing or between bearing cap and bearing.

2) When installing piston and connecting rod assembly into cylinder bore, point front mark or arrow mark (1)

on piston head to crankshaft pulley side. 3) Install piston and connecting rod assembly into

cylinder bore. Use special tool (Piston ring

compressor) to compress rings. Guide connecting

rod into place on crankshaft.

Using a hammer handle, tap piston head to install

piston into bore. Hold ring compressor firmly against

cylinder block until all piston rings have entered

cylinder bore.

Special tool

(A): 09916–77310

4) Install bearing cap (1): Point arrow mark (2) on cap to crankshaft pulley

side.

After applying engine oil to bearing cap bolts and

tighten bolts gradually as follows.

a) Tighten all bolts to 15 N ⋅m (1.5 kgf-m, 11.0 lb-ft).

b) Retighten them to 45 °.

c) Repeat Step b) once again.

NOTE

Before installing bearing cap, make sure that

checking for bearing cap bolt deformation.

Refer to “Piston Pins and Connecting Rods

Inspection”.

Tightening torque

Connecting rod bearing cap bolt: 15 N ⋅m (1.5

kgf-m, 11.0 lb-ft) and then retighten by

turning through 45 ° twice

5) Install cylinder head referring to “Valves and Cylinder Head Removal and Installation”.

A: Crankshaft pulley side

B: Flywheel side

I2RH0B140110-01

I2RH0B140111-01

I6RS0B141025-01

Page 331 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-46

Pistons, Piston Rings, Connecting Rods and

Cylinders Disassembly and Assembly

S7RS0B1406031

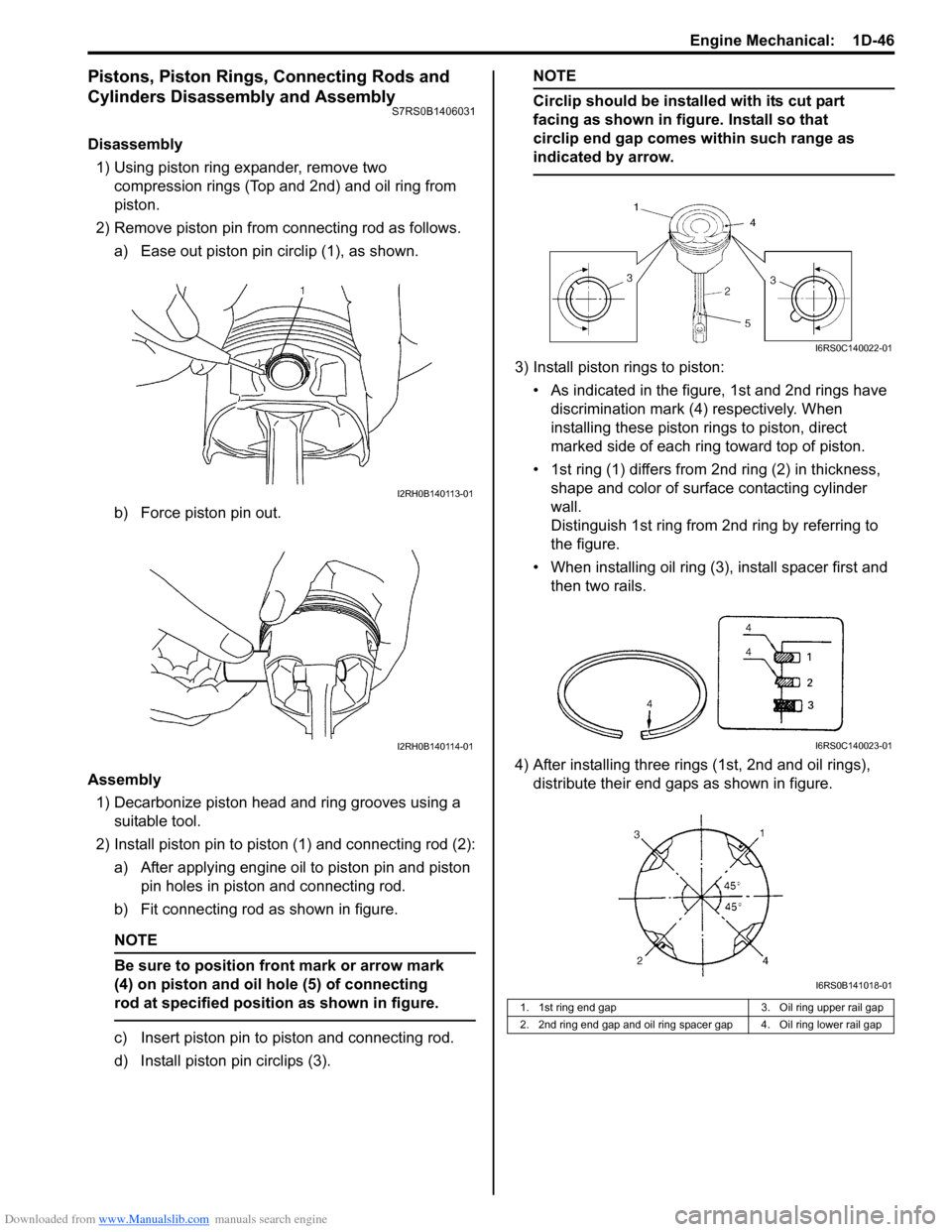

Disassembly1) Using piston ring expander, remove two compression rings (Top and 2nd) and oil ring from

piston.

2) Remove piston pin from connecting rod as follows. a) Ease out piston pin circlip (1), as shown.

b) Force piston pin out.

Assembly 1) Decarbonize piston head and ring grooves using a suitable tool.

2) Install piston pin to piston (1) and connecting rod (2): a) After applying engine oil to piston pin and piston pin holes in piston and connecting rod.

b) Fit connecting rod as shown in figure.

NOTE

Be sure to position front mark or arrow mark

(4) on piston and oil hole (5) of connecting

rod at specified position as shown in figure.

c) Insert piston pin to piston and connecting rod.

d) Install piston pin circlips (3).

NOTE

Circlip should be installed with its cut part

facing as shown in figure. Install so that

circlip end gap comes within such range as

indicated by arrow.

3) Install piston rings to piston:

• As indicated in the figure, 1st and 2nd rings have discrimination mark (4) respectively. When

installing these piston rings to piston, direct

marked side of each ring toward top of piston.

• 1st ring (1) differs from 2nd ring (2) in thickness, shape and color of surface contacting cylinder

wall.

Distinguish 1st ring from 2nd ring by referring to

the figure.

• When installing oil ring (3), install spacer first and then two rails.

4) After installing three rings (1st, 2nd and oil rings), distribute their end gaps as shown in figure.

I2RH0B140113-01

I2RH0B140114-01

1. 1st ring end gap 3. Oil ring upper rail gap

2. 2nd ring end gap and oil ring spacer gap 4. Oil ring lower rail gap

I6RS0C140022-01

I6RS0C140023-01

I6RS0B141018-01

Page 334 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-49 Engine Mechanical:

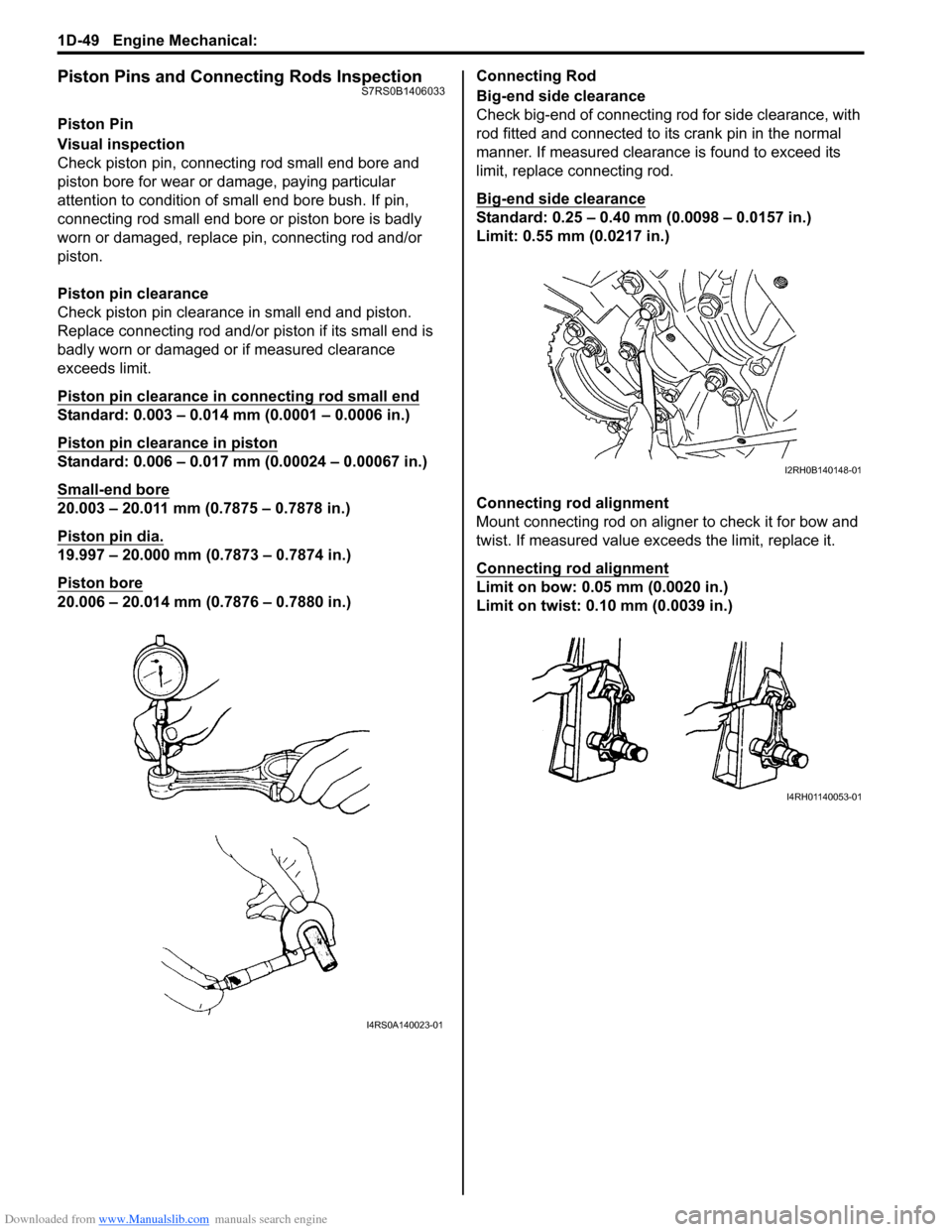

Piston Pins and Connecting Rods InspectionS7RS0B1406033

Piston Pin

Visual inspection

Check piston pin, connecting rod small end bore and

piston bore for wear or damage, paying particular

attention to condition of small end bore bush. If pin,

connecting rod small end bore or piston bore is badly

worn or damaged, replace pin, connecting rod and/or

piston.

Piston pin clearance

Check piston pin clearance in small end and piston.

Replace connecting rod and/or piston if its small end is

badly worn or damaged or if measured clearance

exceeds limit.

Piston pin clearance in connecting rod small end

Standard: 0.003 – 0.014 mm (0.0001 – 0.0006 in.)

Piston pin clearance in piston

Standard: 0.006 – 0.017 mm (0.00024 – 0.00067 in.)

Small-end bore

20.003 – 20.011 mm (0.7875 – 0.7878 in.)

Piston pin dia.

19.997 – 20.000 mm (0.7873 – 0.7874 in.)

Piston bore

20.006 – 20.014 mm (0.7876 – 0.7880 in.)Connecting Rod

Big-end side clearance

Check big-end of connecting rod for side clearance, with

rod fitted and connected to its crank pin in the normal

manner. If measured clearance is found to exceed its

limit, replace connecting rod.

Big-end side clearance

Standard: 0.25 – 0.40 mm (0.0098 – 0.0157 in.)

Limit: 0.55 mm (0.0217 in.)

Connecting rod alignment

Mount connecting rod on aligner to check it for bow and

twist. If measured value exceeds the limit, replace it.

Connecting rod alignment

Limit on bow: 0.05 mm (0.0020 in.)

Limit on twist: 0.10 mm (0.0039 in.)

I4RS0A140023-01

I2RH0B140148-01

I4RH01140053-01