manual transaxle oil change SUZUKI SWIFT 2005 2.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 647 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-3

General Description

A/T DescriptionS7RS0B5101001

This automatic transaxle is electronic control full automatic transaxle with forward 4-speed and reverse 1-speed.

The torque converter is a 3-element, 1-step and 2-phase type and is equipped with an automatically controlled lock-up

mechanism.

The gear change device consists of a ravigneau type planet ary gear unit, 3 multiple disc type clutches, 3 multiple disc

type brakes and 2 one-way clutches.

The hydraulic pressure control device consists of a valve body assembly, pressure control solenoid valve (linear

solenoid), 2 shift solenoid va lves, TCC pressure control solenoid valve (lin ear solenoid) and a timing solenoid valve.

Optimum line pressure complying with engine torque is produced by the pressure control solenoid valve in

dependence upon control signal from transmission control module (TCM). This makes it possible to control the line

pressure with high accuracy in accordance with the engine power and running conditions to achieve smooth shifting

characteristics and high efficiency.

A clutch-to-clutch control system is prov ided for shifting between 3rd gear and 4th gear. This clutch-to-clutch control

system is made to function optimally , so that hydraulic pressure controls such as shown below are conducted.

• When upshifting from 3rd gear to 4th gear, to adjust the drain hydraulic pressure at releasing the forward clutch, a

timing solenoid valve is used to switch a hydraulic passage with an orifice to another during shifting.

• When downshifting from 4th gear to 3rd gear, to adjust the line pressure applied to the forward clutch at engaging the forward clutch, a timing solenoid valve is used to s witch a hydraulic passage with an orifice to another during

shifting.

• When upshifting from 3rd gear to 4th gear with engine throttle opened, to optimize the line pressure applied to the forward clutch at releasing the forward clutch, the learning control is processed to compensate the switching timing

of the timing solenoid at every shifting.

• When downshifting from 4th gear to 3rd gear with engine throttle opened, to optimize the line pressure applied to

the forward clutch at engaging the forw ard clutch, the learning control is processed to compensate the line pressure

at every shifting.

Employing the ravigneau type planetary gear unit and this clutch-to-clutch control system greatly simplifies the

construction to make possible a lightweight and compact transaxle.

A line pressure learning control is conducted to provide opti mum shifting time at every upshifting with engine throttle

opened. If long upshifting time is detected, the subsequent line pressure applied during upshifting is intensified. On the

contrary, if short upshifting time is detected, the subs equent line pressure applied during upshifting is weakened.

Slip controlled lock-up function

Even at a lower speed than when the TCC gets engaged completely, control over the TCC pressure control solenoid

works to cause the TCC to slip (be engaged slightly), ther eby improving the transmission efficiency. While such slip

control is being executed, the oil pressure applied to the TCC is controlled by the TCC pressure control solenoid so

that the difference between the engine speed and the input shaft speed becomes close to the specified value.

Also, during deceleration, the TCC is made to slip (be enga ged slightly) to raise the engine speed and enlarge the fuel

cut operation range so that better fuel consumption is achieved.

Due to this reason, it is absolutely necessary for the automati c transmission to use ATF suitable for slip control. Use of

any fluid other than the specified ATF may cause j uddering or some other faulty condition to occur.

Page 649 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-5

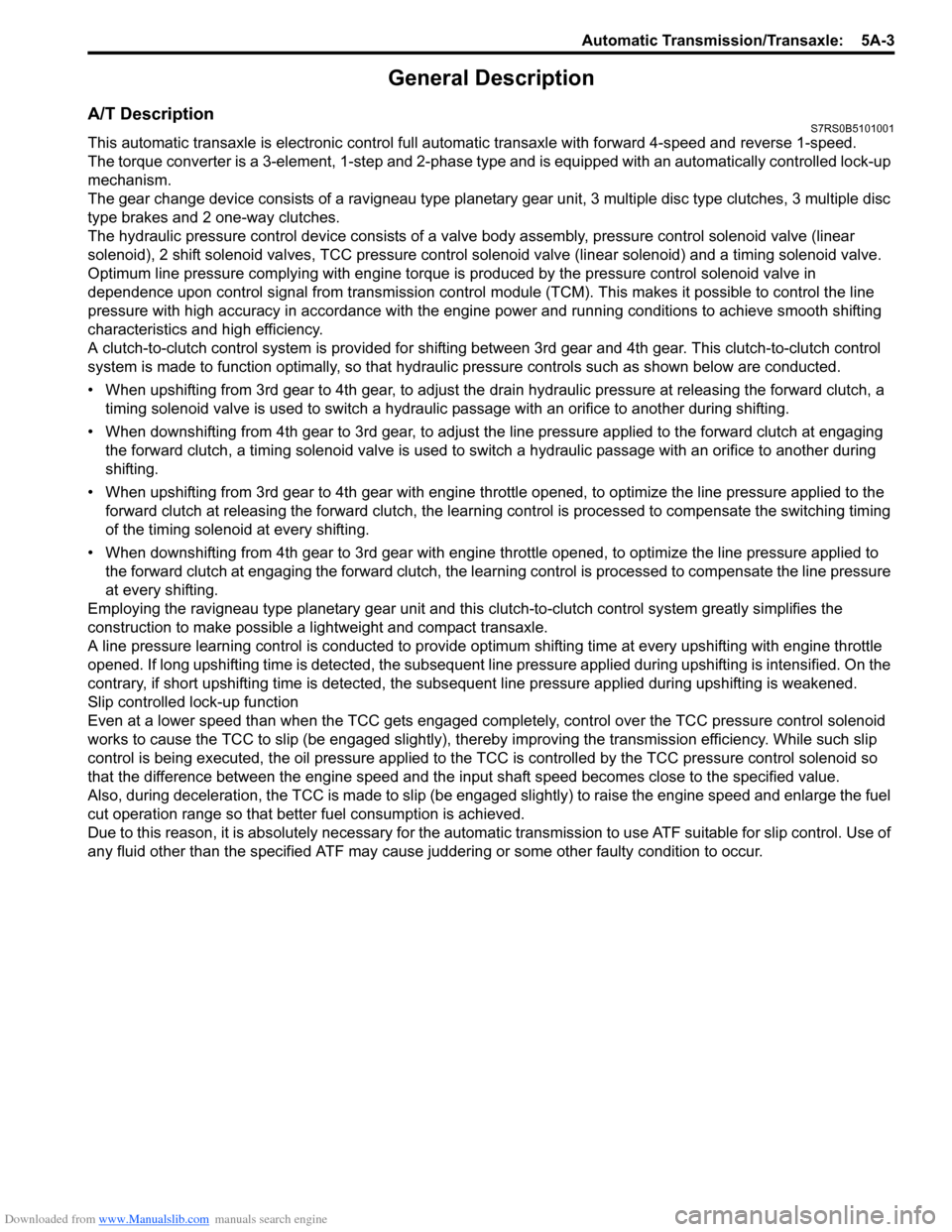

SpecificationsItem Specifications

Torque converter Ty p e

Stall torque ratio 3-element, 1-step, 2-phase type (with TCC (lock-up)

mechanism)

2.0 – 2.2

Oil pump Ty p e

Drive system Internal involute gear type oil pump (non crescent type)

Engine driven

Gear change

device Type Forward 4-step, reverse 1-step planetary gear type

Shift position

“P” range Gear in neutral, output shaft fixed, engine start

“R” range Reverse

“N” range Gear in neutral, engine start

“D” range

Forward 1st

↔ 2nd ↔ 3rd ↔ 4th automatic gear

change

“3” range Forward 1st

↔ 2nd ↔ 3rd ← 4th automatic gear

change

“2” range Forward 1st ↔ 2nd ← 3rd automatic gear change

“L” range Forward 1st

← 2nd ← 3rd reduction, and fixed at 1st

gear

Gear

ratio 1st 2.875 Number of teeth Front sun gear: 24

2nd 1.568 Rear sun gear: 30

3rd 1.000 Long planet pinion: 20

4th (overdrive gear) 0.697 Short planet pinion: 19

Reverse (reverse gear) 2.300 Ring gear: 69

Control elements Wet type multiple-disc clutch... 3 sets

Wet type multiple-d

isc brake... 3 sets

One-way clutch... 2 sets

Reduction gear ratio 1.023

Final gear reduction ratio 4.277

Lubrication Lubrication system Force feed system by oil pump

Cooling Cooling system Radiator assisted cooling (water-cooled)

Fluid used SUZUKI ATF 3317 or Mobil ATF 3309

Page 662 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-18 Automatic Transmission/Transaxle:

Visual InspectionS7RS0B5104002

Visually check the following parts and systems.

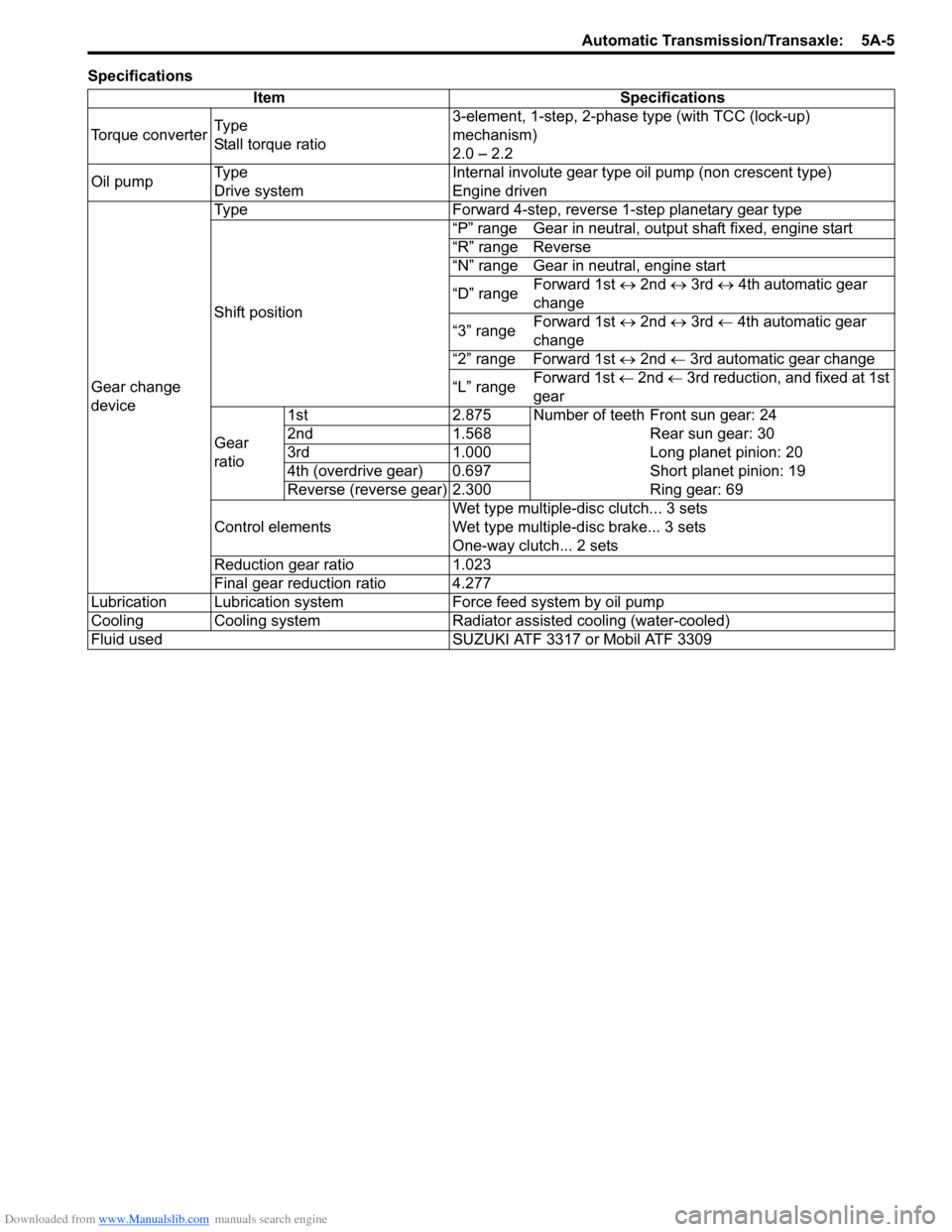

Malfunction Indicator Lamp (MIL) CheckS7RS0B5104003

Refer to the same item in “Malfunction Indicator Lam p (MIL) Check in Section 1A” for checking procedure.

Transmission Warning Light CheckS7RS0B5104004

1) Turn ignition switch ON.

2) Check that transmission warning light lights for about 2 – 4 sec. and then goes OFF.

If anything faulty is found, advance “Transmission Warn ing Light Circuit Check – Light Does Not Come “ON” at

Ignition Switch ON” or “Transmission Warning Light Circu it Check – Light Remains “ON” at Ignition Switch ON”.

Inspection item Referring

• A/T fluid ----- level, leakage, color “Automatic Transaxle Fluid Level Inspection in Section 0B”

• A/T fluid hoses ----- disconnection, looseness, deterioration “A/T Fluid Cooler Hoses Replacement”

• A/T select cable ----- installation “S elect Cable Removal and Installation”

• Engine oil ----- level, leakage “Engine Oil and Filter Change in Section 0B”

• Engine coolant ----- level, leakage “Engine Coolant Change in Section 0B”

• Engine mountings ----- play, looseness, damage “Engine Assembly Removal and Installation in Section 1D”

• Suspension ----- play, looseness “Suspension, Wheels and Tires Symptom Diagnosis in Section 2A”

• Drive shafts ----- damage “Front Drive Shaft Assembly On-Vehicle Inspection in Section 3A”

• Battery ----- indicator condition, corrosion of terminal “Battery Inspection in Section 1J”

• Connectors of electric wire harness ----- disconnection, friction “Electronic Shift Control System Components

Location”

• Fuses ----- burning

• Parts ----- installation, damage

• Bolts ----- looseness

• Other parts that can be checked visually

Also check the following items at engine start, if possible.

• Transmission warning light (if equipped) ----- Operation “Transmission Warning Light Check”

• Malfunction indicator lamp ----- Operation “Malfunction Indicator Lamp (MIL) Check”

• Charge warning lamp ----- Operation “Generator Symptom Diagnosis in Section 1J”

• Engine oil pressure warning lamp ----- Operation “Oil Pressure Warning Ligh t Symptom Diagnosis in

Section 9C”

• Engine coolant temp. meter ----- Operation “Engine Coolant Temperature (ECT) Meter

Symptom Diagnosis in Section 9C”

• Other parts that can be checked visually

I4RS0A510008-01

Page 741 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-97

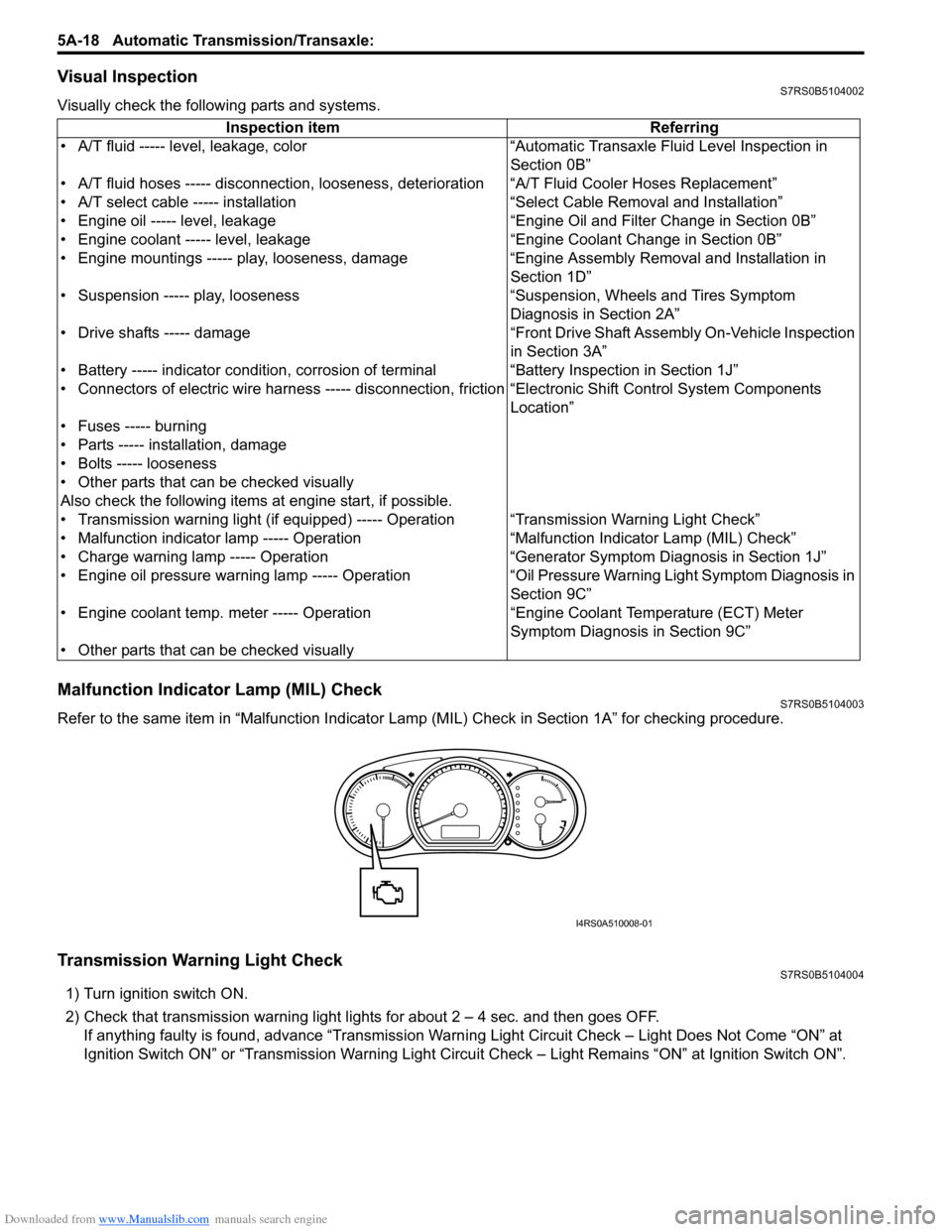

Installation1) Apply A/T fluid to input shaft speed sensor O-ring.

2) Install input shaft speed se nsor (1) to A/T case and

tighten bolt to specified torque.

Tightening torque

Input shaft speed sensor bolt (a): 5.5 N·m (0.55

kgf-m, 4.0 lb-ft)

3) Connect input shaft speed sensor connector (2) to input shaft speed sensor (1).

4) Connect negative cable to battery.

Input Shaft Speed Sensor InspectionS7RS0B5106019

1) Disconnect negative cable at battery.

2) Disconnect input shaft speed sensor connector (2).

3) Check resistance between input shaft speed sensor (1) terminals.

Input shaft speed sensor resistance

Standard: 560 – 680 Ω at 20 °C (68 °F)

Transmission Fluid Temperature Sensor

Removal and Installation

S7RS0B5106020

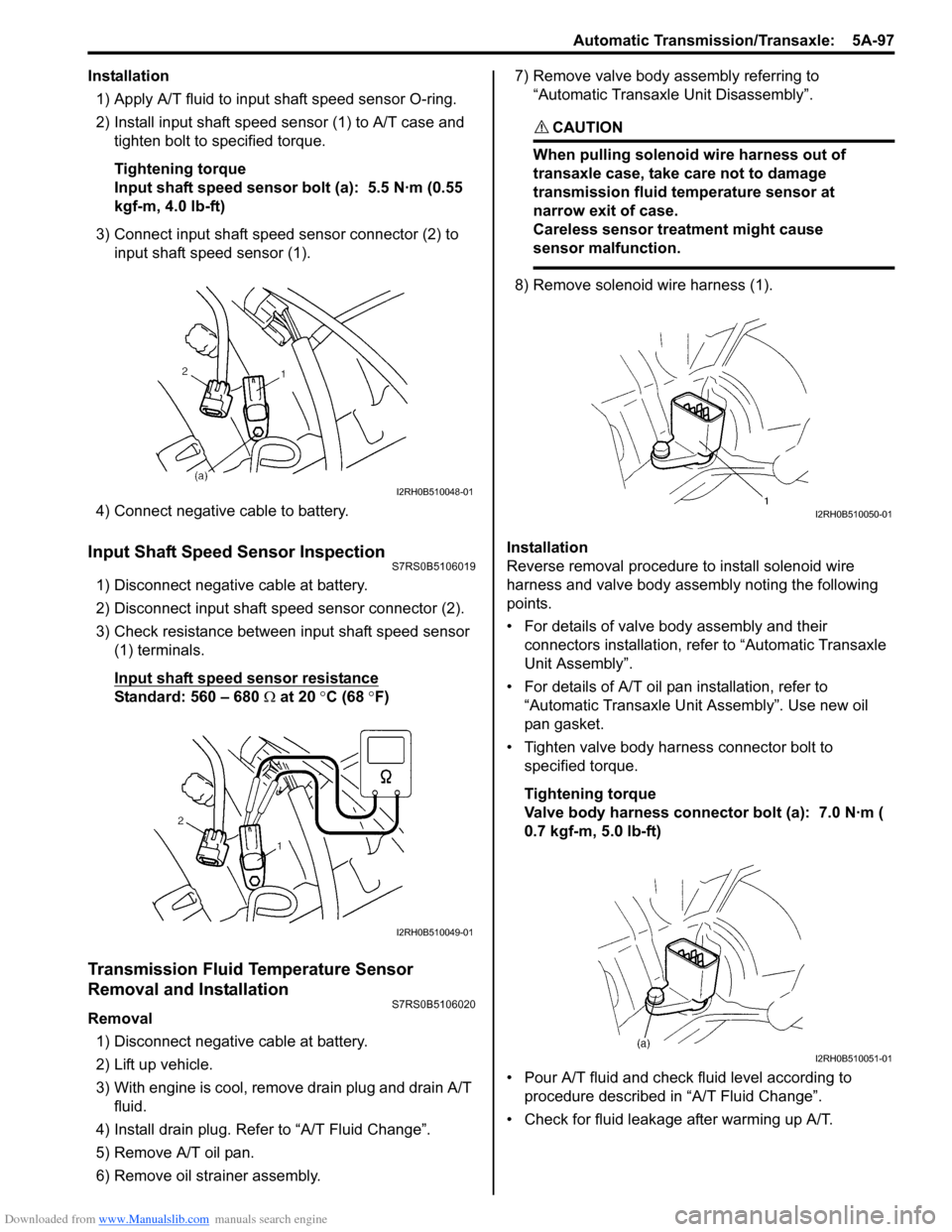

Removal

1) Disconnect negative cable at battery.

2) Lift up vehicle.

3) With engine is cool, remove drain plug and drain A/T fluid.

4) Install drain plug. Refer to “A/T Fluid Change”.

5) Remove A/T oil pan.

6) Remove oil stra iner assembly. 7) Remove valve body assembly referring to

“Automatic Transaxl e Unit Disassembly”.

CAUTION!

When pulling solenoid wire harness out of

transaxle case, take care not to damage

transmission fluid temperature sensor at

narrow exit of case.

Careless sensor treatment might cause

sensor malfunction.

8) Remove solenoid wire harness (1).

Installation

Reverse removal procedure to install solenoid wire

harness and valve body assembly noting the following

points.

• For details of valve body assembly and their connectors installation, refer to “Automatic Transaxle

Unit Assembly”.

• For details of A/T oil pa n installation, refer to

“Automatic Transaxle Unit Assembly”. Use new oil

pan gasket.

• Tighten valve body harness connector bolt to specified torque.

Tightening torque

Valve body harness connector bolt (a): 7.0 N·m (

0.7 kgf-m, 5.0 lb-ft)

• Pour A/T fluid and check fluid level according to procedure described in “A/T Fluid Change”.

• Check for fluid leakage after warming up A/T.

I2RH0B510048-01

I2RH0B510049-01

I2RH0B510050-01

I2RH0B510051-01

Page 745 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-101

Pressure Control Solenoid Valves (Pressure

Control Solenoid and TCC Pressure Control

Solenoid) Removal and Installation

S7RS0B5106024

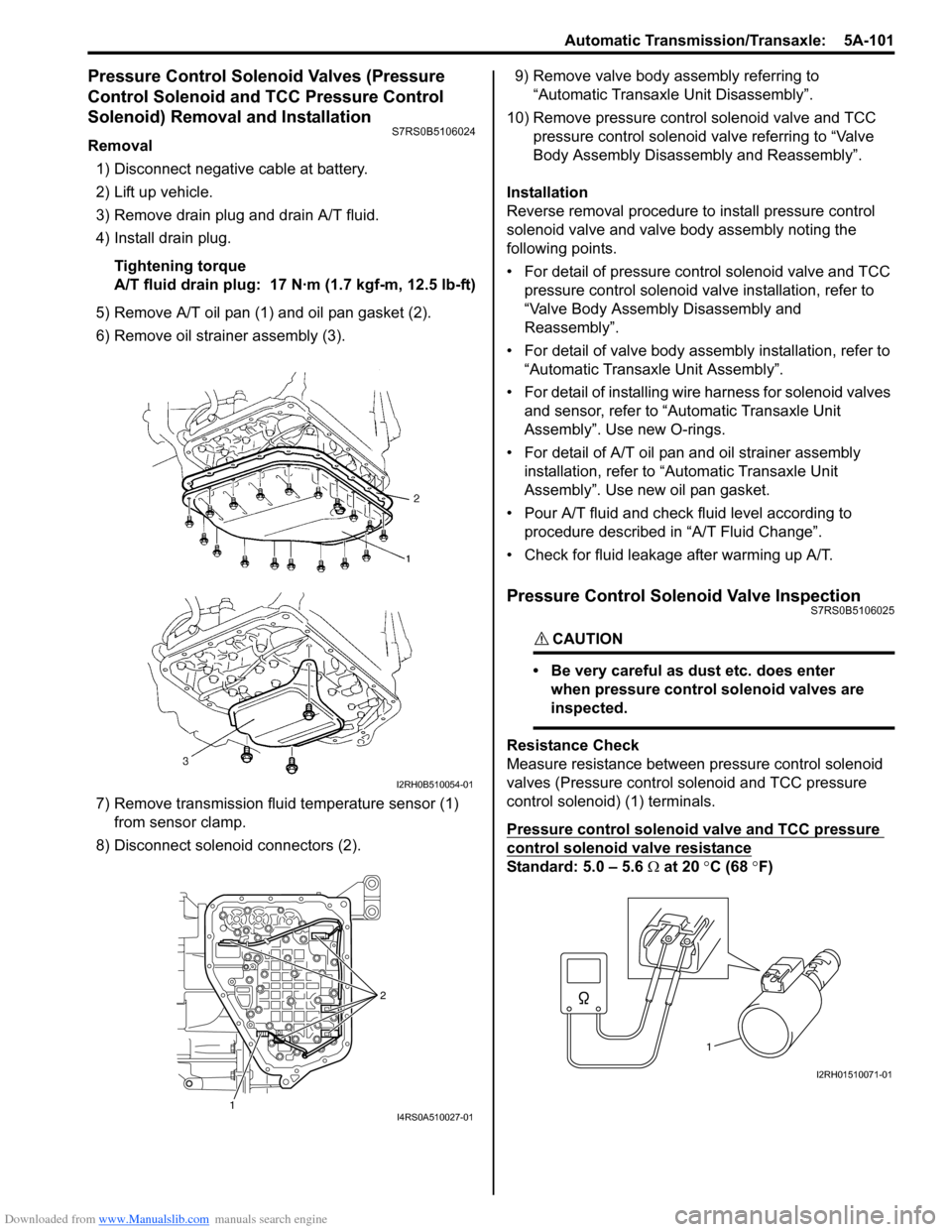

Removal1) Disconnect negative cable at battery.

2) Lift up vehicle.

3) Remove drain plug and drain A/T fluid.

4) Install drain plug.

Tightening torque

A/T fluid drain plug: 17 N·m (1.7 kgf-m, 12.5 lb-ft)

5) Remove A/T oil pan (1) and oil pan gasket (2).

6) Remove oil strain er assembly (3).

7) Remove transmission fluid temperature sensor (1) from sensor clamp.

8) Disconnect solenoid connectors (2). 9) Remove valve body assembly referring to

“Automatic Transaxl e Unit Disassembly”.

10) Remove pressure control solenoid valve and TCC pressure control solenoid valve referring to “Valve

Body Assembly Disassembly and Reassembly”.

Installation

Reverse removal procedure to install pressure control

solenoid valve and valve body assembly noting the

following points.

• For detail of pressure control solenoid valve and TCC pressure control solenoid va lve installation, refer to

“Valve Body Assembly Disassembly and

Reassembly”.

• For detail of valve body asse mbly installation, refer to

“Automatic Transaxle Unit Assembly”.

• For detail of installing wire harness for solenoid valves and sensor, refer to “Automatic Transaxle Unit

Assembly”. Use new O-rings.

• For detail of A/T oil pan and oil strainer assembly

installation, refer to “A utomatic Transaxle Unit

Assembly”. Use new oil pan gasket.

• Pour A/T fluid and check fluid level according to procedure described in “A/T Fluid Change”.

• Check for fluid leakage after warming up A/T.

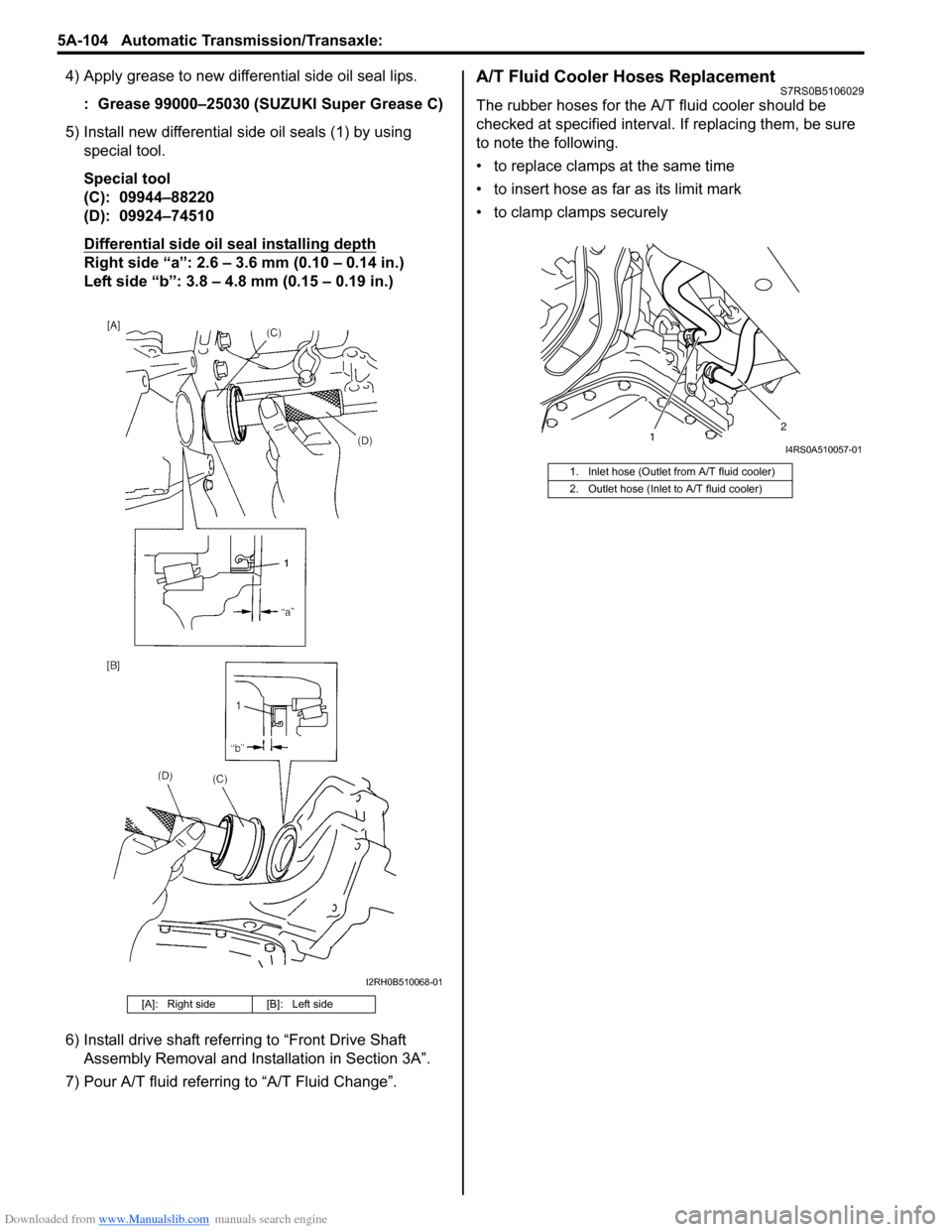

Pressure Control Solenoid Valve InspectionS7RS0B5106025

CAUTION!

• Be very careful as dust etc. does enter when pressure control solenoid valves are

inspected.

Resistance Check

Measure resistance between pressure control solenoid

valves (Pressure control solenoid and TCC pressure

control solenoid) (1) terminals.

Pressure control solenoid valve and TCC pressure

control solenoid valve resistance

Standard: 5.0 – 5.6 Ω at 20 °C (68 °F)

I2RH0B510054-01

1 2I4RS0A510027-01

1

I2RH01510071-01

Page 748 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-104 Automatic Transmission/Transaxle:

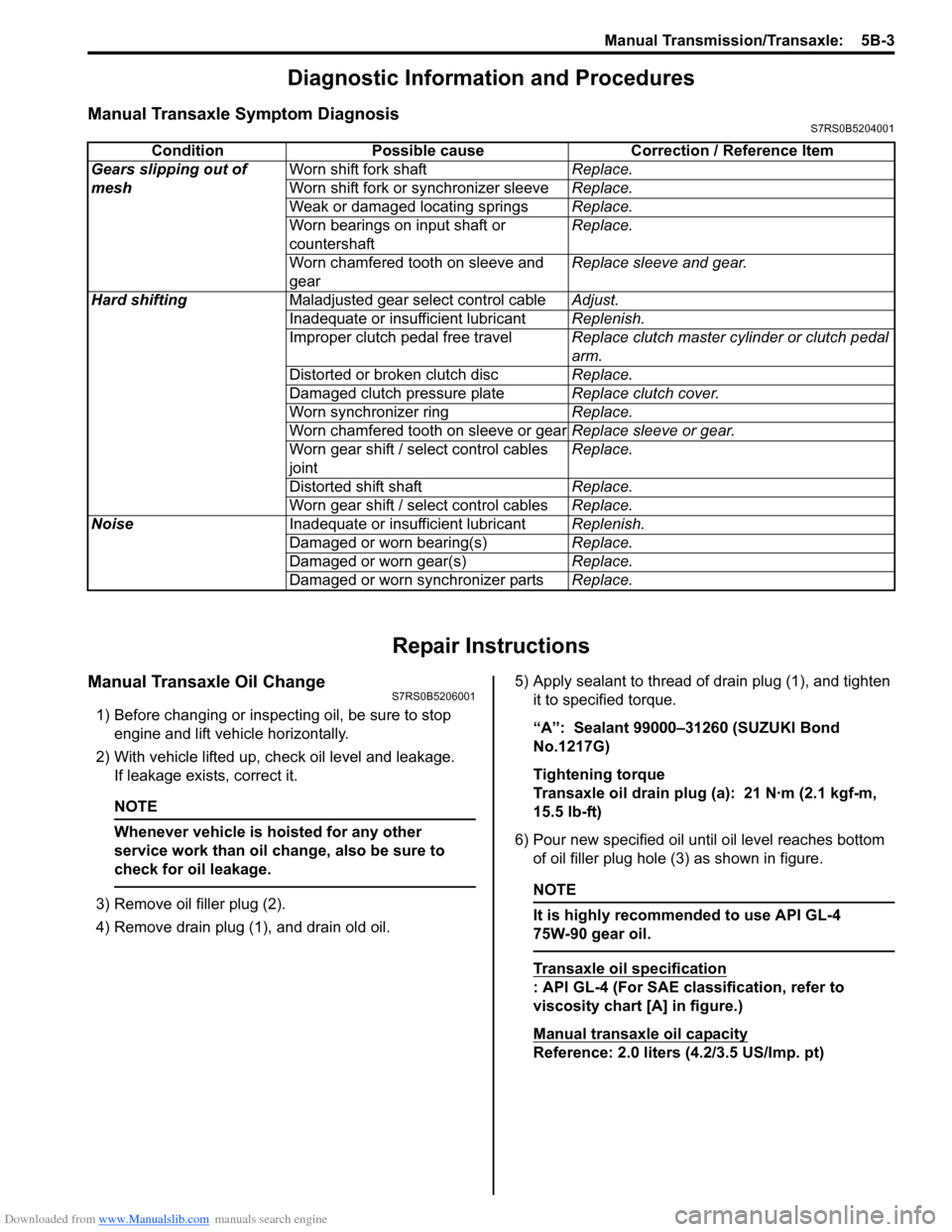

4) Apply grease to new differential side oil seal lips.: Grease 99000–25030 (SUZUKI Super Grease C)

5) Install new differential side oil seals (1) by using special tool.

Special tool

(C): 09944–88220

(D): 09924–74510

Differential side oil seal installing depth

Right side “a”: 2.6 – 3.6 mm (0.10 – 0.14 in.)

Left side “b”: 3.8 – 4.8 mm (0.15 – 0.19 in.)

6) Install drive shaft referring to “Front Drive Shaft Assembly Removal and Installation in Section 3A”.

7) Pour A/T fluid referring to “A/T Fluid Change”.

A/T Fluid Cooler Hoses ReplacementS7RS0B5106029

The rubber hoses for the A/T fluid cooler should be

checked at specified interval. If replacing them, be sure

to note the following.

• to replace clamps at the same time

• to insert hose as far as its limit mark

• to clamp clamps securely

[A]: Right side [B]: Left side

I2RH0B510068-01

1. Inlet hose (Outlet from A/T fluid cooler)

2. Outlet hose (Inlet to A/T fluid cooler)

1 2I4RS0A510057-01

Page 817 of 1496

Downloaded from www.Manualslib.com manuals search engine Manual Transmission/Transaxle: 5B-3

Diagnostic Information and Procedures

Manual Transaxle Symptom DiagnosisS7RS0B5204001

Repair Instructions

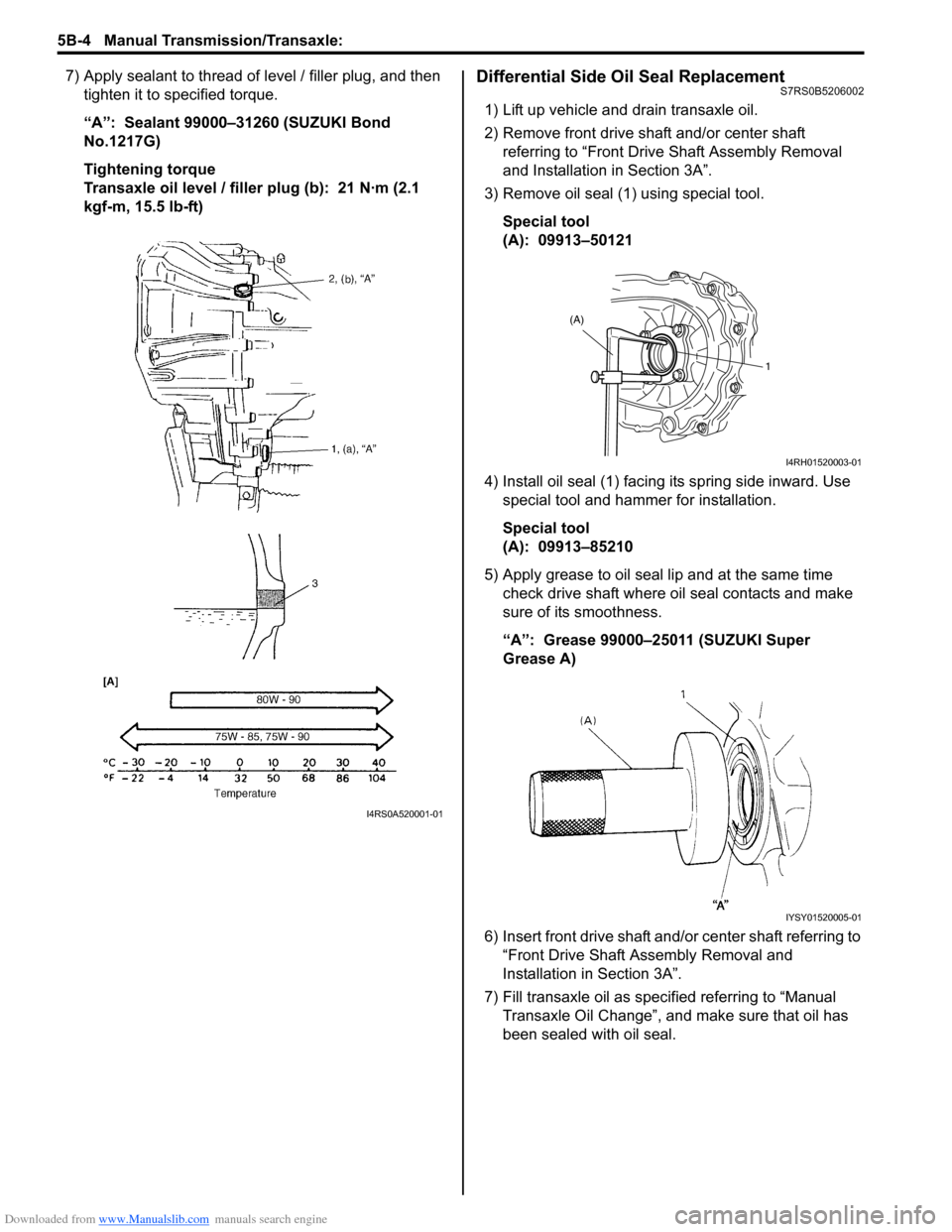

Manual Transaxle Oil ChangeS7RS0B5206001

1) Before changing or inspecting oil, be sure to stop engine and lift vehicle horizontally.

2) With vehicle lifted up, check oil level and leakage. If leakage exists, correct it.

NOTE

Whenever vehicle is hoisted for any other

service work than oil change, also be sure to

check for oil leakage.

3) Remove oil filler plug (2).

4) Remove drain plug (1), and drain old oil. 5) Apply sealant to thread of drain plug (1), and tighten

it to specified torque.

“A”: Sealant 99000–31260 (SUZUKI Bond

No.1217G)

Tightening torque

Transaxle oil drain plug (a): 21 N·m (2.1 kgf-m,

15.5 lb-ft)

6) Pour new specified oil unt il oil level reaches bottom

of oil filler plug hole (3) as shown in figure.NOTE

It is highly recommended to use API GL-4

75W-90 gear oil.

Transaxle oil specification

: API GL-4 (For SAE classification, refer to

viscosity chart [A] in figure.)

Manual transaxle oil capacity

Reference: 2.0 liters (4.2/3.5 US/Imp. pt)

Condition Possible cause Correction / Reference Item

Gears slipping out of

mesh Worn shift fork shaft

Replace.

Worn shift fork or synchronizer sleeve Replace.

Weak or damaged locating springs Replace.

Worn bearings on input shaft or

countershaft Replace.

Worn chamfered tooth on sleeve and

gear Replace sleeve and gear.

Hard shifting Maladjusted gear select control cable Adjust.

Inadequate or insufficient lubricant Replenish.

Improper clutch pedal free travel Replace clutch master cylinder or clutch pedal

arm.

Distorted or broken clutch disc Replace.

Damaged clutch pressure plate Replace clutch cover.

Worn synchronizer ring Replace.

Worn chamfered tooth on sleeve or gear Replace sleeve or gear.

Worn gear shift / select control cables

joint Replace.

Distorted shift shaft Replace.

Worn gear shift / select control cables Replace.

Noise Inadequate or insufficient lubricant Replenish.

Damaged or worn bearing(s) Replace.

Damaged or worn gear(s) Replace.

Damaged or worn synchronizer parts Replace.

Page 818 of 1496

Downloaded from www.Manualslib.com manuals search engine 5B-4 Manual Transmission/Transaxle:

7) Apply sealant to thread of level / filler plug, and then

tighten it to specified torque.

“A”: Sealant 99000–31260 (SUZUKI Bond

No.1217G)

Tightening torque

Transaxle oil level / filler plug (b): 21 N·m (2.1

kgf-m, 15.5 lb-ft)Differential Side Oil Seal ReplacementS7RS0B5206002

1) Lift up vehicle and drain transaxle oil.

2) Remove front drive shaft and/or center shaft referring to “Front Driv e Shaft Assembly Removal

and Installation in Section 3A”.

3) Remove oil seal (1) using special tool.

Special tool

(A): 09913–50121

4) Install oil seal (1) facing its spring side inward. Use special tool and hammer for installation.

Special tool

(A): 09913–85210

5) Apply grease to oil seal lip and at the same time check drive shaft where oil seal contacts and make

sure of its smoothness.

“A”: Grease 99000–25011 (SUZUKI Super

Grease A)

6) Insert front drive shaft and/or center shaft referring to “Front Drive Shaft A ssembly Removal and

Installation in Section 3A”.

7) Fill transaxle oil as specified referring to “Manual Transaxle Oil Change”, and make sure that oil has

been sealed with oil seal.

I4RS0A520001-01

(A)

1

I4RH01520003-01

IYSY01520005-01

Page 824 of 1496

Downloaded from www.Manualslib.com manuals search engine 5B-10 Manual Transmission/Transaxle:

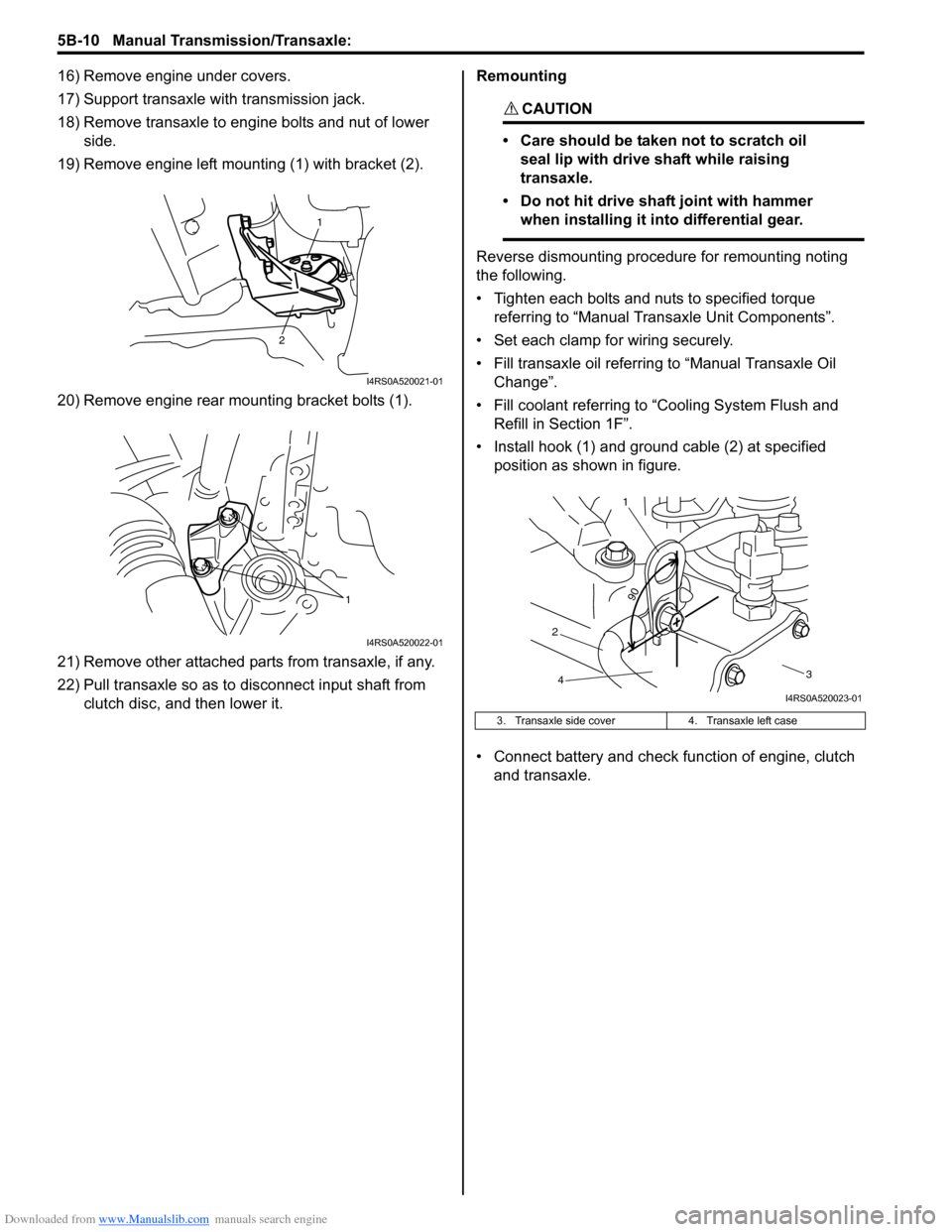

16) Remove engine under covers.

17) Support transaxle with transmission jack.

18) Remove transaxle to engine bolts and nut of lower side.

19) Remove engine left mounting (1) with bracket (2).

20) Remove engine rear mounting bracket bolts (1).

21) Remove other attached parts from transaxle, if any.

22) Pull transaxle so as to disconnect input shaft from clutch disc, and then lower it. Remounting

CAUTION!

• Care should be taken not to scratch oil

seal lip with drive shaft while raising

transaxle.

• Do not hit drive shaft joint with hammer when installing it into differential gear.

Reverse dismounting procedure for remounting noting

the following.

• Tighten each bolts and nuts to specified torque referring to “Manual Transaxle Unit Components”.

• Set each clamp for wiring securely.

• Fill transaxle oil referring to “Manual Transaxle Oil

Change”.

• Fill coolant referring to “Cooling System Flush and

Refill in Section 1F”.

• Install hook (1) and ground cable (2) at specified position as shown in figure.

• Connect battery and check function of engine, clutch

and transaxle.

1

2

I4RS0A520021-01

1

I4RS0A520022-01

3. Transaxle side cover 4. Transaxle left case

90

1

2 3

4

I4RS0A520023-01