air cond SUZUKI SWIFT 2005 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 911 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-29

DTC TroubleshootingStep Action Yes No 1 Was “EPS System Check” performed? Go to Step 2. Go to “EPS System

Check”.

2 DTC check

1) Clear DTC(s) referring to “DTC Clearance”.

2) Run engine at idle speed.

3) Check if any DTC is detecte d referring to “DTC Check”.

Is DTC C1122 still detected? Go to Step 3. Check intermittent

trouble referring to

“Intermittent and Poor

Connection Inspection

in Section 00”.

3 DTC check

1) Check ECM for DTC referring to “DTC Check in Section

1A”.

Is there any DTC related to engine speed? Go to applicable DTC

diag. flow.

Go to Step 4.

4 Engine speed signal circuit check

1) With ignition switch turned OFF, disconnect P/S control

module connector.

2) Check P/S control module connector for proper connection.

3) If OK, turn ON ignition switch, measure voltage between “E52-12” wire terminal of P/S control module connector

and vehicle body ground.

Is voltage 10 – 14 V? Go to Step 6.

Go to Step 5.

5 1) With ignition switch turned OFF, disconnect ECM connector.

2) Check for proper connection to the P/S control module and ECM at each “Engine speed signal circuit” terminal.

3) If connections are OK, chec k that “Engine speed signal

circuit” is as following.

• Insulation resistance of “Engine speed signal circuit” wire is infinity between its terminal and other terminals

at ECM and P/S control module connector.

• Wiring resistance of “Engine speed signal circuit” terminal are less than 1 Ω.

• Insulation resistance of “Engine speed signal circuit” between its terminal and vehicle body ground is

infinity.

• Circuit voltage between “Engine speed signal circuit” and ground circuit is 0 – 1 V with ignition switch turned

ON.

Is circuit in good condition? Go to Step 6.

Repair engine speed

signal circuit.

6 ECM voltage check

1) Connect P/S control mo dule and ECM connectors.

2) Check ECM for engine speed signal and vehicle speed signal output voltage to P/S control module referring to

“Inspection of ECM and Its Circuits in Section 1A”.

Is check result in good condition? Substitute a known-

good P/S control

module and recheck.

Substitute a known-

good ECM and recheck.

Page 913 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-31

DTC Detecting Condition and Trouble Area

DTC TroubleshootingDTC detecting condition Trouble area

DTC C1141:

Voltage between both motor drive circuits is more than 8.5

V or less than 0.2 V for 0.5 seconds continuously while

motor is not drived

(1 driving cycle detection logic)

DTC C1142:

Measured motor drive current is more than 10 A as

compared with target motor drive current.

(1 driving cycle detection logic)

DTC C1143:

Measured motor drive current is more than 50 A.

(1 driving cycle detection logic)

DTC C1145:

Measured motor drive current is less than 2 A

continuously for more than 3 seconds even though target

motor drive current is more than 4 A.

or

Measured motor drive current is less than 0.8 A for total 1

second even though motor cont rol duty is more than 90%

while target motor drive current is less than 8 A.

(1 driving cycle detection logic) • P/S motor circuit

• P/S motor

• P/S control module

Step

Action YesNo

1 Was “EPS System Check” performed? Go to Step 2.Go to “EPS System

Check”.

2 DTC check

Is DTC C1153 and/or DTC C1155 indicated together? Go to applicable DTC

diag. flow.

Go to Step 3.

3 Power supply and ground circuit check

1) Check P/S control module power supply and ground

circuit referring to “P/S Control Module Power Supply

and Ground Circuit Check”.

Is it in good condition? Go to Step 4.

Repair or replace

defective circuit.

4 Motor circuit check

1) With ignition switch tuned OFF, disconnect P/S motor

connector (“E51”).

2) Check that P/S motor circuit is as follows. • Insulation resistance of wire harness is infinity between each “P/S motor circuit” terminal and other

terminal at P/S motor connector.

• Wiring harness resistance of each “P/S motor circuit”

is less than 1 Ω.

• Insulation resistance between each “P/S motor circuit” and vehicle body ground is infinity.

• Circuit voltage between each “P/S motor circuit” and ground circuit is 0 – 1 V with ignition switch turned

ON.

Is circuit in good condition? Go to Step 5.

Repair or replace

defective circuit.

5 P/S motor check

1) Check motor and its circuit referring to “P/S Motor and Its

Circuit Inspection”.

Is motor in good condition? Substitute a known-

good P/S control

module, and recheck.

Replace the steering

gear case assembly.

Page 914 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-32 Power Assisted Steering System:

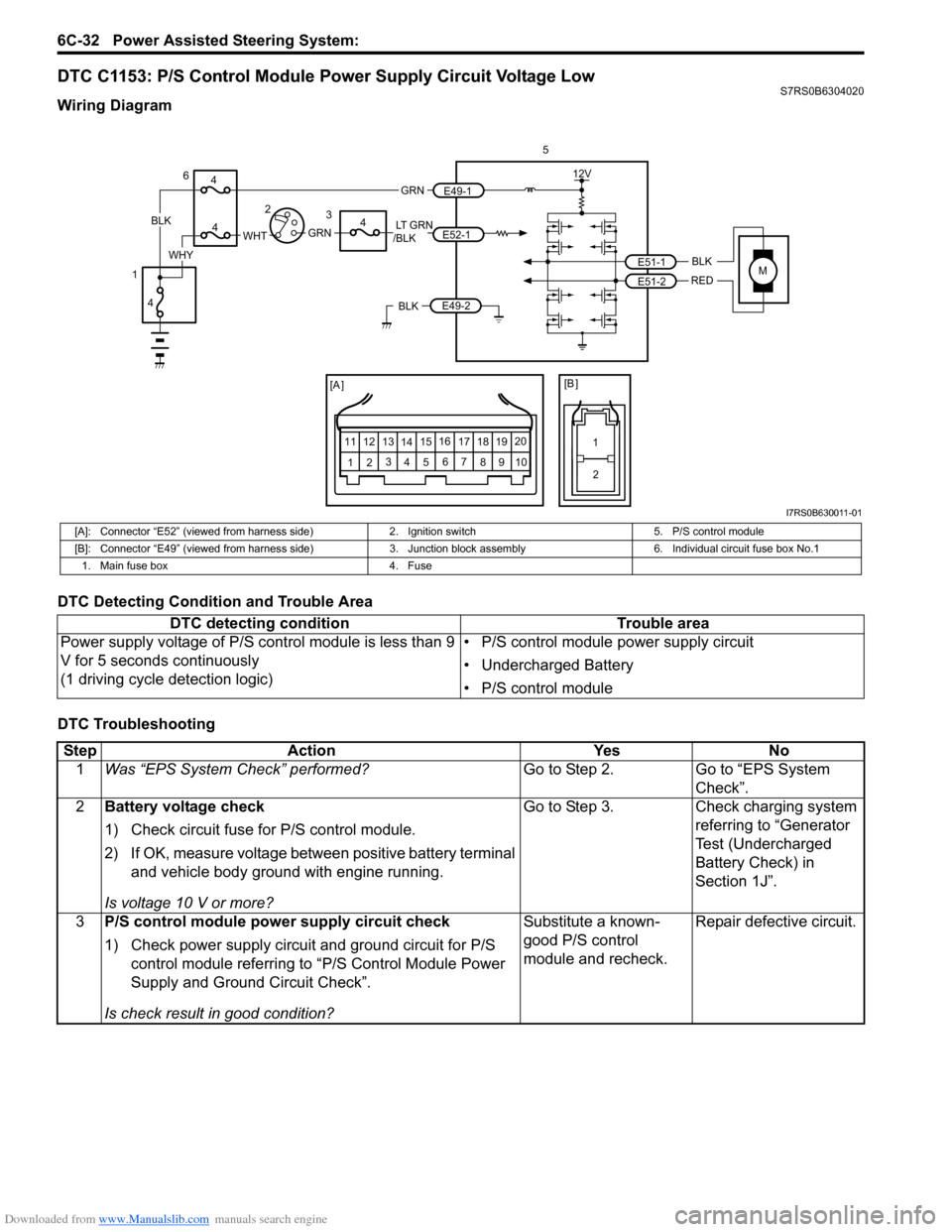

DTC C1153: P/S Control Module Power Supply Circuit Voltage LowS7RS0B6304020

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

MBLK

REDE51-1

E51-2

12V

5

[A ]

12 3

4 5 67

89

11

10

12 13

141516

17 18 19 20

[B ]

1

2

LT GRN

/BLKE52-1 E49-1

GRNGRNWHTBLK

WHY

6

3

4

4

4

4

1 2

E49-2BLK

I7RS0B630011-01

[A]: Connector “E52” (viewed from harness side)

2. Ignition switch5. P/S control module

[B]: Connector “E49” (viewed from harness side) 3. Junction block assembly 6. Individual circuit fuse box No.1

1. Main fuse box 4. Fuse

DTC detecting condition Trouble area

Power supply voltage of P/S control module is less than 9

V for 5 seconds continuously

(1 driving cycle detection logic) • P/S control module power supply circuit

• Undercharged Battery

• P/S control module

Step

Action YesNo

1 Was “EPS System Check” performed? Go to Step 2.Go to “EPS System

Check”.

2 Battery voltage check

1) Check circuit fuse for P/S control module.

2) If OK, measure voltage between positive battery terminal

and vehicle body ground with engine running.

Is voltage 10 V or more? Go to Step 3.

Check charging system

referring to “Generator

Test (Undercharged

Battery Check) in

Section 1J”.

3 P/S control module power supply circuit check

1) Check power supply circuit and ground circuit for P/S

control module referring to “P/S Control Module Power

Supply and Ground Circuit Check”.

Is check result in good condition? Substitute a known-

good P/S control

module and recheck.

Repair defective circuit.

Page 915 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-33

DTC C1155: P/S Control Module FailureS7RS0B6304021

Wiring Diagram

Refer to “DTC C1153: P/S Control Module Power Supply Circuit Voltage Low”.

DTC Detecting Condition and Trouble Area

DTC Troubleshooting DTC detecting condition Trouble area

Internal memory (EEPROM) is data error.

(In this case, MIL does not light up)

or

Internal circuit is faulty.

or

Power supply voltage of P/S control module exceeded

17.5 V.

(1 driving cycle detection logic) • Overcharged Battery

• P/S control module

Step

Action YesNo

1 Was “EPS System Check” performed? Go to Step 2.Go to “EPS System

Check”.

2 P/S control module power supply and ground circuit

check

Check power supply circuit and ground circuit for P/S control

module referring to “P/S Control Module Power Supply and

Ground Circuit Check”.

Is check result in good condition? Go to Step 3.

Repair or replace

defective circuit.

3 Battery voltage check

1) Check voltage between positive (+) battery terminal and

vehicle body ground with engine speed at 3000 rpm.

Is voltage 15.5 V or less? Replace P/S control

module.

Check charging system

referring to “Generator

Test (Overcharged

Battery Check) in

Section 1J”.

Page 921 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-39

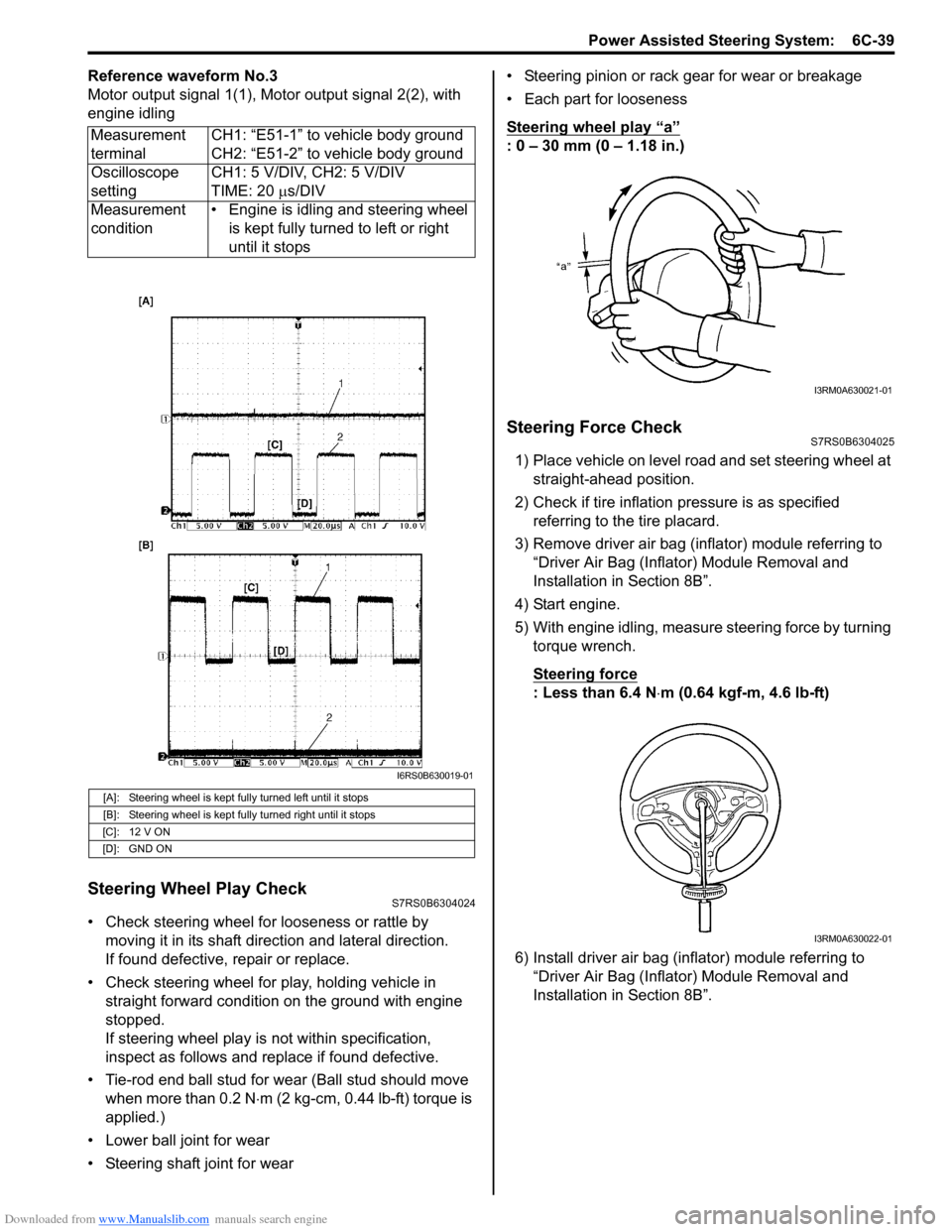

Reference waveform No.3

Motor output signal 1(1), Motor output signal 2(2), with

engine idling

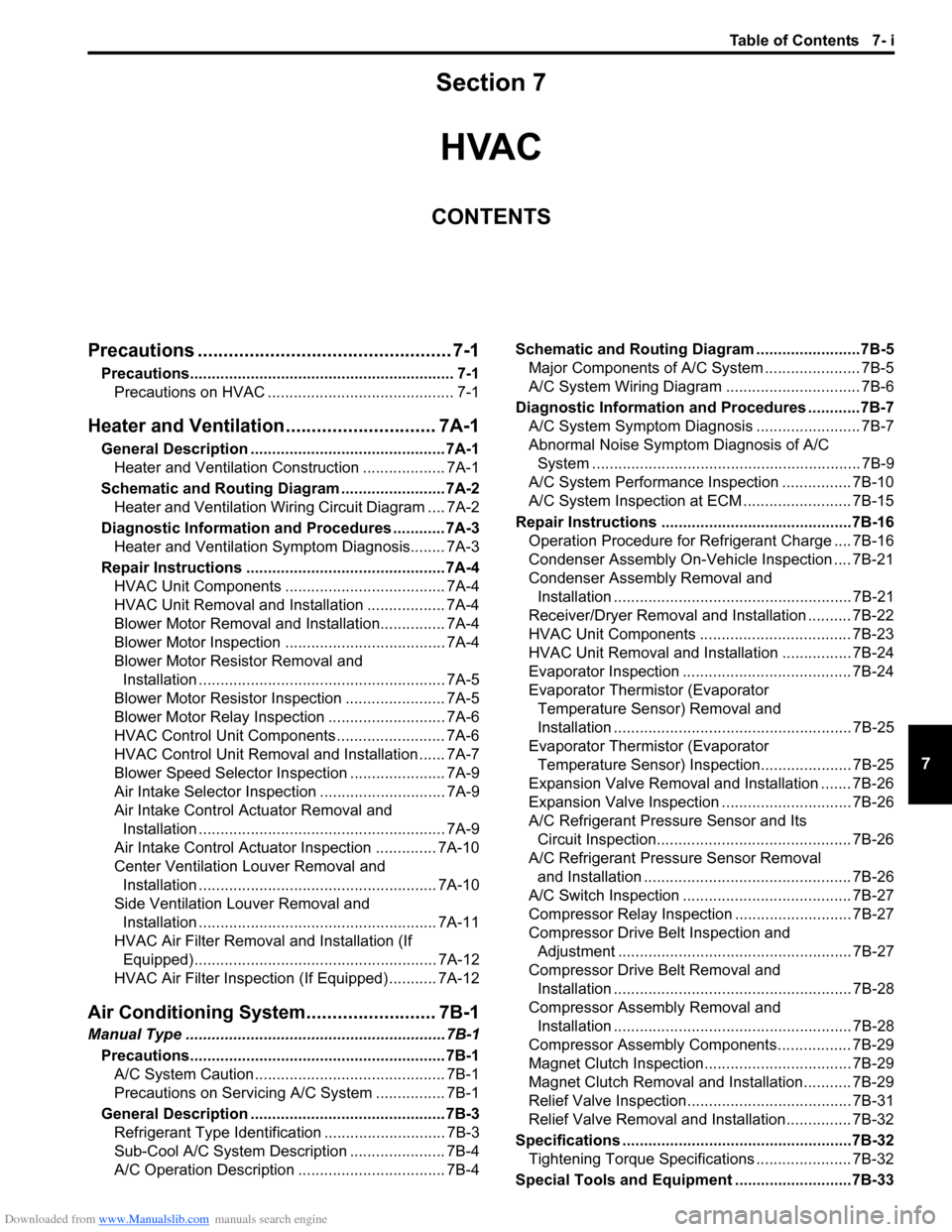

Steering Wheel Play CheckS7RS0B6304024

• Check steering wheel for looseness or rattle by moving it in its shaft direction and lateral direction.

If found defective, repair or replace.

• Check steering wheel for play, holding vehicle in straight forward condition on the ground with engine

stopped.

If steering wheel play is not within specification,

inspect as follows and replace if found defective.

• Tie-rod end ball stud for wear (Ball stud should move when more than 0.2 N ⋅m (2 kg-cm, 0.44 lb-ft) torque is

applied.)

• Lower ball joint for wear

• Steering shaft joint for wear • Steering pinion or rack gear for wear or breakage

• Each part for looseness

Steering wheel play

“a”

: 0 – 30 mm (0 – 1.18 in.)

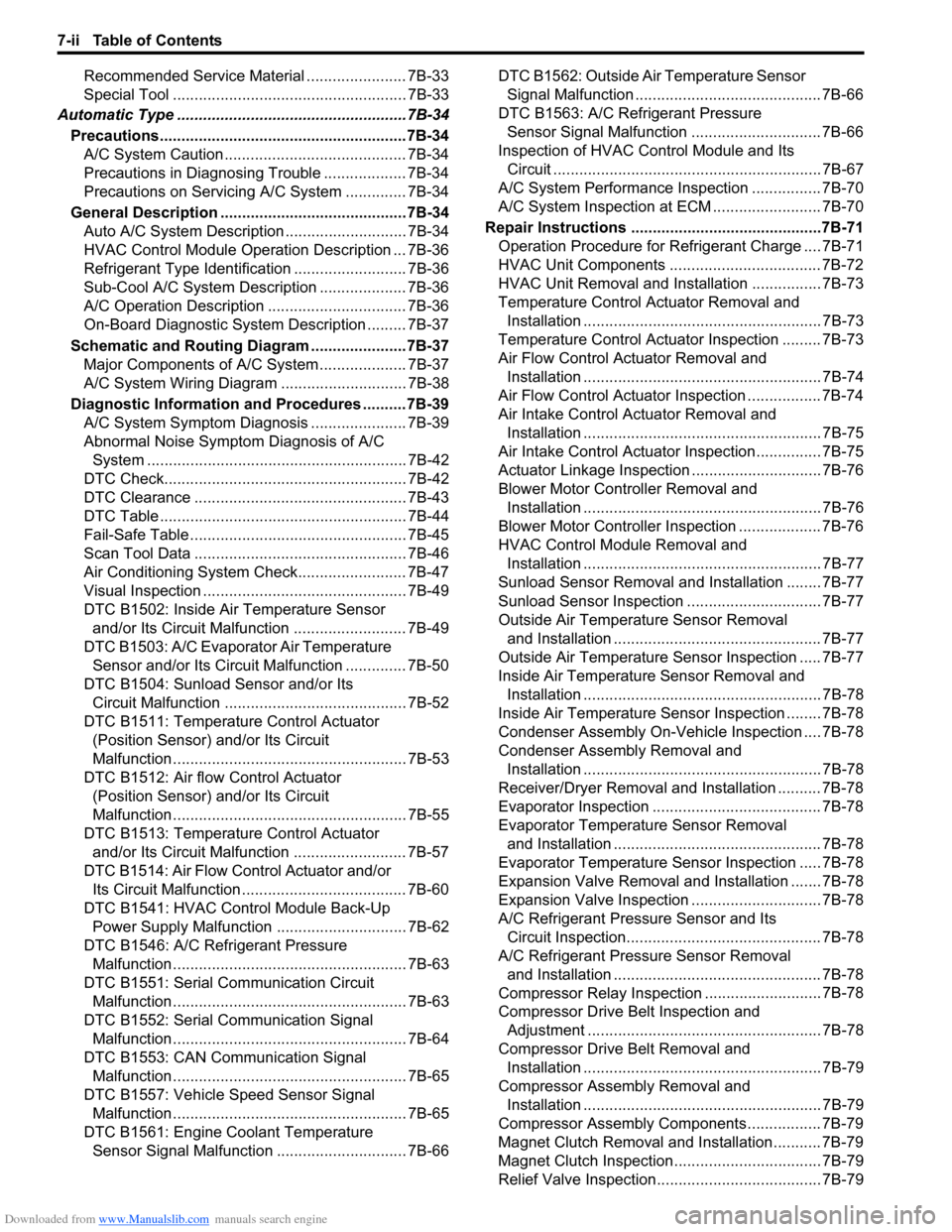

Steering Force CheckS7RS0B6304025

1) Place vehicle on level road and set steering wheel at

straight-ahead position.

2) Check if tire inflation pressure is as specified referring to the tire placard.

3) Remove driver air bag (inflator) module referring to “Driver Air Bag (Inflator) Module Removal and

Installation in Section 8B”.

4) Start engine.

5) With engine idling, measure steering force by turning torque wrench.

Steering force

: Less than 6.4 N ⋅m (0.64 kgf-m, 4.6 lb-ft)

6) Install driver air bag (inflator) module referring to “Driver Air Bag (Inflator) Module Removal and

Installation in Section 8B”.

Measurement

terminal

CH1: “E51-1” to vehicle body ground

CH2: “E51-2” to vehicle body ground

Oscilloscope

setting CH1: 5 V/DIV, CH2: 5 V/DIV

TIME: 20

µs/DIV

Measurement

condition • Engine is idling and steering wheel

is kept fully turned to left or right

until it stops

[A]: Steering wheel is kept fully turned left until it stops

[B]: Steering wheel is kept fully turned right until it stops

[C]: 12 V ON

[D]: GND ON

I6RS0B630019-01

I3RM0A630021-01

I3RM0A630022-01

Page 933 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 7- i

7

Section 7

CONTENTS

HVAC

Precautions ................................................. 7-1

Precautions............................................................. 7-1

Precautions on HVAC ........................................... 7-1

Heater and Ventilation.... ......................... 7A-1

General Description ............................................. 7A-1

Heater and Ventilation Construction ................... 7A-1

Schematic and Routing Diagram ........................ 7A-2 Heater and Ventilation Wiring Circuit Diagram .... 7A-2

Diagnostic Information and Procedures ............ 7A-3 Heater and Ventilation Symptom Diagnosis........ 7A-3

Repair Instructions .............................................. 7A-4 HVAC Unit Components ..................................... 7A-4

HVAC Unit Removal and Installation .................. 7A-4

Blower Motor Removal and Installation............... 7A-4

Blower Motor Inspection ..................................... 7A-4

Blower Motor Resistor Removal and Installation ......................................................... 7A-5

Blower Motor Resistor Inspection ....................... 7A-5

Blower Motor Relay Inspection ........................... 7A-6

HVAC Control Unit Components ......................... 7A-6

HVAC Control Unit Remova l and Installation ...... 7A-7

Blower Speed Selector In spection ...................... 7A-9

Air Intake Selector Inspec tion ............................. 7A-9

Air Intake Control Actuator Removal and Installation ......................................................... 7A-9

Air Intake Control Actuator Inspection .............. 7A-10

Center Ventilation Louver Removal and Installation ....................................................... 7A-10

Side Ventilation Louver Removal and Installation ....................................................... 7A-11

HVAC Air Filter Removal and Installation (If Equipped)........................................................ 7A-12

HVAC Air Filter Inspection (If Equipped) ........... 7A-12

Air Conditioning System... ...................... 7B-1

Manual Type ............................................................ 7B-1

Precautions........................................................... 7B-1A/C System Caution ............................................ 7B-1

Precautions on Servicing A/C System ................ 7B-1

General Description ............................................. 7B-3 Refrigerant Type Identifica tion ............................ 7B-3

Sub-Cool A/C System Description ...................... 7B-4

A/C Operation Description .................................. 7B-4 Schematic and Routing Diagram ........................7B-5

Major Components of A/C System ...................... 7B-5

A/C System Wiring Diagram ............................... 7B-6

Diagnostic Information and Procedures ............7B-7 A/C System Symptom Diagnosis ........................ 7B-7

Abnormal Noise Sympto m Diagnosis of A/C

System .............................................................. 7B-9

A/C System Performance Inspection ................ 7B-10

A/C System Inspection at ECM ......................... 7B-15

Repair Instructions ........... .................................7B-16

Operation Procedure for Re frigerant Charge .... 7B-16

Condenser Assembly On-Vehicle Inspection .... 7B-21

Condenser Assembly Removal and Installation ....................................................... 7B-21

Receiver/Dryer Removal and Installation .......... 7B-22

HVAC Unit Components ................................... 7B-23

HVAC Unit Removal and In stallation ................ 7B-24

Evaporator Inspection ....................................... 7B-24

Evaporator Thermistor (Evaporator Temperature Sensor) Removal and

Installation ....................................................... 7B-25

Evaporator Thermistor (Evaporator Temperature Sensor) Inspec tion..................... 7B-25

Expansion Valve Removal and Installation ....... 7B-26

Expansion Valve Inspection .............................. 7B-26

A/C Refrigerant Pressure Sensor and Its Circuit Inspection............................................. 7B-26

A/C Refrigerant Pressu re Sensor Removal

and Installation ................................................ 7B-26

A/C Switch Inspection ....................................... 7B-27

Compressor Relay Inspection ........................... 7B-27

Compressor Drive Belt Inspection and Adjustment ...................................................... 7B-27

Compressor Drive Belt Removal and Installation ....................................................... 7B-28

Compressor Assembly Removal and Installation ....................................................... 7B-28

Compressor Assembly Components................. 7B-29

Magnet Clutch Inspection.................................. 7B-29

Magnet Clutch Removal and Installation........... 7B-29

Relief Valve Inspection...................................... 7B-31

Relief Valve Removal and Installation............... 7B-32

Specifications .................... .................................7B-32

Tightening Torque Specifications ...................... 7B-32

Special Tools and Equipmen t ...........................7B-33

Page 934 of 1496

Downloaded from www.Manualslib.com manuals search engine 7-ii Table of Contents

Recommended Service Material ....................... 7B-33

Special Tool ...................................................... 7B-33

Automatic Type .................... .................................7B-34

Precautions.........................................................7B-34 A/C System Caution .......................................... 7B-34

Precautions in Diagnosing Trouble ................... 7B-34

Precautions on Servicing A/C System .............. 7B-34

General Description .......... .................................7B-34

Auto A/C System Descript ion ............................ 7B-34

HVAC Control Module Operation Description ... 7B-36

Refrigerant Type Identifica tion .......................... 7B-36

Sub-Cool A/C System Description .................... 7B-36

A/C Operation Description ................................ 7B-36

On-Board Diagnostic System Description ......... 7B-37

Schematic and Routing Diagram ......................7B-37 Major Components of A/C System .................... 7B-37

A/C System Wiring Diagra m ............................. 7B-38

Diagnostic Information and Procedures ..........7B-39 A/C System Symptom Diagnosis ...................... 7B-39

Abnormal Noise Sympto m Diagnosis of A/C

System ............................................................ 7B-42

DTC Check........................................................ 7B-42

DTC Clearance ................................................. 7B-43

DTC Table ......................................................... 7B-44

Fail-Safe Table ................. ................................. 7B-45

Scan Tool Data ................................................. 7B-46

Air Conditioning System Check......................... 7B-47

Visual Inspection ............................................... 7B-49

DTC B1502: Inside Air Temperature Sensor and/or Its Circuit Malfunction .......................... 7B-49

DTC B1503: A/C Evaporator Air Temperature Sensor and/or Its Circuit Malfunction .............. 7B-50

DTC B1504: Sunload Sensor and/or Its Circuit Malfunction ......... ................................. 7B-52

DTC B1511: Temperature Control Actuator (Position Sensor) and/or Its Circuit

Malfunction ...................................................... 7B-53

DTC B1512: Air flow Control Actuator (Position Sensor) and/or Its Circuit

Malfunction ...................................................... 7B-55

DTC B1513: Temperature Control Actuator and/or Its Circuit Malfunction .......................... 7B-57

DTC B1514: Air Flow Co ntrol Actuator and/or

Its Circuit Malfunction ...................................... 7B-60

DTC B1541: HVAC Control Module Back-Up Power Supply Malfunction .............................. 7B-62

DTC B1546: A/C Refrigerant Pressure Malfunction ...................................................... 7B-63

DTC B1551: Serial Communication Circuit Malfunction ...................................................... 7B-63

DTC B1552: Serial Communication Signal Malfunction ...................................................... 7B-64

DTC B1553: CAN Communication Signal Malfunction ...................................................... 7B-65

DTC B1557: Vehicle Speed Sensor Signal Malfunction ...................................................... 7B-65

DTC B1561: Engine Coolant Temperature Sensor Signal Malfunctio n .............................. 7B-66 DTC B1562: Outside Air Temperature Sensor

Signal Malfunction ........................................... 7B-66

DTC B1563: A/C Refr igerant Pressure

Sensor Signal Malfunction .............................. 7B-66

Inspection of HVAC Control Module and Its Circuit .............................................................. 7B-67

A/C System Performance Inspection ................ 7B-70

A/C System Inspection at ECM ......................... 7B-70

Repair Instructions ............ ................................7B-71

Operation Procedure for Refrigerant Charge .... 7B-71

HVAC Unit Components ................................... 7B-72

HVAC Unit Removal and In stallation ................ 7B-73

Temperature Control Actuator Removal and Installation ....................................................... 7B-73

Temperature Control Actuat or Inspection ......... 7B-73

Air Flow Control Actuator Removal and Installation ....................................................... 7B-74

Air Flow Control Actuator Inspection ................. 7B-74

Air Intake Control Actuator Removal and Installation ....................................................... 7B-75

Air Intake Control Actuator Inspection............... 7B-75

Actuator Linkage Inspection .............................. 7B-76

Blower Motor Controller Removal and Installation ....................................................... 7B-76

Blower Motor Controller Inspection ................... 7B-76

HVAC Control Module Removal and Installation ....................................................... 7B-77

Sunload Sensor Removal and Installation ........ 7B-77

Sunload Sensor Inspection ............................... 7B-77

Outside Air Temperature Sensor Removal and Installation ................................................ 7B-77

Outside Air Temperature Sensor Inspection ..... 7B-77

Inside Air Temperature Sensor Removal and Installation ....................................................... 7B-78

Inside Air Temperature Sens or Inspection ........ 7B-78

Condenser Assembly On-Vehicle Inspection .... 7B-78

Condenser Assembly Removal and Installation ....................................................... 7B-78

Receiver/Dryer Removal and Installation .......... 7B-78

Evaporator Inspection ....................................... 7B-78

Evaporator Temperature Sensor Removal and Installation ................................................ 7B-78

Evaporator Temperature Se nsor Inspection ..... 7B-78

Expansion Valve Removal an d Installation ....... 7B-78

Expansion Valve Inspection .............................. 7B-78

A/C Refrigerant Pressure Sensor and Its Circuit Inspection............................................. 7B-78

A/C Refrigerant Pressu re Sensor Removal

and Installation ................................................ 7B-78

Compressor Relay Inspection .

.......................... 7B-78

Compressor Drive Belt Inspection and Adjustment ...................................................... 7B-78

Compressor Drive Belt Removal and Installation ....................................................... 7B-79

Compressor Assembly Removal and Installation ....................................................... 7B-79

Compressor Assembly Components................. 7B-79

Magnet Clutch Removal and Installation........... 7B-79

Magnet Clutch Inspection.................................. 7B-79

Relief Valve Inspection...................................... 7B-79

Page 939 of 1496

Downloaded from www.Manualslib.com manuals search engine Heater and Ventilation: 7A-3

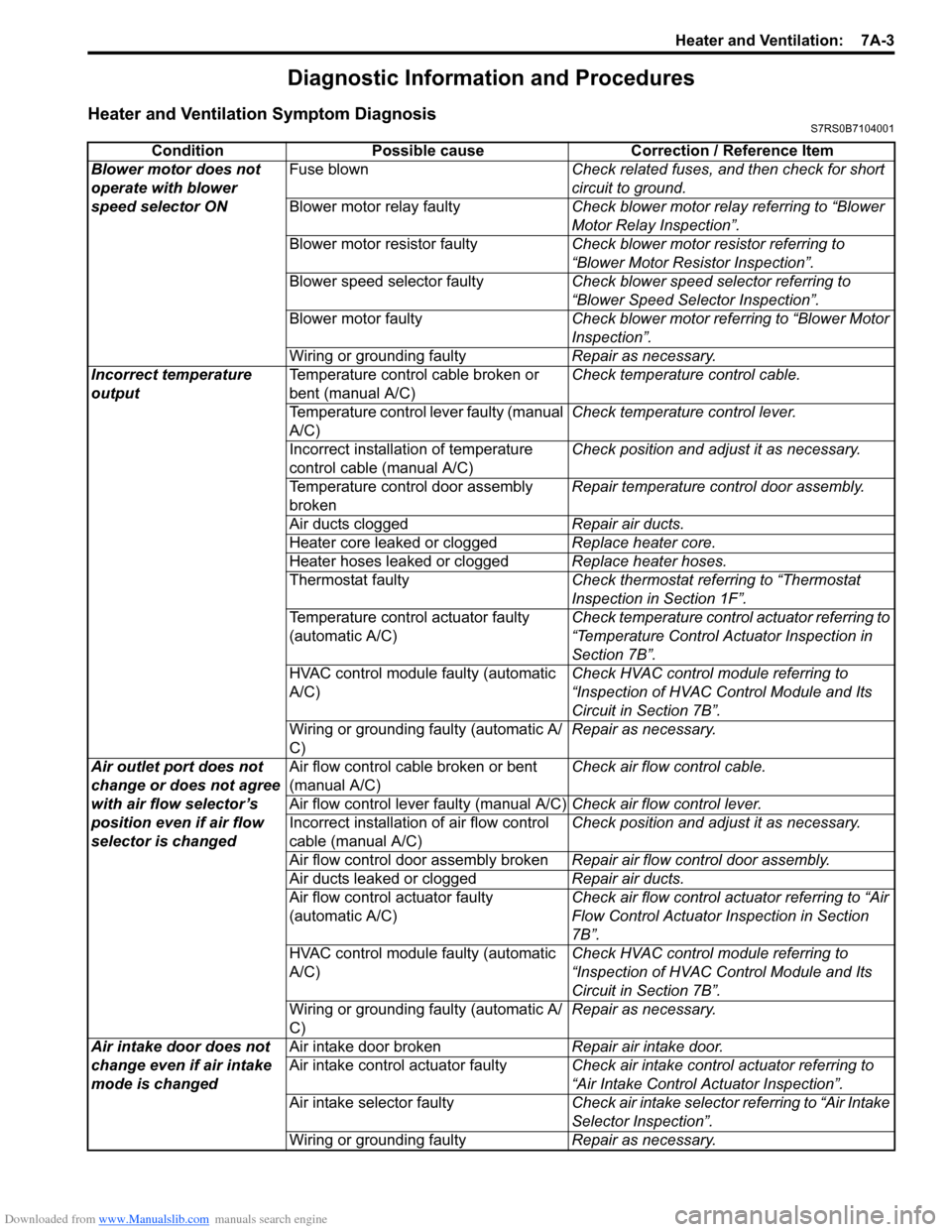

Diagnostic Information and Procedures

Heater and Ventilation Symptom DiagnosisS7RS0B7104001

ConditionPossible cause Correction / Reference Item

Blower motor does not

operate with blower

speed selector ON Fuse blown

Check related fuses, and then check for short

circuit to ground.

Blower motor relay faulty Check blower motor relay referring to “Blower

Motor Relay Inspection”.

Blower motor resistor faulty Check blower motor resistor referring to

“Blower Motor Resistor Inspection”.

Blower speed selector faulty Check blower speed selector referring to

“Blower Speed Selector Inspection”.

Blower motor faulty Check blower motor referring to “Blower Motor

Inspection”.

Wiring or grounding faulty Repair as necessary.

Incorrect temperature

output Temperature control cable broken or

bent (manual A/C) Check temperature control cable.

Temperature control lever faulty (manual

A/C) Check temperature control lever.

Incorrect installation of temperature

control cable (manual A/C) Check position and adjust it as necessary.

Temperature control door assembly

broken Repair temperature control door assembly.

Air ducts clogged Repair air ducts.

Heater core leaked or clogged Replace heater core.

Heater hoses leaked or clogged Replace heater hoses.

Thermostat faulty Check thermostat referring to “Thermostat

Inspection in Section 1F”.

Temperature control actuator faulty

(automatic A/C) Check temperature control actuator referring to

“Temperature Control Actuator Inspection in

Section 7B”.

HVAC control module faulty (automatic

A/C) Check HVAC control module referring to

“Inspection of HVAC Control Module and Its

Circuit in Section 7B”.

Wiring or grounding faulty (automatic A/

C) Repair as necessary.

Air outlet port does not

change or does not agree

with air flow selector’s

position even if air flow

selector is changed Air flow control cable broken or bent

(manual A/C)

Check air flow control cable.

Air flow control lever faulty (manual A/C) Check air flow control lever.

Incorrect installation of air flow control

cable (manual A/C) Check position and adjust it as necessary.

Air flow control door assembly broken Repair air flow control door assembly.

Air ducts leaked or clogged Repair air ducts.

Air flow control actuator faulty

(automatic A/C) Check air flow control actuator referring to “Air

Flow Control Actuator

Inspection in Section

7B”.

HVAC control module faulty (automatic

A/C) Check HVAC control module referring to

“Inspection of HVAC Control Module and Its

Circuit in Section 7B”.

Wiring or grounding faulty (automatic A/

C) Repair as necessary.

Air intake door does not

change even if air intake

mode is changed Air intake door broken

Repair air intake door.

Air intake control actuator faulty Check air intake control actuator referring to

“Air Intake Control Actuator Inspection”.

Air intake selector faulty Check air intake selector referring to “Air Intake

Selector Inspection”.

Wiring or grounding faulty Repair as necessary.

Page 945 of 1496

Downloaded from www.Manualslib.com manuals search engine Heater and Ventilation: 7A-9

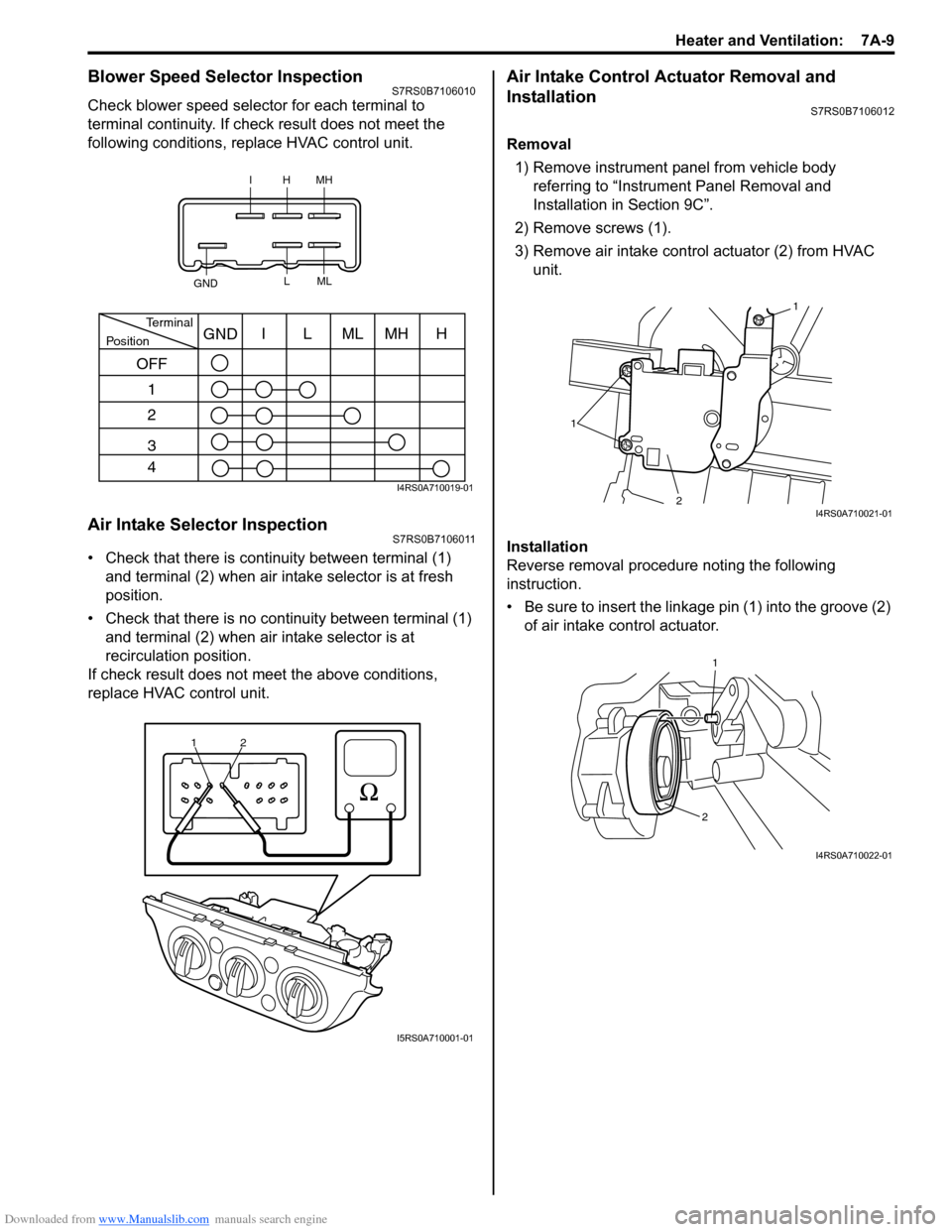

Blower Speed Selector InspectionS7RS0B7106010

Check blower speed selector for each terminal to

terminal continuity. If check result does not meet the

following conditions, replace HVAC control unit.

Air Intake Selector InspectionS7RS0B7106011

• Check that there is continuity between terminal (1) and terminal (2) when air intake selector is at fresh

position.

• Check that there is no continuity between terminal (1) and terminal (2) when air intake selector is at

recirculation position.

If check result does not meet the above conditions,

replace HVAC control unit.

Air Intake Control Actuator Removal and

Installation

S7RS0B7106012

Removal

1) Remove instrument panel from vehicle body referring to “Instrum ent Panel Removal and

Installation in Section 9C”.

2) Remove screws (1).

3) Remove air intake control actuator (2) from HVAC unit.

Installation

Reverse removal procedure noting the following

instruction.

• Be sure to insert the linkage pin (1) into the groove (2) of air intake control actuator.

IHMH

GND LML

PositionTerminalI

OFF 1

2

3

4 LMLMHHGND

I4RS0A710019-01

1

2

I5RS0A710001-01

1 1

2

I4RS0A710021-01

1

2

I4RS0A710022-01

Page 949 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-1

HVAC

Air Conditioning System

Manual Type

Precautions

A/C System CautionS7RS0B7210001

CAUTION!

• The air conditioning system of this vehicle uses refrigerant HFC-134a (R-134a).

None of refrigerant, compressor oil and component parts is interchangeable between two types of

A/C: one using refrigerant HFC-134a (R-134a) and the other using refrigerant CFC-12 (R-12).

Be sure to check which refrigerant is used be fore any service work including inspection and

maintenance. For identification between these two types, refer to “Refrigerant Type Identification”.

When replenishing or changing refrigerant and comp ressor oil and when replacing parts, make sure

that the material or the part to be used is appropriate to the A/C installed in the vehicle being

serviced.

Use of incorrect one will result in leakage of refrigerant, damage in parts or other faulty condition.

• When servicing the compressor, keep dirt or foreign material away from getting on or into the compressor parts and system. Clean tools and a clean work area are important for proper service.

The compressor connection and the outside of the compressor should be cleaned before any “On

vehicle” repair or before removal of the compressor. The parts must be kept clean at all times and

any parts to be reassembled should be cleaned with trichloromethane, naphtha, kerosene or

equivalent solvent and dried with dry air. Use only lint free cloths to wipe parts.

• When compressor is removed from the vehicle for servicing, the oil remaining in the compressor

should be discarded and new refrigerant oil added to the compressor.

Minor repair procedures may be done on the vehicle without discharging the system. Major repair

procedures require that the system be discharged of refrigerant.

Precautions on Servicing A/C SystemS7RS0B7210002

WARNING!

Should refrigerant HFC-134a (R-134a) is exposed to your eye(s), consult a doctor immediately.

• Do not use your hand to rub affected eye(s). Instead, use fresh cold water to splash it over affected area to thus gradually raise its temperature above the freezing point.

• Obtain proper treatment as soon as possible from a doctor or eye specialist. Should liquid refrigerant HFC-134a (R-134a) is exposed to your skin, such affected part should be treated in the

same manner as when skin is frostbitten or frozen.

Handling Refrigerant HFC-134a (R-134a)

• Always wear goggles to protect your eyes.

• Avoid direct contact to liquid refrigerant.

• Do not heat refrigerant container higher than 40 °C (104 ° F).

• Do not discharge refrigerant into atmosphere.

• Do not expose bright metals to liquid refrigerant. Refrig erant combined with moisture is corrosive and tarnishes

surfaces of bright metals including chrome.