air cond SUZUKI SWIFT 2005 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 970 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-22 Air Conditioning System: Manual Type

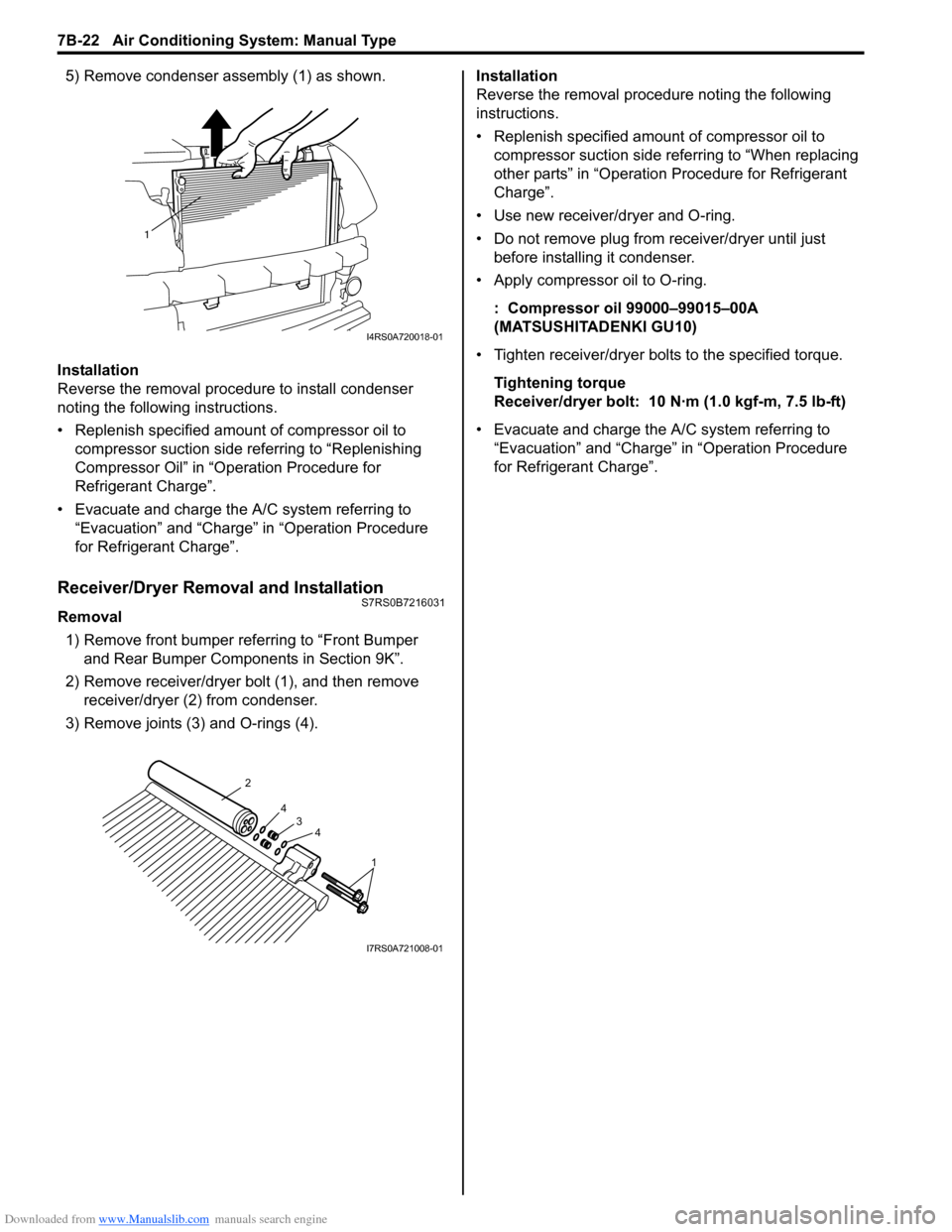

5) Remove condenser assembly (1) as shown.

Installation

Reverse the removal procedure to install condenser

noting the following instructions.

• Replenish specified amount of compressor oil to compressor suction side referring to “Replenishing

Compressor Oil” in “Operation Procedure for

Refrigerant Charge”.

• Evacuate and charge the A/C system referring to “Evacuation” and “Charge” in “Operation Procedure

for Refrigerant Charge”.

Receiver/Dryer Removal and InstallationS7RS0B7216031

Removal

1) Remove front bumper referring to “Front Bumper and Rear Bumper Components in Section 9K”.

2) Remove receiver/dryer bolt (1), and then remove receiver/dryer (2) from condenser.

3) Remove joints (3) and O-rings (4). Installation

Reverse the removal procedure noting the following

instructions.

• Replenish specified amount of compressor oil to

compressor suction side referring to “When replacing

other parts” in “Operation Procedure for Refrigerant

Charge”.

• Use new receiver/dryer and O-ring.

• Do not remove plug from receiver/dryer until just before installin g it condenser.

• Apply compressor oil to O-ring.

: Compressor oil 99000–99015–00A

(MATSUSHITADENKI GU10)

• Tighten receiver/dryer bolts to the specified torque. Tightening torque

Receiver/dryer bolt: 10 N· m (1.0 kgf-m, 7.5 lb-ft)

• Evacuate and charge the A/C system referring to “Evacuation” and “Charge” in “Operation Procedure

for Refrigerant Charge”.

1

I4RS0A720018-01

1

4

4

3

2

I7RS0A721008-01

Page 971 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-23

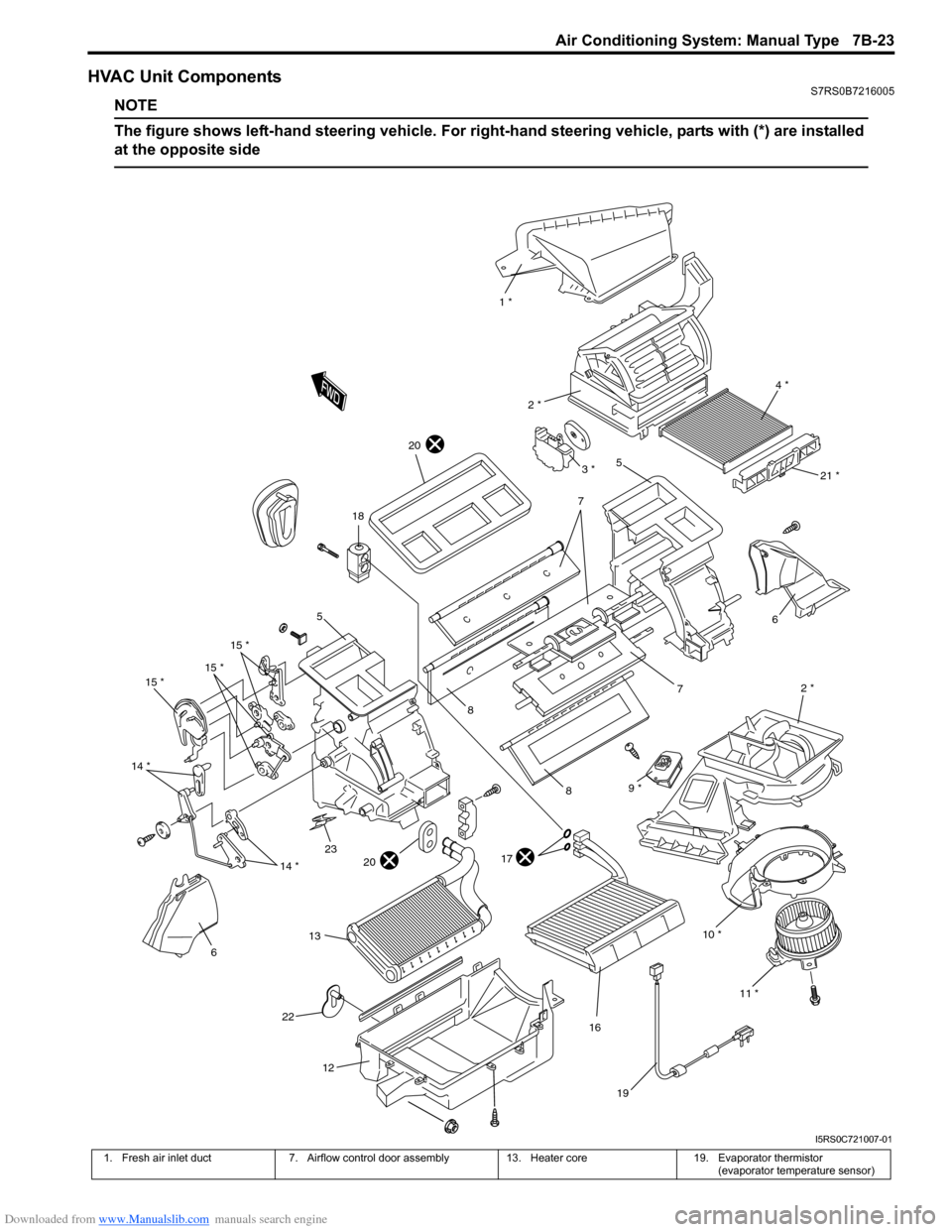

HVAC Unit ComponentsS7RS0B7216005

NOTE

The figure shows left-hand steering vehicle. For right-hand steering vehicle, parts with (*) are installed

at the opposite side

10 * 2 *

6

7

1 *

4 *

2 *

5

7

8

8

17

16

18

19

15 *

15 *

15 *

14 *

614 *

12

11 *

21 *

20

2320

22

9 *

13

3 *

5

I5RS0C721007-01

1. Fresh air inlet duct 7. Airflow control door assembly 13. Heater core19. Evaporator thermistor

(evaporator temperature sensor)

Page 972 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-24 Air Conditioning System: Manual Type

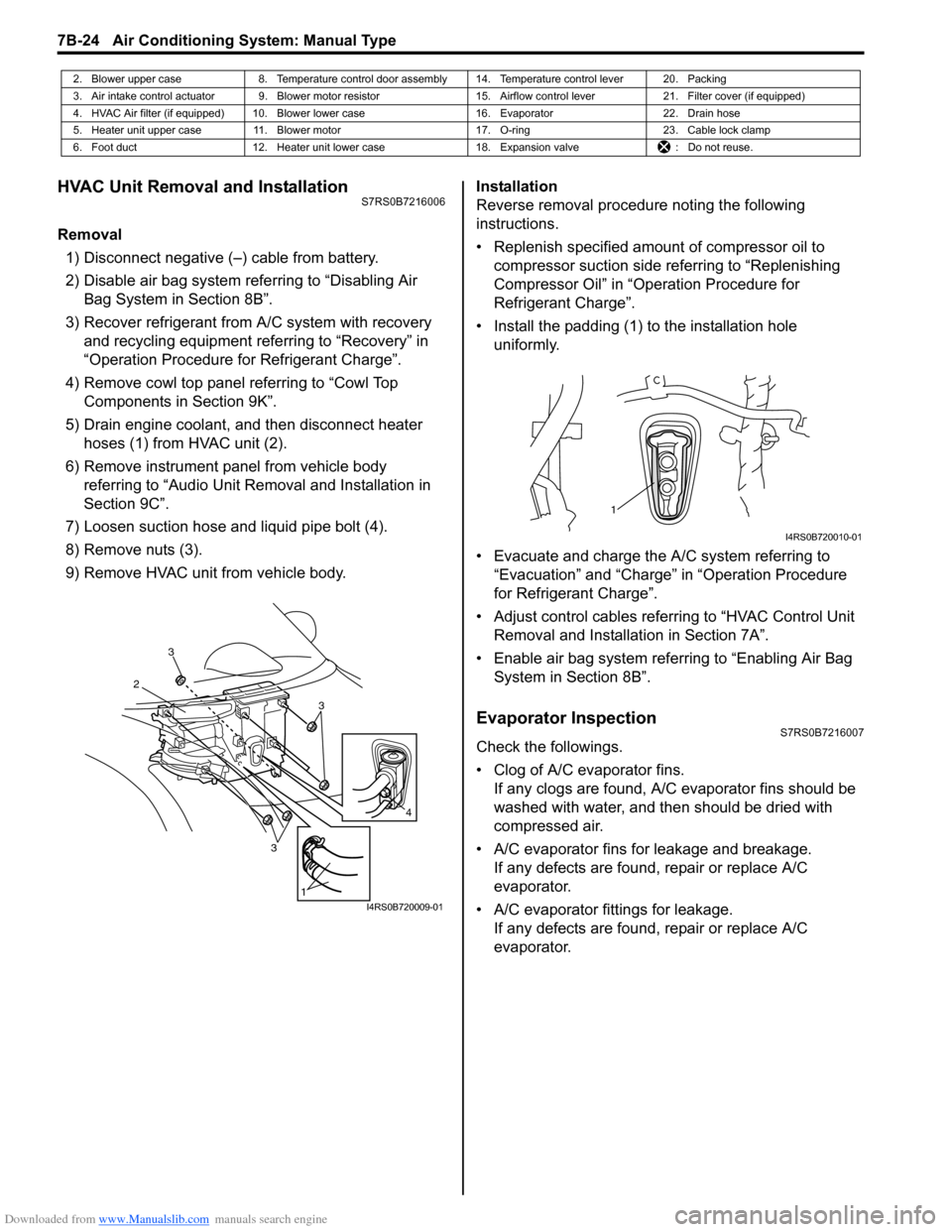

HVAC Unit Removal and InstallationS7RS0B7216006

Removal1) Disconnect negative (–) cable from battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Recover refrigerant from A/C system with recovery and recycling equipment referring to “Recovery” in

“Operation Procedure for Refrigerant Charge”.

4) Remove cowl top panel referring to “Cowl Top Components in Section 9K”.

5) Drain engine coolant, and then disconnect heater hoses (1) from HVAC unit (2).

6) Remove instrument panel from vehicle body referring to “Audio Unit Re moval and Installation in

Section 9C”.

7) Loosen suction hose and liquid pipe bolt (4).

8) Remove nuts (3).

9) Remove HVAC unit from vehicle body. Installation

Reverse removal procedure noting the following

instructions.

• Replenish specified amount of compressor oil to

compressor suction side referring to “Replenishing

Compressor Oil” in “Operation Procedure for

Refrigerant Charge”.

• Install the padding (1) to the installation hole uniformly.

• Evacuate and charge the A/C system referring to “Evacuation” and “Charge” in “Operation Procedure

for Refrigerant Charge”.

• Adjust control cables referr ing to “HVAC Control Unit

Removal and Installati on in Section 7A”.

• Enable air bag system referring to “Enabling Air Bag System in Section 8B”.

Evaporator InspectionS7RS0B7216007

Check the followings.

• Clog of A/C evaporator fins.If any clogs are found, A/C evaporator fins should be

washed with water, and then should be dried with

compressed air.

• A/C evaporator fins for leakage and breakage. If any defects are found, repair or replace A/C

evaporator.

• A/C evaporator fittings for leakage. If any defects are found, repair or replace A/C

evaporator.

2. Blower upper case 8. Temperature control door assembly 14. Temperature control lever 20. Packing

3. Air intake control actuator 9. Blower motor resistor 15. Airflow control lever21. Filter cover (if equipped)

4. HVAC Air filter (if equipped) 10. Blower lower case 16. Evaporator22. Drain hose

5. Heater unit upper case 11. Blower motor 17. O-ring23. Cable lock clamp

6. Foot duct 12. Heater unit lower case 18. Expansion valve: Do not reuse.

3

2

3

3

1

4

I4RS0B720009-01

1

I4RS0B720010-01

Page 973 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-25

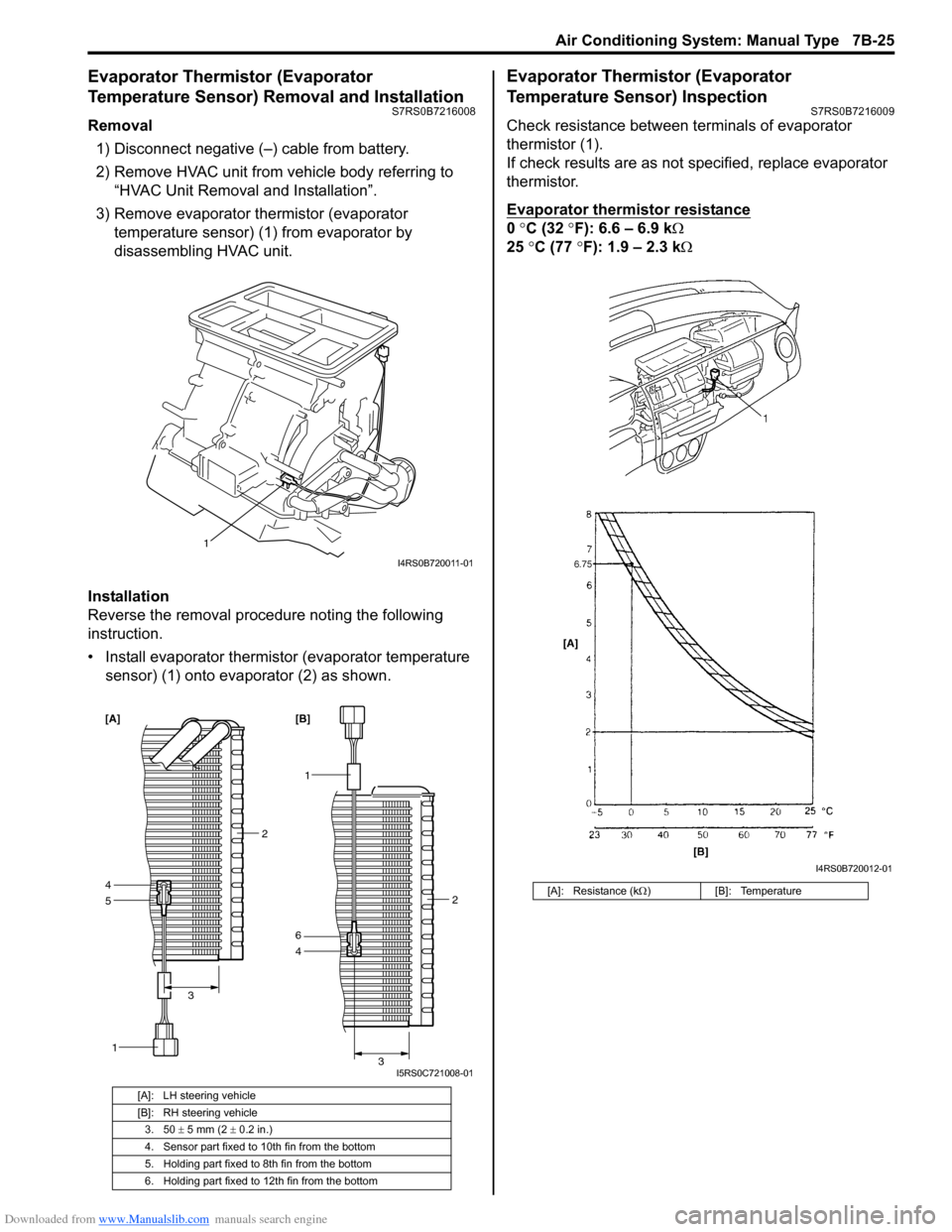

Evaporator Thermistor (Evaporator

Temperature Sensor) Removal and Installation

S7RS0B7216008

Removal1) Disconnect negative (–) cable from battery.

2) Remove HVAC unit from vehicle body referring to “HVAC Unit Removal and Installation”.

3) Remove evaporator thermistor (evaporator temperature sensor) (1) from evaporator by

disassembling HVAC unit.

Installation

Reverse the removal procedure noting the following

instruction.

• Install evaporator thermistor (evaporator temperature sensor) (1) onto evaporator (2) as shown.

Evaporator Thermistor (Evaporator

Temperature Sensor) Inspection

S7RS0B7216009

Check resistance between terminals of evaporator

thermistor (1).

If check results are as not specified, replace evaporator

thermistor.

Evaporator thermistor resistance

0 °C (32 °F): 6.6 – 6.9 k Ω

25 °C (77 °F): 1.9 – 2.3 kΩ

[A]: LH steering vehicle

[B]: RH steering vehicle

3. 50 ± 5 mm (2 ± 0.2 in.)

4. Sensor part fixed to 10th fin from the bottom

5. Holding part fixed to 8th fin from the bottom

6. Holding part fixed to 12th fin from the bottom

1

I4RS0B720011-01

5

1

4

2

3

[A]

1

4 2

3

6 [B]

I5RS0C721008-01

[A]: Resistance (k Ω) [B]: Temperature

I4RS0B720012-01

Page 974 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-26 Air Conditioning System: Manual Type

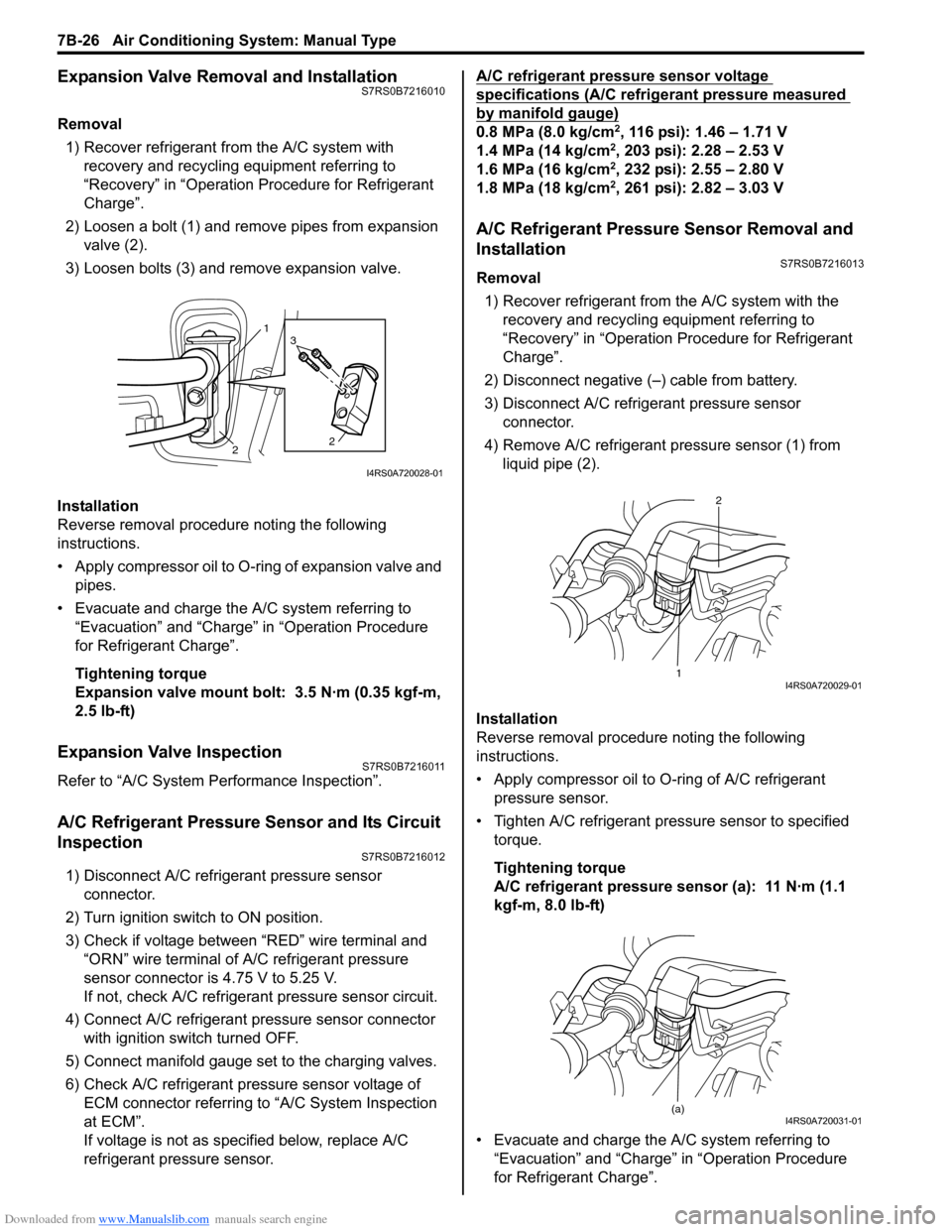

Expansion Valve Removal and InstallationS7RS0B7216010

Removal1) Recover refrigerant fr om the A/C system with

recovery and recycling equipment referring to

“Recovery” in “Operation Procedure for Refrigerant

Charge”.

2) Loosen a bolt (1) and remove pipes from expansion valve (2).

3) Loosen bolts (3) and remove expansion valve.

Installation

Reverse removal procedure noting the following

instructions.

• Apply compressor oil to O-ring of expansion valve and pipes.

• Evacuate and charge the A/C system referring to “Evacuation” and “Charge” in “Operation Procedure

for Refrigerant Charge”.

Tightening torque

Expansion valve mount bolt: 3.5 N·m (0.35 kgf-m,

2.5 lb-ft)

Expansion Valve InspectionS7RS0B7216011

Refer to “A/C System Performance Inspection”.

A/C Refrigerant Pressure Sensor and Its Circuit

Inspection

S7RS0B7216012

1) Disconnect A/C refrigerant pressure sensor connector.

2) Turn ignition switch to ON position.

3) Check if voltage between “RED” wire terminal and “ORN” wire terminal of A/C refrigerant pressure

sensor connector is 4.75 V to 5.25 V.

If not, check A/C refrigerant pressure sensor circuit.

4) Connect A/C refrigerant pressure sensor connector with ignition switch turned OFF.

5) Connect manifold gauge set to the charging valves.

6) Check A/C refrigerant pressure sensor voltage of ECM connector referring to “A/C System Inspection

at ECM”.

If voltage is not as specified below, replace A/C

refrigerant pressure sensor. A/C refrigerant pressure sensor voltage

specifications (A/C refrigerant pressure measured

by manifold gauge)

0.8 MPa (8.0 kg/cm2, 116 psi): 1.46 – 1.71 V

1.4 MPa (14 kg/cm2, 203 psi): 2.28 – 2.53 V

1.6 MPa (16 kg/cm2, 232 psi): 2.55 – 2.80 V

1.8 MPa (18 kg/cm2, 261 psi): 2.82 – 3.03 V

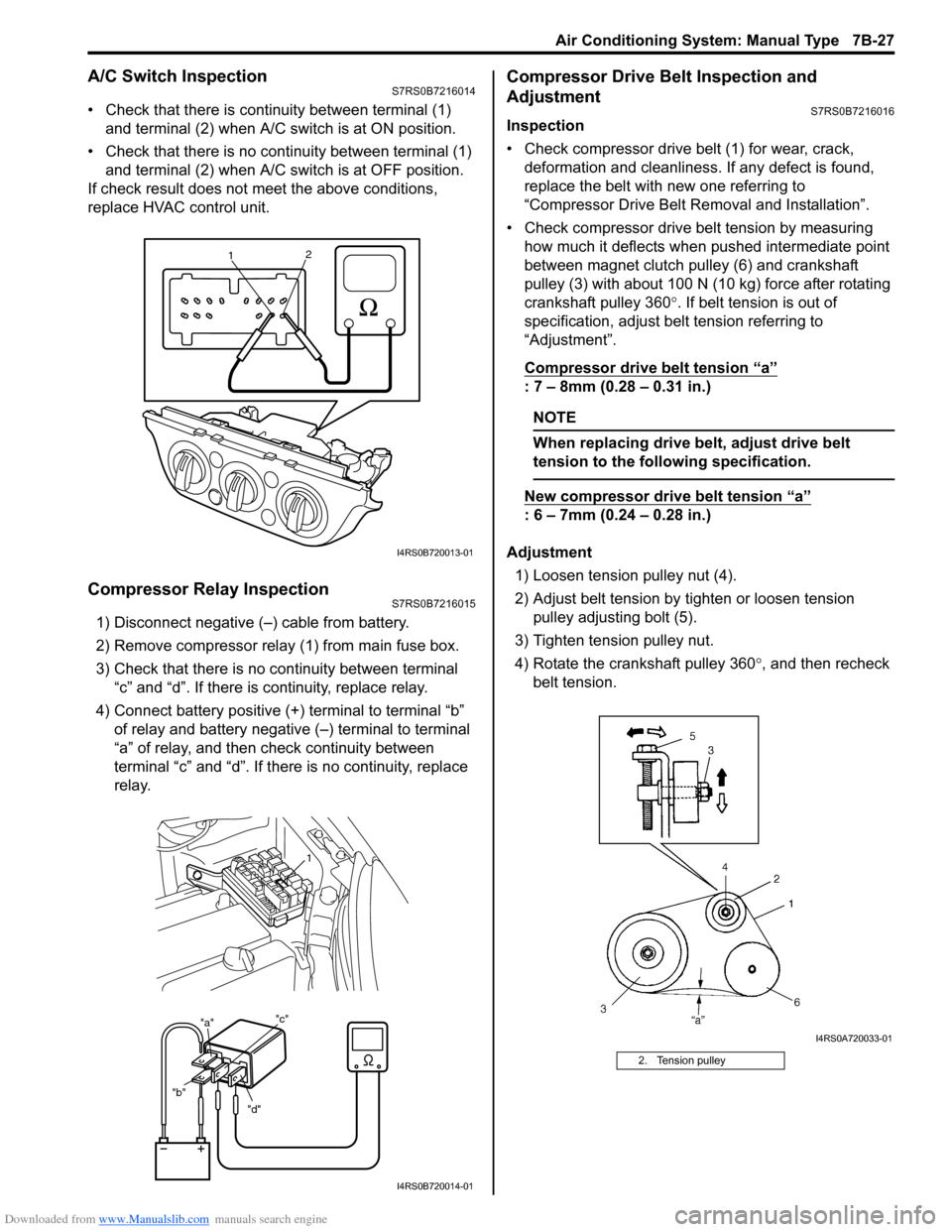

A/C Refrigerant Pressure Sensor Removal and

Installation

S7RS0B7216013

Removal

1) Recover refrigerant from the A/C system with the recovery and recycling equipment referring to

“Recovery” in “Operation Procedure for Refrigerant

Charge”.

2) Disconnect negative (–) cable from battery.

3) Disconnect A/C refrigerant pressure sensor connector.

4) Remove A/C refrigerant pressure sensor (1) from liquid pipe (2).

Installation

Reverse removal procedure noting the following

instructions.

• Apply compressor oil to O-ring of A/C refrigerant

pressure sensor.

• Tighten A/C refrigerant pressure sensor to specified torque.

Tightening torque

A/C refrigerant pressure sensor (a): 11 N·m (1.1

kgf-m, 8.0 lb-ft)

• Evacuate and charge the A/C system referring to “Evacuation” and “Charge” in “Operation Procedure

for Refrigerant Charge”.

1

2 2

3

I4RS0A720028-01

1 2I4RS0A720029-01

(a)I4RS0A720031-01

Page 975 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-27

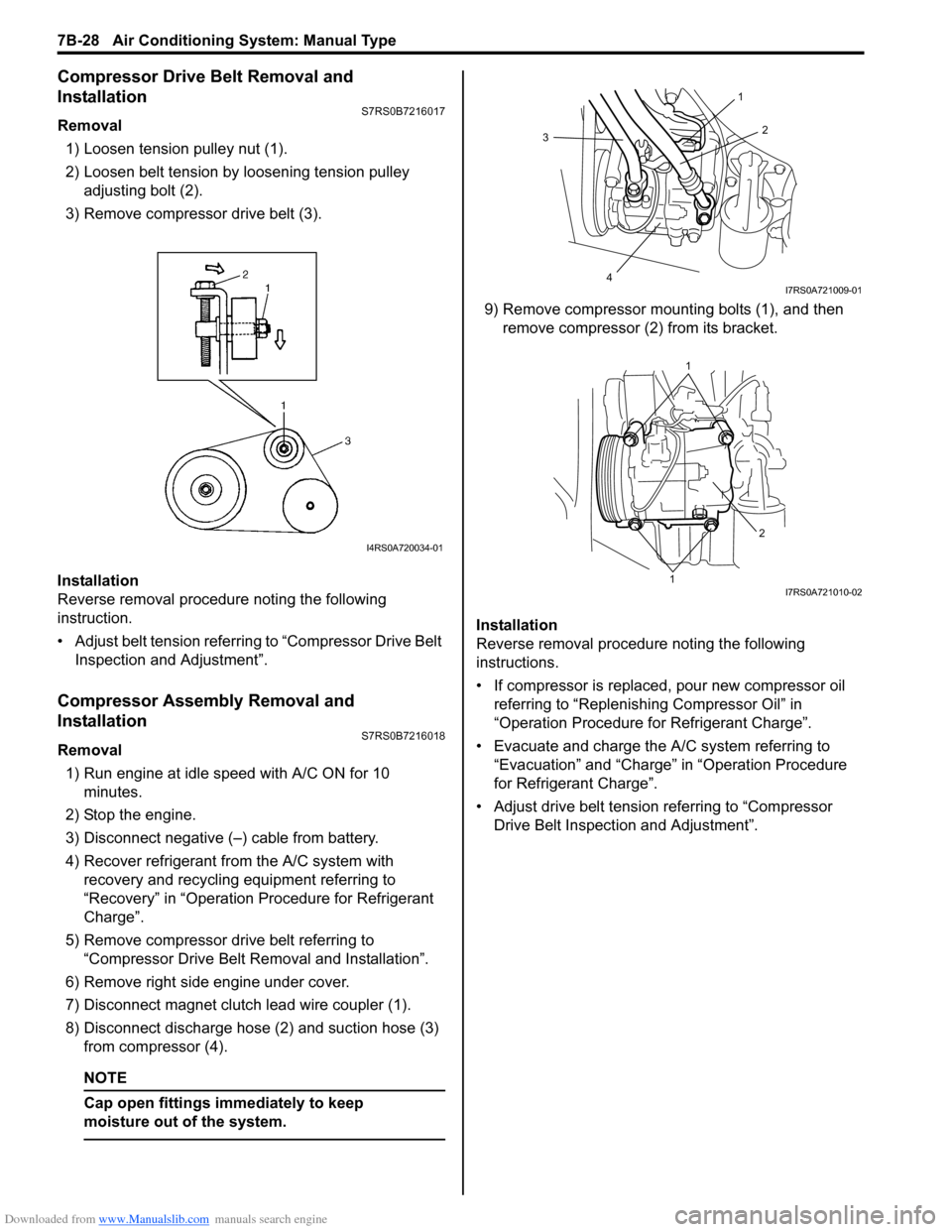

A/C Switch InspectionS7RS0B7216014

• Check that there is continuity between terminal (1) and terminal (2) when A/C s witch is at ON position.

• Check that there is no continuity between terminal (1) and terminal (2) when A/C s witch is at OFF position.

If check result does not meet the above conditions,

replace HVAC control unit.

Compressor Relay InspectionS7RS0B7216015

1) Disconnect negative (–) cable from battery.

2) Remove compressor relay (1) from main fuse box.

3) Check that there is no continuity between terminal “c” and “d”. If there is continuity, replace relay.

4) Connect battery positive (+ ) terminal to terminal “b”

of relay and battery negative (–) terminal to terminal

“a” of relay, and then check continuity between

terminal “c” and “d”. If there is no continuity, replace

relay.

Compressor Drive Belt Inspection and

Adjustment

S7RS0B7216016

Inspection

• Check compressor drive belt (1) for wear, crack, deformation and cleanliness. If any defect is found,

replace the belt with new one referring to

“Compressor Drive Belt Re moval and Installation”.

• Check compressor drive belt tension by measuring how much it deflects when pushed intermediate point

between magnet clutch pulley (6) and crankshaft

pulley (3) with about 100 N (10 kg) force after rotating

crankshaft pulley 360 °. If belt tension is out of

specification, adjust belt tension referring to

“Adjustment”.

Compressor drive belt tension

“a”

: 7 – 8mm (0.28 – 0.31 in.)

NOTE

When replacing drive belt, adjust drive belt

tension to the following specification.

New compressor dr ive belt tension “a”

: 6 – 7mm (0.24 – 0.28 in.)

Adjustment 1) Loosen tension pulley nut (4).

2) Adjust belt tension by ti ghten or loosen tension

pulley adjusting bolt (5).

3) Tighten tension pulley nut.

4) Rotate the crankshaft pulley 360 °, and then recheck

belt tension.

1 2

I4RS0B720013-01

"d"

"b" "a"

"c"

1

I4RS0B720014-01

2. Tension pulley

I4RS0A720033-01

Page 976 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-28 Air Conditioning System: Manual Type

Compressor Drive Belt Removal and

Installation

S7RS0B7216017

Removal1) Loosen tension pulley nut (1).

2) Loosen belt tension by loosening tension pulley adjusting bolt (2).

3) Remove compressor drive belt (3).

Installation

Reverse removal procedure noting the following

instruction.

• Adjust belt tension referring to “Compressor Drive Belt Inspection and Adjustment”.

Compressor Assembly Removal and

Installation

S7RS0B7216018

Removal

1) Run engine at idle speed with A/C ON for 10 minutes.

2) Stop the engine.

3) Disconnect negative (–) cable from battery.

4) Recover refrigerant fr om the A/C system with

recovery and recycling equipment referring to

“Recovery” in “Operation Procedure for Refrigerant

Charge”.

5) Remove compressor drive belt referring to “Compressor Drive Belt Re moval and Installation”.

6) Remove right side engine under cover.

7) Disconnect magnet clutch lead wire coupler (1).

8) Disconnect discharge hose (2) and suction hose (3) from compressor (4).

NOTE

Cap open fittings immediately to keep

moisture out of the system.

9) Remove compressor mounting bolts (1), and then remove compressor (2 ) from its bracket.

Installation

Reverse removal procedure noting the following

instructions.

• If compressor is replaced, pour new compressor oil referring to “Replenishi ng Compressor Oil” in

“Operation Procedure for Refrigerant Charge”.

• Evacuate and charge the A/C system referring to “Evacuation” and “Charge” in “Operation Procedure

for Refrigerant Charge”.

• Adjust drive belt tension referring to “Compressor Drive Belt Inspecti on and Adjustment”.

I4RS0A720034-01

3

4 2

1

I7RS0A721009-01

1

1 2

I7RS0A721010-02

Page 977 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-29

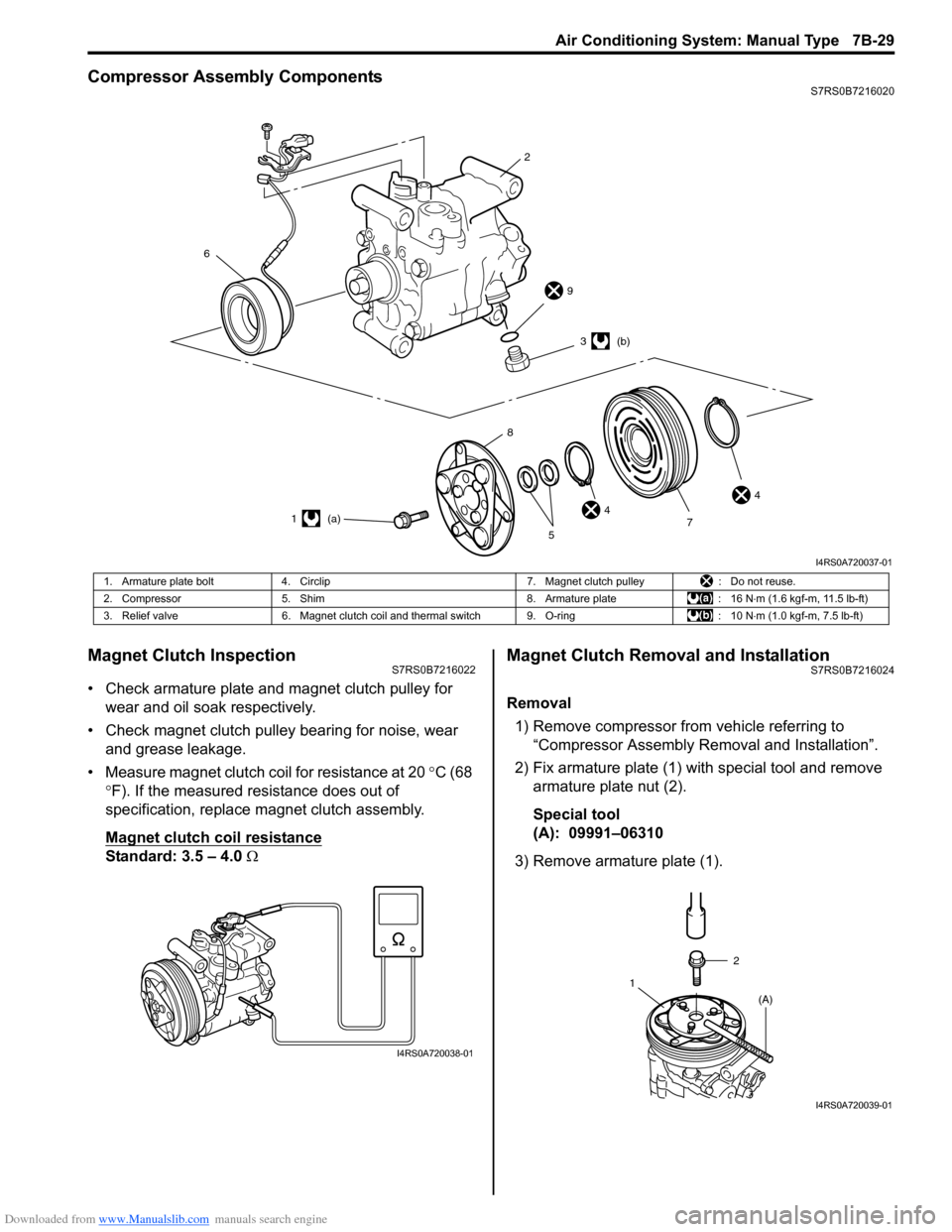

Compressor Assembly ComponentsS7RS0B7216020

Magnet Clutch InspectionS7RS0B7216022

• Check armature plate and magnet clutch pulley for wear and oil soak respectively.

• Check magnet clutch pulley bearing for noise, wear and grease leakage.

• Measure magnet clutch coil for resistance at 20 °C (68

° F). If the measured resistance does out of

specification, replace magnet clutch assembly.

Magnet clutch coil resistance

Standard: 3.5 – 4.0 Ω

Magnet Clutch Removal and InstallationS7RS0B7216024

Removal

1) Remove compressor from vehicle referring to “Compressor Assembly Re moval and Installation”.

2) Fix armature plate (1) with special tool and remove armature plate nut (2).

Special tool

(A): 09991–06310

3) Remove armature plate (1).

6

2

9

44

3 (b)

1 (a) 7

5

8

I4RS0A720037-01

1. Armature plate bolt

4. Circlip 7. Magnet clutch pulley: Do not reuse.

2. Compressor 5. Shim 8. Armature plate: 16 N⋅m (1.6 kgf-m, 11.5 lb-ft)

3. Relief valve 6. Magnet clutch coil and thermal switch 9. O-ring : 10 N⋅m (1.0 kgf-m, 7.5 lb-ft)

I4RS0A720038-01

2

1 (A)

I4RS0A720039-01

Page 978 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-30 Air Conditioning System: Manual Type

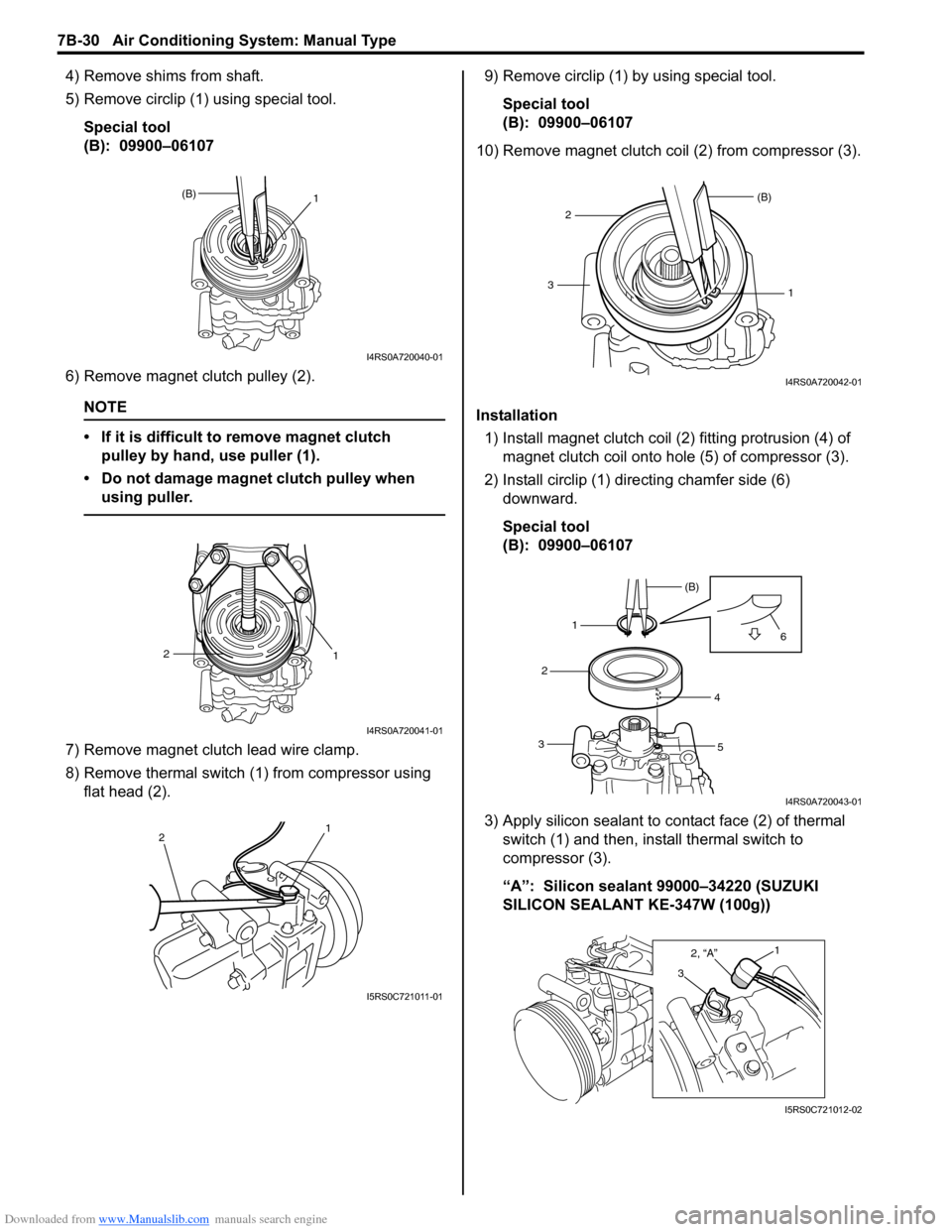

4) Remove shims from shaft.

5) Remove circlip (1) using special tool.Special tool

(B): 09900–06107

6) Remove magnet clutch pulley (2).

NOTE

• If it is difficult to remove magnet clutch pulley by hand, use puller (1).

• Do not damage magnet clutch pulley when using puller.

7) Remove magnet clutch lead wire clamp.

8) Remove thermal switch (1) from compressor using flat head (2). 9) Remove circlip (1) by using special tool.

Special tool

(B): 09900–06107

10) Remove magnet clutch coil (2) from compressor (3).

Installation 1) Install magnet clutch coil (2) fitting protrusion (4) of magnet clutch coil onto hole (5) of compressor (3).

2) Install circlip (1) dire cting chamfer side (6)

downward.

Special tool

(B): 09900–06107

3) Apply silicon sealant to co ntact face (2) of thermal

switch (1) and then, inst all thermal switch to

compressor (3).

“A”: Silicon sealant 99000–34220 (SUZUKI

SILICON SEALANT KE-347W (100g))

(B) 1

I4RS0A720040-01

1

2

I4RS0A720041-01

2 1

I5RS0C721011-01

1

(B)

23

I4RS0A720042-01

1 (B)

2

3 4

5 6

I4RS0A720043-01

3

2, “A”1

I5RS0C721012-02

Page 979 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-31

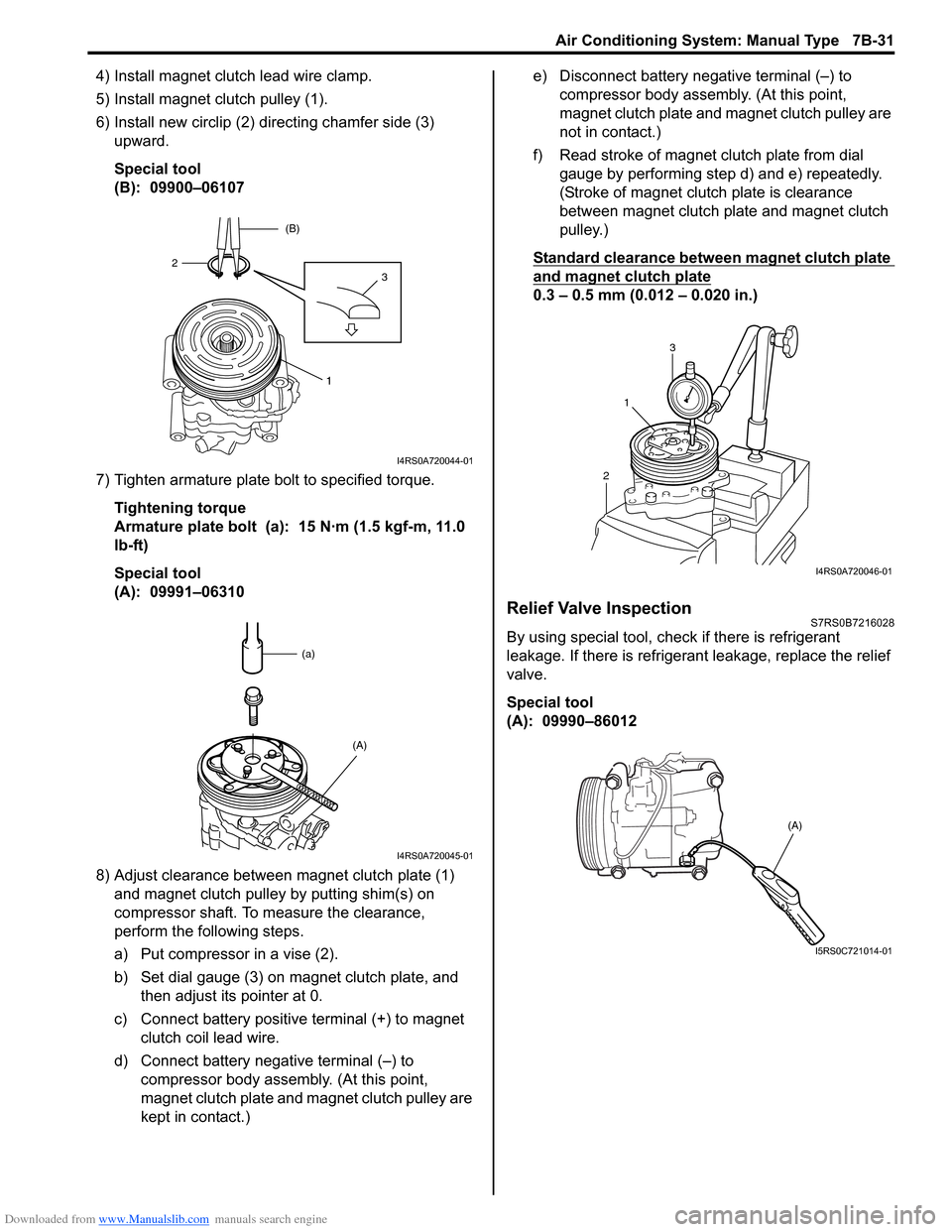

4) Install magnet clutch lead wire clamp.

5) Install magnet clutch pulley (1).

6) Install new circlip (2) directing chamfer side (3) upward.

Special tool

(B): 09900–06107

7) Tighten armature plate bolt to specified torque. Tightening torque

Armature plate bolt (a): 15 N·m (1.5 kgf-m, 11.0

lb-ft)

Special tool

(A): 09991–06310

8) Adjust clearance between magnet clutch plate (1) and magnet clutch pulley by putting shim(s) on

compressor shaft. To measure the clearance,

perform the following steps.

a) Put compressor in a vise (2).

b) Set dial gauge (3) on magnet clutch plate, and then adjust its pointer at 0.

c) Connect battery positive terminal (+) to magnet clutch coil lead wire.

d) Connect battery negative terminal (–) to compressor body assemb ly. (At this point,

magnet clutch plate and magnet clutch pulley are

kept in contact.) e) Disconnect battery negative terminal (–) to

compressor body assembly. (At this point,

magnet clutch plate and magnet clutch pulley are

not in contact.)

f) Read stroke of magnet clutch plate from dial gauge by performing step d) and e) repeatedly.

(Stroke of magnet clutch plate is clearance

between magnet clutch plate and magnet clutch

pulley.)

Standard clearance between magnet clutch plate

and magnet clutch plate

0.3 – 0.5 mm (0.012 – 0.020 in.)

Relief Valve InspectionS7RS0B7216028

By using special tool, chec k if there is refrigerant

leakage. If there is refrigerant leakage, replace the relief

valve.

Special tool

(A): 09990–86012

1

32 (B)

I4RS0A720044-01

(a)

(A)

I4RS0A720045-01

21

3

I4RS0A720046-01

(A)

I5RS0C721014-01