Oil pressure switch SUZUKI SWIFT 2005 2.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 290 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-5 Engine Mechanical:

11) Connect negative cable at battery.

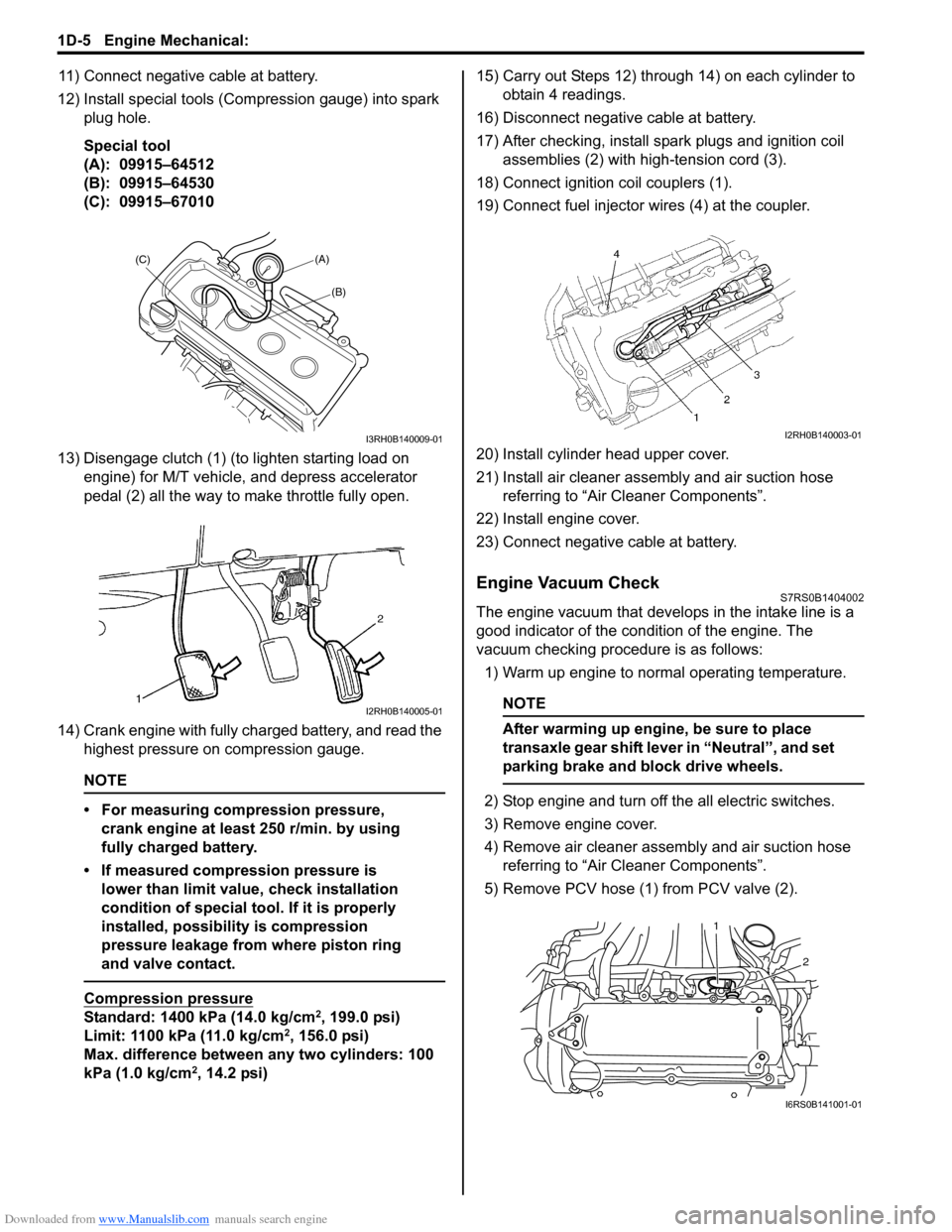

12) Install special tools (Compression gauge) into spark plug hole.

Special tool

(A): 09915–64512

(B): 09915–64530

(C): 09915–67010

13) Disengage clutch (1) (to lighten starting load on engine) for M/T vehicle, and depress accelerator

pedal (2) all the way to make throttle fully open.

14) Crank engine with fully charged battery, and read the highest pressure on compression gauge.

NOTE

• For measuring compression pressure, crank engine at least 250 r/min. by using

fully charged battery.

• If measured compression pressure is lower than limit value, check installation

condition of special tool. If it is properly

installed, possibility is compression

pressure leakage from where piston ring

and valve contact.

Compression pressure

Standard: 1400 kPa (14.0 kg/cm2, 199.0 psi)

Limit: 1100 kPa (11.0 kg/cm2, 156.0 psi)

Max. difference between any two cylinders: 100

kPa (1.0 kg/cm

2, 14.2 psi) 15) Carry out Steps 12) through 14) on each cylinder to

obtain 4 readings.

16) Disconnect negative cable at battery.

17) After checking, install spark plugs and ignition coil assemblies (2) with high-tension cord (3).

18) Connect ignition coil couplers (1).

19) Connect fuel injector wires (4) at the coupler.

20) Install cylinder head upper cover.

21) Install air cleaner assembly and air suction hose referring to “Air Cleaner Components”.

22) Install engine cover.

23) Connect negative cable at battery.

Engine Vacuum CheckS7RS0B1404002

The engine vacuum that develops in the intake line is a

good indicator of the condition of the engine. The

vacuum checking procedure is as follows:

1) Warm up engine to normal operating temperature.

NOTE

After warming up engine, be sure to place

transaxle gear shift lever in “Neutral”, and set

parking brake and block drive wheels.

2) Stop engine and turn off the all electric switches.

3) Remove engine cover.

4) Remove air cleaner assembly and air suction hose referring to “Air Cleaner Components”.

5) Remove PCV hose (1) from PCV valve (2).

(A)

(C)

(B)

I3RH0B140009-01

I2RH0B140005-01

I2RH0B140003-01

2

1

I6RS0B141001-01

Page 302 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-17 Engine Mechanical:

Engine Assembly Removal and InstallationS7RS0B1406011

NOTE

After replacing electric throttle body

assembly, perform calibration of throttle

valve referring to “Electric Throttle Body

System Calibration in Section 1C”.

Removal1) Relieve fuel pressure according to “Fuel Pressure Relief Procedure in Section 1G”.

2) Disconnect negative and pos itive cable at battery.

3) Remove battery and tray.

4) Remove engine hood after disconnecting windshield washer hose.

5) Remove right and left side engine under covers.

6) Remove A/C compressor belt by referring to “Compressor Drive Belt Remo val and Installation in

Section 7B” or “Compressor Drive Belt Removal and

Installation in Section 7B”.

7) Drain engine oil, transaxle oil and coolant.

8) Remove cowl top plate referring to “Cowl Top Components in Section 9K”.

9) Remove air cleaner assembly referring to “Air Cleaner Components”.

10) With hose connected, detach A/C compressor from its bracket (A/C model) referring to “Compressor

Assembly Removal and Installation in Section 7B” or

“Compressor Assembly Removal and Installation in

Section 7B”.

CAUTION!

Suspend removed A/C compressor at a place

where no damage will be caused during

removal and installation of engine assembly.

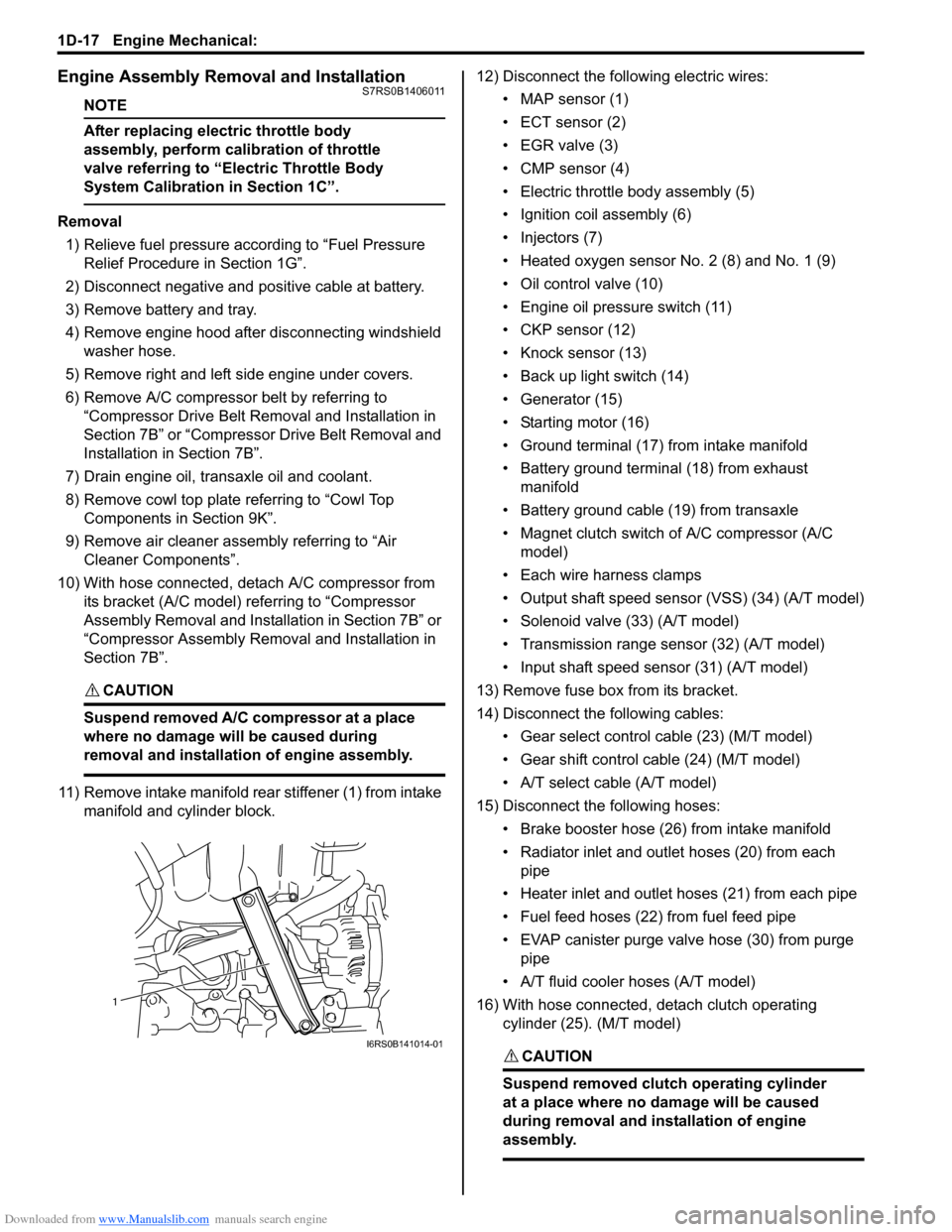

11) Remove intake manifold rear stiffener (1) from intake manifold and cylinder block. 12) Disconnect the following electric wires:

• MAP sensor (1)

• ECT sensor (2)

•EGR valve (3)

• CMP sensor (4)

• Electric throttle body assembly (5)

• Ignition coil assembly (6)

• Injectors (7)

• Heated oxygen sensor No. 2 (8) and No. 1 (9)

• Oil control valve (10)

• Engine oil pressure switch (11)

• CKP sensor (12)

• Knock sensor (13)

• Back up light switch (14)

• Generator (15)

• Starting motor (16)

• Ground terminal (17) from intake manifold

• Battery ground terminal (18) from exhaust manifold

• Battery ground cable (19) from transaxle

• Magnet clutch switch of A/C compressor (A/C model)

• Each wire harness clamps

• Output shaft speed sensor (VSS) (34) (A/T model)

• Solenoid valve (33) (A/T model)

• Transmission range sensor (32) (A/T model)

• Input shaft speed sensor (31) (A/T model)

13) Remove fuse box from its bracket.

14) Disconnect the following cables: • Gear select control cable (23) (M/T model)

• Gear shift control cable (24) (M/T model)

• A/T select cable (A/T model)

15) Disconnect the following hoses: • Brake booster hose (26) from intake manifold

• Radiator inlet and outlet hoses (20) from each pipe

• Heater inlet and outlet hoses (21) from each pipe

• Fuel feed hoses (22) from fuel feed pipe

• EVAP canister purge valve hose (30) from purge pipe

• A/T fluid cooler hoses (A/T model)

16) With hose connected, detach clutch operating cylinder (25). (M/T model)

CAUTION!

Suspend removed clutch operating cylinder

at a place where no damage will be caused

during removal and installation of engine

assembly.

1

I6RS0B141014-01

Page 338 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-53 Engine Mechanical:

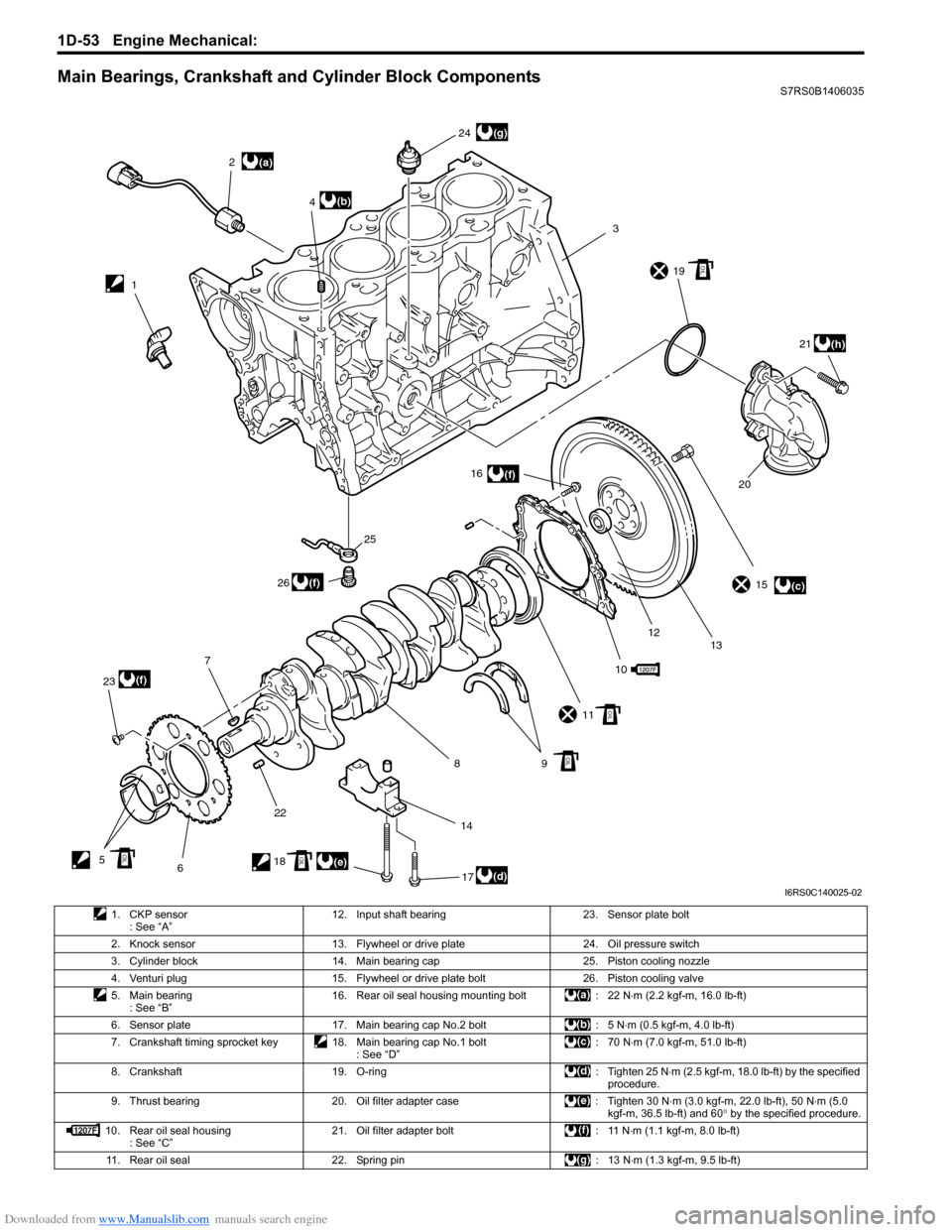

Main Bearings, Crankshaft and Cylinder Block ComponentsS7RS0B1406035

(a)

(c)

(d)(e)

(b)

(f)

(f)

(f)

(g)

(h)

12

3

4

5 67

8910

11 15

12 13

14 16

17

18 19

2021

22

23 24

25

26

OIL

OIL

OIL

OILOIL

I6RS0C140025-02

1. CKP sensor : See “A” 12. Input shaft bearing 23. Sensor plate bolt

2. Knock sensor 13. Flywheel or drive plate 24. Oil pressure switch 3. Cylinder block 14. Main bearing cap 25. Piston cooling nozzle

4. Venturi plug 15. Flywheel or drive plate bolt 26. Piston cooling valve

5. Main bearing : See “B” 16. Rear oil seal housing mounting bolt : 22 N

⋅m (2.2 kgf-m, 16.0 lb-ft)

6. Sensor plate 17. Main bearing cap No.2 bolt : 5 N ⋅m (0.5 kgf-m, 4.0 lb-ft)

7. Crankshaft timing sprocket key 18. Main bearing cap No.1 bolt : See “D”:70 N

⋅m (7.0 kgf-m, 51.0 lb-ft)

8. Crankshaft 19. O-ring : Tighten 25 N ⋅m (2.5 kgf-m, 18.0 lb-ft) by the specified

procedure.

9. Thrust bearing 20. Oil filter adapter case : Tighten 30 N ⋅m (3.0 kgf-m, 22.0 lb-ft), 50 N⋅m (5.0

kgf-m, 36.5 lb-ft) and 60 ° by the specified procedure.

10. Rear oil seal housing : See “C” 21. Oil filter adapter bolt : 11 N

⋅m (1.1 kgf-m, 8.0 lb-ft)

11. Rear oil seal 22. Spring pin : 13 N ⋅m (1.3 kgf-m, 9.5 lb-ft)

Page 354 of 1496

Downloaded from www.Manualslib.com manuals search engine 1E-2 Engine Lubrication System:

Diagnostic Information and Procedures

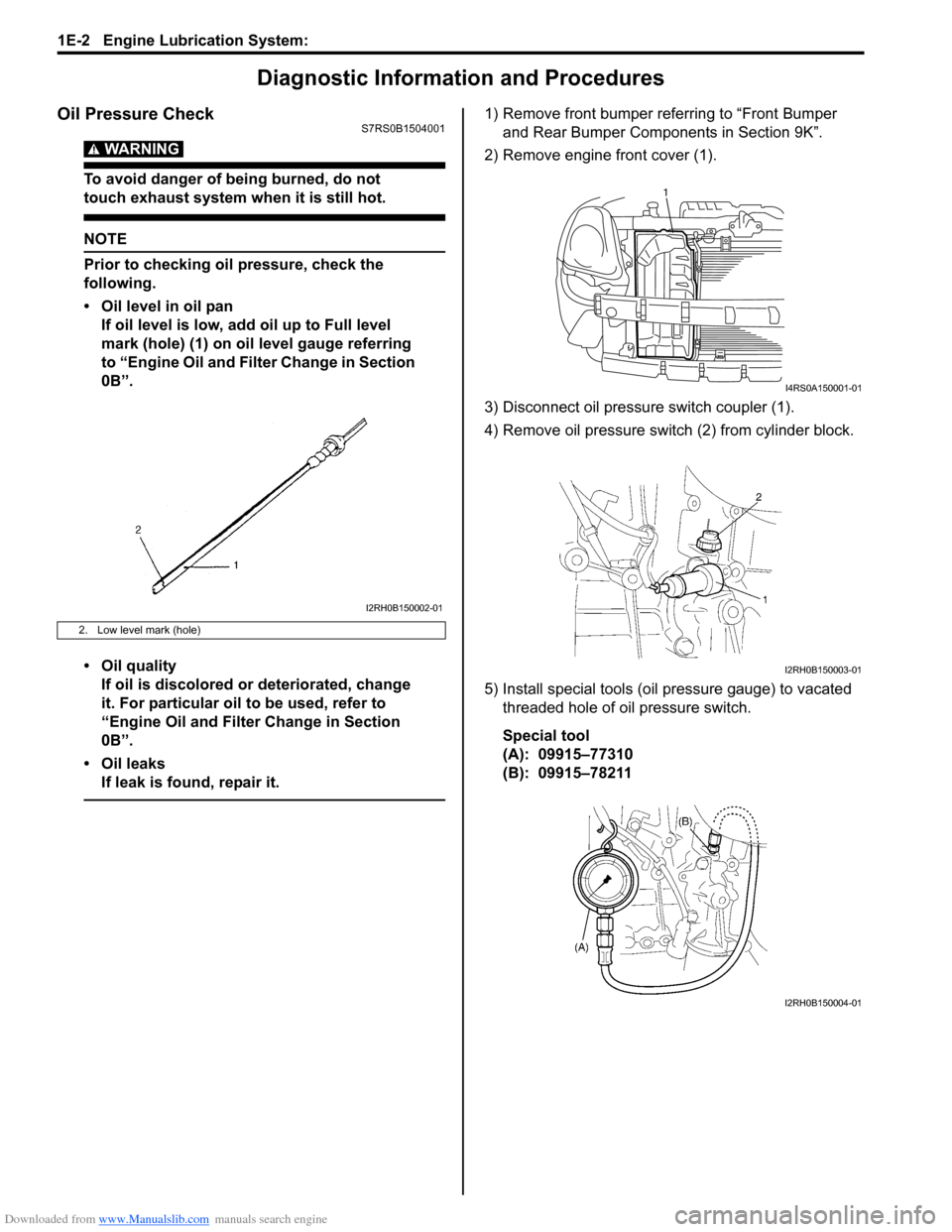

Oil Pressure CheckS7RS0B1504001

WARNING!

To avoid danger of being burned, do not

touch exhaust system when it is still hot.

NOTE

Prior to checking oil pressure, check the

following.

• Oil level in oil pan

If oil level is low, add oil up to Full level

mark (hole) (1) on oil level gauge referring

to “Engine Oil and Filter Change in Section

0B”.

• Oil quality If oil is discolored or deteriorated, change

it. For particular oil to be used, refer to

“Engine Oil and Filter Change in Section

0B”.

• Oil leaks If leak is found, repair it.

1) Remove front bumper referring to “Front Bumper and Rear Bumper Components in Section 9K”.

2) Remove engine front cover (1).

3) Disconnect oil pressure switch coupler (1).

4) Remove oil pressure swit ch (2) from cylinder block.

5) Install special tools (oil pressure gauge) to vacated threaded hole of oil pressure switch.

Special tool

(A): 09915–77310

(B): 09915–78211

2. Low level mark (hole)

I2RH0B150002-01

1

I4RS0A150001-01

I2RH0B150003-01

I2RH0B150004-01

Page 355 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Lubrication System: 1E-3

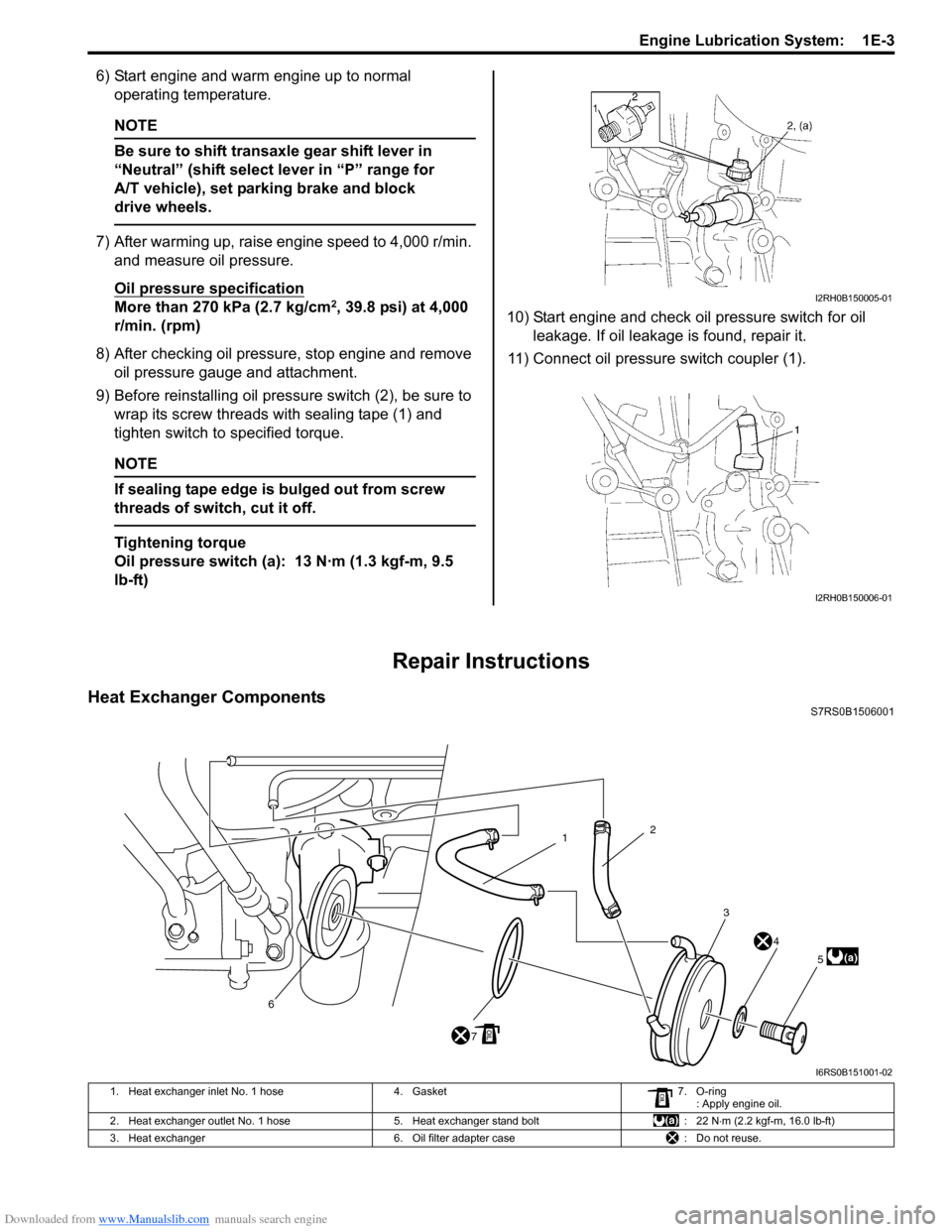

6) Start engine and warm engine up to normal operating temperature.

NOTE

Be sure to shift transaxle gear shift lever in

“Neutral” (shift select lever in “P” range for

A/T vehicle), set parking brake and block

drive wheels.

7) After warming up, raise engine speed to 4,000 r/min. and measure oil pressure.

Oil pressure specification

More than 270 kPa (2.7 kg/cm2, 39.8 psi) at 4,000

r/min. (rpm)

8) After checking oil pressure, stop engine and remove oil pressure gauge and attachment.

9) Before reinstalling oil pressure switch (2), be sure to

wrap its screw threads with sealing tape (1) and

tighten switch to specified torque.

NOTE

If sealing tape edge is bulged out from screw

threads of switch, cut it off.

Tightening torque

Oil pressure switch (a): 13 N·m (1.3 kgf-m, 9.5

lb-ft) 10) Start engine and check oil pressure switch for oil

leakage. If oil leakage is found, repair it.

11) Connect oil pressure switch coupler (1).

Repair Instructions

Heat Exchanger ComponentsS7RS0B1506001

I2RH0B150005-01

I2RH0B150006-01

3

4

5

7

6

(a)

2

1

I6RS0B151001-02

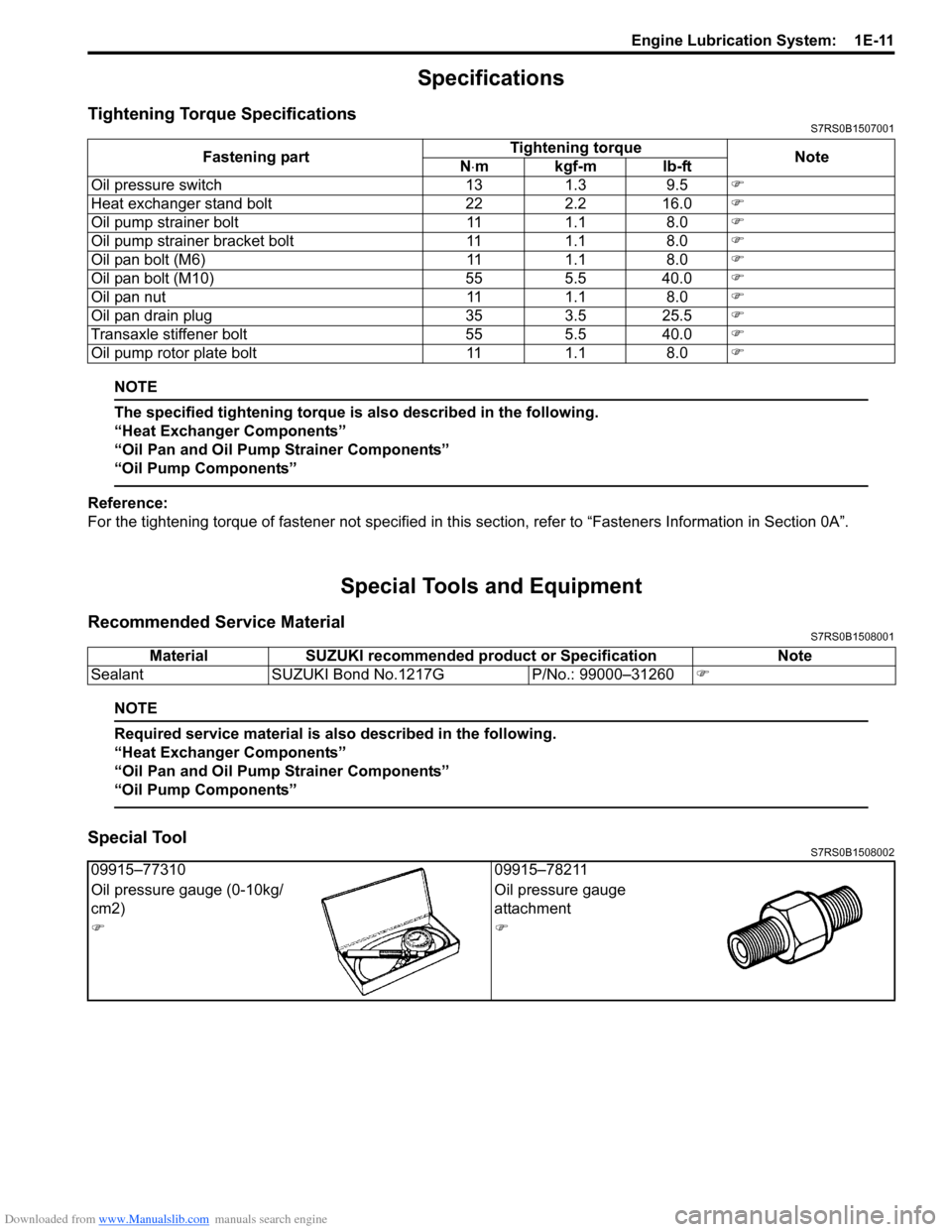

1. Heat exchanger inlet No. 1 hose 4. Gasket7. O-ring

: Apply engine oil.

2. Heat exchanger outlet No. 1 hose 5. Heat exchanger stand bolt : 22 N⋅m (2.2 kgf-m, 16.0 lb-ft)

3. Heat exchanger 6. Oil filter adapter case : Do not reuse.

Page 363 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Lubrication System: 1E-11

Specifications

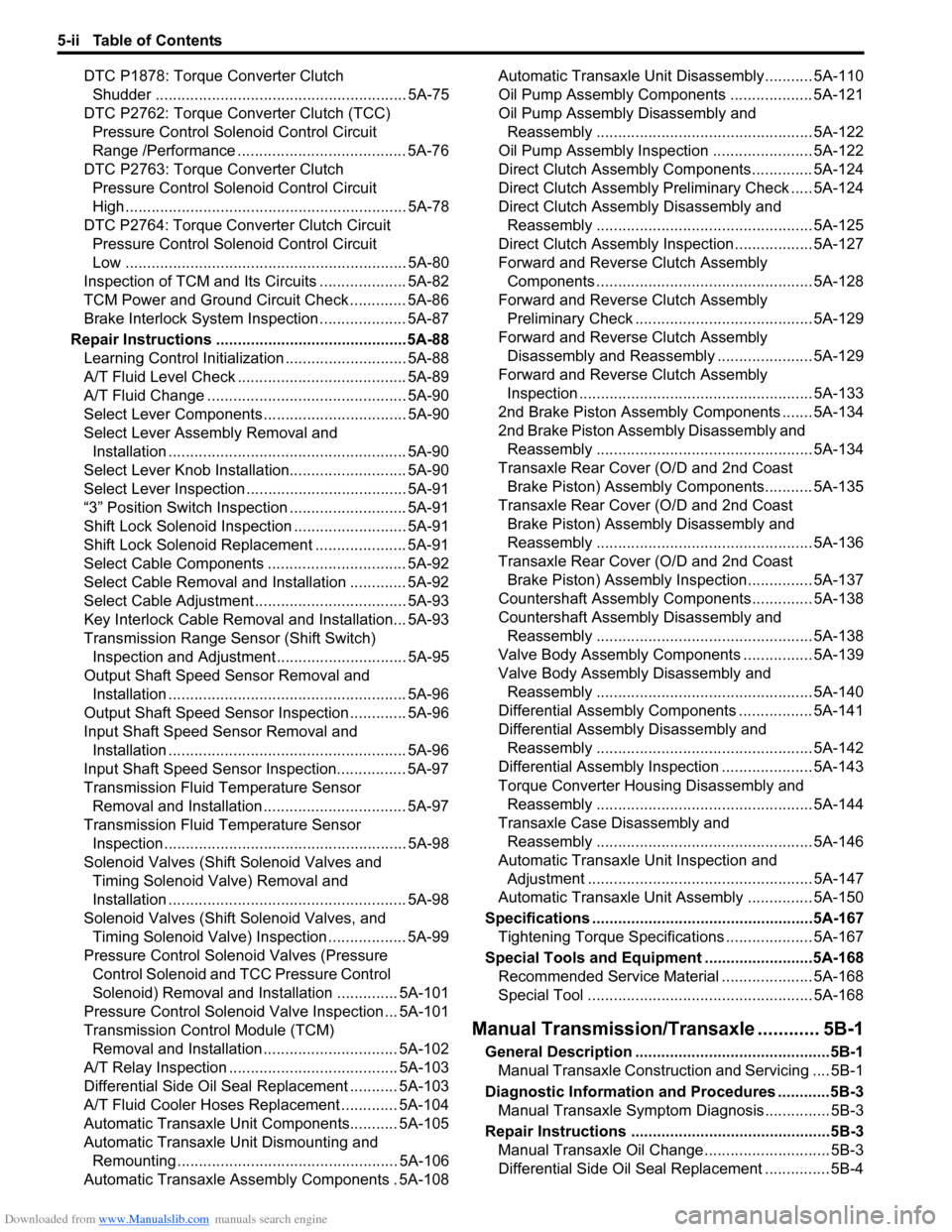

Tightening Torque SpecificationsS7RS0B1507001

NOTE

The specified tightening torque is also described in the following.

“Heat Exchanger Components”

“Oil Pan and Oil Pump Strainer Components”

“Oil Pump Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Recommended Service MaterialS7RS0B1508001

NOTE

Required service material is also described in the following.

“Heat Exchanger Components”

“Oil Pan and Oil Pump Strainer Components”

“Oil Pump Components”

Special ToolS7RS0B1508002

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Oil pressure switch 13 1.3 9.5 �)

Heat exchanger stand bolt 22 2.2 16.0 �)

Oil pump strainer bolt 11 1.1 8.0 �)

Oil pump strainer bracket bolt 11 1.1 8.0 �)

Oil pan bolt (M6) 11 1.1 8.0 �)

Oil pan bolt (M10) 55 5.5 40.0 �)

Oil pan nut 11 1.1 8.0 �)

Oil pan drain plug 35 3.5 25.5 �)

Transaxle stiffener bolt 55 5.5 40.0 �)

Oil pump rotor plate bolt 11 1.1 8.0 �)

MaterialSUZUKI recommended product or Specification Note

Sealant SUZUKI Bond No.1217G P/No.: 99000–31260�)

09915–77310 09915–78211

Oil pressure gauge (0-10kg/

cm2) Oil pressure gauge

attachment

�)�)

Page 642 of 1496

Downloaded from www.Manualslib.com manuals search engine 5-ii Table of Contents

DTC P1878: Torque Converter Clutch Shudder .......................................................... 5A-75

DTC P2762: Torque Converter Clutch (TCC) Pressure Control Sole noid Control Circuit

Range /Performance ....................................... 5A-76

DTC P2763: Torque Converter Clutch Pressure Control Sole noid Control Circuit

High ................................................................. 5A-78

DTC P2764: Torque Converter Clutch Circuit Pressure Control Sole noid Control Circuit

Low ................................................................. 5A-80

Inspection of TCM and Its Circuits .................... 5A-82

TCM Power and Ground Circuit Check ............. 5A-86

Brake Interlock System Inspection .................... 5A-87

Repair Instructions ........... .................................5A-88

Learning Control Initializat ion ............................ 5A-88

A/T Fluid Level Check ....................................... 5A-89

A/T Fluid Change .............................................. 5A-90

Select Lever Components ... .............................. 5A-90

Select Lever Assembly Removal and Installation ....................................................... 5A-90

Select Lever Knob Installa tion........................... 5A-90

Select Lever Inspection .... ................................. 5A-91

“3” Position Switch Inspec tion ........................... 5A-91

Shift Lock Solenoid Inspec tion .......................... 5A-91

Shift Lock Solenoid Replacement ..................... 5A-91

Select Cable Components ................................ 5A-92

Select Cable Removal and Installation ............. 5A-92

Select Cable Adjustment ................................... 5A-93

Key Interlock Cable Removal and Installation... 5A-93

Transmission Range Sensor (Shift Switch) Inspection and Adjustment .............................. 5A-95

Output Shaft Speed Sensor Removal and Installation ....................................................... 5A-96

Output Shaft Speed Sensor Inspection ............. 5A-96

Input Shaft Speed Sensor Removal and Installation ....................................................... 5A-96

Input Shaft Speed Sensor Inspection................ 5A-97

Transmission Fluid Temperature Sensor Removal and Installation ................................. 5A-97

Transmission Fluid Temperature Sensor Inspection ........................................................ 5A-98

Solenoid Valves (Shift Solenoid Valves and Timing Solenoid Valve) Removal and

Installation ....................................................... 5A-98

Solenoid Valves (Shift Solenoid Valves, and Timing Solenoid Valve) Inspection .................. 5A-99

Pressure Control Soleno id Valves (Pressure

Control Solenoid and TCC Pressure Control

Solenoid) Removal and Inst allation .............. 5A-101

Pressure Control Solenoid Valve Inspection ... 5A-101

Transmission Control Module (TCM) Removal and Installation ............................... 5A-102

A/T Relay Inspection ....................................... 5A-103

Differential Side Oil Seal Replacement ........... 5A-103

A/T Fluid Cooler Hoses Replacement ............. 5A-104

Automatic Transaxle Unit Components........... 5A-105

Automatic Transaxle Unit Dismounting and Remounting ................................................... 5A-106

Automatic Transaxle Asse mbly Components . 5A-108 Automatic Transaxle Unit

Disassembly........... 5A-110

Oil Pump Assembly Components ................... 5A-121

Oil Pump Assembly Disassembly and Reassembly .................................................. 5A-122

Oil Pump Assembly Inspection ....................... 5A-122

Direct Clutch Assembly Components.............. 5A-124

Direct Clutch Assembly Preliminary Check ..... 5A-124

Direct Clutch Assembly Disassembly and Reassembly .................................................. 5A-125

Direct Clutch Assembly Inspection.................. 5A-127

Forward and Reverse Clutch Assembly Components .................................................. 5A-128

Forward and Reverse Clutch Assembly Preliminary Check ......................................... 5A-129

Forward and Reverse Clutch Assembly Disassembly and Reassembly ...................... 5A-129

Forward and Reverse Clutch Assembly Inspection ...................................................... 5A-133

2nd Brake Piston Assembly Components ....... 5A-134

2nd Brake Piston Assembly Disassembly and Reassembly .................................................. 5A-134

Transaxle Rear Cover (O/D and 2nd Coast Brake Piston) Assembly Components........... 5A-135

Transaxle Rear Cover (O/D and 2nd Coast Brake Piston) Assembly Disassembly and

Reassembly .................................................. 5A-136

Transaxle Rear Cover (O/D and 2nd Coast Brake Piston) Assembly Inspection............... 5A-137

Countershaft Assembly Co mponents.............. 5A-138

Countershaft Assembly Disassembly and Reassembly .................................................. 5A-138

Valve Body Assembly Components ................ 5A-139

Valve Body Assembly Disassembly and Reassembly .................................................. 5A-140

Differential Assembly Components ................. 5A-141

Differential Assembly Disassembly and Reassembly .................................................. 5A-142

Differential Assembly Inspection ..................... 5A-143

Torque Converter Housing Disassembly and Reassembly .................................................. 5A-144

Transaxle Case Disassembly and Reassembly .................................................. 5A-146

Automatic Transaxle Unit Inspection and Adjus

tment .................................................... 5A-147

Automatic Transaxle Unit Assembly ............... 5A-150

Specifications .................. .................................5A-167

Tightening Torque Specifications .................... 5A-167

Special Tools and Equipmen t .........................5A-168

Recommended Service Material ..................... 5A-168

Special Tool .................................................... 5A-168

Manual Transmission/Tr ansaxle ............ 5B-1

General Description .............................................5B-1

Manual Transaxle Construction and Servicing .... 5B-1

Diagnostic Information and Procedures ............5B-3 Manual Transaxle Symptom Diagnosis............... 5B-3

Repair Instructions ............ ..................................5B-3

Manual Transaxle Oil Change............................. 5B-3

Differential Side Oil Seal Replacement ............... 5B-4

Page 647 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-3

General Description

A/T DescriptionS7RS0B5101001

This automatic transaxle is electronic control full automatic transaxle with forward 4-speed and reverse 1-speed.

The torque converter is a 3-element, 1-step and 2-phase type and is equipped with an automatically controlled lock-up

mechanism.

The gear change device consists of a ravigneau type planet ary gear unit, 3 multiple disc type clutches, 3 multiple disc

type brakes and 2 one-way clutches.

The hydraulic pressure control device consists of a valve body assembly, pressure control solenoid valve (linear

solenoid), 2 shift solenoid va lves, TCC pressure control solenoid valve (lin ear solenoid) and a timing solenoid valve.

Optimum line pressure complying with engine torque is produced by the pressure control solenoid valve in

dependence upon control signal from transmission control module (TCM). This makes it possible to control the line

pressure with high accuracy in accordance with the engine power and running conditions to achieve smooth shifting

characteristics and high efficiency.

A clutch-to-clutch control system is prov ided for shifting between 3rd gear and 4th gear. This clutch-to-clutch control

system is made to function optimally , so that hydraulic pressure controls such as shown below are conducted.

• When upshifting from 3rd gear to 4th gear, to adjust the drain hydraulic pressure at releasing the forward clutch, a

timing solenoid valve is used to switch a hydraulic passage with an orifice to another during shifting.

• When downshifting from 4th gear to 3rd gear, to adjust the line pressure applied to the forward clutch at engaging the forward clutch, a timing solenoid valve is used to s witch a hydraulic passage with an orifice to another during

shifting.

• When upshifting from 3rd gear to 4th gear with engine throttle opened, to optimize the line pressure applied to the forward clutch at releasing the forward clutch, the learning control is processed to compensate the switching timing

of the timing solenoid at every shifting.

• When downshifting from 4th gear to 3rd gear with engine throttle opened, to optimize the line pressure applied to

the forward clutch at engaging the forw ard clutch, the learning control is processed to compensate the line pressure

at every shifting.

Employing the ravigneau type planetary gear unit and this clutch-to-clutch control system greatly simplifies the

construction to make possible a lightweight and compact transaxle.

A line pressure learning control is conducted to provide opti mum shifting time at every upshifting with engine throttle

opened. If long upshifting time is detected, the subsequent line pressure applied during upshifting is intensified. On the

contrary, if short upshifting time is detected, the subs equent line pressure applied during upshifting is weakened.

Slip controlled lock-up function

Even at a lower speed than when the TCC gets engaged completely, control over the TCC pressure control solenoid

works to cause the TCC to slip (be engaged slightly), ther eby improving the transmission efficiency. While such slip

control is being executed, the oil pressure applied to the TCC is controlled by the TCC pressure control solenoid so

that the difference between the engine speed and the input shaft speed becomes close to the specified value.

Also, during deceleration, the TCC is made to slip (be enga ged slightly) to raise the engine speed and enlarge the fuel

cut operation range so that better fuel consumption is achieved.

Due to this reason, it is absolutely necessary for the automati c transmission to use ATF suitable for slip control. Use of

any fluid other than the specified ATF may cause j uddering or some other faulty condition to occur.

Page 662 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-18 Automatic Transmission/Transaxle:

Visual InspectionS7RS0B5104002

Visually check the following parts and systems.

Malfunction Indicator Lamp (MIL) CheckS7RS0B5104003

Refer to the same item in “Malfunction Indicator Lam p (MIL) Check in Section 1A” for checking procedure.

Transmission Warning Light CheckS7RS0B5104004

1) Turn ignition switch ON.

2) Check that transmission warning light lights for about 2 – 4 sec. and then goes OFF.

If anything faulty is found, advance “Transmission Warn ing Light Circuit Check – Light Does Not Come “ON” at

Ignition Switch ON” or “Transmission Warning Light Circu it Check – Light Remains “ON” at Ignition Switch ON”.

Inspection item Referring

• A/T fluid ----- level, leakage, color “Automatic Transaxle Fluid Level Inspection in Section 0B”

• A/T fluid hoses ----- disconnection, looseness, deterioration “A/T Fluid Cooler Hoses Replacement”

• A/T select cable ----- installation “S elect Cable Removal and Installation”

• Engine oil ----- level, leakage “Engine Oil and Filter Change in Section 0B”

• Engine coolant ----- level, leakage “Engine Coolant Change in Section 0B”

• Engine mountings ----- play, looseness, damage “Engine Assembly Removal and Installation in Section 1D”

• Suspension ----- play, looseness “Suspension, Wheels and Tires Symptom Diagnosis in Section 2A”

• Drive shafts ----- damage “Front Drive Shaft Assembly On-Vehicle Inspection in Section 3A”

• Battery ----- indicator condition, corrosion of terminal “Battery Inspection in Section 1J”

• Connectors of electric wire harness ----- disconnection, friction “Electronic Shift Control System Components

Location”

• Fuses ----- burning

• Parts ----- installation, damage

• Bolts ----- looseness

• Other parts that can be checked visually

Also check the following items at engine start, if possible.

• Transmission warning light (if equipped) ----- Operation “Transmission Warning Light Check”

• Malfunction indicator lamp ----- Operation “Malfunction Indicator Lamp (MIL) Check”

• Charge warning lamp ----- Operation “Generator Symptom Diagnosis in Section 1J”

• Engine oil pressure warning lamp ----- Operation “Oil Pressure Warning Ligh t Symptom Diagnosis in

Section 9C”

• Engine coolant temp. meter ----- Operation “Engine Coolant Temperature (ECT) Meter

Symptom Diagnosis in Section 9C”

• Other parts that can be checked visually

I4RS0A510008-01

Page 676 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-32 Automatic Transmission/Transaxle:

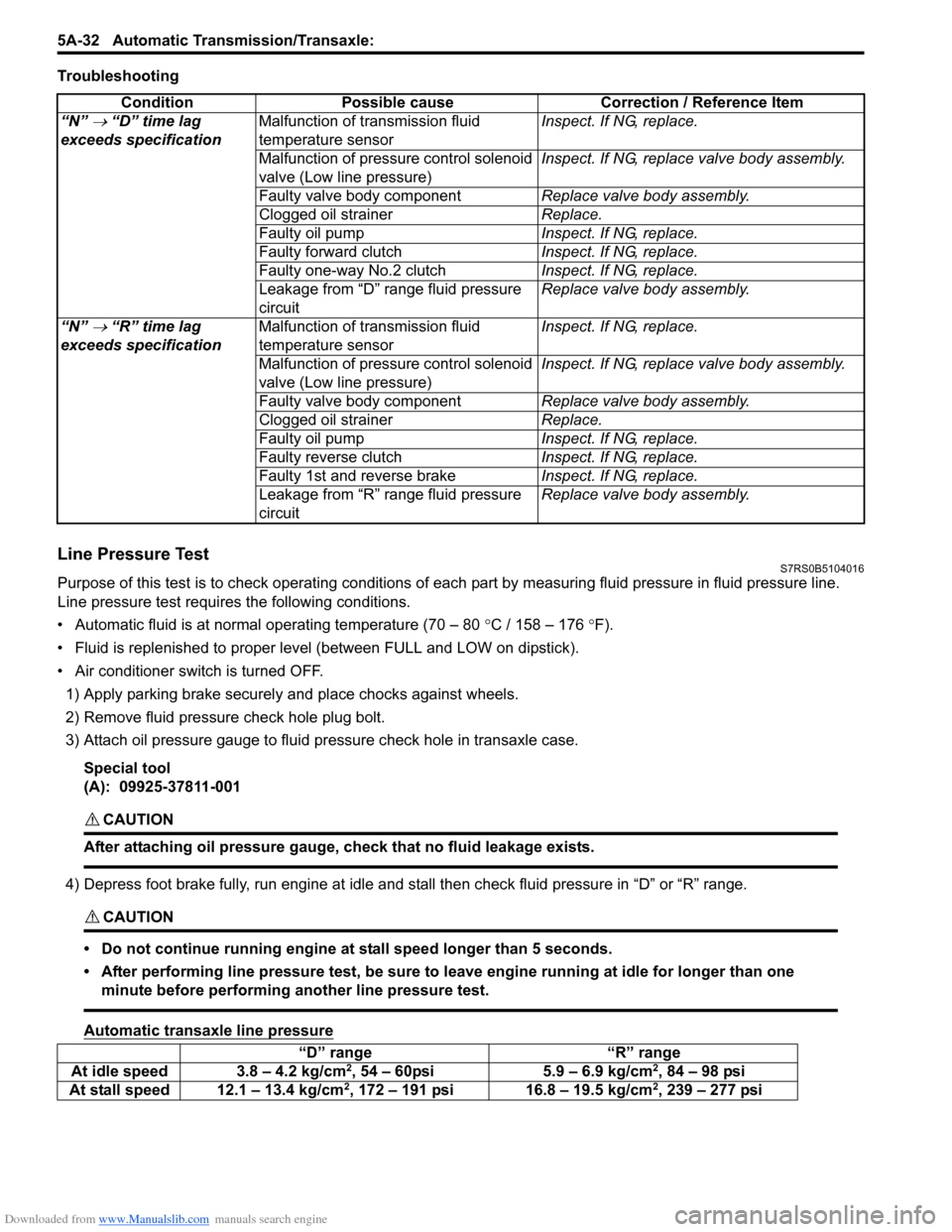

Troubleshooting

Line Pressure TestS7RS0B5104016

Purpose of this test is to check operat ing conditions of each part by measuring fluid pressure in fluid pressure line.

Line pressure test requires the following conditions.

• Automatic fluid is at normal operating temperature (70 – 80 °C / 158 – 176 °F).

• Fluid is replenished to proper level (between FULL and LOW on dipstick).

• Air conditioner switch is turned OFF.

1) Apply parking brake securely and place chocks against wheels.

2) Remove fluid pressure check hole plug bolt.

3) Attach oil pressure gauge to fluid pr essure check hole in transaxle case.

Special tool

(A): 09925-37811-001

CAUTION!

After attaching oil pressure gauge, check that no fluid leakage exists.

4) Depress foot brake fully, run engine at idle and stall then check fluid pressure in “D” or “R” range.

CAUTION!

• Do not continue running engine at stall speed longer than 5 seconds.

• After performing line pressure test, be sure to leave engine running at idle for longer than one minute before performing another line pressure test.

Automatic transaxle line pressure

Condition Possible cause Correction / Reference Item

“N”

→ “D” time lag

exceeds specification Malfunction of transmission fluid

temperature sensor Inspect. If NG, replace.

Malfunction of pressure control solenoid

valve (Low line pressure) Inspect. If NG, replace valve body assembly.

Faulty valve body component Replace valve body assembly.

Clogged oil strainer Replace.

Faulty oil pump Inspect. If NG, replace.

Faulty forward clutch Inspect. If NG, replace.

Faulty one-way No.2 clutch Inspect. If NG, replace.

Leakage from “D” range fluid pressure

circuit Replace valve body assembly.

“N”

→ “R” time lag

exceeds specification Malfunction of transmission fluid

temperature sensor Inspect. If NG, replace.

Malfunction of pressure control solenoid

valve (Low line pressure) Inspect. If NG, replace valve body assembly.

Faulty valve body component Replace valve body assembly.

Clogged oil strainer Replace.

Faulty oil pump Inspect. If NG, replace.

Faulty reverse clutch Inspect. If NG, replace.

Faulty 1st and reverse brake Inspect. If NG, replace.

Leakage from “R” range fluid pressure

circuit Replace valve body assembly.

“D” range

“R” range

At idle speed 3.8 – 4.2 kg/cm2, 54 – 60psi 5.9 – 6.9 kg/cm2, 84 – 98 psi

At stall speed 12.1 – 13.4 kg/cm2, 172 – 191 psi 16.8 – 19.5 kg/cm2, 239 – 277 psi