Oil pressure switch SUZUKI SWIFT 2005 2.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 87 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-37

TP SENSOR 2 VOLT (THROTTLE POSITION SENSOR

(SUB) OUTPUT VOLTAGE, V)

The TP sensor (sub) reading provides throttle valve

opening information in the form of voltage.

APP SENSOR 1 VOLT (ACCELERATOR PEDAL

POSITION (APP) SENSOR (MAIN) OUTPUT

VOLTAGE, V)

The APP sensor (main) read ing provides accelerator

pedal opening information in the form of voltage.

APP SENSOR 2 VOLT (ACCELERATOR PEDAL

POSITION (APP) SENSOR (S UB) OUTPUT VOLTAGE,

V)

The APP sensor (sub) reading provides accelerator

pedal opening information in the form of voltage.

ACCEL POSITION (ABSOLUTE ACCELERATOR

PEDAL POSITION, %)

When accelerator pedal is at fully released position,

accelerator pedal is indicated as 0 – 5% and 90 – 100%

fully depressed position. THROTTLE TARGET POSI (TARGET THROTTLE

VALVE POSITION, %)

Target throttle valve position is ECM internal parameter

which indicates the ECM requested throttle valve

position.

BATTERY CURRENT (A)

This parameter indicates elec

tric load value (current

consumption) that detected by electric load current

sensor.

GENERATOR CONT DUTY (GENERATOR CONTROL

DUTY, %)

This parameter indicates generator control duty ratio that

controls production electricity of generator by ECM.

100%: No limitation for the generating

0%: Maximum limitation for the generating

GENERATOR FIELD DUTY (GENERATOR FIELD

COIL DUTY, %)

This parameter indicates ope rating rate (status of

production electricity) for gen erator by field coil duty

ratio.

100%: maximum operation.

0%: minimum operation.

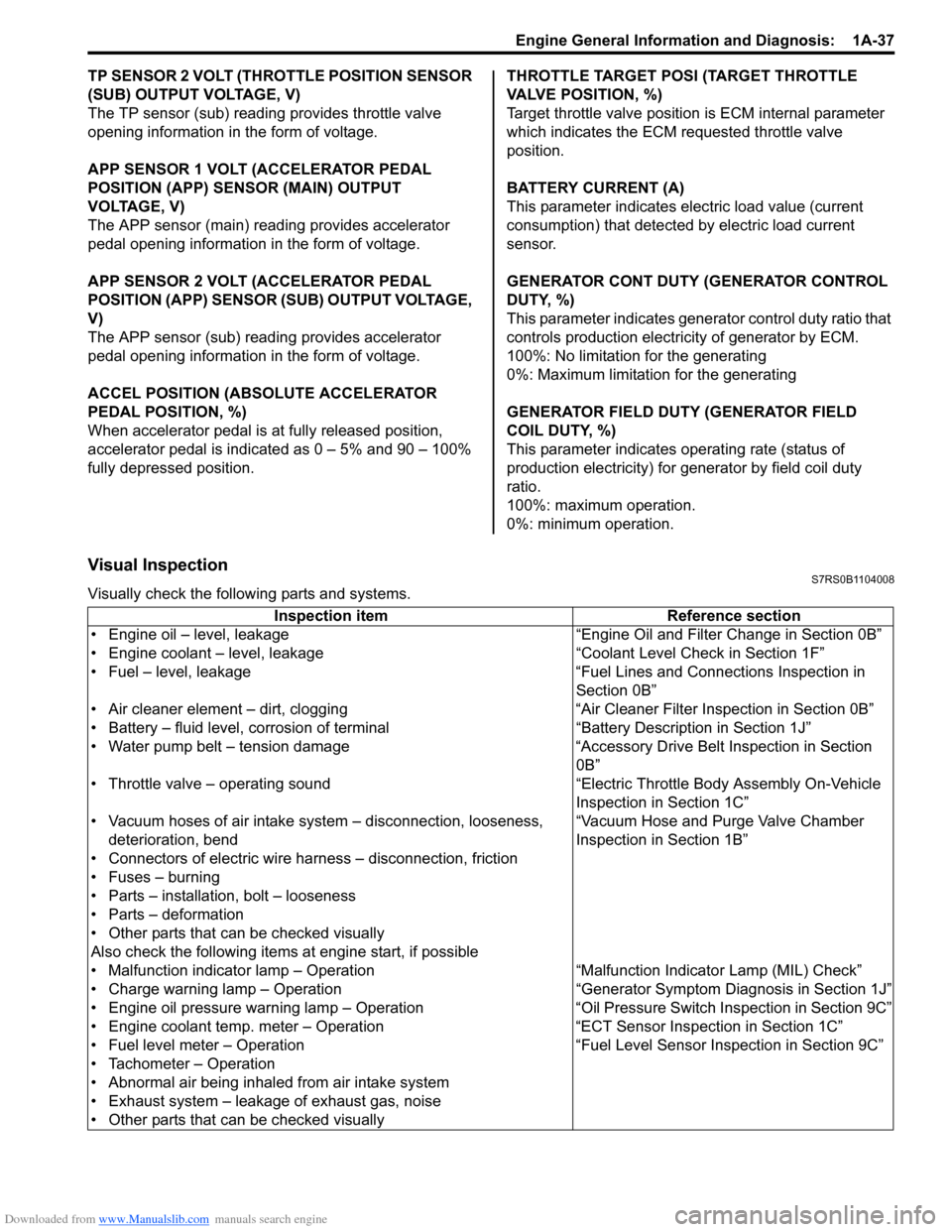

Visual InspectionS7RS0B1104008

Visually check the following parts and systems.

Inspection item Reference section

• Engine oil – level, leakage “Engine Oil and Filter Change in Section 0B”

• Engine coolant – level, leakage “Co olant Level Check in Section 1F”

• Fuel – level, leakage “Fuel Lines and Connections Inspection in Section 0B”

• Air cleaner element – dirt, clogging “Air Cleaner Filter Inspection in Section 0B”

• Battery – fluid level, corrosion of terminal “Battery Description in Section 1J”

• Water pump belt – tension damage “Accessory Drive Belt Inspection in Section 0B”

• Throttle valve – operating sound “Electric Throttle Body Assembly On-Vehicle Inspection in Section 1C”

• Vacuum hoses of air intake system – disconnection, looseness,

deterioration, bend “Vacuum Hose and Purge Valve Chamber

Inspection in Section 1B”

• Connectors of electric wire harness – disconnection, friction

• Fuses – burning

• Parts – installation, bolt – looseness

• Parts – deformation

• Other parts that can be checked visually

Also check the following items at engine start, if possible

• Malfunction indicator lamp – Operation “Malfunction Indicator Lamp (MIL) Check”

• Charge warning lamp – Operation “Genera tor Symptom Diagnosis in Section 1J”

• Engine oil pressure warning lamp – Operation “O il Pressure Switch Inspection in Section 9C”

• Engine coolant temp. meter – Operation “ECT Sensor Inspection in Section 1C”

• Fuel level meter – Operation “Fuel Level Sensor Inspection in Section 9C”

• Tachometer – Operation

• Abnormal air being inhaled from air intake system

• Exhaust system – leakage of exhaust gas, noise

• Other parts that can be checked visually

Page 90 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-40 Engine General Information and Diagnosis:

11Check fuel pump for operation

Was fuel pump operating sou nd heard from fuel filler for

about 2 seconds after ignition switch ON and stop? Go to “Fuel Pressure

Check”.

Go to “Fuel Pump and

Its Circuit Check”.

12 Check ignition spark

1) Disconnect injector couplers.

2) Remove spark plugs and connect them to high-tension

cords or ignition coil assemblies.

3) Ground spark plugs.

4) Crank engine and check if each spark plug sparks.

Is it in good condition? Go to Step 13. Go to “Ignition Spark

Test in Section 1H”.

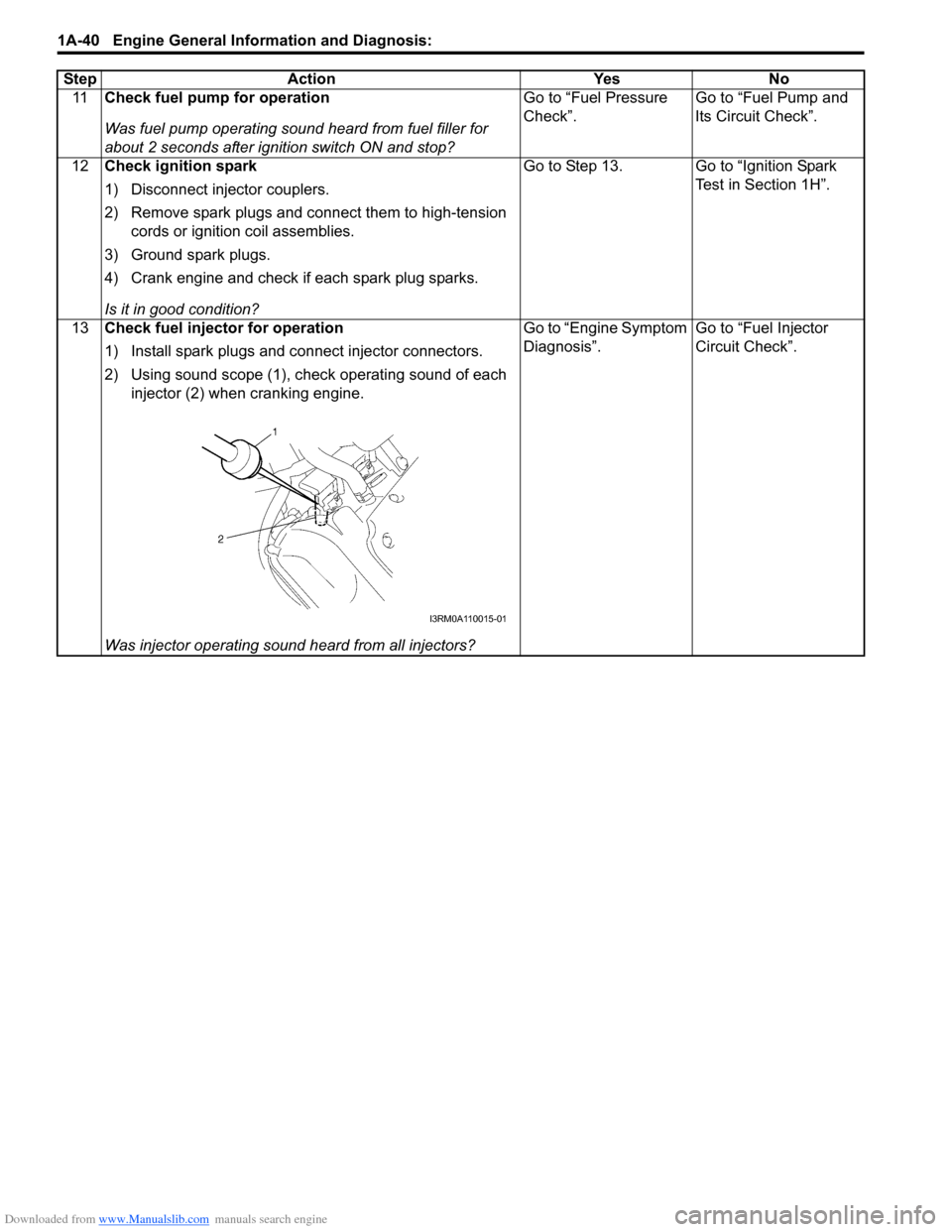

13 Check fuel injector for operation

1) Install spark plugs and connect injector connectors.

2) Using sound scope (1), check operating sound of each

injector (2) when cranking engine.

Was injector operating sound heard from all injectors? Go to “Engine Symptom

Diagnosis”.

Go to “Fuel Injector

Circuit Check”.

Step Action Yes No

I3RM0A110015-01

Page 91 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-41

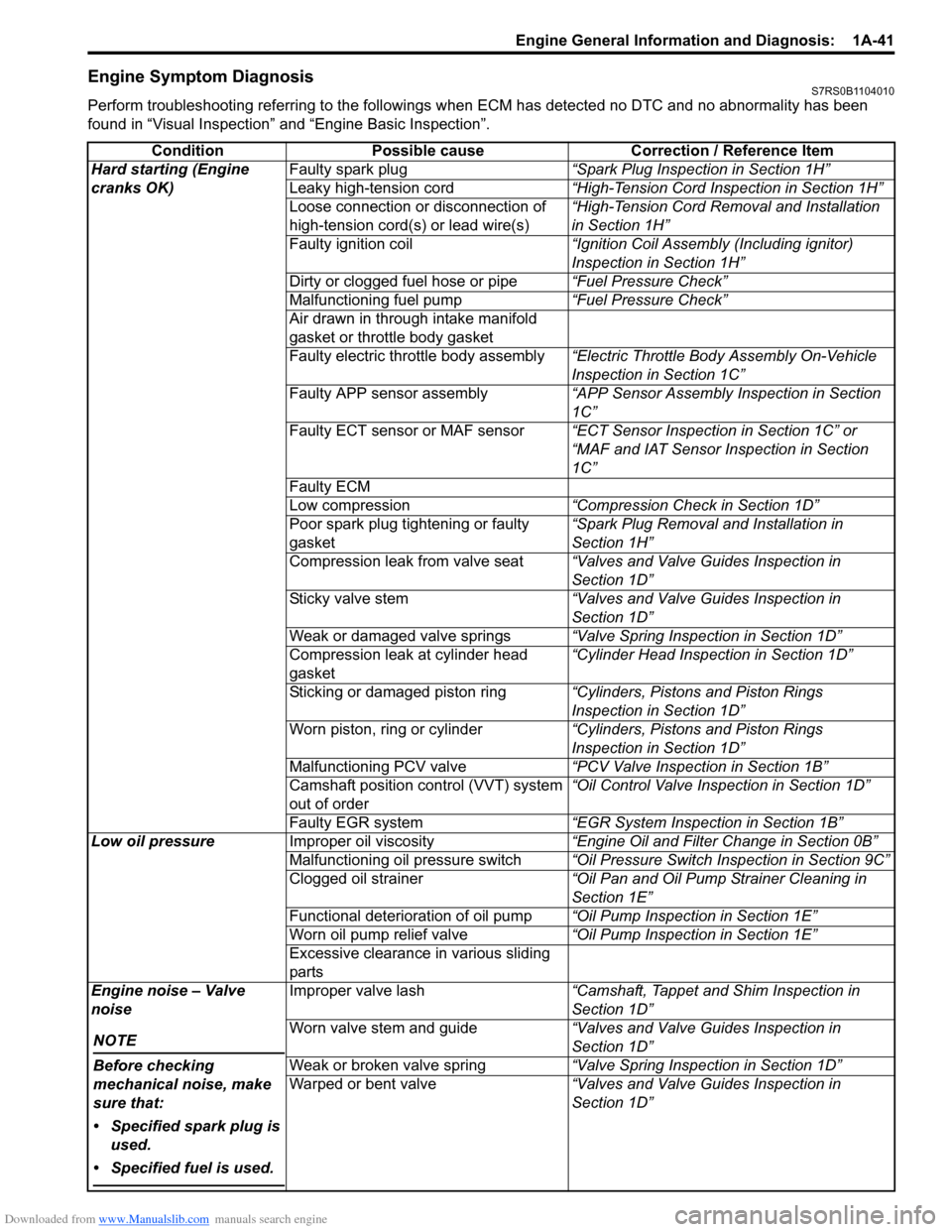

Engine Symptom DiagnosisS7RS0B1104010

Perform troubleshooting referring to the followings when ECM has detected no DTC and no abnormality has been

found in “Visual Inspection” and “Engine Basic Inspection”.

Condition Possible cause Correction / Reference Item

Hard starting (Engine

cranks OK) Faulty spark plug

“Spark Plug Inspection in Section 1H”

Leaky high-tension cord “High-Tension Cord Inspection in Section 1H”

Loose connection or disconnection of

high-tension cord(s) or lead wire(s) “High-Tension Cord Removal and Installation

in Section 1H”

Faulty ignition coil “Ignition Coil Assembly (Including ignitor)

Inspection in Section 1H”

Dirty or clogged fuel hose or pipe “Fuel Pressure Check”

Malfunctioning fuel pump “Fuel Pressure Check”

Air drawn in through intake manifold

gasket or throttle body gasket

Faulty electric throttle body assembly “Electric Throttle Body Assembly On-Vehicle

Inspection in Section 1C”

Faulty APP sensor assembly “APP Sensor Assembly Inspection in Section

1C”

Faulty ECT sensor or MAF sensor “ECT Sensor Inspection in Section 1C” or

“MAF and IAT Sensor Inspection in Section

1C”

Faulty ECM

Low compression “Compression Check in Section 1D”

Poor spark plug tightening or faulty

gasket “Spark Plug Removal and Installation in

Section 1H”

Compression leak from valve seat “Valves and Valve Guides Inspection in

Section 1D”

Sticky valve stem “Valves and Valve Guides Inspection in

Section 1D”

Weak or damaged valve springs “Valve Spring Inspection in Section 1D”

Compression leak at cylinder head

gasket “Cylinder Head Inspection in Section 1D”

Sticking or damaged piston ring “Cylinders, Pistons and Piston Rings

Inspection in Section 1D”

Worn piston, ring or cylinder “Cylinders, Pistons and Piston Rings

Inspection in Section 1D”

Malfunctioning PCV valve “PCV Valve Inspection in Section 1B”

Camshaft position control (VVT) system

out of order “Oil Control Valve Inspection in Section 1D”

Faulty EGR system “EGR System Inspection in Section 1B”

Low oil pressure Improper oil viscosity “Engine Oil and Filter Change in Section 0B”

Malfunctioning oil pressure switch “Oil Pressure Switch Inspection in Section 9C”

Clogged oil strainer “Oil Pan and Oil Pump Strainer Cleaning in

Section 1E”

Functional deterioration of oil pump “Oil Pump Inspection in Section 1E”

Worn oil pump relief valve “Oil Pump Inspection in Section 1E”

Excessive clearance in various sliding

parts

Engine noise – Valve

noise

NOTE

Before checking

mechanical noise, make

sure that:

• Specified spark plug is used.

• Specified fuel is used.

Improper valve lash “Camshaft, Tappet and Shim Inspection in

Section 1D”

Worn valve stem and guide “Valves and Valve Guides Inspection in

Section 1D”

Weak or broken valve spring “Valve Spring Inspection in Section 1D”

Warped or bent valve “Valves and Valve Guides Inspection in

Section 1D”

Page 102 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-52 Engine General Information and Diagnosis:

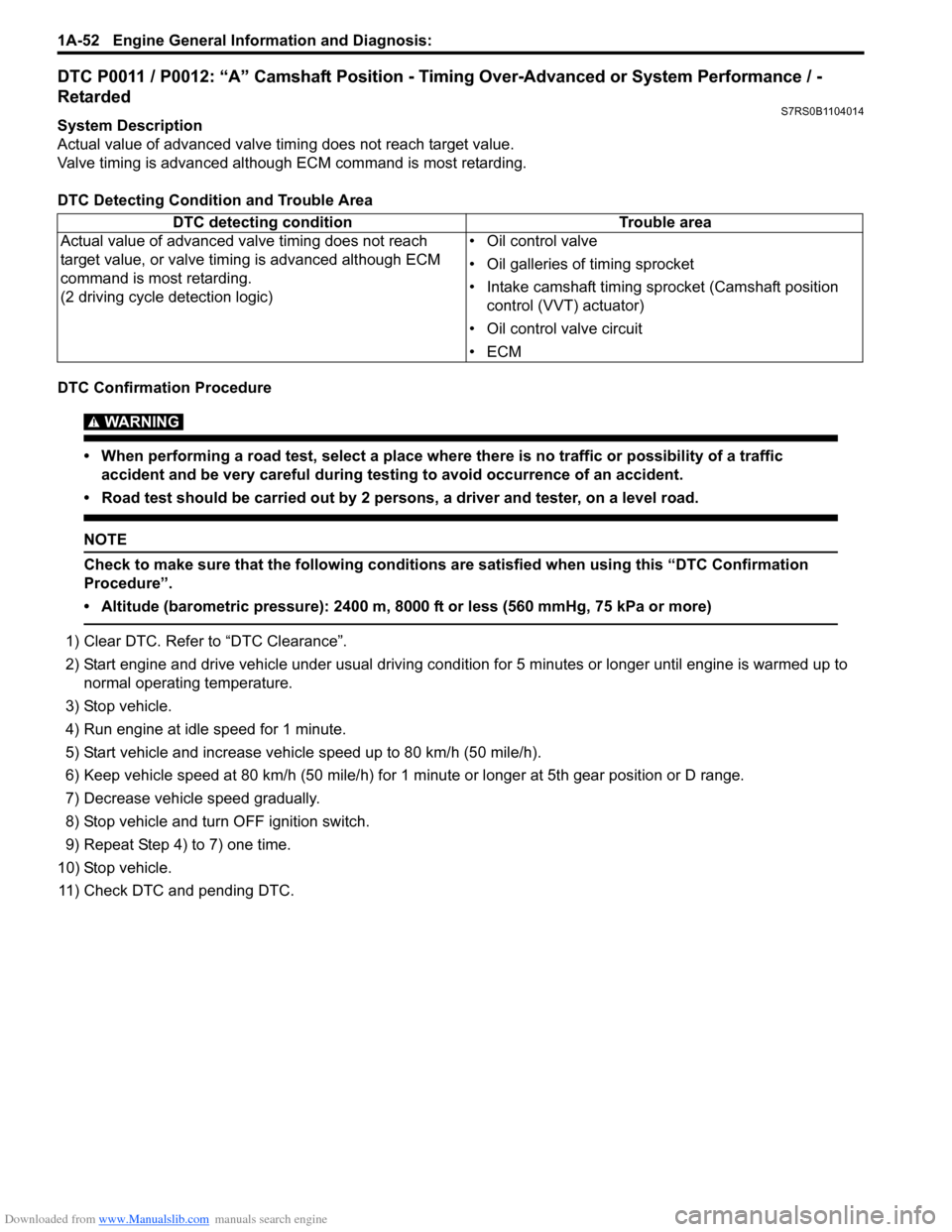

DTC P0011 / P0012: “A” Camshaft Position - Timing Over-Advanced or System Performance / -

Retarded

S7RS0B1104014

System Description

Actual value of advanced valve timing does not reach target value.

Valve timing is advanced although ECM command is most retarding.

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out by 2 persons, a driver and tester, on a level road.

NOTE

Check to make sure that the following conditions are satisfied when using this “DTC Confirmation

Procedure”.

• Altitude (barometric pressure): 2400 m, 8000 ft or less (560 mmHg, 75 kPa or more)

1) Clear DTC. Refer to “DTC Clearance”.

2) Start engine and drive vehicle under usual driving condition for 5 minutes or longer until engine is warmed up to normal operating temperature.

3) Stop vehicle.

4) Run engine at idle speed for 1 minute.

5) Start vehicle and increase vehicle speed up to 80 km/h (50 mile/h).

6) Keep vehicle speed at 80 km/h (50 mile/h) for 1 minute or longer at 5th gear position or D range.

7) Decrease vehicle speed gradually.

8) Stop vehicle and turn OFF ignition switch.

9) Repeat Step 4) to 7) one time.

10) Stop vehicle. 11) Check DTC and pending DTC. DTC detecting condition

Trouble area

Actual value of advanced valve timing does not reach

target value, or valve timi ng is advanced although ECM

command is most retarding.

(2 driving cycle detection logic) • Oil control valve

• Oil galleries of timing sprocket

• Intake camshaft timing sprocket (Camshaft position

control (VVT) actuator)

• Oil control valve circuit

•ECM

Page 103 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-53

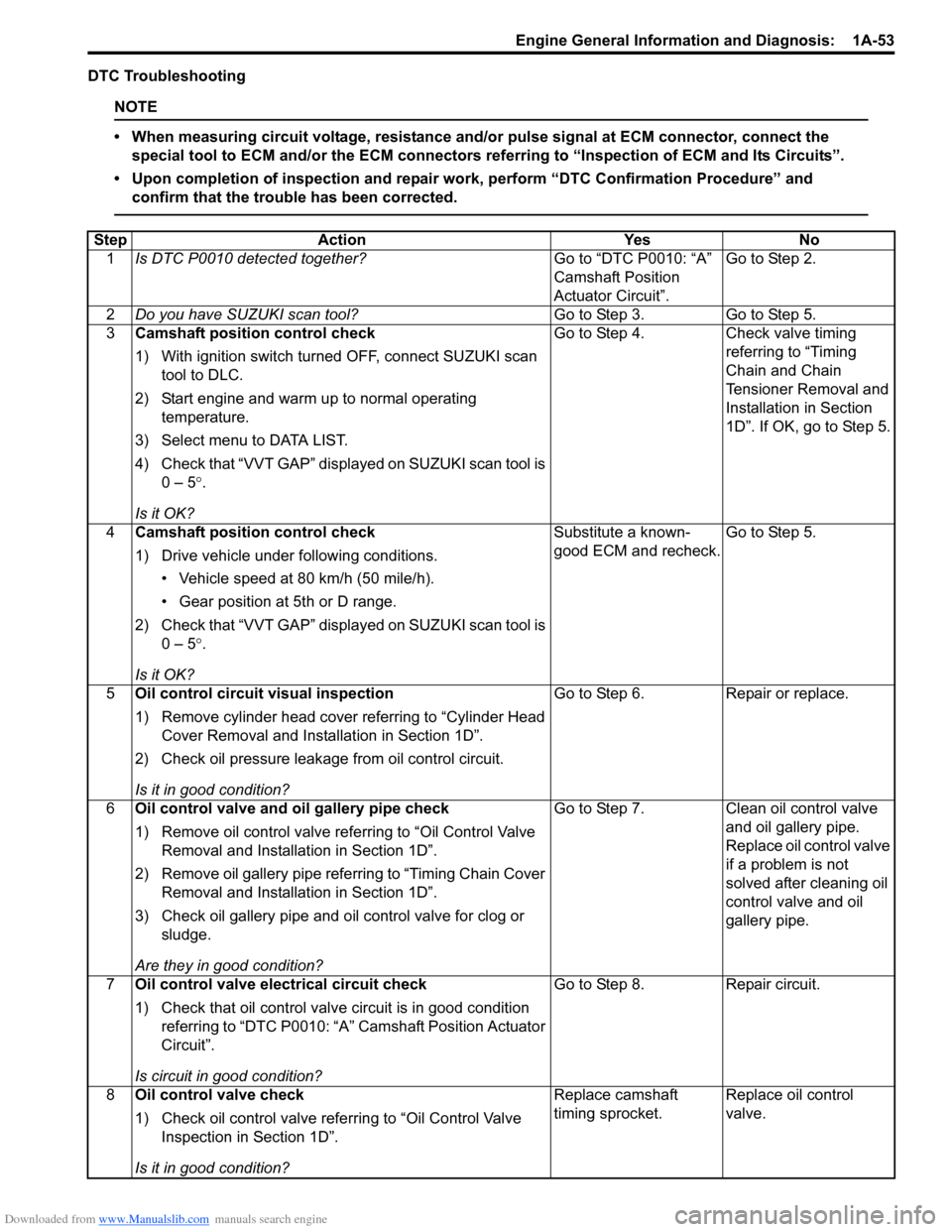

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

Step Action YesNo

1 Is DTC P0010 detected together? Go to “DTC P0010: “A”

Camshaft Position

Actuator Circuit”.Go to Step 2.

2 Do you have SUZUKI scan tool? Go to Step 3.Go to Step 5.

3 Camshaft position control check

1) With ignition switch turned OFF, connect SUZUKI scan

tool to DLC.

2) Start engine and warm up to normal operating temperature.

3) Select menu to DATA LIST.

4) Check that “VVT GAP” displayed on SUZUKI scan tool is 0 – 5 °.

Is it OK? Go to Step 4.

Check valve timing

referring to “Timing

Chain and Chain

Tensioner Removal and

Installation in Section

1D”. If OK, go to Step 5.

4 Camshaft position control check

1) Drive vehicle under following conditions.

• Vehicle speed at 80 km/h (50 mile/h).

• Gear position at 5th or D range.

2) Check that “VVT GAP” displayed on SUZUKI scan tool is 0 – 5 °.

Is it OK? Substitute a known-

good ECM and recheck.

Go to Step 5.

5 Oil control circuit visual inspection

1) Remove cylinder head cover referring to “Cylinder Head

Cover Removal and Insta llation in Section 1D”.

2) Check oil pressure leakage from oil control circuit.

Is it in good condition? Go to Step 6.

Repair or replace.

6 Oil control valve and oil gallery pipe check

1) Remove oil control valve re ferring to “Oil Control Valve

Removal and Installation in Section 1D”.

2) Remove oil gallery pipe refe rring to “Timing Chain Cover

Removal and Installation in Section 1D”.

3) Check oil gallery pipe and o il control valve for clog or

sludge.

Are they in good condition? Go to Step 7.

Clean oil control valve

and oil gallery pipe.

Replace oil control valve

if a problem is not

solved after cleaning oil

control valve and oil

gallery pipe.

7 Oil control valve electrical circuit check

1) Check that oil control valve circuit is in good condition

referring to “DTC P0010: “A” Camshaft Position Actuator

Circuit”.

Is circuit in good condition? Go to Step 8.

Repair circuit.

8 Oil control valve check

1) Check oil control valve refe rring to “Oil Control Valve

Inspection in Section 1D”.

Is it in good condition? Replace camshaft

timing sprocket.

Replace oil control

valve.

Page 227 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-177

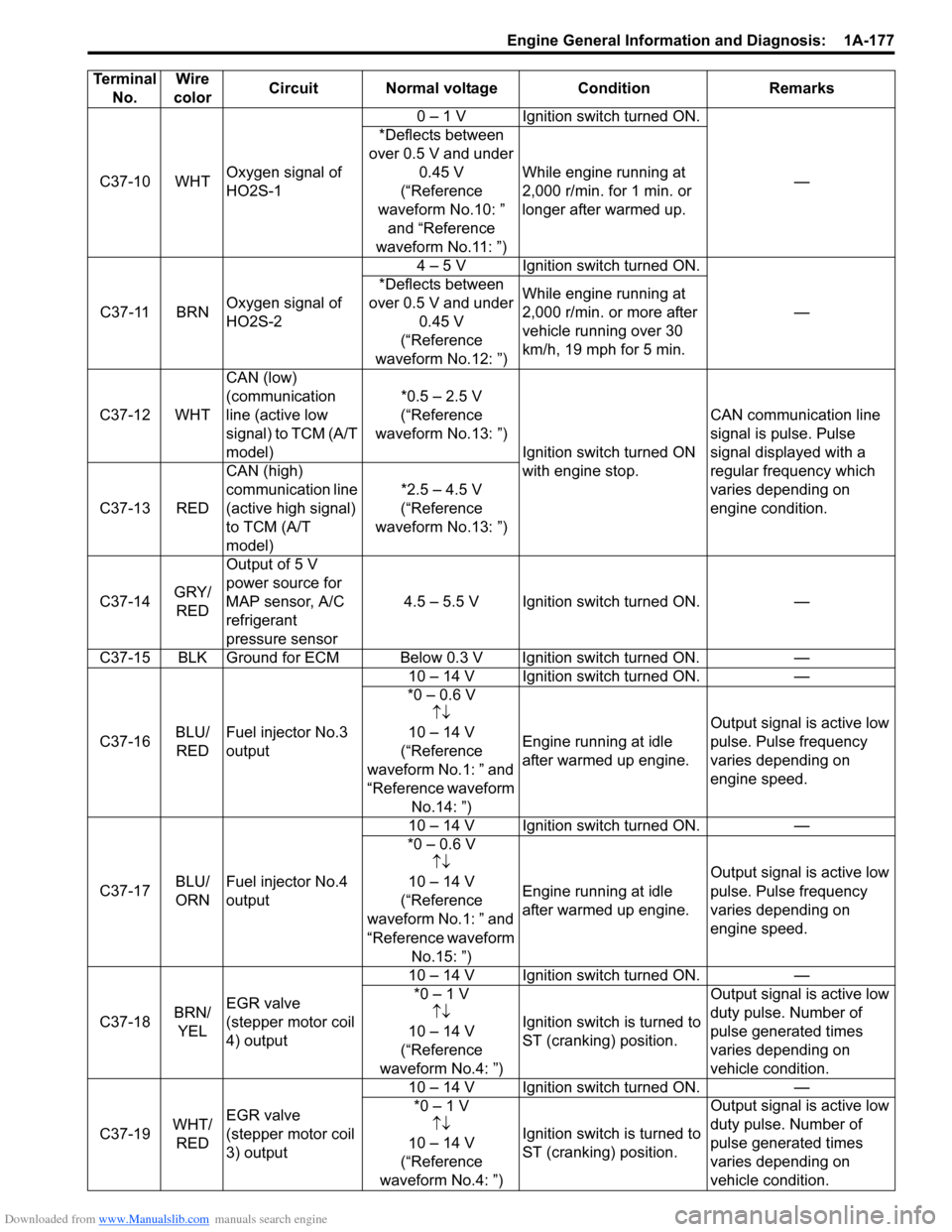

C37-10 WHTOxygen signal of

HO2S-1 0 – 1 V Ignition switch turned ON.

—

*Deflects between

over 0.5 V and under 0.45 V

(“Reference

waveform No.10: ” and “Reference

waveform No.11: ”) While engine running at

2,000 r/min. for 1 min. or

longer after warmed up.

C37-11 BRN Oxygen signal of

HO2S-2 4 – 5 V Ignition switch turned ON.

—

*Deflects between

over 0.5 V and under 0.45 V

(“Reference

waveform No.12: ”) While engine running at

2,000 r/min. or more after

vehicle running over 30

km/h, 19 mph for 5 min.

C37-12 WHT CAN (low)

(communication

line (active low

signal) to TCM (A/T

model) *0.5 – 2.5 V

(“Reference

waveform No.13: ”) Ignition switch turned ON

with engine stop. CAN communication line

signal is pulse. Pulse

signal displayed with a

regular frequency which

varies depending on

engine condition.

C37-13 RED CAN (high)

communication line

(active high signal)

to TCM (A/T

model) *2.5 – 4.5 V

(“Reference

waveform No.13: ”)

C37-14 GRY/

RED Output of 5 V

power source for

MAP sensor, A/C

refrigerant

pressure sensor

4.5 – 5.5 V Ignition switch turned ON. —

C37-15 BLK Ground for ECM Below 0.3 V Ignition switch turned ON. —

C37-16 BLU/

RED Fuel injector No.3

output 10 – 14 V Ignition switch turned ON. —

*0 – 0.6 V ↑↓

10 – 14 V

(“Reference

waveform No.1: ” and

“Reference waveform No.14: ”) Engine running at idle

after warmed up engine.

Output signal is active low

pulse. Pulse frequency

varies depending on

engine speed.

C37-17 BLU/

ORNFuel injector No.4

output 10 – 14 V Ignition switch turned ON. —

*0 – 0.6 V ↑↓

10 – 14 V

(“Reference

waveform No.1: ” and

“Reference waveform No.15: ”) Engine running at idle

after warmed up engine.

Output signal is active low

pulse. Pulse frequency

varies depending on

engine speed.

C37-18 BRN/

YEL EGR valve

(stepper motor coil

4) output 10 – 14 V Ignition switch turned ON. —

*0 – 1 V ↑↓

10 – 14 V

(“Reference

waveform No.4: ”) Ignition switch is turned to

ST (cranking) position. Output signal is active low

duty pulse. Number of

pulse generated times

varies depending on

vehicle condition.

C37-19 WHT/

RED EGR valve

(stepper motor coil

3) output 10 – 14 V Ignition switch turned ON. —

*0 – 1 V ↑↓

1

0 – 14 V

(“Reference

waveform No.4: ”) Ignition switch is turned to

ST (cranking) position. Output signal is active low

duty pulse. Number of

pulse generated times

varies depending on

vehicle condition.

Terminal

No. Wire

color Circuit Normal voltage

ConditionRemarks

Page 230 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-180 Engine General Information and Diagnosis:

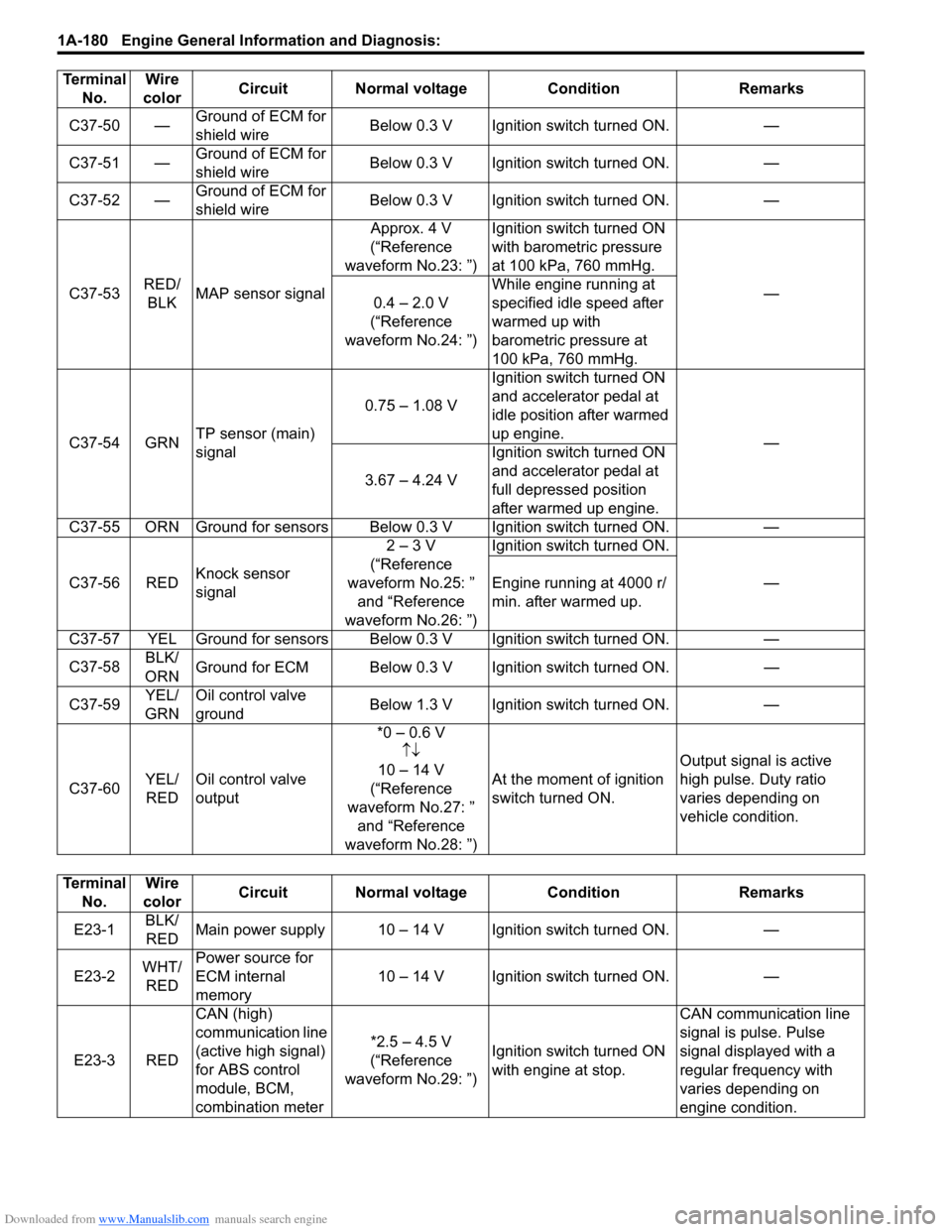

C37-50 —Ground of ECM for

shield wire Below 0.3 V Ignition switch turned ON. —

C37-51 — Ground of ECM for

shield wire Below 0.3 V Ignition switch turned ON. —

C37-52 — Ground of ECM for

shield wire Below 0.3 V Ignition switch turned ON. —

C37-53 RED/

BLK MAP sensor signal Approx. 4 V

(“Reference

waveform No.23: ”) Ignition switch turned ON

with barometric pressure

at 100 kPa, 760 mmHg.

—

0.4 – 2.0 V

(“Reference

waveform No.24: ”) While engine running at

specified idle speed after

warmed up with

barometric pressure at

100 kPa, 760 mmHg.

C37-54 GRN TP sensor (main)

signal 0.75 – 1.08 V

Ignition switch turned ON

and accelerator pedal at

idle position after warmed

up engine.

—

3.67 – 4.24 V Ignition switch turned ON

and accelerator pedal at

full depressed position

after warmed up engine.

C37-55 ORN Ground for sensors Below 0.3 V Ignition switch turned ON. —

C37-56 RED Knock sensor

signal 2 – 3 V

(“Reference

waveform No.25: ” and “Reference

waveform No.26: ”) Ignition switch turned ON.

—

Engine running at 4000 r/

min. after warmed up.

C37-57 YEL Ground for sensors Below 0.3 V Ignition switch turned ON. —

C37-58 BLK/

ORN Ground for ECM Below 0.3 V Ignition switch turned ON.

—

C37-59 YEL/

GRN Oil control valve

ground

Below 1.3 V Ignition switch turned ON.

—

C37-60 YEL/

RED Oil control valve

output *0 – 0.6 V

↑↓

10 – 14 V

(“Reference

waveform No.27: ” and “Reference

waveform No.28: ”) At the moment of ignition

switch turned ON.

Output signal is active

high pulse. Duty ratio

varies depending on

vehicle condition.

Terminal

No. Wire

color Circuit Normal voltage

ConditionRemarks

Terminal

No. Wire

color Circuit Normal voltage Condition Remarks

E23-1 BLK/

RED Main power supply 10 – 14 V Ignition switch turned ON. —

E23-2 WHT/

RED Power source for

ECM internal

memory

10 – 14 V Ignition switch turned ON. —

E23-3 RED CAN (high)

communication line

(active high signal)

for ABS control

module, BCM,

combination meter *2.5 – 4.5 V

(“Reference

waveform No.29: ”) Ignition switch turned ON

with engine at stop. CAN communication line

signal is pulse. Pulse

signal displayed with a

regular frequency with

varies depending on

engine condition.

Page 244 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-194 Engine General Information and Diagnosis:

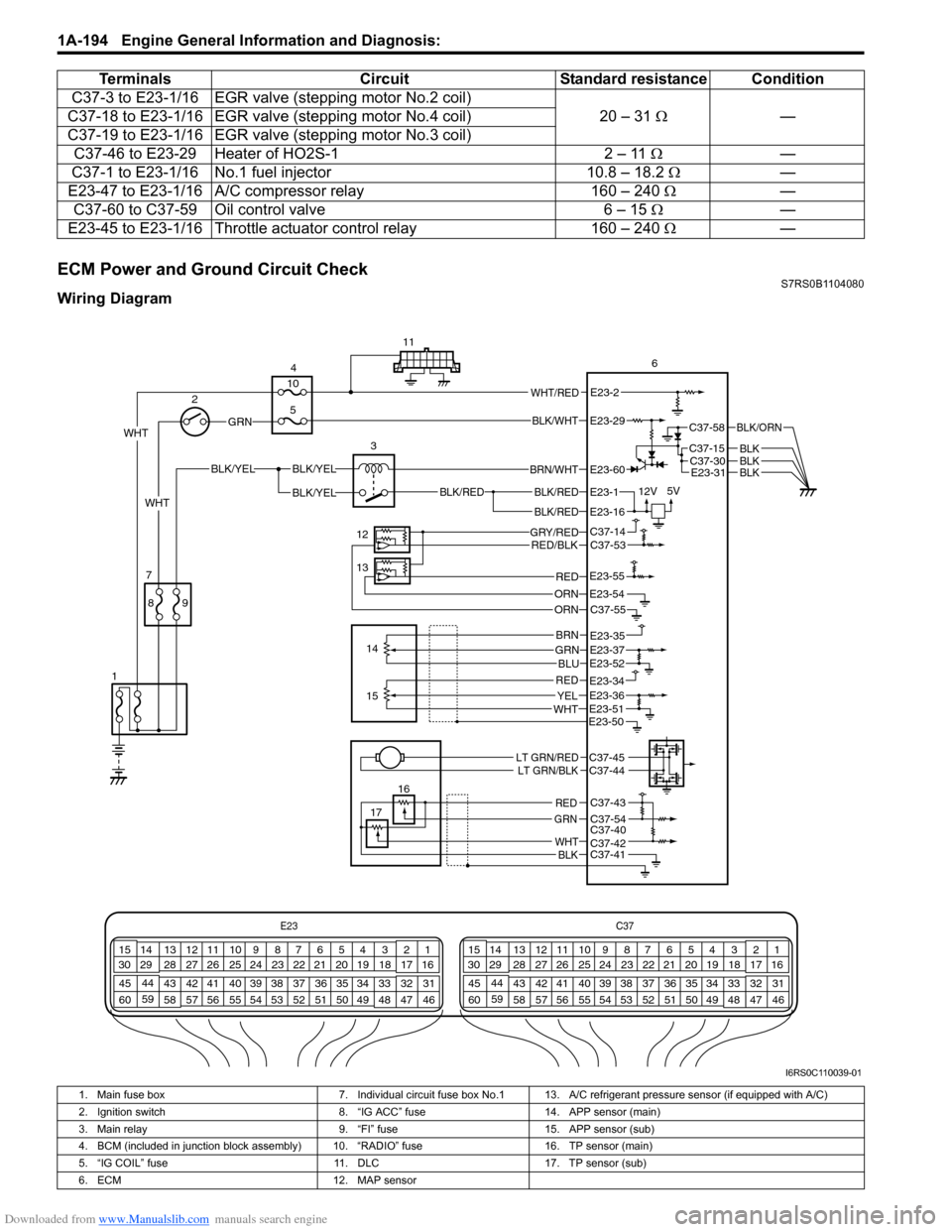

ECM Power and Ground Circuit CheckS7RS0B1104080

Wiring DiagramC37-3 to E23-1/16 EGR valve

(stepping motor No.2 coil)

20 – 31 Ω —

C37-18 to E23-1/16 EGR valv e (stepping motor No.4 coil)

C37-19 to E23-1/16 EGR valv e (stepping motor No.3 coil)

C37-46 to E23-29 Heater of HO2S-1 2 – 11 Ω—

C37-1 to E23-1/16 No.1 fuel injector 10.8 – 18.2 Ω —

E23-47 to E23-1/16 A/C compressor relay 160 – 240 Ω —

C37-60 to C37-59 Oil control valve 6 – 15 Ω —

E23-45 to E23-1/16 Throttle actuator control relay 160 – 240 Ω —

Terminals

CircuitStandard resistance Condition

E23 C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

BLK/RED

BLK/REDBLK/RED

BLK/YELBLK/YEL

BLK/YEL

GRN

BRN/WHT

12V

5VE23-1

E23-60

E23-16

WHT 2

4

11

6

3

12

13 14

7

1

16

17

89

15

10

5

WHT/REDE23-2

C37-58

C37-15C37-30

BLK/ORN

BLKBLKE23-31BLK

WHT

GRY/REDRED/BLK

ORN

C37-14C37-53

C37-55E23-54

REDE23-55

GRNBRN

BLU

REDYELWHT

E23-35E23-37E23-52

E23-51

E23-34E23-36

E23-50

LT GRN/REDLT GRN/BLKC37-45C37-44

C37-43

C37-54C37-40C37-42C37-41

RED

GRN

WHTBLK

ORN

BLK/WHTE23-29

I6RS0C110039-01

1. Main fuse box 7. Individual circuit fuse box No.1 13. A/C refrigerant pressure sensor (if equipped with A/C)

2. Ignition switch 8. “IG ACC” fuse14. APP sensor (main)

3. Main relay 9. “FI” fuse15. APP sensor (sub)

4. BCM (included in junction block assembly) 10. “RADIO” fuse 16. TP sensor (main)

5. “IG COIL” fuse 11. DLC17. TP sensor (sub)

6. ECM 12. MAP sensor

Page 287 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-2

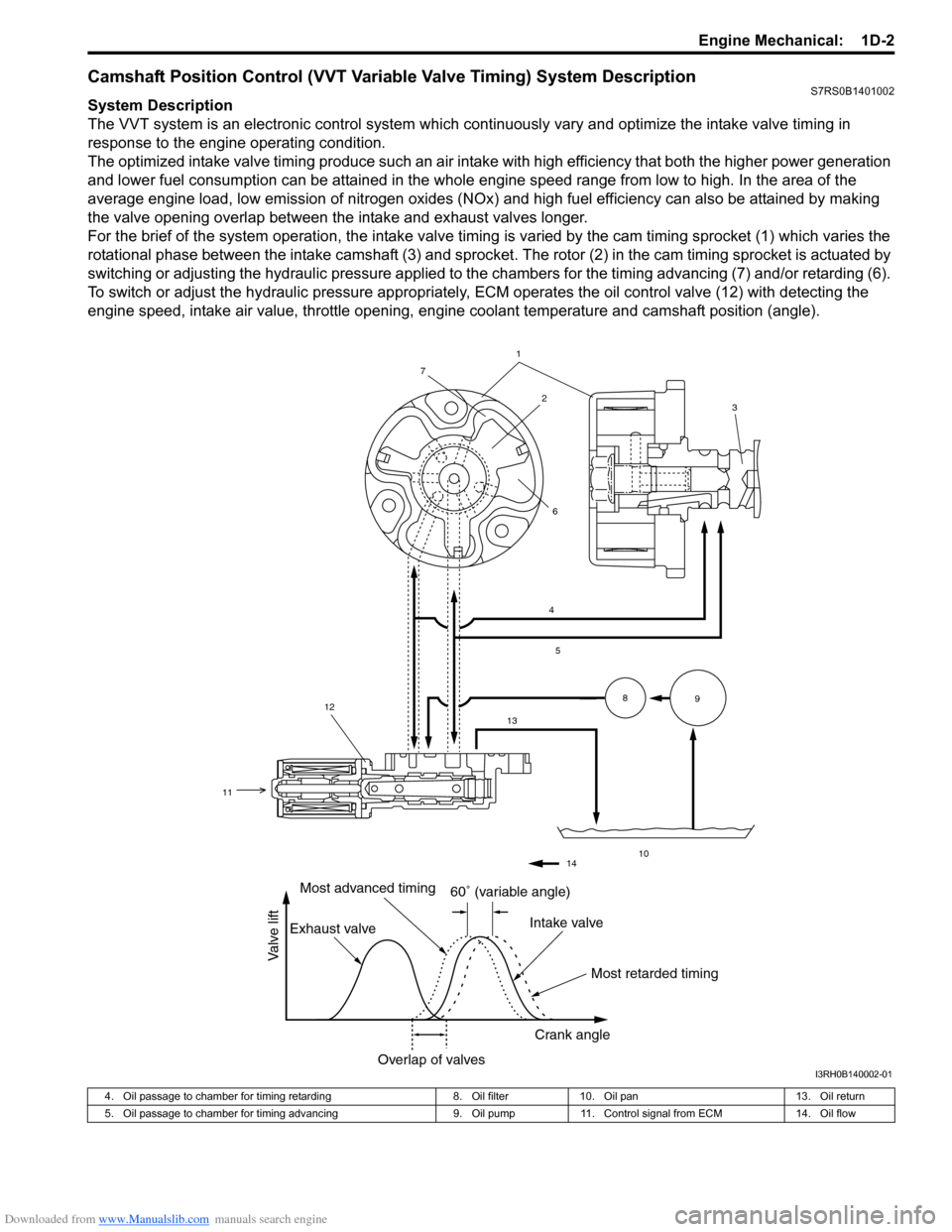

Camshaft Position Control (VVT Variable Valve Timing) System DescriptionS7RS0B1401002

System Description

The VVT system is an electronic control system which continuously vary and optimize the intake valve timing in

response to the engine operating condition.

The optimized intake valve timing produce such an air intake with high efficiency that both the higher power generation

and lower fuel consumption can be attained in the whole engine speed range from low to high. In the area of the

average engine load, low emission of nitrogen oxides (NOx) and high fuel efficiency can also be attained by making

the valve opening overlap between the intake and exhaust valves longer.

For the brief of the system operation, the intake valve timing is varied by the cam timing sprocket (1) which varies the

rotational phase between the intake camshaft (3) and sprocket . The rotor (2) in the cam timing sprocket is actuated by

switching or adjusting the hydraulic pressure applied to the chambers for the timing advancing (7) and/or retarding (6).

To switch or adjust the hydraulic pressure appropriately, ECM operates the oil control valve (12) with detecting the

engine speed, intake air value, throttle opening, engine coolant temperature and camshaft position (angle).

1

4

5

13

10

89

2

7

6

12

11

3

14

60� (variable angle)

Most retarded timing

Most advanced timing

Exhaust valve Intake valve

Crank angle

Overlap of valves

Valve lift

I3RH0B140002-01

4. Oil passage to chamber for timing retarding 8. Oil filter10. Oil pan 13. Oil return

5. Oil passage to chamber for timing advancing 9. Oil pump11. Control signal from ECM 14. Oil flow

Page 288 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-3 Engine Mechanical:

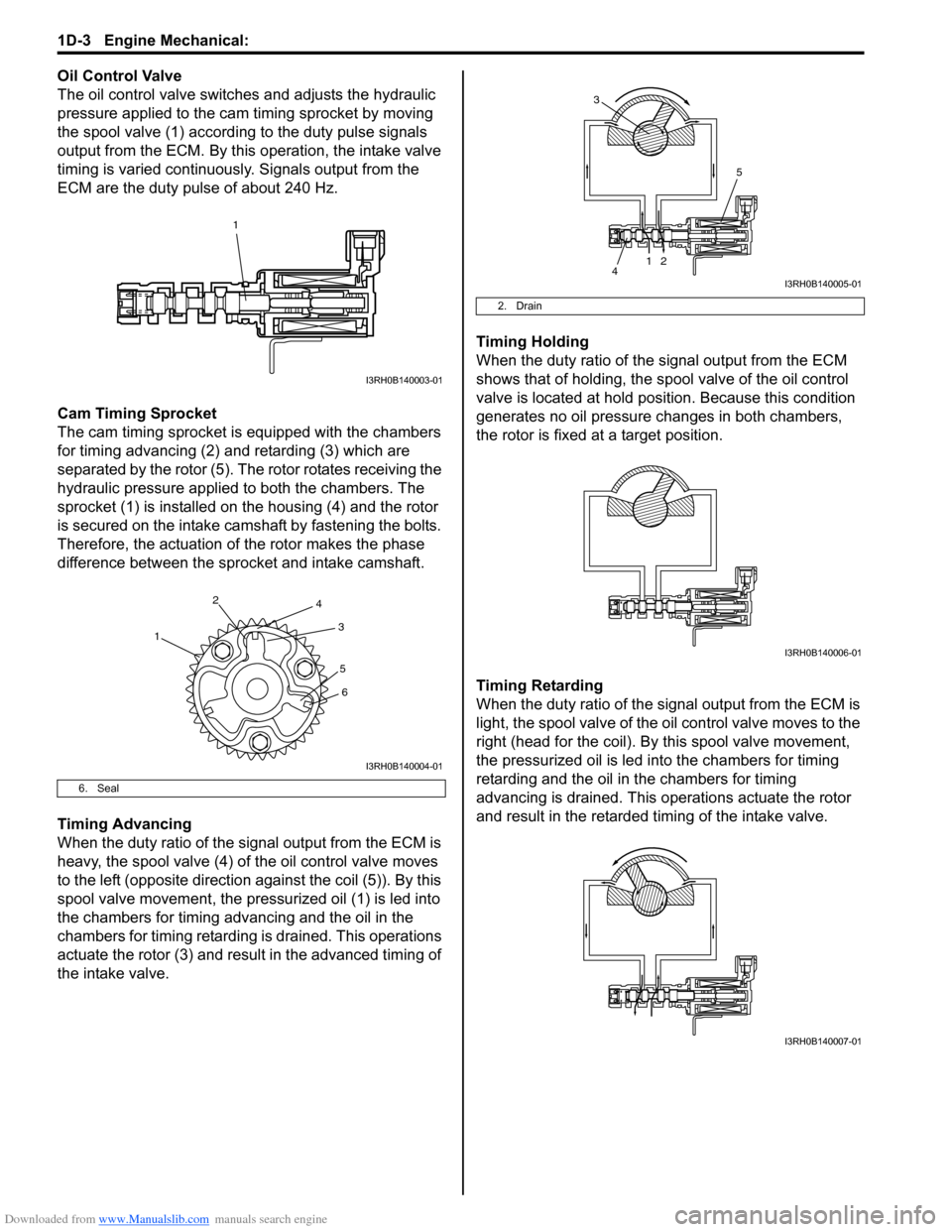

Oil Control Valve

The oil control valve switches and adjusts the hydraulic

pressure applied to the cam timing sprocket by moving

the spool valve (1) according to the duty pulse signals

output from the ECM. By this operation, the intake valve

timing is varied continuously. Signals output from the

ECM are the duty pulse of about 240 Hz.

Cam Timing Sprocket

The cam timing sprocket is equipped with the chambers

for timing advancing (2) and retarding (3) which are

separated by the rotor (5). The rotor rotates receiving the

hydraulic pressure applied to both the chambers. The

sprocket (1) is installed on the housing (4) and the rotor

is secured on the intake camshaft by fastening the bolts.

Therefore, the actuation of the rotor makes the phase

difference between the sprocket and intake camshaft.

Timing Advancing

When the duty ratio of the signal output from the ECM is

heavy, the spool valve (4) of the oil control valve moves

to the left (opposite direction against the coil (5)). By this

spool valve movement, the pressurized oil (1) is led into

the chambers for timing advancing and the oil in the

chambers for timing retarding is drained. This operations

actuate the rotor (3) and result in the advanced timing of

the intake valve. Timing Holding

When the duty ratio of the si

gnal output from the ECM

shows that of holding, the sp ool valve of the oil control

valve is located at hold posi tion. Because this condition

generates no oil pressure changes in both chambers,

the rotor is fixed at a target position.

Timing Retarding

When the duty ratio of the sig nal output from the ECM is

light, the spool valve of the o il control valve moves to the

right (head for the coil). By this spool valve movement,

the pressurized oil is led into the chambers for timing

retarding and the oil in the chambers for timing

advancing is drained. This operations actuate the rotor

and result in the retarded timing of the intake valve.

6. Seal

1

I3RH0B140003-01

1 2

3

4

56

I3RH0B140004-01

2. Drain

12

5

4

3

I3RH0B140005-01

I3RH0B140006-01

I3RH0B140007-01