timing SUZUKI SWIFT 2005 2.G Service Owner's Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 310 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-25 Engine Mechanical:

Timing Chain and Chain Tensioner Removal

and Installation

S7RS0B1406018

Removal

CAUTION!

After timing chain is removed, never turn

crankshaft and camshafts independently

more than its allowable turning range

described in “Installation”.

If turned, interferen ce may occur between

piston and valves and valves themselves,

and parts related to piston and valves may be

damaged.

1) Remove timing chain cover referring to “Timing Chain Cover Removal and Installation”.

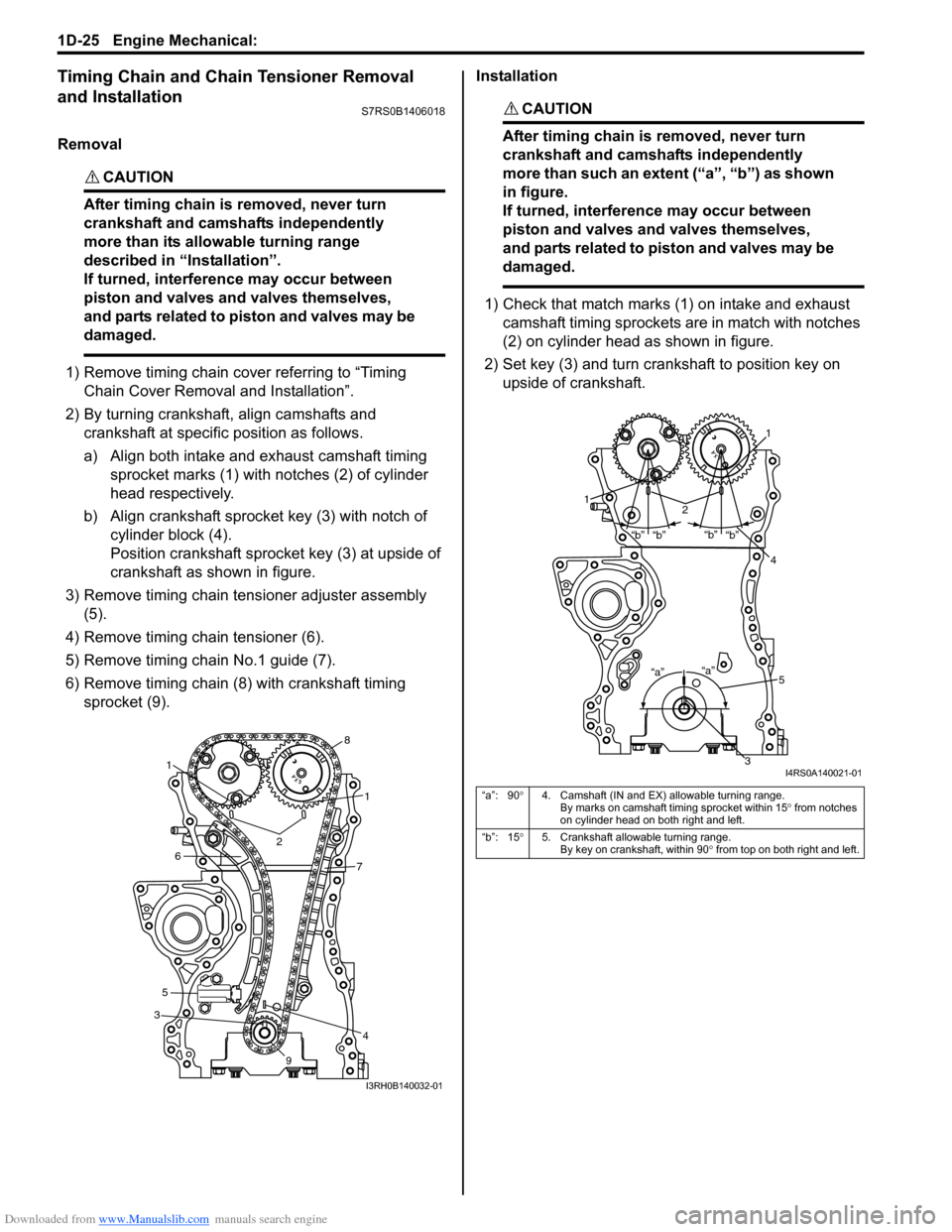

2) By turning crankshaft, align camshafts and crankshaft at specific position as follows.

a) Align both intake and exhaust camshaft timing sprocket marks (1) with notches (2) of cylinder

head respectively.

b) Align crankshaft sprocket key (3) with notch of cylinder block (4).

Position crankshaft sprocke t key (3) at upside of

crankshaft as shown in figure.

3) Remove timing chain tensioner adjuster assembly (5).

4) Remove timing chain tensioner (6).

5) Remove timing chain No.1 guide (7).

6) Remove timing chain (8) with crankshaft timing sprocket (9). Installation

CAUTION!

After timing chain is removed, never turn

crankshaft and camshafts independently

more than such an extent (“a”, “b”) as shown

in figure.

If turned, interferen

ce may occur between

piston and valves and valves themselves,

and parts related to piston and valves may be

damaged.

1) Check that match marks (1) on intake and exhaust camshaft timing sprockets are in match with notches

(2) on cylinder head as shown in figure.

2) Set key (3) and turn crankshaft to position key on upside of crankshaft.

3

4

1

1

2

5

67

8

9

I3RH0B140032-01

“a”: 90 °4. Camshaft (IN and EX) allowable turning range.

By marks on camshaft timing sprocket within 15 ° from notches

on cylinder head on both right and left.

“b”: 15 °5. Crankshaft allowable turning range.

By key on crankshaft, within 90 ° from top on both right and left.

“a”

“b”

“b”“b”

“b”

“a”

1

12

4

3

5

I4RS0A140021-01

Page 311 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-26

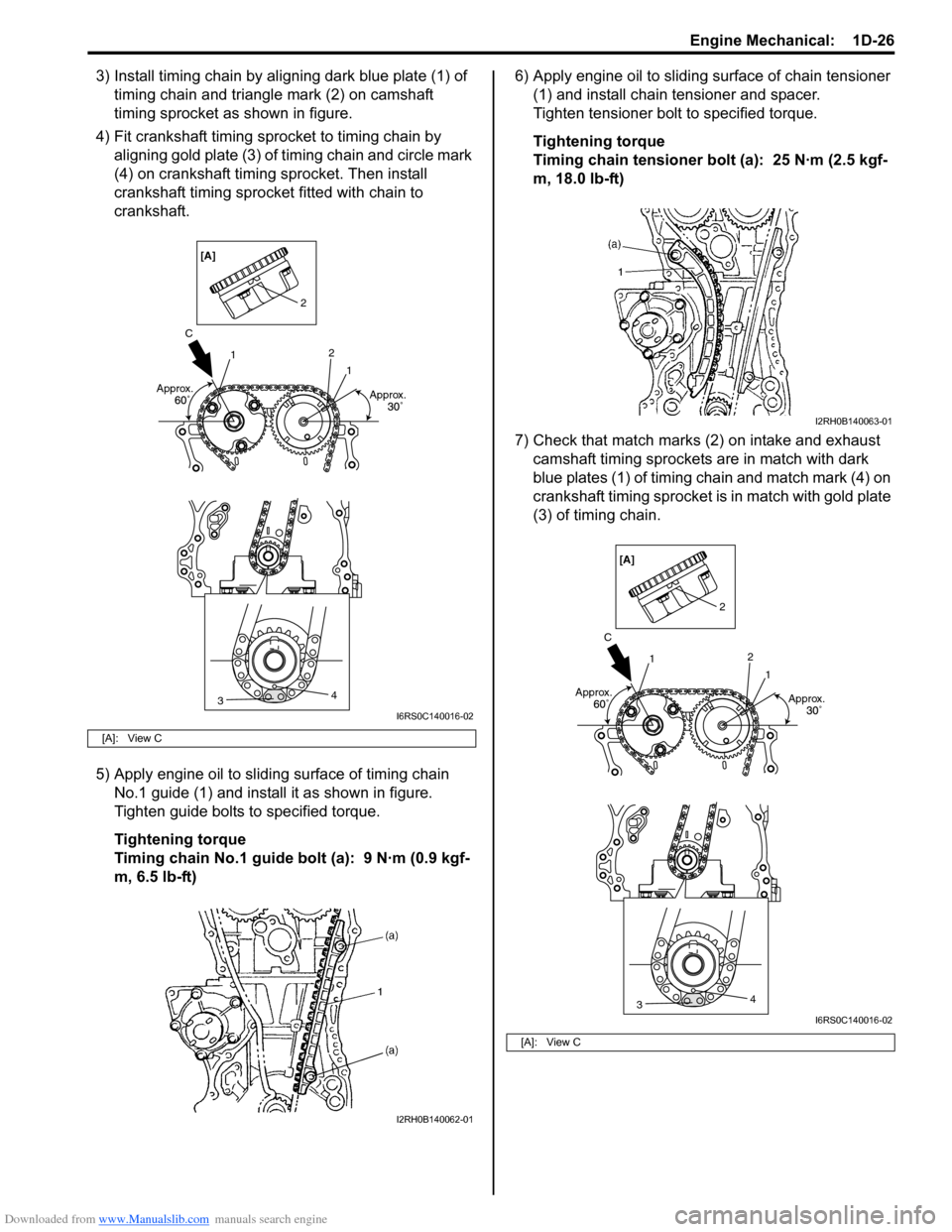

3) Install timing chain by aligning dark blue plate (1) of timing chain and triangle mark (2) on camshaft

timing sprocket as shown in figure.

4) Fit crankshaft timing sprocket to timing chain by aligning gold plate (3) of timing chain and circle mark

(4) on crankshaft timing sprocket. Then install

crankshaft timing sprocket fitted with chain to

crankshaft.

5) Apply engine oil to sliding surface of timing chain No.1 guide (1) and install it as shown in figure.

Tighten guide bolts to specified torque.

Tightening torque

Timing chain No.1 guide bolt (a): 9 N·m (0.9 kgf-

m, 6.5 lb-ft) 6) Apply engine oil to sliding surface of chain tensioner

(1) and install chain tensioner and spacer.

Tighten tensioner bolt to specified torque.

Tightening torque

Timing chain tensioner bolt (a): 25 N·m (2.5 kgf-

m, 18.0 lb-ft)

7) Check that match marks (2) on intake and exhaust camshaft timing sprockets are in match with dark

blue plates (1) of timing chain and match mark (4) on

crankshaft timing sprocket is in match with gold plate

(3) of timing chain.

[A]: View C

34

1

1

2

2

Approx. Approx.

C[A]

I6RS0C140016-02

I2RH0B140062-01

[A]: View C

I2RH0B140063-01

34

1

1

2

2

Approx. Approx.

C[A]

I6RS0C140016-02

Page 312 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-27 Engine Mechanical:

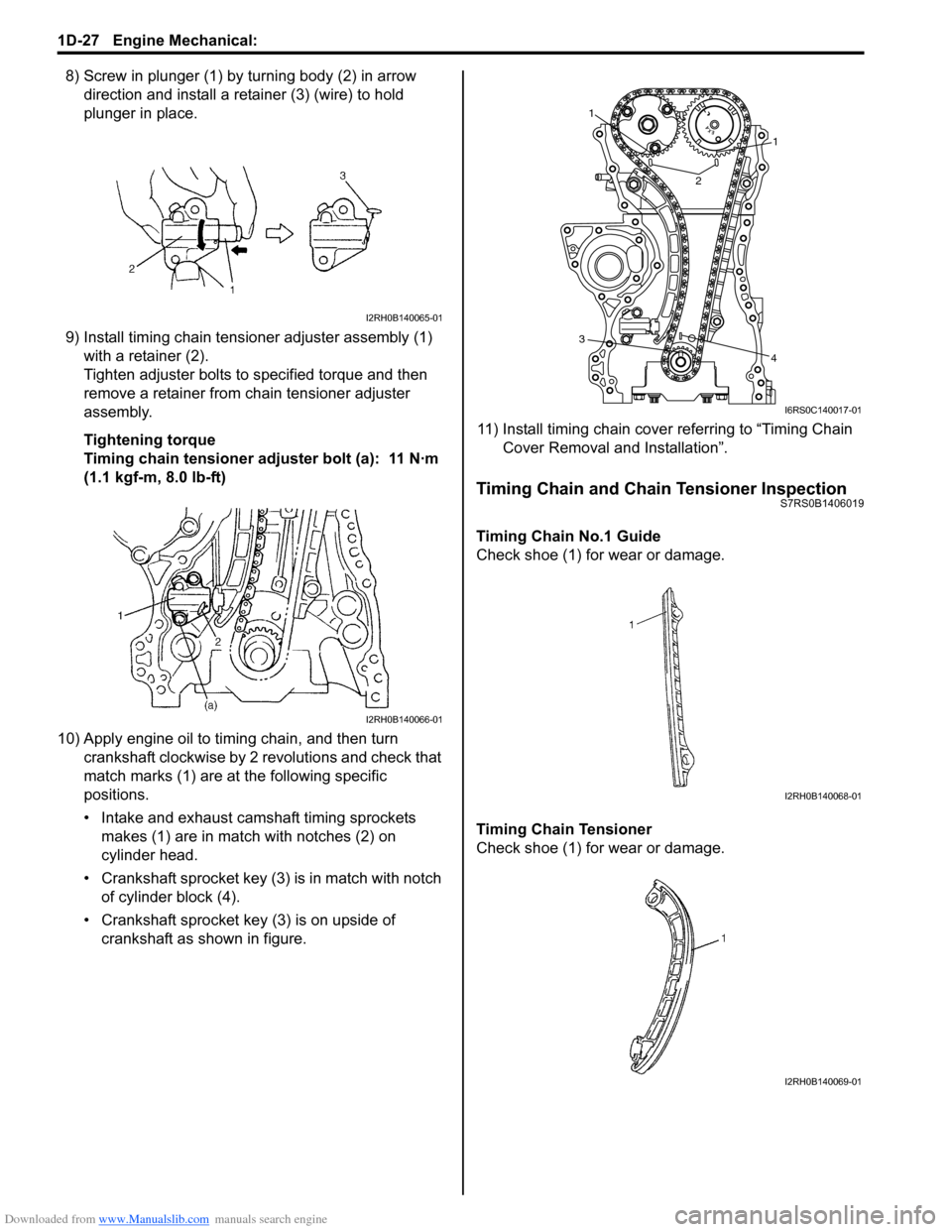

8) Screw in plunger (1) by turning body (2) in arrow direction and install a reta iner (3) (wire) to hold

plunger in place.

9) Install timing chain tensioner adjuster assembly (1) with a retainer (2).

Tighten adjuster bolts to specified torque and then

remove a retainer from chain tensioner adjuster

assembly.

Tightening torque

Timing chain tensioner adjuster bolt (a): 11 N·m

(1.1 kgf-m, 8.0 lb-ft)

10) Apply engine oil to timing chain, and then turn crankshaft clockwise by 2 revolutions and check that

match marks (1) are at the following specific

positions.

• Intake and exhaust camshaft timing sprockets makes (1) are in match with notches (2) on

cylinder head.

• Crankshaft sprocket key (3) is in match with notch of cylinder block (4).

• Crankshaft sprocket key (3) is on upside of crankshaft as shown in figure. 11) Install timing chain cover referring to “Timing Chain

Cover Removal and Installation”.

Timing Chain and Chain Tensioner InspectionS7RS0B1406019

Timing Chain No.1 Guide

Check shoe (1) for wear or damage.

Timing Chain Tensioner

Check shoe (1) for wear or damage.

I2RH0B140065-01

I2RH0B140066-01

1

1

2

3 4

I6RS0C140017-01

I2RH0B140068-01

I2RH0B140069-01

Page 313 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-28

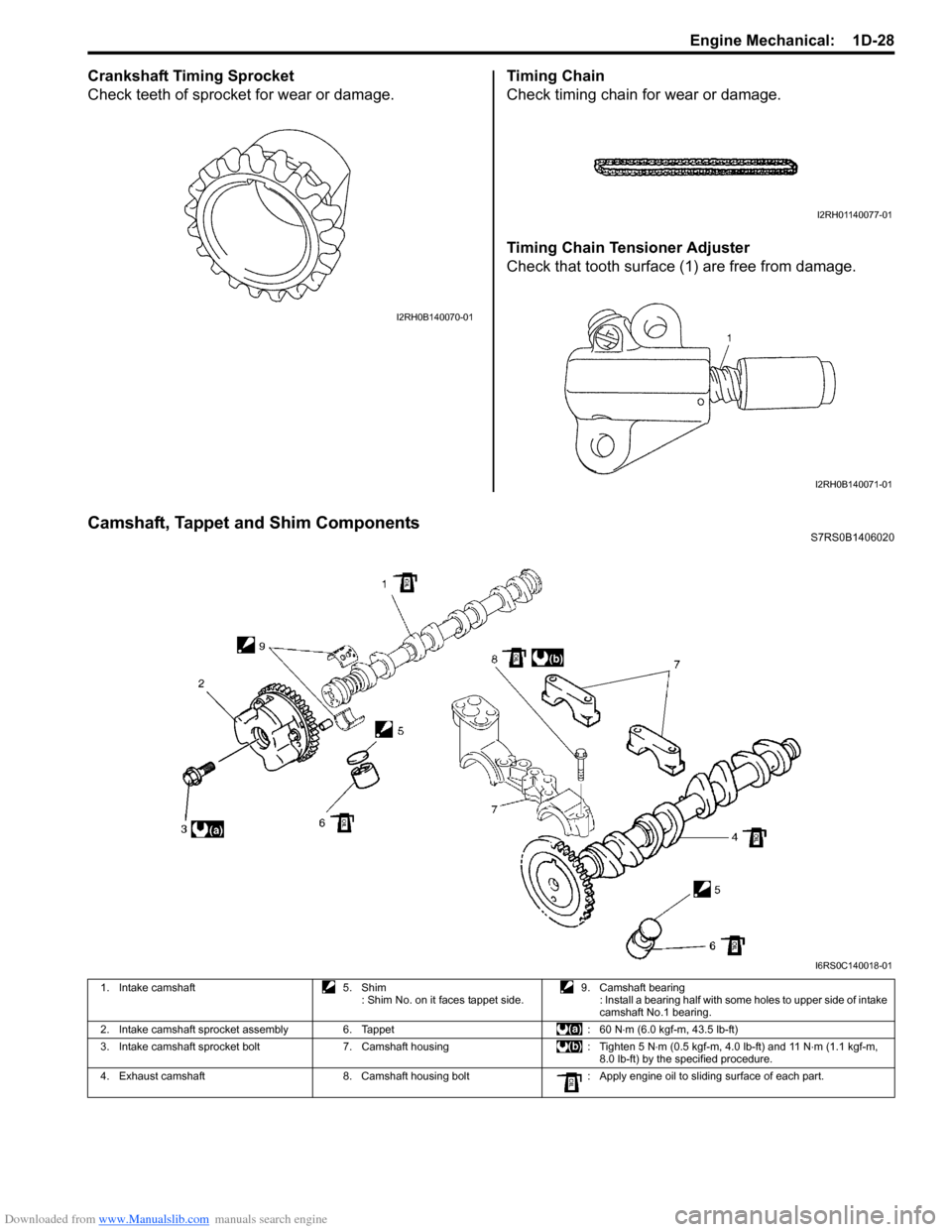

Crankshaft Timing Sprocket

Check teeth of sprocket for wear or damage.Timing Chain

Check timing chain for wear or damage.

Timing Chain Tensioner Adjuster

Check that tooth surface (1) are free from damage.

Camshaft, Tappet and Shim ComponentsS7RS0B1406020

I2RH0B140070-01

I2RH01140077-01

I2RH0B140071-01

I6RS0C140018-01

1. Intake camshaft

5. Shim

: Shim No. on it faces tappet side. 9. Camshaft bearing

: Install a bearing half with some holes to upper side of intake

camshaft No.1 bearing.

2. Intake camshaft sprocket assembly 6. Tappet : 60 N⋅m (6.0 kgf-m, 43.5 lb-ft)

3. Intake camshaft sprocket bolt 7. Camshaft housing : Tighten 5 N⋅m (0.5 kgf-m, 4.0 lb-ft) and 11 N ⋅m (1.1 kgf-m,

8.0 lb-ft) by the specified procedure.

4. Exhaust camshaft 8. Camshaft housing bolt : Apply engine oil to sliding surface of each part.

Page 314 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-29 Engine Mechanical:

Camshaft, Tappet and Shim Removal and

Installation

S7RS0B1406021

CAUTION!

• Keep working table, tools and hands clean while overhauling.

• Use special care to handle aluminum parts so as not to damage them.

• Do not expose removed parts to dust. Keep them always clean.

Removal

1) Remove timing chain cover referring to “Timing Chain Cover Removal and Installation”.

2) Remove timing chain referring to “Timing Chain and Chain Tensioner Removal and Installation”.

3) With hexagonal section (1) of intake camshaft (2) held stationary with spanner or the like, loosen

mounting bolt of intake cam timing sprocket

assembly (3) and remove it.

CAUTION!

Never attempt to loosen mounting bolt with

intake cam timing sprocket assembly held

stationary. Failure to fo llow this could result

in damage to lock pin.

Do not loosen bolt “a” because intake cam

timing sprocket assembly is not serviceable.

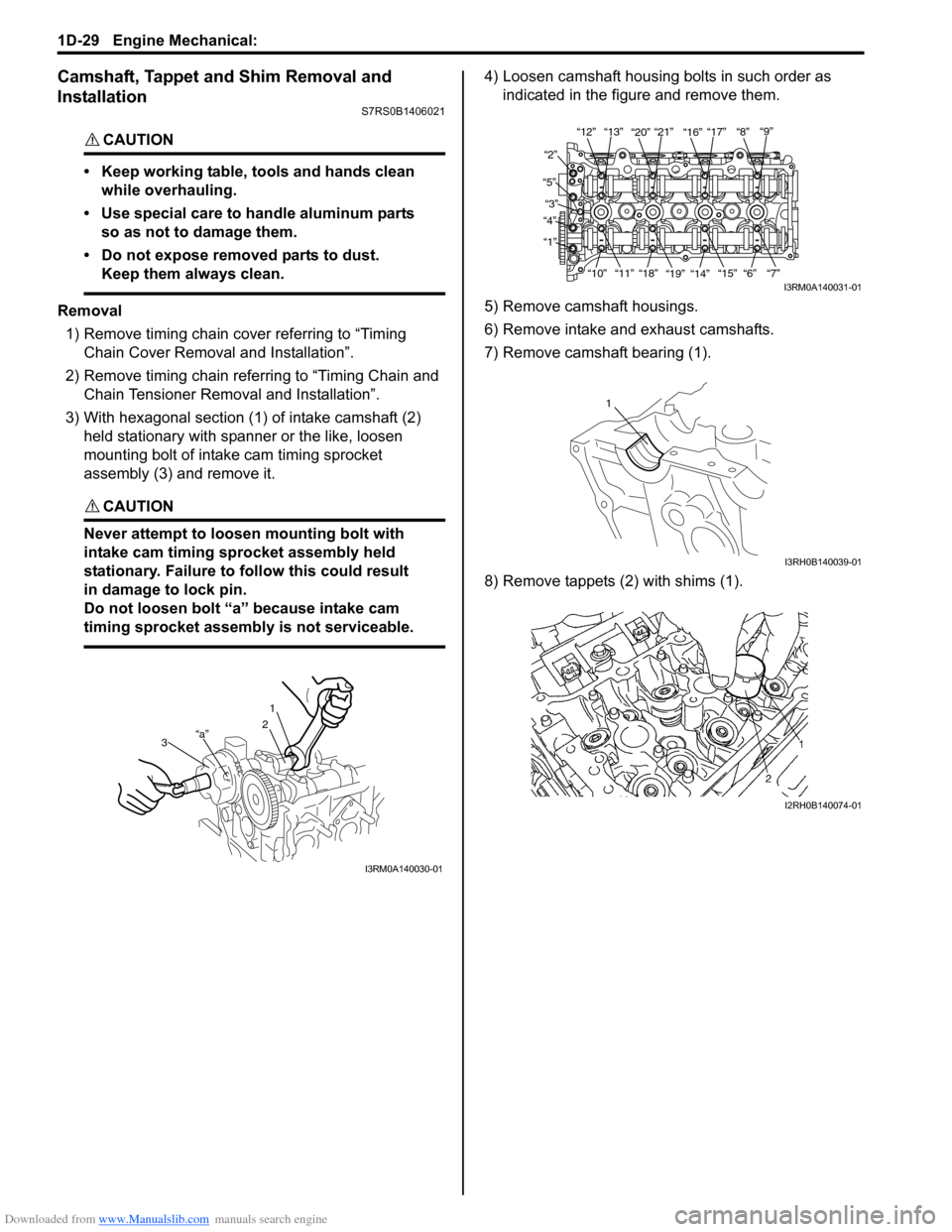

4) Loosen camshaft housing bolts in such order as indicated in the figure and remove them.

5) Remove camshaft housings.

6) Remove intake and exhaust camshafts.

7) Remove camshaft bearing (1).

8) Remove tappets (2) with shims (1).

3“a”

1

2

I3RM0A140030-01

“12”“13” “20”“21”

“16”“17” “8” “9”

“2”

“5” “3”

“4”

“1”

“10”“11”“18”

“19” “14” “15” “6” “7”

I3RM0A140031-01

1

I3RH0B140039-01

I2RH0B140074-01

Page 315 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-30

Installation1) Install tappets and shims to cylinder head. Apply engine oil around tappet and then install it to

cylinder head.

NOTE

When installing shim, make sure to direct

shim No. side toward tappet.

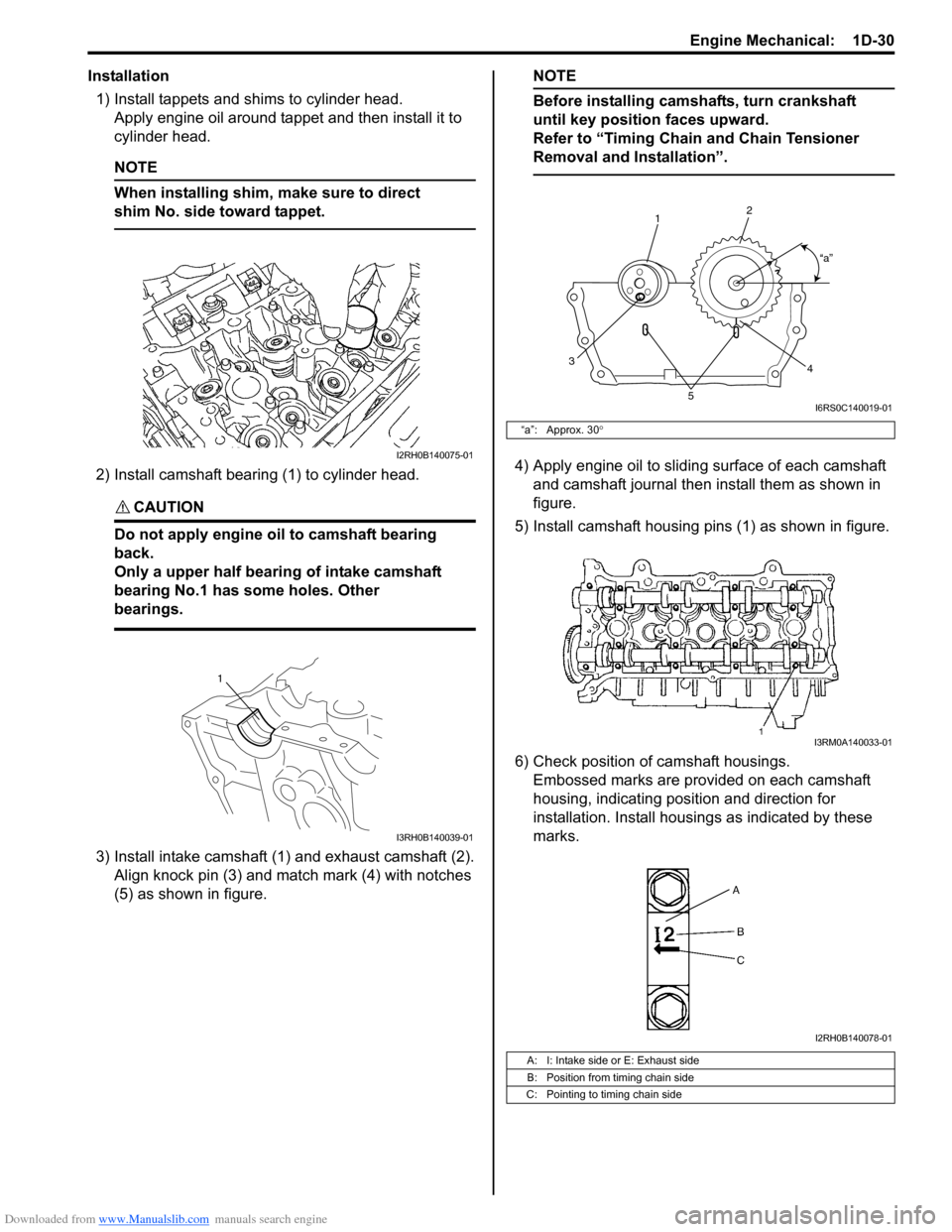

2) Install camshaft bearing (1) to cylinder head.

CAUTION!

Do not apply engine oil to camshaft bearing

back.

Only a upper half bearing of intake camshaft

bearing No.1 has some holes. Other

bearings.

3) Install intake camshaft (1) and exhaust camshaft (2). Align knock pin (3) and match mark (4) with notches

(5) as shown in figure.

NOTE

Before installing camshafts, turn crankshaft

until key position faces upward.

Refer to “Timing Chain and Chain Tensioner

Removal and Installation”.

4) Apply engine oil to sliding surface of each camshaft and camshaft journal then install them as shown in

figure.

5) Install camshaft housing pins (1) as shown in figure.

6) Check position of camshaft housings. Embossed marks are provided on each camshaft

housing, indicating position and direction for

installation. Install housings as indicated by these

marks.I2RH0B140075-01

1

I3RH0B140039-01

“a”: Approx. 30 °

A: I: Intake side or E: Exhaust side

B: Position from timing chain side

C: Pointing to timing chain side

1 2

3 4

5

“a”

I6RS0C140019-01

I3RM0A140033-01

I2RH0B140078-01

Page 316 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-31 Engine Mechanical:

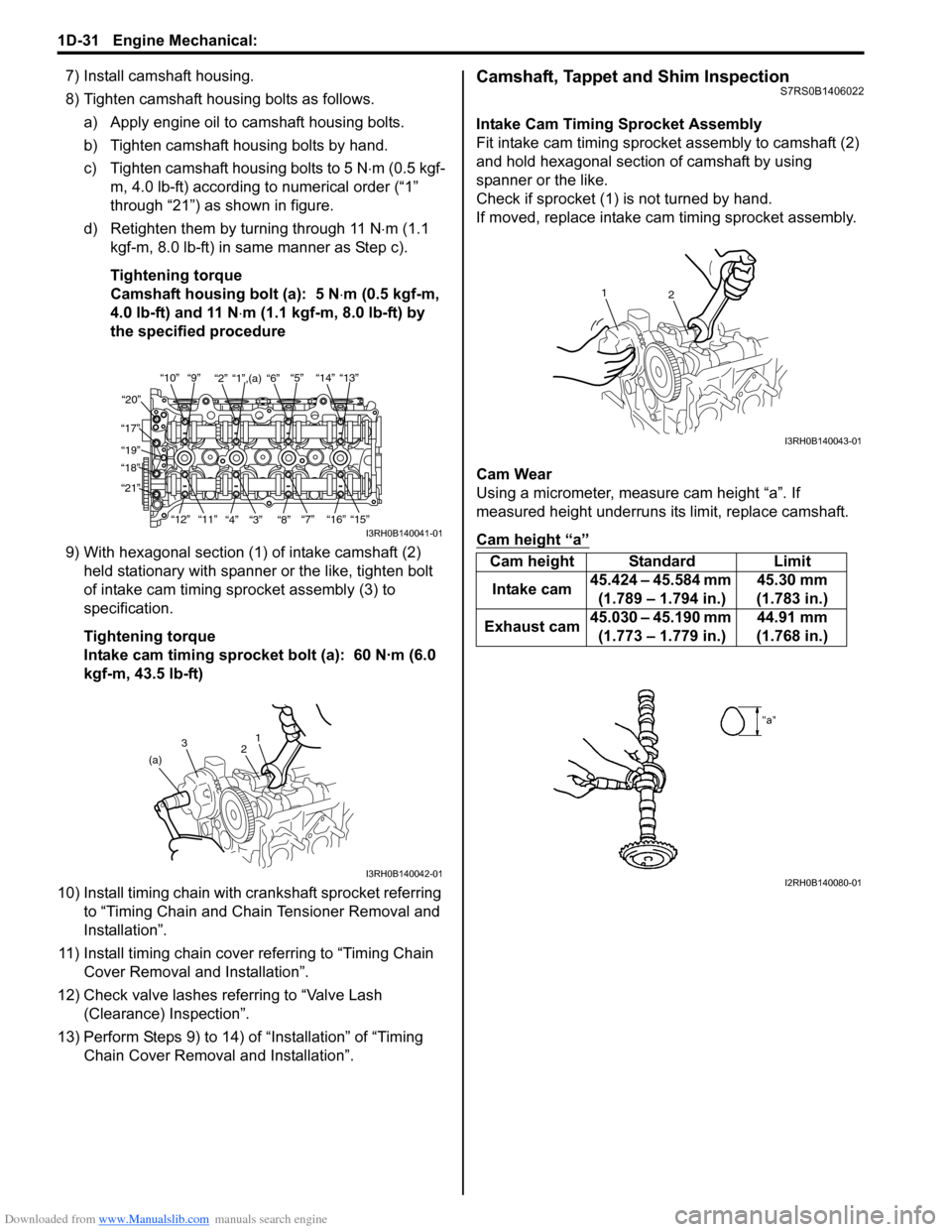

7) Install camshaft housing.

8) Tighten camshaft housing bolts as follows.a) Apply engine oil to camshaft housing bolts.

b) Tighten camshaft housing bolts by hand.

c) Tighten camshaft housing bolts to 5 N ⋅m (0.5 kgf-

m, 4.0 lb-ft) according to numerical order (“1”

through “21”) as shown in figure.

d) Retighten them by turning through 11 N⋅ m (1.1

kgf-m, 8.0 lb-ft) in same manner as Step c).

Tightening torque

Camshaft housing bolt (a): 5 N ⋅m (0.5 kgf-m,

4.0 lb-ft) and 11 N ⋅m (1.1 kgf-m, 8.0 lb-ft) by

the specified procedure

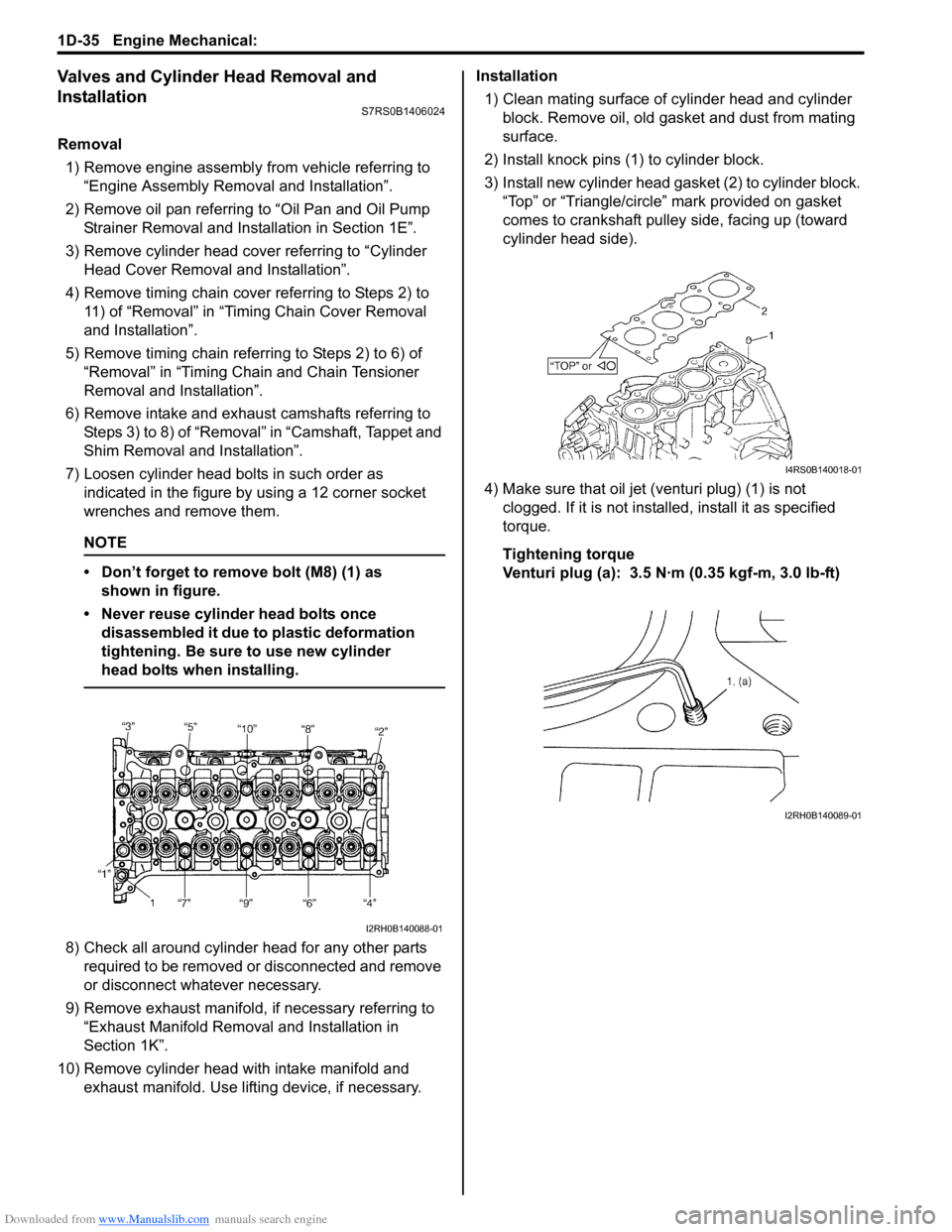

9) With hexagonal section (1) of intake camshaft (2) held stationary with spanner or the like, tighten bolt

of intake cam timing sp rocket assembly (3) to

specification.

Tightening torque

Intake cam timing sprocket bolt (a): 60 N·m (6.0

kgf-m, 43.5 lb-ft)

10) Install timing chain with cr ankshaft sprocket referring

to “Timing Chain and Chain Tensioner Removal and

Installation”.

11) Install timing chain cover referring to “Timing Chain Cover Removal and Installation”.

12) Check valve lashes referring to “Valve Lash (Clearance) Inspection”.

13) Perform Steps 9) to 14) of “Installation” of “Timing Chain Cover Removal and Installation”.Camshaft, Tappet and Shim InspectionS7RS0B1406022

Intake Cam Timing Sprocket Assembly

Fit intake cam timing sprocket assembly to camshaft (2)

and hold hexagonal section of camshaft by using

spanner or the like.

Check if sprocket (1) is not turned by hand.

If moved, replace intake ca m timing sprocket assembly.

Cam Wear

Using a micrometer, measure cam height “a”. If

measured height underruns its limit, replace camshaft.

Cam height “a”

“10”“9” “2” “1”,(a) “6” “5” “14” “13”

“20”

“17” “19”

“18”

“21”

“12”“11”

“4” “3” “8” “7” “16” “15”

I3RH0B140041-01

1

2

3

(a)

I3RH0B140042-01

Cam height Standard Limit

Intake cam 45.424 – 45.584 mm

(1.789 – 1.794 in.) 45.30 mm

(1.783 in.)

Exhaust cam 45.030 – 45.190 mm

(1.773 – 1.779 in.) 44.91 mm

(1.768 in.)

2

1

I3RH0B140043-01

I2RH0B140080-01

Page 320 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-35 Engine Mechanical:

Valves and Cylinder Head Removal and

Installation

S7RS0B1406024

Removal1) Remove engine assembly from vehicle referring to “Engine Assembly Removal and Installation”.

2) Remove oil pan referring to “Oil Pan and Oil Pump

Strainer Removal and Installation in Section 1E”.

3) Remove cylinder head cover referring to “Cylinder Head Cover Removal and Installation”.

4) Remove timing chain cover referring to Steps 2) to 11) of “Removal” in “Tim ing Chain Cover Removal

and Installation”.

5) Remove timing chain referring to Steps 2) to 6) of “Removal” in “Timing Chain and Chain Tensioner

Removal and Installation”.

6) Remove intake and exhaust camshafts referring to Steps 3) to 8) of “Removal” in “Camshaft, Tappet and

Shim Removal and Installation”.

7) Loosen cylinder head bolts in such order as indicated in the figure by using a 12 corner socket

wrenches and remove them.

NOTE

• Don’t forget to remove bolt (M8) (1) as shown in figure.

• Never reuse cylinder head bolts once disassembled it due to plastic deformation

tightening. Be sure to use new cylinder

head bolts when installing.

8) Check all around cylinder head for any other parts required to be removed or disconnected and remove

or disconnect whatever necessary.

9) Remove exhaust manifold, if necessary referring to

“Exhaust Manifold Removal and Installation in

Section 1K”.

10) Remove cylinder head wi th intake manifold and

exhaust manifold. Use lifting device, if necessary. Installation

1) Clean mating surface of cylinder head and cylinder block. Remove oil, old gasket and dust from mating

surface.

2) Install knock pins (1) to cylinder block.

3) Install new cylinder head gasket (2) to cylinder block. “Top” or “Triangle/circle” mark provided on gasket

comes to crankshaft pulley side, facing up (toward

cylinder head side).

4) Make sure that oil jet (venturi plug) (1) is not clogged. If it is not install ed, install it as specified

torque.

Tightening torque

Venturi plug (a): 3.5 N·m (0.35 kgf-m, 3.0 lb-ft)

I2RH0B140088-01

I4RS0B140018-01

I2RH0B140089-01

Page 321 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-36

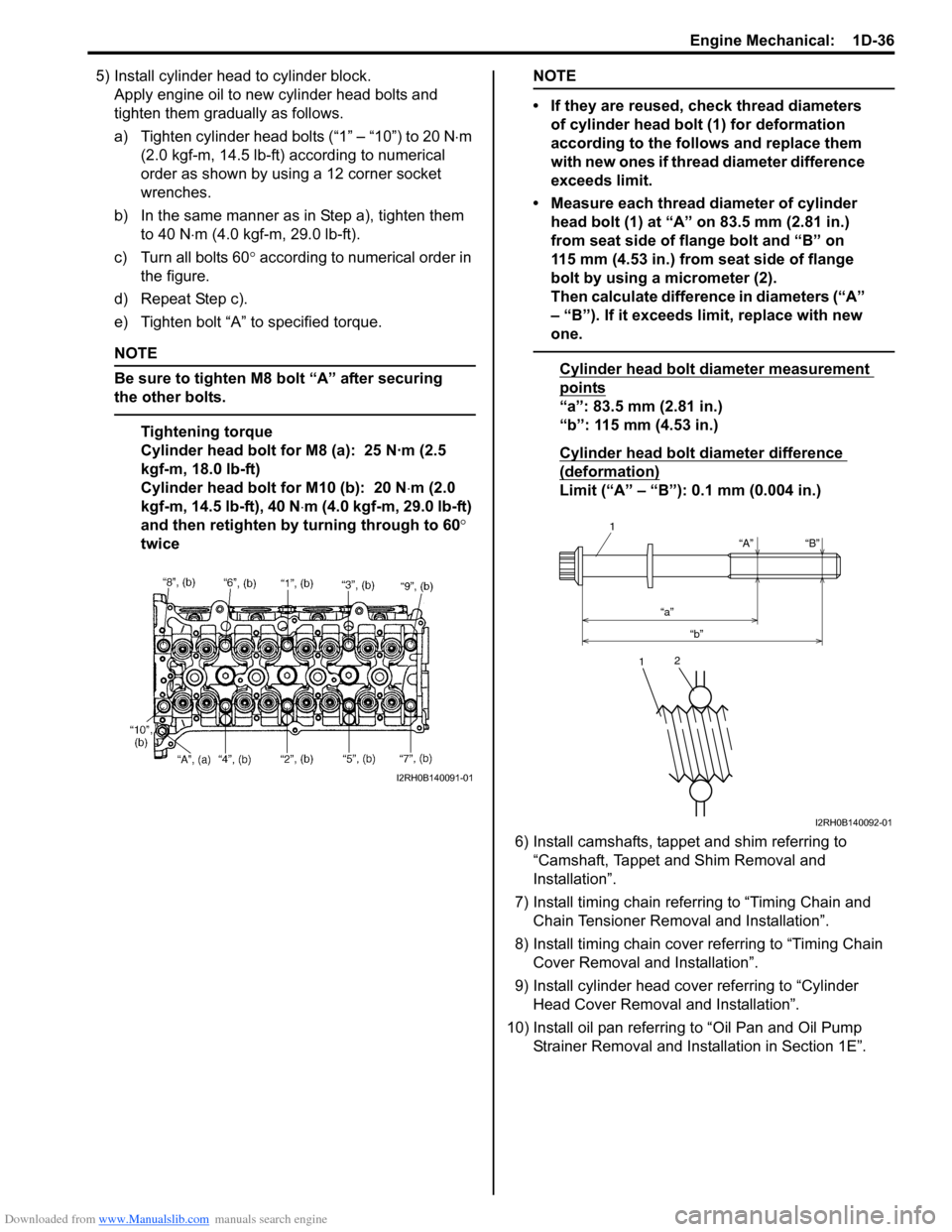

5) Install cylinder head to cylinder block.Apply engine oil to new cylinder head bolts and

tighten them gradually as follows.

a) Tighten cylinder head bolts (“1” – “10”) to 20 N ⋅m

(2.0 kgf-m, 14.5 lb-ft) according to numerical

order as shown by using a 12 corner socket

wrenches.

b) In the same manner as in Step a), tighten them to 40 N ⋅m (4.0 kgf-m, 29.0 lb-ft).

c) Turn all bolts 60 ° according to numerical order in

the figure.

d) Repeat Step c).

e) Tighten bolt “A” to specified torque.

NOTE

Be sure to tighten M8 bolt “A” after securing

the other bolts.

Tightening torque

Cylinder head bolt for M8 (a): 25 N·m (2.5

kgf-m, 18.0 lb-ft)

Cylinder head bolt for M10 (b): 20 N ⋅m (2.0

kgf-m, 14.5 lb-ft), 40 N ⋅m (4.0 kgf-m, 29.0 lb-ft)

and then retighten by turning through to 60 °

twice

NOTE

• If they are reused, check thread diameters of cylinder head bolt (1) for deformation

according to the follows and replace them

with new ones if thread diameter difference

exceeds limit.

• Measure each thread diameter of cylinder head bolt (1) at “A” on 83.5 mm (2.81 in.)

from seat side of flange bolt and “B” on

115 mm (4.53 in.) from seat side of flange

bolt by using a micrometer (2).

Then calculate difference in diameters (“A”

– “B”). If it exceeds limit, replace with new

one.

Cylinder head bolt diameter measurement

points

“a”: 83.5 mm (2.81 in.)

“b”: 115 mm (4.53 in.)

Cylinder head bolt diameter difference

(deformation)

Limit (“A” – “B”): 0.1 mm (0.004 in.)

6) Install camshafts, tappet and shim referring to “Camshaft, Tappet and Shim Removal and

Installation”.

7) Install timing chain referring to “Timing Chain and Chain Tensioner Remova l and Installation”.

8) Install timing chain cover referring to “Timing Chain Cover Removal and Installation”.

9) Install cylinder head cover referring to “Cylinder Head Cover Removal and Installation”.

10) Install oil pan referring to “Oil Pan and Oil Pump

Strainer Removal and Inst allation in Section 1E”.

I2RH0B140091-01

“A”

“a” “b” “B”

1

1

2

I2RH0B140092-01

Page 338 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-53 Engine Mechanical:

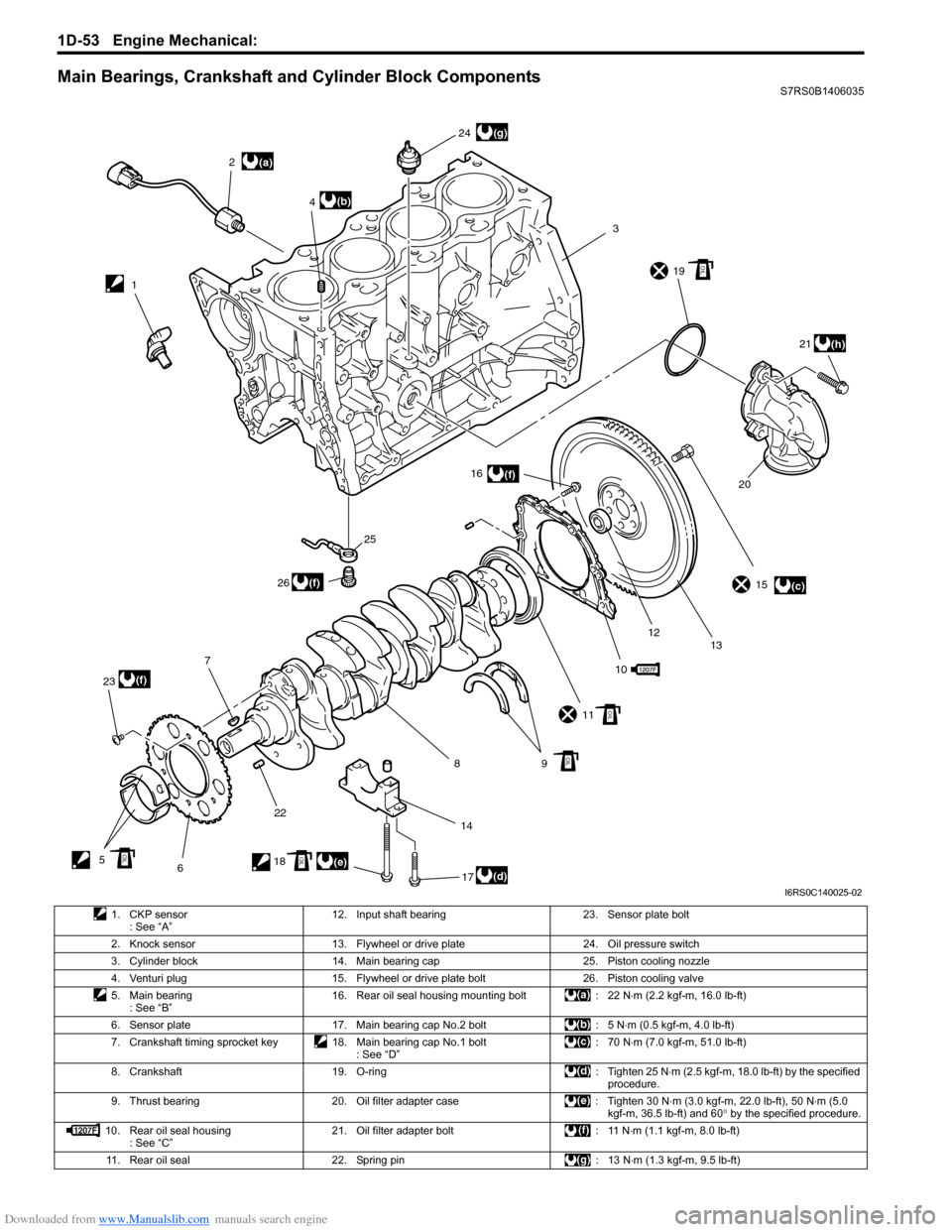

Main Bearings, Crankshaft and Cylinder Block ComponentsS7RS0B1406035

(a)

(c)

(d)(e)

(b)

(f)

(f)

(f)

(g)

(h)

12

3

4

5 67

8910

11 15

12 13

14 16

17

18 19

2021

22

23 24

25

26

OIL

OIL

OIL

OILOIL

I6RS0C140025-02

1. CKP sensor : See “A” 12. Input shaft bearing 23. Sensor plate bolt

2. Knock sensor 13. Flywheel or drive plate 24. Oil pressure switch 3. Cylinder block 14. Main bearing cap 25. Piston cooling nozzle

4. Venturi plug 15. Flywheel or drive plate bolt 26. Piston cooling valve

5. Main bearing : See “B” 16. Rear oil seal housing mounting bolt : 22 N

⋅m (2.2 kgf-m, 16.0 lb-ft)

6. Sensor plate 17. Main bearing cap No.2 bolt : 5 N ⋅m (0.5 kgf-m, 4.0 lb-ft)

7. Crankshaft timing sprocket key 18. Main bearing cap No.1 bolt : See “D”:70 N

⋅m (7.0 kgf-m, 51.0 lb-ft)

8. Crankshaft 19. O-ring : Tighten 25 N ⋅m (2.5 kgf-m, 18.0 lb-ft) by the specified

procedure.

9. Thrust bearing 20. Oil filter adapter case : Tighten 30 N ⋅m (3.0 kgf-m, 22.0 lb-ft), 50 N⋅m (5.0

kgf-m, 36.5 lb-ft) and 60 ° by the specified procedure.

10. Rear oil seal housing : See “C” 21. Oil filter adapter bolt : 11 N

⋅m (1.1 kgf-m, 8.0 lb-ft)

11. Rear oil seal 22. Spring pin : 13 N ⋅m (1.3 kgf-m, 9.5 lb-ft)