timing SUZUKI SWIFT 2005 2.G Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 401 of 1496

Downloaded from www.Manualslib.com manuals search engine Ignition System: 1H-9

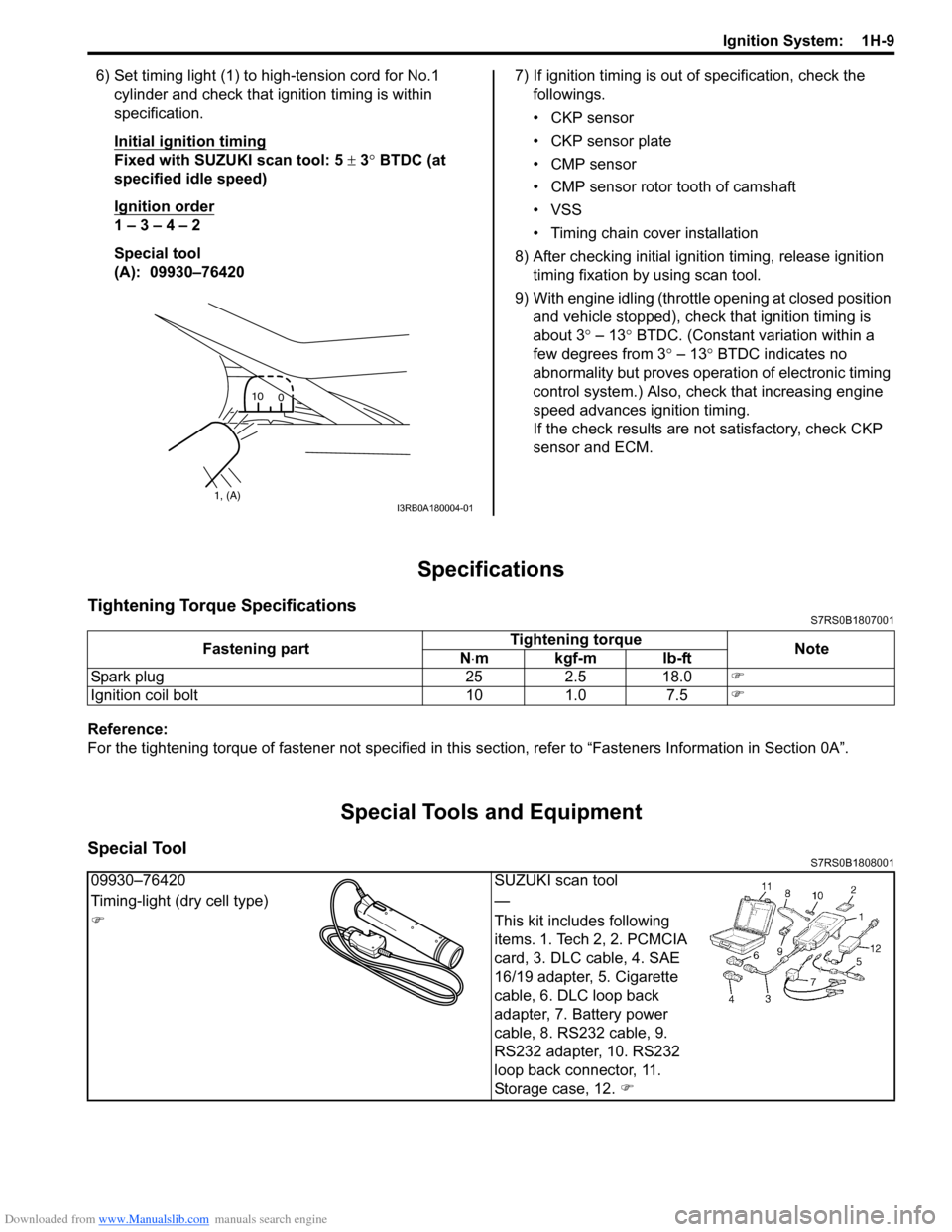

6) Set timing light (1) to high-tension cord for No.1 cylinder and check that ignition timing is within

specification.

Initial ignition timing

Fixed with SUZUKI scan tool: 5 ± 3° BTDC (at

specified idle speed)

Ignition order

1 – 3 – 4 – 2

Special tool

(A): 09930–76420 7) If ignition timing is out

of specification, check the

followings.

• CKP sensor

• CKP sensor plate

• CMP sensor

• CMP sensor rotor tooth of camshaft

• VSS

• Timing chain cover installation

8) After checking initial igniti on timing, release ignition

timing fixation by using scan tool.

9) With engine idling (throttl e opening at closed position

and vehicle stopped), check that ignition timing is

about 3 ° – 13° BTDC. (Constant variation within a

few degrees from 3 ° – 13° BTDC indicates no

abnormality but proves operation of electronic timing

control system.) Also, check that increasing engine

speed advances ignition timing.

If the check results are not satisfactory, check CKP

sensor and ECM.

Specifications

Tightening Torque SpecificationsS7RS0B1807001

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Special ToolS7RS0B1808001

1, (A)10

0I3RB0A180004-01

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Spark plug 25 2.5 18.0 �)

Ignition coil bolt 10 1.0 7.5 �)

09930–76420SUZUKI scan tool

Timing-light (dry cell type) —

�) This kit includes following

items. 1. Tech 2, 2. PCMCIA

card, 3. DLC cable, 4. SAE

16/19 adapter, 5. Cigarette

cable, 6. DLC loop back

adapter, 7. Battery power

cable, 8. RS232 cable, 9.

RS232 adapter, 10. RS232

loop back connector, 11.

Storage case, 12. �)

Page 641 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 5- i

5

Section 5

CONTENTS

Transmission / Transaxle

Precautions ................................................. 5-1

Precautions............................................................. 5-1

Precautions on Transmission / Transaxle ............. 5-1

Automatic Transmission/Transaxle ....... 5A-1

Precautions........................................................... 5A-1Precautions in Diagnosing Trouble ..................... 5A-1

Precautions for Disassembly and Reassembly ...................................................... 5A-1

General Description ............................................. 5A-3 A/T Description ................................................... 5A-3

Clutch / Brake / Planetary Gear Function of Automatic Transaxle ......................................... 5A-6

Table of Component Operation ........................... 5A-7

Brake Interlock System Construction .................. 5A-8

A/T Diagnosis General Description ..................... 5A-8

On-Board Diagnostic System Description ........... 5A-8

CAN Communication System Description........... 5A-9

Schematic and Routing Diagram ...................... 5A-10 Transmission Control Module (TCM) Wiring

Diagram .......................................................... 5A-10

Automatic Gear Shift Table ............................... 5A-12

Component Locatio n ......................................... 5A-13

Electronic Shift Cont rol System Components

Location .......................................................... 5A-13

Diagnostic Information and Procedures .......... 5A-15 A/T System Check ............................................ 5A-15

Visual Inspection ............................................... 5A-18

Malfunction Indicator Lamp (MIL) Check .......... 5A-18

Transmission Warning Ligh t Check .................. 5A-18

DTC Table ......................................................... 5A-19

DTC Check ....................................................... 5A-20

DTC Clearance ................................................. 5A-20

Fail-Safe Table ................ .................................. 5A-21

Scan Tool Data ................................................. 5A-23

A/T Basic Check ............................................... 5A-26

Road Test ......................................................... 5A-27

Manual Road Test ........... .................................. 5A-29

Engine Brake Test ............................................ 5A-30

Stall Test ........................................................... 5A-30

Time Lag Test ................................................... 5A-31

Line Pressure Test .......... .................................. 5A-32

“P” Range Test.................................................. 5A-33

A/T Symptom Diagnosis ..... .............................. 5A-34 No Gear Shift to 4th gear .................................. 5A-41

No Lock-Up Occurs ........................................... 5A-42

Transmission Warning Light Circuit Check –

Light Does Not Come “ON” at Ignition Switch

ON ................................................................... 5A-43

Transmission Warning Light Circuit Check – Light Remains “ON” at Ignition Switch ON ...... 5A-43

DTC P0602: Control Module Programming Error ................................................................ 5A-44

DTC P0705: Transmission Range Sensor Circuit Malfunction (PRNDL input) .................. 5A-44

DTC P0707: Transmission Range Sensor Circuit Low ...................................................... 5A-46

DTC P0712: Transmission Fluid Temperature Sensor “A” Circuit Low ... ................................. 5A-48

DTC P0713: Transmission Fluid Temperature Sensor “A” Circuit High .. ................................. 5A-49

DTC P0717: Input / Turbine Speed Sensor “A” Circuit Malfunction........................................... 5A-51

DTC P0722: Output Speed Sensor Circuit No Signal .............................................................. 5A-52

DTC P0787: Shift / Timing Solenoid Low .......... 5A-54

DTC P0788: Shift / Timing Solenoid High ......... 5A-56

DTC P0961: Pressure Control Solenoid “A”

Control Circuit Range / Performance .............. 5A-58

DTC P0962: Pressure Control Solenoid “A”

Control Circuit Low .......................................... 5A-60

DTC P0963: Pressure Control Solenoid “A”

Control Circuit High ......................................... 5A-62

DTC P0973 / P0976: Shift Solenoid “A” Control Circuit Low / Shift Solenoid “B”

Control Circuit Low .......................................... 5A-64

DTC P0974 / P0977: Shift Solenoid “A” / Shift Solenoid “B” Control Circuit High .................... 5A-66

DTC P1702: Internal Co ntrol Module Memory

Check Sum Error............................................. 5A-68

DTC P1703: Can Invalid Data - TCM ................ 5A-68

DTC P1723: Range Select Switch Malfunction ...................................................... 5A-69

DTC P1774: CAN Communication Bus Off ....... 5A-71

DTC P1777: TCM Lost Communication with ECM (Reception Error).................................... 5A-73

DTC P1778: TCM Lost Communication with BCM (Reception Error).................................... 5A-74

Page 642 of 1496

Downloaded from www.Manualslib.com manuals search engine 5-ii Table of Contents

DTC P1878: Torque Converter Clutch Shudder .......................................................... 5A-75

DTC P2762: Torque Converter Clutch (TCC) Pressure Control Sole noid Control Circuit

Range /Performance ....................................... 5A-76

DTC P2763: Torque Converter Clutch Pressure Control Sole noid Control Circuit

High ................................................................. 5A-78

DTC P2764: Torque Converter Clutch Circuit Pressure Control Sole noid Control Circuit

Low ................................................................. 5A-80

Inspection of TCM and Its Circuits .................... 5A-82

TCM Power and Ground Circuit Check ............. 5A-86

Brake Interlock System Inspection .................... 5A-87

Repair Instructions ........... .................................5A-88

Learning Control Initializat ion ............................ 5A-88

A/T Fluid Level Check ....................................... 5A-89

A/T Fluid Change .............................................. 5A-90

Select Lever Components ... .............................. 5A-90

Select Lever Assembly Removal and Installation ....................................................... 5A-90

Select Lever Knob Installa tion........................... 5A-90

Select Lever Inspection .... ................................. 5A-91

“3” Position Switch Inspec tion ........................... 5A-91

Shift Lock Solenoid Inspec tion .......................... 5A-91

Shift Lock Solenoid Replacement ..................... 5A-91

Select Cable Components ................................ 5A-92

Select Cable Removal and Installation ............. 5A-92

Select Cable Adjustment ................................... 5A-93

Key Interlock Cable Removal and Installation... 5A-93

Transmission Range Sensor (Shift Switch) Inspection and Adjustment .............................. 5A-95

Output Shaft Speed Sensor Removal and Installation ....................................................... 5A-96

Output Shaft Speed Sensor Inspection ............. 5A-96

Input Shaft Speed Sensor Removal and Installation ....................................................... 5A-96

Input Shaft Speed Sensor Inspection................ 5A-97

Transmission Fluid Temperature Sensor Removal and Installation ................................. 5A-97

Transmission Fluid Temperature Sensor Inspection ........................................................ 5A-98

Solenoid Valves (Shift Solenoid Valves and Timing Solenoid Valve) Removal and

Installation ....................................................... 5A-98

Solenoid Valves (Shift Solenoid Valves, and Timing Solenoid Valve) Inspection .................. 5A-99

Pressure Control Soleno id Valves (Pressure

Control Solenoid and TCC Pressure Control

Solenoid) Removal and Inst allation .............. 5A-101

Pressure Control Solenoid Valve Inspection ... 5A-101

Transmission Control Module (TCM) Removal and Installation ............................... 5A-102

A/T Relay Inspection ....................................... 5A-103

Differential Side Oil Seal Replacement ........... 5A-103

A/T Fluid Cooler Hoses Replacement ............. 5A-104

Automatic Transaxle Unit Components........... 5A-105

Automatic Transaxle Unit Dismounting and Remounting ................................................... 5A-106

Automatic Transaxle Asse mbly Components . 5A-108 Automatic Transaxle Unit

Disassembly........... 5A-110

Oil Pump Assembly Components ................... 5A-121

Oil Pump Assembly Disassembly and Reassembly .................................................. 5A-122

Oil Pump Assembly Inspection ....................... 5A-122

Direct Clutch Assembly Components.............. 5A-124

Direct Clutch Assembly Preliminary Check ..... 5A-124

Direct Clutch Assembly Disassembly and Reassembly .................................................. 5A-125

Direct Clutch Assembly Inspection.................. 5A-127

Forward and Reverse Clutch Assembly Components .................................................. 5A-128

Forward and Reverse Clutch Assembly Preliminary Check ......................................... 5A-129

Forward and Reverse Clutch Assembly Disassembly and Reassembly ...................... 5A-129

Forward and Reverse Clutch Assembly Inspection ...................................................... 5A-133

2nd Brake Piston Assembly Components ....... 5A-134

2nd Brake Piston Assembly Disassembly and Reassembly .................................................. 5A-134

Transaxle Rear Cover (O/D and 2nd Coast Brake Piston) Assembly Components........... 5A-135

Transaxle Rear Cover (O/D and 2nd Coast Brake Piston) Assembly Disassembly and

Reassembly .................................................. 5A-136

Transaxle Rear Cover (O/D and 2nd Coast Brake Piston) Assembly Inspection............... 5A-137

Countershaft Assembly Co mponents.............. 5A-138

Countershaft Assembly Disassembly and Reassembly .................................................. 5A-138

Valve Body Assembly Components ................ 5A-139

Valve Body Assembly Disassembly and Reassembly .................................................. 5A-140

Differential Assembly Components ................. 5A-141

Differential Assembly Disassembly and Reassembly .................................................. 5A-142

Differential Assembly Inspection ..................... 5A-143

Torque Converter Housing Disassembly and Reassembly .................................................. 5A-144

Transaxle Case Disassembly and Reassembly .................................................. 5A-146

Automatic Transaxle Unit Inspection and Adjus

tment .................................................... 5A-147

Automatic Transaxle Unit Assembly ............... 5A-150

Specifications .................. .................................5A-167

Tightening Torque Specifications .................... 5A-167

Special Tools and Equipmen t .........................5A-168

Recommended Service Material ..................... 5A-168

Special Tool .................................................... 5A-168

Manual Transmission/Tr ansaxle ............ 5B-1

General Description .............................................5B-1

Manual Transaxle Construction and Servicing .... 5B-1

Diagnostic Information and Procedures ............5B-3 Manual Transaxle Symptom Diagnosis............... 5B-3

Repair Instructions ............ ..................................5B-3

Manual Transaxle Oil Change............................. 5B-3

Differential Side Oil Seal Replacement ............... 5B-4

Page 647 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-3

General Description

A/T DescriptionS7RS0B5101001

This automatic transaxle is electronic control full automatic transaxle with forward 4-speed and reverse 1-speed.

The torque converter is a 3-element, 1-step and 2-phase type and is equipped with an automatically controlled lock-up

mechanism.

The gear change device consists of a ravigneau type planet ary gear unit, 3 multiple disc type clutches, 3 multiple disc

type brakes and 2 one-way clutches.

The hydraulic pressure control device consists of a valve body assembly, pressure control solenoid valve (linear

solenoid), 2 shift solenoid va lves, TCC pressure control solenoid valve (lin ear solenoid) and a timing solenoid valve.

Optimum line pressure complying with engine torque is produced by the pressure control solenoid valve in

dependence upon control signal from transmission control module (TCM). This makes it possible to control the line

pressure with high accuracy in accordance with the engine power and running conditions to achieve smooth shifting

characteristics and high efficiency.

A clutch-to-clutch control system is prov ided for shifting between 3rd gear and 4th gear. This clutch-to-clutch control

system is made to function optimally , so that hydraulic pressure controls such as shown below are conducted.

• When upshifting from 3rd gear to 4th gear, to adjust the drain hydraulic pressure at releasing the forward clutch, a

timing solenoid valve is used to switch a hydraulic passage with an orifice to another during shifting.

• When downshifting from 4th gear to 3rd gear, to adjust the line pressure applied to the forward clutch at engaging the forward clutch, a timing solenoid valve is used to s witch a hydraulic passage with an orifice to another during

shifting.

• When upshifting from 3rd gear to 4th gear with engine throttle opened, to optimize the line pressure applied to the forward clutch at releasing the forward clutch, the learning control is processed to compensate the switching timing

of the timing solenoid at every shifting.

• When downshifting from 4th gear to 3rd gear with engine throttle opened, to optimize the line pressure applied to

the forward clutch at engaging the forw ard clutch, the learning control is processed to compensate the line pressure

at every shifting.

Employing the ravigneau type planetary gear unit and this clutch-to-clutch control system greatly simplifies the

construction to make possible a lightweight and compact transaxle.

A line pressure learning control is conducted to provide opti mum shifting time at every upshifting with engine throttle

opened. If long upshifting time is detected, the subsequent line pressure applied during upshifting is intensified. On the

contrary, if short upshifting time is detected, the subs equent line pressure applied during upshifting is weakened.

Slip controlled lock-up function

Even at a lower speed than when the TCC gets engaged completely, control over the TCC pressure control solenoid

works to cause the TCC to slip (be engaged slightly), ther eby improving the transmission efficiency. While such slip

control is being executed, the oil pressure applied to the TCC is controlled by the TCC pressure control solenoid so

that the difference between the engine speed and the input shaft speed becomes close to the specified value.

Also, during deceleration, the TCC is made to slip (be enga ged slightly) to raise the engine speed and enlarge the fuel

cut operation range so that better fuel consumption is achieved.

Due to this reason, it is absolutely necessary for the automati c transmission to use ATF suitable for slip control. Use of

any fluid other than the specified ATF may cause j uddering or some other faulty condition to occur.

Page 652 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-8 Automatic Transmission/Transaxle:

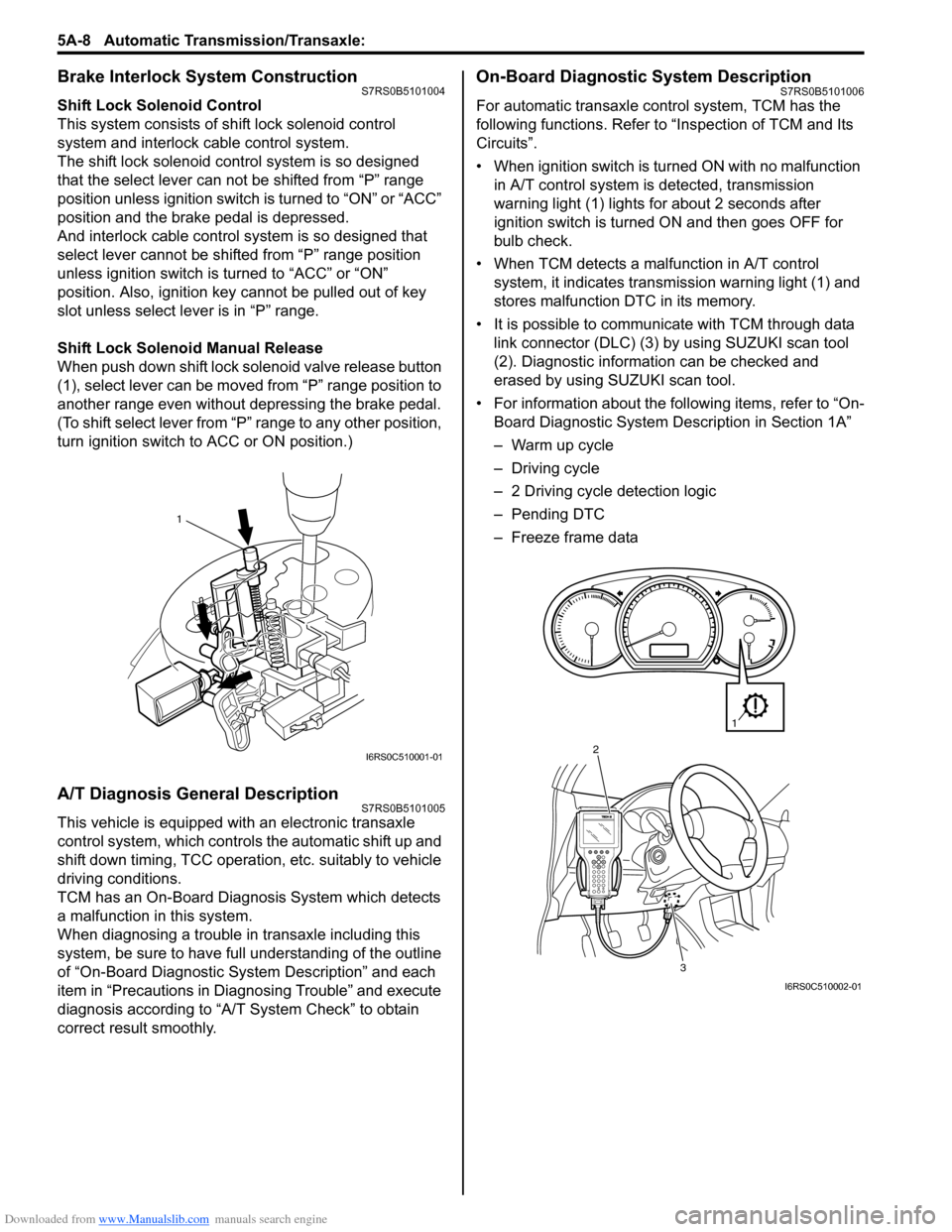

Brake Interlock System ConstructionS7RS0B5101004

Shift Lock Solenoid Control

This system consists of shift lock solenoid control

system and interlock cable control system.

The shift lock solenoid cont rol system is so designed

that the select lever can not be shifted from “P” range

position unless ignition switch is turned to “ON” or “ACC”

position and the brake pedal is depressed.

And interlock cable control system is so designed that

select lever cannot be shifted from “P” range position

unless ignition switch is turned to “ACC” or “ON”

position. Also, ignition key cannot be pulled out of key

slot unless select le ver is in “P” range.

Shift Lock Solenoid Manual Release

When push down shift lock solenoid valve release button

(1), select lever can be moved from “P” range position to

another range even without depressing the brake pedal.

(To shift select lever from “P” range to any other position,

turn ignition switch to ACC or ON position.)

A/T Diagnosis General DescriptionS7RS0B5101005

This vehicle is equipped with an electronic transaxle

control system, which controls the automatic shift up and

shift down timing, TCC operation, etc. suitably to vehicle

driving conditions.

TCM has an On-Board Diagnosis System which detects

a malfunction in this system.

When diagnosing a trouble in transaxle including this

system, be sure to have full understanding of the outline

of “On-Board Diagnostic System Description” and each

item in “Precautions in Diagnosing Trouble” and execute

diagnosis according to “A/T System Check” to obtain

correct result smoothly.

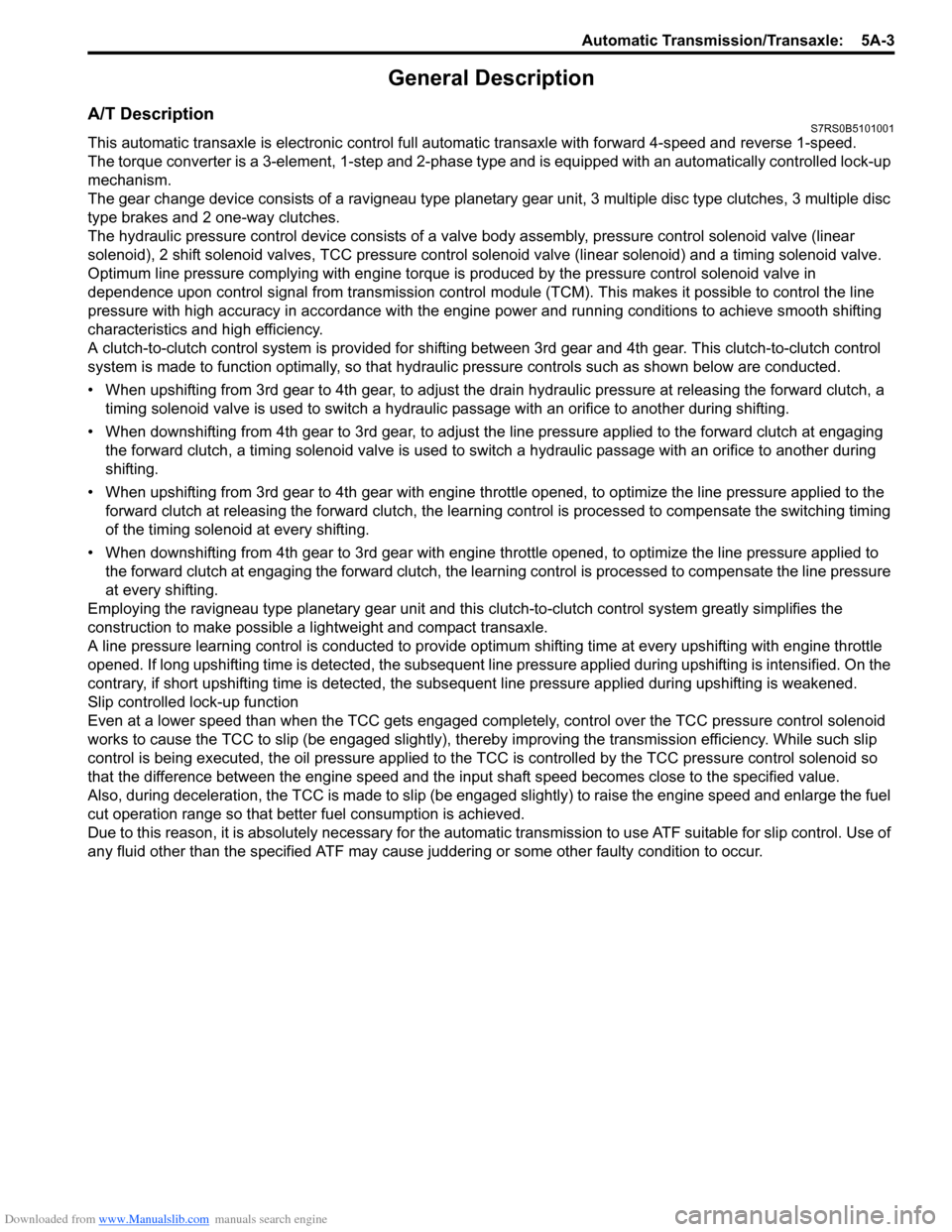

On-Board Diagnostic System DescriptionS7RS0B5101006

For automatic transaxle co ntrol system, TCM has the

following functions. Refer to “Inspection of TCM and Its

Circuits”.

• When ignition switch is turned ON with no malfunction in A/T control system is detected, transmission

warning light (1) lights for about 2 seconds after

ignition switch is turned ON and then goes OFF for

bulb check.

• When TCM detects a malfunction in A/T control system, it indicates transmission warning light (1) and

stores malfunction DTC in its memory.

• It is possible to communicate with TCM through data link connector (DLC) (3) by using SUZUKI scan tool

(2). Diagnostic information can be checked and

erased by using SUZUKI scan tool.

• For information about the following items, refer to “On- Board Diagnostic System De scription in Section 1A”

– Warm up cycle

– Driving cycle

– 2 Driving cycle detection logic

– Pending DTC

– Freeze frame data

1

I6RS0C510001-01

3

2

1

I6RS0C510002-01

Page 654 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-10 Automatic Transmission/Transaxle:

Schematic and Routing Diagram

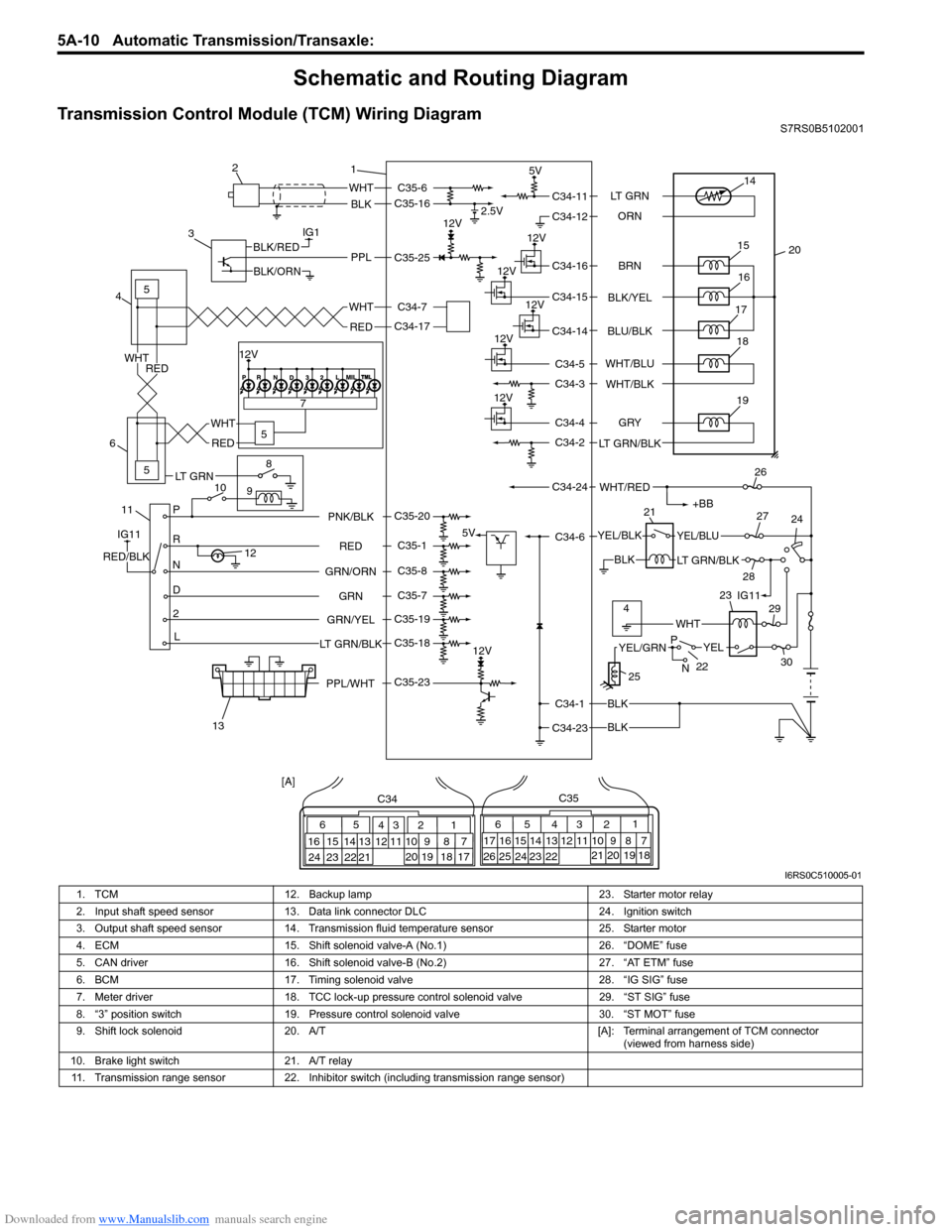

Transmission Control Module (TCM) Wiring DiagramS7RS0B5102001

IG1

115

5

5

8

9

10 7

P

R

N

D

2

L

12

12V 2.5V

5V

12V

5V

12V

12V

12V

12V

WHT

BLK

BLK

BLK

BLK

PPLBLK/RED

BLK/ORN

IG11

RED/BLK

YEL/BLKYEL/BLU

LT GRN/BLK

+BB

WHT/RED

14

20

15

16

17

19

12V18

1

2

3

4

6

13 21

26

24

27

28 29

30

WHT

WHT

RED

RED

WHT

RED

65

16 15 14 13 12 11 43

24 23 2122 10 9 8 721

1920 18 17

C34

17 16

26 25

15 14

65 3

42

13 12

23 2224 11 10 9

21 20 19 87

18

1

C35

[A]

22

25

YELYEL/GRN

WHT

P

N

BRN

LT GRN

ORN

BLK/YEL

BLU/BLK

GRY

LT GRN/BLK WHT/BLU

WHT/BLK

C34-11

C34-12

C34-16

C34-15

C34-14

C34-4

C34-2

C34-1

C34-23 C34-6

C34-24 C34-5

C34-3

RED

GRN

GRN/ORN PNK/BLK

GRN/YEL

LT GRN/BLKC35-6

C35-16

C35-23 C35-25

C35-20

C35-1

C35-8

C35-7

C35-19

C35-18 C34-17 C34-7

4IG11

12V

23

PPL/WHT

LT GRN

I6RS0C510005-01

1. TCM 12. Backup lamp 23. Starter motor relay

2. Input shaft speed sensor 13. Data link connector DLC 24. Ignition switch

3. Output shaft speed sensor 14. Transmission fluid temperature sensor 25. Starter motor

4. ECM 15. Shift solenoid valve-A (No.1) 26. “DOME” fuse

5. CAN driver 16. Shift solenoid valve-B (No.2) 27. “AT ETM” fuse

6. BCM 17. Timing solenoid valve 28. “IG SIG” fuse

7. Meter driver 18. TCC lock-up pressure control solenoid valve 29. “ST SIG” fuse

8. “3” position switch 19. Pressure control solenoid valve 30. “ST MOT” fuse

9. Shift lock solenoid 20. A/T [A]: Terminal arrangement of TCM connector

(viewed from harness side)

10. Brake light switch 21. A/T relay

11. Transmission range sensor 22. Inhibitor switch (including transmission range sensor)

Page 655 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-11

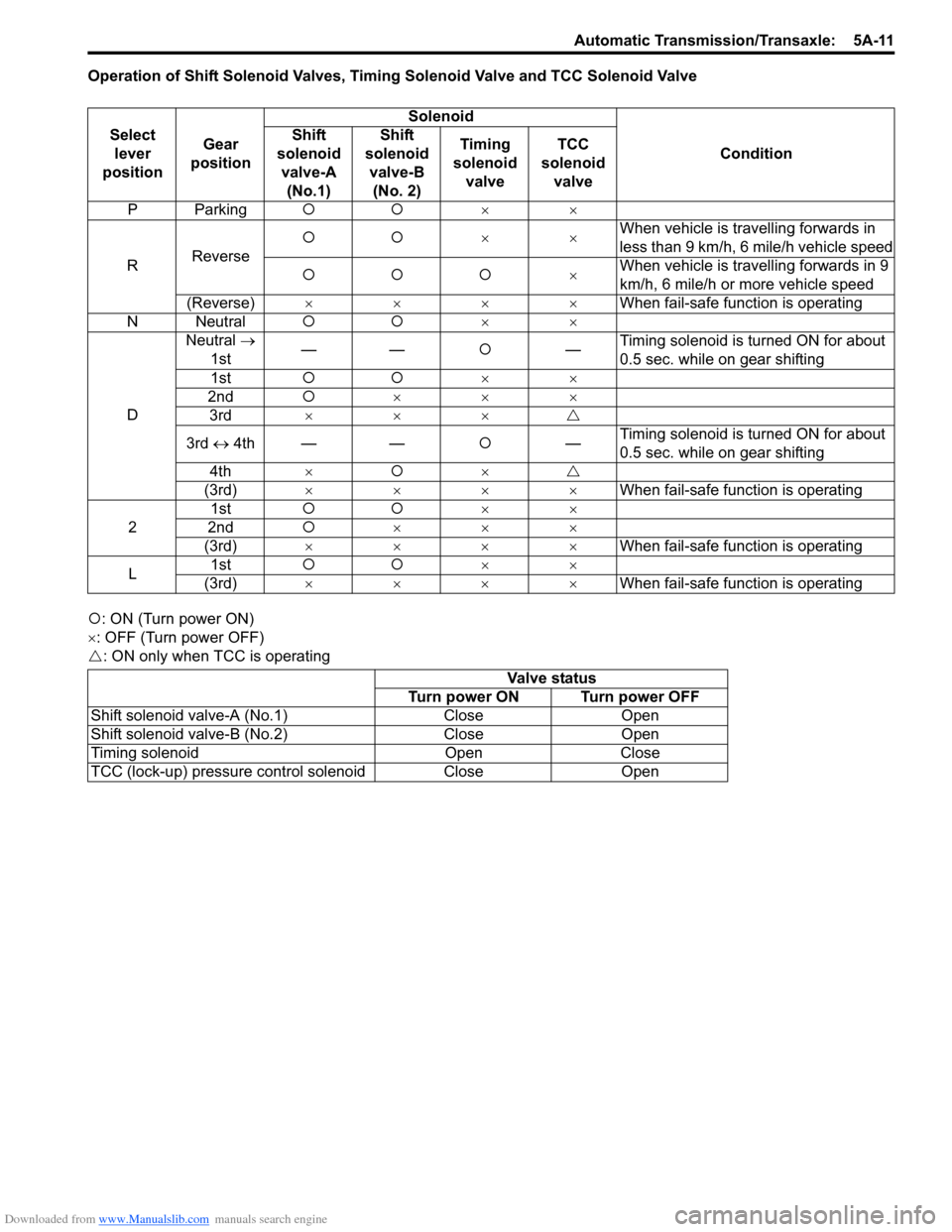

Operation of Shift Solenoid Valves, Timing Solenoid Valve and TCC Solenoid Valve

�{: ON (Turn power ON)

×: OFF (Turn power OFF)

�U : ON only when TCC is operatingSelect

lever

position Gear

position Solenoid

Condition

Shift

solenoid valve-A (No.1) Shift

solenoid valve-B (No. 2) Timing

solenoid valve TCC

solenoid valve

PParking �{�{ ××

R Reverse �{�{

××When vehicle is travelling forwards in

less than 9 km/h, 6 mile/h vehicle speed

�{�{�{ ×When vehicle is travelling forwards in 9

km/h, 6 mile/h or more vehicle speed

(Reverse) ×××× When fail-safe function is operating

N Neutral �{�{ ××

D Neutral

→

1st ——

�{—Timing solenoid is turned ON for about

0.5 sec. while on gear shifting

1st �{�{ ××

2nd �{×××

3rd ××× �U

3rd ↔ 4th — — �{—Timing solenoid is turned ON for about

0.5 sec. while on gear shifting

4th �{ �U

(3rd) ×××× When fail-safe function is operating

2 1st

�{�{ ××

2nd �{×××

(3rd) ×××× When fail-safe function is operating

L 1st

�{�{ ××

(3rd) ×××× When fail-safe function is operating

Valve status

Turn power ON Turn power OFF

Shift solenoid valv e-A (No.1) Close Open

Shift solenoid valv e-

B (No.2) CloseOpen

Timing solenoid OpenClose

TCC (lock-up) pressure control solenoid CloseOpen

Page 657 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-13

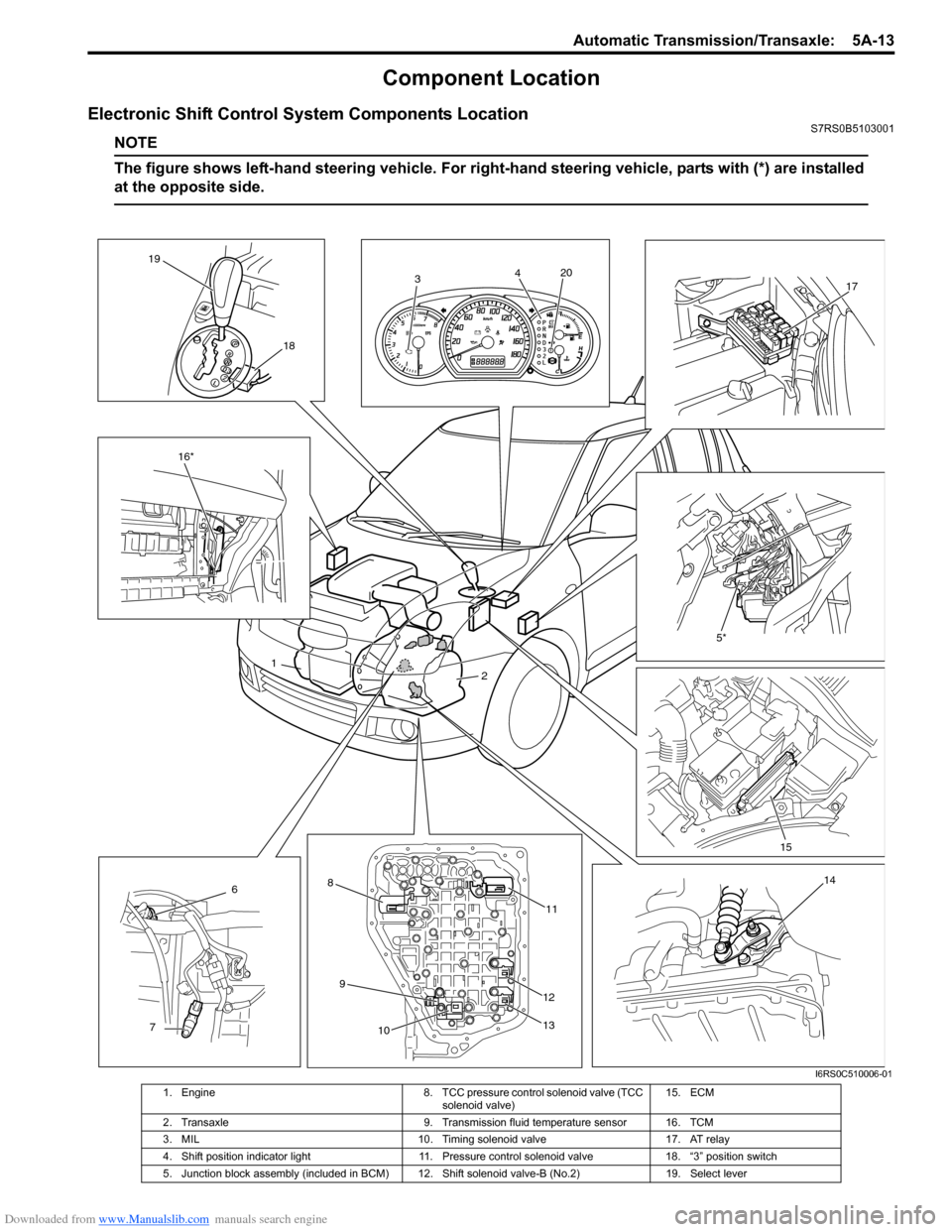

Component Location

Electronic Shift Control System Components LocationS7RS0B5103001

NOTE

The figure shows left-hand steering vehicle. For right-hand steering vehicle, parts with (*) are installed

at the opposite side.

3 4

5*

1 2

6

7 8

9 10 11

12

13 14

16*

18

19

17

15

20

I6RS0C510006-01

1. Engine

8. TCC pressure control solenoid valve (TCC

solenoid valve) 15. ECM

2. Transaxle 9. Transmission fluid temperature sensor 16. TCM

3. MIL 10. Timing solenoid valve17. AT relay

4. Shift position indicator light 11. Pressure control solenoid valve18. “3” position switch

5. Junction block assembly (included in BCM) 12. Shift solenoid valve-B (No.2)19. Select lever

Page 663 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-19

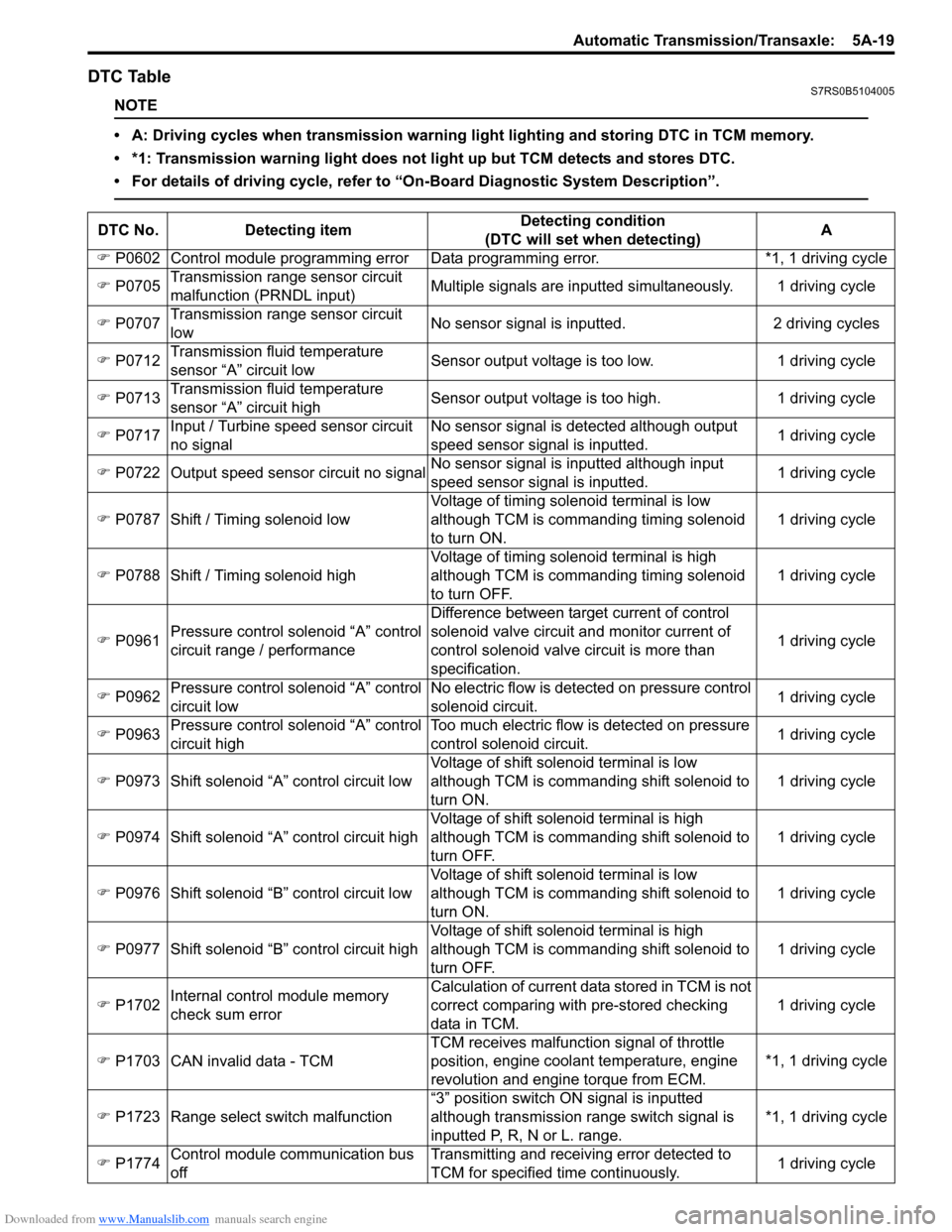

DTC TableS7RS0B5104005

NOTE

• A: Driving cycles when transmission warning light lighting and storing DTC in TCM memory.

• *1: Transmission warning light does not light up but TCM detects and stores DTC.

• For details of driving cycle, refer to “On-Board Diagnostic System Description”.

DTC No.Detecting item Detecting condition

(DTC will set when detecting) A

�) P0602 Control module programming error D ata programming error. *1, 1 driving cycle

�) P0705 Transmission range sensor circuit

malfunction (PRNDL input) Multiple signals are inputted

simultaneously. 1 driving cycle

�) P0707 Transmission range sensor circuit

low No sensor signal is inputted.

2 driving cycles

�) P0712 Transmission fluid temperature

sensor “A” circuit low Sensor output voltage is too low.

1 driving cycle

�) P0713 Transmission fluid temperature

sensor “A” circuit high Sensor output voltage is too high.

1 driving cycle

�) P0717 Input / Turbine speed sensor circuit

no signal No sensor signal is detected although output

speed sensor signal is inputted.

1 driving cycle

�) P0722 Output speed sensor circuit no signal No sensor signal is inputted although input

speed sensor signal is inputted. 1 driving cycle

�) P0787 Shift / Timing solenoid low Voltage of timing solenoid terminal is low

although TCM is commanding timing solenoid

to turn ON. 1 driving cycle

�) P0788 Shift / Timing solenoid high Voltage of timing solenoid terminal is high

although TCM is commanding timing solenoid

to turn OFF. 1 driving cycle

�) P0961 Pressure control solenoid “A” control

circuit range / performance Difference between target current of control

solenoid valve circuit and monitor current of

control solenoid valve circuit is more than

specification.

1 driving cycle

�) P0962 Pressure control solenoid “A” control

circuit low No electric flow is detected on pressure control

solenoid circuit.

1 driving cycle

�) P0963 Pressure control solenoid “A” control

circuit high Too much electric flow is detected on pressure

control solenoid circuit.

1 driving cycle

�) P0973 Shift solenoid “A” control circuit low Voltage of shift solenoid terminal is low

although TCM is commanding shift solenoid to

turn ON. 1 driving cycle

�) P0974 Shift solenoid “A” control circuit high Voltage of shift solenoid terminal is high

although TCM is commanding shift solenoid to

turn OFF. 1 driving cycle

�) P0976 Shift solenoid “B” control circuit low Voltage of shift solenoid terminal is low

although TCM is commanding shift solenoid to

turn ON. 1 driving cycle

�) P0977 Shift solenoid “B” control circuit high Voltage of shift solenoid terminal is high

although TCM is commanding shift solenoid to

turn OFF. 1 driving cycle

�) P1702 Internal control module memory

check sum error Calculation of current data stored in TCM is not

correct comparing with pre-stored checking

data in TCM.

1 driving cycle

�) P1703 CAN invalid data - TCM TCM receives malfunction signal of throttle

position

, engine coolan t temperature, engine

revolution and engine torque from ECM. *1, 1 driving cycle

�) P1723 Range select switch malfunction “3” position switch ON signal is inputted

although transmission range switch signal is

inputted P, R, N or L. range. *1, 1 driving cycle

�) P1774 Control module communication bus

off Transmitting and receiving error detected to

TCM for specified time continuously.

1 driving cycle

Page 665 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-21

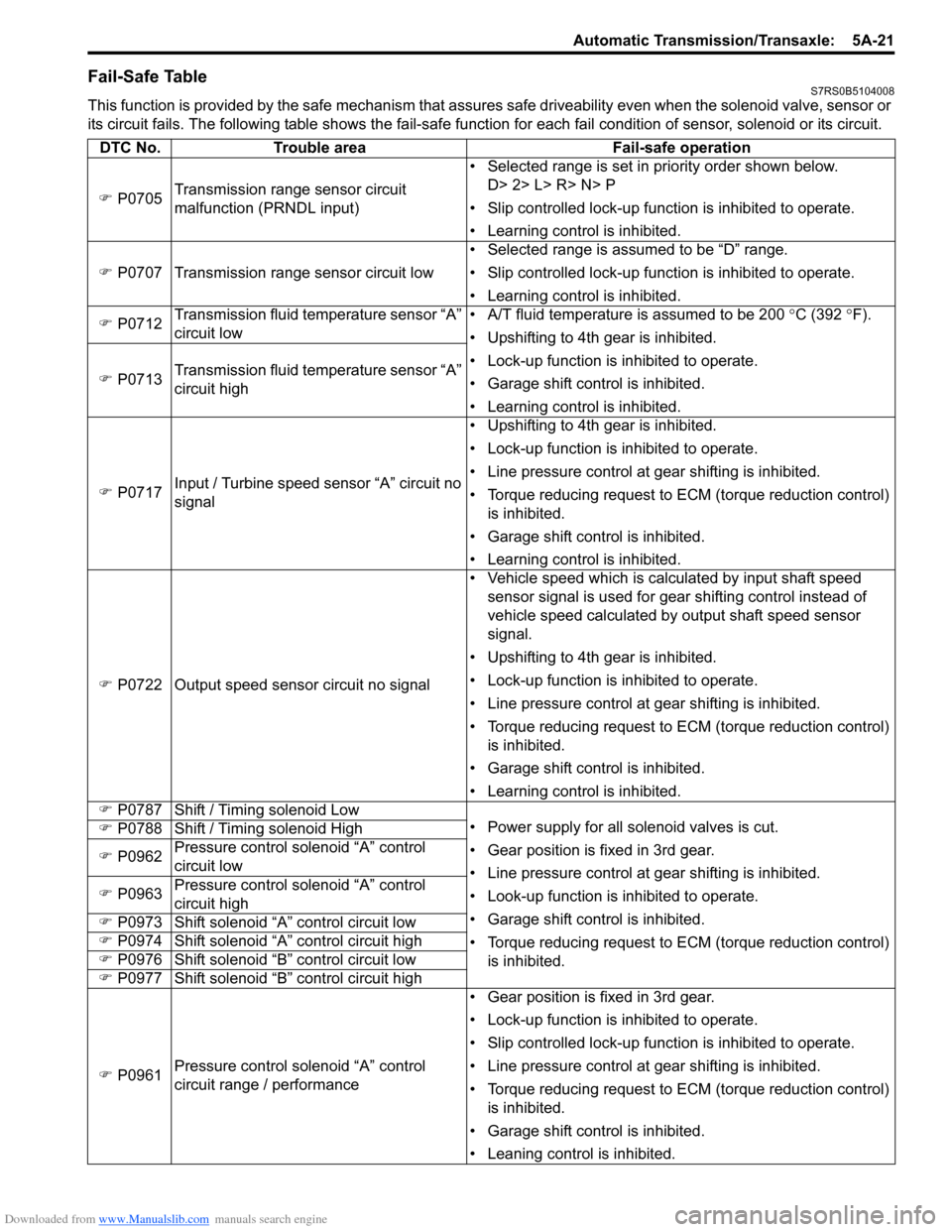

Fail-Safe TableS7RS0B5104008

This function is provided by the safe mechanism that assures safe driveability even when the solenoid valve, sensor or

its circuit fails. The following table shows th e fail-safe function for each fail condition of sensor, solenoid or its circuit.

DTC No. Trouble area Fail-safe operation

�) P0705 Transmission range sensor circuit

malfunction (PRNDL input) • Selected range is set in priority order shown below.

D> 2> L> R> N> P

• Slip controlled lock-up function is inhibited to operate.

• Learning control is inhibited.

�) P0707 Transmission range sensor circuit low • Selected range is assumed to be “D” range.

• Slip controlled lock-up function is inhibited to operate.

• Learning control is inhibited.

�) P0712 Transmission fluid temperature sensor “A”

circuit low • A/T fluid temperature is assumed to be 200

°C (392 °F).

• Upshifting to 4th gear is inhibited.

• Lock-up function is inhibited to operate.

• Garage shift control is inhibited.

• Learning control is inhibited.

�)

P0713 Transmission fluid temperature sensor “A”

circuit high

�) P0717 Input / Turbine speed sensor “A” circuit no

signal • Upshifting to 4th gear is inhibited.

• Lock-up function is inhibited to operate.

• Line pressure control at gear shifting is inhibited.

• Torque reducing request to ECM (torque reduction control)

is inhibited.

• Garage shift control is inhibited.

• Learning control is inhibited.

�) P0722 Output speed sensor circuit no signal • Vehicle speed which is calculated by input shaft speed

sensor signal is used for gear shifting control instead of

vehicle speed calculated by output shaft speed sensor

signal.

• Upshifting to 4th gear is inhibited.

• Lock-up function is inhibited to operate.

• Line pressure control at gear shifting is inhibited.

• Torque reducing request to ECM (torque reduction control) is inhibited.

• Garage shift control is inhibited.

• Learning control is inhibited.

�) P0787 Shift / Timing solenoid Low

• Power supply for all solenoid valves is cut.

• Gear position is fixed in 3rd gear.

• Line pressure control at gear shifting is inhibited.

• Look-up function is inhibited to operate.

• Garage shift control is inhibited.

• Torque reducing request to ECM (torque reduction control)

is inhibited.

�)

P0788 Shift / Timing solenoid High

�) P0962 Pressure control solenoid “A” control

circuit low

�) P0963 Pressure control solenoid “A” control

circuit high

�) P0973 Shift solenoid “A” control circuit low

�) P0974 Shift solenoid “A” control circuit high

�) P0976 Shift solenoid “B” control circuit low

�) P0977 Shift solenoid “B” control circuit high

�) P0961 Pressure control solenoid “A” control

circuit range / performance • Gear position is fixed in 3rd gear.

• Lock-up function is inhibited to operate.

• Slip controlled lock-up function is inhibited to operate.

• Line pressure control at gear shifting is inhibited.

• Torque reducing request to ECM (torque reduction control)

is inhibited.

• Garage shift control is inhibited.

• Leaning control is inhibited.