timing SUZUKI SWIFT 2005 2.G Service Manual PDF

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2005, Model line: SWIFT, Model: SUZUKI SWIFT 2005 2.GPages: 1496, PDF Size: 34.44 MB

Page 699 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-55

DTC TroubleshootingStep Action Yes No 1 Was “A/T System Check” performed? Go to Step 2. Go to “A/T System

Check”.

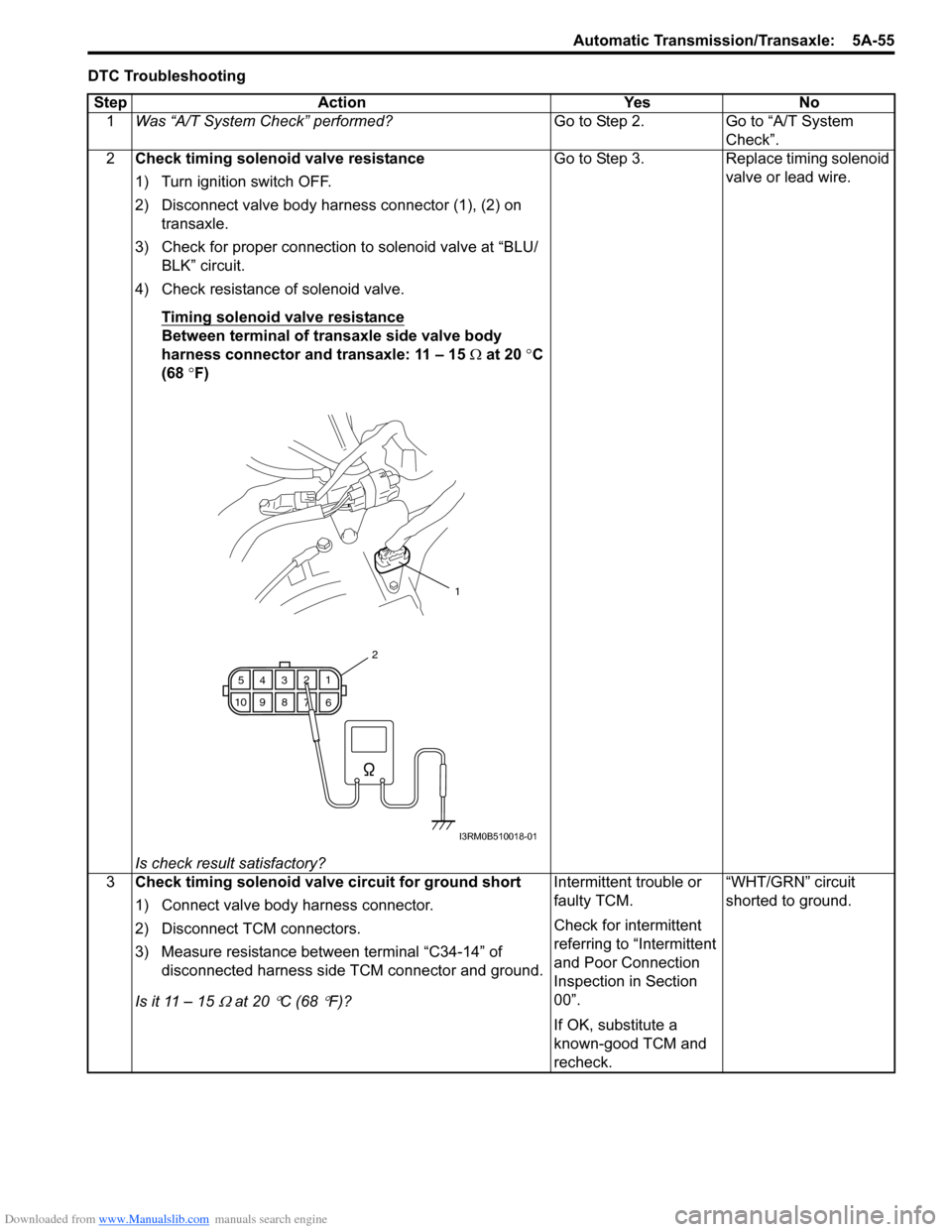

2 Check timing solenoid valve resistance

1) Turn ignition switch OFF.

2) Disconnect valve body harness connector (1), (2) on

transaxle.

3) Check for proper connection to solenoid valve at “BLU/ BLK” circuit.

4) Check resistance of solenoid valve.

Timing solenoid valve resistance

Between terminal of transaxle side valve body

harness connector and transaxle: 11 – 15 Ω at 20 °C

(68 °F)

Is check result satisfactory? Go to Step 3. Replace timing solenoid

valve or lead wire.

3 Check timing solenoid valve circuit for ground short

1) Connect valve body harness connector.

2) Disconnect TCM connectors.

3) Measure resistance between terminal “C34-14” of

disconnected harness side TCM connector and ground.

Is it 11 – 15

Ω at 20 °C (68 °F)? Intermittent trouble or

faulty TCM.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

If OK, substitute a

known-good TCM and

recheck.“WHT/GRN” circuit

shorted to ground.

1

6

7

89

10 5

43 2

1

2

I3RM0B510018-01

Page 700 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-56 Automatic Transmission/Transaxle:

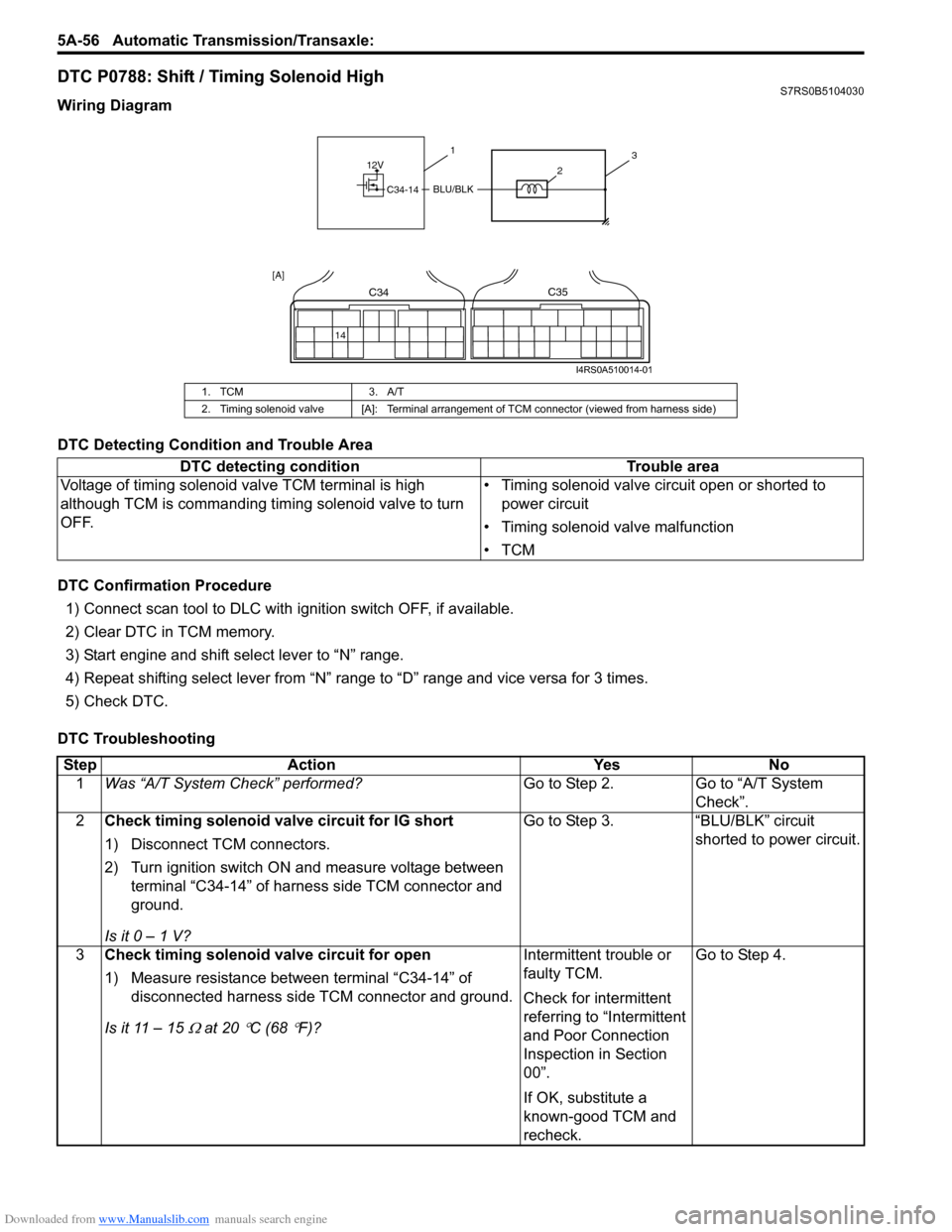

DTC P0788: Shift / Timing Solenoid HighS7RS0B5104030

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

1) Connect scan tool to DLC with ig nition switch OFF, if available.

2) Clear DTC in TCM memory.

3) Start engine and shift select lever to “N” range.

4) Repeat shifting select lever from “N” range to “D” range and vice versa for 3 times.

5) Check DTC.

DTC Troubleshooting

1. TCM 3. A/T

2. Timing solenoid valve [A]: Terminal arrangement of TCM connector (viewed from harness side)

DTC detecting condition Trouble area

Voltage of timing solenoid valve TCM terminal is high

although TCM is commanding timing solenoid valve to turn

OFF. • Timing solenoid valve circuit open or shorted to

power circuit

• Timing solenoid valve malfunction

•TCM

12V

C34-14BLU/BLK

31

2

14

C34C35

[A]

I4RS0A510014-01

Step Action YesNo

1 Was “A/T System Check” performed? Go to Step 2.Go to “A/T System

Check”.

2 Check timing solenoid valve circuit for IG short

1) Disconnect TCM connectors.

2) Turn ignition switch ON and measure voltage between

terminal “C34-14” of harness side TCM connector and

ground.

Is it 0 – 1 V? Go to Step 3.

“BLU/BLK” circuit

shorted to power circuit.

3 Check timing solenoid valve circuit for open

1) Measure resistance between terminal “C34-14” of

disconnected harness side TCM connector and ground.

Is it 11 – 15

Ω at 20 °C (68 °F)? Intermittent trouble or

faulty TCM.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

If OK, substitute a

known-good TCM and

recheck.Go to Step 4.

Page 701 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-57

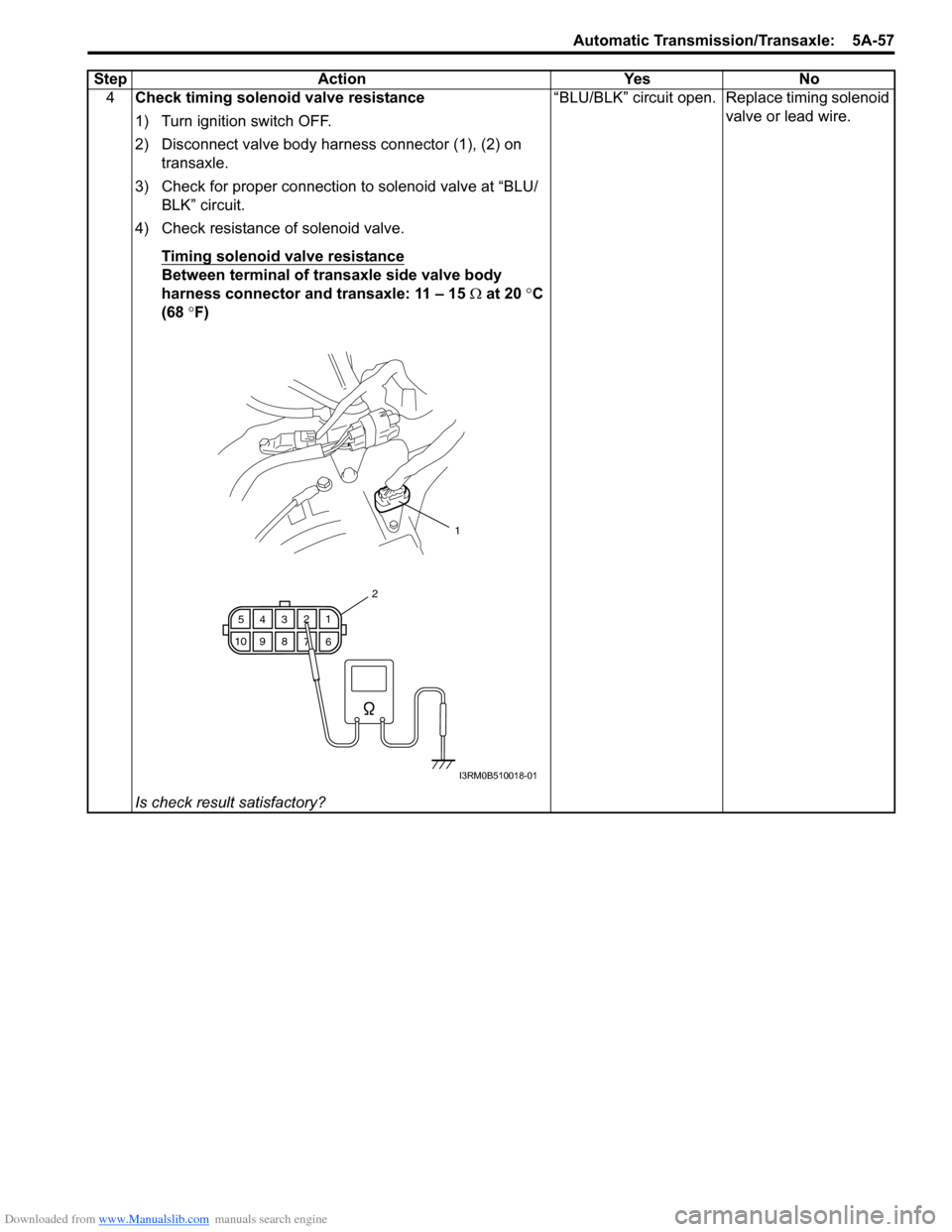

4Check timing solenoid valve resistance

1) Turn ignition switch OFF.

2) Disconnect valve body harness connector (1), (2) on

transaxle.

3) Check for proper connection to solenoid valve at “BLU/ BLK” circuit.

4) Check resistance of solenoid valve.

Timing solenoid valve resistance

Between terminal of transaxle side valve body

harness connector and transaxle: 11 – 15 Ω at 20 °C

(68 °F)

Is check result satisfactory? “BLU/BLK” circuit open. Replace timing solenoid

valve or lead wire.

Step Action Yes No

1

6

7

89

10 5

43 2

1

2

I3RM0B510018-01

Page 727 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-83

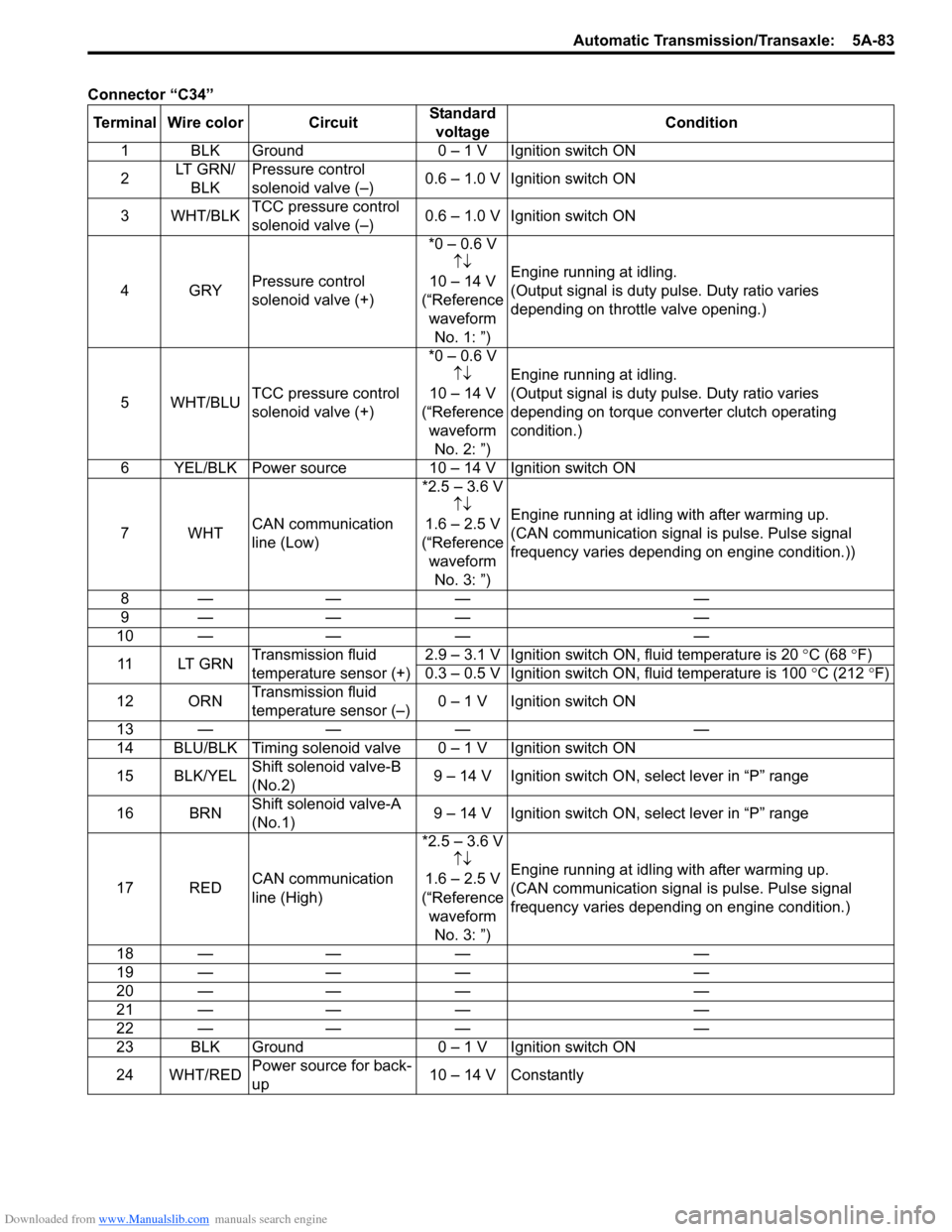

Connector “C34”Terminal Wire color Circuit Standard

voltage Condition

1 BLK Ground 0 – 1 V Ignition switch ON

2 LT GRN/

BLK Pressure control

solenoid valve (–)

0.6 – 1.0 V Ignition switch ON

3WHT/BLK TCC pressure control

solenoid valve (–) 0.6 – 1.0 V Ignition switch ON

4GRY Pressure control

solenoid valve (+) *0 – 0.6 V

↑↓

10 – 14 V

(“Reference waveform No. 1: ”) Engine running at idling.

(Output signal is duty pulse. Duty ratio varies

depending on throttle valve opening.)

5WHT/BLU TCC pressure control

solenoid valve (+) *0 – 0.6 V

↑↓

10 – 14 V

(“Reference waveform No. 2: ”) Engine running at idling.

(Output signal is duty pulse. Duty ratio varies

depending on torque converter clutch operating

condition.)

6 YEL/BLK Power source 10 – 14 V Ignition switch ON

7WHT CAN communication

line (Low) *2.5 – 3.6 V

↑↓

1.6 – 2.5 V

(“Reference waveform No. 3: ”) Engine running at idling with after warming up.

(CAN communication signal is pulse. Pulse signal

frequency varies depending on engine condition.))

8— — — —

9— — — —

10 — —— —

11 LT G R N Transmission fluid

temperature sensor (+) 2.9 – 3.1 V Ignition switch ON, fluid temperature is 20

°C (68 °F)

0.3 – 0.5 V Ignition switch ON, fluid temperature is 100 °C (212 °F)

12 ORN Transmission fluid

temperature sensor (–) 0 – 1 V Ignition switch ON

13 — —— —

14 BLU/BLK Timing solenoid valv e 0 – 1 V Ignition switch ON

15 BLK/YEL Shift solenoid valve-B

(No.2) 9 – 14 V Ignition switch ON, select lever in “P” range

16 BRN Shift solenoid valve-A

(No.1) 9 – 14 V Ignition switch ON, select lever in “P” range

17 RED CAN communication

line (High) *2.5 – 3.6 V

↑↓

1.6 – 2.5 V

(“Reference waveform No. 3: ”) Engine running at idling with after warming up.

(CAN communication signal is pulse. Pulse signal

frequency varies depending on engine condition.)

18 — —— —

19 — —— —

20 — —— —

21 — —— —

22 — —— —

23 BLK Ground 0 – 1 V Ignition switch ON

24 WHT/RED Power source

for back-

up 10 – 14 V Constantly

Page 742 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-98 Automatic Transmission/Transaxle:

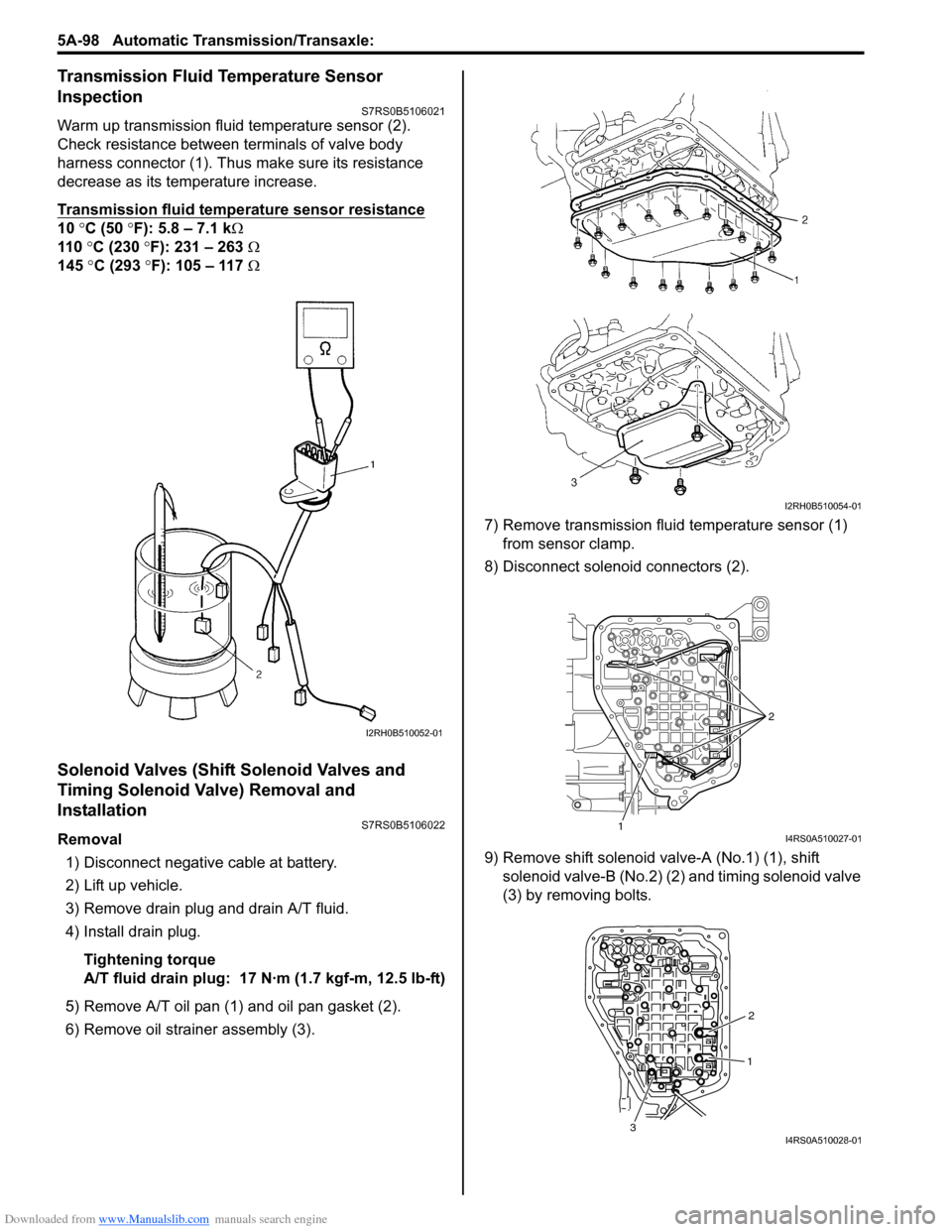

Transmission Fluid Temperature Sensor

Inspection

S7RS0B5106021

Warm up transmission fluid temperature sensor (2).

Check resistance between terminals of valve body

harness connector (1). Thus make sure its resistance

decrease as its temperature increase.

Transmission fluid temperature sensor resistance

10 °C (50 °F): 5.8 – 7.1 k Ω

110 °C (230 °F): 231 – 263 Ω

145 °C (293 °F): 105 – 117 Ω

Solenoid Valves (Shift Solenoid Valves and

Timing Solenoid Valve) Removal and

Installation

S7RS0B5106022

Removal

1) Disconnect negative cable at battery.

2) Lift up vehicle.

3) Remove drain plug and drain A/T fluid.

4) Install drain plug.

Tightening torque

A/T fluid drain plug: 17 N· m (1.7 kgf-m, 12.5 lb-ft)

5) Remove A/T oil pan (1) and oil pan gasket (2).

6) Remove oil strain er assembly (3). 7) Remove transmission fluid temperature sensor (1)

from sensor clamp.

8) Disconnect solenoid connectors (2).

9) Remove shift solenoid va lve-A (No.1) (1), shift

solenoid valve-B (No.2) (2) and timing solenoid valve

(3) by removing bolts.

I2RH0B510052-01

I2RH0B510054-01

1 2I4RS0A510027-01

1

2

3

I4RS0A510028-01

Page 743 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-99

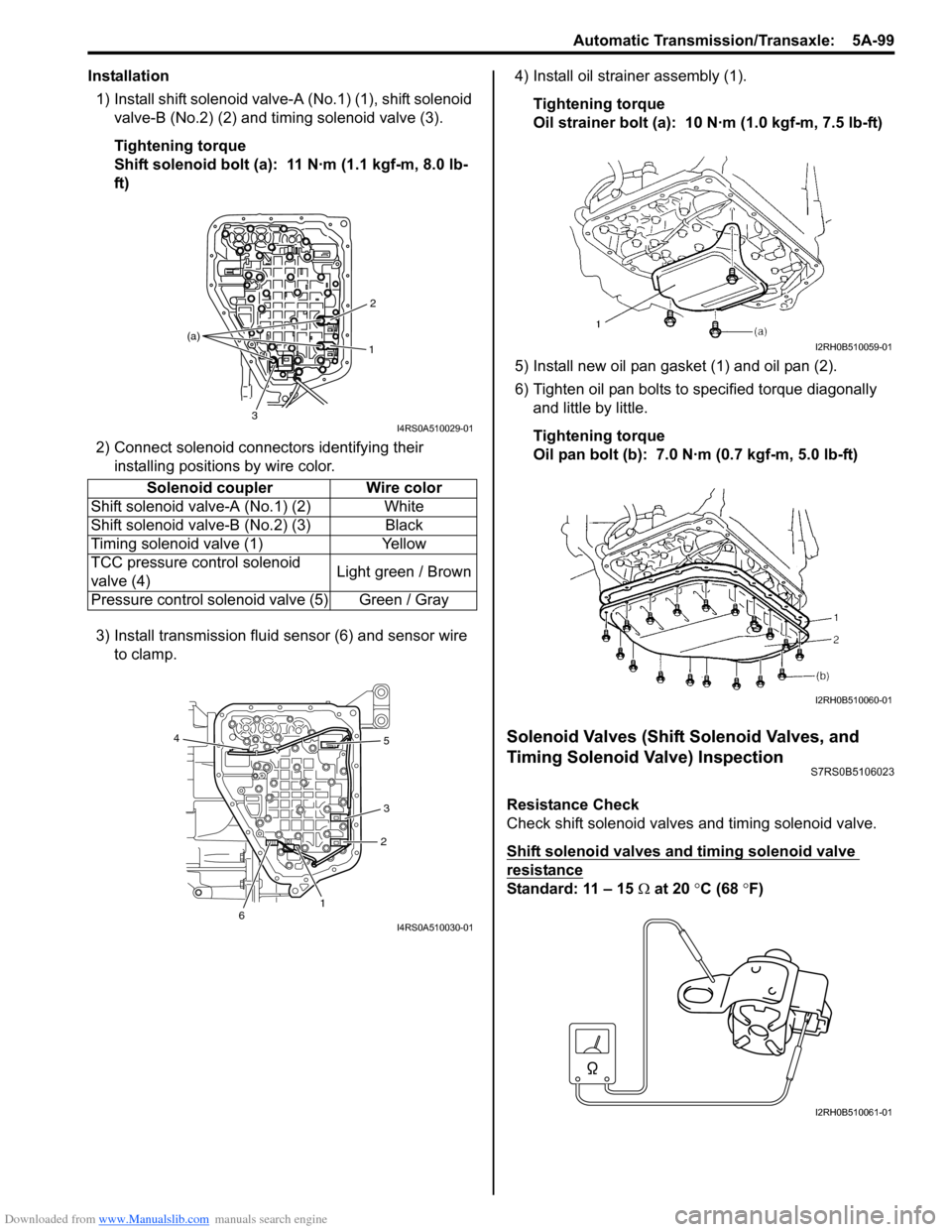

Installation1) Install shift solenoid valve- A (No.1) (1), shift solenoid

valve-B (No.2) (2) and timing solenoid valve (3).

Tightening torque

Shift solenoid bolt (a): 11 N·m (1.1 kgf-m, 8.0 lb-

ft)

2) Connect solenoid connectors identifying their installing positions by wire color.

3) Install transmission fluid sensor (6) and sensor wire to clamp. 4) Install oil strain

er assembly (1).

Tightening torque

Oil strainer bolt (a): 10 N·m (1.0 kgf-m, 7.5 lb-ft)

5) Install new oil pan gasket (1) and oil pan (2).

6) Tighten oil pan bolts to specified torque diagonally and little by little.

Tightening torque

Oil pan bolt (b): 7.0 N·m (0.7 kgf-m, 5.0 lb-ft)

Solenoid Valves (Shift Solenoid Valves, and

Timing Solenoid Valve) Inspection

S7RS0B5106023

Resistance Check

Check shift solenoid valves and timing solenoid valve.

Shift solenoid valves and timing solenoid valve

resistance

Standard: 11 – 15 Ω at 20 °C (68 ° F)

Solenoid coupler Wire color

Shift solenoid valv e-A (No.1) (2) White

Shift solenoid valv e-B (No.2) (3) Black

Timing solenoid valve (1) Yellow

TCC pressure control solenoid

valve (4) Light green / Brown

Pressure control solenoid valve (5) Green / Gray

1 2

3

(a)

I4RS0A510029-01

1

2

3 5

4

6

I4RS0A510030-01

I2RH0B510059-01

I2RH0B510060-01

I2RH0B510061-01

Page 744 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-100 Automatic Transmission/Transaxle:

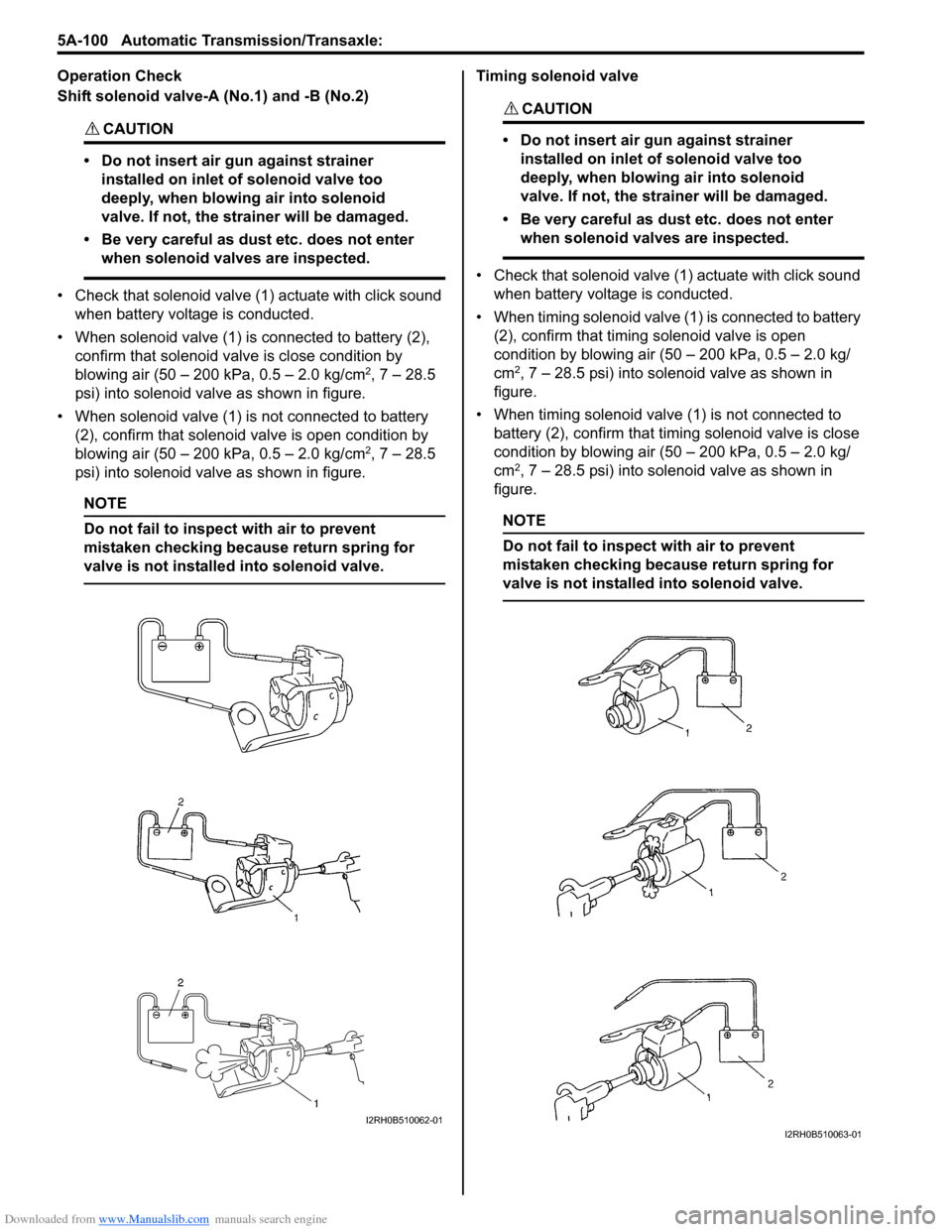

Operation Check

Shift solenoid valve-A (No.1) and -B (No.2)

CAUTION!

• Do not insert air gun against strainer installed on inlet of solenoid valve too

deeply, when blowing air into solenoid

valve. If not, the strainer will be damaged.

• Be very careful as dust etc. does not enter when solenoid valves are inspected.

• Check that solenoid valve (1) actuate with click sound when battery voltage is conducted.

• When solenoid valve (1) is connected to battery (2), confirm that solenoid valve is close condition by

blowing air (50 – 200 kPa, 0.5 – 2.0 kg/cm

2, 7 – 28.5

psi) into solenoid valve as shown in figure.

• When solenoid valve (1) is not connected to battery (2), confirm that solenoid valve is open condition by

blowing air (50 – 200 kPa, 0.5 – 2.0 kg/cm

2, 7 – 28.5

psi) into solenoid valve as shown in figure.

NOTE

Do not fail to inspect with air to prevent

mistaken checking because return spring for

valve is not installe d into solenoid valve.

Timing solenoid valve

CAUTION!

• Do not insert air gun against strainer

installed on inlet of solenoid valve too

deeply, when blowing air into solenoid

valve. If not, the strainer will be damaged.

• Be very careful as dust etc. does not enter when solenoid valves are inspected.

• Check that solenoid valve (1) actuate with click sound

when battery voltage is conducted.

• When timing solenoid valve (1 ) is connected to battery

(2), confirm that timing solenoid valve is open

condition by blowing air (50 – 200 kPa, 0.5 – 2.0 kg/

cm

2, 7 – 28.5 psi) into solenoid valve as shown in

figure.

• When timing solenoid valve (1) is not connected to battery (2), confirm that timi ng solenoid valve is close

condition by blowing air (50 – 200 kPa, 0.5 – 2.0 kg/

cm

2, 7 – 28.5 psi) into solenoid valve as shown in

figure.

NOTE

Do not fail to inspect with air to prevent

mistaken checking because return spring for

valve is not installed into solenoid valve.

I2RH0B510062-01I2RH0B510063-01

Page 783 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-139

2) Install reduction driven gear (1) with special tools and hydraulic press.

Special tool

(A): 09913–84510

(B): 09925–88210 3) Install countershaft LH bearing (1) with special tools

and hydraulic press.

Special tool

(A): 09913–84510

(B): 09925–88210

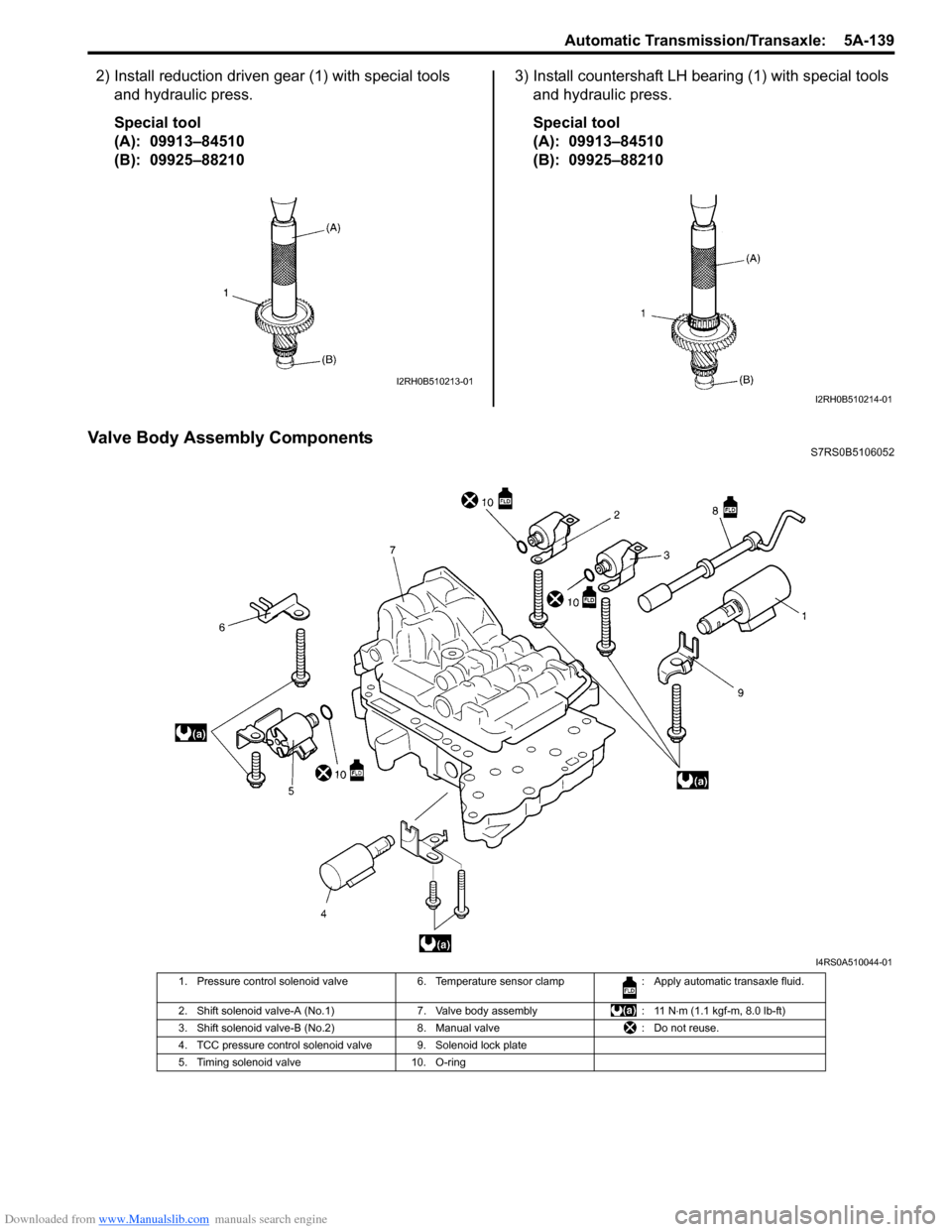

Valve Body Assembly ComponentsS7RS0B5106052

I2RH0B510213-01

I2RH0B510214-01

I4RS0A510044-01

1. Pressure control solenoid valve 6. Temperature sensor clamp : Apply automatic transaxle fluid.

2. Shift solenoid valve-A (No.1) 7. Valve body assembly: 11 N⋅m (1.1 kgf-m, 8.0 lb-ft)

3. Shift solenoid valve-B (No.2) 8. Manual valve: Do not reuse.

4. TCC pressure control solenoid valve 9. Solenoid lock plate

5. Timing solenoid valve 10. O-ring

Page 784 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-140 Automatic Transmission/Transaxle:

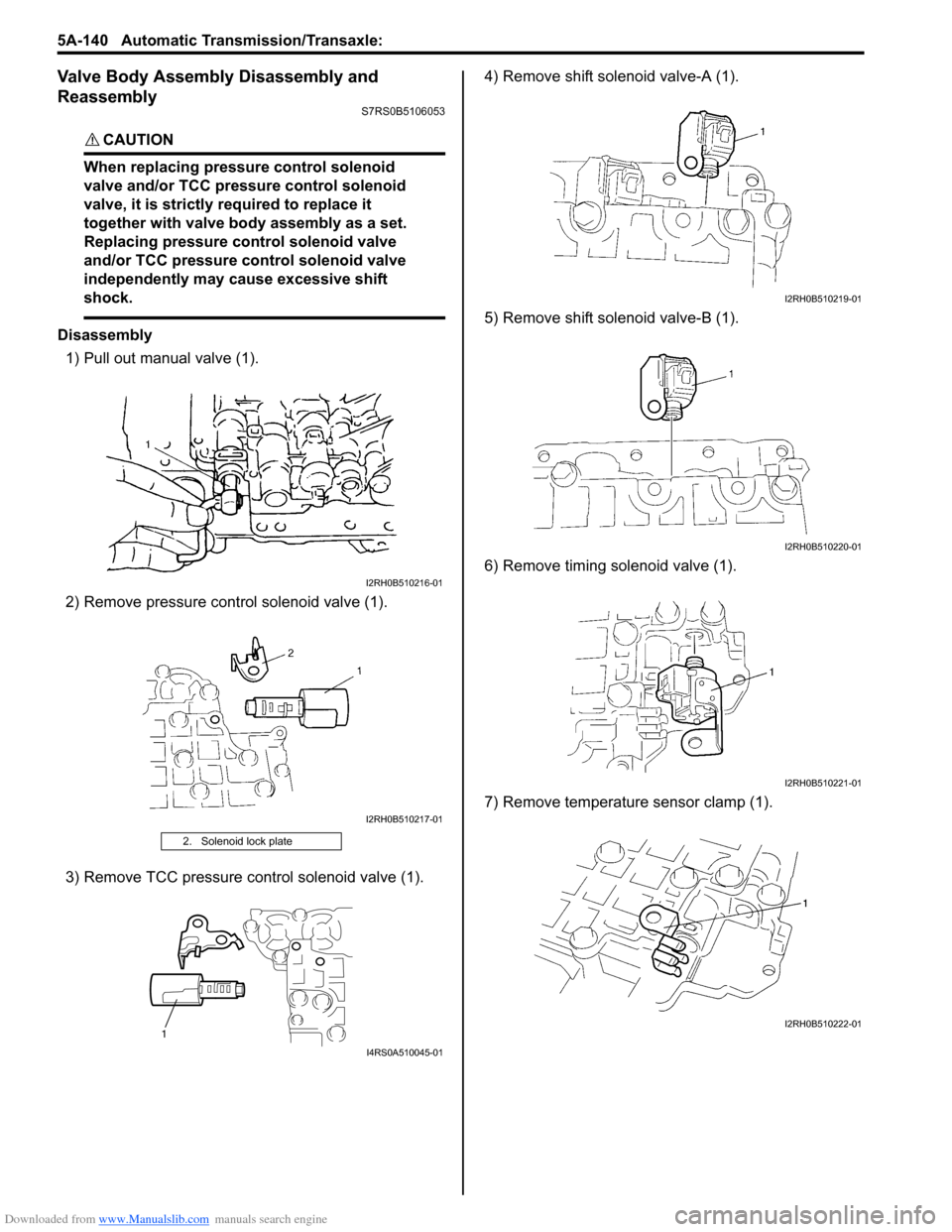

Valve Body Assembly Disassembly and

Reassembly

S7RS0B5106053

CAUTION!

When replacing pressure control solenoid

valve and/or TCC pressure control solenoid

valve, it is strictly required to replace it

together with valve body assembly as a set.

Replacing pressure control solenoid valve

and/or TCC pressure control solenoid valve

independently may cause excessive shift

shock.

Disassembly1) Pull out manual valve (1).

2) Remove pressure cont rol solenoid valve (1).

3) Remove TCC pressure control solenoid valve (1). 4) Remove shift solenoid valve-A (1).

5) Remove shift solenoid valve-B (1).

6) Remove timing solenoid valve (1).

7) Remove temperature sensor clamp (1).

2. Solenoid lock plate

I2RH0B510216-01

I2RH0B510217-01

1

I4RS0A510045-01

I2RH0B510219-01

I2RH0B510220-01

I2RH0B510221-01

I2RH0B510222-01

Page 808 of 1496

Downloaded from www.Manualslib.com manuals search engine 5A-164 Automatic Transmission/Transaxle:

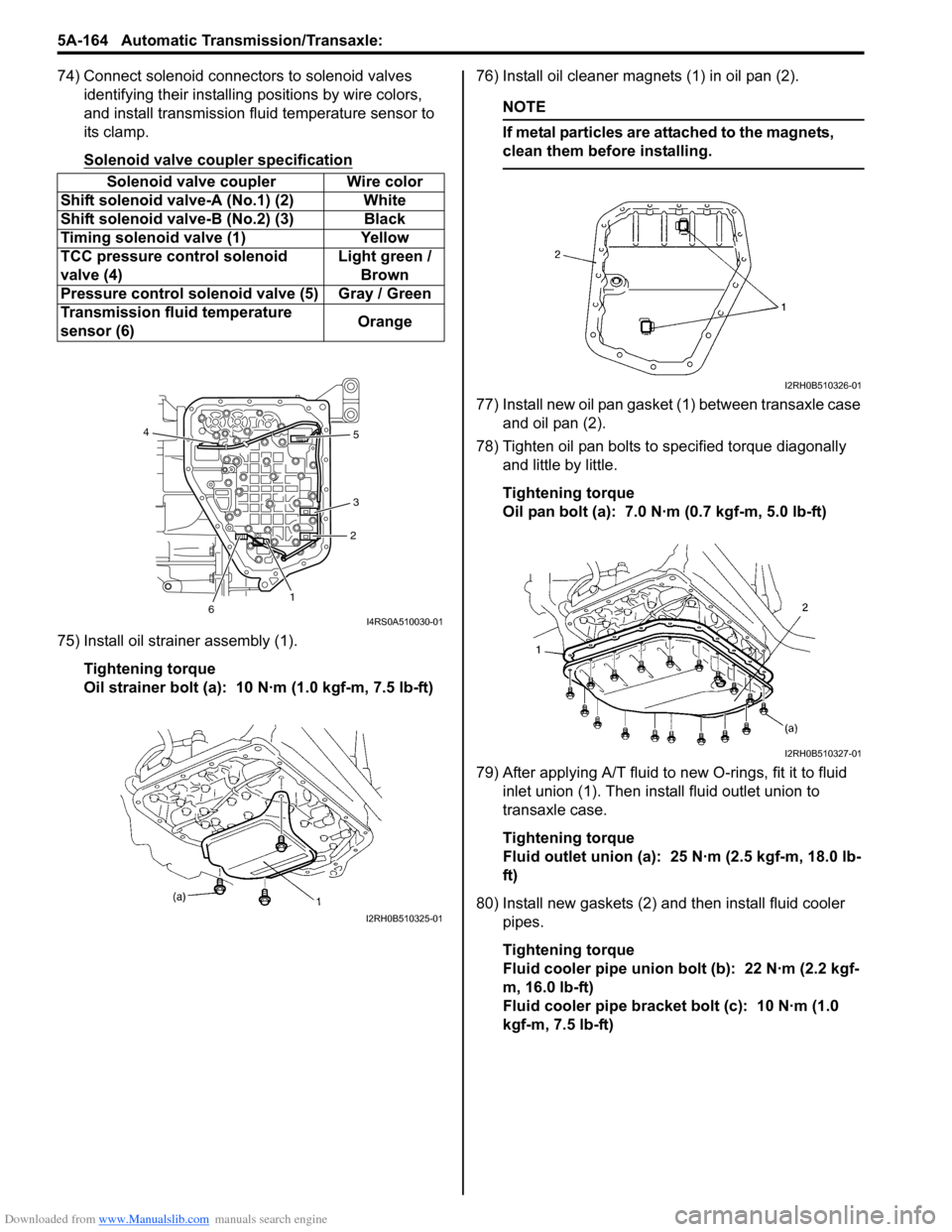

74) Connect solenoid connectors to solenoid valves identifying their installing positions by wire colors,

and install transmission fluid temperature sensor to

its clamp.

Solenoid valve coupler specification

75) Install oil strainer assembly (1).

Tightening torque

Oil strainer bolt (a): 10 N·m (1.0 kgf-m, 7.5 lb-ft) 76) Install oil cleaner magnets (1) in oil pan (2).

NOTE

If metal particles are attached to the magnets,

clean them before installing.

77) Install new oil pan gasket (1) between transaxle case

and oil pan (2).

78) Tighten oil pan bolts to specified torque diagonally and little by little.

Tightening torque

Oil pan bolt (a): 7.0 N·m (0.7 kgf-m, 5.0 lb-ft)

79) After applying A/T fluid to new O-rings, fit it to fluid inlet union (1). Then inst all fluid outlet union to

transaxle case.

Tightening torque

Fluid outlet union (a): 25 N·m (2.5 kgf-m, 18.0 lb-

ft)

80) Install new gaskets (2) and then install fluid cooler pipes.

Tightening torque

Fluid cooler pipe union bolt (b): 22 N·m (2.2 kgf-

m, 16.0 lb-ft)

Fluid cooler pipe bracket bolt (c): 10 N·m (1.0

kgf-m, 7.5 lb-ft)

Solenoid valve coupler Wire color

Shift solenoid valve-A (No.1) (2) White

Shift solenoid val ve-B (No.2) (3) Black

Timing solenoid valve (1) Yellow

TCC pressure control solenoid

valve (4) Light green /

Brown

Pressure control solenoid valve (5) Gray / Green

Transmission fluid temperature

sensor (6) Orange

12

3 5

4

6

I4RS0A510030-01

I2RH0B510325-01

I2RH0B510326-01

I2RH0B510327-01