Back up SUZUKI SWIFT 2006 2.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 86 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-36 Engine General Information and Diagnosis:

O2S B1 S1 ACT (HEATED OXYGEN SENSOR-1,

ACTIVE / INACTIVE)

This parameter indicates activation condition of HO2S-1.

ACTIVE: Activating

INACTIVE: warming up or at stop

O2S SENSOR B1 S2 (HEATED OXYGEN SENSOR-2,

V)

It indicates output voltage of HO2S-2 installed on

exhaust pipe (post-catalyst). It is used to detect catalyst

deterioration.

O2S B1 S2 ACT (HEATED OXYGEN SENSOR-2,

ACTIVE / INACTIVE)

This parameter indicates acti vation condition of HO2S-2.

ACTIVE: Activating

INACTIVE: warming up or at stop

FUEL SYSTEM (FUEL SYSTEM STATUS)

Air/fuel ratio feedback loop status displayed as one of

the followings.

OPEN: Open-loop has not yet satisfied conditions to go

closed loop.

CLOSED: Closed-loop using oxygen sensor(s) as

feedback for fuel control.

OPEN-DRIVE COND: Open-loop due to driving

conditions (Power enrichment, etc.).

OPEN SYS FAULT: Open-loop due to detected system

fault.

MAP (MANIFOLD ABSOLUTE PRESSURE, in.Hg,

kPa)

This value indicates how much correction is necessary

to keep the air/fuel mixture stoichiometrical.

It is detected by manifold absolute pressure sensor.

BAROMETRIC PRESS (kPa, in.Hg)

This parameter represents a measurement of barometric

air pressure and is used for al titude correction of the fuel

injection quantity and IAC valve control.

STEP EGR FLOW DUTY (%)

This parameter indicates opening rate of EGR valve

which controls the amount of EGR flow.

FUEL CUT (ON/OFF)

ON: Fuel being cut (output signal to injector is stopped)

OFF: Fuel not being cut

A/C PRESSURE (A/C REFRIGERANT ABSOLUTE

PRESSURE, kPa)

This parameter indicates A/C refrigerant absolute

pressure calculated by ECM.

CLOSED THROTTLE PO S (CLOSED THROTTLE

POSITION, ON/OFF)

This parameter reads ON wh en throttle valve is fully

closed, or OFF when it is not fully closed. CANIST PRG DUTY (EVAP CANISTER PURGE FLOW

DUTY, %)

This parameter indicates valve ON (valve open) time

rate within a certain set cycle of EVAP canister purge

valve which controls the amount of EVAP purge.

IGNITION ADVANCE (IGNITION TIMING ADVANCE

FOR NO.1 CYLINDER,

°)

Ignition timing of No.1 cylinder is commanded by ECM.

The actual ignition timing should be checked by using

the timing light.

BATTERY VOLTAGE (V)

This parameter indicates battery positive voltage

inputted from main relay to ECM.

FUEL PUMP (ON/OFF)

ON is displayed when ECM activates the fuel pump via

the fuel pump relay switch.

ELECTRIC LOAD (ON/OFF)

ON: Headlight or small light ON signal inputted.

OFF: Above electric loads all turned OFF.

BRAKE SW (ON/OFF)

This parameter indicates the state of the brake switch.

RADIATOR COOLING FAN (RADIATOR COOLING

FAN CONTROL RELAY, ON/OFF)

ON: Command for radiator cooling fan control relay

operation being output.

OFF: Command for relay operation not being output.

BLOWER FAN (ON/OFF)

This parameter indicates the state of the blower fan

motor switch.

A/C SWITCH (ON/OFF)

ON: Command for A/C operatio n being output from ECM

to HVAC.

OFF: Command for A/C oper ation not being output.

A/C COMP RELAY (A/C COMPRESSOR RELAY, ON/

OFF)

This parameter indicates the state of the A/C switch.

VEHICLE SPEED (km/h, mph)

It is computed based on pulse signals from vehicle

speed sensor.

VVT GAP (TARGET-ACTUAL POSITION, °)

It is calculated using the formula: target valve timing

advance – actual valve timing advance.

TP SENSOR 1 VOLT (THROTTLE POSITION SENSOR

(MAIN) OUTPUT VOLTAGE, V)

The TP sensor (main) reading provides throttle valve

opening information in the form of voltage.

Page 96 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-46 Engine General Information and Diagnosis:

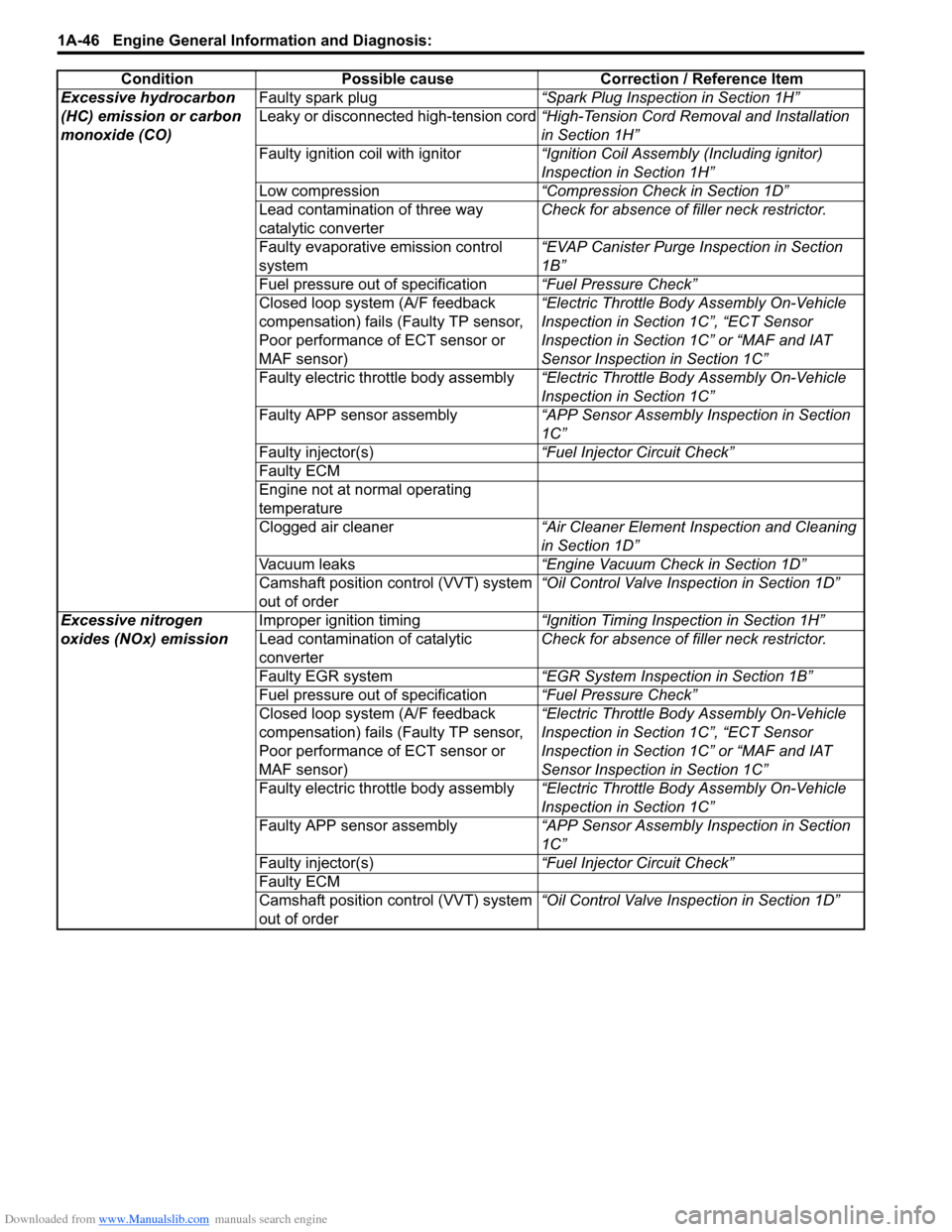

Excessive hydrocarbon

(HC) emission or carbon

monoxide (CO)Faulty spark plug

“Spark Plug Inspection in Section 1H”

Leaky or disconnected high-tension cord “High-Tension Cord Removal and Installation

in Section 1H”

Faulty ignition coil with ignitor “Ignition Coil Assembly (Including ignitor)

Inspection in Section 1H”

Low compression “Compression Check in Section 1D”

Lead contamination of three way

catalytic converter Check for absence of f

iller neck restrictor.

Faulty evaporative emission control

system “EVAP Canister Purge Inspection in Section

1B”

Fuel pressure out of specification “Fuel Pressure Check”

Closed loop system (A/F feedback

compensation) fails (Faulty TP sensor,

Poor performance of ECT sensor or

MAF sensor) “Electric Throttle Body Assembly On-Vehicle

Inspection in Section 1C”, “ECT Sensor

Inspection in Section 1C” or “MAF and IAT

Sensor Inspection in Section 1C”

Faulty electric throttle body assembly “Electric Throttle Body Assembly On-Vehicle

Inspection in Section 1C”

Faulty APP sensor assembly “APP Sensor Assembly Inspection in Section

1C”

Faulty injector(s) “Fuel Injector Circuit Check”

Faulty ECM

Engine not at normal operating

temperature

Clogged air cleaner “Air Cleaner Element Inspection and Cleaning

in Section 1D”

Vacuum leaks “Engine Vacuum Check in Section 1D”

Camshaft position control (VVT) system

out of order “Oil Control Valve Inspection in Section 1D”

Excessive nitrogen

oxides (NOx) emission Improper ignition timing

“Ignition Timing Inspection in Section 1H”

Lead contamination of catalytic

converter Check for absence of f

iller neck restrictor.

Faulty EGR system “EGR System Inspection in Section 1B”

Fuel pressure out of specification “Fuel Pressure Check”

Closed loop system (A/F feedback

compensation) fails (Faulty TP sensor,

Poor performance of ECT sensor or

MAF sensor) “Electric Throttle Body Assembly On-Vehicle

Inspection in Section 1C”, “ECT Sensor

Inspection in Section 1C” or “MAF and IAT

Sensor Inspection in Section 1C”

Faulty electric throttle body assembly “Electric Throttle Body Assembly On-Vehicle

Inspection in Section 1C”

Faulty APP sensor assembly “APP Sensor Assembly Inspection in Section

1C”

Faulty injector(s) “Fuel Injector Circuit Check”

Faulty ECM

Camshaft position control (VVT) system

out of order “Oil Control Valve Inspection in Section 1D”

Condition Possible cause Correction / Reference Item

Page 171 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-121

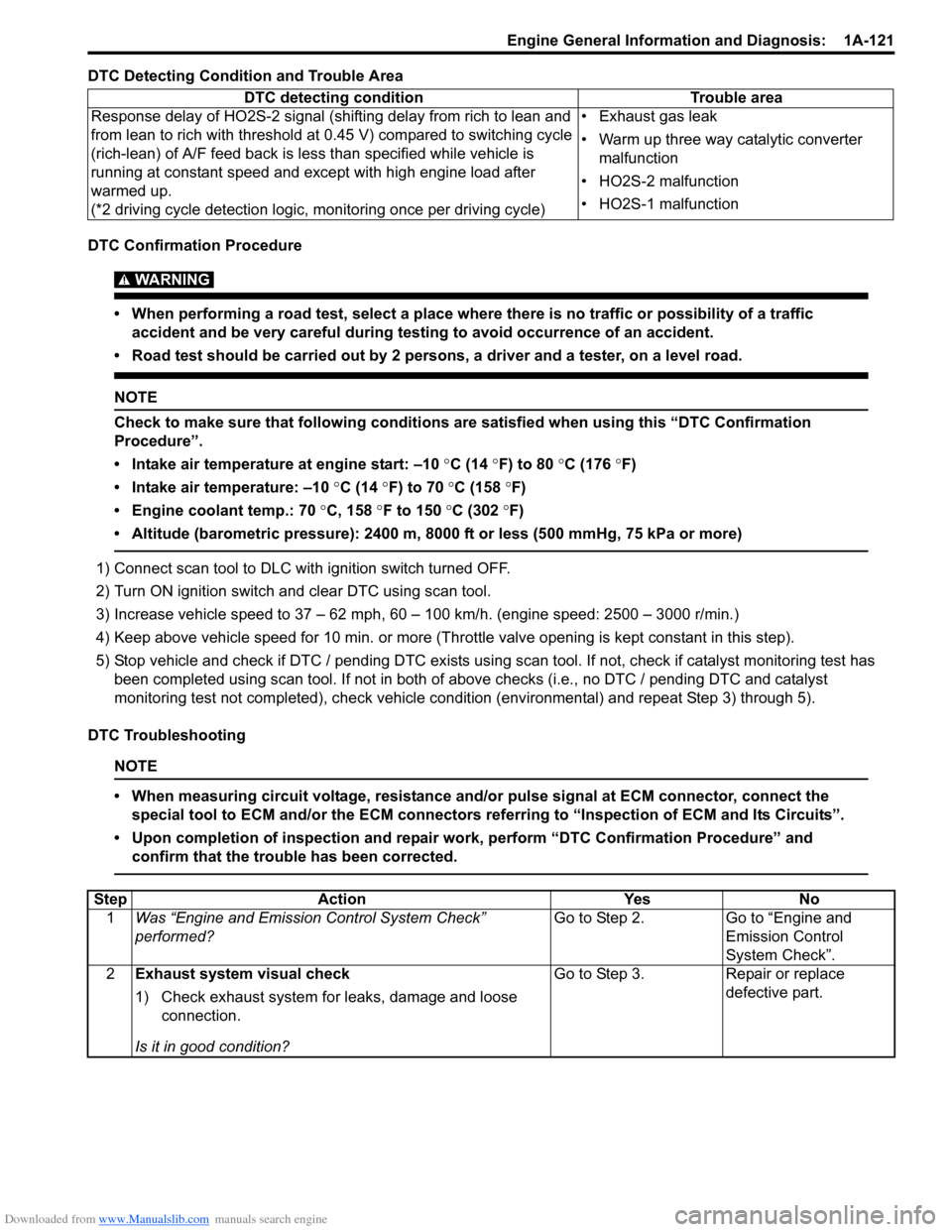

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out by 2 persons, a driver and a tester, on a level road.

NOTE

Check to make sure that following conditions ar e satisfied when using this “DTC Confirmation

Procedure”.

• Intake air temperature at engine start: –10 °C (14 ° F) to 80 °C (176 °F)

• Intake air temperature: –10 °C (14 °F) to 70 °C (158 °F)

• Engine coolant temp.: 70 °C, 158 °F to 150 °C (302 °F)

• Altitude (barometric pressure): 2400 m, 8000 ft or less (500 mmHg, 75 kPa or more)

1) Connect scan tool to DLC with ignition switch turned OFF.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Increase vehicle speed to 37 – 62 mph, 60 – 100 km/h. (engine speed: 2500 – 3000 r/min.)

4) Keep above vehicle speed for 10 min. or more (Thr ottle valve opening is kept constant in this step).

5) Stop vehicle and check if DTC / pending DTC exists using sc an tool. If not, check if catalyst monitoring test has

been completed using scan tool. If not in both of above checks (i.e., no DTC / pending DTC and catalyst

monitoring test not completed), check vehicle cond ition (environmental) and repeat Step 3) through 5).

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/ or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

DTC detecting condition Trouble area

Response delay of HO2S-2 signal (shifting delay from rich to lean and

from lean to rich with threshold at 0.45 V) compared to switching cycle

(rich-lean) of A/F feed back is less than specified while vehicle is

running at constant speed and except with high engine load after

warmed up.

(*2 driving cycle detection logic, monitoring once per driving cycle) • Exhaust gas leak

• Warm up three way catalytic converter

malfunction

• HO2S-2 malfunction

• HO2S-1 malfunction

Step Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 Exhaust system visual check

1) Check exhaust system for leaks, damage and loose

connection.

Is it in good condition? Go to Step 3.

Repair or replace

defective part.

Page 193 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-143

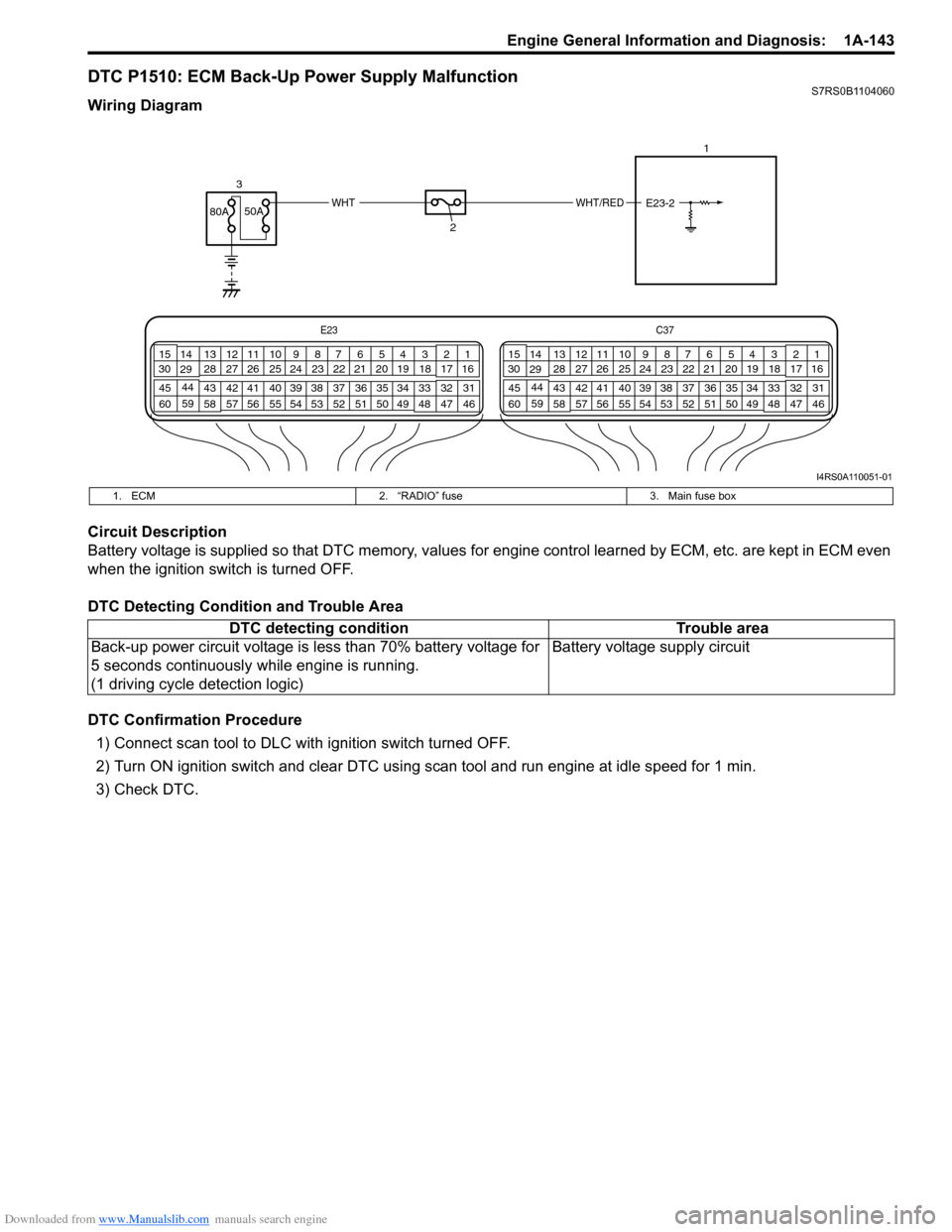

DTC P1510: ECM Back-Up Power Supply MalfunctionS7RS0B1104060

Wiring Diagram

Circuit Description

Battery voltage is supplied so that DTC memory, values for engine control learned by ECM, etc. are kept in ECM even

when the ignition switch is turned OFF.

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

1) Connect scan tool to DLC with ignition switch turned OFF.

2) Turn ON ignition switch and clear DTC using scan tool and run engine at idle speed for 1 min.

3) Check DTC.

E23 C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

WHT/REDWHT80A

50A

3

2 1

E23-2

I4RS0A110051-01

1. ECM

2. “RADIO” fuse 3. Main fuse box

DTC detecting condition Trouble area

Back-up power circuit voltage is less than 70% battery voltage for

5 seconds continuously while engine is running.

(1 driving cycle detection logic) Battery voltage supply circuit

Page 255 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-205

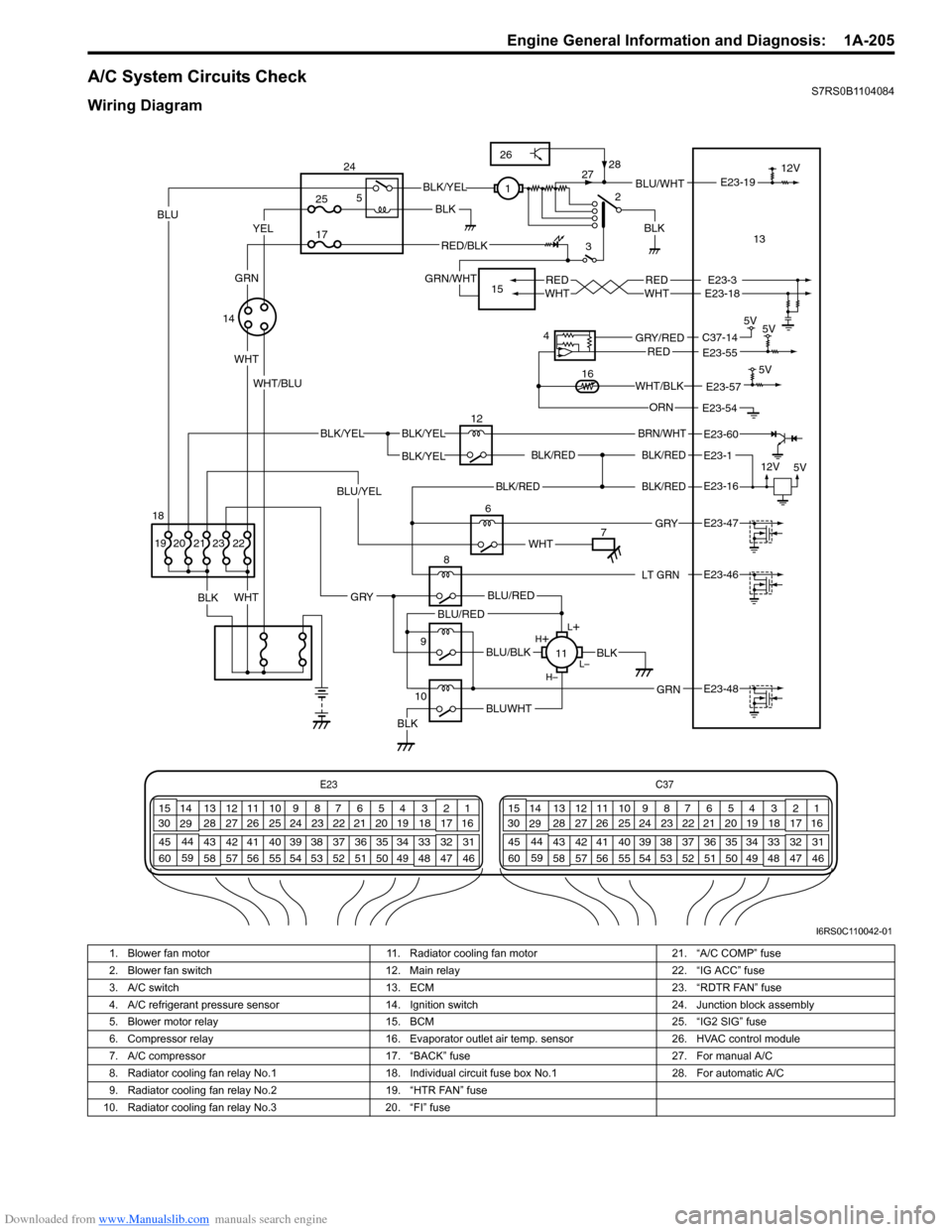

A/C System Circuits CheckS7RS0B1104084

Wiring Diagram

E23C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

BLK/REDBLK/RED

BLK/YELBLK/YEL

BLK/YEL

BRN/WHT

12V

5V

12

E23-1

E23-60

BLK/RED

LT GRN

BLK/REDE23-16

E23-46

L+

L–

H–

H

+

BLU/RED

BLK

BLUWHTBLK

BLU/BLK

BLU/RED

GRN

GRY

E23-48

8

11

2

3BLU/WHT

REDWHTREDWHTE23-3E23-18

E23-19

6

BLK

WHT

BLK 12V

E23-47 GRY

WHT

YELBLU

WHT

BLK/YEL

RED/BLK

GRN/WHT

WHT/BLU1

713

14

5V

5V

4

E23-55C37-14GRY/REDRED

E23-54ORN 5V

E23-57WHT/BLK16

9

10

25

17

5

24

15

22

BLU/YEL

23212019

GRN

BLK

18

26

28

27

I6RS0C110042-01

1. Blower fan motor 11. Radiator cooling fan motor 21. “A/C COMP” fuse

2. Blower fan switch 12. Main relay 22. “IG ACC” fuse

3. A/C switch 13. ECM 23. “RDTR FAN” fuse

4. A/C refrigerant pressure sensor 14. Ignition switch 24. Junction block assembly

5. Blower motor relay 15. BCM 25. “IG2 SIG” fuse

6. Compressor relay 16. Evaporator outlet air temp. sensor 26. HVAC control module

7. A/C compressor 17. “BACK” fuse 27. For manual A/C

8. Radiator cooling fan relay No.1 18. Individual circuit fuse box No.1 28. For automatic A/C

9. Radiator cooling fan relay No.2 19. “HTR FAN” fuse

10. Radiator cooling fan relay No.3 20. “FI” fuse

Page 267 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-217

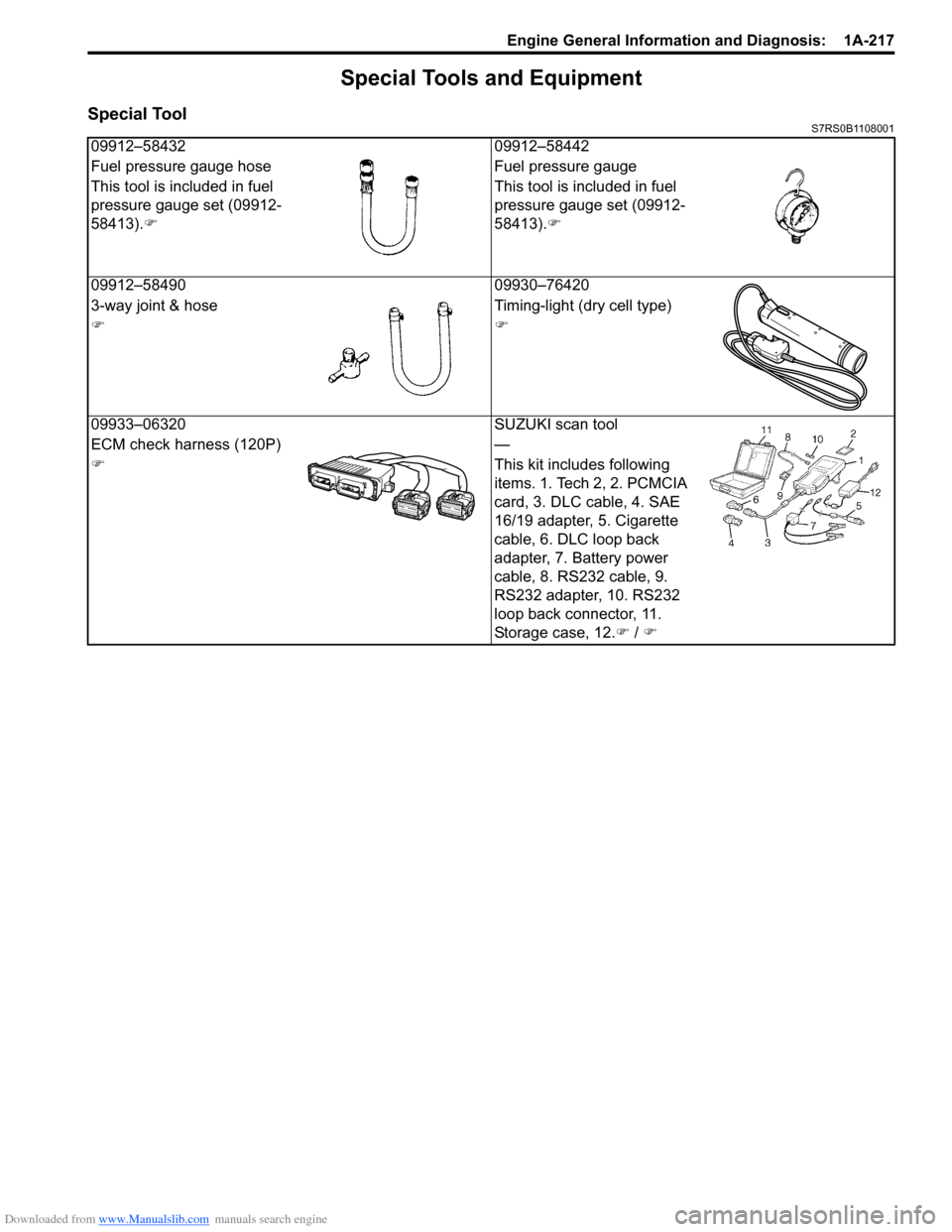

Special Tools and Equipment

Special ToolS7RS0B1108001

09912–5843209912–58442

Fuel pressure gauge hose Fuel pressure gauge

This tool is included in fuel

pressure gauge set (09912-

58413). �) This tool is included in fuel

pressure gauge set (09912-

58413).

�)

09912–58490 09930–76420

3-way joint & hose Timing-light (dry cell type)

�)�)

09933–06320 SUZUKI scan tool

ECM check harness (120P) —

�) This kit includes following

items. 1. Tech 2, 2. PCMCIA

card, 3. DLC cable, 4. SAE

16/19 adapter, 5. Cigarette

cable, 6. DLC loop back

adapter, 7. Battery power

cable, 8. RS232 cable, 9.

RS232 adapter, 10. RS232

loop back connector, 11.

Storage case, 12.�) / �)

Page 272 of 1496

Downloaded from www.Manualslib.com manuals search engine 1B-5 Aux. Emission Control Devices:

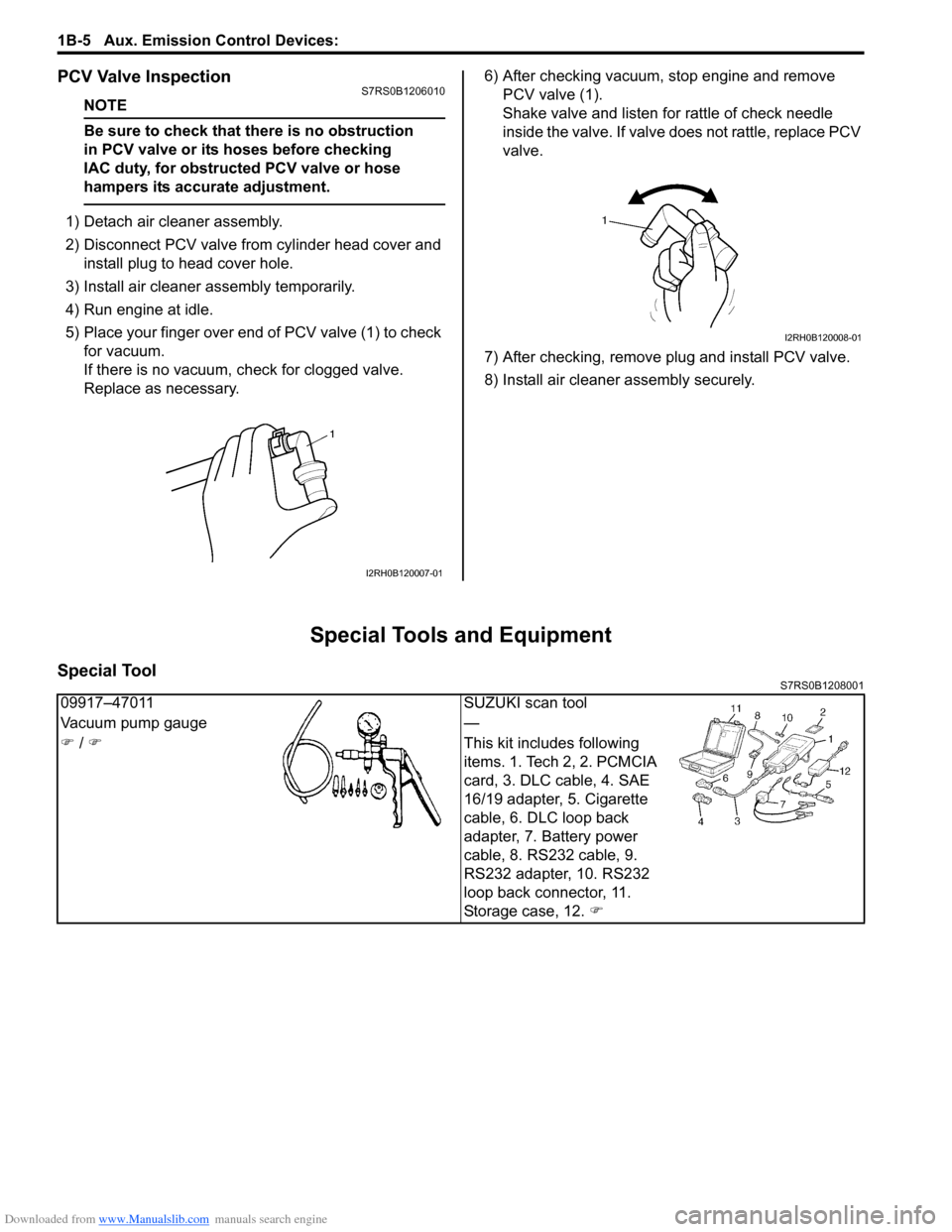

PCV Valve InspectionS7RS0B1206010

NOTE

Be sure to check that there is no obstruction

in PCV valve or its hoses before checking

IAC duty, for obstructed PCV valve or hose

hampers its accurate adjustment.

1) Detach air cleaner assembly.

2) Disconnect PCV valve from cylinder head cover and install plug to head cover hole.

3) Install air cleaner assembly temporarily.

4) Run engine at idle.

5) Place your finger over end of PCV valve (1) to check for vacuum.

If there is no vacuum, ch eck for clogged valve.

Replace as necessary. 6) After checking vacuum, stop engine and remove

PCV valve (1).

Shake valve and listen for rattle of check needle

inside the valve. If valve does not rattle, replace PCV

valve.

7) After checking, remove plug and install PCV valve.

8) Install air cleaner assembly securely.

Special Tools and Equipment

Special ToolS7RS0B1208001

I2RH0B120007-01

I2RH0B120008-01

09917–47011 SUZUKI scan tool

Vacuum pump gauge —

�) / �) This kit includes following

items. 1. Tech 2, 2. PCMCIA

card, 3. DLC cable, 4. SAE

16/19 adapter, 5. Cigarette

cable, 6. DLC loop back

adapter, 7. Battery power

cable, 8. RS232 cable, 9.

RS232 adapter, 10. RS232

loop back connector, 11.

Storage case, 12. �)

Page 275 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Electrical Devices: 1C-3

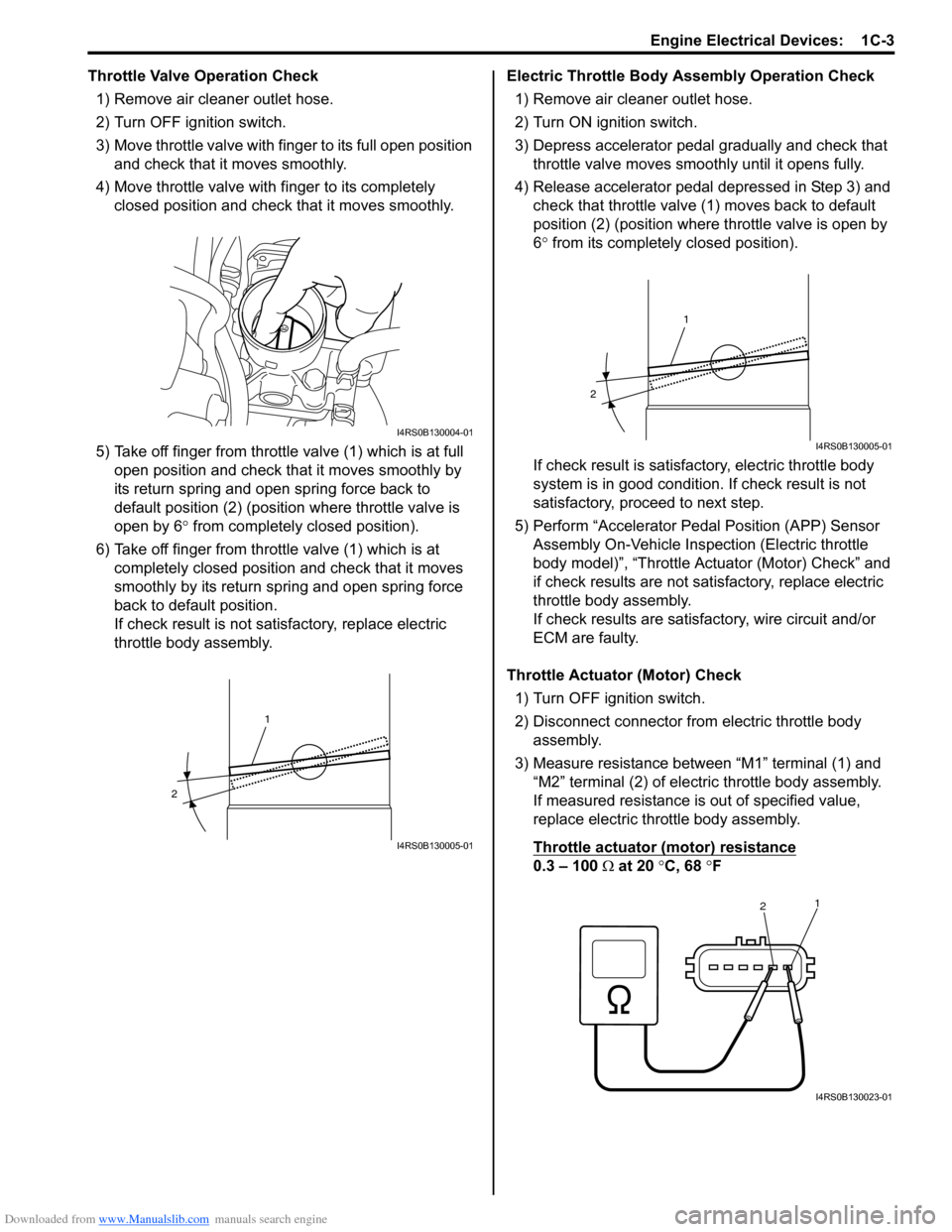

Throttle Valve Operation Check1) Remove air cleaner outlet hose.

2) Turn OFF ignition switch.

3) Move throttle valve with finger to its full open position and check that it moves smoothly.

4) Move throttle valve with fi nger to its completely

closed position and check that it moves smoothly.

5) Take off finger from throttle valve (1) which is at full open position and check that it moves smoothly by

its return spring and open spring force back to

default position (2) (positio n where throttle valve is

open by 6 ° from completely closed position).

6) Take off finger from throttle valve (1) which is at completely closed position and check that it moves

smoothly by its return spring and open spring force

back to default position.

If check result is not satisfactory, replace electric

throttle body assembly. Electric Throttle Body

Assembly Operation Check

1) Remove air cleaner outlet hose.

2) Turn ON ignition switch.

3) Depress accelerator pedal gradually and check that throttle valve moves smoo thly until it opens fully.

4) Release accelerator pedal depressed in Step 3) and check that throttle valve (1) moves back to default

position (2) (position where throttle valve is open by

6° from its completely closed position).

If check result is satisfactory, electric throttle body

system is in good condition. If check result is not

satisfactory, proceed to next step.

5) Perform “Accelerator Pe dal Position (APP) Sensor

Assembly On-Vehicle Inspection (Electric throttle

body model)”, “Throttle Actuator (Motor) Check” and

if check results are not satisfactory, replace electric

throttle body assembly.

If check results are satisfactory, wire circuit and/or

ECM are faulty.

Throttle Actuator (Motor) Check 1) Turn OFF ignition switch.

2) Disconnect connector from electric throttle body assembly.

3) Measure resistance between “M1” terminal (1) and “M2” terminal (2) of electric throttle body assembly.

If measured resistance is out of specified value,

replace electric throttle body assembly.

Throttle actuator (motor) resistance

0.3 – 100 Ω at 20 °C, 68 °F

I4RS0B130004-01

1

2

I4RS0B130005-01

1

2

I4RS0B130005-01

2 1

I4RS0B130023-01

Page 302 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-17 Engine Mechanical:

Engine Assembly Removal and InstallationS7RS0B1406011

NOTE

After replacing electric throttle body

assembly, perform calibration of throttle

valve referring to “Electric Throttle Body

System Calibration in Section 1C”.

Removal1) Relieve fuel pressure according to “Fuel Pressure Relief Procedure in Section 1G”.

2) Disconnect negative and pos itive cable at battery.

3) Remove battery and tray.

4) Remove engine hood after disconnecting windshield washer hose.

5) Remove right and left side engine under covers.

6) Remove A/C compressor belt by referring to “Compressor Drive Belt Remo val and Installation in

Section 7B” or “Compressor Drive Belt Removal and

Installation in Section 7B”.

7) Drain engine oil, transaxle oil and coolant.

8) Remove cowl top plate referring to “Cowl Top Components in Section 9K”.

9) Remove air cleaner assembly referring to “Air Cleaner Components”.

10) With hose connected, detach A/C compressor from its bracket (A/C model) referring to “Compressor

Assembly Removal and Installation in Section 7B” or

“Compressor Assembly Removal and Installation in

Section 7B”.

CAUTION!

Suspend removed A/C compressor at a place

where no damage will be caused during

removal and installation of engine assembly.

11) Remove intake manifold rear stiffener (1) from intake manifold and cylinder block. 12) Disconnect the following electric wires:

• MAP sensor (1)

• ECT sensor (2)

•EGR valve (3)

• CMP sensor (4)

• Electric throttle body assembly (5)

• Ignition coil assembly (6)

• Injectors (7)

• Heated oxygen sensor No. 2 (8) and No. 1 (9)

• Oil control valve (10)

• Engine oil pressure switch (11)

• CKP sensor (12)

• Knock sensor (13)

• Back up light switch (14)

• Generator (15)

• Starting motor (16)

• Ground terminal (17) from intake manifold

• Battery ground terminal (18) from exhaust manifold

• Battery ground cable (19) from transaxle

• Magnet clutch switch of A/C compressor (A/C model)

• Each wire harness clamps

• Output shaft speed sensor (VSS) (34) (A/T model)

• Solenoid valve (33) (A/T model)

• Transmission range sensor (32) (A/T model)

• Input shaft speed sensor (31) (A/T model)

13) Remove fuse box from its bracket.

14) Disconnect the following cables: • Gear select control cable (23) (M/T model)

• Gear shift control cable (24) (M/T model)

• A/T select cable (A/T model)

15) Disconnect the following hoses: • Brake booster hose (26) from intake manifold

• Radiator inlet and outlet hoses (20) from each pipe

• Heater inlet and outlet hoses (21) from each pipe

• Fuel feed hoses (22) from fuel feed pipe

• EVAP canister purge valve hose (30) from purge pipe

• A/T fluid cooler hoses (A/T model)

16) With hose connected, detach clutch operating cylinder (25). (M/T model)

CAUTION!

Suspend removed clutch operating cylinder

at a place where no damage will be caused

during removal and installation of engine

assembly.

1

I6RS0B141014-01

Page 305 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-20

15) Install A/C compressor to its bracket (if equipped) referring to “Compressor Assembly Removal and

Installation in Section 7B” or “Compressor Assembly

Removal and Installa tion in Section 7B”.

16) Adjust A/C compressor belt tension (if equipped) referring to “Compressor Drive Belt Inspection and

Adjustment in Section 7B” or “Compressor Drive Belt

Inspection and Adjustment in Section 7B”.

17) Check to ensure that a ll removed parts are back in

place.

Reinstall any necessary parts which have not been

reinstalled.

18) Refill cooling system with coolant referring to “Cooling System Flush and Refill in Section 1F”. 19) Refill engine with engine oil

referring to “Engine Oil

and Filter Change in Section 0B”.

20) Refill transaxle with transa xle oil referring to“Manual

Transaxle Oil Change in Section 5B” or “A/T Fluid

Change in Section 5A”.

21) Install battery and tray.

22) Connect positive and negative cable at battery.

23) Install engine hood and connect windshield washer hose.

24) Verify that there is no fu el leakage, coolant leakage,

oil leakage and exhaust gas leakage at each

connection.

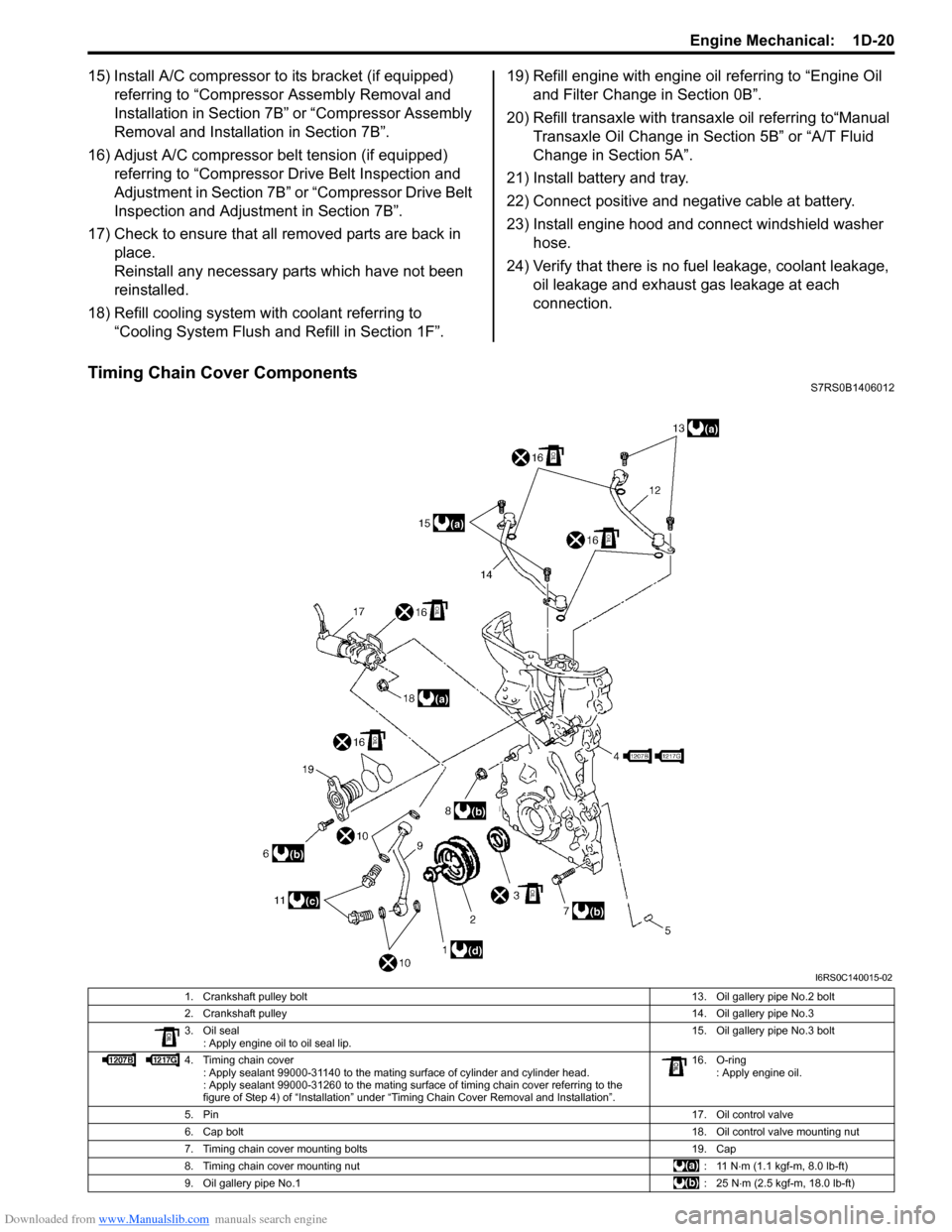

Timing Chain Cover ComponentsS7RS0B1406012

I6RS0C140015-02

1. Crankshaft pulley bolt 13. Oil gallery pipe No.2 bolt

2. Crankshaft pulley 14. Oil gallery pipe No.3

3. Oil seal : Apply engine oil to oil seal lip. 15. Oil gallery pipe No.3 bolt

4. Timing chain cover : Apply sealant 99000-31140 to the mating surface of cylinder and cylinder head.

: Apply sealant 99000-31260 to the mating surface of timing chain cover referring to the

figure of Step 4) of “Installation” under “Timing Chain Cover Removal and Installation”. 16. O-ring

: Apply engine oil.

5. Pin 17. Oil control valve

6. Cap bolt 18. Oil control valve mounting nut

7. Timing chain cover mounting bolts 19. Cap

8. Timing chain cover mounting nut : 11 N ⋅m (1.1 kgf-m, 8.0 lb-ft)

9. Oil gallery pipe No.1 :25 N⋅m (2.5 kgf-m, 18.0 lb-ft)