Back up SUZUKI SWIFT 2006 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 14 of 1496

Downloaded from www.Manualslib.com manuals search engine 00-9 Precautions:

• Be careful not to touch the electrical terminals of parts which use microcomputers (e.g. electronic control unit

like as ECM, PCM, P/S controller, etc.). The static

electricity from your body can damage these parts.

• Never connect any tester (voltmeter, ohmmeter, or whatever) to electronic control unit when its coupler is

disconnected. Attempt to do it may cause damage to

it.

• Never connect an ohmmeter to electronic control unit with its coupler connected to it. Attempt to do it may

cause damage to electronic control unit and sensors.

• Be sure to use a specified voltmeter / ohmmeter. Otherwise, accurate measurements may not be

obtained or personal injury ma y result. If not specified,

use a voltmeter with high impedance (M Ω/V

minimum) or a digital type voltmeter.

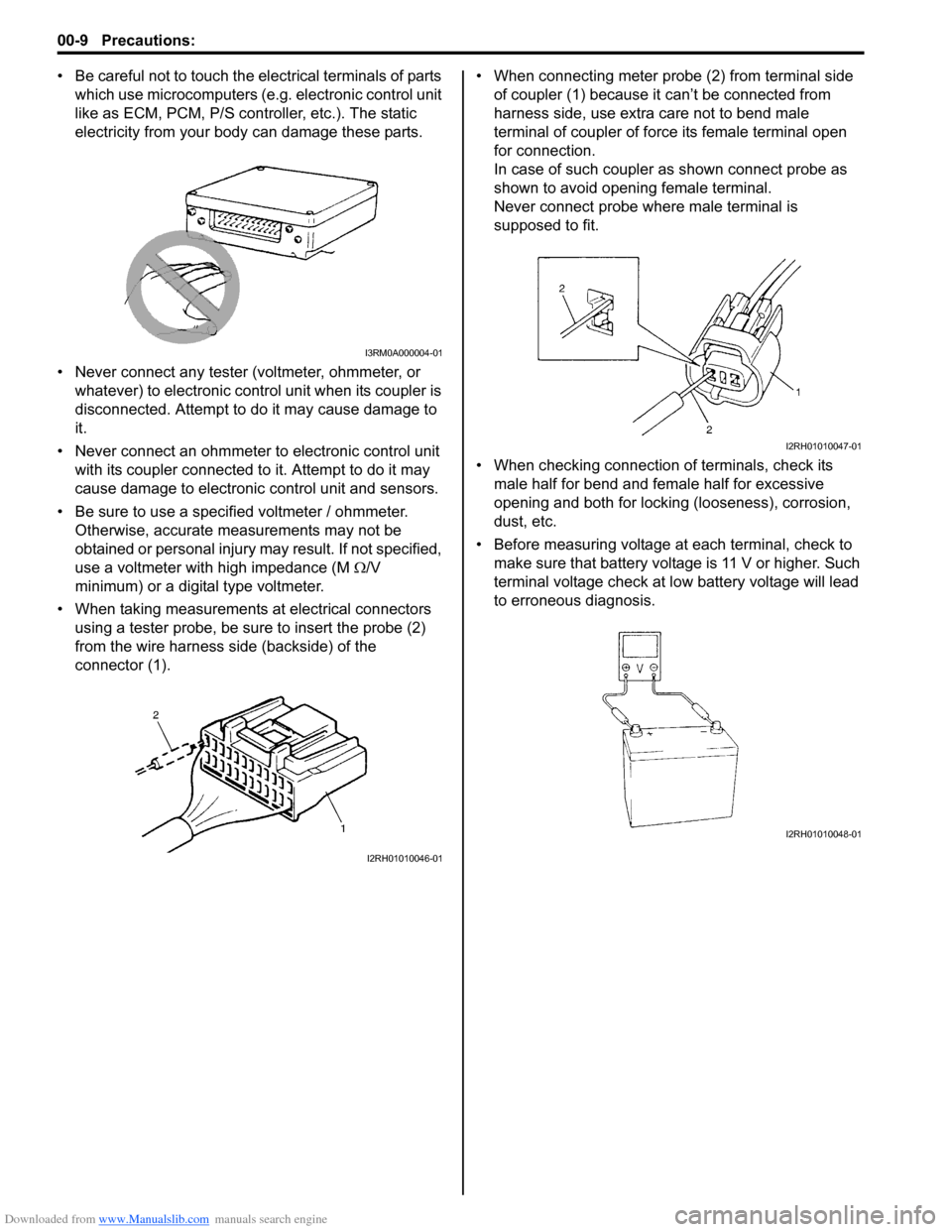

• When taking measurements at electrical connectors using a tester probe, be sure to insert the probe (2)

from the wire harness side (backside) of the

connector (1). • When connecting meter probe (2) from terminal side

of coupler (1) because it can’t be connected from

harness side, use extra care not to bend male

terminal of coupler of force its female terminal open

for connection.

In case of such coupler as shown connect probe as

shown to avoid opening female terminal.

Never connect probe where male terminal is

supposed to fit.

• When checking connection of terminals, check its

male half for bend and female half for excessive

opening and both for locking (looseness), corrosion,

dust, etc.

• Before measuring voltage at each terminal, check to make sure that battery voltage is 11 V or higher. Such

terminal voltage check at lo w battery voltage will lead

to erroneous diagnosis.

I3RM0A000004-01

I2RH01010046-01

I2RH01010047-01

I2RH01010048-01

Page 18 of 1496

Downloaded from www.Manualslib.com manuals search engine 00-13 Precautions:

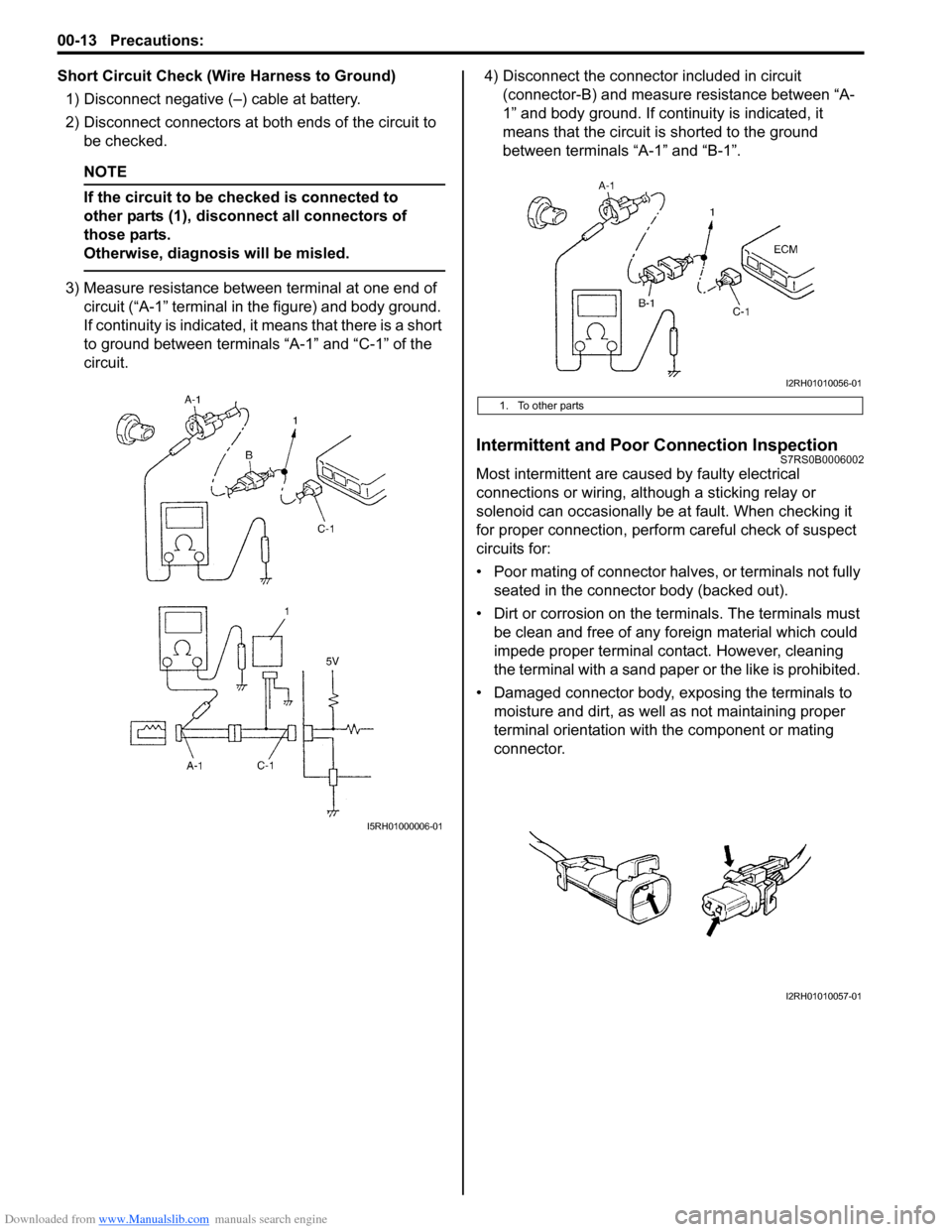

Short Circuit Check (Wire Harness to Ground)1) Disconnect negative (–) cable at battery.

2) Disconnect connectors at bot h ends of the circuit to

be checked.

NOTE

If the circuit to be checked is connected to

other parts (1), disconnect all connectors of

those parts.

Otherwise, diagnosis will be misled.

3) Measure resistance between terminal at one end of circuit (“A-1” terminal in the figure) and body ground.

If continuity is indicated, it means that there is a short

to ground between terminals “A-1” and “C-1” of the

circuit. 4) Disconnect the connector included in circuit

(connector-B) and measure resistance between “A-

1” and body ground. If continuity is indicated, it

means that the circuit is shorted to the ground

between terminals “A-1” and “B-1”.

Intermittent and Poor Connection InspectionS7RS0B0006002

Most intermittent are caused by faulty electrical

connections or wiring, although a sticking relay or

solenoid can occasionally be at fault. When checking it

for proper connection, perfor m careful check of suspect

circuits for:

• Poor mating of connector halves, or terminals not fully seated in the connector body (backed out).

• Dirt or corrosion on the terminals. The terminals must be clean and free of any foreign material which could

impede proper terminal contact. However, cleaning

the terminal with a sand paper or the like is prohibited.

• Damaged connector body, exposing the terminals to moisture and dirt, as well as not maintaining proper

terminal orientation with the component or mating

connector.

I5RH01000006-01

1. To other parts

I2RH01010056-01

I2RH01010057-01

Page 41 of 1496

Downloaded from www.Manualslib.com manuals search engine Maintenance and Lubrication: 0B-11

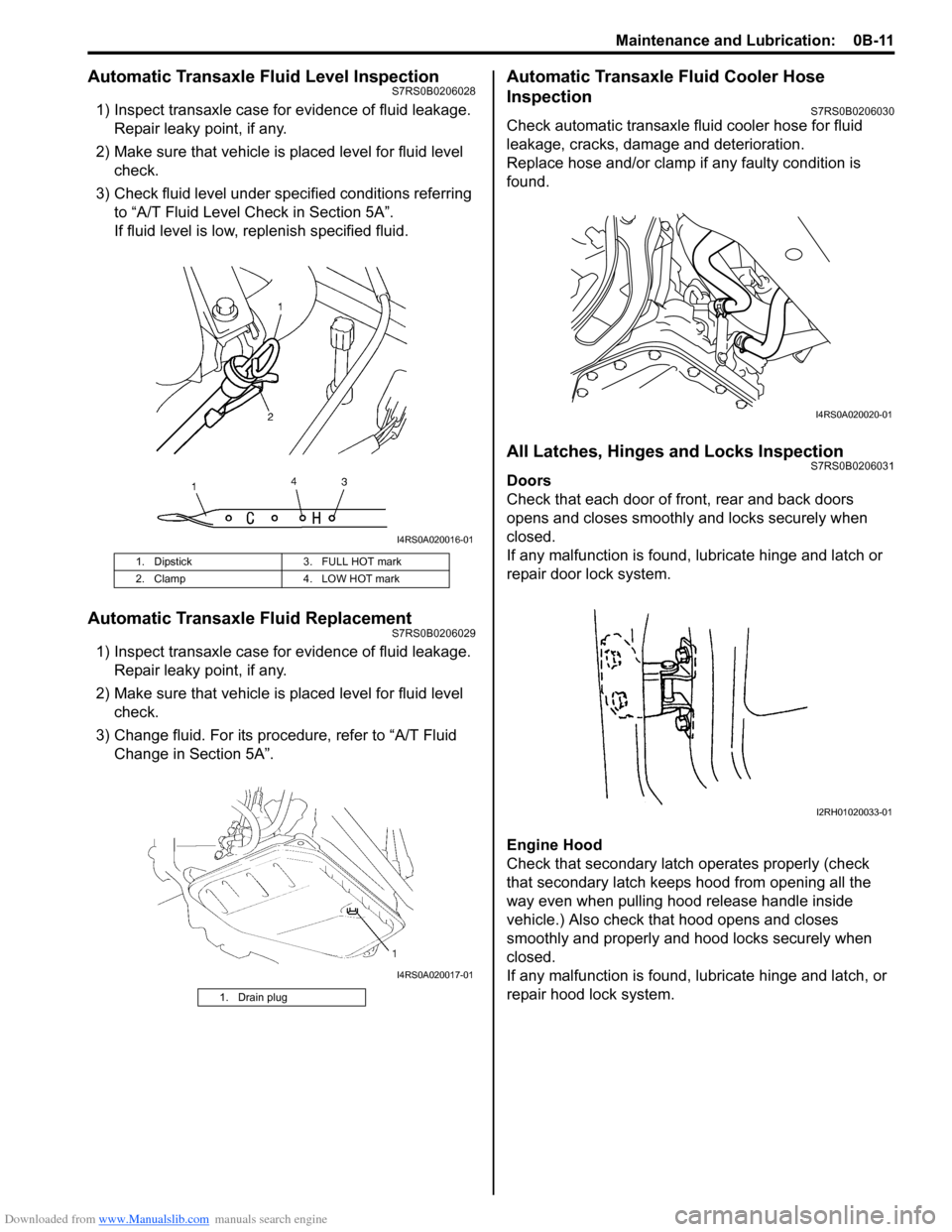

Automatic Transaxle Fluid Level InspectionS7RS0B0206028

1) Inspect transaxle case for evidence of fluid leakage.Repair leaky point, if any.

2) Make sure that vehicle is placed level for fluid level check.

3) Check fluid level under spec ified conditions referring

to “A/T Fluid Level Check in Section 5A”.

If fluid level is low, replenish specified fluid.

Automatic Transaxle Fluid ReplacementS7RS0B0206029

1) Inspect transaxle case for evidence of fluid leakage. Repair leaky point, if any.

2) Make sure that vehicle is placed level for fluid level check.

3) Change fluid. For its procedure, refer to “A/T Fluid Change in Section 5A”.

Automatic Transaxle Fluid Cooler Hose

Inspection

S7RS0B0206030

Check automatic transaxle fluid cooler hose for fluid

leakage, cracks, damage and deterioration.

Replace hose and/or clamp if any faulty condition is

found.

All Latches, Hinges and Locks InspectionS7RS0B0206031

Doors

Check that each door of front, rear and back doors

opens and closes smoothly and locks securely when

closed.

If any malfunction is found, lubricate hinge and latch or

repair door lock system.

Engine Hood

Check that secondary latch operates properly (check

that secondary latch keeps hood from opening all the

way even when pulling hood release handle inside

vehicle.) Also check that hood opens and closes

smoothly and properly and hood locks securely when

closed.

If any malfunction is found, l ubricate hinge and latch, or

repair hood lock system.

1. Dipstick 3. FULL HOT mark

2. Clamp 4. LOW HOT mark

1. Drain plug

I4RS0A020016-01

I4RS0A020017-01

I4RS0A020020-01

I2RH01020033-01

Page 42 of 1496

Downloaded from www.Manualslib.com manuals search engine 0B-12 Maintenance and Lubrication:

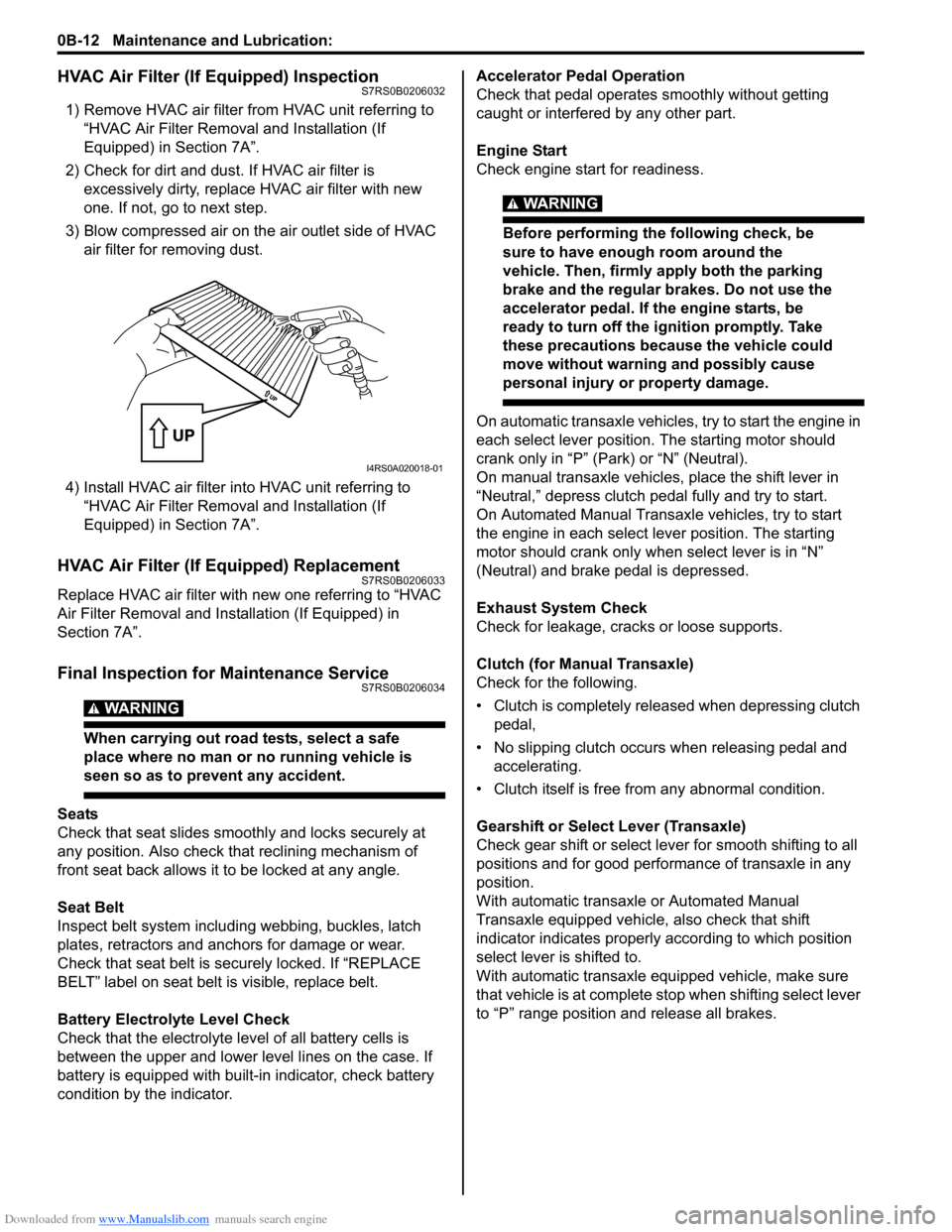

HVAC Air Filter (If Equipped) InspectionS7RS0B0206032

1) Remove HVAC air filter from HVAC unit referring to

“HVAC Air Filter Removal and Installation (If

Equipped) in Section 7A”.

2) Check for dirt and dust. If HVAC air filter is excessively dirty, replace HVAC air filter with new

one. If not, go to next step.

3) Blow compressed air on the air outlet side of HVAC air filter for removing dust.

4) Install HVAC air filter in to HVAC unit referring to

“HVAC Air Filter Removal and Installation (If

Equipped) in Section 7A”.

HVAC Air Filter (If Equipped) ReplacementS7RS0B0206033

Replace HVAC air filter with new one referring to “HVAC

Air Filter Removal and Installation (If Equipped) in

Section 7A”.

Final Inspection for Maintenance ServiceS7RS0B0206034

WARNING!

When carrying out road tests, select a safe

place where no man or no running vehicle is

seen so as to prevent any accident.

Seats

Check that seat slides smoot hly and locks securely at

any position. Also check that reclining mechanism of

front seat back allows it to be locked at any angle.

Seat Belt

Inspect belt system including webbing, buckles, latch

plates, retractors and anchors for damage or wear.

Check that seat belt is securely locked. If “REPLACE

BELT” label on seat belt is visible, replace belt.

Battery Electrolyte Level Check

Check that the electrolyte le vel of all battery cells is

between the upper and lower level lines on the case. If

battery is equipped with built-in indicator, check battery

condition by the indicator. Accelerator Pedal Operation

Check that pedal operates

smoothly without getting

caught or interfered by any other part.

Engine Start

Check engine start for readiness.

WARNING!

Before performing th e following check, be

sure to have enough room around the

vehicle. Then, firmly apply both the parking

brake and the regular brakes. Do not use the

accelerator pedal. If the engine starts, be

ready to turn off the ignition promptly. Take

these precautions because the vehicle could

move without warning and possibly cause

personal injury or property damage.

On automatic transaxle vehicles, try to start the engine in

each select lever position. The starting motor should

crank only in “P” (Park) or “N” (Neutral).

On manual transaxle vehicles, place the shift lever in

“Neutral,” depress clutch pedal fully and try to start.

On Automated Manual Transaxl e vehicles, try to start

the engine in each select le ver position. The starting

motor should crank only when select lever is in “N”

(Neutral) and brake pedal is depressed.

Exhaust System Check

Check for leakage, cracks or loose supports.

Clutch (for Manual Transaxle)

Check for the following.

• Clutch is completely released when depressing clutch pedal,

• No slipping clutch occurs when releasing pedal and accelerating.

• Clutch itself is free fr om any abnormal condition.

Gearshift or Select Lever (Transaxle)

Check gear shift or select lever for smooth shifting to all

positions and for good performance of transaxle in any

position.

With automatic transaxle or Automated Manual

Transaxle equipped vehicle, also check that shift

indicator indicates properly according to which position

select lever is shifted to.

With automatic transaxle equipped vehicle, make sure

that vehicle is at complete stop when shifting select lever

to “P” range position and release all brakes.

I4RS0A020018-01

Page 46 of 1496

Downloaded from www.Manualslib.com manuals search engine 1-ii Table of Contents

DTC P0123: Throttle / Pedal Position Sensor / Switch “A” (Main) Circuit High ....................... 1A-85

DTC P0131 / P0132: O2 Sensor (HO2S) Circuit Low Voltage / High Voltage (Sensor-

1) ..................................................................... 1A-88

DTC P0133: O2 Sensor (HO2S) Circuit Slow

Response (Sensor- 1) ...................................... 1A-91

DTC P0134: O2 Sensor (HO2S) Circuit No Activity Detected (Sensor -1) ........................... 1A-92

DTC P0137 / P0138: O2 Sensor (HO2S) Circuit Low Voltage / High Voltage (Sensor-

2) ..................................................................... 1A-94

DTC P0140: O2 Sensor (HO2S) Circuit No Activity Detected (Sensor -2) ........................... 1A-97

DTC P0171 / P0172: Fuel System Too Lean / Rich ................................................................. 1A-98

DTC P0222: Throttle / Pedal Position Sensor / Switch “B” (Sub) Circuit Low ....................... 1A-100

DTC P0223: Throttle / Pedal Position Sensor / Switch “B” (Sub) Circuit High ...................... 1A-102

DTC P0300 / P0301 / P0302 / P0303 / P0304: Random / Multiple Cylin der Misfire Detected

/ Cylinder 1 / Cylinder 2 / Cylinder 3 /

Cylinder 4 Misfire Detected ........................... 1A-105

DTC P0327 / P0328: Knoc k Sensor 1 Circuit

Low / High ..................................................... 1A-107

DTC P0335: Crankshaft Position (CKP) Sensor “A” Circuit .......................................... 1A-109

DTC P0340: Camshaft Position (CMP) Sensor “A” Circuit .......................................... 1A-111

DTC P0350: Ignition Coil Primary / Secondary Circuit ............................................................ 1A-114

DTC P0401 / P0402: Exhaust Gas Recirculation Flow Insufficient Detected /

Excessive Detected ...................................... 1A-116

DTC P0403: Exhaust Gas Recirculation Control Circuit ................... ............................ 1A-118

DTC P0420: Catalyst System Efficiency

below Threshold ................ ............................ 1A-120

DTC P0443: Evaporativ e Emission System

Purge Control Valve Circuit ........................... 1A-122

DTC P0480: Fan 1 (Radiator Cooling Fan) Control Circuit ................... ............................ 1A-124

DTC P0500: Vehicle Speed Sensor “A” Malfunction .................................................... 1A-128

DTC P0532: A/C Refrigerant Pressure Sensor “A” Circuit Low ... ............................... 1A-130

DTC P0533: A/C Refrigerant Pressure Sensor “A” Circuit High ................................. 1A-132

DTC P0601 / P0602 / P0607: Internal Control Module Memory Check Sum Error / Control

Module Programming Error / Control Module

Performance ................................................. 1A-134

DTC P0616: Starter Relay Circuit Low............ 1A-135

DTC P0617: Starter Relay Circuit High ........... 1A-136

DTC P0620: Generator Control Circuit ........... 1A-137

DTC P0625 / P0626: Generator Field Terminal Circuit Low / High . .......................... 1A-139

DTC P1501 / P1502: Electric Load Current Sensor Circuit Low / High . ............................ 1A-141 DTC P1510: ECM Back-Up Power Supply

Malfunction .................................................... 1A-143

DTC P1603: TCM Trouble Code Detected ..... 1A-144

DTC P1674: CAN Communication (Bus Off Error) ............................................................. 1A-145

DTC P1676: CAN Communication (Reception Error for TCM) ............................................... 1A-148

DTC P1678: CAN Communication (Reception Error for BCM) ............................................... 1A-149

DTC P1685: CAN Communication (Reception Error for ABS/ESP ® Control Module) ........... 1A-150

DTC P2101: Throttle Actuator Control Motor Circuit Range / Performance ......................... 1A-152

DTC P2102: Throttle Actuator Control Motor Circuit Low .................................................... 1A-154

DTC P2103: Throttle Actuator Control Motor Circuit High.................................................... 1A-155

DTC P2111 / P2112: Throttle Actuator Control System - Stuck Open / Closed ...................... 1A-156

DTC P2119: Throttle Actu ator Control Throttle

Body Range / Performance ........................... 1A-157

DTC P2122: Throttle / Pedal Position Sensor / Switch “D” (Main) Circuit Low Input............. 1A-159

DTC P2123: Throttle / Pedal Position Sensor / Switch “D” (Main) Circuit High Input ............ 1A-161

DTC P2127: Throttle Pedal Position Sensor / Switch “E” (Sub) Circuit Low Input ................ 1A-164

DTC P2128: Throttle / Pedal Position Sensor

/ Switc

h “E” (Sub) Circuit High Input ............. 1A-166

DTC P2135: Throttle / Pedal Position Sensor / Switch “A”/“B” (Main / Sub) Voltage

Correlation..................................................... 1A-168

DTC P2138: Throttle / Pedal Position Sensor / Switch “D”/“E” (Main / Sub) Voltage

Correlation..................................................... 1A-171

DTC P2227 / P2228 / P2229: Barometric Pressure Circuit Malfunction ......................... 1A-173

Inspection of ECM and Its Circuits .................. 1A-175

ECM Power and Ground Circuit Check........... 1A-194

Fuel Injector Circuit Check .............................. 1A-198

Fuel Pump and Its Circuit Check..................... 1A-200

Fuel Pressure Check....................................... 1A-203

A/C System Circuits Check ............................. 1A-205

Electric Load Signal Circuit Check .................. 1A-209

Radiator Cooling Fan Low Speed Control System Check ............................................... 1A-211

Radiator Cooling Fan High Speed Control System Check ............................................... 1A-213

Repair Instructions ......... .................................1A-216

Idle Speed and IAC Throttle Valve Opening Inspection ...................................................... 1A-216

Special Tools and Equipmen t .........................1A-217

Special Tool .................................................... 1A-217

Aux. Emission Control Devices ............. 1B-1

Diagnostic Information and Procedures ............1B-1

EGR System Inspection ...................................... 1B-1

Repair Instructions ............ ..................................1B-1

EVAP Canister Purge Inspec tion ........................ 1B-1

Page 52 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-2 Engine General Information and Diagnosis:

• Be sure to read “Precautions for Electrical Circuit Service in Section 00” befo re inspection and observe

what is written there.

• ECM replacement: When substituting a known-good ECM, check for the

following conditions. Neglec ting this check may cause

damage to a known-good ECM.

– Resistance value of all relays, actuators is as specified respectively.

– MAP sensor, A/C refrigerant pressure sensor and TP sensor are in good condition and none of power

circuits of these sensors is shorted to ground.

• Communication of ECM, BCM, ABS/ESP ® control

module, combination meter, keyless start control

module, steering angle sensor (ESP ® model) and

TCM (A/T model), is esta blished by CAN (Controller

Area Network). (For more detail of CAN

communication for ECM, refer to “CAN

Communication System Description”). Therefore,

handle CAN communication line with care referring to

“Precaution for CAN Communication System in

Section 00”.

• Immobilizer transponder code registration after

replacing ECM

When ECM is replaced with new one or with another

one, make sure to register immobilizer transponder

code to ECM correctly according to “Procedure after

ECM Replacement in Section 10C”.Precautions of ECM Circuit InspectionS7RS0B1100003

• ECM connectors are waterproofed. Each terminal of the ECM connectors is sealed up with the grommet.

Therefore, when measuring ci rcuit voltage, resistance

and/or pulse signal at ECM connector, do not insert

the tester’s probe into th e sealed terminal at the

harness side. When measuring circuit voltage,

resistance and/or pulse signal at ECM connector,

connect the special tool to the ECM connectors. And,

insert the tester’s probe into the special tool’s

connectors at the harness side, and then measure

voltage, resistance and/or pulse signal. Or, ECM and

its circuits may be damaged by water.

• Wire colors of the special tool’s connectors are different from the ones of the ECM connectors.

However, the circuit arrangement of the special tool’s

connectors is same as the one of the ECM

connectors. Therefore, measure circuit voltage and

resistance by identifying the terminal location subject

to the measurement.

Precautions of Electric Throttle Body System

Calibration

S7RS0B1100004

After performing one of works described below, it is

necessary to re-register the completely closed throttle

valve reference position stored in memory of ECM. (For

detailed information, refer to “Description of Electric

Throttle Body System Calibration”.) For the procedure to

register such data in ECM, refer to “Electric Throttle

Body System Calibration in Section 1C”.

• To shut off backup power of ECM for such purposes of battery replacement or “DOME” fuse removal

• To erase DTCs P0122, P01 23, P0222, P0223, P2101,

P2102, P2103, P2111, P2112, P2113, P2119, P2123,

P2127, P2128, P2135 and/or P2138

• To replace ECM

• To replace throttle body and/or accelerator pedal position (APP) sensor assembly

General Description

Statement on Cleanliness and CareS7RS0B1101001

An automobile engine is a combination of many

machined, honed, polished and lapped surfaces with

tolerances that are measured in the thousands of an

millimeter (ten thous ands of an inch).

Accordingly, when any internal engine parts are

serviced, care and cleanliness are important.

It should be understood that proper cleaning and

protection of machined surfaces and friction areas is part

of the repair procedure. This is considered standard

shop practice even if not specifically stated.

• A liberal coating of engine oil should be applied to friction areas during assembly to protect and lubricate

the surfaces on initial operation. • Whenever valve train components, pistons, piston

rings, connecting rods, rod bearings, and crankshaft

journal bearings are removed for service, they should

be retained in order.

At the time of installation, they should be installed in

the same locations and with the same mating

surfaces as when removed.

• Battery cables should be disconnected before any major work is performed on the engine.

Failure to disconnect cables may result in damage to

wire harness or other electrical parts.

Page 55 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-5

Freeze frame data clearance:

The freeze frame data is cleared at the same time as

clearance of DTC.

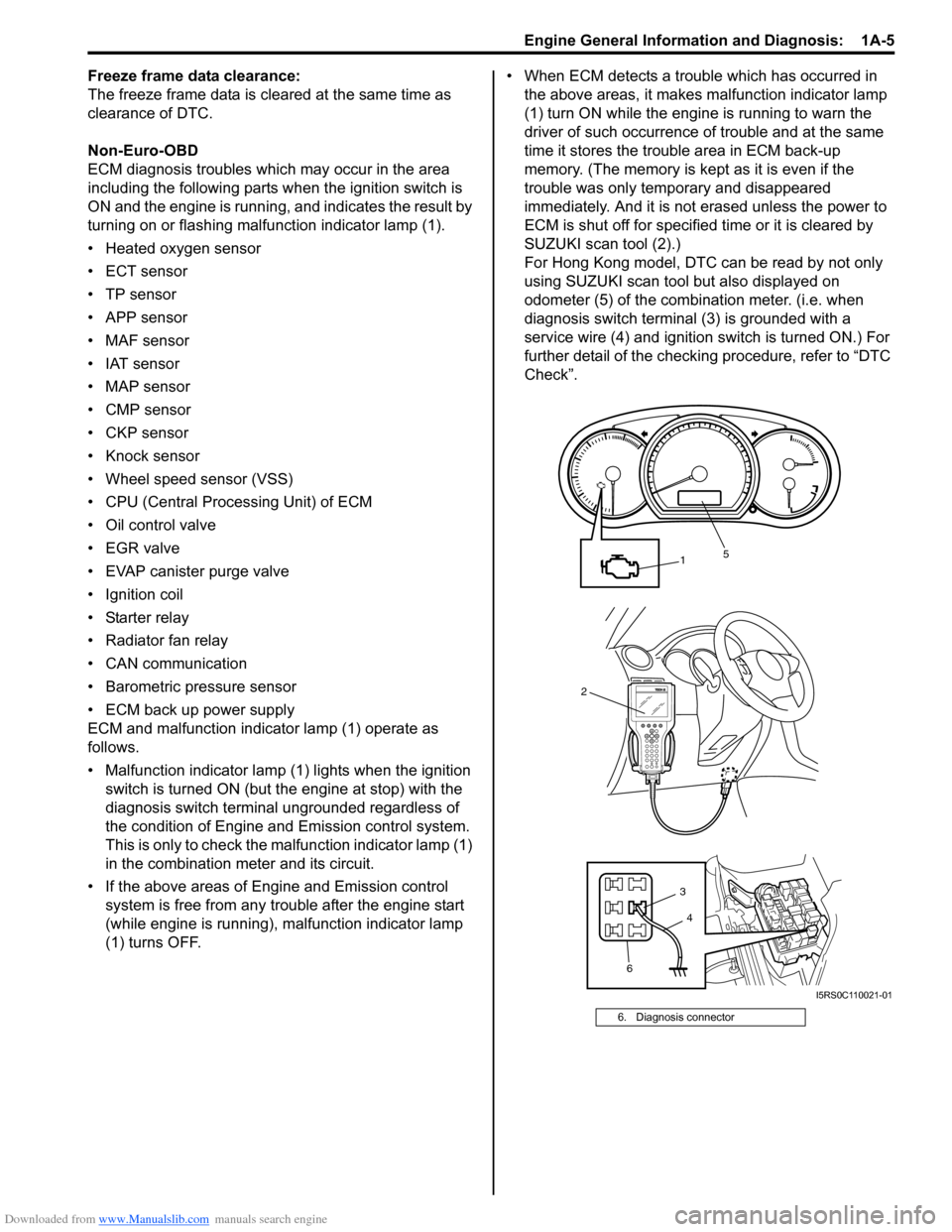

Non-Euro-OBD

ECM diagnosis troubles which may occur in the area

including the following parts w hen the ignition switch is

ON and the engine is running, and indicates the result by

turning on or flashing malfunction indicator lamp (1).

• Heated oxygen sensor

• ECT sensor

•TP sensor

• APP sensor

• MAF sensor

• IAT sensor

• MAP sensor

• CMP sensor

• CKP sensor

• Knock sensor

• Wheel speed sensor (VSS)

• CPU (Central Processing Unit) of ECM

• Oil control valve

• EGR valve

• EVAP canister purge valve

• Ignition coil

• Starter relay

• Radiator fan relay

• CAN communication

• Barometric pressure sensor

• ECM back up power supply

ECM and malfunction indicator lamp (1) operate as

follows.

• Malfunction indicator lamp (1) lights when the ignition switch is turned ON (but t he engine at stop) with the

diagnosis switch terminal ungrounded regardless of

the condition of Engine and Emission control system.

This is only to check the ma lfunction indicator lamp (1)

in the combination meter and its circuit.

• If the above areas of Engine and Emission control system is free from any trouble after the engine start

(while engine is running), malfunction indicator lamp

(1) turns OFF. • When ECM detects a trouble which has occurred in

the above areas, it makes malfunction indicator lamp

(1) turn ON while the engi ne is running to warn the

driver of such occurrence of trouble and at the same

time it stores the trouble area in ECM back-up

memory. (The memory is kept as it is even if the

trouble was only temporary and disappeared

immediately. And it is not erased unless the power to

ECM is shut off for specified time or it is cleared by

SUZUKI scan tool (2).)

For Hong Kong model, DTC can be read by not only

using SUZUKI scan tool but also displayed on

odometer (5) of the combination meter. (i.e. when

diagnosis switch terminal (3) is grounded with a

service wire (4) and ignition switch is turned ON.) For

further detail of the checking procedure, refer to “DTC

Check”.

6. Diagnosis connector

2

1

6 3

5

4

I5RS0C110021-01

Page 61 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-11

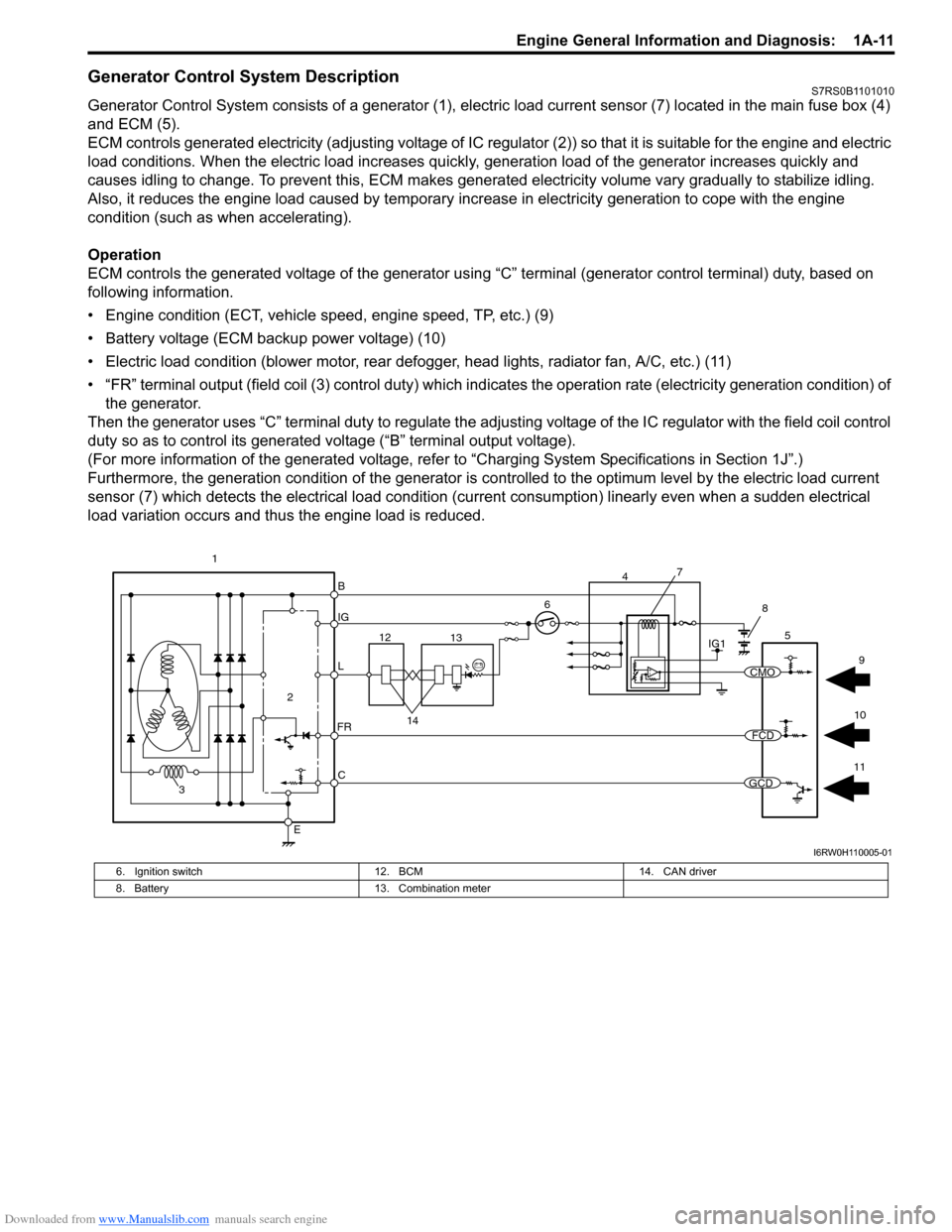

Generator Control System DescriptionS7RS0B1101010

Generator Control System consists of a generator (1), electric load current sensor (7) located in the main fuse box (4)

and ECM (5).

ECM controls generated electricity (adjusting voltage of IC regulator (2)) so that it is suitable for the engine and electric

load conditions. When the electric load increases quickly, generation load of the generator increases quickly and

causes idling to change. To prevent this, ECM makes generated electricity volume vary gradually to stabilize idling.

Also, it reduces the engine load caused by temporary incr ease in electricity generation to cope with the engine

condition (such as when accelerating).

Operation

ECM controls the generated voltage of the generator using “C” terminal (generator control terminal) duty, based on

following information.

• Engine condition (ECT, vehicle speed, engine speed, TP, etc.) (9)

• Battery voltage (ECM backup power voltage) (10)

• Electric load condition (blower motor, rear defogger, head lights, radiator fan, A/C, etc.) (11)

• “FR” terminal output (field coil (3) cont rol duty) which indicates the operation rate (electricity generation condition) of

the generator.

Then the generator uses “C” terminal duty to regulate the adju sting voltage of the IC regulator with the field coil control

duty so as to control its generated voltage (“B” terminal output voltage).

(For more information of the generated voltage, refer to “Charging System Specifications in Section 1J”.)

Furthermore, the generation condition of the generator is co ntrolled to the optimum level by the electric load current

sensor (7) which detects the electrical load condition (cur rent consumption) linearly even when a sudden electrical

load variation occurs and thus the engine load is reduced.

B

IG

L

C

E

6

2

3

FR

5

12 13

14

1IG1

7

4

8

11

10 9

CMO

FCD

GCD

I6RW0H110005-01

6. Ignition switch

12. BCM 14. CAN driver

8. Battery 13. Combination meter

Page 80 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-30 Engine General Information and Diagnosis:

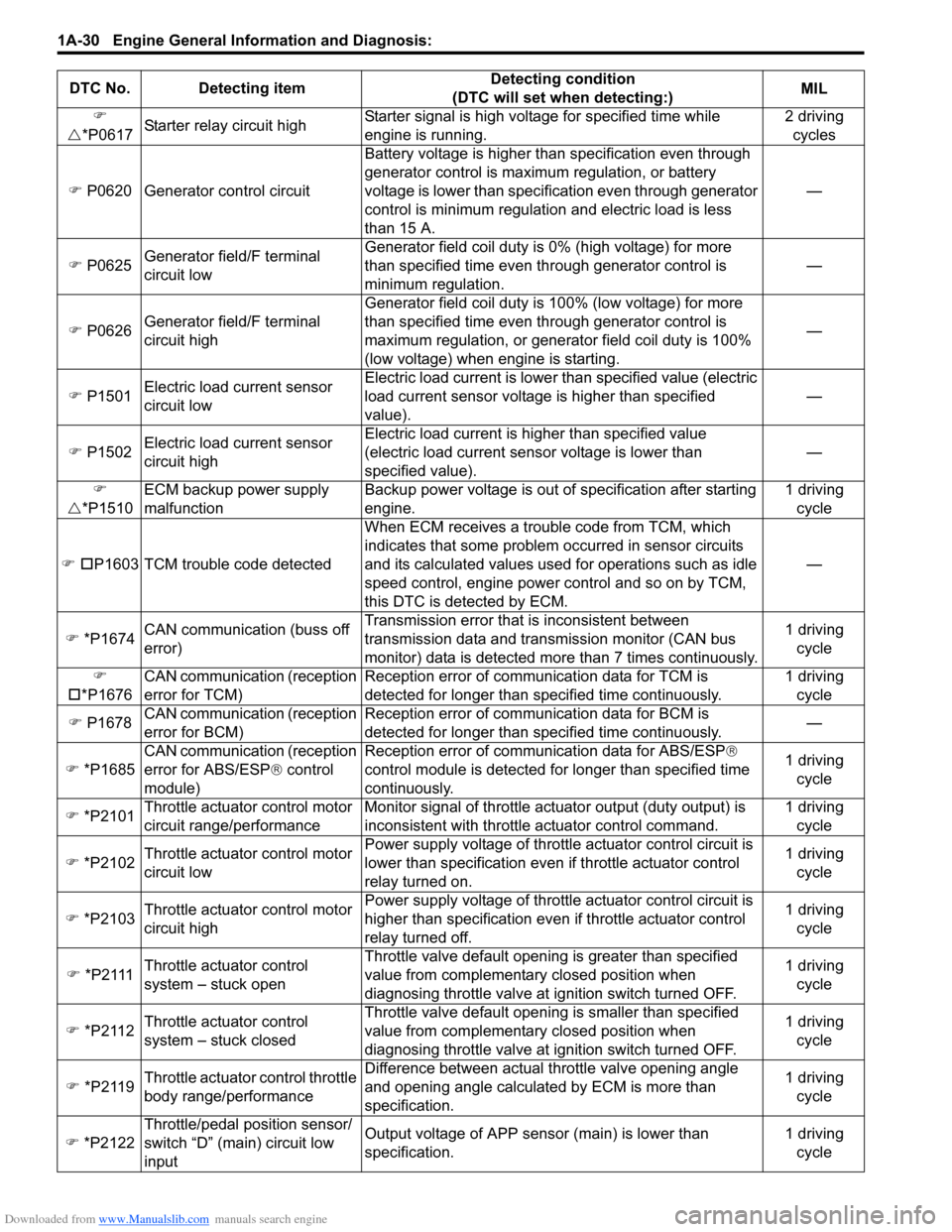

�)

�U *P0617 Starter relay circuit high Starter signal is high voltage for specified time while

engine is running. 2 driving

cycles

�) P0620 Generator control circuit Battery voltage is higher than specification even through

generator control is maximum regulation, or battery

voltage is lower than specification even through generator

control is minimum regulation

and electric load is less

than 15 A. —

�) P0625 Generator field/F terminal

circuit low Generator field coil duty is

0% (high voltage) for more

than specified time even through generator control is

minimum regulation. —

�) P0626 Generator field/F terminal

circuit high Generator field coil duty is

100% (low voltage) for more

than specified time even through generator control is

maximum regulation, or generator field coil duty is 100%

(low voltage) when engine is starting. —

�) P1501 Electric load current sensor

circuit low Electric load current is lowe

r than specified value (electric

load current sensor voltage is higher than specified

value). —

�) P1502 Electric load current sensor

circuit high Electric load current is higher than specified value

(electric load current sens

or voltage is lower than

specified value). —

�)

�U *P1510 ECM backup power supply

malfunction Backup power voltage is out of

specification after starting

engine. 1 driving

cycle

�) �† P1603 TCM trouble code detected When ECM receives a trouble code from TCM, which

indicates that some problem occurred in sensor circuits

and its calculated values used for operations such as idle

speed control, engine power control and so on by TCM,

this DTC is detected by ECM. —

�) *P1674 CAN communication (buss off

error) Transmission error that

is inconsistent between

transmission data and transmission monitor (CAN bus

monitor) data is detected more than 7 times continuously. 1 driving

cycle

�)

�† *P1676 CAN communication (reception

error for TCM) Reception error of communication data for TCM is

detected for longer than specified time continuously. 1 driving

cycle

�) P1678 CAN communication (reception

error for BCM) Reception error of communication data for BCM is

detected for longer than specified time continuously.

—

�) *P1685 CAN communication (reception

error for ABS/ESP

® control

module) Reception error of communication data for ABS/ESP

®

co

ntrol module is detected for longer than specified time

continuously. 1 driving

cycle

�) *P2101 Throttle actuator control motor

circuit range/performance Monitor signal of throttle actuator output (duty output) is

inconsistent with throttle actuator control command. 1 driving

cycle

�) *P2102 Throttle actuator control motor

circuit low Power supply voltage of throttle actuator control circuit is

lower than specification even

if throttle actuator control

relay turned on. 1 driving

cycle

�) *P2103 Throttle actuator control motor

circuit high Power supply voltage of throttle actuator control circuit is

higher than specification even if throttle actuator control

relay turned off. 1 driving

cycle

�) *P2111 Throttle actuator control

system – stuck open Throttle valve default opening is greater than specified

value from complementary closed position when

diagnosing throttle valve at ignition switch turned OFF. 1 driving

cycle

�) *P2112 Throttle actuator control

system – stuck closed Throttle valve default opening is smaller than specified

value from complementary closed position when

diagnosing throttle valve at ignition switch turned OFF. 1 driving

cycle

�) *P2119 Throttle actuator control throttle

body range/performance Difference between actual throttle valve opening angle

and opening angle calculated by ECM is more than

specification. 1 driving

cycle

�) *P2122 Throttle/pedal position sensor/

switch “D” (main) circuit low

input Output voltage of APP sensor (main) is lower than

specification.

1 driving

cycle

DTC No. Detecting item

Detecting condition

(DTC will set when detecting:) MIL

Page 82 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-32 Engine General Information and Diagnosis:

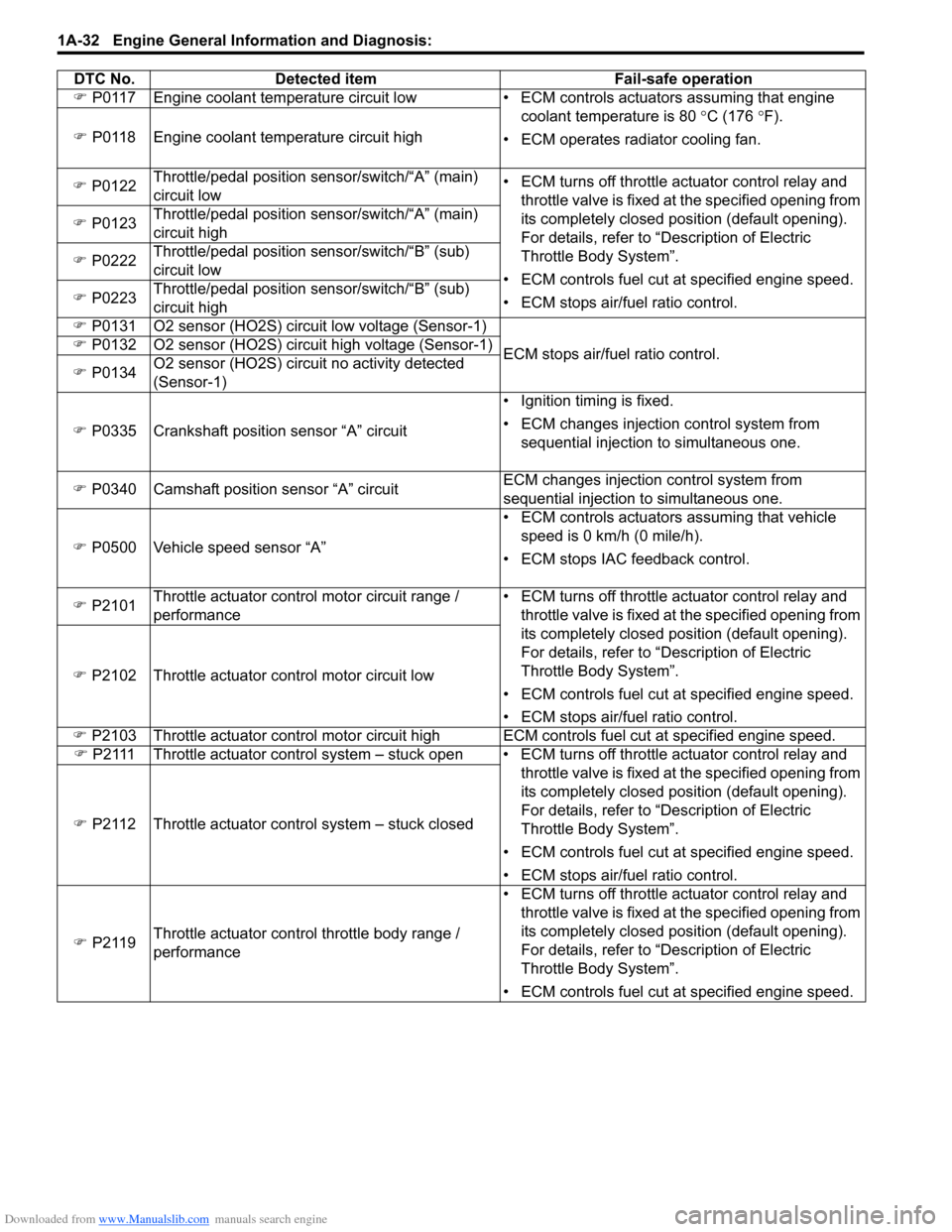

�) P0117 Engine coolant temperature circuit low • EC M controls actuators assuming that engine

coolant temperature is 80 °C (176 °F).

• ECM operates radiator cooling fan.

�)

P0118 Engine coolant temperature circuit high

�) P0122 Throttle/pedal position sensor/switch/“A” (main)

circuit low • ECM turns off throttle actuator control relay and

throttle valve is fixed at the specified opening from

its completely closed position (default opening).

For details, refer to “Description of Electric

Throttle Body System”.

• ECM controls fuel cut at specified engine speed.

• ECM stops air/fuel ratio control.

�)

P0123 Throttle/pedal position sensor/switch/“A” (main)

circuit high

�) P0222 Throttle/pedal position sensor/switch/“B” (sub)

circuit low

�) P0223 Throttle/pedal position sensor/switch/“B” (sub)

circuit high

�) P0131 O2 sensor (HO2S) circuit low voltage (Sensor-1)

ECM stops air/fuel ratio control.

�)

P0132 O2 sensor (HO2S) circuit high voltage (Sensor-1)

�) P0134 O2 sensor (HO2S) circuit no activity detected

(Sensor-1)

�) P0335 Crankshaft position sensor “A” circuit • Ignition timing is fixed.

• ECM changes injection control system from

sequential injection to simultaneous one.

�) P0340 Camshaft position sensor “A” circuit ECM changes injection

control system from

sequential injection to simultaneous one.

�) P0500 Vehicle speed sensor “A” • ECM controls actuators assuming that vehicle

speed is 0 km/h (0 mile/h).

• ECM stops IAC feedback control.

�) P2101 Throttle actuator control motor circuit range /

performance • ECM turns off throttle actuator control relay and

throttle valve is fixed at the specified opening from

its completely closed position (default opening).

For details, refer to “Description of Electric

Throttle Body System”.

• ECM controls fuel cut at specified engine speed.

• ECM stops air/fuel ratio control.

�)

P2102 Throttle actuator control motor circuit low

�) P2103 Throttle actuator control motor circuit high ECM controls fuel cut at specified engine speed.

�) P2111 Throttle actuator control system – stuck open • EC M turns off throttle actuator control relay and

throttle valve is fixed at the specified opening from

its completely closed position (default opening).

For details, refer to “Description of Electric

Throttle Body System”.

• ECM controls fuel cut at specified engine speed.

• ECM stops air/fuel ratio control.

�)

P2112 Throttle actuator control system – stuck closed

�) P2119 Throttle actuator control throttle body range /

performance • ECM turns off throttle actuator control relay and

throttle valve is fixed at the specified opening from

its completely closed position (default opening).

For details, refer to “Description of Electric

Throttle Body System”.

• ECM controls fuel cut at specified engine speed.

DTC No.

Detected item Fail-safe operation