Engine parts SUZUKI SWIFT 2006 2.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 18 of 1496

Downloaded from www.Manualslib.com manuals search engine 00-13 Precautions:

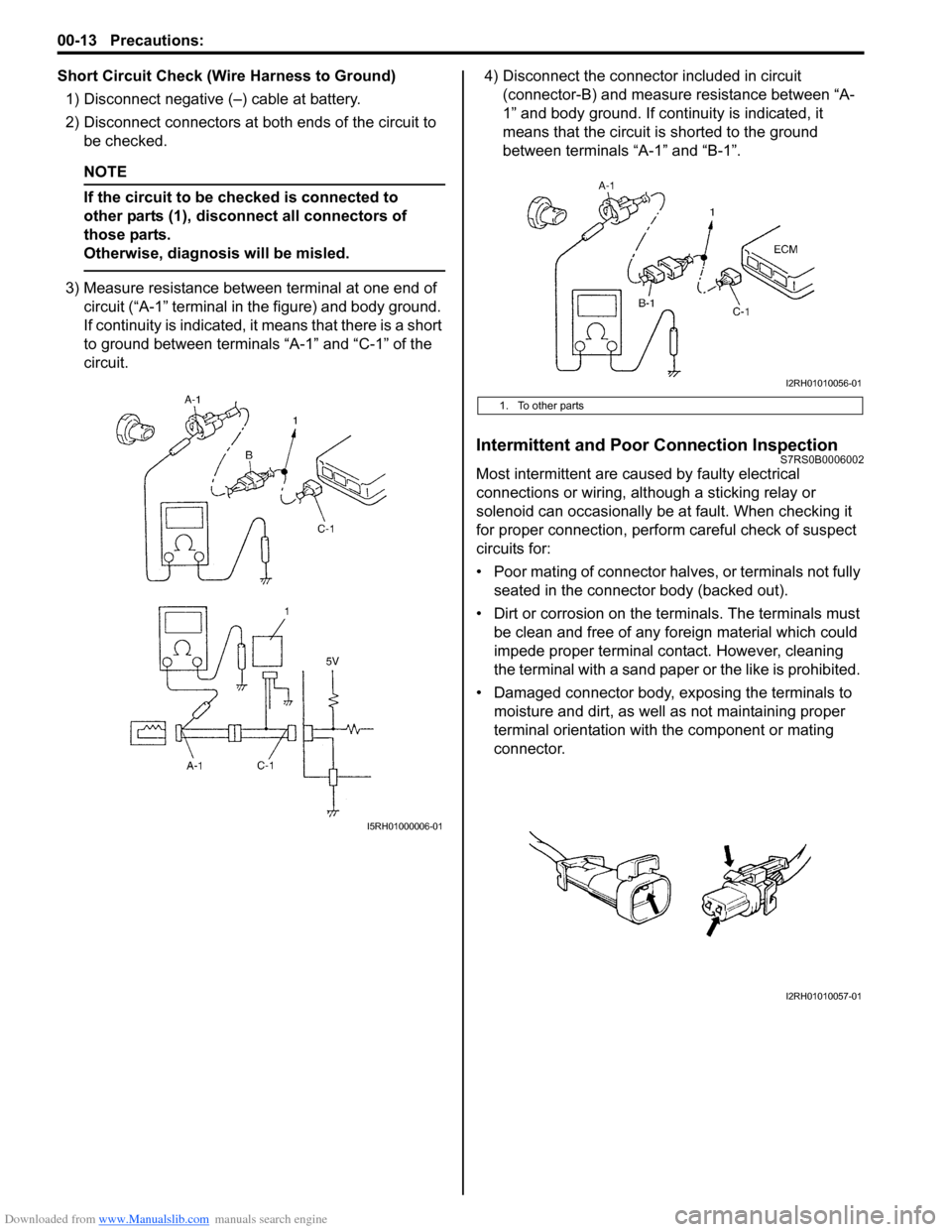

Short Circuit Check (Wire Harness to Ground)1) Disconnect negative (–) cable at battery.

2) Disconnect connectors at bot h ends of the circuit to

be checked.

NOTE

If the circuit to be checked is connected to

other parts (1), disconnect all connectors of

those parts.

Otherwise, diagnosis will be misled.

3) Measure resistance between terminal at one end of circuit (“A-1” terminal in the figure) and body ground.

If continuity is indicated, it means that there is a short

to ground between terminals “A-1” and “C-1” of the

circuit. 4) Disconnect the connector included in circuit

(connector-B) and measure resistance between “A-

1” and body ground. If continuity is indicated, it

means that the circuit is shorted to the ground

between terminals “A-1” and “B-1”.

Intermittent and Poor Connection InspectionS7RS0B0006002

Most intermittent are caused by faulty electrical

connections or wiring, although a sticking relay or

solenoid can occasionally be at fault. When checking it

for proper connection, perfor m careful check of suspect

circuits for:

• Poor mating of connector halves, or terminals not fully seated in the connector body (backed out).

• Dirt or corrosion on the terminals. The terminals must be clean and free of any foreign material which could

impede proper terminal contact. However, cleaning

the terminal with a sand paper or the like is prohibited.

• Damaged connector body, exposing the terminals to moisture and dirt, as well as not maintaining proper

terminal orientation with the component or mating

connector.

I5RH01000006-01

1. To other parts

I2RH01010056-01

I2RH01010057-01

Page 19 of 1496

Downloaded from www.Manualslib.com manuals search engine Precautions: 00-14

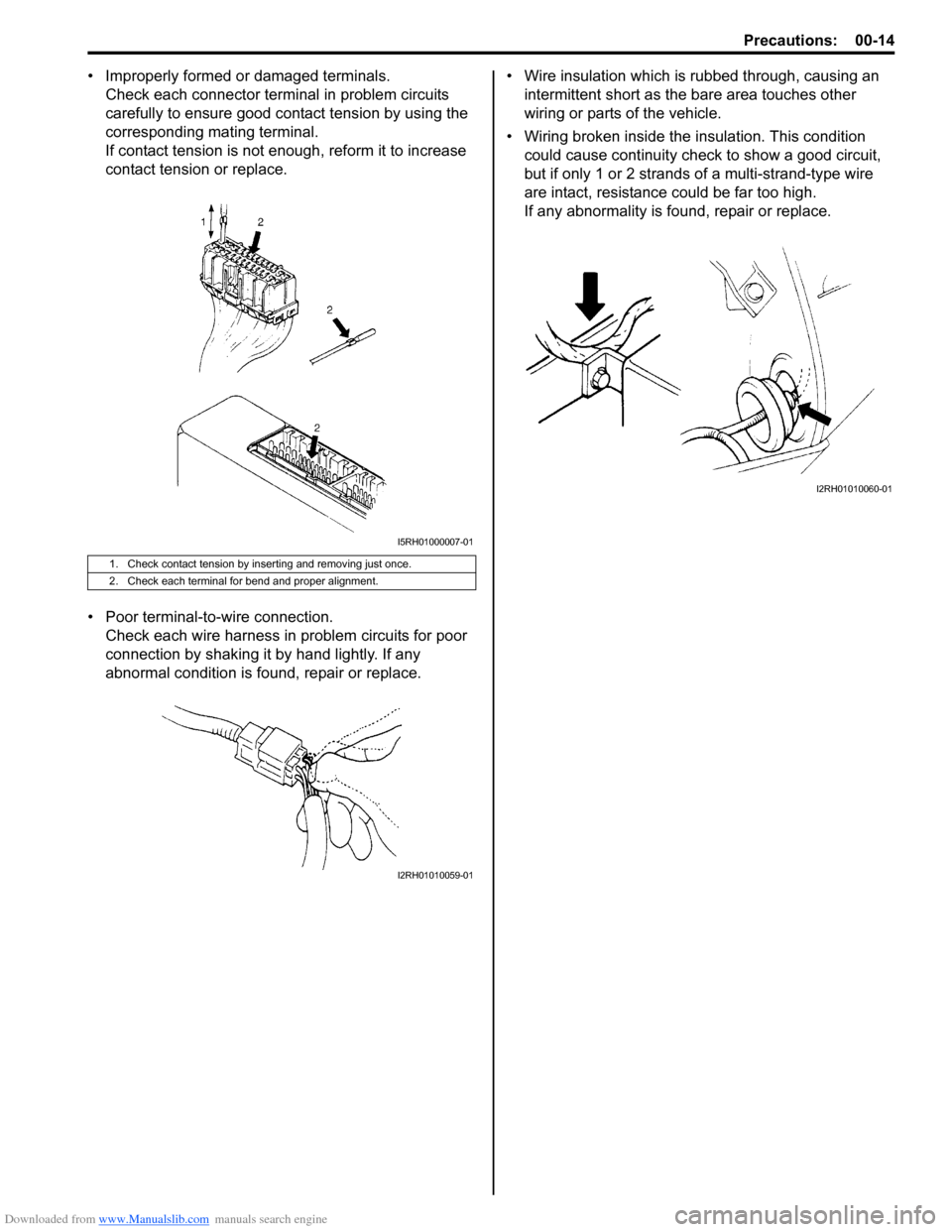

• Improperly formed or damaged terminals.Check each connector terminal in problem circuits

carefully to ensure good contact tension by using the

corresponding mating terminal.

If contact tension is not enough, reform it to increase

contact tension or replace.

• Poor terminal-to -wire connection.

Check each wire harness in problem circuits for poor

connection by shaking it by hand lightly. If any

abnormal condition is found, repair or replace. • Wire insulation which is rubbed through, causing an

intermittent short as the bare area touches other

wiring or parts of the vehicle.

• Wiring broken inside the insulation. This condition

could cause continuity check to show a good circuit,

but if only 1 or 2 strands of a multi-strand-type wire

are intact, resistance could be far too high.

If any abnormality is found, repair or replace.

1. Check contact tension by inserting and removing just once.

2. Check each terminal for bend and proper alignment.

I5RH01000007-01

I2RH01010059-01

I2RH01010060-01

Page 24 of 1496

Downloaded from www.Manualslib.com manuals search engine 0A-3 General Information:

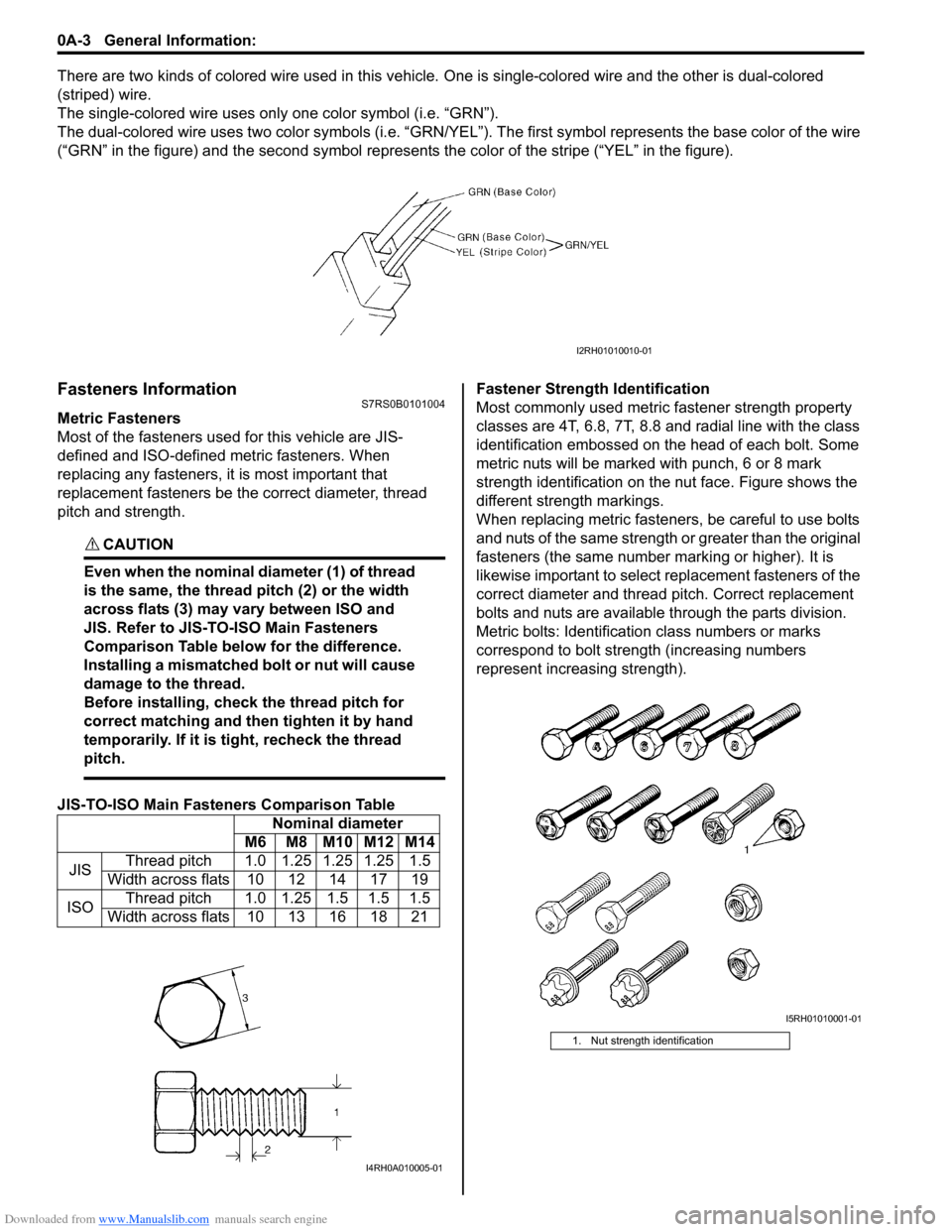

There are two kinds of colored wire used in this vehicle. One is single-colored wire and the other is dual-colored

(striped) wire.

The single-colored wire uses only one color symbol (i.e. “GRN”).

The dual-colored wire uses two color sy mbols (i.e. “GRN/YEL”). The first symbo l represents the base color of the wire

(“GRN” in the figure) and the second symbol represents the color of the stripe (“YEL” in the figure).

Fasteners InformationS7RS0B0101004

Metric Fasteners

Most of the fasteners used for this vehicle are JIS-

defined and ISO-defined metric fasteners. When

replacing any fasteners, it is most important that

replacement fasteners be the correct diameter, thread

pitch and strength.

CAUTION!

Even when the nominal diameter (1) of thread

is the same, the thread pitch (2) or the width

across flats (3) may vary between ISO and

JIS. Refer to JIS-TO-ISO Main Fasteners

Comparison Table below for the difference.

Installing a mismatched bolt or nut will cause

damage to the thread.

Before installing, check the thread pitch for

correct matching and then tighten it by hand

temporarily. If it is tight, recheck the thread

pitch.

JIS-TO-ISO Main Fasteners Comparison Table Fastener Strength Identification

Most commonly used metric fastener strength property

classes are 4T, 6.8, 7T, 8.8 and radial line with the class

identification embossed on the head of each bolt. Some

metric nuts will be marked with punch, 6 or 8 mark

strength identification on the nut face. Figure shows the

different strength markings.

When replacing metric fasteners, be careful to use bolts

and nuts of the same strength or greater than the original

fasteners (the same number marking or higher). It is

likewise important to select replacement fasteners of the

correct diameter and thread

pitch. Correct replacement

bolts and nuts are available through the parts division.

Metric bolts: Identification class numbers or marks

correspond to bolt strength (increasing numbers

represent increasing strength).

I2RH01010010-01

Nominal diameter

M6 M8 M10 M12 M14

JIS Thread pitch 1.0 1.25 1.25 1.25 1.5

Width across flats 10 12 14 17 19

ISO Thread pitch 1.0 1.25 1.5 1.5 1.5

Width across flats 10 13 16 18 21

I4RH0A010005-01

1. Nut strength identification

I5RH01010001-01

Page 25 of 1496

Downloaded from www.Manualslib.com manuals search engine General Information: 0A-4

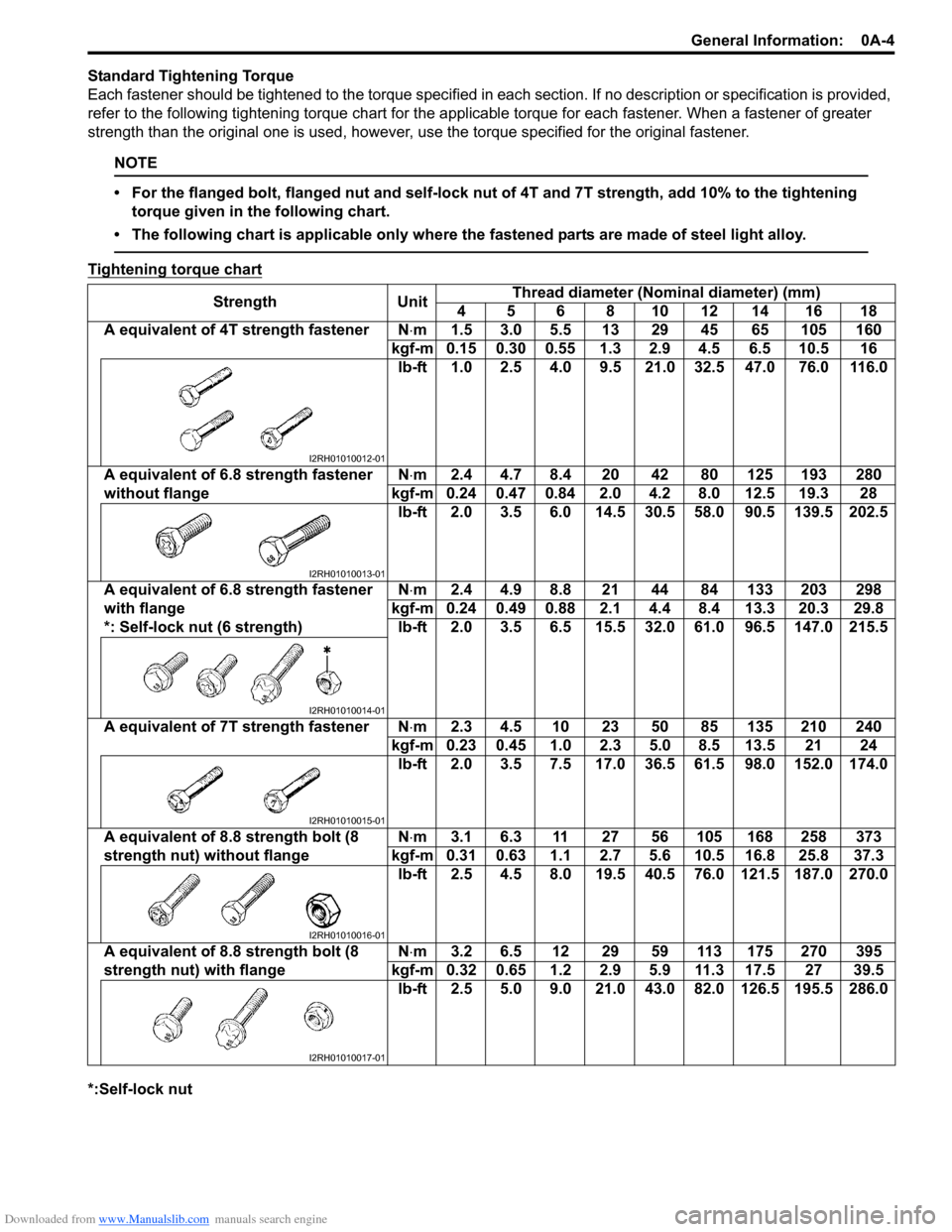

Standard Tightening Torque

Each fastener should be tightened to the torque specified in each section. If no description or specification is provided,

refer to the following tightening torque chart for the applicable torque for each fastener. When a fastener of greater

strength than the original one is used, however, use the torque specified for the original fastener.

NOTE

• For the flanged bolt, flanged nut and self-lock nut of 4T and 7T strength, add 10% to the tightening torque given in the following chart.

• The following chart is applicable only where the fastened parts are made of steel light alloy.

Tightening torque chart

*:Self-lock nut Strength Unit

Thread diameter (Nominal diameter) (mm)

4 5 6 8 10 12 14 16 18

A equivalent of 4T strength fastener N⋅ m 1.5 3.0 5.5 13 29 45 65 105 160

kgf-m 0.15 0.30 0.55 1.3 2.9 4.5 6.5 10.5 16 lb-ft 1.0 2.5 4.0 9.5 21.0 32.5 47.0 76.0 116.0

A equivalent of 6.8 strength fastener

without flange N

⋅m 2.4 4.7 8.4 20 42 80 125 193 280

kgf-m 0.24 0.47 0.84 2.0 4.2 8.0 12.5 19.3 28 lb-ft 2.0 3.5 6.0 14.5 30.5 58.0 90.5 139.5 202.5

A equivalent of 6.8 strength fastener

with flange

*: Self-lock nut (6 strength) N

⋅m 2.4 4.9 8.8 21 44 84 133 203 298

kgf-m 0.24 0.49 0.88 2.1 4.4 8.4 13.3 20.3 29.8 lb-ft 2.0 3.5 6.5 15.5 32.0 61.0 96.5 147.0 215.5

A equivalent of 7T strength fastener N⋅ m 2.3 4.5 10 23 50 85 135 210 240

kgf-m 0.23 0.45 1.0 2.3 5.0 8.5 13.5 21 24 lb-ft 2.0 3.5 7.5 17.0 36.5 61.5 98.0 152.0 174.0

A equivalent of 8.8 strength bolt (8

strength nut) without flange N

⋅m 3.1 6.3 11 27 56 105 168 258 373

kgf-m 0.31 0.63 1.1 2.7 5.6 10.5 16.8 25.8 37.3 lb-ft 2.5 4.5 8.0 19.5 40.5 76.0 121.5 187.0 270.0

A equivalent of 8.8 strength bolt (8

strength nut) with flange N

⋅m 3.2 6.5 12 29 59 113 175 270 395

kgf-m 0.32 0.65 1.2 2.9 5.9 11.3 17.5 27 39.5 lb-ft 2.5 5.0 9.0 21.0 43.0 82.0 126.5 195.5 286.0

I2RH01010012-01

I2RH01010013-01

I2RH01010014-01

I2RH01010015-01

I2RH01010016-01

I2RH01010017-01

Page 27 of 1496

Downloaded from www.Manualslib.com manuals search engine General Information: 0A-6

When Using Floor Jack

WARNING!

If the vehicle to be jacked up only at the front

or rear end, be sure to block the wheels on

ground in order to ensure safety.

After the vehicle is jacked up, be sure to

support it on stands. It is extremely

dangerous to do any work on the vehicle

raised on jack alone.

CAUTION!

• Never apply jack against rear suspension parts (i.e., stabilizer, etc.) or vehicle floor,

or it may get deformed.

• When jacking up the front end, be sure to use an air type floor jack with the following

specified height or a manual type floor jack

of the following size. Otherwise, the jack

may cause the bumper or vehicle body

panel a damage.

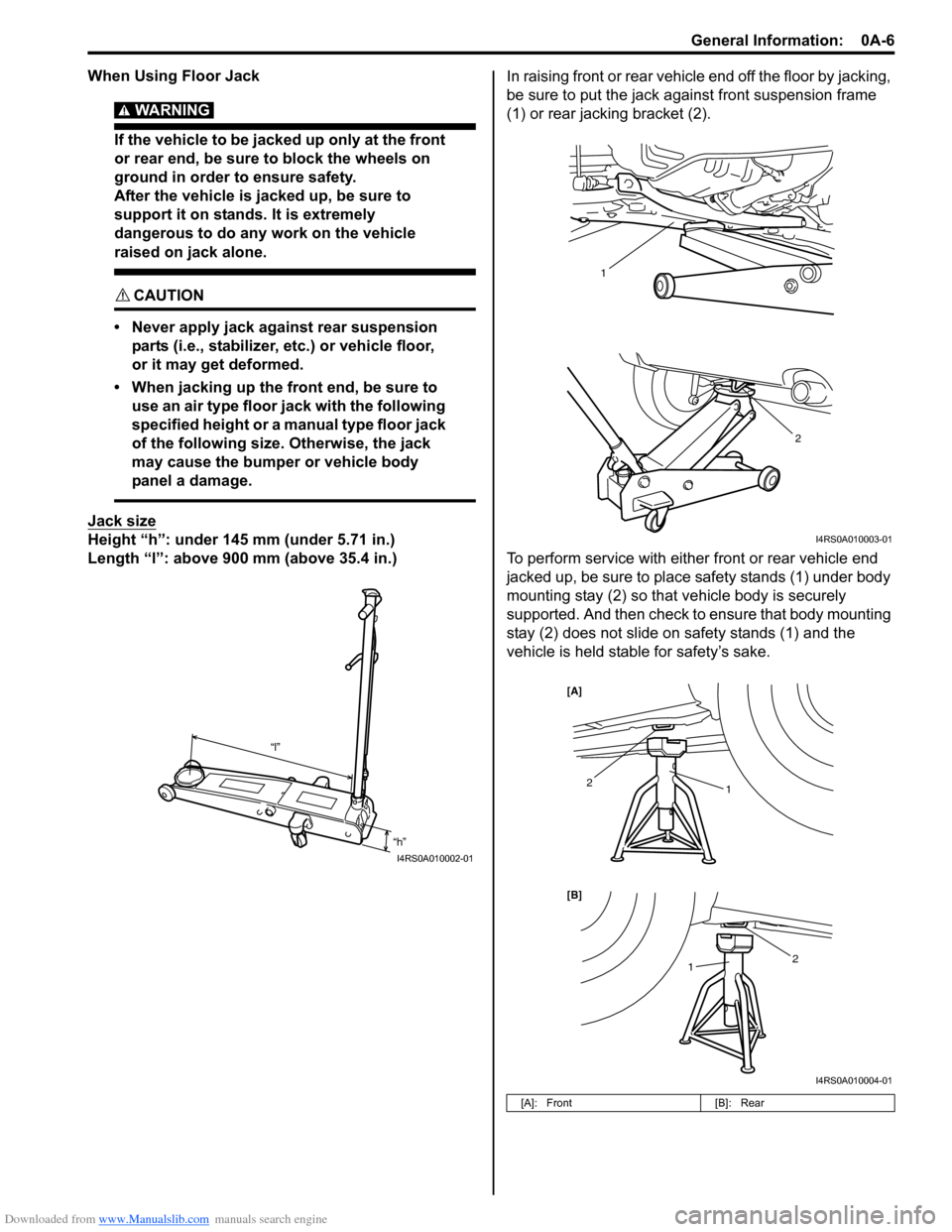

Jack size

Height “h”: under 145 mm (under 5.71 in.)

Length “l”: above 900 mm (above 35.4 in.) In raising front or rear vehicl

e end off the floor by jacking,

be sure to put the jack a gainst front suspension frame

(1) or rear jacking bracket (2).

To perform service with either front or rear vehicle end

jacked up, be sure to place safety stands (1) under body

mounting stay (2) so that vehicle body is securely

supported. And then check to ensure that body mounting

stay (2) does not slide on safety stands (1) and the

vehicle is held stable for safety’s sake.

“h”

“l”

I4RS0A010002-01

[A]: Front

[B]: Rear

2

1

I4RS0A010003-01

1

1

2

2

[B] [A]

I4RS0A010004-01

Page 28 of 1496

Downloaded from www.Manualslib.com manuals search engine 0A-7 General Information:

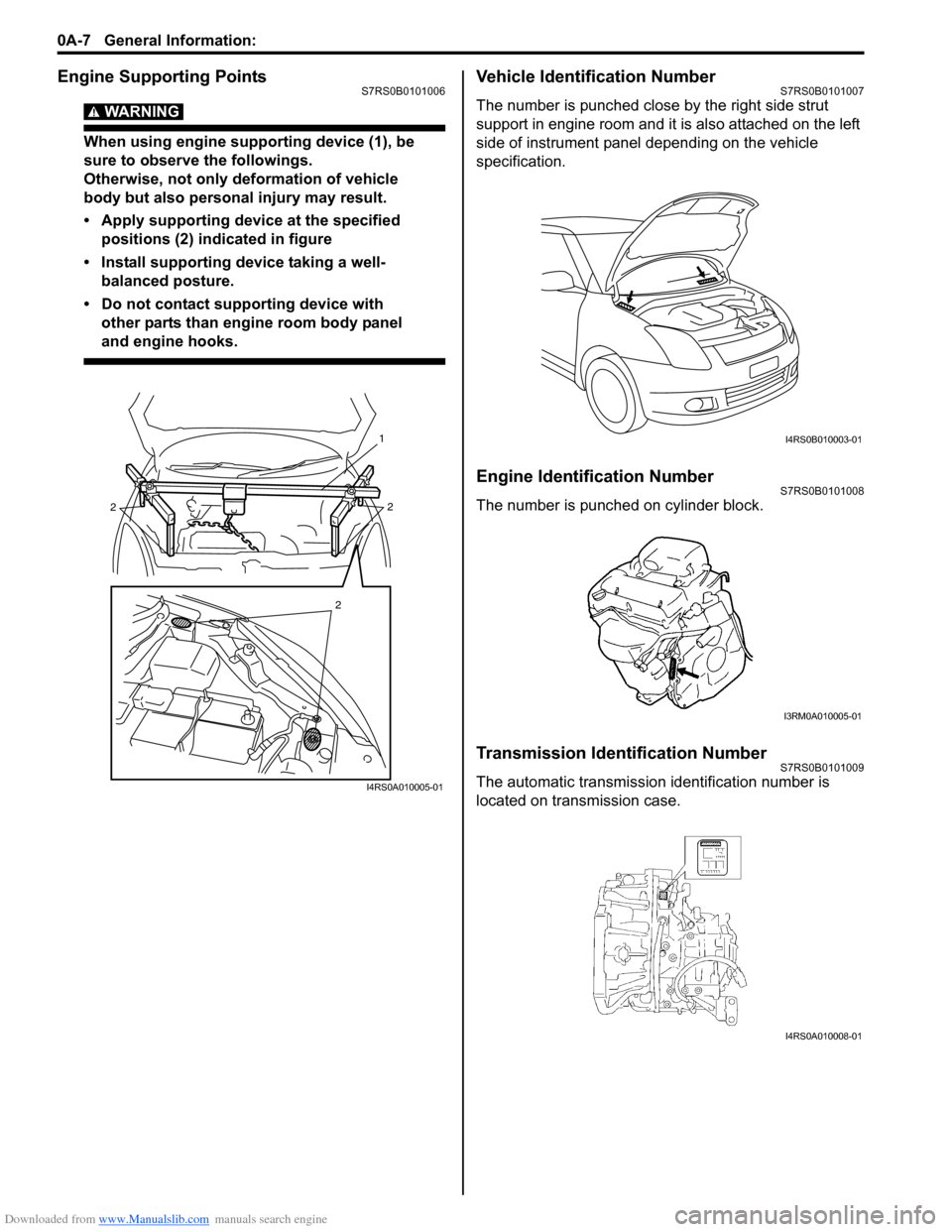

Engine Supporting PointsS7RS0B0101006

WARNING!

When using engine supporting device (1), be

sure to observe the followings.

Otherwise, not only deformation of vehicle

body but also personal injury may result.

• Apply supporting device at the specified positions (2) indicated in figure

• Install supporting device taking a well- balanced posture.

• Do not contact supporting device with other parts than engine room body panel

and engine hooks.

Vehicle Identification NumberS7RS0B0101007

The number is punched close by the right side strut

support in engine room and it is also attached on the left

side of instrument panel depending on the vehicle

specification.

Engine Identification NumberS7RS0B0101008

The number is punched on cylinder block.

Transmission Identification NumberS7RS0B0101009

The automatic transmission identification number is

located on transmission case.

2

2

2

1

I4RS0A010005-01

I4RS0B010003-01

I3RM0A010005-01

I4RS0A010008-01

Page 29 of 1496

Downloaded from www.Manualslib.com manuals search engine General Information: 0A-8

Component Location

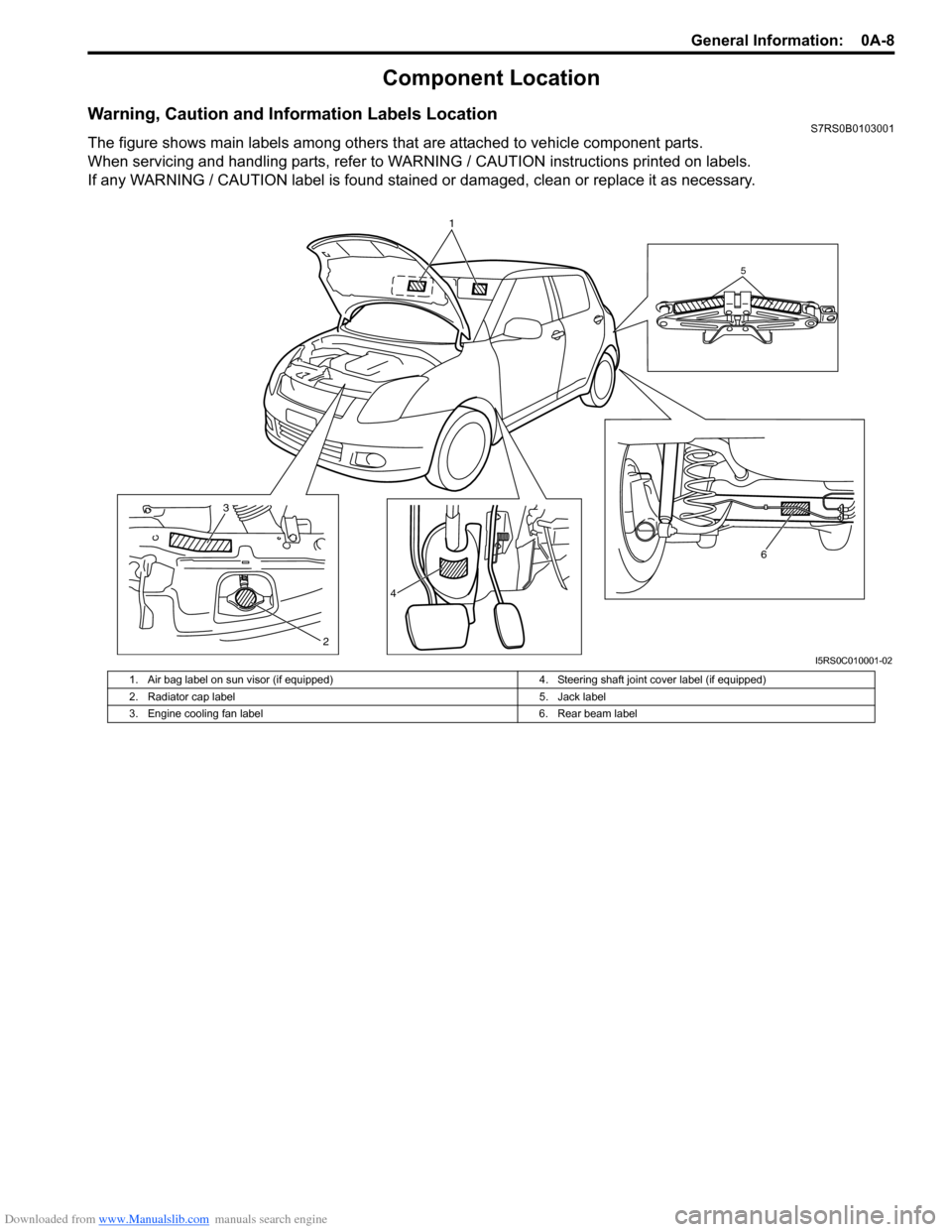

Warning, Caution and Information Labels LocationS7RS0B0103001

The figure shows main labels among others that are attached to vehicle component parts.

When servicing and handling parts, refer to WARNING / CAUTION instructions printed on labels.

If any WARNING / CAUTION label is found stained or damaged, clean or replace it as necessary.

1

2

3

4

6

5

I5RS0C010001-02

1. Air bag label on sun visor (if equipped) 4.Steering shaft joint cover label (if equipped)

2. Radiator cap label 5. Jack label

3. Engine cooling fan label 6. Rear beam label

Page 36 of 1496

Downloaded from www.Manualslib.com manuals search engine 0B-6 Maintenance and Lubrication:

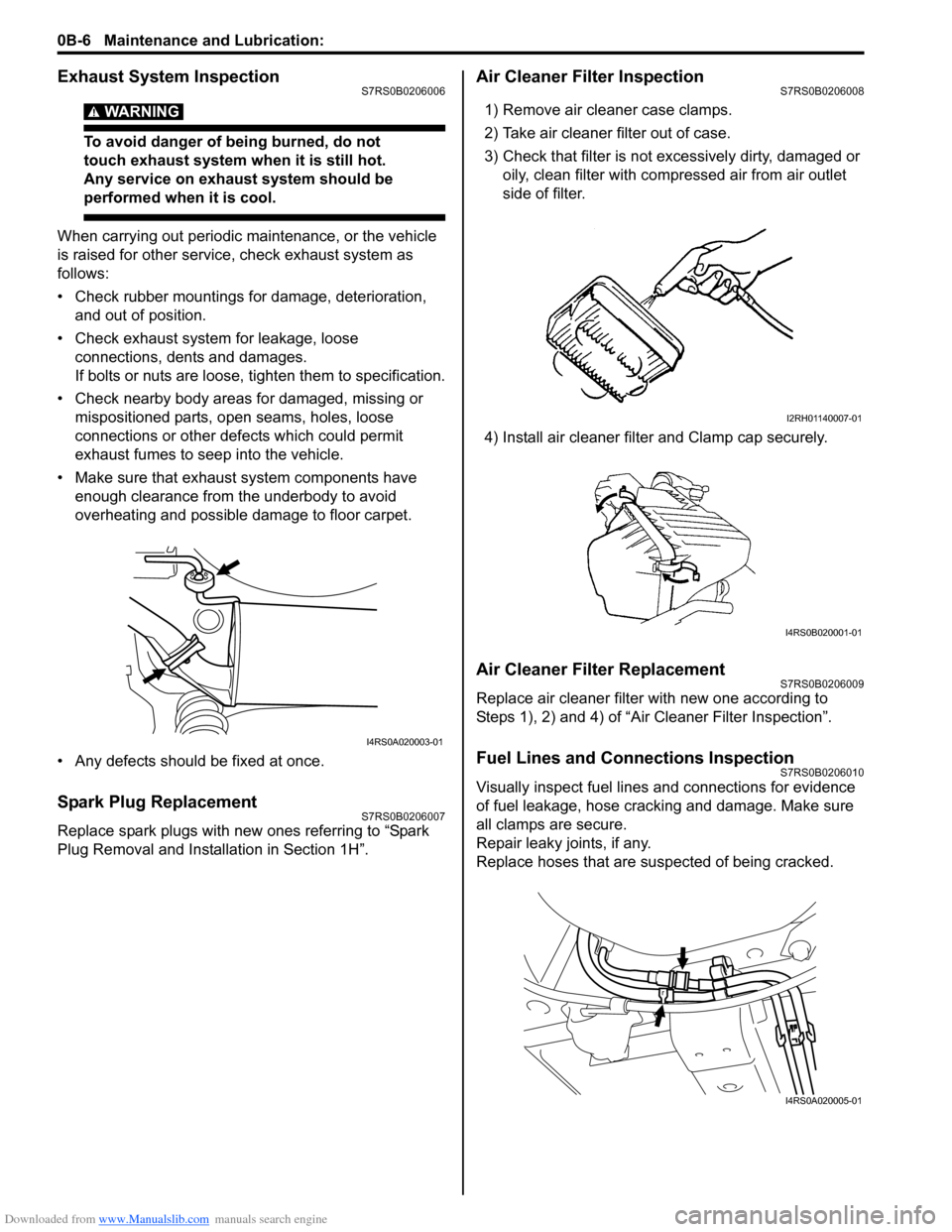

Exhaust System InspectionS7RS0B0206006

WARNING!

To avoid danger of being burned, do not

touch exhaust system when it is still hot.

Any service on exhaust system should be

performed when it is cool.

When carrying out periodic maintenance, or the vehicle

is raised for other service, check exhaust system as

follows:

• Check rubber mountings for damage, deterioration, and out of position.

• Check exhaust system for leakage, loose connections, dents and damages.

If bolts or nuts are loose, tighten them to specification.

• Check nearby body areas for damaged, missing or mispositioned parts, ope n seams, holes, loose

connections or other defects which could permit

exhaust fumes to seep into the vehicle.

• Make sure that exhaust system components have enough clearance from the underbody to avoid

overheating and possible damage to floor carpet.

• Any defects should be fixed at once.

Spark Plug ReplacementS7RS0B0206007

Replace spark plugs with new ones referring to “Spark

Plug Removal and Installation in Section 1H”.

Air Cleaner Filter InspectionS7RS0B0206008

1) Remove air cleaner case clamps.

2) Take air cleaner filter out of case.

3) Check that filter is not excessively dirty, damaged or oily, clean filter with compressed air from air outlet

side of filter.

4) Install air cleaner filter and Clamp cap securely.

Air Cleaner Filter ReplacementS7RS0B0206009

Replace air cleaner filter with new one according to

Steps 1), 2) and 4) of “Air Cleaner Filter Inspection”.

Fuel Lines and Connections InspectionS7RS0B0206010

Visually inspect fuel lines and connections for evidence

of fuel leakage, hose cracking and damage. Make sure

all clamps are secure.

Repair leaky joints, if any.

Replace hoses that are suspected of being cracked.

I4RS0A020003-01

I2RH01140007-01

I4RS0B020001-01

I4RS0A020005-01

Page 37 of 1496

Downloaded from www.Manualslib.com manuals search engine Maintenance and Lubrication: 0B-7

Fuel Filter ReplacementS7RS0B0206011

Fuel filter is installed in fuel pump assembly in fuel tank.

Replace fuel filter or fuel pump assembly with new one,

referring to “Fuel Pump Assembly Removal and

Installation in Section 1G” for proper procedure.

Fuel Tank InspectionS7RS0B0206012

Check fuel tank damage, cracks, fuel leakage, corrosion

and tank bolts looseness.

If a problem is found, repair or replace.

PCV Valve InspectionS7RS0B0206013

Check crankcase ventilation hose and PCV hose for

leaks, cracks or clog, and PCV valve for stick or clog.

Refer to “PCV Valve Inspection in Section 1B” for PCV

valve checking procedure.

Fuel Evaporative Emission Control System

Inspection

S7RS0B0206014

1) Visually inspect hoses for cracks, damage, or excessive bends. Inspect a ll clamps for damage and

proper position.

2) Check EVAP canister for operation and clog, referring to “EVAP Canister Inspection in Section

1B”.

If a malfunction is found, repair or replace.

Brake Discs and Pads InspectionS7RS0B0206015

1) Remove wheel and caliper but don’t disconnect brake hose from caliper. 2) Check disc brake pads and discs for excessive wear,

damage and deflection. Replace parts as necessary.

For details, refer to “Front Disc Brake Pad Inspection

in Section 4B”, “Front Brake Disc Inspection in

Section 4B”, “Rear Disc Brake Pad Inspection in

Section 4C” and/or “Rear Brake Disc Inspection in

Section 4C”.

Be sure to torque caliper pin bolts to specification.

Brake Hoses and Pipes InspectionS7RS0B0206016

Perform this inspection where these is enough light and

use a mirror as necessary.

• Check brake hoses and pipes for proper hookup, leaks, cracks, chafing and other damage.

• Check that hoses and pipes are clear of sharp edges and moving parts.

Repair or replace any of these parts as necessary.

CAUTION!

After replacing any brake pipe or hose, be

sure to carry out air purge operation.

I4RS0B020002-02

I4RS0A020006-01

I3RM0A020006-01

I4RS0A020008-01

Page 39 of 1496

Downloaded from www.Manualslib.com manuals search engine Maintenance and Lubrication: 0B-9

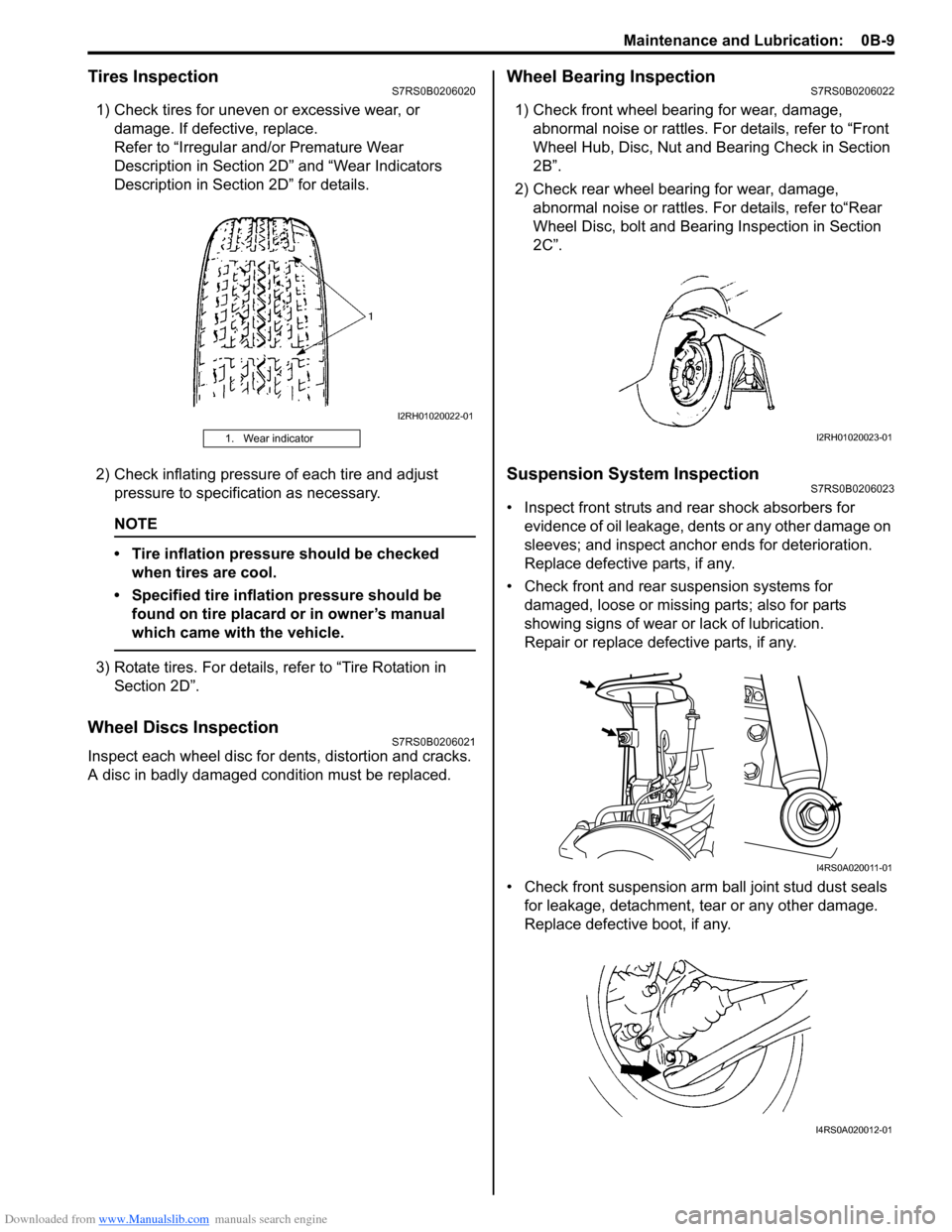

Tires InspectionS7RS0B0206020

1) Check tires for uneven or excessive wear, or damage. If defective, replace.

Refer to “Irregular and/or Premature Wear

Description in Section 2D” and “Wear Indicators

Description in Section 2D” for details.

2) Check inflating pressure of each tire and adjust pressure to specification as necessary.

NOTE

• Tire inflation pressure should be checked when tires are cool.

• Specified tire inflation pressure should be found on tire placard or in owner’s manual

which came with the vehicle.

3) Rotate tires. For details, refer to “Tire Rotation in Section 2D”.

Wheel Discs InspectionS7RS0B0206021

Inspect each wheel disc for de nts, distortion and cracks.

A disc in badly damaged condition must be replaced.

Wheel Bearing InspectionS7RS0B0206022

1) Check front wheel bearing for wear, damage, abnormal noise or rattles. For details, refer to “Front

Wheel Hub, Disc, Nut and Bearing Check in Section

2B”.

2) Check rear wheel bearing for wear, damage, abnormal noise or rattles. For details, refer to“Rear

Wheel Disc, bolt and Bearing Inspection in Section

2C”.

Suspension System InspectionS7RS0B0206023

• Inspect front struts and rear shock absorbers for evidence of oil leakage, dents or any other damage on

sleeves; and inspect anchor ends for deterioration.

Replace defective parts, if any.

• Check front and rear suspension systems for damaged, loose or missing parts; also for parts

showing signs of wear or lack of lubrication.

Repair or replace defective parts, if any.

• Check front suspension arm ball joint stud dust seals for leakage, detachment, tear or any other damage.

Replace defective boot, if any.

1. Wear indicator

I2RH01020022-01

I2RH01020023-01

I4RS0A020011-01

I4RS0A020012-01