Engine parts SUZUKI SWIFT 2006 2.G Service Service Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 320 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-35 Engine Mechanical:

Valves and Cylinder Head Removal and

Installation

S7RS0B1406024

Removal1) Remove engine assembly from vehicle referring to “Engine Assembly Removal and Installation”.

2) Remove oil pan referring to “Oil Pan and Oil Pump

Strainer Removal and Installation in Section 1E”.

3) Remove cylinder head cover referring to “Cylinder Head Cover Removal and Installation”.

4) Remove timing chain cover referring to Steps 2) to 11) of “Removal” in “Tim ing Chain Cover Removal

and Installation”.

5) Remove timing chain referring to Steps 2) to 6) of “Removal” in “Timing Chain and Chain Tensioner

Removal and Installation”.

6) Remove intake and exhaust camshafts referring to Steps 3) to 8) of “Removal” in “Camshaft, Tappet and

Shim Removal and Installation”.

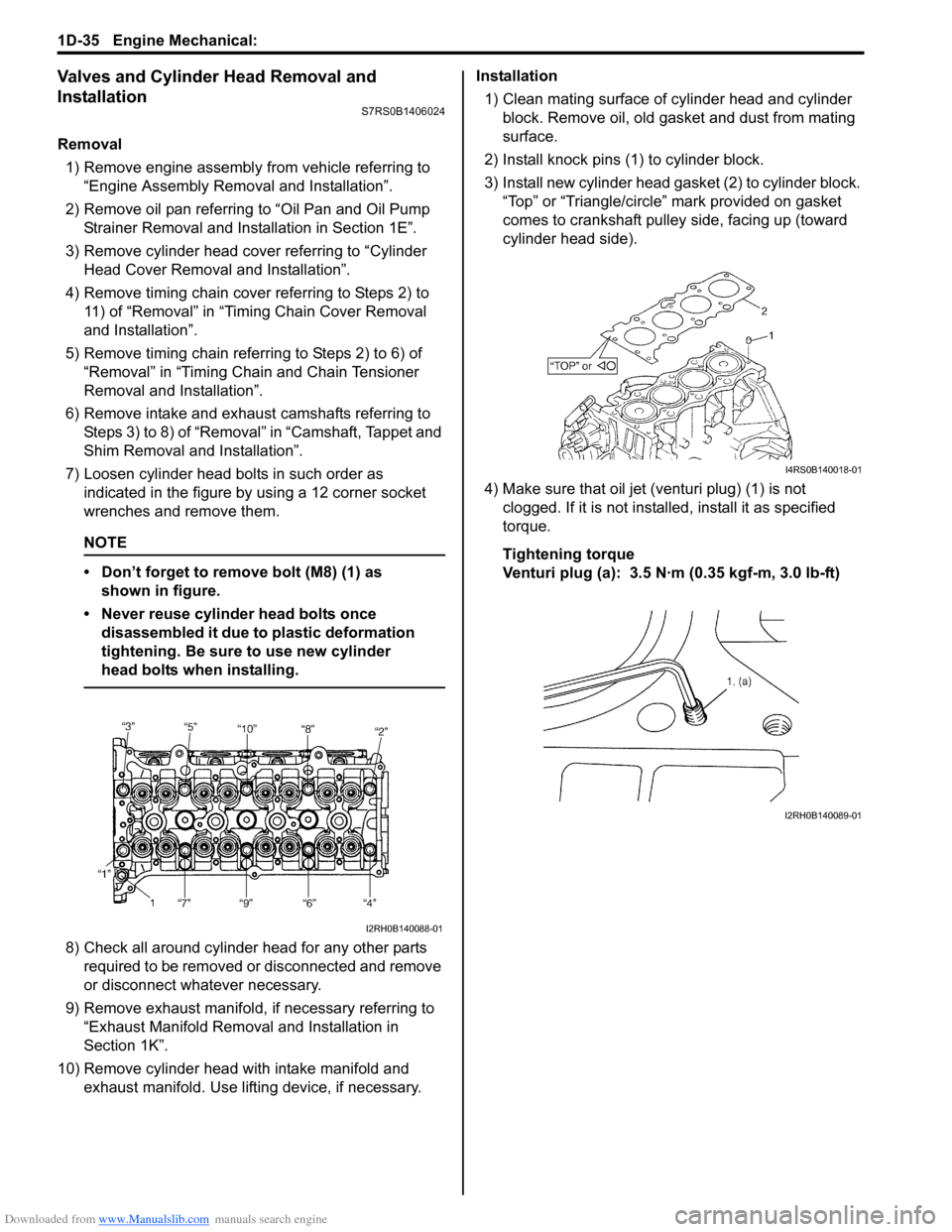

7) Loosen cylinder head bolts in such order as indicated in the figure by using a 12 corner socket

wrenches and remove them.

NOTE

• Don’t forget to remove bolt (M8) (1) as shown in figure.

• Never reuse cylinder head bolts once disassembled it due to plastic deformation

tightening. Be sure to use new cylinder

head bolts when installing.

8) Check all around cylinder head for any other parts required to be removed or disconnected and remove

or disconnect whatever necessary.

9) Remove exhaust manifold, if necessary referring to

“Exhaust Manifold Removal and Installation in

Section 1K”.

10) Remove cylinder head wi th intake manifold and

exhaust manifold. Use lifting device, if necessary. Installation

1) Clean mating surface of cylinder head and cylinder block. Remove oil, old gasket and dust from mating

surface.

2) Install knock pins (1) to cylinder block.

3) Install new cylinder head gasket (2) to cylinder block. “Top” or “Triangle/circle” mark provided on gasket

comes to crankshaft pulley side, facing up (toward

cylinder head side).

4) Make sure that oil jet (venturi plug) (1) is not clogged. If it is not install ed, install it as specified

torque.

Tightening torque

Venturi plug (a): 3.5 N·m (0.35 kgf-m, 3.0 lb-ft)

I2RH0B140088-01

I4RS0B140018-01

I2RH0B140089-01

Page 322 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-37 Engine Mechanical:

Valves and Cylinder Head Disassembly and

Assembly

S7RS0B1406025

Disassembly1) For ease in servicing cylinder head, remove intake manifold, injectors, exhaust manifold from cylinder

head.

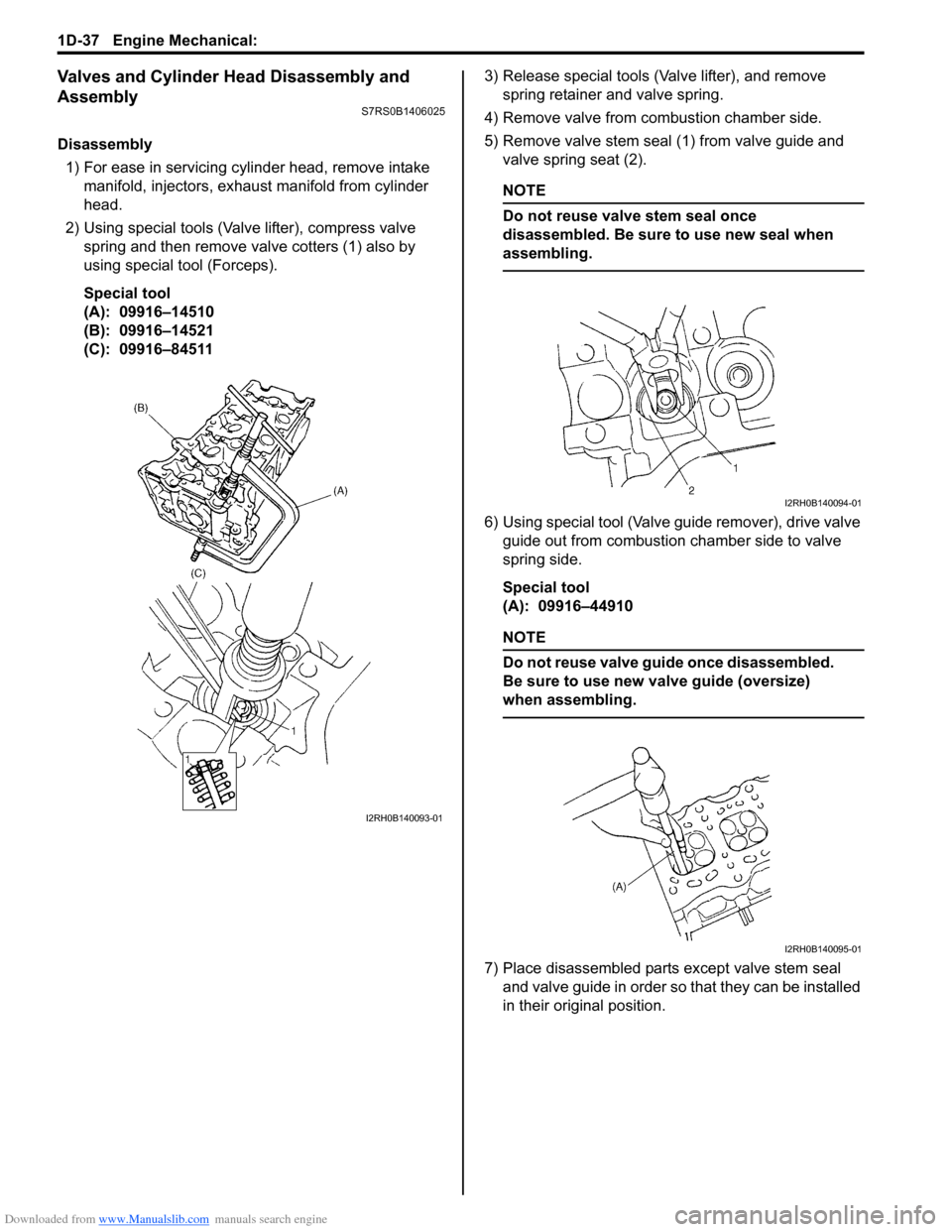

2) Using special tools (Val ve lifter), compress valve

spring and then remove valve cotters (1) also by

using special tool (Forceps).

Special tool

(A): 09916–14510

(B): 09916–14521

(C): 09916–84511 3) Release special tools (Valve lifter), and remove

spring retainer and valve spring.

4) Remove valve from combustion chamber side.

5) Remove valve stem seal (1) from valve guide and valve spring seat (2).

NOTE

Do not reuse valve stem seal once

disassembled. Be sure to use new seal when

assembling.

6) Using special tool (Valve guide remover), drive valve guide out from combustion chamber side to valve

spring side.

Special tool

(A): 09916–44910

NOTE

Do not reuse valve guide once disassembled.

Be sure to use new va lve guide (oversize)

when assembling.

7) Place disassembled parts except valve stem seal

and valve guide in order so that they can be installed

in their original position.

I2RH0B140093-01

I2RH0B140094-01

I2RH0B140095-01

Page 340 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-55 Engine Mechanical:

Installation

NOTE

• Use new bearing cap No.1 bolts. They are deformed once they are used because they

are plastic deformation tightening bolts.

• All parts to be insta lled must be perfectly

clean.

• Be sure to oil crankshaft journals, journal bearings, thrust bearings, crankpins,

connecting rod bearings, pistons, piston

rings and cylinder bores.

• Journal bearings, bearing caps, connecting rods, rod bearings, rod bearing

caps, pistons and piston rings are in

combination sets. Do not disturb such

combination and make sure that each part

goes back to where it came from, when

installing.

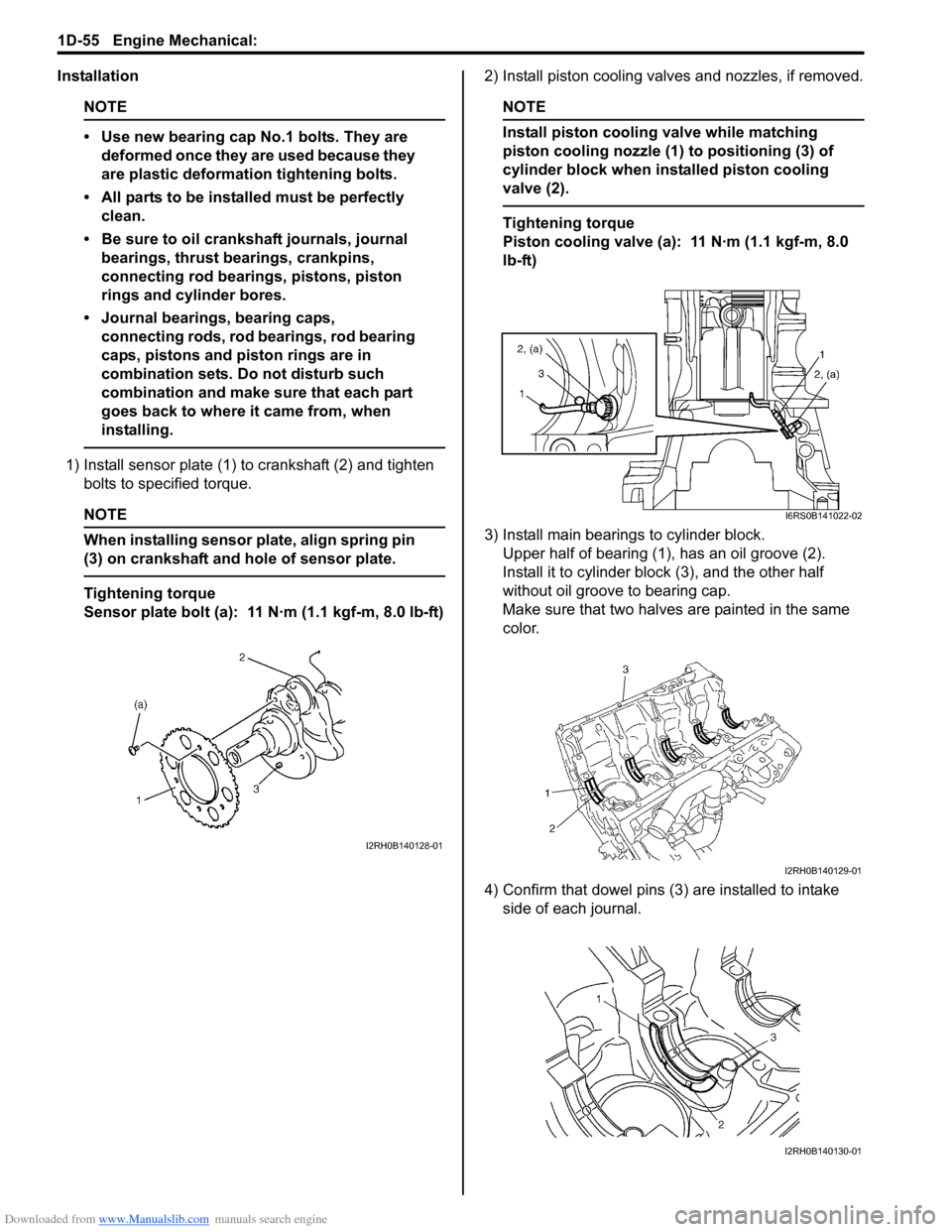

1) Install sensor plate (1) to crankshaft (2) and tighten bolts to spec ified torque.

NOTE

When installing sensor plate, align spring pin

(3) on crankshaft and hole of sensor plate.

Tightening torque

Sensor plate bolt (a): 11 N·m (1.1 kgf-m, 8.0 lb-ft) 2) Install piston cooling valves and nozzles, if removed.

NOTE

Install piston cooling valve while matching

piston cooling nozzle (1) to positioning (3) of

cylinder block when installed piston cooling

valve (2).

Tightening torque

Piston cooling valve (a): 11 N·m (1.1 kgf-m, 8.0

lb-ft)

3) Install main bearings to cylinder block. Upper half of bearing (1), has an oil groove (2).

Install it to cylinder block (3), and the other half

without oil groove to bearing cap.

Make sure that two halves are painted in the same

color.

4) Confirm that dowel pins (3 ) are installed to intake

side of each journal.

I2RH0B140128-01

I6RS0B141022-02

I2RH0B140129-01

I2RH0B140130-01

Page 361 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Lubrication System: 1E-9

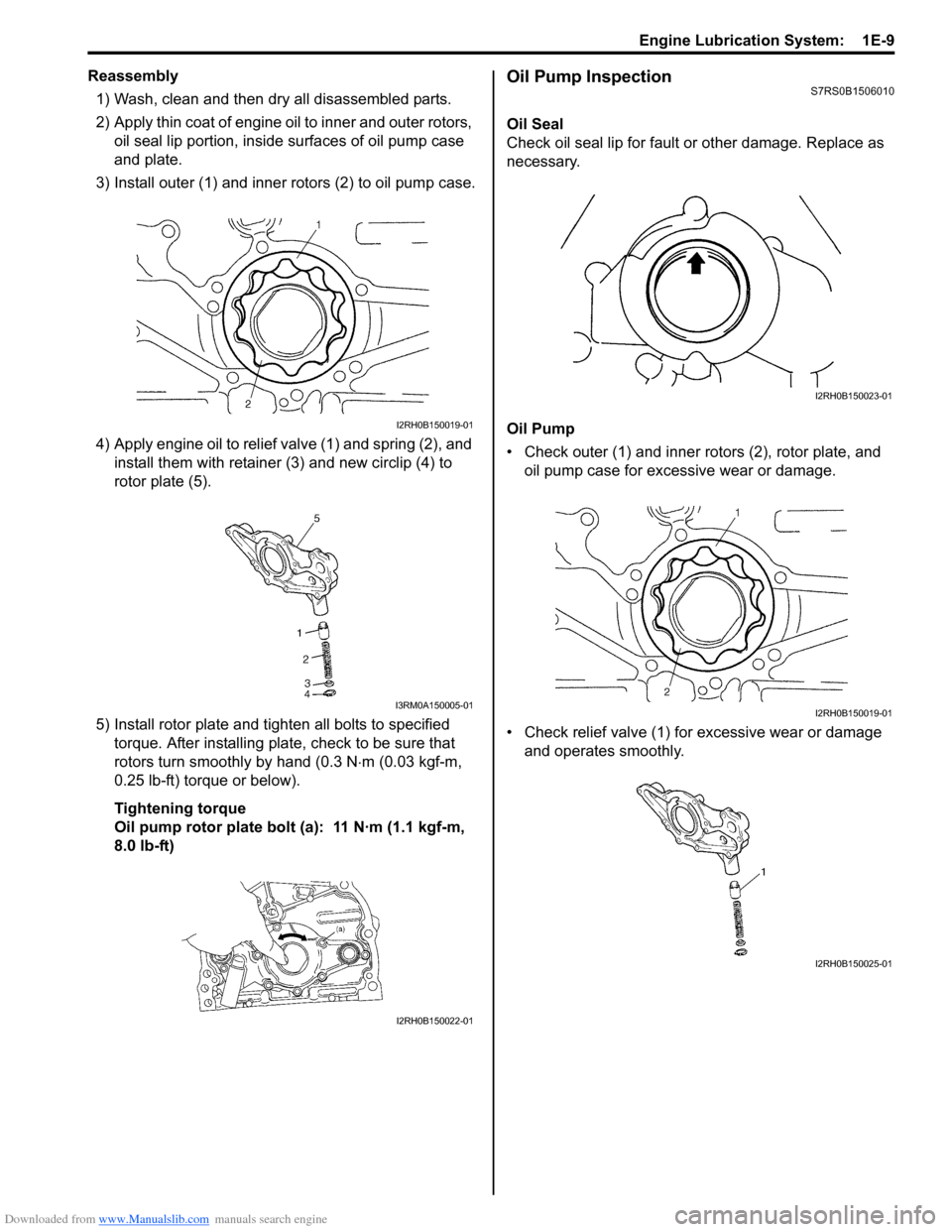

Reassembly1) Wash, clean and then dry all disassembled parts.

2) Apply thin coat of engine oil to inner and outer rotors, oil seal lip portion, inside surfaces of oil pump case

and plate.

3) Install outer (1) and inner rotors (2) to oil pump case.

4) Apply engine oil to relief valve (1) and spring (2), and install them with retainer (3) and new circlip (4) to

rotor plate (5).

5) Install rotor plate and tighten all bolts to specified torque. After installing plate, check to be sure that

rotors turn smoothly by hand (0.3 N ⋅m (0.03 kgf-m,

0.25 lb-ft) torque or below).

Tightening torque

Oil pump rotor plate bolt (a): 11 N·m (1.1 kgf-m,

8.0 lb-ft)Oil Pump InspectionS7RS0B1506010

Oil Seal

Check oil seal lip for fault or other damage. Replace as

necessary.

Oil Pump

• Check outer (1) and inner rotors (2), rotor plate, and oil pump case for excessive wear or damage.

• Check relief valve (1) for excessive wear or damage

and operates smoothly.

I2RH0B150019-01

I3RM0A150005-01

I2RH0B150022-01

I2RH0B150023-01

I2RH0B150019-01

I2RH0B150025-01

Page 370 of 1496

Downloaded from www.Manualslib.com manuals search engine 1F-7 Engine Cooling System:

Cooling System Flush and RefillS7RS0B1606005

WARNING!

To help avoid danger of being burned, do not

remove radiator cap while engine and

radiator are still hot. Scalding fluid and steam

can be blown out under pressure if cap is

taken off too soon.

NOTE

For detail of coolant specification, refer to

“Coolant Description”.

1) Remove radiator cap when engine is cool as follows.a) Turn cap counterclockwise slowly until it reaches a “stop” (Do not press down while turning it).

b) Wait until pressure is relieved (indicated by a hissing sound) then press down on cap and

continue to turn it counterclockwise.

2) With radiator cap removed, run engine until upper radiator hose is hot (this shows that thermostat is

open and coolant is flowing through system).

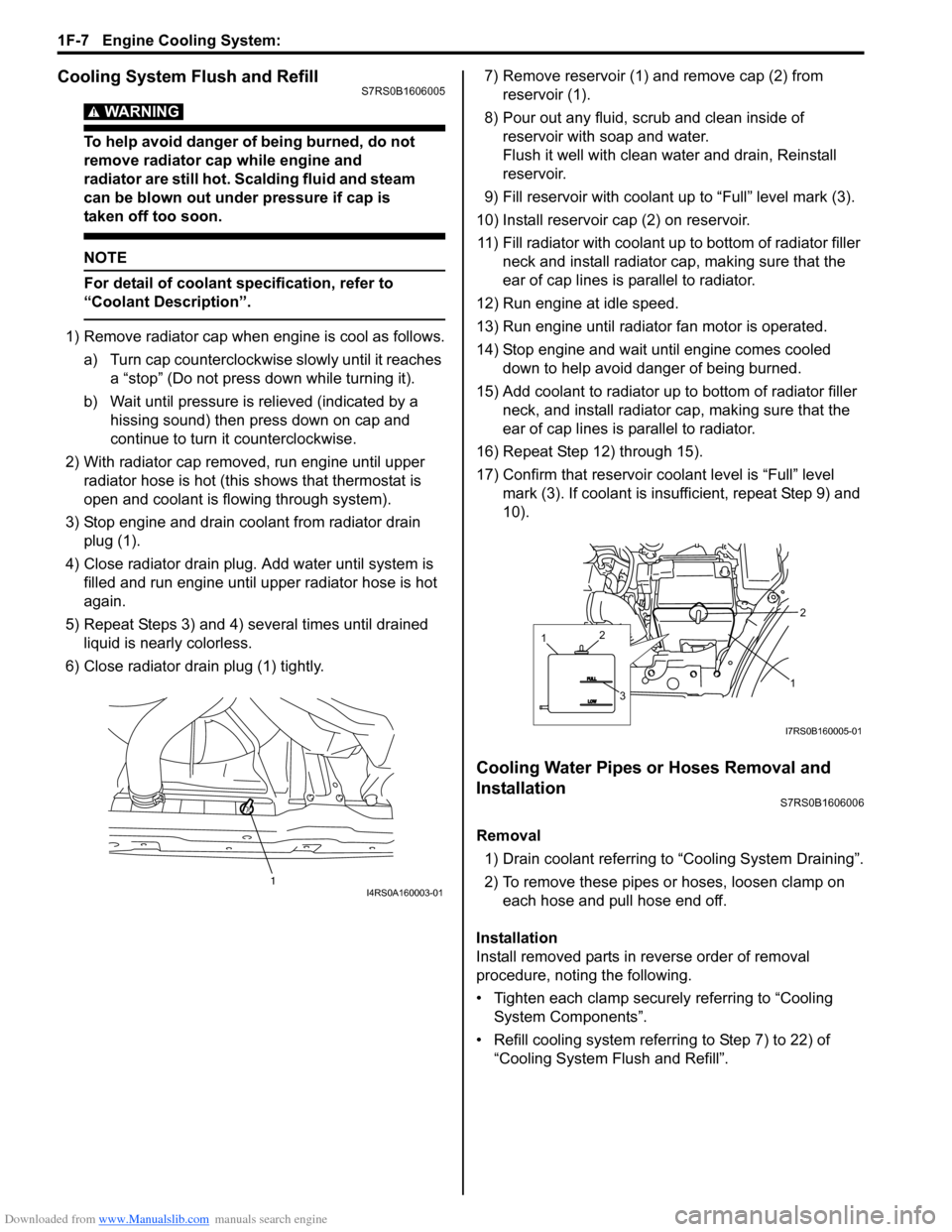

3) Stop engine and drain coolant from radiator drain plug (1).

4) Close radiator drain plug. Add water until system is filled and run engine until up per radiator hose is hot

again.

5) Repeat Steps 3) and 4) several times until drained liquid is nearly colorless.

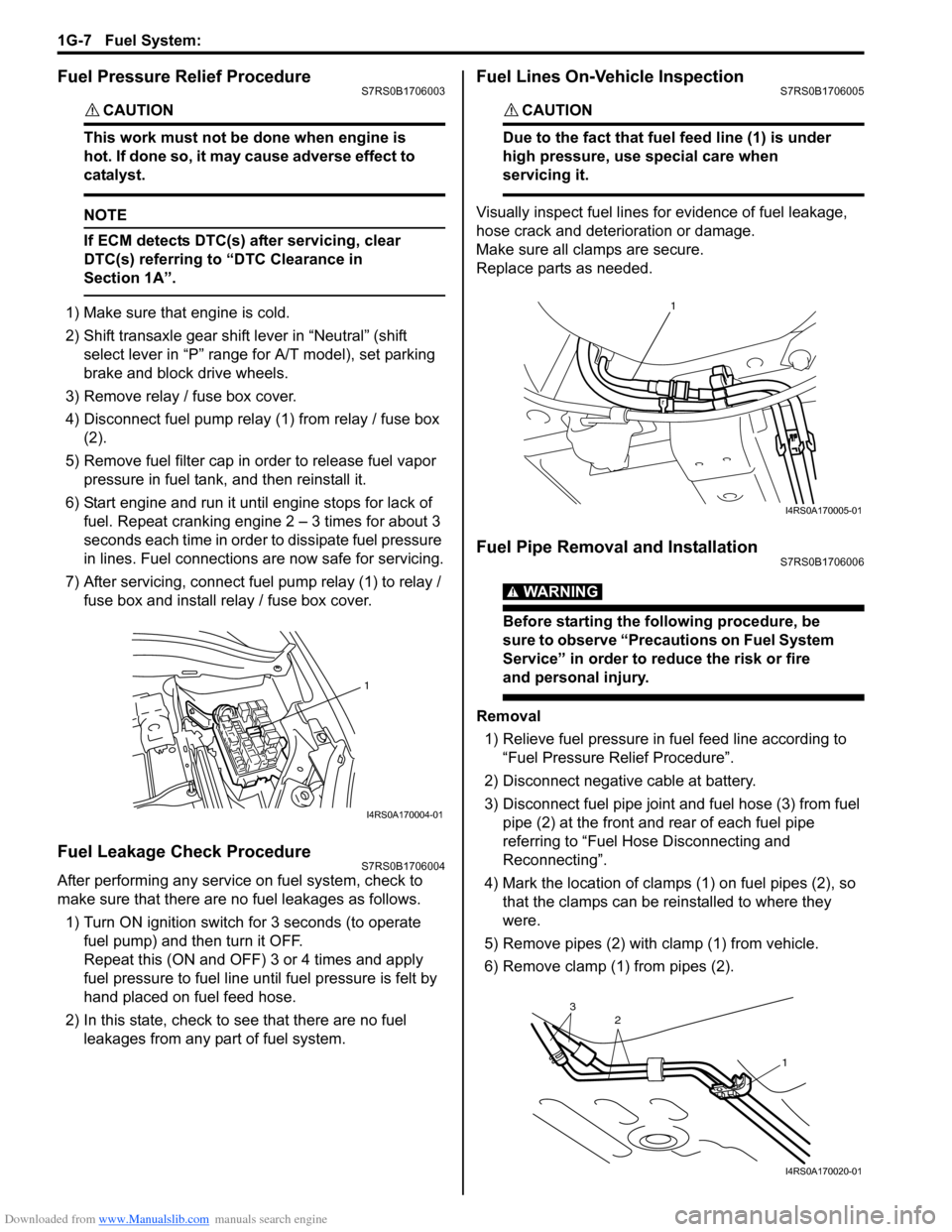

6) Close radiator drain plug (1) tightly. 7) Remove reservoir (1) and remove cap (2) from

reservoir (1).

8) Pour out any fluid, scrub and clean inside of reservoir with soap and water.

Flush it well with clean water and drain, Reinstall

reservoir.

9) Fill reservoir with coolant up to “Full” level mark (3).

10) Install reservoir cap (2) on reservoir. 11) Fill radiator with coolant up to bottom of radiator filler neck and install radiator cap, making sure that the

ear of cap lines is parallel to radiator.

12) Run engine at idle speed.

13) Run engine until radiator fan motor is operated.

14) Stop engine and wait until engine comes cooled down to help avoid danger of being burned.

15) Add coolant to radiator up to bottom of radiator filler

neck, and install radiator ca p, making sure that the

ear of cap lines is parallel to radiator.

16) Repeat Step 12) through 15).

17) Confirm that reservoir cool ant level is “Full” level

mark (3). If coolant is insu fficient, repeat Step 9) and

10).

Cooling Water Pipes or Hoses Removal and

Installation

S7RS0B1606006

Removal

1) Drain coolant referring to “Cooling System Draining”.

2) To remove these pipes or hoses, loosen clamp on each hose and pull hose end off.

Installation

Install removed parts in reverse order of removal

procedure, noting the following.

• Tighten each clamp securely referring to “Cooling System Components”.

• Refill cooling system referrin g to Step 7) to 22) of

“Cooling System Flush and Refill”.

1I4RS0A160003-01

1

2

1

3

2

I7RS0B160005-01

Page 382 of 1496

Downloaded from www.Manualslib.com manuals search engine 1G-7 Fuel System:

Fuel Pressure Relief ProcedureS7RS0B1706003

CAUTION!

This work must not be done when engine is

hot. If done so, it may cause adverse effect to

catalyst.

NOTE

If ECM detects DTC(s) after servicing, clear

DTC(s) referring to “DTC Clearance in

Section 1A”.

1) Make sure that engine is cold.

2) Shift transaxle gear shift lever in “Neutral” (shift select lever in “P” range for A/T model), set parking

brake and block drive wheels.

3) Remove relay / fuse box cover.

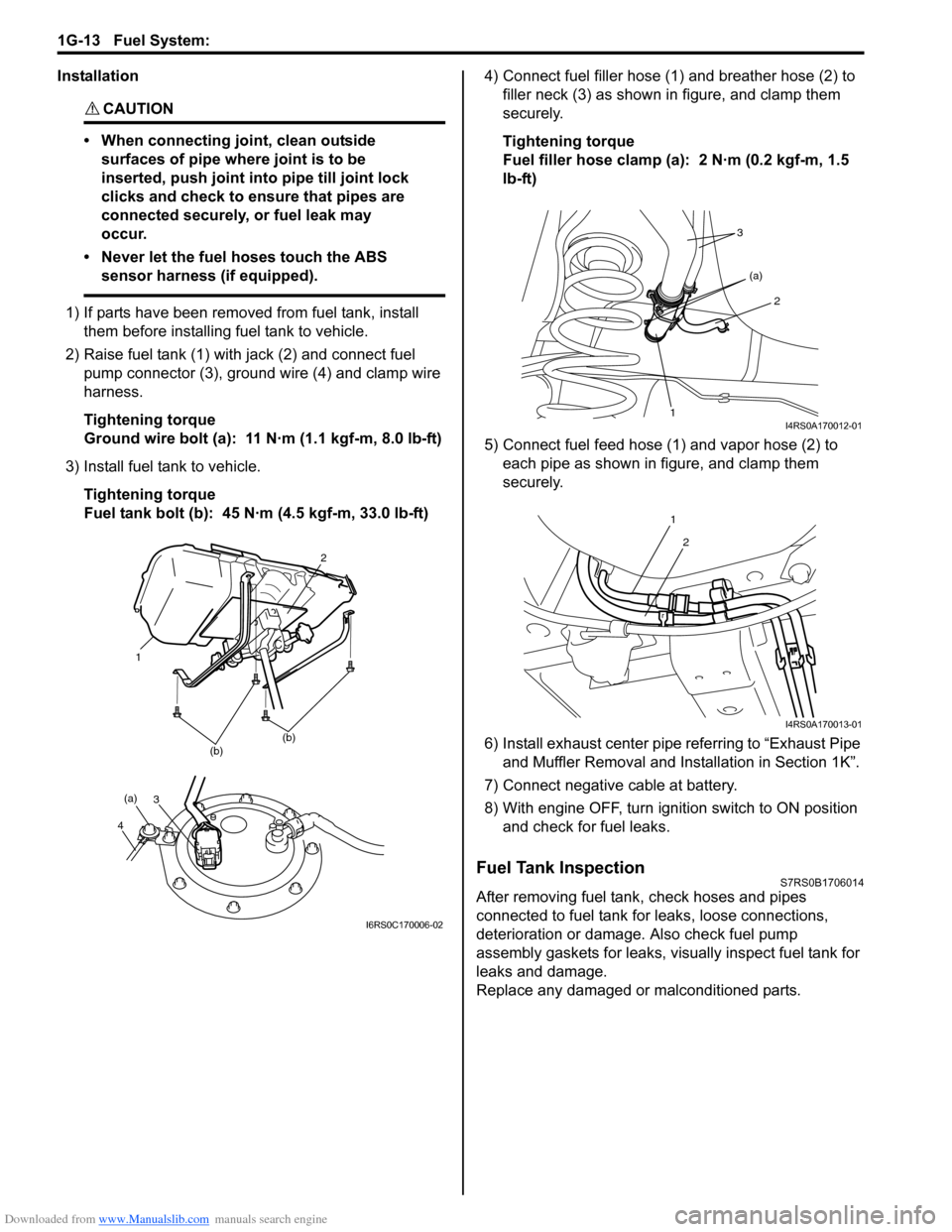

4) Disconnect fuel pump relay (1) from relay / fuse box (2).

5) Remove fuel filter cap in order to release fuel vapor pressure in fuel tank, and then reinstall it.

6) Start engine and run it until engine stops for lack of fuel. Repeat cranking engine 2 – 3 times for about 3

seconds each time in order to dissipate fuel pressure

in lines. Fuel connections are now safe for servicing.

7) After servicing, connect fuel pump relay (1) to relay / fuse box and install re lay / fuse box cover.

Fuel Leakage Check ProcedureS7RS0B1706004

After performing any service on fuel system, check to

make sure that there are no fuel leakages as follows.

1) Turn ON ignition switch for 3 seconds (to operate fuel pump) and then turn it OFF.

Repeat this (ON and OFF) 3 or 4 times and apply

fuel pressure to fuel line until fuel pressure is felt by

hand placed on fuel feed hose.

2) In this state, check to see that there are no fuel leakages from any part of fuel system.

Fuel Lines On-Vehicle InspectionS7RS0B1706005

CAUTION!

Due to the fact that fuel feed line (1) is under

high pressure, use special care when

servicing it.

Visually inspect fuel lines for evidence of fuel leakage,

hose crack and deterioration or damage.

Make sure all cl amps are secure.

Replace parts as needed.

Fuel Pipe Removal and InstallationS7RS0B1706006

WARNING!

Before starting the following procedure, be

sure to observe “Precautions on Fuel System

Service” in order to reduce the risk or fire

and personal injury.

Removal

1) Relieve fuel pressure in fuel feed line according to “Fuel Pressure Relief Procedure”.

2) Disconnect negative cable at battery.

3) Disconnect fuel pipe joint and fuel hose (3) from fuel pipe (2) at the front and rear of each fuel pipe

referring to “Fuel Hose Disconnecting and

Reconnecting”.

4) Mark the location of clamps (1) on fuel pipes (2), so that the clamps can be reinstalled to where they

were.

5) Remove pipes (2) with clamp (1) from vehicle.

6) Remove clamp (1) from pipes (2).

1

I4RS0A170004-01

1

I4RS0A170005-01

2

13

I4RS0A170020-01

Page 388 of 1496

Downloaded from www.Manualslib.com manuals search engine 1G-13 Fuel System:

Installation

CAUTION!

• When connecting joint, clean outside surfaces of pipe where joint is to be

inserted, push joint into pipe till joint lock

clicks and check to ensure that pipes are

connected securely, or fuel leak may

occur.

• Never let the fuel hoses touch the ABS sensor harness (if equipped).

1) If parts have been removed from fuel tank, install them before installing fuel tank to vehicle.

2) Raise fuel tank (1) with jack (2) and connect fuel pump connector (3), ground wire (4) and clamp wire

harness.

Tightening torque

Ground wire bolt (a): 11 N·m (1.1 kgf-m, 8.0 lb-ft)

3) Install fuel tank to vehicle. Tightening torque

Fuel tank bolt (b): 45 N·m (4.5 kgf-m, 33.0 lb-ft) 4) Connect fuel filler hose (1

) and breather hose (2) to

filler neck (3) as shown in figure, and clamp them

securely.

Tightening torque

Fuel filler hose clamp (a): 2 N·m (0.2 kgf-m, 1.5

lb-ft)

5) Connect fuel feed hose (1) and vapor hose (2) to each pipe as shown in figure, and clamp them

securely.

6) Install exhaust center pipe referring to “Exhaust Pipe and Muffler Removal and Installation in Section 1K”.

7) Connect negative cable at battery.

8) With engine OFF, turn ignition switch to ON position and check for fuel leaks.

Fuel Tank InspectionS7RS0B1706014

After removing fuel tank, check hoses and pipes

connected to fuel tank for leaks, loose connections,

deterioration or damage. Also check fuel pump

assembly gaskets for leaks, visually inspect fuel tank for

leaks and damage.

Replace any damaged or malconditioned parts.

(b)(b)

1

2

3

4

(a)

I6RS0C170006-02

1

2

(a)

3

I4RS0A170012-01

1

2

I4RS0A170013-01

Page 393 of 1496

Downloaded from www.Manualslib.com manuals search engine Ignition System: 1H-1

Engine

Ignition System

General Description

Ignition System ConstructionS7RS0B1801001

The ignition system is an electronic (distributorless) ignition system. It consists of the parts as described below.

• ECM

It detects the engine and vehicle conditions through the si gnals from the sensors, determines the most suitable

ignition timing and time for electricity to flow to the primar y coil and sends a signal to the ignitor (power unit) in the

ignition coil assembly.

• Ignition coil assembly (including an ignitor)

The ignition coil assembly has a built -in ignitor which turns ON and OFF the current flow to the primary coil

according to the signal from ECM. When the current flow to the primary coil is turned OFF, a high voltage is induced

in the secondary coil.

• High-tension cords and spark plugs

• CMP sensor (Camshaft position sensor) and CKP sensor (Crankshaft position sensor)

Using signals from these sensors, ECM identifies the specific cylinder whose piston is in the compression stroke,

detects the crank angle and adjusts in itial ignition timing automatically.

• TP sensor, ECT sensor, MAP sensor, MAF sensor, IAT sensor, knock sensor and other sensors / switches

Although this ignition system does not have a distributor, it has two ignition coil assemblies (one is for No.1 and No.4

spark plugs and the other is for No.2 and No.3 spark plugs). W hen an ignition signal is sent from ECM to the ignitor in

the ignition coil assembly for No.1 and No.4 spark plugs, a high voltage is induced in the secondary coil and that

passes through the high-tension cords and causes No.1 and No.4 spark plugs to spark simultaneously. Likewise,

when an ignition signal is sent to the ignitor in the ot her ignition coil assembly, No.2 and No.3 spark plugs spark

simultaneously.

Page 395 of 1496

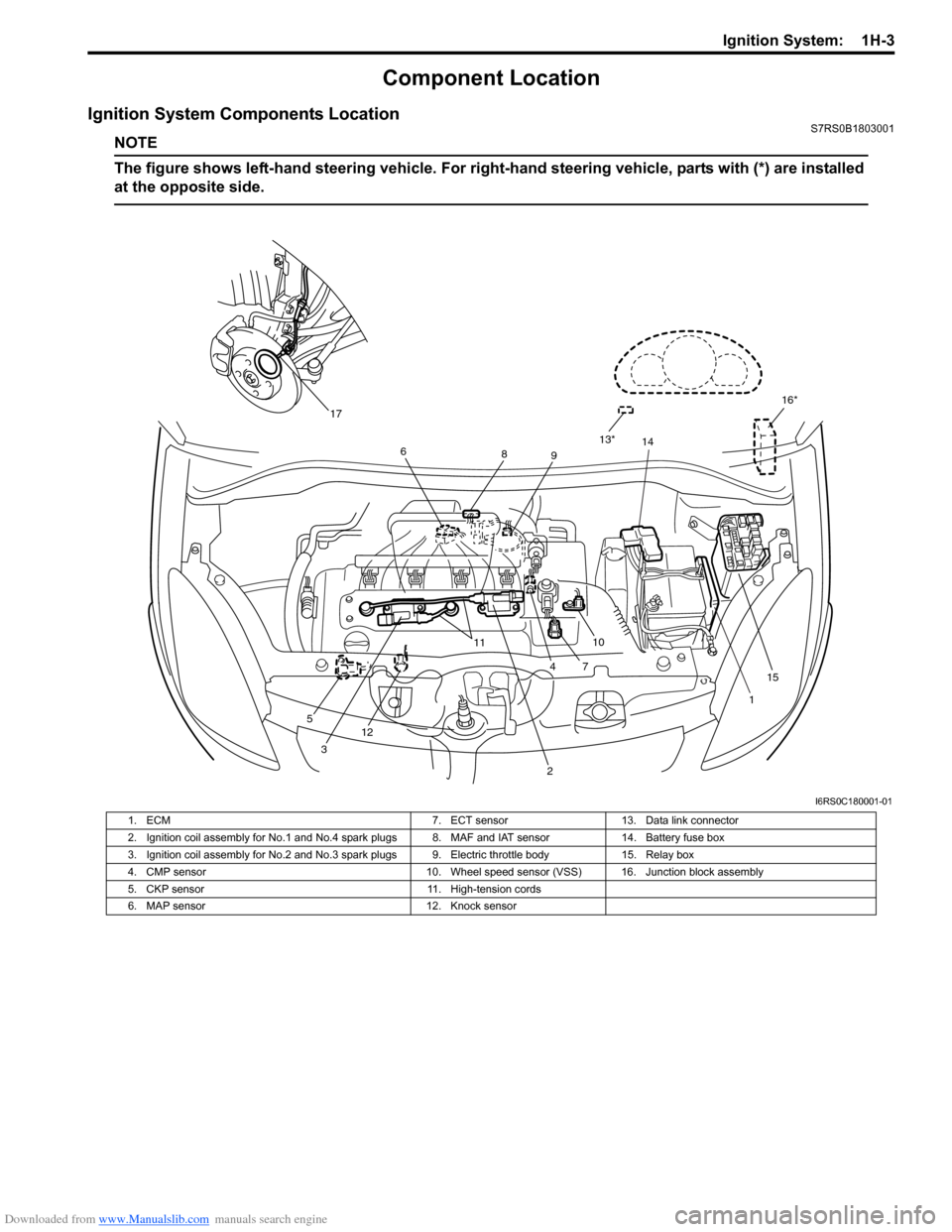

Downloaded from www.Manualslib.com manuals search engine Ignition System: 1H-3

Component Location

Ignition System Components LocationS7RS0B1803001

NOTE

The figure shows left-hand steering vehicle. For right-hand steering vehicle, parts with (*) are installed

at the opposite side.

16*

1

2

14

7

5 12 11

410

6

89

3 13*

15

17

I6RS0C180001-01

1. ECM 7. ECT sensor13. Data link connector

2. Ignition coil assembly for No.1 and No.4 spark plugs 8. MAF and IAT sensor 14. Battery fuse box

3. Ignition coil assembly for No.2 and No.3 spark plugs 9. Electric throttle body 15. Relay box

4. CMP sensor 10. Wheel speed sensor (VSS) 16. Junction block assembly

5. CKP sensor 11. High-tension cords

6. MAP sensor 12. Knock sensor

Page 398 of 1496

Downloaded from www.Manualslib.com manuals search engine 1H-6 Ignition System:

Ignition Spark TestS7RS0B1804004

1) Remove air cleaner assembly with air intake pipe.

2) Disconnect all injector couplers from injectors.

WARNING!

Without disconnection of injector couplers,

combustible gas may come out from spark

plug holes during this test and may get

ignited in engine room.

3) Remove spark plug and check it for condition and

type referring to “Spark Plug Inspection”.

4) If OK, connect ignition coil coupler to ignition coil assembly and connect spark plug to ignition coil

assembly or high-tension cord. Ground spark plug. 5) Crank engine and check if each spark plug sparks.

6) If no spark is emitted, inspect the related parts as

described in “Ignition System Symptom Diagnosis”.

Repair Instructions

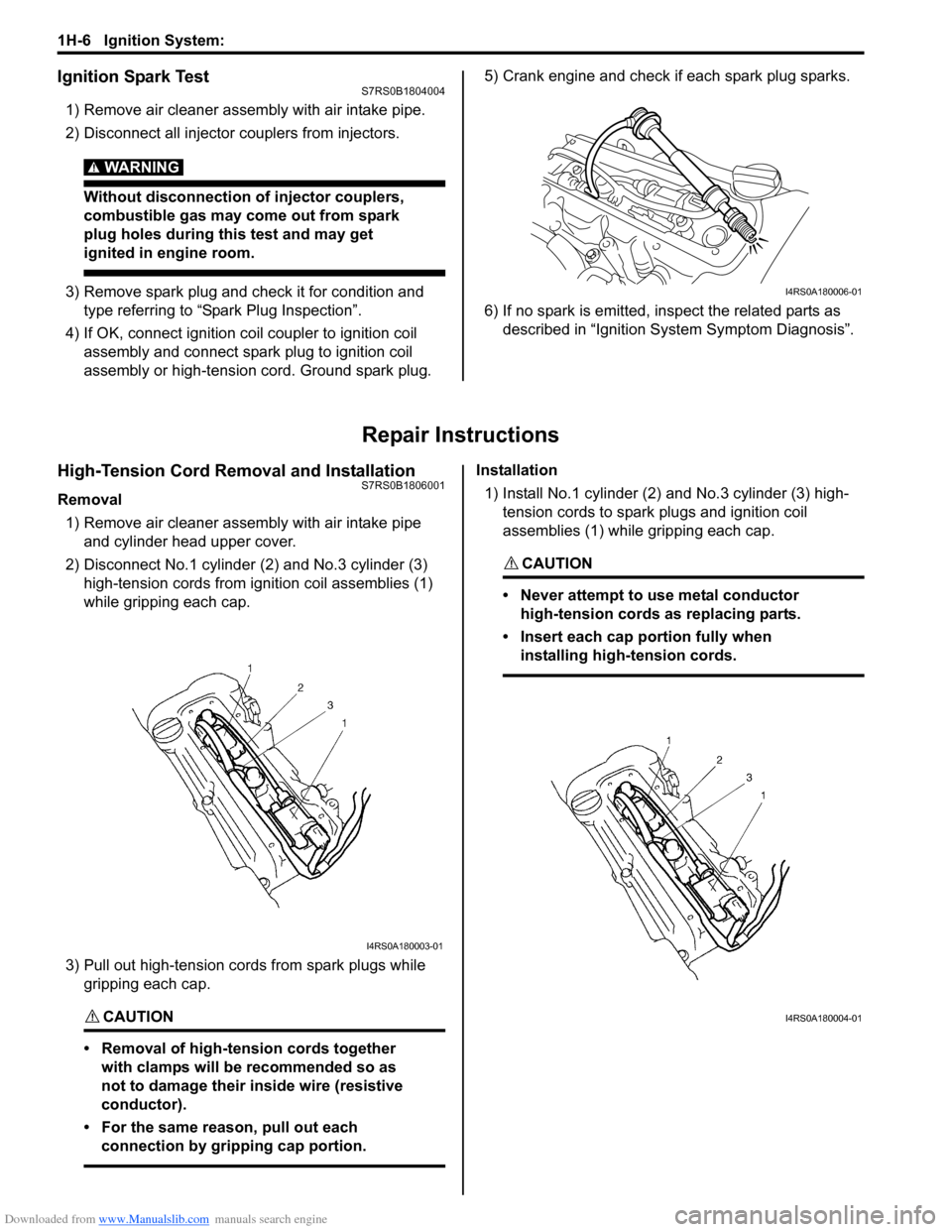

High-Tension Cord Removal and InstallationS7RS0B1806001

Removal

1) Remove air cleaner assembly with air intake pipe and cylinder head upper cover.

2) Disconnect No.1 cylinder (2) and No.3 cylinder (3)

high-tension cords from ignition coil assemblies (1)

while gripping each cap.

3) Pull out high-tension cords from spark plugs while gripping each cap.

CAUTION!

• Removal of high-tension cords together with clamps will be recommended so as

not to damage their inside wire (resistive

conductor).

• For the same reason, pull out each connection by gripping cap portion.

Installation

1) Install No.1 cylinder (2) and No.3 cylinder (3) high-

tension cords to spark plugs and ignition coil

assemblies (1) while gripping each cap.

CAUTION!

• Never attempt to use metal conductor high-tension cords as replacing parts.

• Insert each cap portion fully when installing high-tension cords.

I4RS0A180006-01

I4RS0A180003-01

I4RS0A180004-01