engine check light SUZUKI SWIFT 2006 2.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 76 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-26 Engine General Information and Diagnosis:

DTC CheckS7RS0B1104003

NOTE

• There are two types of OBD system depending on the vehicle specification.

For details, refer to “Precaution on On-

Board Diagnostic (OBD) System”.

• The MIL is turned on when the ECM and/or TCM detect malfunction(s). Each ECM and

TCM stores diagnostic information as the

diagnostic trouble code (DTC) in its

memory and outputs th e DTC to the scan

tool.

Therefore, check both of the ECM and TCM

for any DTC with the SUZUKI scan tool

because the DTC stored in ECM and TCM

is not read and displayed at a time.

However, each of the ECM and TCM needs

not to be checked with the generic scan

tool because the DTC stored in ECM and

TCM is read and displayed at a time.

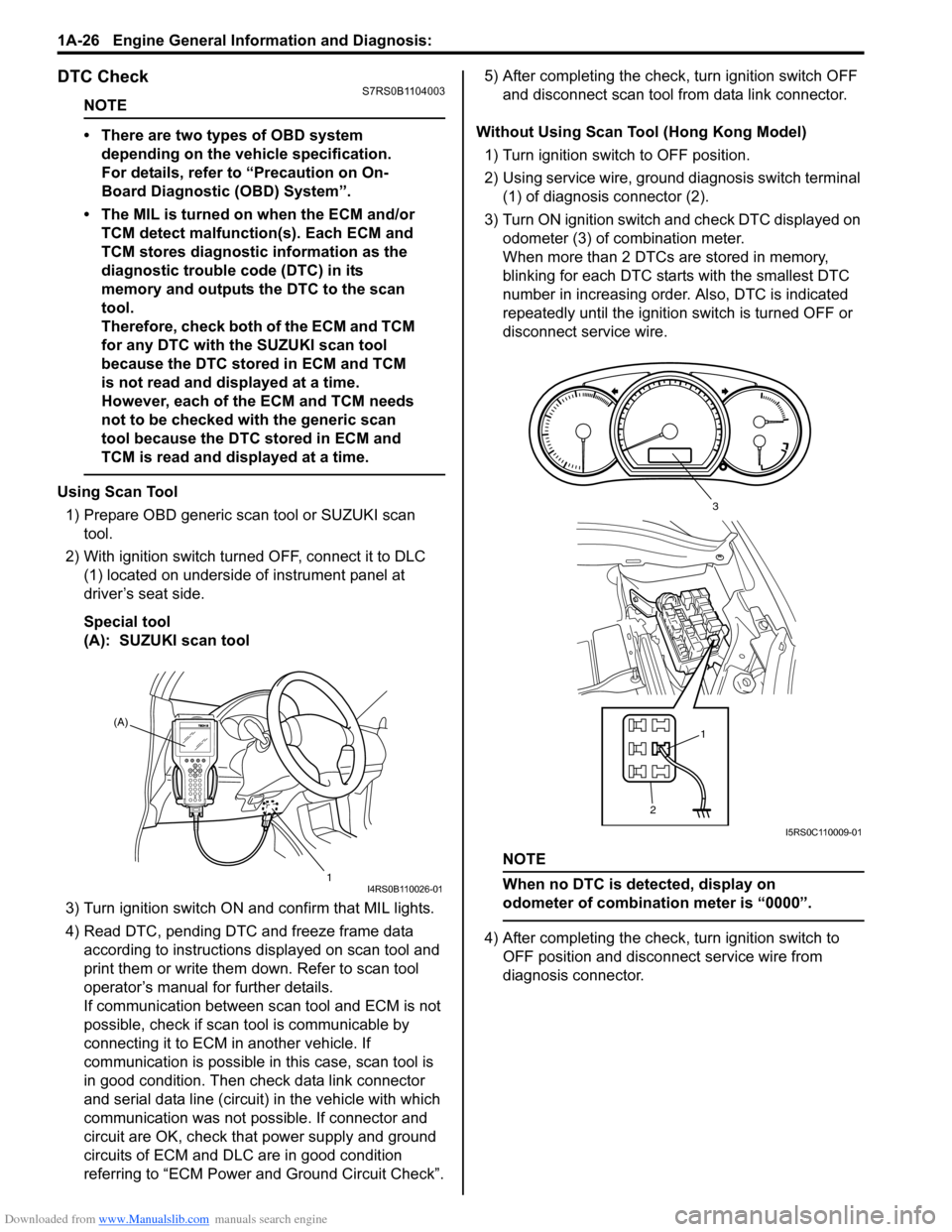

Using Scan Tool

1) Prepare OBD generic scan tool or SUZUKI scan tool.

2) With ignition switch turned OFF, connect it to DLC (1) located on underside of instrument panel at

driver’s seat side.

Special tool

(A): SUZUKI scan tool

3) Turn ignition switch ON and confirm that MIL lights.

4) Read DTC, pending DTC and freeze frame data according to instructions displayed on scan tool and

print them or write them down. Refer to scan tool

operator’s manual for further details.

If communication between scan tool and ECM is not

possible, check if scan tool is communicable by

connecting it to ECM in another vehicle. If

communication is possible in this case, scan tool is

in good condition. Then check data link connector

and serial data line (circuit) in the vehicle with which

communication was not possible. If connector and

circuit are OK, check that power supply and ground

circuits of ECM and DLC are in good condition

referring to “ECM Power and Ground Circuit Check”. 5) After completing the check,

turn ignition switch OFF

and disconnect scan tool from data link connector.

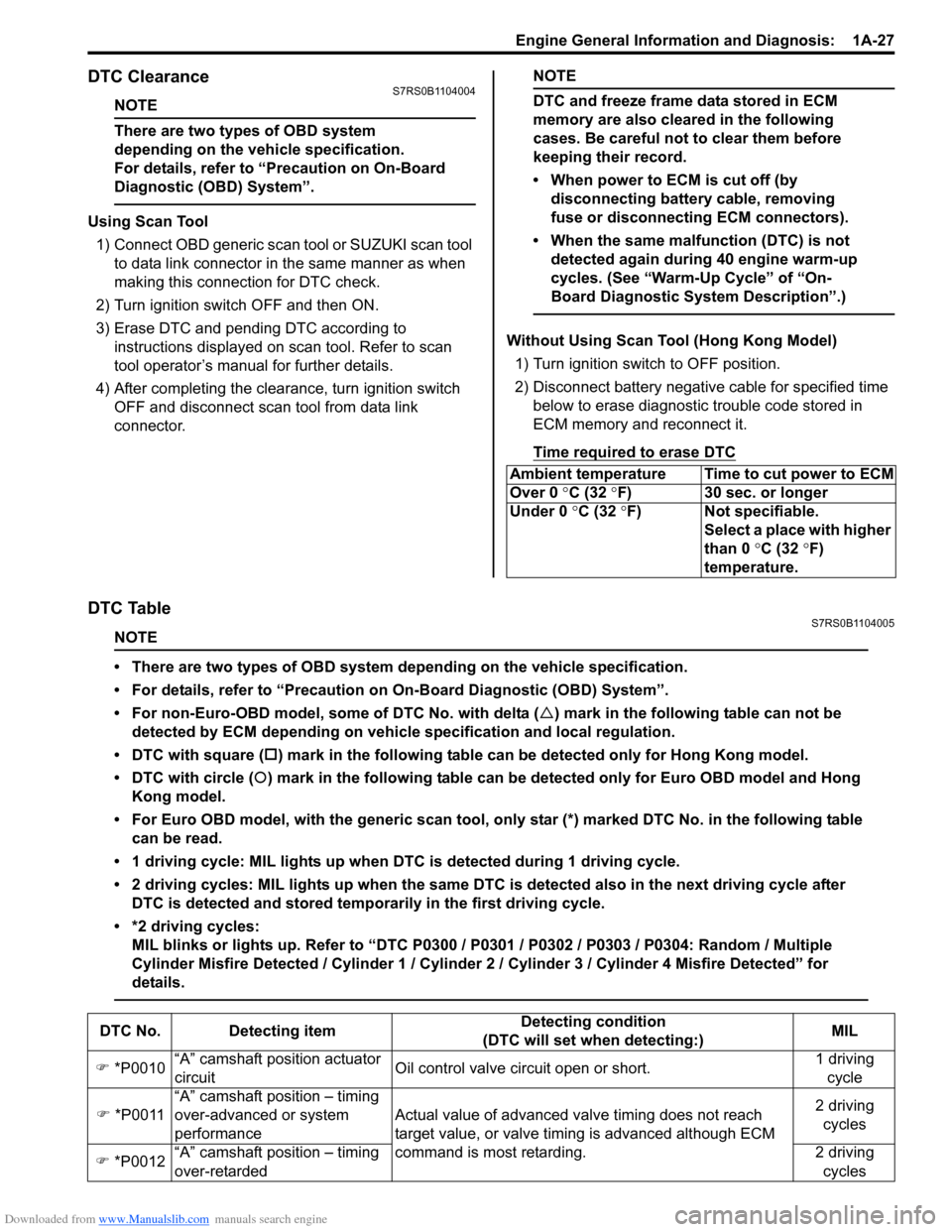

Without Using Scan Tool (Hong Kong Model) 1) Turn ignition switch to OFF position.

2) Using service wire, ground diagnosis switch terminal (1) of diagnosis connector (2).

3) Turn ON ignition switch and check DTC displayed on

odometer (3) of combination meter.

When more than 2 DTCs are stored in memory,

blinking for each DTC star ts with the smallest DTC

number in increasing order. Also, DTC is indicated

repeatedly until the ignition switch is turned OFF or

disconnect service wire.

NOTE

When no DTC is detected, display on

odometer of combinatio n meter is “0000”.

4) After completing the check, turn ignition switch to

OFF position and disconnect service wire from

diagnosis connector.

(A)

1

I4RS0B110026-01

21

3

I5RS0C110009-01

Page 77 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-27

DTC ClearanceS7RS0B1104004

NOTE

There are two types of OBD system

depending on the vehicle specification.

For details, refer to “Precaution on On-Board

Diagnostic (OBD) System”.

Using Scan Tool1) Connect OBD generic scan to ol or SUZUKI scan tool

to data link connector in the same manner as when

making this connection for DTC check.

2) Turn ignition switch OFF and then ON.

3) Erase DTC and pending DTC according to instructions displayed on scan tool. Refer to scan

tool operator’s manual for further details.

4) After completing the clear ance, turn ignition switch

OFF and disconnect scan tool from data link

connector.

NOTE

DTC and freeze frame data stored in ECM

memory are also cleared in the following

cases. Be careful not to clear them before

keeping their record.

• When power to ECM is cut off (by disconnecting battery cable, removing

fuse or disconnecting ECM connectors).

• When the same malfunction (DTC) is not detected again during 40 engine warm-up

cycles. (See “Warm-Up Cycle” of “On-

Board Diagnostic System Description”.)

Without Using Scan Tool (Hong Kong Model)

1) Turn ignition switch to OFF position.

2) Disconnect battery negative cable for specified time below to erase diagnostic trouble code stored in

ECM memory and reconnect it.

Time required to erase DTC

DTC TableS7RS0B1104005

NOTE

• There are two types of OBD system depending on the vehicle specification.

• For details, refer to “Precaution on On-Board Diagnostic (OBD) System”.

• For non-Euro-OBD model, some of DTC No. with delta ( �U) mark in the following table can not be

detected by ECM depending on vehicl e specification and local regulation.

• DTC with square ( �†) mark in the following table can be detected only for Hong Kong model.

• DTC with circle ( �{) mark in the following table can be detected only for Euro OBD model and Hong

Kong model.

• For Euro OBD model, with the generic scan tool, onl y star (*) marked DTC No. in the following table

can be read.

• 1 driving cycle: MIL lights up when DTC is detected during 1 driving cycle.

• 2 driving cycles: MIL lights up when the same DTC is detected also in the next driving cycle after DTC is detected and stored temporarily in the first driving cycle.

• *2 driving cycles: MIL blinks or lights up. Refer to “DTC P0300 / P0301 / P0302 / P0303 / P0304: Random / Multiple

Cylinder Misfire Detected / Cylinder 1 / Cylinder 2 / Cylinder 3 / Cylinder 4 Misfire Detected” for

details.

Ambient temperature Time to cut power to ECM

Over 0 °C (32 ° F) 30 sec. or longer

Under 0 °C (32 °F) Not specifiable.

Select a place with higher

than 0 °C (32 °F)

temperature.

DTC No. Detecting item Detecting condition

(DTC will set when detecting:) MIL

�) *P0010 “A” camshaft position actuator

circuit Oil control valve circuit open or short. 1 driving

cycle

�) *P0011 “A” camshaft position – timing

over-advanced or system

performance Actual value of advanced va

lve timing does not reach

target value, or valve timi ng is advanced although ECM

command is most retarding. 2 driving

cycles

�) *P0012 “A” camshaft position – timing

over-retarded 2 driving

cycles

Page 83 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-33

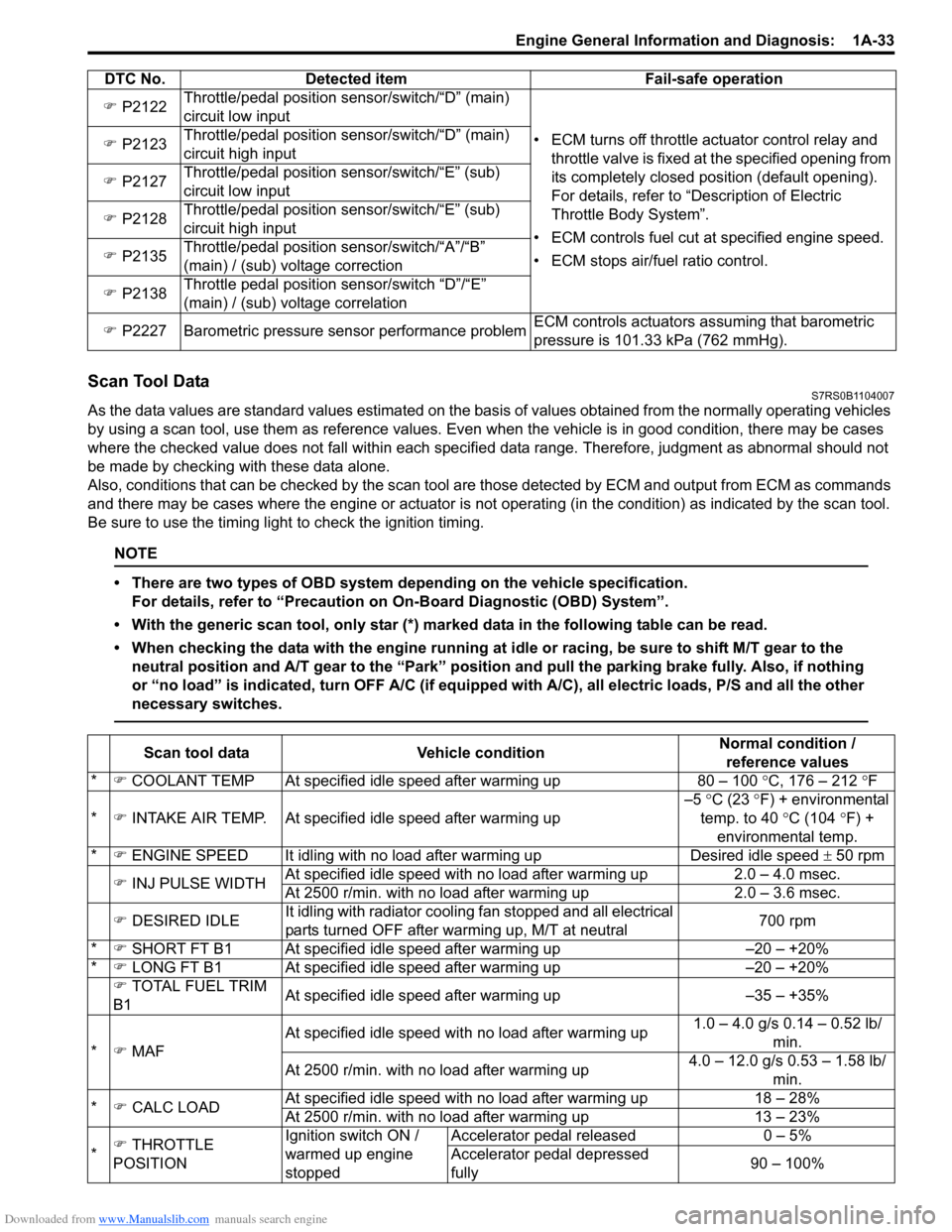

Scan Tool DataS7RS0B1104007

As the data values are standard values estimated on the basis of values obtained from the normally operating vehicles

by using a scan tool, use them as re ference values. Even when the vehicle is in good condition, there may be cases

where the checked value does not fall within each specified data range. Therefore, judgment as abnormal should not

be made by checking with these data alone.

Also, conditions that can be checked by the scan tool are those detected by ECM and output from ECM as commands

and there may be cases where the engine or actuator is not operating (in the condition) as indicated by the scan tool.

Be sure to use the timing light to check the ignition timing.

NOTE

• There are two types of OBD system depending on the vehicle specification.

For details, refer to “Precaution on On-Board Diagnostic (OBD) System”.

• With the generic scan tool, only star (*) marked data in the following table can be read.

• When checking the data with the engine running at idle or racing, be sure to shift M/T gear to the neutral position and A/T gear to the “Park” position and pull the parking brake fully. Also, if nothing

or “no load” is indicated, turn O FF A/C (if equipped with A/C), all electric loads, P/S and all the other

necessary switches.

�) P2122 Throttle/pedal position sensor/switch/“D” (main)

circuit low input

• ECM turns off throttle actuator control relay and throttle valve is fixed at the specified opening from

its completely closed position (default opening).

For details, refer to “Description of Electric

Throttle Body System”.

• ECM controls fuel cut at specified engine speed.

• ECM stops air/fuel ratio control.

�)

P2123 Throttle/pedal position sensor/switch/“D” (main)

circuit high input

�) P2127 Throttle/pedal position sensor/switch/“E” (sub)

circuit low input

�) P2128 Throttle/pedal position sensor/switch/“E” (sub)

circuit high input

�) P2135 Throttle/pedal position sensor/switch/“A”/“B”

(main) / (sub) voltage correction

�) P2138 Throttle pedal position sensor/switch “D”/“E”

(main) / (sub) voltage correlation

�) P2227 Barometric pressure sensor performance problem ECM controls actuators assuming that barometric

pressure is 101.33 kPa (762 mmHg).

DTC No. Detected item Fail-safe operation

Scan tool data

Vehicle condition Normal condition /

reference values

* �) COOLANT TEMP At specified idle speed after warming up 80 – 100 °C, 176 – 212 °F

* �) INTAKE AIR TEMP. At specifie d idle speed after warming up –5

°C (23 °F) + environmental

temp. to 40 °C (104 °F) +

environmental temp.

* �) ENGINE SPEED It idling with no load after warming upDesired idle speed ± 50 rpm

�) INJ PULSE WIDTH At specified idle speed with no load after warming up

2.0 – 4.0 msec.

At 2500 r/min. with no load after warming up 2.0 – 3.6 msec.

�) DESIRED IDLE It idling with radiator cooling fan stopped and all electrical

parts turned OFF after warming up, M/T at neutral 700 rpm

* �) SHORT FT B1 At specified idle speed after warming up –20 – +20%

* �) LONG FT B1 At specified idle speed after warming up –20 – +20%

�) TOTAL FUEL TRIM

B1 At specified idle speed after warming up

–35 – +35%

* �) MAF At specified idle speed wit

h no load after warming up 1.0 – 4.0 g/s 0.14 – 0.52 lb/

min.

At 2500 r/min. with no load after warming up 4.0 – 12.0 g/s 0.53 – 1.58 lb/

min.

* �) CALC LOAD At specified idle speed with no load after warming up

18 – 28%

At 2500 r/min. with no load after warming up 13 – 23%

* �)

THROTTLE

POSITION Ignition switch ON /

warmed up engine

stoppedAccelerator pedal released

0 – 5%

Accelerator pedal depressed

fully 90 – 100%

Page 86 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-36 Engine General Information and Diagnosis:

O2S B1 S1 ACT (HEATED OXYGEN SENSOR-1,

ACTIVE / INACTIVE)

This parameter indicates activation condition of HO2S-1.

ACTIVE: Activating

INACTIVE: warming up or at stop

O2S SENSOR B1 S2 (HEATED OXYGEN SENSOR-2,

V)

It indicates output voltage of HO2S-2 installed on

exhaust pipe (post-catalyst). It is used to detect catalyst

deterioration.

O2S B1 S2 ACT (HEATED OXYGEN SENSOR-2,

ACTIVE / INACTIVE)

This parameter indicates acti vation condition of HO2S-2.

ACTIVE: Activating

INACTIVE: warming up or at stop

FUEL SYSTEM (FUEL SYSTEM STATUS)

Air/fuel ratio feedback loop status displayed as one of

the followings.

OPEN: Open-loop has not yet satisfied conditions to go

closed loop.

CLOSED: Closed-loop using oxygen sensor(s) as

feedback for fuel control.

OPEN-DRIVE COND: Open-loop due to driving

conditions (Power enrichment, etc.).

OPEN SYS FAULT: Open-loop due to detected system

fault.

MAP (MANIFOLD ABSOLUTE PRESSURE, in.Hg,

kPa)

This value indicates how much correction is necessary

to keep the air/fuel mixture stoichiometrical.

It is detected by manifold absolute pressure sensor.

BAROMETRIC PRESS (kPa, in.Hg)

This parameter represents a measurement of barometric

air pressure and is used for al titude correction of the fuel

injection quantity and IAC valve control.

STEP EGR FLOW DUTY (%)

This parameter indicates opening rate of EGR valve

which controls the amount of EGR flow.

FUEL CUT (ON/OFF)

ON: Fuel being cut (output signal to injector is stopped)

OFF: Fuel not being cut

A/C PRESSURE (A/C REFRIGERANT ABSOLUTE

PRESSURE, kPa)

This parameter indicates A/C refrigerant absolute

pressure calculated by ECM.

CLOSED THROTTLE PO S (CLOSED THROTTLE

POSITION, ON/OFF)

This parameter reads ON wh en throttle valve is fully

closed, or OFF when it is not fully closed. CANIST PRG DUTY (EVAP CANISTER PURGE FLOW

DUTY, %)

This parameter indicates valve ON (valve open) time

rate within a certain set cycle of EVAP canister purge

valve which controls the amount of EVAP purge.

IGNITION ADVANCE (IGNITION TIMING ADVANCE

FOR NO.1 CYLINDER,

°)

Ignition timing of No.1 cylinder is commanded by ECM.

The actual ignition timing should be checked by using

the timing light.

BATTERY VOLTAGE (V)

This parameter indicates battery positive voltage

inputted from main relay to ECM.

FUEL PUMP (ON/OFF)

ON is displayed when ECM activates the fuel pump via

the fuel pump relay switch.

ELECTRIC LOAD (ON/OFF)

ON: Headlight or small light ON signal inputted.

OFF: Above electric loads all turned OFF.

BRAKE SW (ON/OFF)

This parameter indicates the state of the brake switch.

RADIATOR COOLING FAN (RADIATOR COOLING

FAN CONTROL RELAY, ON/OFF)

ON: Command for radiator cooling fan control relay

operation being output.

OFF: Command for relay operation not being output.

BLOWER FAN (ON/OFF)

This parameter indicates the state of the blower fan

motor switch.

A/C SWITCH (ON/OFF)

ON: Command for A/C operatio n being output from ECM

to HVAC.

OFF: Command for A/C oper ation not being output.

A/C COMP RELAY (A/C COMPRESSOR RELAY, ON/

OFF)

This parameter indicates the state of the A/C switch.

VEHICLE SPEED (km/h, mph)

It is computed based on pulse signals from vehicle

speed sensor.

VVT GAP (TARGET-ACTUAL POSITION, °)

It is calculated using the formula: target valve timing

advance – actual valve timing advance.

TP SENSOR 1 VOLT (THROTTLE POSITION SENSOR

(MAIN) OUTPUT VOLTAGE, V)

The TP sensor (main) reading provides throttle valve

opening information in the form of voltage.

Page 89 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-39

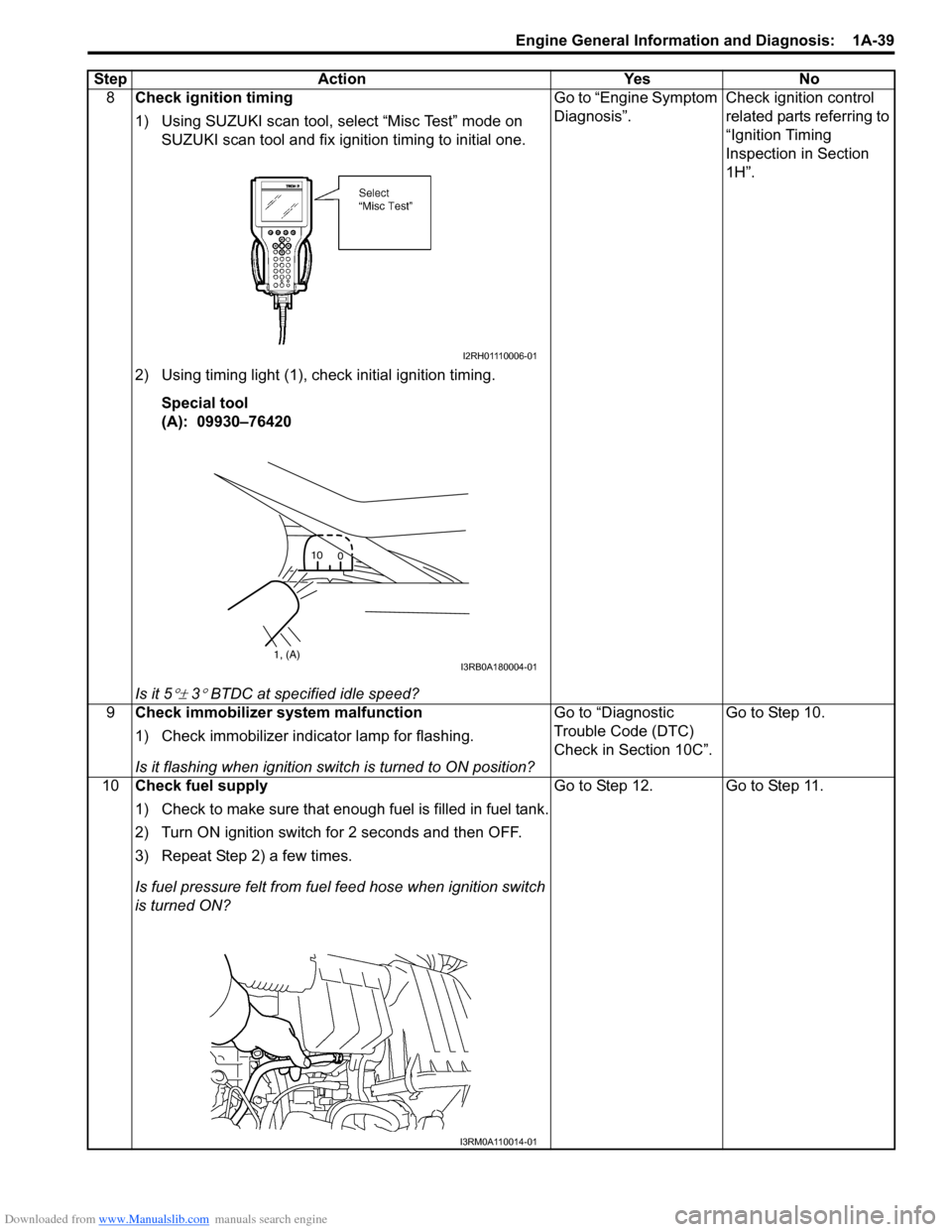

8Check ignition timing

1) Using SUZUKI scan tool, select “Misc Test” mode on

SUZUKI scan tool and fix ignition timing to initial one.

2) Using timing light (1), check initial ignition timing. Special tool

(A): 09930–76420

Is it 5

°± 3° BTDC at specif ied idle speed? Go to “Engine Symptom

Diagnosis”.

Check ignition control

related parts referring to

“Ignition Timing

Inspection in Section

1H”.

9 Check immobilizer system malfunction

1) Check immobilizer indica tor lamp for flashing.

Is it flashing when ignition switch is turned to ON position? Go to “Diagnostic

Trouble Code (DTC)

Check in Section 10C”.

Go to Step 10.

10 Check fuel supply

1) Check to make sure that enough fuel is filled in fuel tank.

2) Turn ON ignition switch for 2 seconds and then OFF.

3) Repeat Step 2) a few times.

Is fuel pressure felt from fuel feed hose when ignition switch

is turned ON? Go to Step 12. Go to Step 11.

Step Action Yes No

I2RH01110006-01

1, (A)

10

0I3RB0A180004-01

I3RM0A110014-01

Page 98 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-48 Engine General Information and Diagnosis:

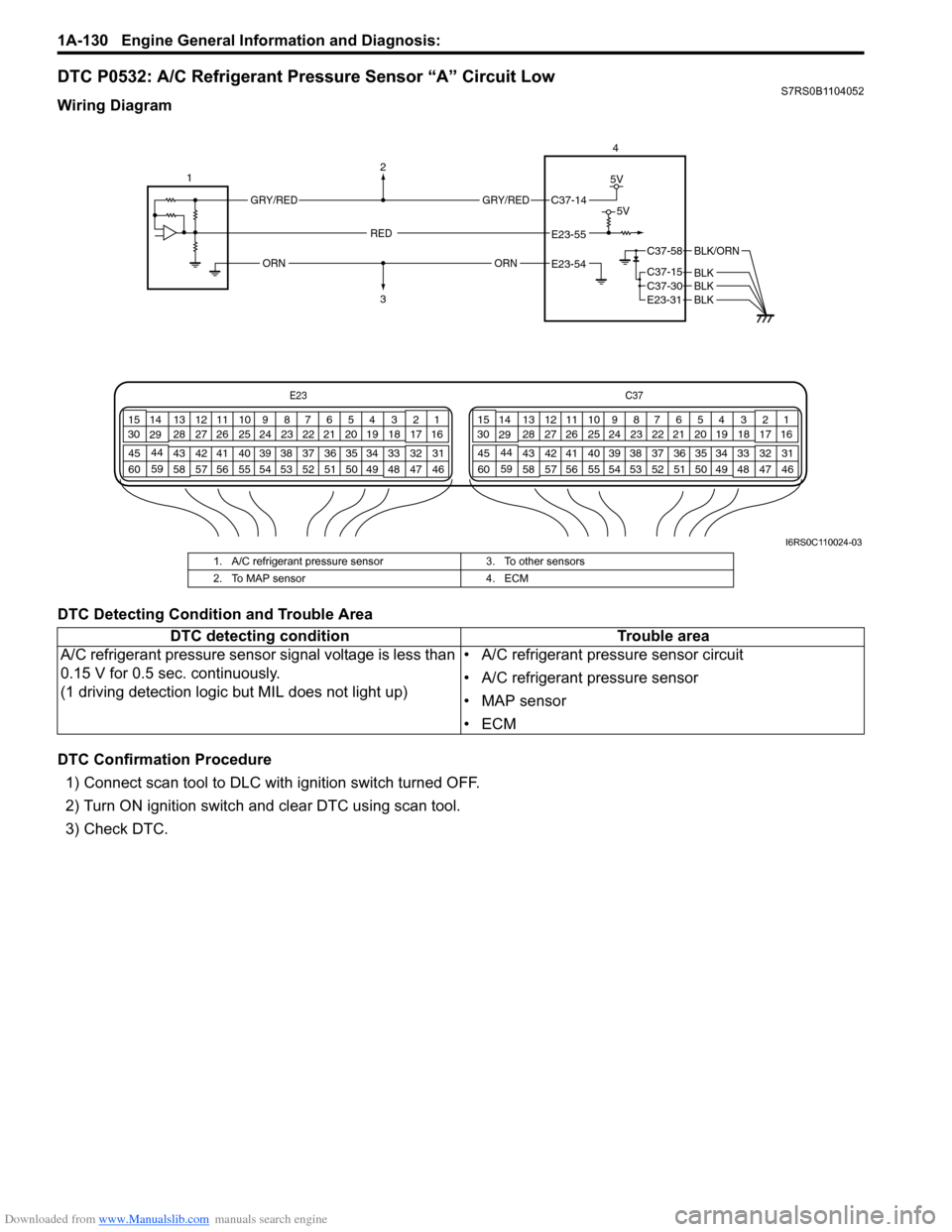

Troubleshooting

NOTE

When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the special

tool to ECM and/or the ECM connectors referri ng to “Inspection of ECM and Its Circuits”.

Malfunction Indicator Lamp Remains ON after Engine StartsS7RS0B1104012

Wiring Diagram and Circuit Description

Refer to “MIL Does Not Come ON wit h Ignition Switch ON and Engine Stop (but Engine Can Be Started)”.

Step

Action YesNo

1 MIL power supply check

1) Turn ignition switch to ON position.

Do other warning lights come ON? Go to Step 2.

Go to Step 3.

2 DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch and check DTC.

Is there DTC(s) P1674, P1676, P1678 and/or P1685? Go to applicable DTC

diag. flow.

Substitute a known-

good combination meter

and recheck. If MIL still

remains OFF, substitute

a known-good ECM and

recheck.

3 CAN communication line circuit check

1) Check CAN communication circuit between combination

meter and ECM, TCM (A/T model) referring to Step 3 of

“DTC P1674: CAN Communication (Bus Off Error)”

Is circuit in good condition? Go to Step 4.

Repair or replace.

4 “METER” fuse check

1) Turn ignition switch to OFF position.

2) Check for fuse blown at “M ETER” fuse in junction block

assembly.

Is “METER” fuse in good condition? Go to Step 5.

Replace “METER” fuse

and check for short.

5 Combination meter power supply check

1) Remove combination meter referring to “Combination

Meter Removal and Installation in Section 9C”.

2) Check for proper connection to combination meter connector at “G28-31” and “G28-16” terminals.

3) If OK, then turn ignition switch to ON position and measure voltage between combination meter connector

at “G28-31” terminal and vehicle body ground.

Is it 10 – 14 V? Go to Step 6.

“RED/BLK” wire is open

circuit.

6 Combination meter circuit check

1) Turn ignition switch to OFF position.

2) Measure resistance between “G28-16” terminal of

combination meter connector and vehicle body ground.

Is resistance 1

Ω or less? Substitute a known-

good combination meter

and recheck. If MIL still

remains OFF, substitute

a known-good ECM and

recheck.

“BLK/ORN” wire is open

or high resistance

circuit.

Page 180 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-130 Engine General Information and Diagnosis:

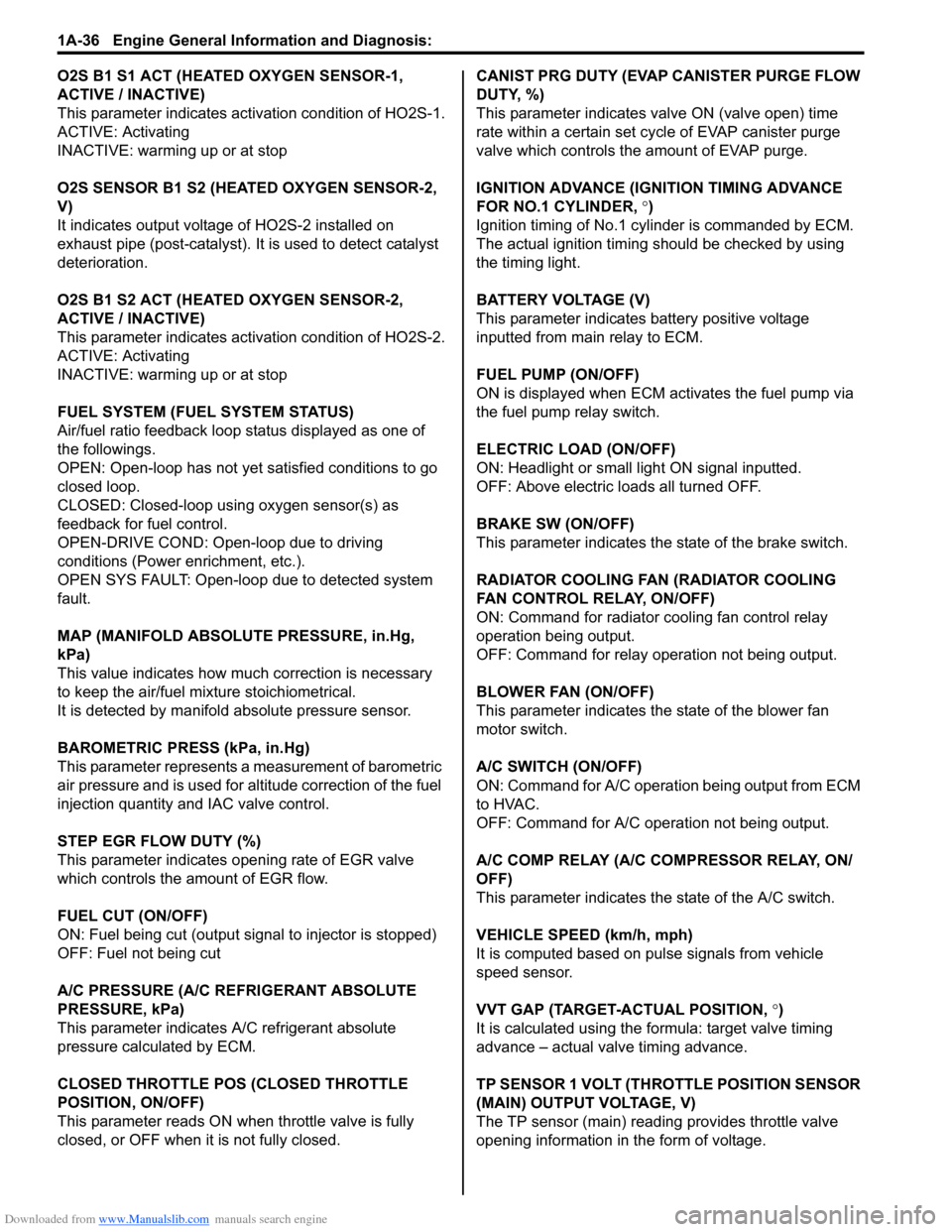

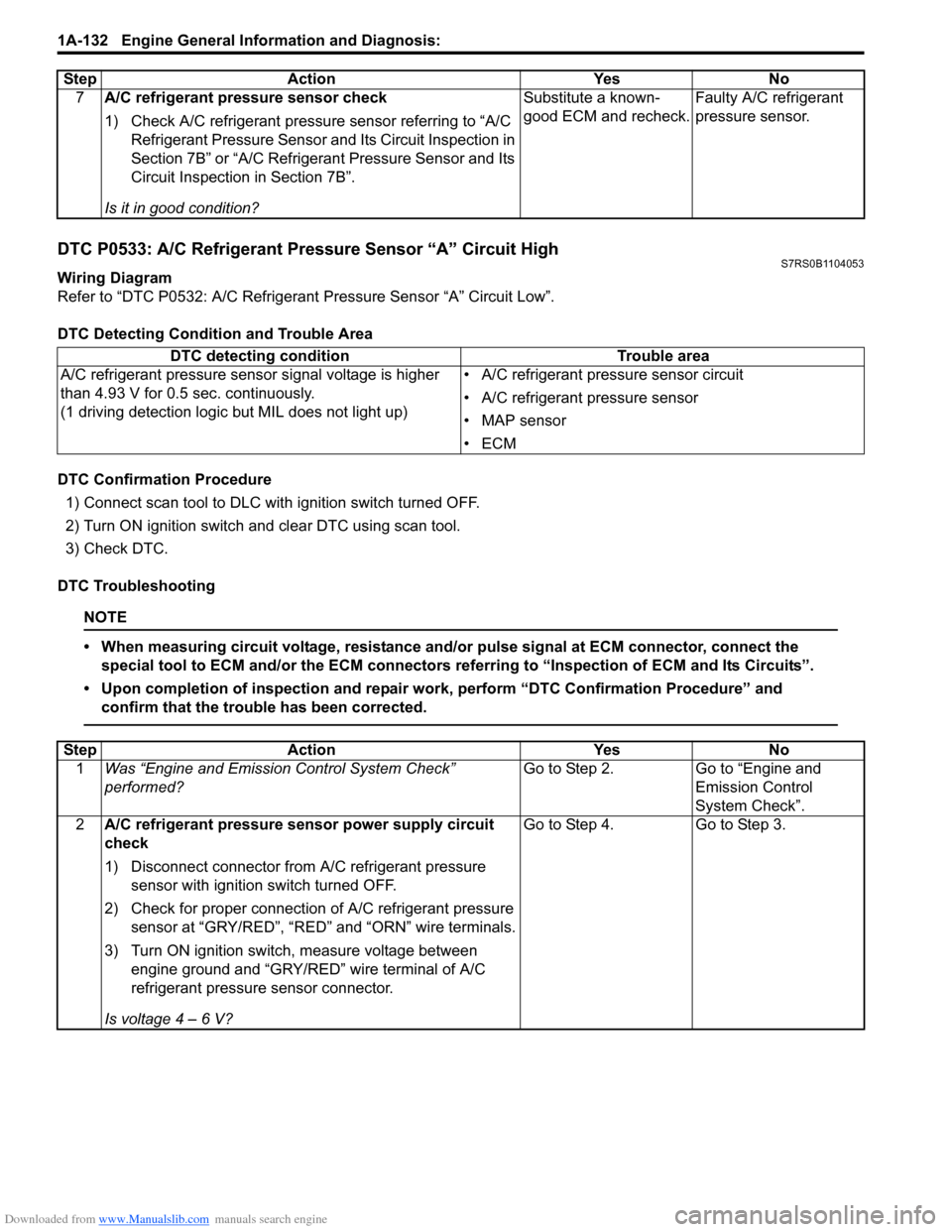

DTC P0532: A/C Refrigerant Pressure Sensor “A” Circuit LowS7RS0B1104052

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure1) Connect scan tool to DLC with ignition switch turned OFF.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Check DTC.

E23 C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

4

C37-58

C37-15 C37-30

BLK/ORN

BLKBLKE23-31 BLK

1

2

3

GRY/REDGRY/RED

ORNORN

5V

5VC37-14

E23-55

E23-54

RED

I6RS0C110024-03

1. A/C refrigerant pressure sensor

3. To other sensors

2. To MAP sensor 4. ECM

DTC detecting condition Trouble area

A/C refrigerant pressure sensor signal voltage is less than

0.15 V for 0.5 sec. continuously.

(1 driving detection logic but MIL does not light up) • A/C refrigerant pressure sensor circuit

• A/C refrigerant pressure sensor

• MAP sensor

•ECM

Page 182 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-132 Engine General Information and Diagnosis:

DTC P0533: A/C Refrigerant Pressure Sensor “A” Circuit HighS7RS0B1104053

Wiring Diagram

Refer to “DTC P0532: A/C Refrigerant Pressure Sensor “A” Circuit Low”.

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure1) Connect scan tool to DLC with ignition switch turned OFF.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Check DTC.

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/ or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

7 A/C refrigerant pressure sensor check

1) Check A/C refrigerant pressure sensor referring to “A/C

Refrigerant Pressure Sensor and Its Circuit Inspection in

Section 7B” or “A/C Refrigerant Pressure Sensor and Its

Circuit Inspection in Section 7B”.

Is it in good condition? Substitute a known-

good ECM and recheck.

Faulty A/C refrigerant

pressure sensor.

Step Action Yes No

DTC detecting condition

Trouble area

A/C refrigerant pressure sensor signal voltage is higher

than 4.93 V for 0.5 sec. continuously.

(1 driving detection logic but MIL does not light up) • A/C refrigerant pressure sensor circuit

• A/C refrigerant pressure sensor

• MAP sensor

•ECM

Step

Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 A/C refrigerant pressure sensor power supply circuit

check

1) Disconnect connector from A/C refrigerant pressure

sensor with ignition switch turned OFF.

2) Check for proper connection of A/C refrigerant pressure sensor at “GRY/RED”, “RED ” and “ORN” wire terminals.

3) Turn ON ignition switch, measure voltage between engine ground and “GRY/RED” wire terminal of A/C

refrigerant pressure sensor connector.

Is voltage 4 – 6 V? Go to Step 4.

Go to Step 3.

Page 184 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-134 Engine General Information and Diagnosis:

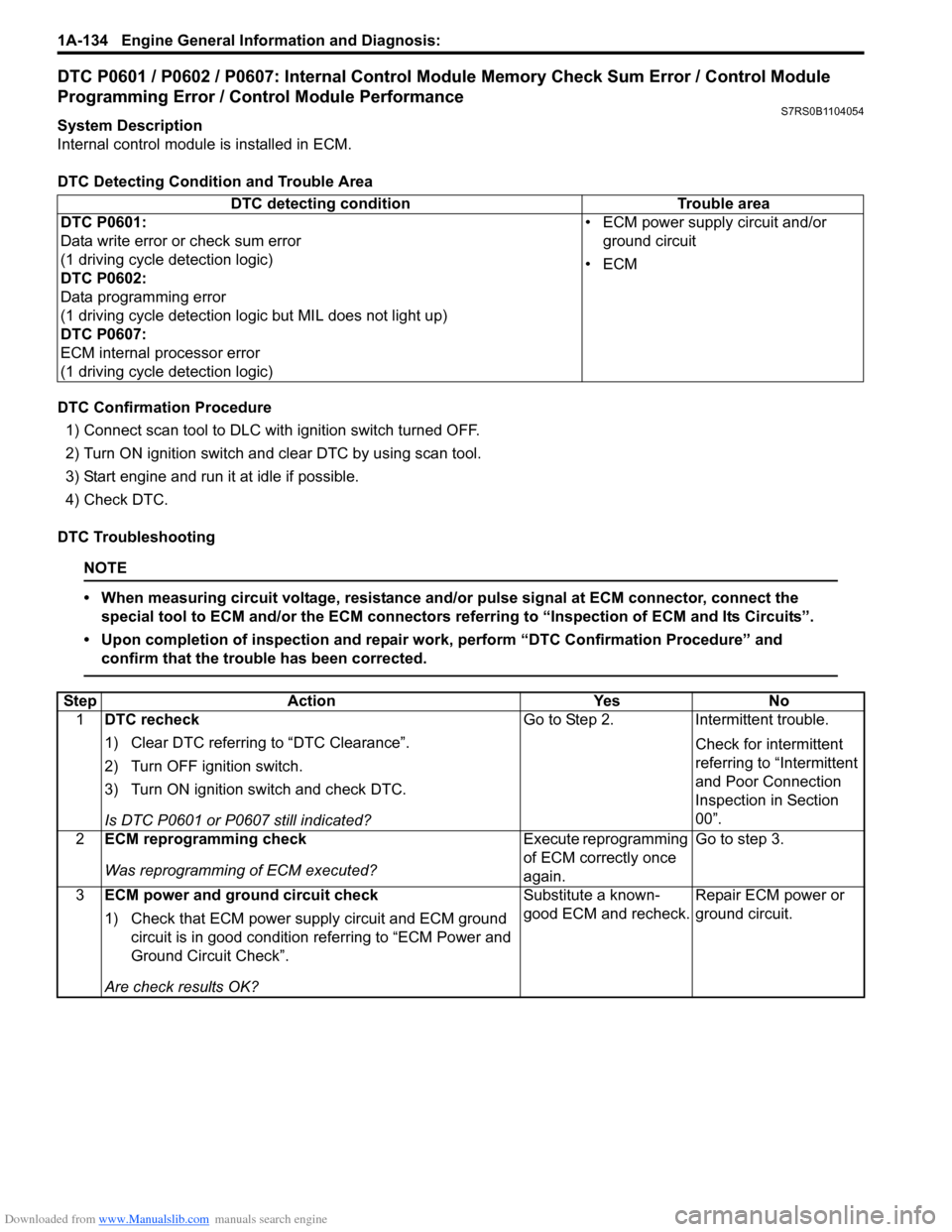

DTC P0601 / P0602 / P0607: Internal Control Module Memory Check Sum Error / Control Module

Programming Error / Control Module Performance

S7RS0B1104054

System Description

Internal control module is installed in ECM.

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure 1) Connect scan tool to DLC with ignition switch turned OFF.

2) Turn ON ignition switch and clear DTC by using scan tool.

3) Start engine and run it at idle if possible.

4) Check DTC.

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/ or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

DTC detecting condition Trouble area

DTC P0601:

Data write error or check sum error

(1 driving cycle detection logic)

DTC P0602:

Data programming error

(1 driving cycle detection logic but MIL does not light up)

DTC P0607:

ECM internal processor error

(1 driving cycle detection logic) • ECM power supply circuit and/or

ground circuit

•ECM

Step Action YesNo

1 DTC recheck

1) Clear DTC referring to “DTC Clearance”.

2) Turn OFF ignition switch.

3) Turn ON ignition switch and check DTC.

Is DTC P0601 or P0 607 still indicated? Go to Step 2.

Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

2 ECM reprogramming check

Was reprogramming of ECM executed? Execute reprogramming

of ECM correctly once

again.Go to step 3.

3 ECM power and ground circuit check

1) Check that ECM power supply circuit and ECM ground

circuit is in good condition referring to “ECM Power and

Ground Circuit Check”.

Are check results OK? Substitute a known-

good ECM and recheck.

Repair ECM power or

ground circuit.

Page 188 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-138 Engine General Information and Diagnosis:

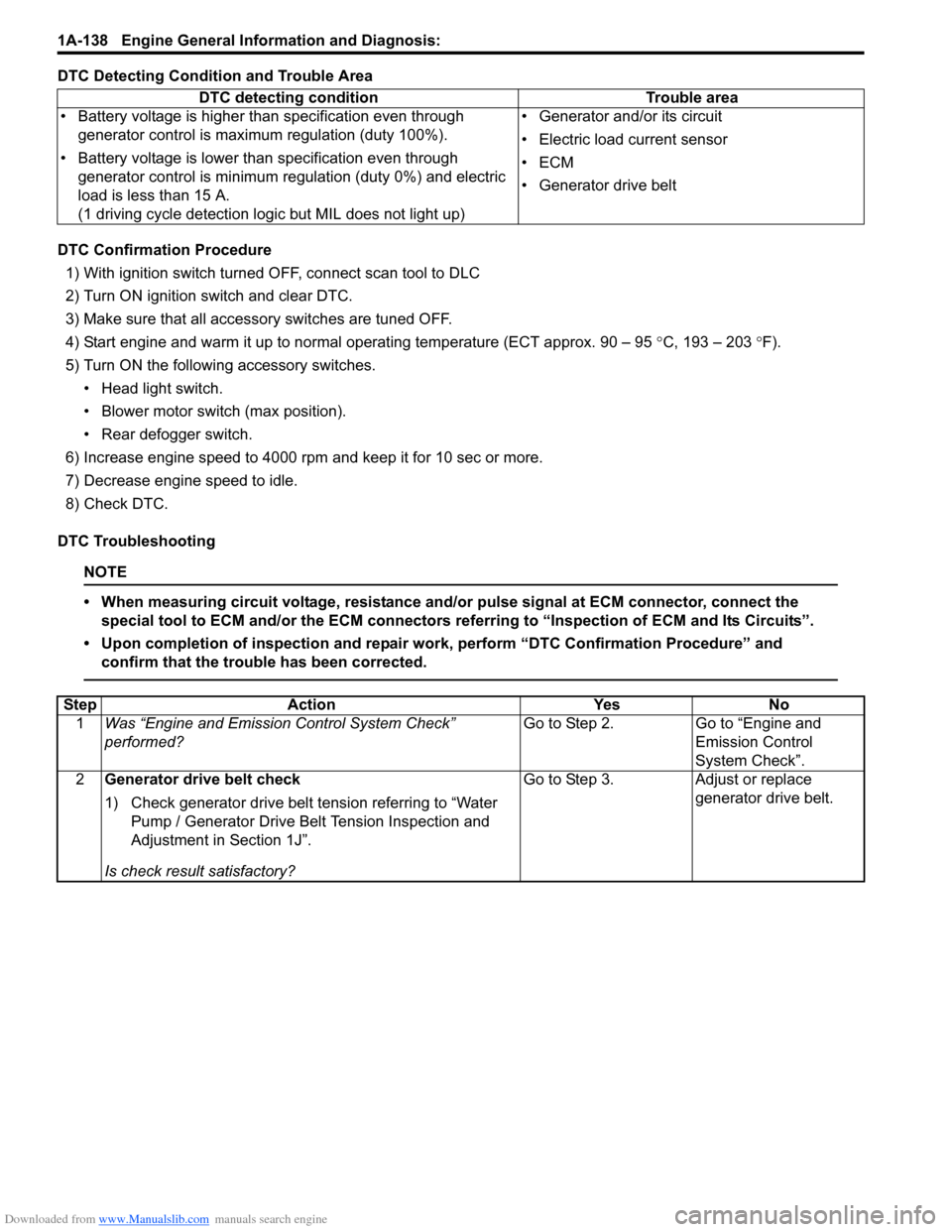

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure1) With ignition switch turned OFF, connect scan tool to DLC

2) Turn ON ignition switch and clear DTC.

3) Make sure that all accessory switches are tuned OFF.

4) Start engine and warm it up to normal operating temperature (ECT approx. 90 – 95 °C, 193 – 203 °F).

5) Turn ON the followi ng accessory switches.

• Head light switch.

• Blower motor switch (max position).

• Rear defogger switch.

6) Increase engine speed to 4000 rpm and keep it for 10 sec or more.

7) Decrease engine speed to idle.

8) Check DTC.

DTC Troubleshooting

NOTE

• When measuring circuit voltage, resistance and/ or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors re ferring to “Inspection of ECM and Its Circuits”.

• Upon completion of inspection and repair work, perform “DTC Confirmation Procedure” and confirm that the trouble has been corrected.

DTC detecting condition Trouble area

• Battery voltage is higher than specification even through generator control is maximum regulation (duty 100%).

• Battery voltage is lower than specification even through generator control is minimum regulation (duty 0%) and electric

load is less than 15 A.

(1 driving cycle detection logic but MIL does not light up) • Generator and/or its circuit

• Electric load current sensor

•ECM

• Generator drive belt

Step

Action YesNo

1 Was “Engine and Emission Control System Check”

performed? Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2 Generator drive belt check

1) Check generator drive belt tension referring to “Water

Pump / Generator Drive Belt Tension Inspection and

Adjustment in Section 1J”.

Is check result satisfactory? Go to Step 3.

Adjust or replace

generator drive belt.