torque SUZUKI SWIFT 2006 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 970 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-22 Air Conditioning System: Manual Type

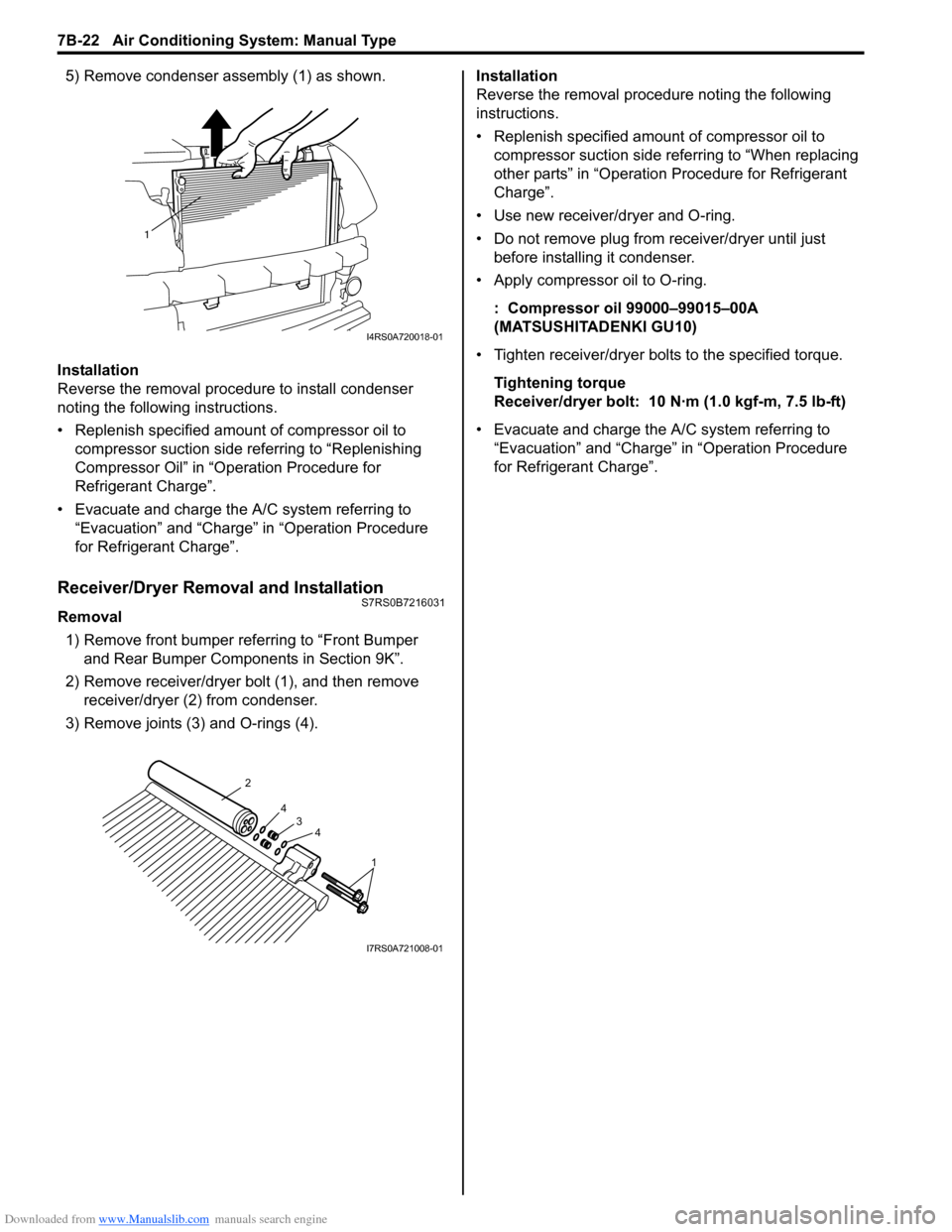

5) Remove condenser assembly (1) as shown.

Installation

Reverse the removal procedure to install condenser

noting the following instructions.

• Replenish specified amount of compressor oil to compressor suction side referring to “Replenishing

Compressor Oil” in “Operation Procedure for

Refrigerant Charge”.

• Evacuate and charge the A/C system referring to “Evacuation” and “Charge” in “Operation Procedure

for Refrigerant Charge”.

Receiver/Dryer Removal and InstallationS7RS0B7216031

Removal

1) Remove front bumper referring to “Front Bumper and Rear Bumper Components in Section 9K”.

2) Remove receiver/dryer bolt (1), and then remove receiver/dryer (2) from condenser.

3) Remove joints (3) and O-rings (4). Installation

Reverse the removal procedure noting the following

instructions.

• Replenish specified amount of compressor oil to

compressor suction side referring to “When replacing

other parts” in “Operation Procedure for Refrigerant

Charge”.

• Use new receiver/dryer and O-ring.

• Do not remove plug from receiver/dryer until just before installin g it condenser.

• Apply compressor oil to O-ring.

: Compressor oil 99000–99015–00A

(MATSUSHITADENKI GU10)

• Tighten receiver/dryer bolts to the specified torque. Tightening torque

Receiver/dryer bolt: 10 N· m (1.0 kgf-m, 7.5 lb-ft)

• Evacuate and charge the A/C system referring to “Evacuation” and “Charge” in “Operation Procedure

for Refrigerant Charge”.

1

I4RS0A720018-01

1

4

4

3

2

I7RS0A721008-01

Page 974 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-26 Air Conditioning System: Manual Type

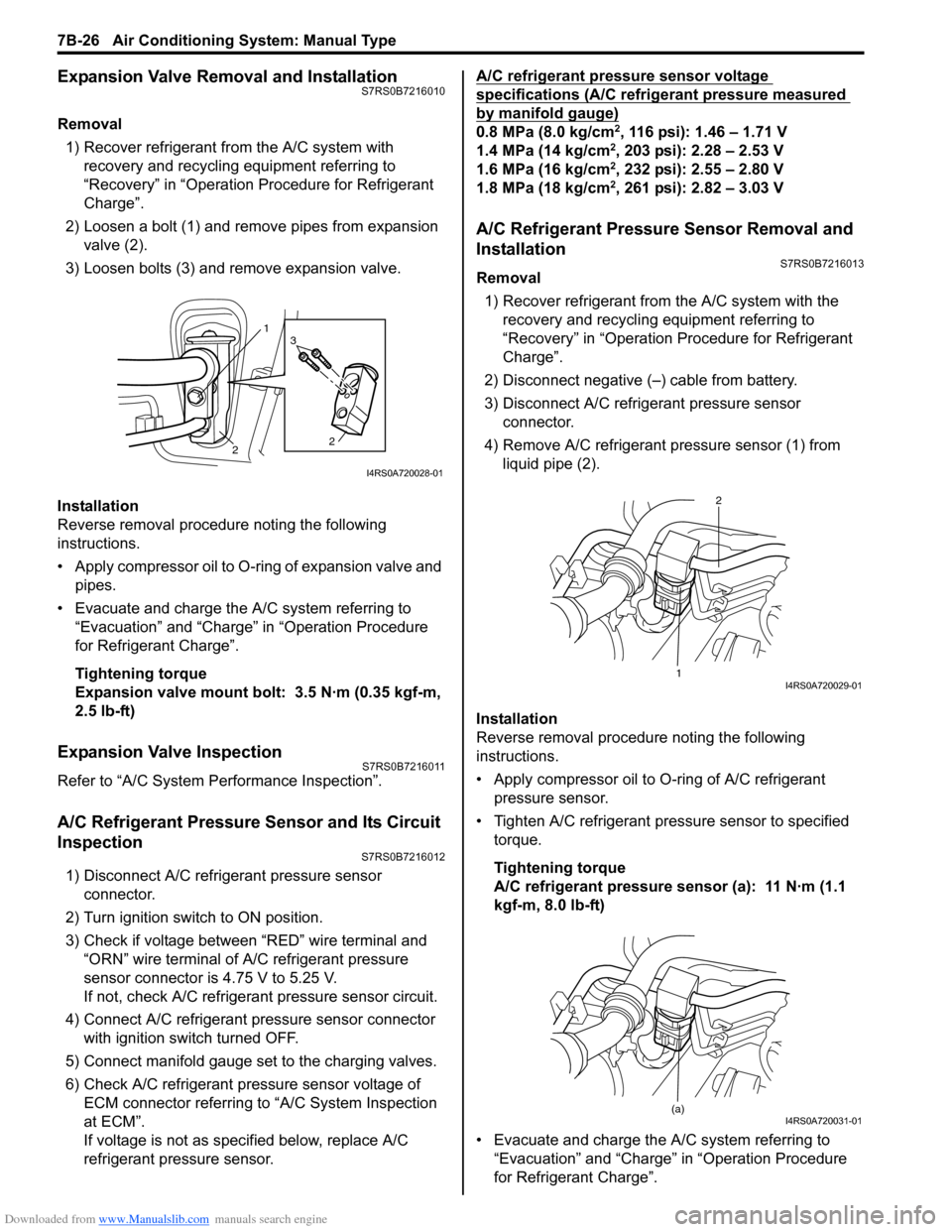

Expansion Valve Removal and InstallationS7RS0B7216010

Removal1) Recover refrigerant fr om the A/C system with

recovery and recycling equipment referring to

“Recovery” in “Operation Procedure for Refrigerant

Charge”.

2) Loosen a bolt (1) and remove pipes from expansion valve (2).

3) Loosen bolts (3) and remove expansion valve.

Installation

Reverse removal procedure noting the following

instructions.

• Apply compressor oil to O-ring of expansion valve and pipes.

• Evacuate and charge the A/C system referring to “Evacuation” and “Charge” in “Operation Procedure

for Refrigerant Charge”.

Tightening torque

Expansion valve mount bolt: 3.5 N·m (0.35 kgf-m,

2.5 lb-ft)

Expansion Valve InspectionS7RS0B7216011

Refer to “A/C System Performance Inspection”.

A/C Refrigerant Pressure Sensor and Its Circuit

Inspection

S7RS0B7216012

1) Disconnect A/C refrigerant pressure sensor connector.

2) Turn ignition switch to ON position.

3) Check if voltage between “RED” wire terminal and “ORN” wire terminal of A/C refrigerant pressure

sensor connector is 4.75 V to 5.25 V.

If not, check A/C refrigerant pressure sensor circuit.

4) Connect A/C refrigerant pressure sensor connector with ignition switch turned OFF.

5) Connect manifold gauge set to the charging valves.

6) Check A/C refrigerant pressure sensor voltage of ECM connector referring to “A/C System Inspection

at ECM”.

If voltage is not as specified below, replace A/C

refrigerant pressure sensor. A/C refrigerant pressure sensor voltage

specifications (A/C refrigerant pressure measured

by manifold gauge)

0.8 MPa (8.0 kg/cm2, 116 psi): 1.46 – 1.71 V

1.4 MPa (14 kg/cm2, 203 psi): 2.28 – 2.53 V

1.6 MPa (16 kg/cm2, 232 psi): 2.55 – 2.80 V

1.8 MPa (18 kg/cm2, 261 psi): 2.82 – 3.03 V

A/C Refrigerant Pressure Sensor Removal and

Installation

S7RS0B7216013

Removal

1) Recover refrigerant from the A/C system with the recovery and recycling equipment referring to

“Recovery” in “Operation Procedure for Refrigerant

Charge”.

2) Disconnect negative (–) cable from battery.

3) Disconnect A/C refrigerant pressure sensor connector.

4) Remove A/C refrigerant pressure sensor (1) from liquid pipe (2).

Installation

Reverse removal procedure noting the following

instructions.

• Apply compressor oil to O-ring of A/C refrigerant

pressure sensor.

• Tighten A/C refrigerant pressure sensor to specified torque.

Tightening torque

A/C refrigerant pressure sensor (a): 11 N·m (1.1

kgf-m, 8.0 lb-ft)

• Evacuate and charge the A/C system referring to “Evacuation” and “Charge” in “Operation Procedure

for Refrigerant Charge”.

1

2 2

3

I4RS0A720028-01

1 2I4RS0A720029-01

(a)I4RS0A720031-01

Page 979 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-31

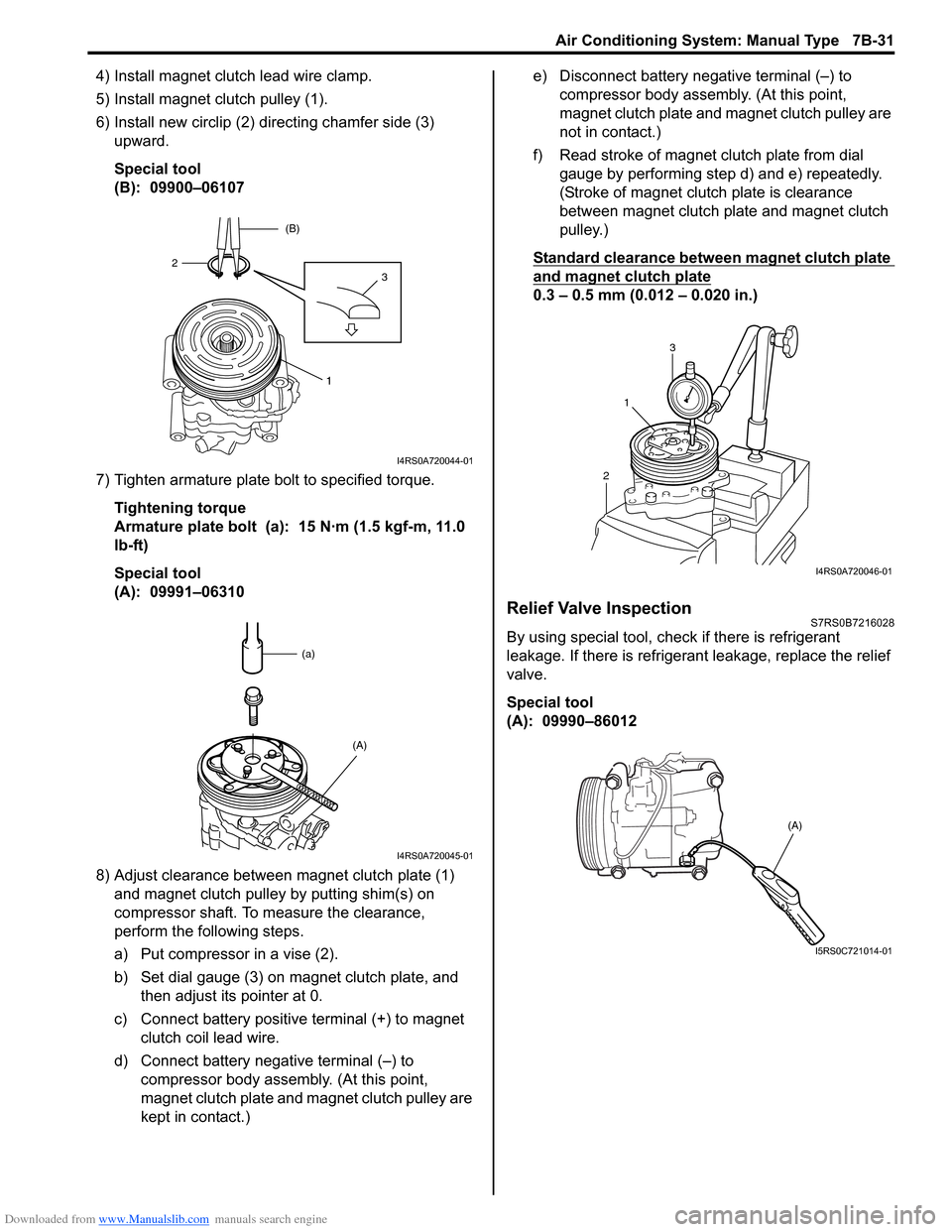

4) Install magnet clutch lead wire clamp.

5) Install magnet clutch pulley (1).

6) Install new circlip (2) directing chamfer side (3) upward.

Special tool

(B): 09900–06107

7) Tighten armature plate bolt to specified torque. Tightening torque

Armature plate bolt (a): 15 N·m (1.5 kgf-m, 11.0

lb-ft)

Special tool

(A): 09991–06310

8) Adjust clearance between magnet clutch plate (1) and magnet clutch pulley by putting shim(s) on

compressor shaft. To measure the clearance,

perform the following steps.

a) Put compressor in a vise (2).

b) Set dial gauge (3) on magnet clutch plate, and then adjust its pointer at 0.

c) Connect battery positive terminal (+) to magnet clutch coil lead wire.

d) Connect battery negative terminal (–) to compressor body assemb ly. (At this point,

magnet clutch plate and magnet clutch pulley are

kept in contact.) e) Disconnect battery negative terminal (–) to

compressor body assembly. (At this point,

magnet clutch plate and magnet clutch pulley are

not in contact.)

f) Read stroke of magnet clutch plate from dial gauge by performing step d) and e) repeatedly.

(Stroke of magnet clutch plate is clearance

between magnet clutch plate and magnet clutch

pulley.)

Standard clearance between magnet clutch plate

and magnet clutch plate

0.3 – 0.5 mm (0.012 – 0.020 in.)

Relief Valve InspectionS7RS0B7216028

By using special tool, chec k if there is refrigerant

leakage. If there is refrigerant leakage, replace the relief

valve.

Special tool

(A): 09990–86012

1

32 (B)

I4RS0A720044-01

(a)

(A)

I4RS0A720045-01

21

3

I4RS0A720046-01

(A)

I5RS0C721014-01

Page 980 of 1496

Downloaded from www.Manualslib.com manuals search engine 7B-32 Air Conditioning System: Manual Type

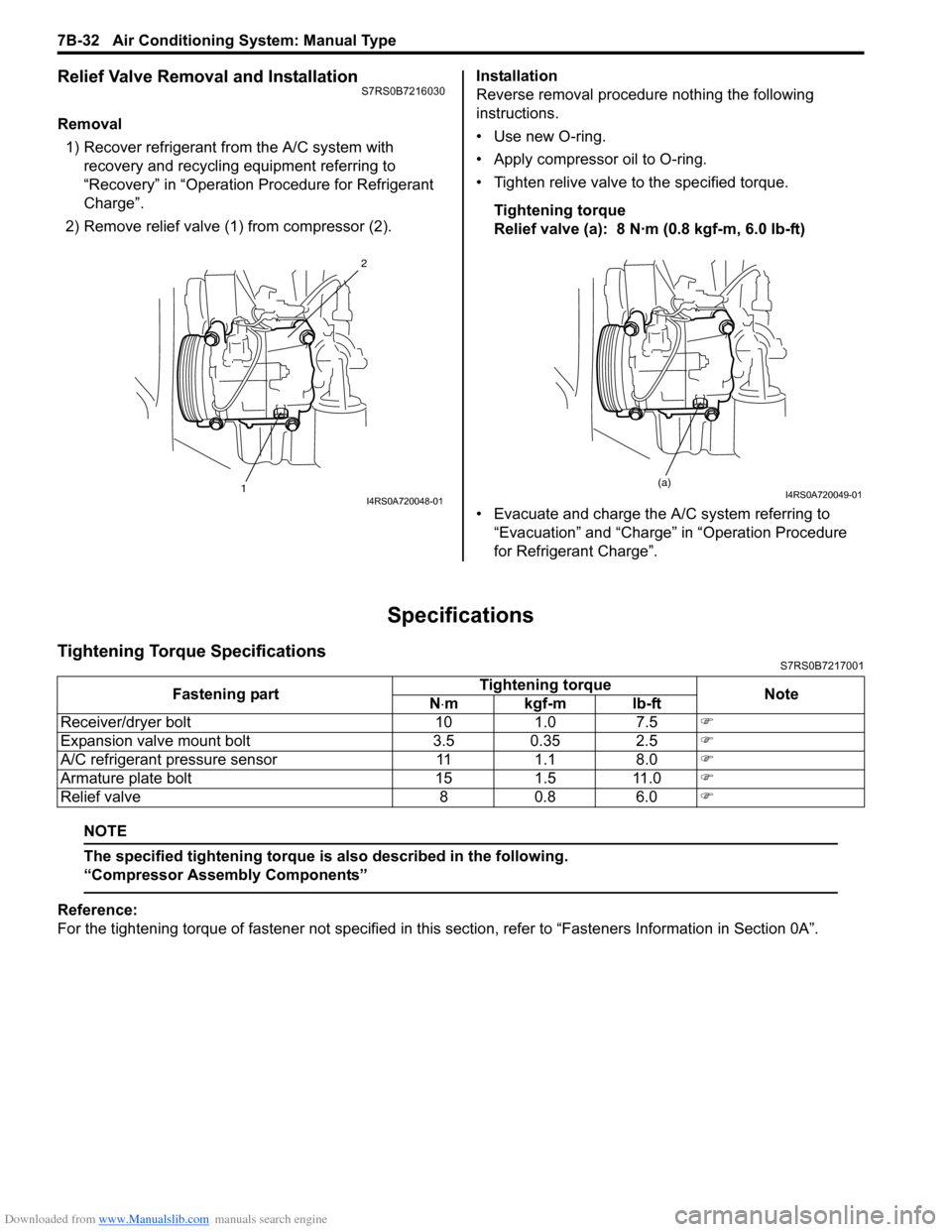

Relief Valve Removal and InstallationS7RS0B7216030

Removal1) Recover refrigerant fr om the A/C system with

recovery and recycling equipment referring to

“Recovery” in “Operation Procedure for Refrigerant

Charge”.

2) Remove relief valve (1) from compressor (2). Installation

Reverse removal procedure nothing the following

instructions.

• Use new O-ring.

• Apply compressor oil to O-ring.

• Tighten relive valve to the specified torque.

Tightening torque

Relief valve (a): 8 N·m (0.8 kgf-m, 6.0 lb-ft)

• Evacuate and charge the A/C system referring to “Evacuation” and “Charge” in “Operation Procedure

for Refrigerant Charge”.

Specifications

Tightening Torque SpecificationsS7RS0B7217001

NOTE

The specified tightening torque is also described in the following.

“Compressor Assembly Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

12I4RS0A720048-01

(a)I4RS0A720049-01

Fastening part

Tightening torque

Note

N ⋅mkgf-mlb-ft

Receiver/dryer bolt 10 1.0 7.5 �)

Expansion valve mount bolt 3.5 0.35 2.5 �)

A/C refrigerant pressure sensor 11 1.1 8.0 �)

Armature plate bolt 15 1.5 11.0 �)

Relief valve 8 0.8 6.0 �)

Page 1029 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 8- i

8

Section 8

CONTENTS

Restraint

Precautions ................................................. 8-1

Precautions............................................................. 8-1

Precautions on Restraint ....................................... 8-1

Seat Belts .......... ............................... ........ 8A-1

Precautions........................................................... 8A-1

Precautions on Service a nd Diagnosis of Seat

Belt .................................................................... 8A-1

General Description ............................................. 8A-1 Seat Belt Construction ........................................ 8A-1

Diagnostic Information and Procedures ............ 8A-2 Repair and Inspection Required after Accident ............................................................ 8A-2

Repair Instructions .............................................. 8A-3 Front Seat Belt Components ............................... 8A-3

Front Seat Belt Removal and Installation ............ 8A-4

Front Seat Belt Inspection ................................... 8A-4

Rear Seat Belt Components ............................... 8A-6

Rear Seat Belt Removal and Installation ............ 8A-7

Rear Seat Belt Inspection ................................... 8A-7

Specifications ....................................................... 8A-7

Tightening Torque Specifications ........................ 8A-7

Air Bag System ............... ......................... 8B-1

Precautions........................................................... 8B-1

Precautions on Service and Diagnosis of Air Bag System....................................................... 8B-1

Precautions on Handling and Storage of Air Bag System Components . ................................ 8B-2

Precautions on Disposal of Air Bag and Seat

Belt Pretensioner .............................................. 8B-5

General Description ............................................. 8B-5 Air Bag System Construction .............................. 8B-5

Air Bag System Input / Output Table .................. 8B-6

Schematic and Routing Diagram ........................ 8B-7 Air Bag System Wiring Circuit Diagram .............. 8B-7

Component Locatio n ........................................... 8B-9

Air Bag System Components, Wiring and Connectors Location ......................................... 8B-9

Diagnostic Information and Procedures .......... 8B-10 Air Bag Diagnostic System Check .................... 8B-10

Air Bag Diagnostic System Check Flow ............ 8B-10

DTC Table ......................................................... 8B-11

DTC Check ....................................................... 8B-12 DTC Clearance ................................................. 8B-12

Scan Tool Data ................................................. 8B-13

“AIR BAG” Warning Right Comes ON Steady .. 8B-13

“AIR BAG” Warning Right Does Not Come

ON ................................................................... 8B-15

“AIR BAG” Warning Right Flashes .................... 8B-16

DTC B1013: SDM fault...................................... 8B-17

DTC B1014: “AIR BAG” Warning Right Circuit Failure ............................................................. 8B-17

DTC B1016: Power Source Voltage High ......... 8B-18

DTC B1017: Power Source Voltage Low .......... 8B-20

DTC B1021: Front Air Bag Module Deployed ... 8B-22

DTC B1024 / B1025: Side-Air Bag (Driver / Passenger) Deployed...................................... 8B-22

DTC B1026: Pretensioner Activated ................. 8B-23

DTC B1027: Reusable Number Exceeded ....... 8B-24

DTC B1031: Driver Air Bag Initiator Circuit

Resistance High .............................................. 8B-24

DTC B1032: Driver Air Bag Initiator Circuit

Resistance Low ............................................... 8B-29

DTC B1033: Driver Air Bag Initiator Circuit

Short to Ground............................................... 8B-34

DTC B1034: Driver Air Bag Initiator Circuit

Short to Power Circuit .... ................................. 8B-39

DTC B1041: Passenger Air Bag Initiator Circuit Resistance High ................................... 8B-44

DTC B1042: Passenger Air Bag Initiator Circuit Resistance Low.................................... 8B-47

DTC B1043: Passenger Air Bag Initiator Circuit Short to Ground ................................... 8B-50

DTC B1044: Passenger Air Bag Initiator Circuit Short to Power Circ uit .......................... 8B-53

DTC B1051 / B1055: Driver / Passenger Pretensioner Initiator Circuit Resistance

High ................................................................. 8B-56

DTC B1052 / B1056: Driver / Passenger Pretensioner Initiator Circu it Resistance Low .. 8B-58

DTC B1053 / B1057: Driver / Passenger Pretensioner Initiator Circuit Short to Ground .. 8B-60

DTC B1054 / B1058: Driver / Passenger Pretensioner Initiator Circuit Short to Power

Circuit .............................................................. 8B-62

DTC B1061 / B1065: Driver / Passenger Side- Air Bag Initiator Circuit Resistance High ......... 8B-64

Page 1030 of 1496

Downloaded from www.Manualslib.com manuals search engine 8-ii Table of Contents

DTC B1062 / B1066: Driver / Passenger Side-Air Bag Initiator Circuit Resistance Low .......... 8B-67

DTC B1063 / B1067: Driver / Passenger Side- Air Bag Initiator Circuit S hort to Ground .......... 8B-70

DTC B1064 / B1068: Driver / Passenger Side- Air Bag Initiator Circu it Short to Power

Circuit .............................................................. 8B-73

DTC B1071: Forward-Sensor Performance Problem ........................................................... 8B-76

DTC B1072: Forward-Sensor Communication Error ................................................................ 8B-76

DTC B1073: Forward-Sensor Circuit Short to Ground ............................................................ 8B-76

DTC B1074: Forward-Sensor Circuit Short to Power Circuit or Open ..................................... 8B-78

DTC B1081 / B1091: Driver / Passenger Side- Sensor Performance Probl em ......................... 8B-80

DTC B1082 / B1092: Driver / Passenger Side- Sensor Communication Erro r .......................... 8B-80

DTC B1083 / B1093: Driver / Passenger Side- Sensor Circuit Short to Ground ....................... 8B-80

DTC B1084 / B1094: Driver / Passenger Side- Sensor Circuit Short to Power Circuit or

Open ............................................................... 8B-81

DTC B1085 / B1095: Wrong Side-Sensor (Driver Side / Passenger) ID ........................... 8B-83

DTC B1361 / B1365: Driver / Passenger Side Curtain-Air Bag Initiator Circuit Resistance

High ................................................................. 8B-84

DTC B1362 / B1366: Driver / Passenger Side Curtain-Air Bag Initiator Circuit Resistance

Low ................................................................. 8B-86

DTC B1363 / B1367: Driver / Passenger Side Curtain-Air Bag Initiator Circuit Short to

Ground ............................................................ 8B-88

DTC B1364 / B1368: Driver / Passenger Side Curtain-Air Bag Initiator Circuit Short to

Power Circuit ................................................... 8B-90

Contact Coil Cable and Its Circuit Check .......... 8B-93 Inspection of Intermittent and Poor

Connections .................................................... 8B-95

Repair and Inspection Required after Accident .......................................................... 8B-96

Repair Instructions ............ ................................8B-98

Disabling Air Bag System.................................. 8B-98

Enabling Air Bag System .................................. 8B-99

SDM Removal and Installation ........................ 8B-100

SDM Inspection ............................................... 8B-101

Driver Air Bag (Inflato r) Module Removal and

Installation ..................................................... 8B-101

Driver Air Bag (Inflator) Module Inspection ..... 8B-103

Passenger Air Bag (Inflator) Module Removal and Installation .............................................. 8B-103

Passenger Air Bag (I nflator) Module

Inspection ...................................................... 8B-105

Side-Air Bag (Inflator) Module Removal and

Installation ..................................................... 8B-105

Side-Air Bag (Inflator) Inspection .................... 8B-107

Side Curtain-Air Bag (Inflator) Module Removal and Installation ............................... 8B-107

Side Curtain-Air Bag (Inflator) Module Inspection ...................................................... 8B-109

Forward-Sensor Removal and Installation ...... 8B-109

Forward-Sensor In spection ............................. 8B-110

Side-Sensor Removal and Installation ............ 8B-110

Side-Sensor Inspection ................................... 8B-111

Passenger Air Bag (Inflator) Module Repair

Harness Installation....................................... 8B-112

Air Bag (Inflator) Module and Seat Belt Pretensioner Disposal ................................... 8B-113

Deployed Air Bag (Inflator) Module and Activated Seat Belt Pretensioner Disposal.... 8B-124

Specifications .................. .................................8B-125

Tightening Torque Specifications .................... 8B-125

Special Tools and Equipmen t .........................8B-125

Use of Special Tools ....................................... 8B-125

Recommended Service Material ..................... 8B-127

Special Tool .................................................... 8B-127

Page 1032 of 1496

Downloaded from www.Manualslib.com manuals search engine 8A-1 Seat Belts:

Restraint

Seat Belts

Precautions

Precautions on Service and Diagnosis of Seat

Belt

S7RS0B8100001

WARNING!

If replacing seat belt is necessary, replace

buckle and seat belt assembly together as a

set. This is for the reason of ensuring locking

of tongue plate with buckle. If these parts are

replaced individually, such a locking

condition may become unreliable. For this

reason, SUZUKI will supply only the spare

buckle and seat belt assembly in a set part.

Before servicing or replacing seat belts, refer to the

following precautionary items.

• Seat belts should be normal relative to strap retractor and buckle portions. • Keep sharp edges and damaging objects away from

belts.

• Avoid bending or damaging any portion of belt buckle or latch plate.

• Do not bleach or dye belt webbing. (Use only mild soap and lukewarm water to clean it.)

• When installing a seat belt anchor bolt, it should be tightened by hand at first to prevent cross-threading

and then to specified torque.

• Do not attempt any repair s on retractor mechanisms

or retractor covers. Replace defective assemblies with

new replacement parts.

• Keep belts dry and clean at all times.

• If there exist any parts in question, replace such parts.

• Replace belts whose webbing is cut or otherwise damaged.

• Do not put anything into trim panel opening which seat belt webbing passes through.

General Description

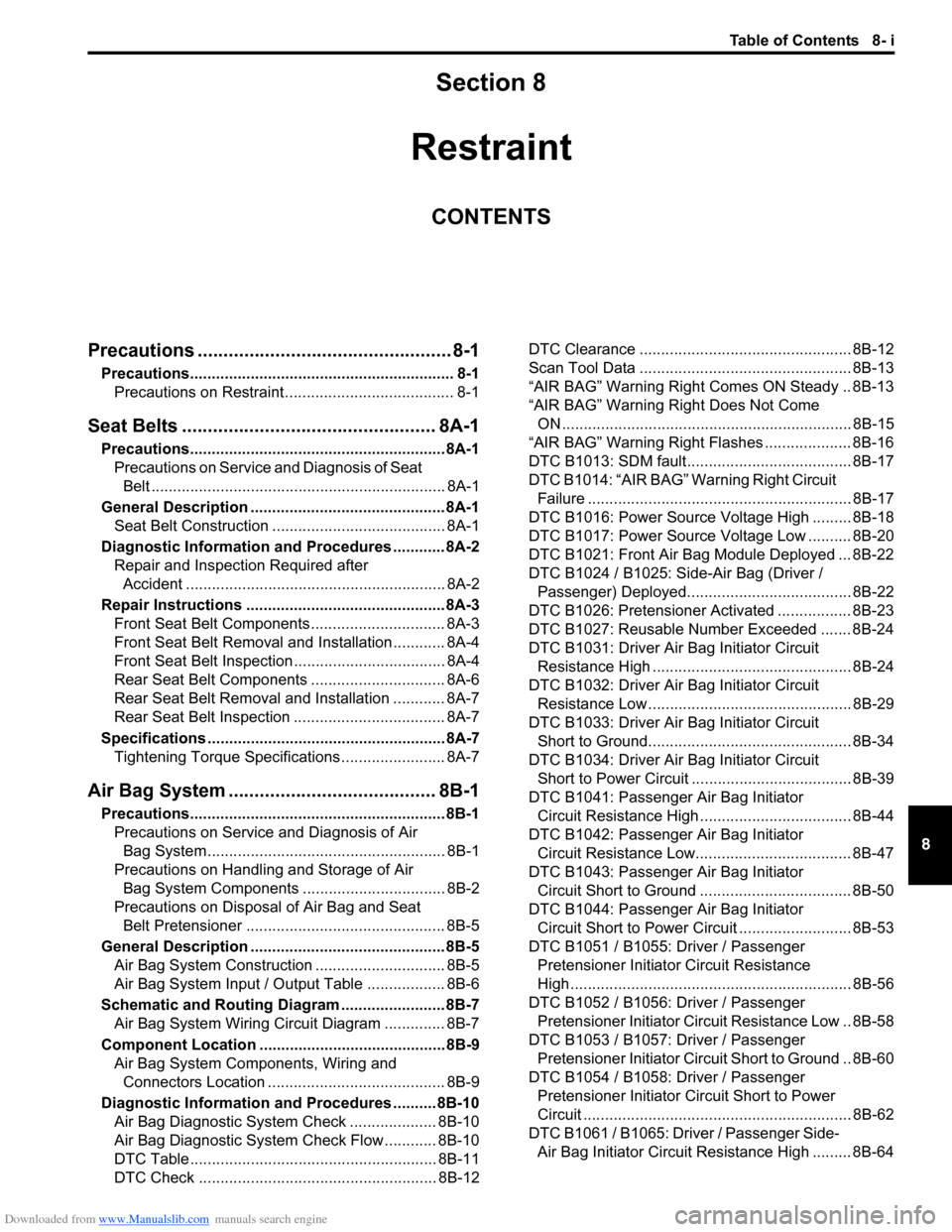

Seat Belt ConstructionS7RS0B8101001

1

1

6

6

6

5

5

7

6

6

2

2

3

4

I4RS0A810001-02

1. Front seat belt assembly (with ELR and pretensioner) 4. Buckle for front seat belt assembly7. Buckle for rear center seat belt

2. Rear seat belt assembly (with A-ELR or ELR) 5. Buckle for rear seat belt assembly

3. Rear center seat belt (with A-ELR or ELR) 6. Retractor assembly

Page 1036 of 1496

Downloaded from www.Manualslib.com manuals search engine 8A-5 Seat Belts:

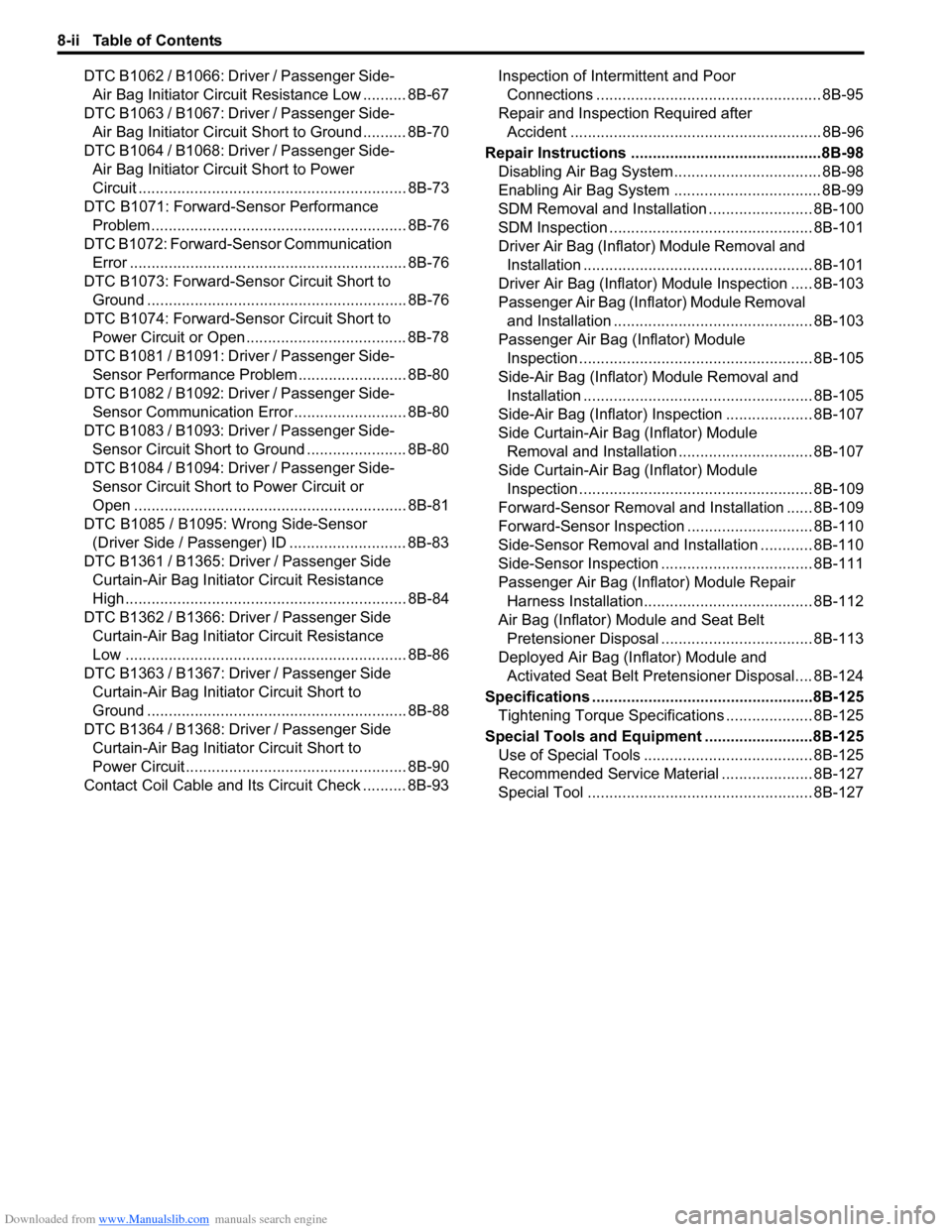

Seat Belt

• The seat belt webbing or strap should be free from damage.

Retractor Assembly (with Seat Belt Pretensioner) 1) Let the seat belt retract fully to confirm its easy retraction.

• The retractor assembly should lock webbing when

pulled quickly.

• The front seat belt retractor assembly (1) should pass the inspection and should lock webbing even

when tilted (approx. 15 °) toward the fore and aft or

right and left directions.

2) Check retractor assembly (1) with seat belt pretensioner appearance visually for following

symptoms and if any one of them is applicable,

replace it with a new one as an assembly.

• Pretensioner has activated.

• There is a crack in seat belt pretensioner (retractor assembly).

• Seat belt pretensioner (retractor assembly) is damaged or a strong impact (e.g., dropping) was

applied to it. Anchor Bolt

• Anchor bolts should be torqued to specification.

Belt Latch

• It should be secure when latched.

Seat Belt Switch

Check driver side seat belt s

witch for continuity by using

ohmmeter.

Seat belt switch specification

Without inserted buckle tongue to buckle catch:

Terminal “A” and “B”: Continuity

With inserted buckle tongue to buckle catch:

Terminal “A” and “B”: No continuity

I2RH01810005-01

1. Buckle tongue

2. Buckle catch

I4RS0B810001-01

Page 1038 of 1496

Downloaded from www.Manualslib.com manuals search engine 8A-7 Seat Belts:

Rear Seat Belt Removal and InstallationS7RS0B8106005

WARNING!

Be sure to read “Precautions on Service and

Diagnosis of Seat Belt” before starting to

work and observe every precaution during

work.

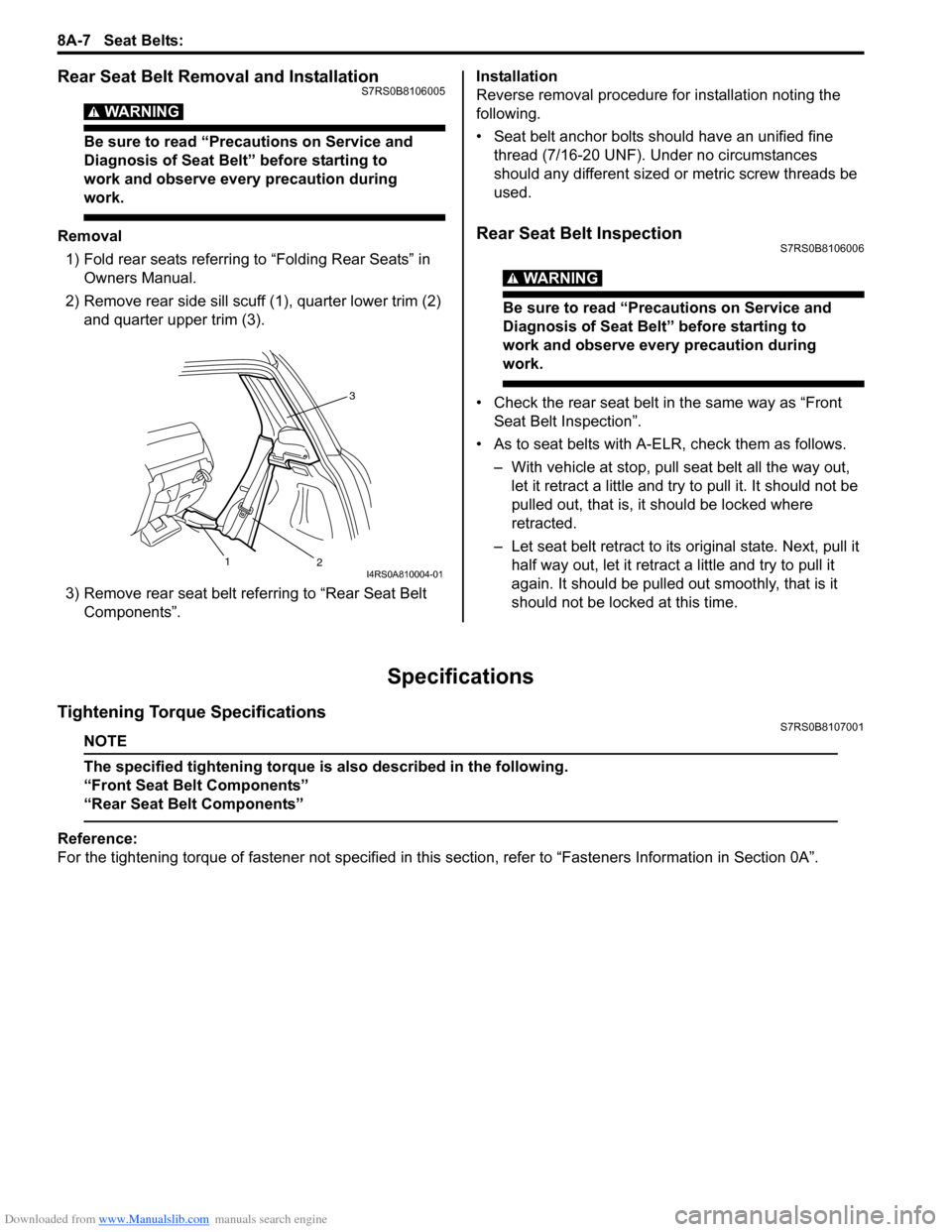

Removal1) Fold rear seats referring to “Folding Rear Seats” in Owners Manual.

2) Remove rear side sill scuff (1), quarter lower trim (2)

and quarter upper trim (3).

3) Remove rear seat belt referring to “Rear Seat Belt Components”. Installation

Reverse removal procedure for installation noting the

following.

• Seat belt anchor bolts should have an unified fine

thread (7/16-20 UNF). Under no circumstances

should any different sized or metric screw threads be

used.Rear Seat Belt InspectionS7RS0B8106006

WARNING!

Be sure to read “Precautions on Service and

Diagnosis of Seat Belt” before starting to

work and observe every precaution during

work.

• Check the rear seat belt in the same way as “Front Seat Belt Inspection”.

• As to seat belts with A-ELR, check them as follows. – With vehicle at stop, pull seat belt all the way out, let it retract a little and try to pull it. It should not be

pulled out, that is, it should be locked where

retracted.

– Let seat belt retract to its original state. Next, pull it

half way out, let it retrac t a little and try to pull it

again. It should be pulled out smoothly, that is it

should not be locked at this time.

Specifications

Tightening Torque SpecificationsS7RS0B8107001

NOTE

The specified tightening torque is also described in the following.

“Front Seat Belt Components”

“Rear Seat Belt Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

3

2

1

I4RS0A810004-01

Page 1040 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-2 Air Bag System:

Precautions on Handling and Storage of Air Bag

System Components

S7RS0B8200002

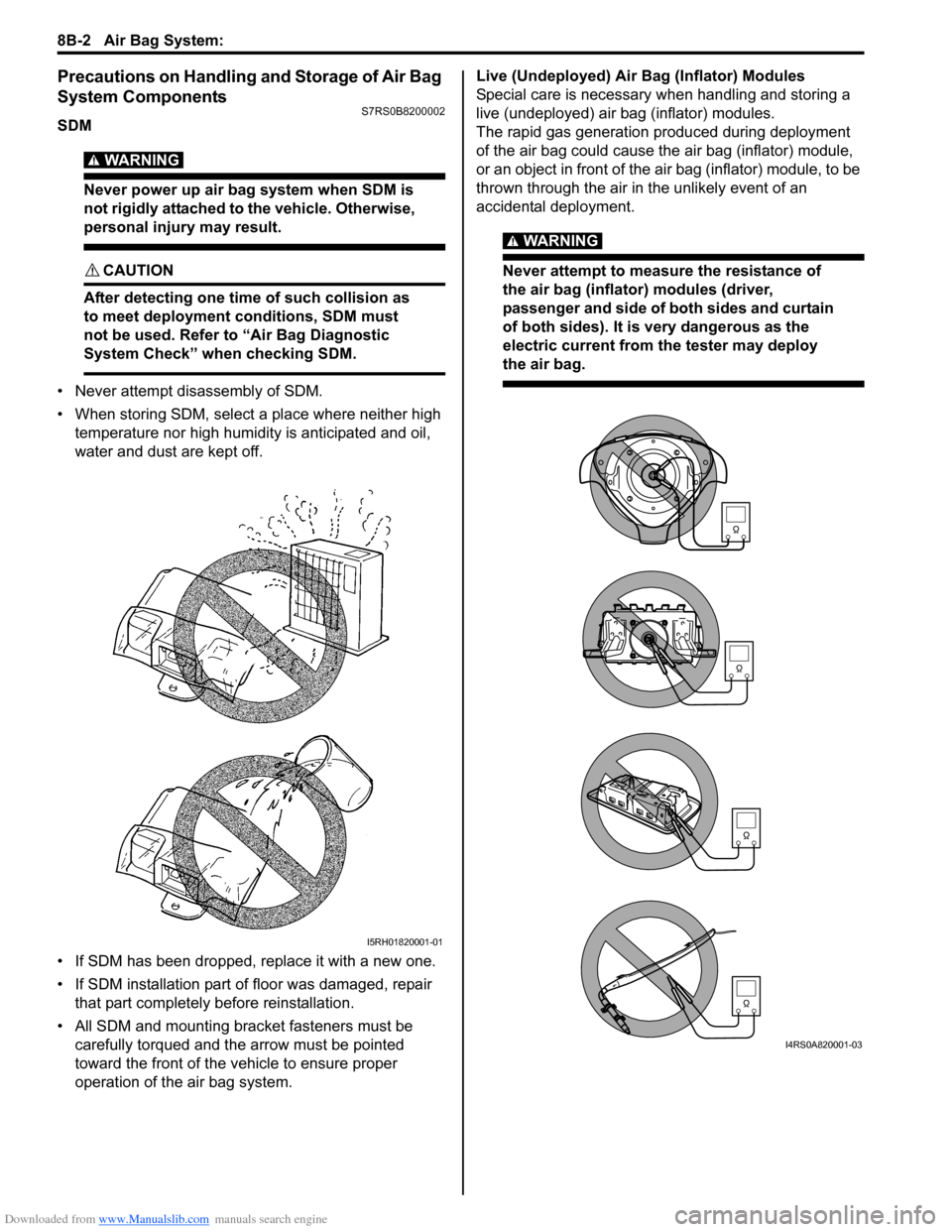

SDM

WARNING!

Never power up air bag system when SDM is

not rigidly attached to the vehicle. Otherwise,

personal injury may result.

CAUTION!

After detecting one time of such collision as

to meet deployment conditions, SDM must

not be used. Refer to “Air Bag Diagnostic

System Check” when checking SDM.

• Never attempt disassembly of SDM.

• When storing SDM, select a place where neither high temperature nor high humidity is anticipated and oil,

water and dust are kept off.

• If SDM has been dropped, replace it with a new one.

• If SDM installation part of floor was damaged, repair that part completely before reinstallation.

• All SDM and mounting bracket fasteners must be carefully torqued and the arrow must be pointed

toward the front of the vehicle to ensure proper

operation of the air bag system. Live (Undeployed) Air Bag (Inflator) Modules

Special care is necessary when handling and storing a

live (undeployed) air bag (inflator) modules.

The rapid gas generation produced during deployment

of the air bag could cause the air bag (inflator) module,

or an object in front of the air bag (inflator) module, to be

thrown through the air in the unlikely event of an

accidental deployment.

WARNING!

Never attempt to measure the resistance of

the air bag (inflator) modules (driver,

passenger and side of both sides and curtain

of both sides). It is

very dangerous as the

electric current from the tester may deploy

the air bag.

I5RH01820001-01

I4RS0A820001-03