section 9 SUZUKI SWIFT 2006 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 1369 of 1496

Downloaded from www.Manualslib.com manuals search engine Interior Trim: 9H-3

Specifications

Tightening Torque SpecificationsS7RS0B9807001

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Fastening part

Tightening torque

Note

N ⋅mkgf-mlb-ft

Sun visor screw 40.4 3.0 �)

Page 1370 of 1496

Downloaded from www.Manualslib.com manuals search engine 9J-1 Hood / Fenders / Doors:

Body, Cab and Accessories

Hood / Fenders / Doors

Repair Instructions

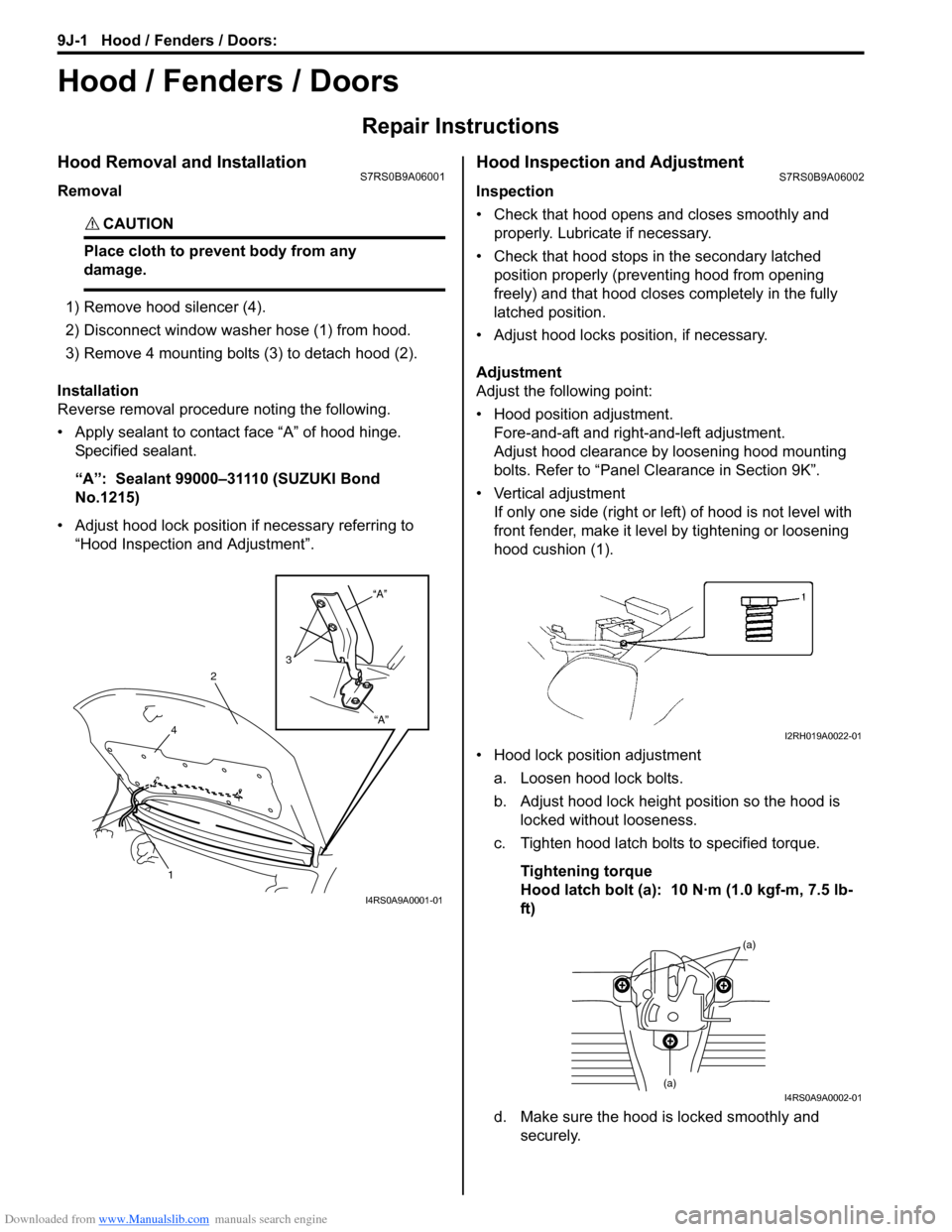

Hood Removal and InstallationS7RS0B9A06001

Removal

CAUTION!

Place cloth to prevent body from any

damage.

1) Remove hood silencer (4).

2) Disconnect window washer hose (1) from hood.

3) Remove 4 mounting bolts (3) to detach hood (2).

Installation

Reverse removal procedure noting the following.

• Apply sealant to contact face “A” of hood hinge. Specified sealant.

“A”: Sealant 99000–31110 (SUZUKI Bond

No.1215)

• Adjust hood lock position if necessary referring to “Hood Inspection and Adjustment”.

Hood Inspection and AdjustmentS7RS0B9A06002

Inspection

• Check that hood opens and closes smoothly and properly. Lubricate if necessary.

• Check that hood stops in the secondary latched position properly (preventing hood from opening

freely) and that hood closes completely in the fully

latched position.

• Adjust hood locks position, if necessary.

Adjustment

Adjust the following point:

• Hood position adjustment. Fore-and-aft and right-and-left adjustment.

Adjust hood clearance by loosening hood mounting

bolts. Refer to “Panel Clearance in Section 9K”.

• Vertical adjustment If only one side (right or left) of hood is not level with

front fender, make it level by tightening or loosening

hood cushion (1).

• Hood lock position adjustment a. Loosen hood lock bolts.

b. Adjust hood lock height position so the hood is locked without looseness.

c. Tighten hood latch bolts to specified torque.

Tightening torque

Hood latch bolt (a): 10 N·m (1.0 kgf-m, 7.5 lb-

ft)

d. Make sure the hood is locked smoothly and securely.

“A”

“A”

3

2

4

1

I4RS0A9A0001-01

I2RH019A0022-01

(a)

(a)I4RS0A9A0002-01

Page 1371 of 1496

Downloaded from www.Manualslib.com manuals search engine Hood / Fenders / Doors: 9J-2

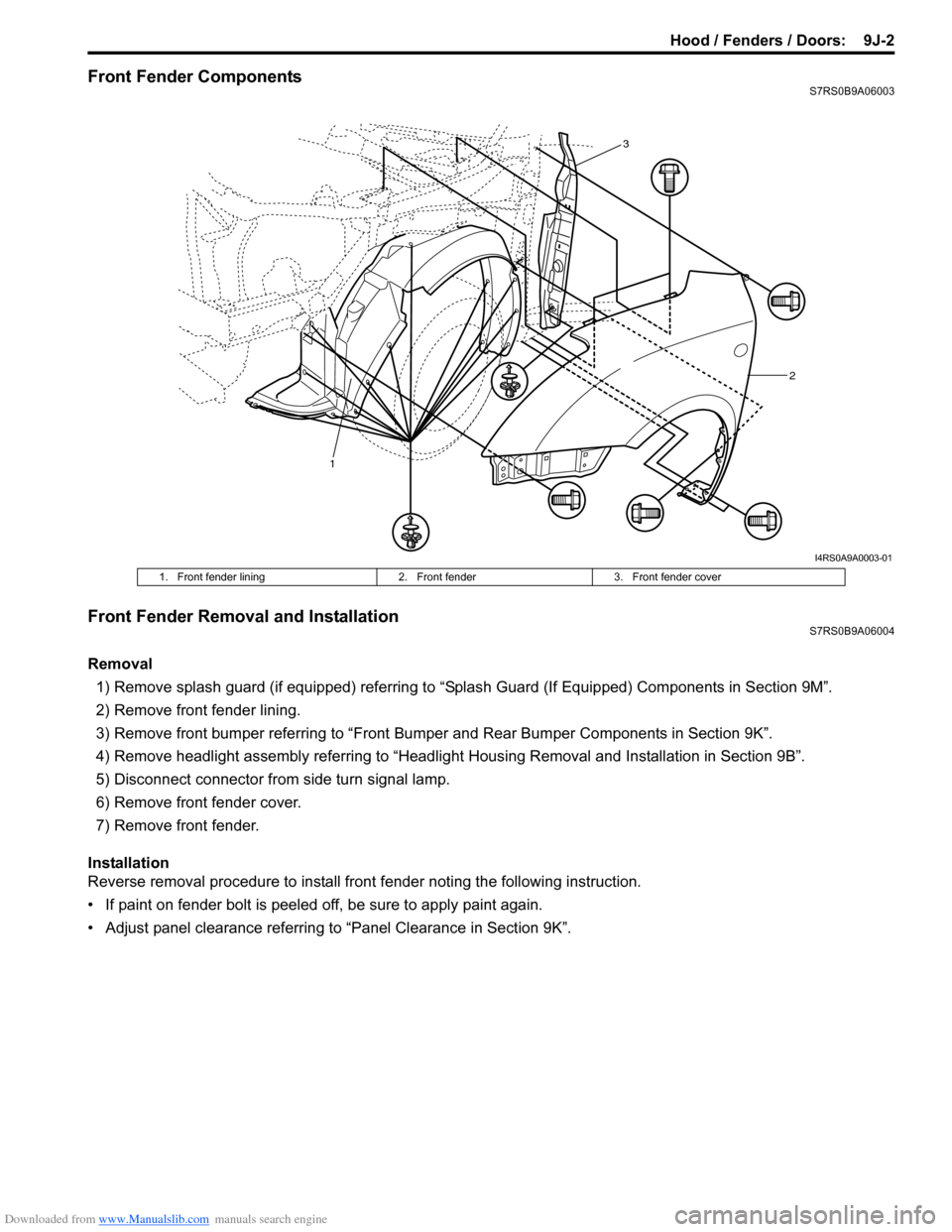

Front Fender ComponentsS7RS0B9A06003

Front Fender Removal and InstallationS7RS0B9A06004

Removal1) Remove splash guard (if equipped) referring to “Splash Guard (If Equipped) Components in Section 9M”.

2) Remove front fender lining.

3) Remove front bumper referring to “Front Bumper and Rear Bumper Components in Section 9K”.

4) Remove headlight assembly referring to “Headlig ht Housing Removal and Installation in Section 9B”.

5) Disconnect connector from side turn signal lamp.

6) Remove front fender cover.

7) Remove front fender.

Installation

Reverse removal procedure to install fron t fender noting the following instruction.

• If paint on fender bolt is peeled off, be sure to apply paint again.

• Adjust panel clearance referring to “Panel Clearance in Section 9K”.

1 2

3

I4RS0A9A0003-01

1. Front fender lining

2. Front fender3. Front fender cover

Page 1372 of 1496

Downloaded from www.Manualslib.com manuals search engine 9J-3 Hood / Fenders / Doors:

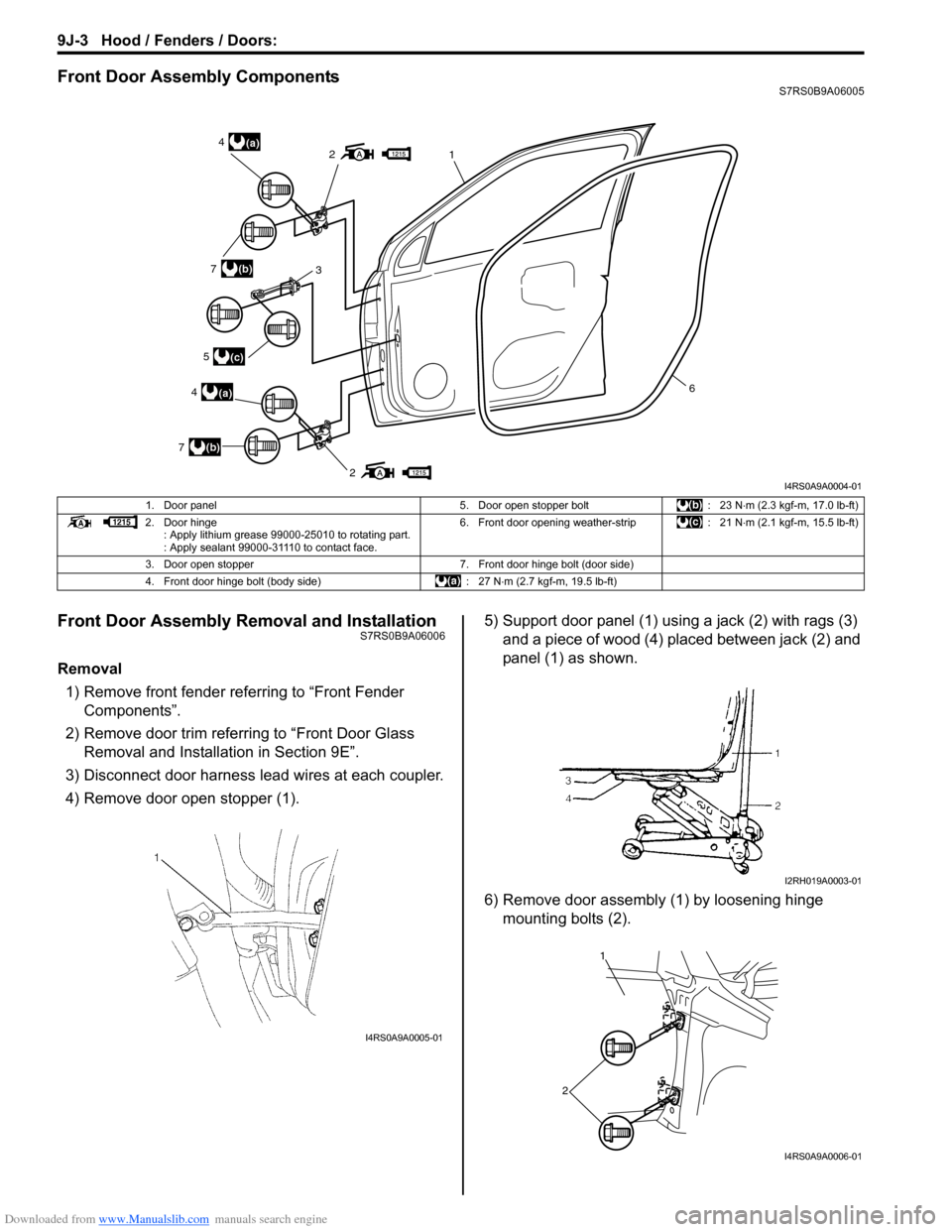

Front Door Assembly ComponentsS7RS0B9A06005

Front Door Assembly Removal and InstallationS7RS0B9A06006

Removal1) Remove front fender referring to “Front Fender Components”.

2) Remove door trim referring to “Front Door Glass Removal and Installa tion in Section 9E”.

3) Disconnect door harness lead wires at each coupler.

4) Remove door open stopper (1). 5) Support door panel (1) using a jack (2) with rags (3)

and a piece of wood (4) placed between jack (2) and

panel (1) as shown.

6) Remove door assembly (1) by loosening hinge mounting bolts (2).

2

21(a)4

(a)4

3(b)7

(b)7

(c)5

6

I4RS0A9A0004-01

1. Door panel 5. Door open stopper bolt: 23 N⋅m (2.3 kgf-m, 17.0 lb-ft)

2. Door hinge : Apply lithium grease 99000-25010 to rotating part.

: Apply sealant 99000-31110 to contact face. 6. Front door opening weather-strip

: 21 N⋅m (2.1 kgf-m, 15.5 lb-ft)

3. Door open stopper 7. Front door hinge bolt (door side)

4. Front door hinge bolt (body side) : 27 N⋅m (2.7 kgf-m, 19.5 lb-ft)

I4RS0A9A0005-01

I2RH019A0003-01

1

2

I4RS0A9A0006-01

Page 1373 of 1496

Downloaded from www.Manualslib.com manuals search engine Hood / Fenders / Doors: 9J-4

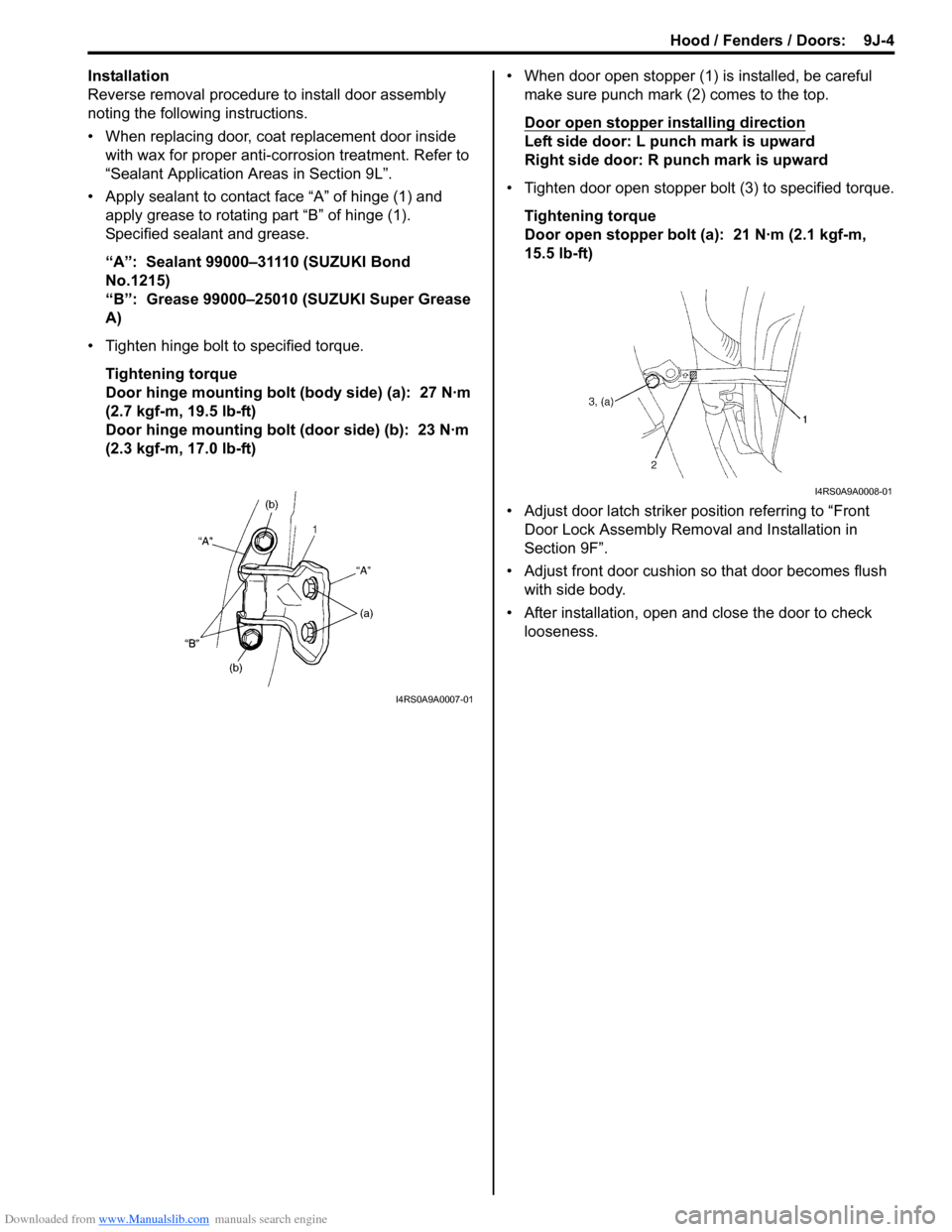

Installation

Reverse removal procedure to install door assembly

noting the following instructions.

• When replacing door, coat replacement door inside with wax for proper anti-cor rosion treatment. Refer to

“Sealant Application Areas in Section 9L”.

• Apply sealant to contact face “A” of hinge (1) and apply grease to rotating part “B” of hinge (1).

Specified sealant and grease.

“A”: Sealant 99000–31110 (SUZUKI Bond

No.1215)

“B”: Grease 99000–25010 (SUZUKI Super Grease

A)

• Tighten hinge bolt to specified torque. Tightening torque

Door hinge mounting bolt (body side) (a): 27 N·m

(2.7 kgf-m, 19.5 lb-ft)

Door hinge mounting bolt (door side) (b): 23 N·m

(2.3 kgf-m, 17.0 lb-ft) • When door open stopper (1) is installed, be careful

make sure punch mark (2) comes to the top.

Door open stopper installing direction

Left side door: L punch mark is upward

Right side door: R punch mark is upward

• Tighten door open stopper bolt (3) to specified torque. Tightening torque

Door open stopper bolt (a): 21 N·m (2.1 kgf-m,

15.5 lb-ft)

• Adjust door latch striker position referring to “Front Door Lock Assembly Removal and Installation in

Section 9F”.

• Adjust front door cushion so that door becomes flush with side body.

• After installation, open and close the door to check looseness.

I4RS0A9A0007-01

I4RS0A9A0008-01

Page 1375 of 1496

Downloaded from www.Manualslib.com manuals search engine Hood / Fenders / Doors: 9J-6

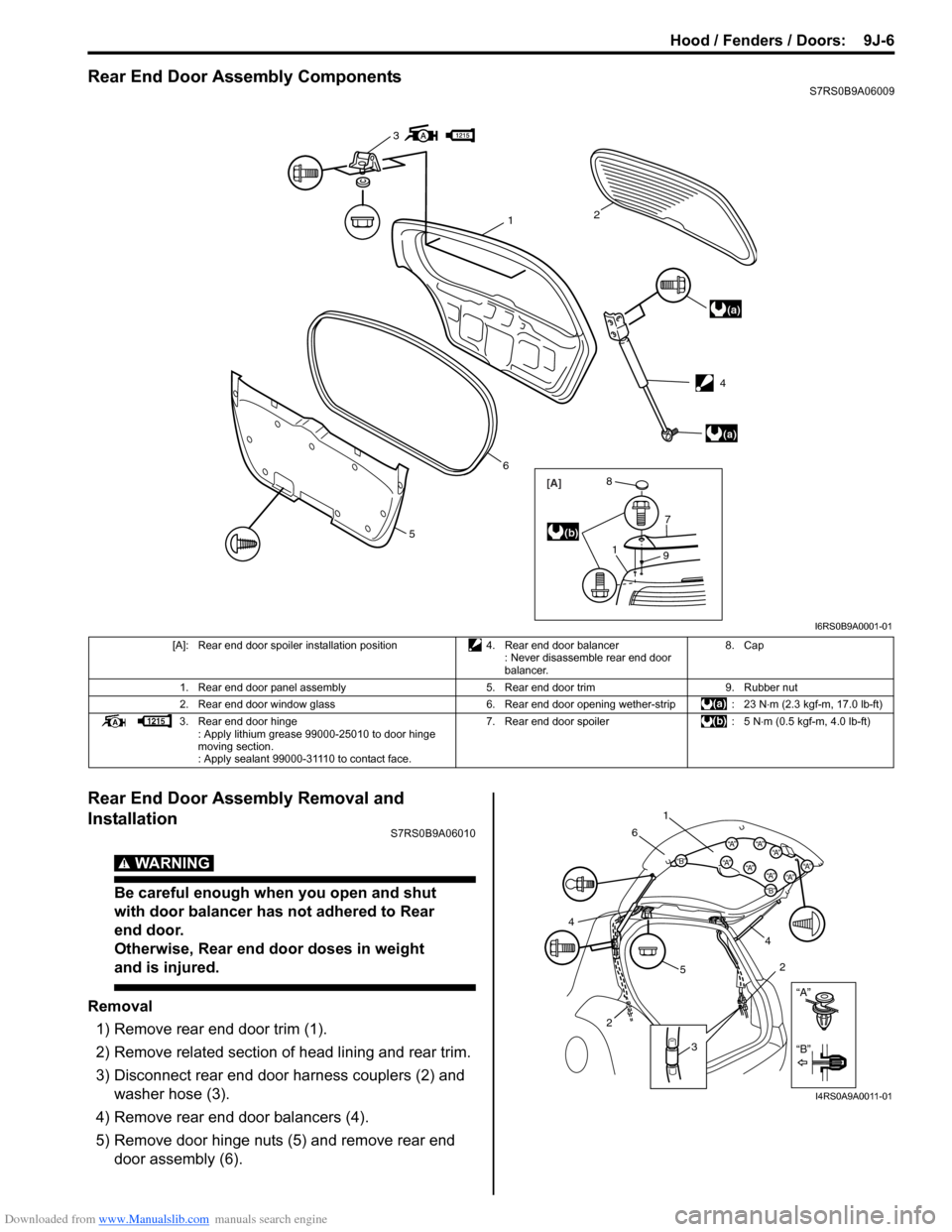

Rear End Door Assembly ComponentsS7RS0B9A06009

Rear End Door Assembly Removal and

Installation

S7RS0B9A06010

WARNING!

Be careful enough when you open and shut

with door balancer has not adhered to Rear

end door.

Otherwise, Rear end door doses in weight

and is injured.

Removal1) Remove rear end door trim (1).

2) Remove related section of head lining and rear trim.

3) Disconnect rear end door harness couplers (2) and washer hose (3).

4) Remove rear end door balancers (4).

5) Remove door hinge nuts (5) and remove rear end door assembly (6).

3

(a)

(a)

12

6

5

[A]

1

7

9

8

(b)

4

I6RS0B9A0001-01

[A]: Rear end door spoiler installation position 4. Rear end door balancer

: Never disassemble rear end door

balancer. 8. Cap

1. Rear end door panel assembly 5. Rear end door trim9. Rubber nut

2. Rear end door window glass 6. Rear end door opening wether-strip: 23 N⋅m (2.3 kgf-m, 17.0 lb-ft)

3. Rear end door hinge : Apply lithium grease 99000-25010 to door hinge

moving section.

: Apply sealant 99000-31110 to contact face. 7. Rear end door spoiler

: 5 N⋅m (0.5 kgf-m, 4.0 lb-ft)

“A”

“B”

“B”

“A”“B”“A”“A”“A”

“A”“A”“A”

“A”

1

6

5 4

2

3

2

4

I4RS0A9A0011-01

Page 1376 of 1496

Downloaded from www.Manualslib.com manuals search engine 9J-7 Hood / Fenders / Doors:

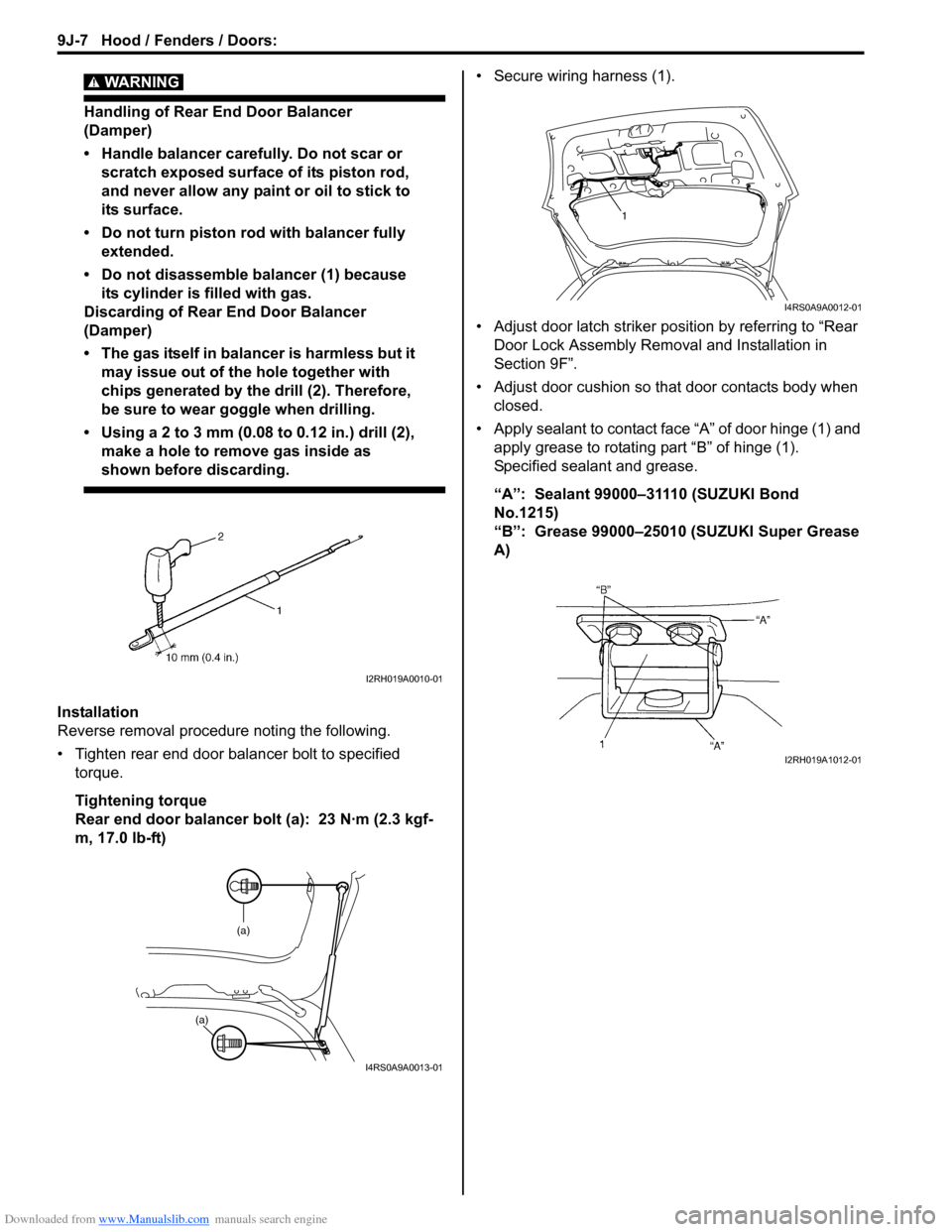

WARNING!

Handling of Rear End Door Balancer

(Damper)

• Handle balancer carefully. Do not scar or scratch exposed surface of its piston rod,

and never allow any paint or oil to stick to

its surface.

• Do not turn piston rod with balancer fully extended.

• Do not disassemble balancer (1) because its cylinder is filled with gas.

Discarding of Rear End Door Balancer

(Damper)

• The gas itself in balancer is harmless but it may issue out of the hole together with

chips generated by th e drill (2). Therefore,

be sure to wear goggle when drilling.

• Using a 2 to 3 mm (0.08 to 0.12 in.) drill (2),

make a hole to remove gas inside as

shown before discarding.

Installation

Reverse removal procedure noting the following.

• Tighten rear end door balancer bolt to specified torque.

Tightening torque

Rear end door balancer bolt (a): 23 N·m (2.3 kgf-

m, 17.0 lb-ft) • Secure wiring harness (1).

• Adjust door latch striker position by referring to “Rear

Door Lock Assembly Removal and Installation in

Section 9F”.

• Adjust door cushion so that door contacts body when closed.

• Apply sealant to contact face “A” of door hinge (1) and apply grease to rotating part “B” of hinge (1).

Specified sealant and grease.

“A”: Sealant 99000–31110 (SUZUKI Bond

No.1215)

“B”: Grease 99000–25010 (SUZUKI Super Grease

A)

I2RH019A0010-01

(a)

(a)

I4RS0A9A0013-01

1

I4RS0A9A0012-01

I2RH019A1012-01

Page 1377 of 1496

Downloaded from www.Manualslib.com manuals search engine Hood / Fenders / Doors: 9J-8

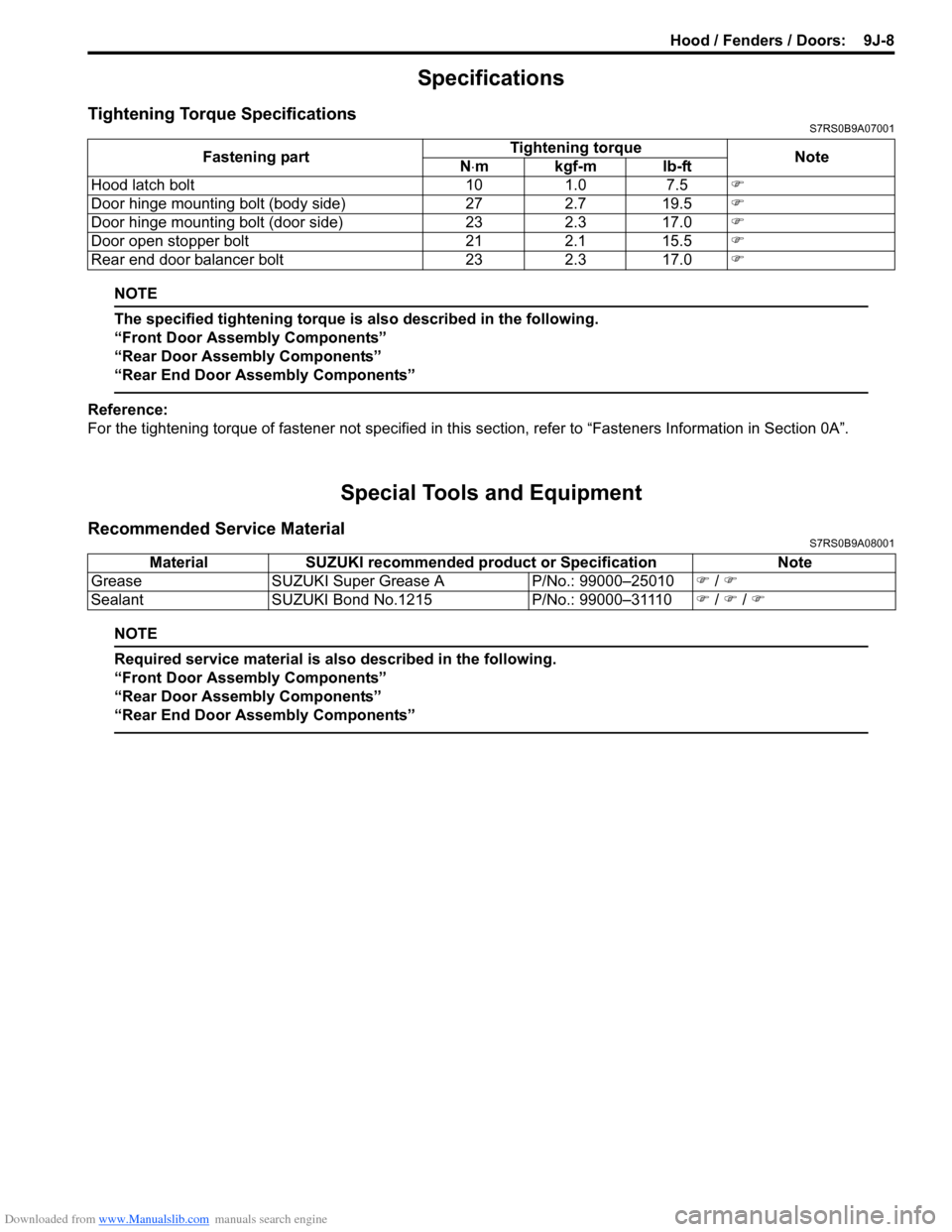

Specifications

Tightening Torque SpecificationsS7RS0B9A07001

NOTE

The specified tightening torque is also described in the following.

“Front Door Assembly Components”

“Rear Door Assembly Components”

“Rear End Door Assembly Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Recommended Service MaterialS7RS0B9A08001

NOTE

Required service material is also described in the following.

“Front Door Assembly Components”

“Rear Door Assembly Components”

“Rear End Door Assembly Components”

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Hood latch bolt 10 1.0 7.5 �)

Door hinge mounting bolt (body side) 27 2.7 19.5 �)

Door hinge mounting bolt (door side) 23 2.3 17.0 �)

Door open stopper bolt 21 2.1 15.5 �)

Rear end door balancer bolt 23 2.3 17.0 �)

MaterialSUZUKI recommended product or Specification Note

Grease SUZUKI Super Grease A P/No.: 99000–25010�) / �)

Sealant SUZUKI Bond No.1215 P/No.: 99000–31110�) / �) / �)

Page 1401 of 1496

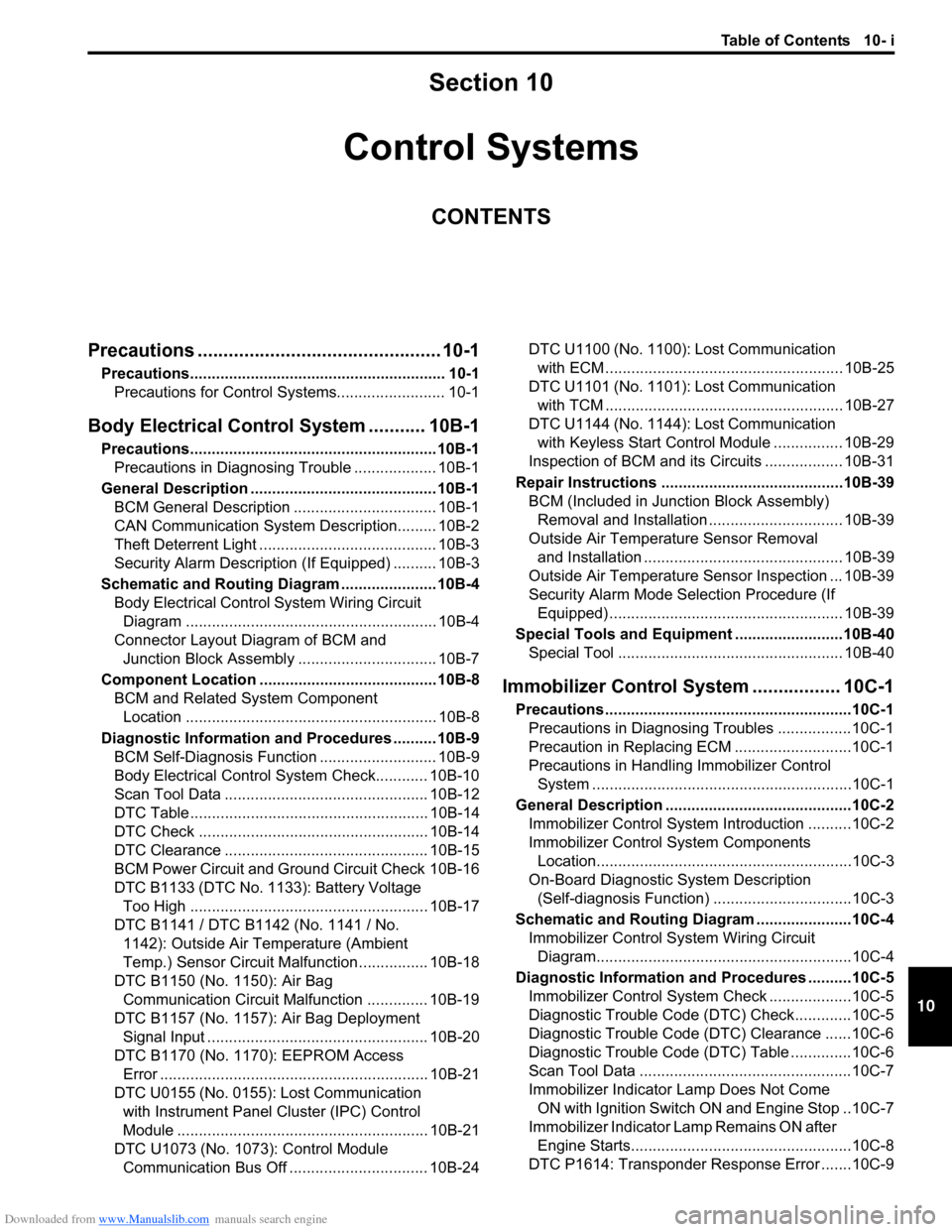

Downloaded from www.Manualslib.com manuals search engine Table of Contents 10- i

10

Section 10

CONTENTS

Control Systems

Precautions ............................................... 10-1

Precautions........................................................... 10-1

Precautions for Control Systems......................... 10-1

Body Electrical Contro l System ........... 10B-1

Precautions......................................................... 10B-1

Precautions in Diagnosing Trouble ................... 10B-1

General Description ........................................... 10B-1 BCM General Description ................................. 10B-1

CAN Communication System Description......... 10B-2

Theft Deterrent Light ......................................... 10B-3

Security Alarm Description (If Equipped) .......... 10B-3

Schematic and Routing Diagram ...................... 10B-4 Body Electrical Control System Wiring Circuit Diagram .......................................................... 10B-4

Connector Layout Diagram of BCM and Junction Block Assembly ................................ 10B-7

Component Locatio n ......................................... 10B-8

BCM and Related System Component Location .......................................................... 10B-8

Diagnostic Information an d Procedures .......... 10B-9

BCM Self-Diagnosis Function ........................... 10B-9

Body Electrical Control System Check............ 10B-10

Scan Tool Data ............................................... 10B-12

DTC Table ....................................................... 10B-14

DTC Check ..................................................... 10B-14

DTC Clearance ............................................... 10B-15

BCM Power Circuit and Ground Circuit Check 10B-16

DTC B1133 (DTC No. 1133): Battery Voltage Too High ....................................................... 10B-17

DTC B1141 / DTC B1142 (No. 1141 / No. 1142): Outside Air Temperature (Ambient

Temp.) Sensor Circuit Ma lfunction ................ 10B-18

DTC B1150 (No. 1150): Air Bag Communication Circuit Malfunction .............. 10B-19

DTC B1157 (No. 1157): Air Bag Deployment Signal Input ................................................... 10B-20

DTC B1170 (No. 1170 ): EEPROM Access

Error .............................................................. 10B-21

DTC U0155 (No. 0155): Lost Communication with Instrument Panel Cluster (IPC) Control

Module .......................................................... 10B-21

DTC U1073 (No. 1073): Control Module Communication Bus Off ................................ 10B-24 DTC U1100 (No. 1100): Lost Communication

with ECM ....................................................... 10B-25

DTC U1101 (No. 1101): Lost Communication with TCM ....................................................... 10B-27

DTC U1144 (No. 1144): Lost Communication with Keyless Start Control Module ................ 10B-29

Inspection of BCM and its Circuits .................. 10B-31

Repair Instructions ........... ...............................10B-39

BCM (Included in Junction Block Assembly) Removal and Installation ............................... 10B-39

Outside Air Temperature Sensor Removal and Installation .............................................. 10B-39

Outside Air Temperature Sensor Inspection ... 10B-39

Security Alarm Mode Selection Procedure (If Equipped) ...................................................... 10B-39

Special Tools and Equipmen t .........................10B-40

Special Tool .................................................... 10B-40

Immobilizer Control Syst em ................. 10C-1

Precautions.........................................................10C-1

Precautions in Diagnosing Troubles .................10C-1

Precaution in Replacing ECM ...........................10C-1

Precautions in Handli ng Immobilizer Control

System ............................................................10C-1

General Description ...........................................10C-2 Immobilizer Control System Introduction ..........10C-2

Immobilizer Control System Components Location...........................................................10C-3

On-Board Diagnostic System Description (Self-diagnosis Function) ................................10C-3

Schematic and Routing Diag ram ......................10C-4

Immobilizer Control System Wiring Circuit Diagram...........................................................10C-4

Diagnostic Information an d Procedures ..........10C-5

Immobilizer Control System Check ...................10C-5

Diagnostic Trouble Code (DTC) Check.............10C-5

Diagnostic Trouble Code (DTC) Clearance ......10C-6

Diagnostic Trouble Code (DTC) Table ..............10C-6

Scan Tool Data .................................................10C-7

Immobilizer Indicator Lamp Does Not Come ON with Ignition Switch ON and Engine Stop ..10C-7

Immobilizer Indicator Lamp Remains ON after Engine Starts...................................................10C-8

DTC P1614: Transponder Re sponse Error .......10C-9

Page 1403 of 1496

Downloaded from www.Manualslib.com manuals search engine Precautions: 10-1

Control Systems

Precautions

Precautions

Precautions for Control SystemsS7RS0BA000001

Air Bag Warning

Refer to “Air Bag Warning in Section 00”.