Air bag connection SUZUKI SWIFT 2006 2.G Service Manual PDF

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 1126 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-88 Air Bag System:

NOTE

Upon completion of inspection and repair work, perform the following items.

• Reconnect all air bag system components, ensure all components are properly mounted.

• Clear DTCs referring to “DTC Clearance”, if any.

• Repeat “Air Bag Diagnostic System Check” to confirm that the trouble has been corrected.

DTC B1363 / B1367: Driver / Passenger Side Curtain-Air Bag Initiator Circuit Short to GroundS7RS0B8204045

Wiring Diagram2 1) With ignition switch OFF, disconnect SDM connector

“L29”.

2) Check proper connection to SDM at terminals “L29-19” and “L29-20” or “L29-21” and “L29-22”.

3) If OK, release shorting bar in SDM connector inserting

release tool (1) included in special tool (A).

4) Measure resistance between “L29-19” and “L29-20” terminals (for DTC B1362) or “L29-21” and “L29-22”

terminals (for DTC B1366) with connected special tools

(A), (B) and (C).

Special tool

(A): 09932–76010

(B): 09932–75010

(C): 09932–78310

Is resistance 1.8

Ω or more? Substitute a known-

good SDM and recheck.

DTC B1362: Repair

short from “YEL/GRN”

wire circuit to “YEL/

BLU” wire circuit or from

“YEL/GRN” or “YEL/

BLU” wire circuit to

other wire circuit.

DTC B1366: Repair

short from “BLK/YEL”

wire circuit to “BRN/

YEL” wire circuit or from

“BLK/YEL” or “BRN/

YEL” wire circuit to

other wire circuit.

Step Action Yes No

(A)

"L29-20""L29-21""L29-22"

"L29-19"

STEERING WHEEL(B)

(C)

(A)

"L18", "L41"

I7RS0A820033-02

1

2

3

GRN

RED

8

BLK

L29-27

L29-28 IG

E1

4

“L29”

“L04”

“G32”

“L29”

L29-20

DC+

L29-19

DC-YEL/BLU

YEL/GRN

56

“L18”

L29-21

PC+

L29-22

PC-BRN/YEL BLK/YEL7

“L41”[A]

I7RS0A820031-04

[A]: Shorting bar 3. “A/BAG” fuse 6. Driver side curtain-air bag (inflator) module

1. From main fuse 4. Junction block assembly 7. Passenger side curtain-air bag (inflator) module

2. Ignition switch 5. SDM 8. Ground for air bag system

Page 1127 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-89

CAUTION!

• Be sure to perform “Air Bag Diagnostic System Check” before starting diagnosis according to flow.

• When measurement of resistance or voltage is required in this flow, use a tester along with a correct terminal adapter from special tool (Connector test adapter kit).

• When a check for proper connection is required, refer to “Inspection of Intermittent and Poor Connections”.

• If there is open circuit in the air bag wire harnes s, connector or terminal is found damaged, replace

the wire harness, connector and terminal as an assembly.

DTC Will Set when

The voltage measured at side curtain-air bag (driver or passenger) initiator circuit is below a specified value for

specified time.

Flow Test Description

Step 1: Check whether malfunction is in side curtain-air bag (inflator) module.

Step 2: Check side curtain-air bag initiator circuit.

DTC Troubleshooting

Step Action YesNo

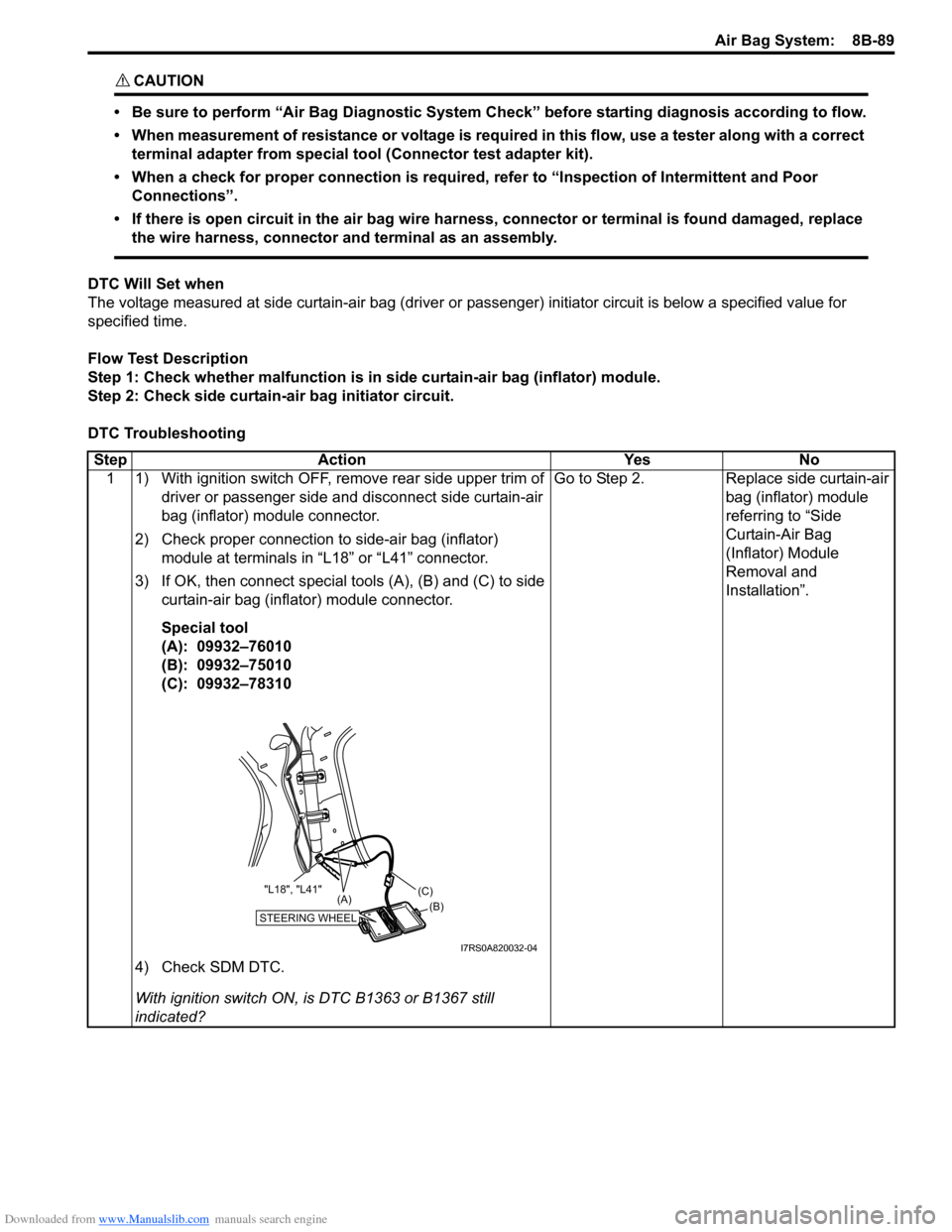

1 1) With ignition switch OFF, remove rear side upper trim of driver or passenger side and disconnect side curtain-air

bag (inflator) module connector.

2) Check proper connection to side-air bag (inflator) module at terminals in “L18” or “L41” connector.

3) If OK, then connect special tools (A), (B) and (C) to side curtain-air bag (inflator) module connector.

Special tool

(A): 09932–76010

(B): 09932–75010

(C): 09932–78310

4) Check SDM DTC.

With ignition switch ON, is DTC B1363 or B1367 still

indicated? Go to Step 2.

Replace side curtain-air

bag (inflator) module

referring to “Side

Curtain-Air Bag

(Inflator) Module

Removal and

Installation”.

STEERING WHEEL(B)

(C)

(A)

"L18", "L41"

I7RS0A820032-04

Page 1129 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-91

CAUTION!

• Be sure to perform “Air Bag Diagnostic System Check” before starting diagnosis according to flow.

• When measurement of resistance or voltage is required in this flow, use a tester along with a correct terminal adapter from special tool (Connector test adapter kit).

• When a check for proper connection is required, refer to “Inspection of Intermittent and Poor Connections”.

• If there is open circuit in the air bag wire harnes s, connector or terminal is found damaged, replace

the wire harness, connector and terminal as an assembly.

DTC Will Set when

The voltage measured at side curtain-air bag (driver or passenger) initiator circuit is above a specified value for

specified time.

Flow Test Description

Step 1: Check whether malfunction is in side curtain-air bag (inflator) module.

Step 2: Check side curtain-air bag initiator circuit.

DTC Troubleshooting

Step Action YesNo

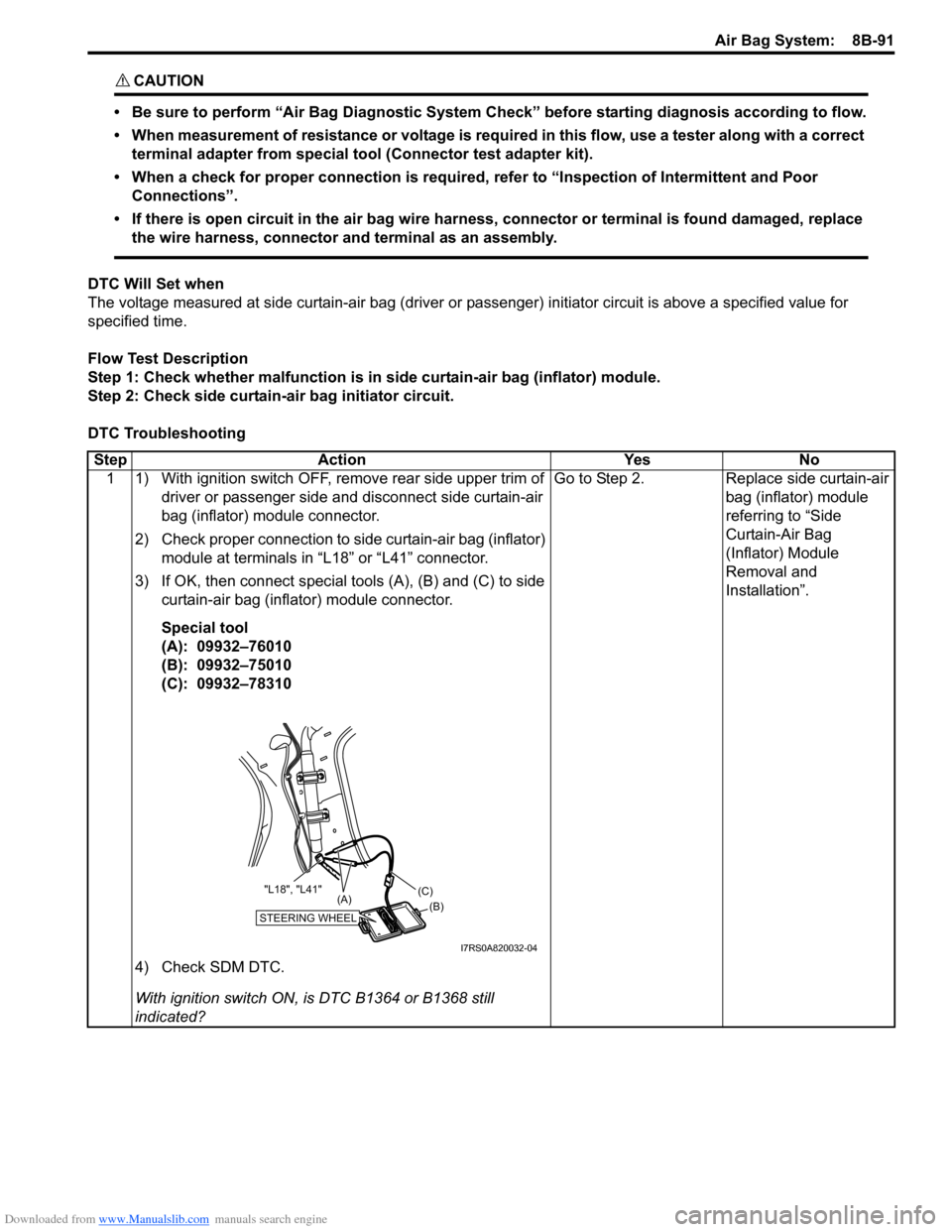

1 1) With ignition switch OFF, remove rear side upper trim of driver or passenger side and disconnect side curtain-air

bag (inflator) module connector.

2) Check proper connection to side curtain-air bag (inflator) module at terminals in “L18” or “L41” connector.

3) If OK, then connect special tools (A), (B) and (C) to side curtain-air bag (inflator) module connector.

Special tool

(A): 09932–76010

(B): 09932–75010

(C): 09932–78310

4) Check SDM DTC.

With ignition switch ON, is DTC B1364 or B1368 still

indicated? Go to Step 2.

Replace side curtain-air

bag (inflator) module

referring to “Side

Curtain-Air Bag

(Inflator) Module

Removal and

Installation”.

STEERING WHEEL(B)

(C)

(A)

"L18", "L41"

I7RS0A820032-04

Page 1131 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-93

Contact Coil Cable and Its Circuit CheckS7RS0B8204047

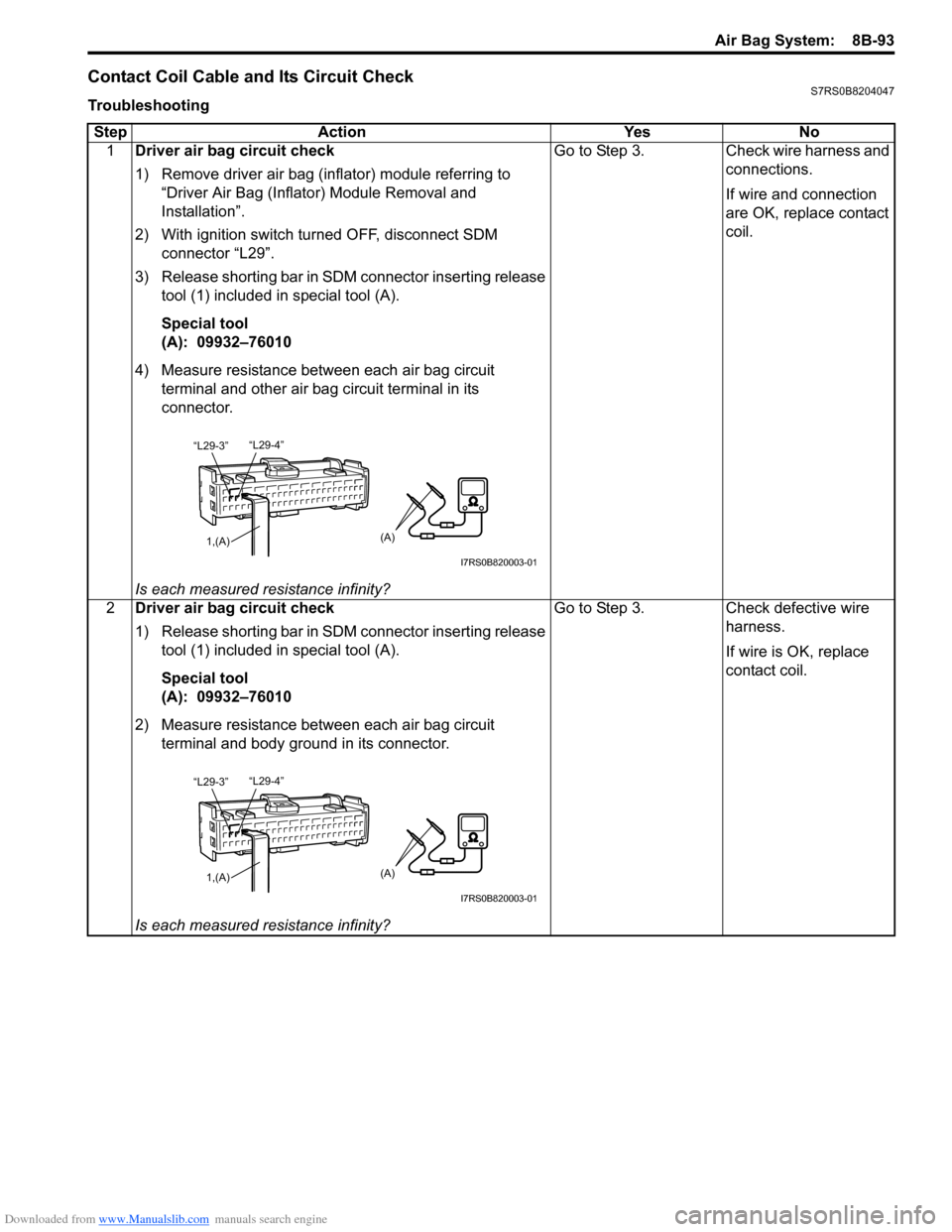

TroubleshootingStep Action Yes No 1 Driver air bag circuit check

1) Remove driver air bag (inflator) module referring to

“Driver Air Bag (Inflator) Module Removal and

Installation”.

2) With ignition switch turned OFF, disconnect SDM connector “L29”.

3) Release shorting bar in SDM connector inserting release tool (1) included in special tool (A).

Special tool

(A): 09932–76010

4) Measure resistance between each air bag circuit terminal and other air bag circuit terminal in its

connector.

Is each measured resistance infinity? Go to Step 3. Check wire harness and

connections.

If wire and connection

are OK, replace contact

coil.

2 Driver air bag circuit check

1) Release shorting bar in SDM connector inserting release

tool (1) included in special tool (A).

Special tool

(A): 09932–76010

2) Measure resistance between each air bag circuit terminal and body ground in its connector.

Is each measured resistance infinity? Go to Step 3. Check defective wire

harness.

If wire is OK, replace

contact coil.

“L29-4”

“L29-3”

1,(A)(A)

I7RS0B820003-01

“L29-4”

“L29-3”

1,(A)(A)

I7RS0B820003-01

Page 1133 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-95

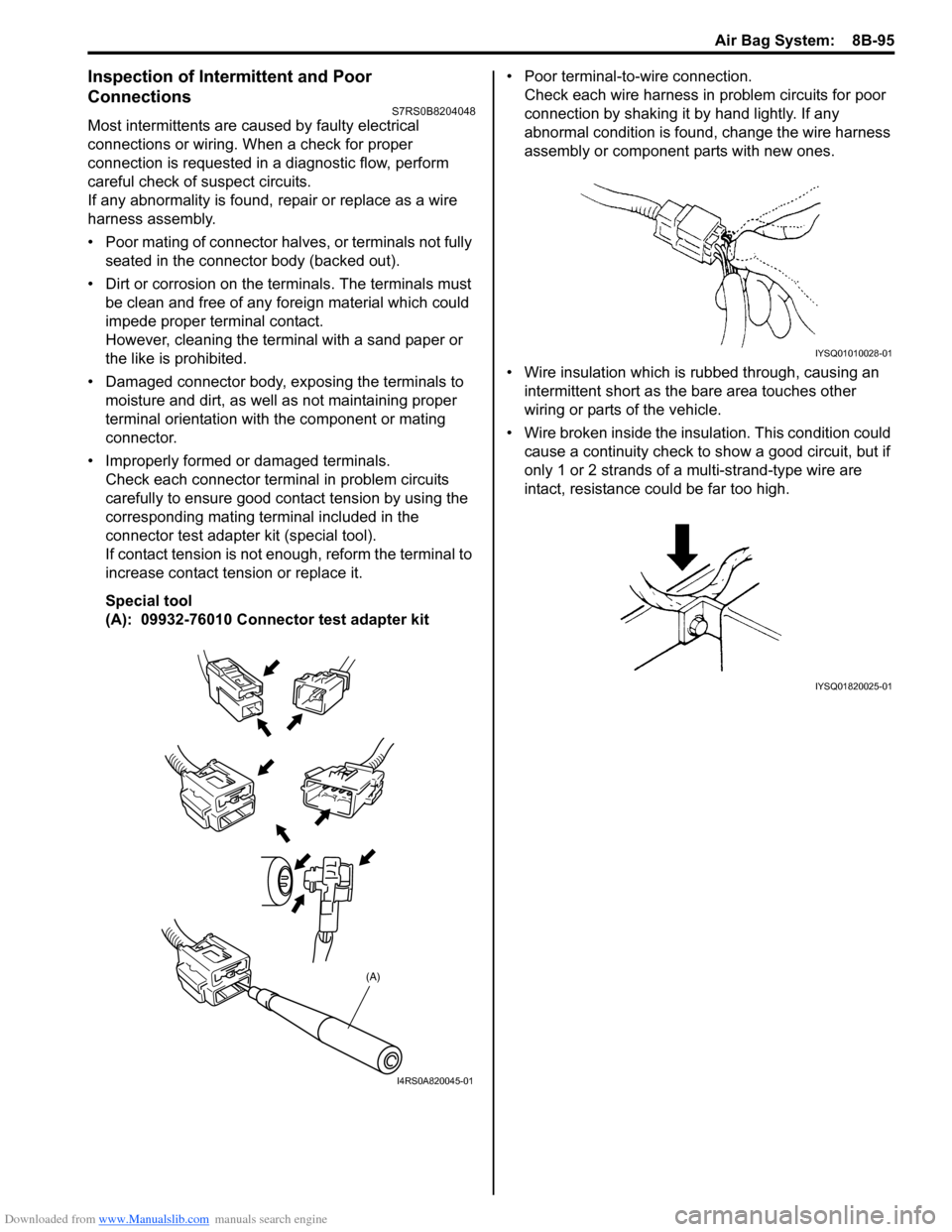

Inspection of Intermittent and Poor

Connections

S7RS0B8204048

Most intermittents are caused by faulty electrical

connections or wiring. When a check for proper

connection is requested in a diagnostic flow, perform

careful check of suspect circuits.

If any abnormality is found, repair or replace as a wire

harness assembly.

• Poor mating of connector halves, or terminals not fully seated in the connector body (backed out).

• Dirt or corrosion on the terminals. The terminals must be clean and free of any foreign material which could

impede proper terminal contact.

However, cleaning the terminal with a sand paper or

the like is prohibited.

• Damaged connector body, exposing the terminals to moisture and dirt, as well as not maintaining proper

terminal orientation with the component or mating

connector.

• Improperly formed or damaged terminals. Check each connector terminal in problem circuits

carefully to ensure good contact tension by using the

corresponding mating terminal included in the

connector test adapter kit (special tool).

If contact tension is not e nough, reform the terminal to

increase contact tension or replace it.

Special tool

(A): 09932-76010 Connector test adapter kit • Poor terminal-to-wire connection.

Check each wire harness in problem circuits for poor

connection by shaking it by hand lightly. If any

abnormal condition is found, change the wire harness

assembly or component parts with new ones.

• Wire insulation which is rubbed through, causing an intermittent short as the bare area touches other

wiring or parts of the vehicle.

• Wire broken inside the insulation. This condition could cause a continuity check to show a good circuit, but if

only 1 or 2 strands of a multi-strand-type wire are

intact, resistance could be far too high.

(A)

I4RS0A820045-01

IYSQ01010028-01

IYSQ01820025-01

Page 1135 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-97

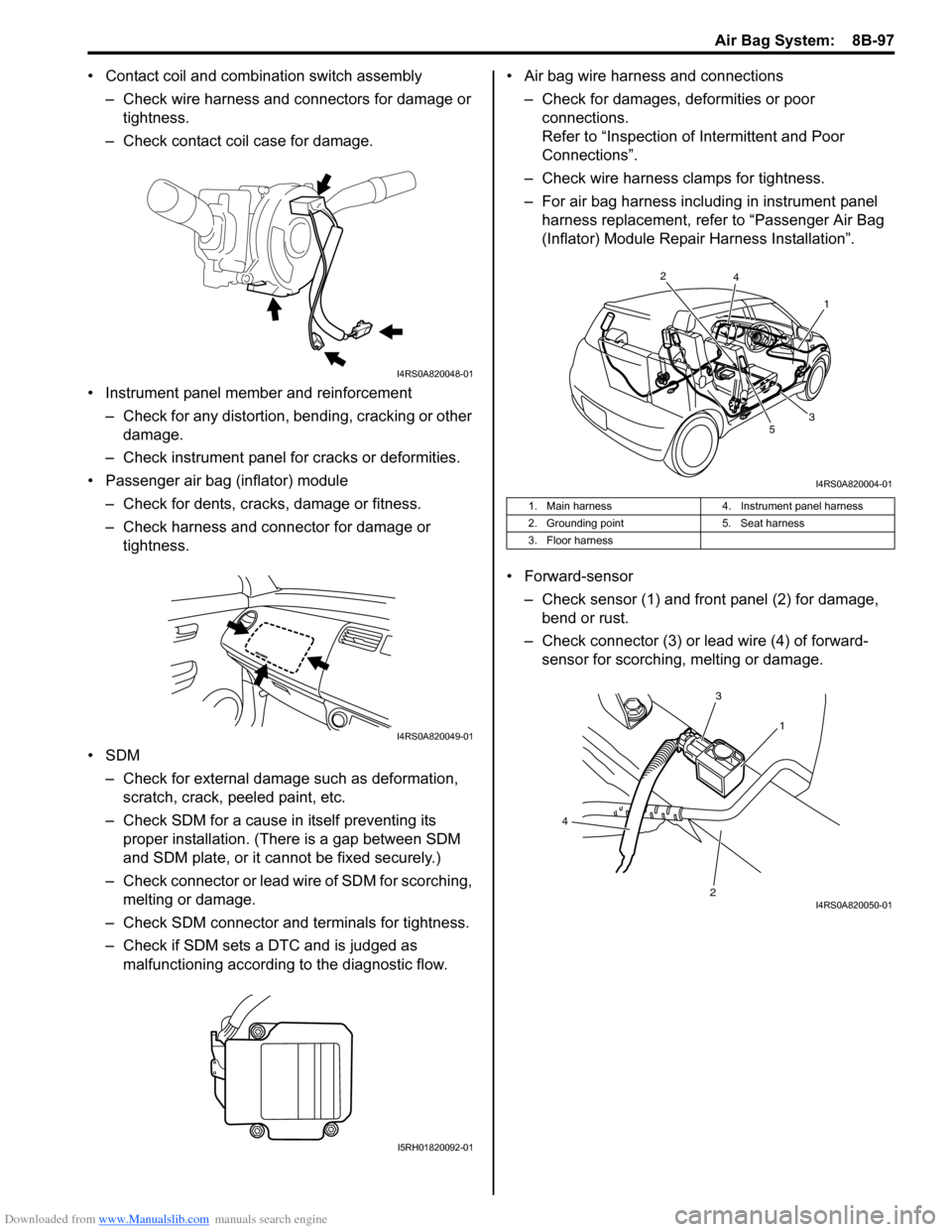

• Contact coil and combination switch assembly

– Check wire harness and connectors for damage or tightness.

– Check contact coil case for damage.

• Instrument panel member and reinforcement – Check for any distortion, bending, cracking or other damage.

– Check instrument panel fo r cracks or deformities.

• Passenger air bag (inflator) module

– Check for dents, cracks, damage or fitness.

– Check harness and connector for damage or tightness.

•SDM – Check for external damage such as deformation, scratch, crack, peeled paint, etc.

– Check SDM for a cause in itself preventing its proper installation. (There is a gap between SDM

and SDM plate, or it cannot be fixed securely.)

– Check connector or lead wire of SDM for scorching, melting or damage.

– Check SDM connector and terminals for tightness.

– Check if SDM sets a DTC and is judged as malfunctioning according to the diagnostic flow. • Air bag wire harness and connections

– Check for damages, deformities or poor connections.

Refer to “Inspection of Intermittent and Poor

Connections”.

– Check wire harness clamps for tightness.

– For air bag harness including in instrument panel harness replacement, refer to “Passenger Air Bag

(Inflator) Module Repair Harness Installation”.

• Forward-sensor – Check sensor (1) and front panel (2) for damage, bend or rust.

– Check connector (3) or lead wire (4) of forward- sensor for scorching, melting or damage.

I4RS0A820048-01

I4RS0A820049-01

I5RH01820092-01

1. Main harness 4. Instrument panel harness

2. Grounding point 5. Seat harness

3. Floor harness

1

2

3

4

5

I4RS0A820004-01

1

3

2

4

I4RS0A820050-01

Page 1147 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-109

Side Curtain-Air Bag (Inflator) Module

Inspection

S7RS0B8206012

WARNING!

• Never measure resistance of side curtain-air bag (inflator) module or disassemble it.

Otherwise personal injury may result.

• Never attempt to disassemble or repair the side curtain-air bag (inflator) module. If any

abnormality is found, be sure to replace it

with new one as an assembly.

• Be sure to read “Precautions on Service and Diagnosis of Air Bag System”,

“Precautions on Handling and Storage of

Air Bag System Components” and

“Precautions on Disposal of Air Bag and

Seat Belt Pretensioner” before starting to

work and observe every precaution during

work. Neglecting them may result in

personal injury or undeployment of the air

bag when necessary.

CAUTION!

If air bag (inflator) module was dropped from

a height of 90 cm (3 ft) or more, it should be

replaced.

Check air bag (inflator) module appearance visually for

the following symptoms and if any one of them is found,

replace with a new one.

• Air bag has deployed.

• Inflator case being damaged or having been exposed to strong impact (dropped).

Forward-Sensor Removal and InstallationS7RS0B8206013

WARNING!

During service procedures, be very careful

when handling a sensor.

• Never strike or jar a sensor.

• A sensor and mounting bracket bolts must be carefully torqued to assure proper

operation. Under loose connection, it

could cause improper operation of the air

bag system.

Removal

1) Disconnect negative cable at battery.

2) Disable air bag system referring to “Disabling Air Bag System”.

3) Disconnect forward-sensor connector sliding connector outer (2) as shown.

4) Remove forward-sensor bolt (1) and forward-sensor (2).

I4RS0A820078-03

1

2

I4RS0A820079-01

1

2

I5RH01820119-01

Page 1148 of 1496

Downloaded from www.Manualslib.com manuals search engine 8B-110 Air Bag System:

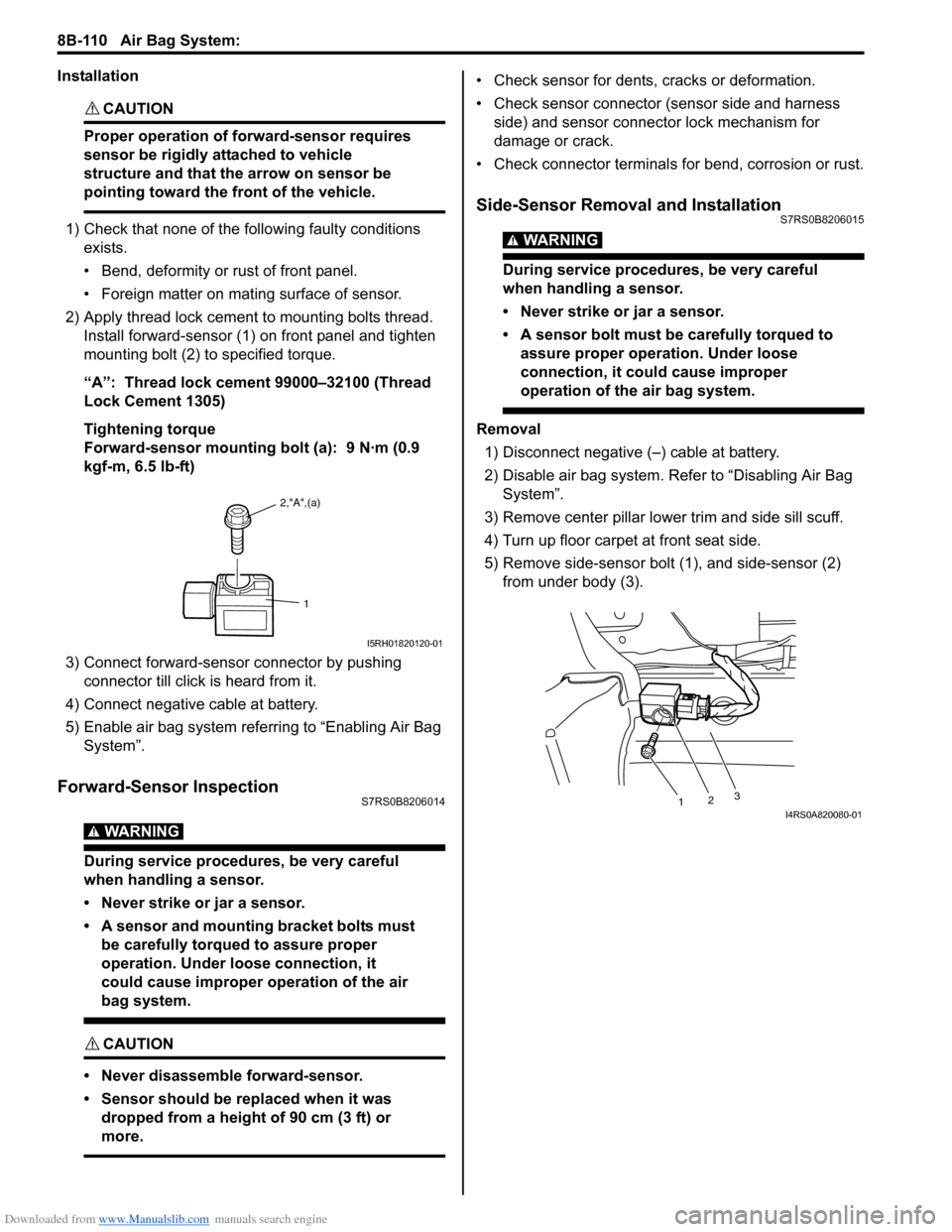

Installation

CAUTION!

Proper operation of forward-sensor requires

sensor be rigidly attached to vehicle

structure and that the arrow on sensor be

pointing toward the front of the vehicle.

1) Check that none of the following faulty conditions exists.

• Bend, deformity or rust of front panel.

• Foreign matter on mating surface of sensor.

2) Apply thread lock cement to mounting bolts thread. Install forward-sensor (1) on front panel and tighten

mounting bolt (2) to specified torque.

“A”: Thread lock cement 99000–32100 (Thread

Lock Cement 1305)

Tightening torque

Forward-sensor mounting bolt (a): 9 N·m (0.9

kgf-m, 6.5 lb-ft)

3) Connect forward-sensor connector by pushing connector till click is heard from it.

4) Connect negative cable at battery.

5) Enable air bag system referring to “Enabling Air Bag System”.

Forward-Sensor InspectionS7RS0B8206014

WARNING!

During service procedures, be very careful

when handling a sensor.

• Never strike or jar a sensor.

• A sensor and mounting bracket bolts must be carefully torqued to assure proper

operation. Under loose connection, it

could cause improper operation of the air

bag system.

CAUTION!

• Never disassemble forward-sensor.

• Sensor should be replaced when it was dropped from a height of 90 cm (3 ft) or

more.

• Check sensor for dents, cracks or deformation.

• Check sensor connector (sensor side and harness side) and sensor connector lock mechanism for

damage or crack.

• Check connector terminals for bend, corrosion or rust.

Side-Sensor Removal and InstallationS7RS0B8206015

WARNING!

During service procedures, be very careful

when handling a sensor.

• Never strike or jar a sensor.

• A sensor bolt must be carefully torqued to assure proper operation. Under loose

connection, it could cause improper

operation of the air bag system.

Removal

1) Disconnect negative (–) cable at battery.

2) Disable air bag system. Re fer to “Disabling Air Bag

System”.

3) Remove center pillar lowe r trim and side sill scuff.

4) Turn up floor carpet at front seat side.

5) Remove side-sensor bolt (1), and side-sensor (2) from under body (3).

2,"A",(a)

1

I5RH01820120-01

1 23I4RS0A820080-01

Page 1149 of 1496

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-111

6) Disconnect side-sensor connector sliding connector

outer (1) as shown.

Installation

CAUTION!

Proper operation of side-sensor requires

sensor be rigidly attached to specified

position.

1) Check that none of following faulty conditions exists.

• Bend, deformity or rust of under body.

• Foreign matter on mating surface of sensor.

2) Install side-sensor (1) on under body (2) and tighten side-sensor bolt (3) to specified torque.

Tightening torque

Side-sensor bolt (a): 9 N·m (0.9 kgf-m, 6.5 lb-ft) 3) Connect side-sensor connector pushing connector

inner (1) as shown.

4) Connect negative cable at battery.

5) Enable air bag system. Refer to “Enabling Air Bag System”.

Side-Sensor InspectionS7RS0B8206016

WARNING!

During service procedures, be very careful

when handling a sensor.

• Never strike or jar a sensor.

• A sensor and mounting bracket bolts must be carefully torqued to assure proper

operation. Under loose connection, it

could cause improper operation of the air

bag system.

CAUTION!

• Never disassemble side-sensor.

• Sensor should be replaced when it was dropped from a height of 90 cm (3 ft) or

more.

1

1

I4RS0A820109-01

1 2

3, (a)I4RS0A820081-01

1

1

I4RS0A820106-01

Page 1422 of 1496

Downloaded from www.Manualslib.com manuals search engine 10B-19 Body Electrical Control System:

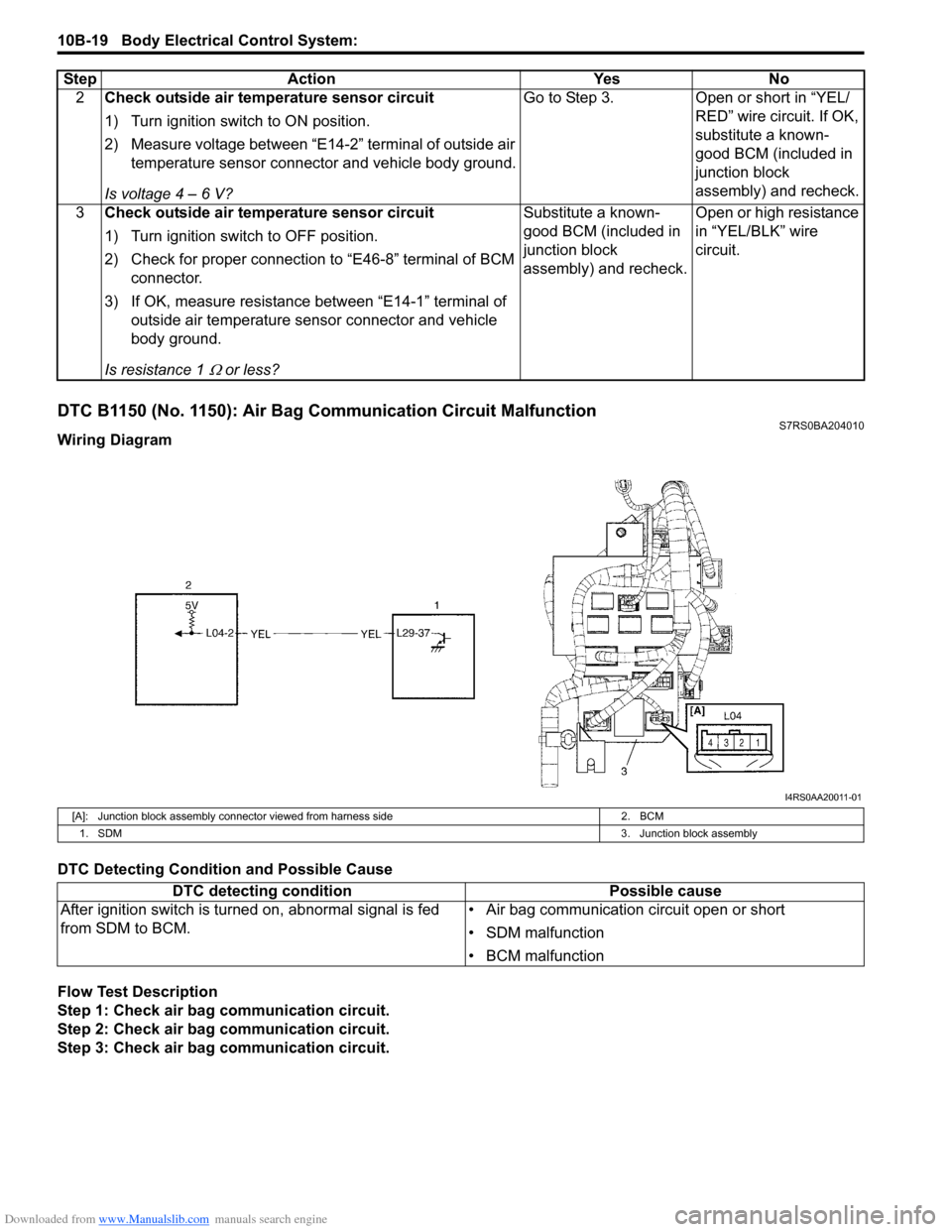

DTC B1150 (No. 1150): Air Bag Communication Circuit MalfunctionS7RS0BA204010

Wiring Diagram

DTC Detecting Condition and Possible Cause

Flow Test Description

Step 1: Check air bag communication circuit.

Step 2: Check air bag communication circuit.

Step 3: Check air bag communication circuit. 2

Check outside air temperature sensor circuit

1) Turn ignition switch to ON position.

2) Measure voltage between “E14-2” terminal of outside air

temperature sensor connector and vehicle body ground.

Is voltage 4 – 6 V? Go to Step 3. Open or short in “YEL/

RED” wire circuit. If OK,

substitute a known-

good BCM (included in

junction block

assembly) and recheck.

3 Check outside air temperature sensor circuit

1) Turn ignition switch to OFF position.

2) Check for proper connection to “E46-8” terminal of BCM

connector.

3) If OK, measure resistance between “E14-1” terminal of outside air temperature sens or connector and vehicle

body ground.

Is resistance 1

Ω or less? Substitute a known-

good BCM (included in

junction block

assembly) and recheck.

Open or high resistance

in “YEL/BLK” wire

circuit.

Step Action Yes No

I4RS0AA20011-01

[A]: Junction block assembly connect

or viewed from harness side 2. BCM

1. SDM 3. Junction block assembly

DTC detecting conditionPossible cause

After ignition switch is turned on, abnormal signal is fed

from SDM to BCM. • Air bag communication circuit open or short

• SDM malfunction

• BCM malfunction