roller SUZUKI SWIFT 2006 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SWIFT, Model: SUZUKI SWIFT 2006 2.GPages: 1496, PDF Size: 34.44 MB

Page 14 of 1496

Downloaded from www.Manualslib.com manuals search engine 00-9 Precautions:

• Be careful not to touch the electrical terminals of parts which use microcomputers (e.g. electronic control unit

like as ECM, PCM, P/S controller, etc.). The static

electricity from your body can damage these parts.

• Never connect any tester (voltmeter, ohmmeter, or whatever) to electronic control unit when its coupler is

disconnected. Attempt to do it may cause damage to

it.

• Never connect an ohmmeter to electronic control unit with its coupler connected to it. Attempt to do it may

cause damage to electronic control unit and sensors.

• Be sure to use a specified voltmeter / ohmmeter. Otherwise, accurate measurements may not be

obtained or personal injury ma y result. If not specified,

use a voltmeter with high impedance (M Ω/V

minimum) or a digital type voltmeter.

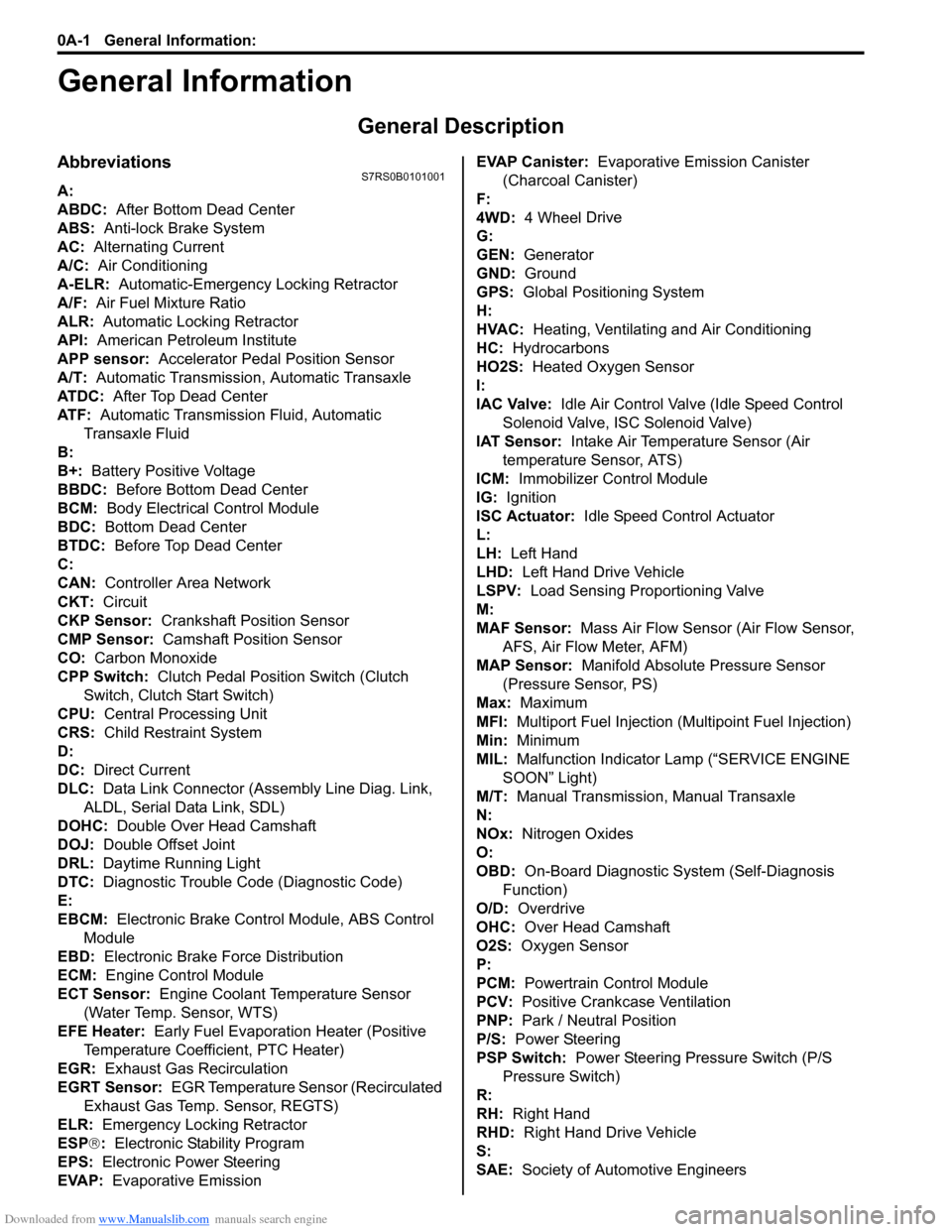

• When taking measurements at electrical connectors using a tester probe, be sure to insert the probe (2)

from the wire harness side (backside) of the

connector (1). • When connecting meter probe (2) from terminal side

of coupler (1) because it can’t be connected from

harness side, use extra care not to bend male

terminal of coupler of force its female terminal open

for connection.

In case of such coupler as shown connect probe as

shown to avoid opening female terminal.

Never connect probe where male terminal is

supposed to fit.

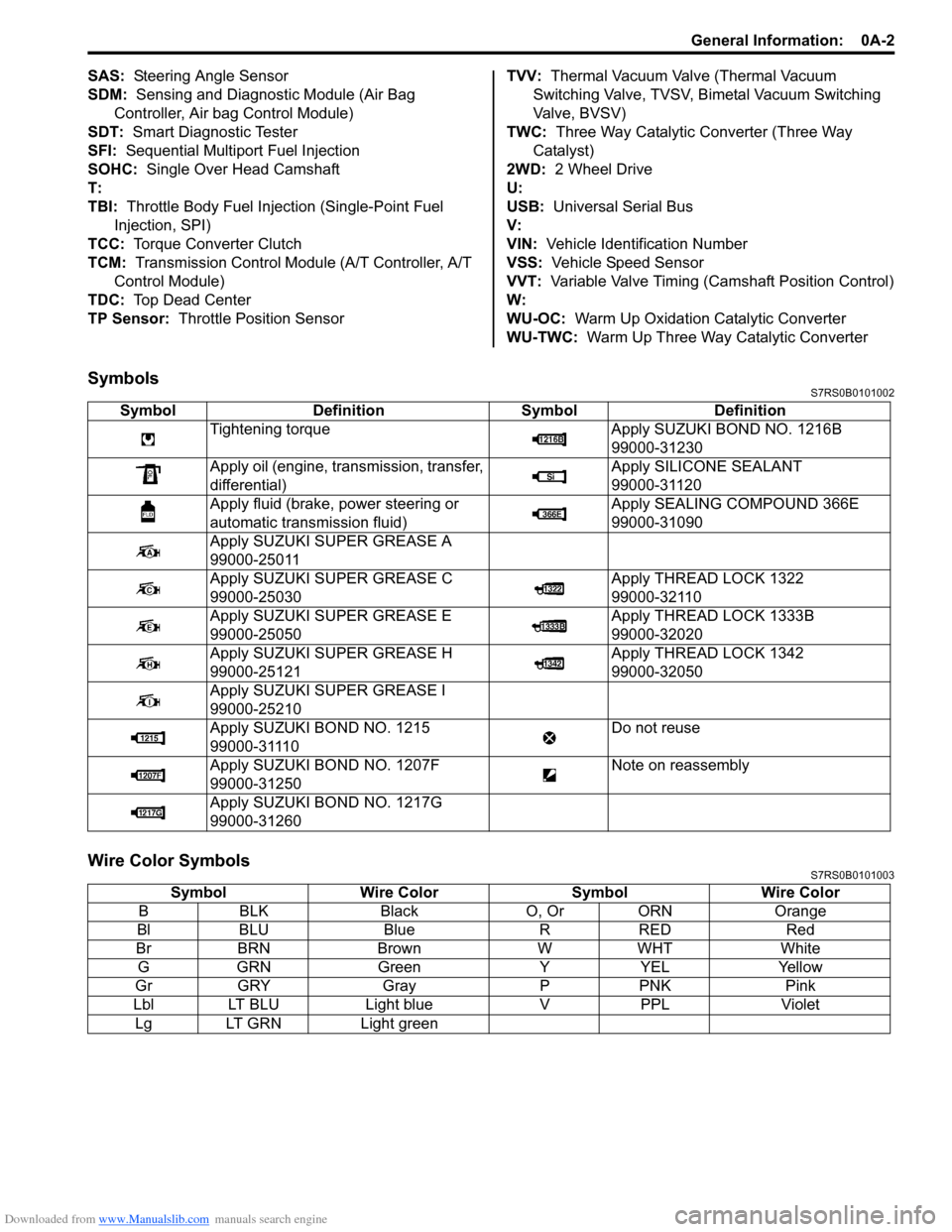

• When checking connection of terminals, check its

male half for bend and female half for excessive

opening and both for locking (looseness), corrosion,

dust, etc.

• Before measuring voltage at each terminal, check to make sure that battery voltage is 11 V or higher. Such

terminal voltage check at lo w battery voltage will lead

to erroneous diagnosis.

I3RM0A000004-01

I2RH01010046-01

I2RH01010047-01

I2RH01010048-01

Page 22 of 1496

Downloaded from www.Manualslib.com manuals search engine 0A-1 General Information:

General Information

General Information

General Description

AbbreviationsS7RS0B0101001

A:

ABDC: After Bottom Dead Center

ABS: Anti-lock Brake System

AC: Alternating Current

A/C: Air Conditioning

A-ELR: Automatic-Emergency Locking Retractor

A/F: Air Fuel Mixture Ratio

ALR: Automatic Locking Retractor

API: American Petroleum Institute

APP sensor: Accelerator Pedal Position Sensor

A/T: Automatic Transmission , Automatic Transaxle

AT D C : After Top Dead Center

ATF: Automatic Transmission Fluid, Automatic

Transaxle Fluid

B:

B+: Battery Positive Voltage

BBDC: Before Bottom Dead Center

BCM: Body Electrical Control Module

BDC: Bottom Dead Center

BTDC: Before Top Dead Center

C:

CAN: Controller Area Network

CKT: Circuit

CKP Sensor: Crankshaft Position Sensor

CMP Sensor: Camshaft Position Sensor

CO: Carbon Monoxide

CPP Switch: Clutch Pedal Position Switch (Clutch

Switch, Clutch Start Switch)

CPU: Central Processing Unit

CRS: Child Restraint System

D:

DC: Direct Current

DLC: Data Link Connector (Assembly Line Diag. Link,

ALDL, Serial Data Link, SDL)

DOHC: Double Over Head Camshaft

DOJ: Double Offset Joint

DRL: Daytime Running Light

DTC: Diagnostic Trouble Code (Diagnostic Code)

E:

EBCM: Electronic Brake Cont rol Module, ABS Control

Module

EBD: Electronic Brake Force Distribution

ECM: Engine Control Module

ECT Sensor: Engine Coolant Temperature Sensor (Water Temp. Sensor, WTS)

EFE Heater: Early Fuel Evaporation Heater (Positive

Temperature Coefficient, PTC Heater)

EGR: Exhaust Gas Recirculation

EGRT Sensor: EGR Temperature Sensor (Recirculated

Exhaust Gas Temp. Sensor, REGTS)

ELR: Emergency Locking Retractor

ESP ®: Electronic Stability Program

EPS: Electronic Power Steering

EVAP: Evaporative Emission EVAP Canister:

Evaporative Emission Canister

(Charcoal Canister)

F:

4WD: 4 Wheel

Drive

G:

GEN: Generator

GND: Ground

GPS: Global Positioning System

H:

HVAC: Heating, Ventilating and Air Conditioning

HC: Hydrocarbons

HO2S: Heated Oxygen Sensor

I:

IAC Valve: Idle Air Control Valve (Idle Speed Control

Solenoid Valve, ISC Solenoid Valve)

IAT Sensor: Intake Air Temperature Sensor (Air

temperature Sensor, ATS)

ICM: Immobilizer Control Module

IG: Ignition

ISC Actuator: Idle Speed Control Actuator

L:

LH: Left Hand

LHD: Left Hand Drive Vehicle

LSPV: Load Sensing Proportioning Valve

M:

MAF Sensor: Mass Air Flow Sensor (Air Flow Sensor, AFS, Air Flow Meter, AFM)

MAP Sensor: Manifold Absolute Pressure Sensor

(Pressure Sensor, PS)

Max: Maximum

MFI: Multiport Fuel Injection (Mu ltipoint Fuel Injection)

Min: Minimum

MIL: Malfunction Indicator Lamp (“SERVICE ENGINE

SOON” Light)

M/T: Manual Transmission, Manual Transaxle

N:

NOx: Nitrogen Oxides

O:

OBD: On-Board Diagnostic System (Self-Diagnosis

Function)

O/D: Overdrive

OHC: Over Head Camshaft

O2S: Oxygen Sensor

P:

PCM: Powertrain Control Module

PCV: Positive Crankcase Ventilation

PNP: Park / Neutral Position

P/S: Power Steering

PSP Switch: Power Steering Pressure Switch (P/S

Pressure Switch)

R:

RH: Right Hand

RHD: Right Hand Drive Vehicle

S:

SAE: Society of Automotive Engineers

Page 23 of 1496

Downloaded from www.Manualslib.com manuals search engine General Information: 0A-2

SAS: Steering Angle Sensor

SDM: Sensing and Diagnostic Module (Air Bag Controller, Air bag Control Module)

SDT: Smart Diagnostic Tester

SFI: Sequential Multipor t Fuel Injection

SOHC: Single Over Head Camshaft

T:

TBI: Throttle Body Fuel Injection (Single-Point Fuel

Injection, SPI)

TCC: Torque Converter Clutch

TCM: Transmission Control Module (A/T Controller, A/T

Control Module)

TDC: Top Dead Center

TP Sensor: Throttle Position Sensor TVV:

Thermal Vacuum Valve (Thermal Vacuum

Switching Valve, TVSV, Bi metal Vacuum Switching

Valve, BVSV)

TWC: Three Way Catalytic Converter (Three Way

Catalyst)

2WD: 2 Wheel Drive

U:

USB: Universal Serial Bus

V:

VIN: Vehicle Identification Number

VSS: Vehicle Speed Sensor

VVT: Variable Valve Timing (Camshaft Position Control)

W:

WU-OC: Warm Up Oxidation Catalytic Converter

WU-TWC: Warm Up Three Way Catalytic Converter

SymbolsS7RS0B0101002

Wire Color SymbolsS7RS0B0101003

Symbol Definition SymbolDefinition

Tightening torque Apply SUZUKI BOND NO. 1216B

99000-31230

Apply oil (engine, transmission, transfer,

differential) Apply SILICONE SEALANT

99000-31120

Apply fluid (brake, power steering or

automatic transmission fluid) Apply SEALING COMPOUND 366E

99000-31090

Apply SUZUKI SUPER GREASE A

99000-25011

Apply SUZUKI SUPER GREASE C

99000-25030 Apply THREAD LOCK 1322

99000-32110

Apply SUZUKI SUPER GREASE E

99000-25050 Apply THREAD LOCK 1333B

99000-32020

Apply SUZUKI SUPER GREASE H

99000-25121 Apply THREAD LOCK 1342

99000-32050

Apply SUZUKI SUPER GREASE I

99000-25210

Apply SUZUKI BOND NO. 1215

99000-31110 Do not reuse

Apply SUZUKI BO ND NO. 1207F

99000-31250 Note on reassembly

Apply SUZUKI BO ND NO. 1217G

99000-31260

Symbol Wire Color SymbolWire Color

B BLK Black O, Or ORN Orange

Bl BLU Blue RRED Red

Br BRN Brown WWHT White

G GRN Green YYEL Yellow

Gr GRY Gray PPNK Pink

Lbl LT BLU Light blueVPPL Violet

Lg LT GRN Light green

Page 52 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-2 Engine General Information and Diagnosis:

• Be sure to read “Precautions for Electrical Circuit Service in Section 00” befo re inspection and observe

what is written there.

• ECM replacement: When substituting a known-good ECM, check for the

following conditions. Neglec ting this check may cause

damage to a known-good ECM.

– Resistance value of all relays, actuators is as specified respectively.

– MAP sensor, A/C refrigerant pressure sensor and TP sensor are in good condition and none of power

circuits of these sensors is shorted to ground.

• Communication of ECM, BCM, ABS/ESP ® control

module, combination meter, keyless start control

module, steering angle sensor (ESP ® model) and

TCM (A/T model), is esta blished by CAN (Controller

Area Network). (For more detail of CAN

communication for ECM, refer to “CAN

Communication System Description”). Therefore,

handle CAN communication line with care referring to

“Precaution for CAN Communication System in

Section 00”.

• Immobilizer transponder code registration after

replacing ECM

When ECM is replaced with new one or with another

one, make sure to register immobilizer transponder

code to ECM correctly according to “Procedure after

ECM Replacement in Section 10C”.Precautions of ECM Circuit InspectionS7RS0B1100003

• ECM connectors are waterproofed. Each terminal of the ECM connectors is sealed up with the grommet.

Therefore, when measuring ci rcuit voltage, resistance

and/or pulse signal at ECM connector, do not insert

the tester’s probe into th e sealed terminal at the

harness side. When measuring circuit voltage,

resistance and/or pulse signal at ECM connector,

connect the special tool to the ECM connectors. And,

insert the tester’s probe into the special tool’s

connectors at the harness side, and then measure

voltage, resistance and/or pulse signal. Or, ECM and

its circuits may be damaged by water.

• Wire colors of the special tool’s connectors are different from the ones of the ECM connectors.

However, the circuit arrangement of the special tool’s

connectors is same as the one of the ECM

connectors. Therefore, measure circuit voltage and

resistance by identifying the terminal location subject

to the measurement.

Precautions of Electric Throttle Body System

Calibration

S7RS0B1100004

After performing one of works described below, it is

necessary to re-register the completely closed throttle

valve reference position stored in memory of ECM. (For

detailed information, refer to “Description of Electric

Throttle Body System Calibration”.) For the procedure to

register such data in ECM, refer to “Electric Throttle

Body System Calibration in Section 1C”.

• To shut off backup power of ECM for such purposes of battery replacement or “DOME” fuse removal

• To erase DTCs P0122, P01 23, P0222, P0223, P2101,

P2102, P2103, P2111, P2112, P2113, P2119, P2123,

P2127, P2128, P2135 and/or P2138

• To replace ECM

• To replace throttle body and/or accelerator pedal position (APP) sensor assembly

General Description

Statement on Cleanliness and CareS7RS0B1101001

An automobile engine is a combination of many

machined, honed, polished and lapped surfaces with

tolerances that are measured in the thousands of an

millimeter (ten thous ands of an inch).

Accordingly, when any internal engine parts are

serviced, care and cleanliness are important.

It should be understood that proper cleaning and

protection of machined surfaces and friction areas is part

of the repair procedure. This is considered standard

shop practice even if not specifically stated.

• A liberal coating of engine oil should be applied to friction areas during assembly to protect and lubricate

the surfaces on initial operation. • Whenever valve train components, pistons, piston

rings, connecting rods, rod bearings, and crankshaft

journal bearings are removed for service, they should

be retained in order.

At the time of installation, they should be installed in

the same locations and with the same mating

surfaces as when removed.

• Battery cables should be disconnected before any major work is performed on the engine.

Failure to disconnect cables may result in damage to

wire harness or other electrical parts.

Page 57 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-7

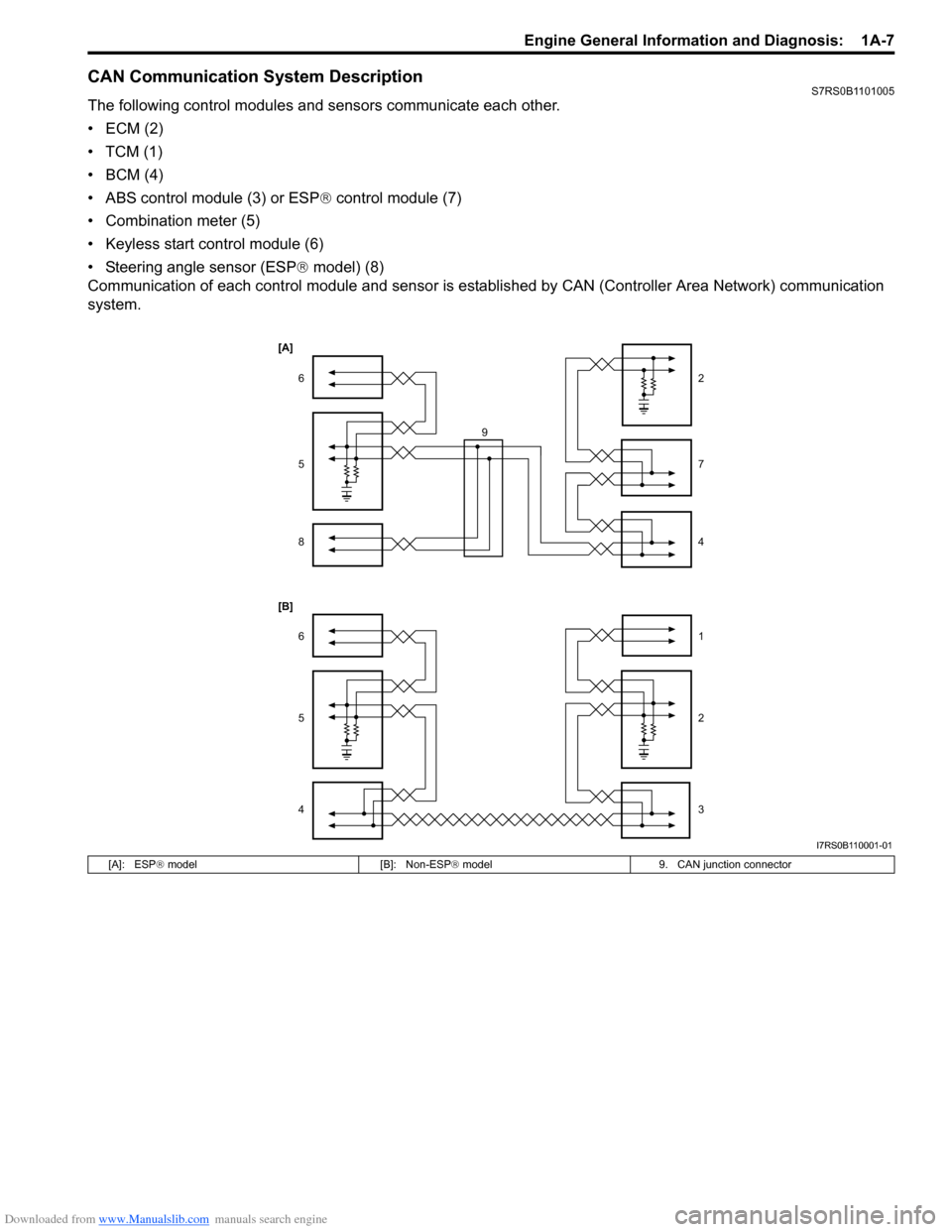

CAN Communication System DescriptionS7RS0B1101005

The following control modules and sensors communicate each other.

•ECM (2)

•TCM (1)

•BCM (4)

• ABS control module (3) or ESP® control module (7)

• Combination meter (5)

• Keyless start control module (6)

• Steering angle sensor (ESP ® model) (8)

Communication of each control module and sensor is es tablished by CAN (Controller Area Network) communication

system.

1

2

3

6

5

4

2

7

4

6

5

8

9

[A]

[B]

I7RS0B110001-01

[A]: ESP

® model [B]: Non-ESP ® model 9. CAN junction connector

Page 62 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-12 Engine General Information and Diagnosis:

Electronic Control System DescriptionS7RS0B1101011

The electronic control system consists of 1) various sensors which detect the state of engine and driving conditions, 2)

ECM which controls various devices ac cording to the signals from the sensors and 3) various controlled devices.

Functionally, it is divided into the following sub systems:

• Fuel injection control system

• Ignition control system

• Electric throttle body control system

• Fuel pump control system

• Radiator cooling fan control system

• Evaporative emission control system

• EGR system

• Oxygen sensor heater control system

• A/C control system (A/C model)

• Camshaft position control system

• Immobilizer control system

• Generator control system

• Controller (computer) communication system

Especially, ECM, BCM, combination meter, TCM (A/T model), ABS/ESP ® control module, steering angle sensor

(ESP® model) and keyless start control module (if equipped) intercommunicate by means of CAN communication.

Page 65 of 1496

![SUZUKI SWIFT 2006 2.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-15

Terminal Arrangement of ECM Coupler (Viewed from Harness Side)

[A]: Manual A/C model24. ABS / SUZUKI SWIFT 2006 2.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-15

Terminal Arrangement of ECM Coupler (Viewed from Harness Side)

[A]: Manual A/C model24. ABS /](/img/20/7607/w960_7607-64.png)

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-15

Terminal Arrangement of ECM Coupler (Viewed from Harness Side)

[A]: Manual A/C model24. ABS / ESP® control module 49. Radiator cooling fan motor

[B]: Auto A/C model 25. TCM 50. “RDTR FAN” fuse

1. ECM 26. To other control module connected CAN 51. A/C compressor relay

2. APP sensor assembly 27. Generator 52. Magnet clutch of compressor (A/C model)

3. Shield wire 28. Electric load current sensor (if equipped) 53. “A/C CPRSR” fuse

4. CMP sensor 29. Brake light 54. Ignition coil assembly (for No.1 and No.4 spark

plugs)

5. CKP sensor 30. Brake light switch 55. Ignition coil assembly (for No.2 and No.3 spark

plugs)

6. MAF and IAT sensor 31. Diagnosis connector (Hong Kong model) 56. P/S control module

7. MAP sensor 32. Throttle actuator control relay 57. “RADIO” fuse

8. ECT sensor 33. “THR MOT” fuse 58. Main relay

9. A/C refrigerant pressure sensor 34. Throttle throttle body assembly 59. “IG COIL” fuse

10. A/C evaporator outlet air temp. sensor (Manual A/C model) 35. Throttle actuator

60. Ignition switch

11. HO2S-1 36. TP sensor 61. “IG ACC” fuse

12. HO2S-2 37. Injector No.1 62. “FI” fuse

13. Knock sensor 38. Injector No.2 63. Starting motor control relay

14. Blower motor relay 39. Injector No.3 64. “ST SIG” fuse

15. Blower motor 40. Injector No.4 65. “ST MOT” fuse

16. Blower motor resistor 41. EVAP canister purge valve66. Transmission range switch (A/T model) or CPP

switch (Hong Kong model with M/T)

17. Blower speed selector 42. EGR valve 67. Starting motor

18. A/C switch 43. Oil control valve (Camshaft position

control) (VVT model) 68. Immobilizer coil antenna

19. Blower motor controller 44. Fuel pump relay 69. Main fuse box

20. HVAC control module 45. Fuel pump 70. Battery

21. Data link connector (DLC) 46. Radiator cooling fan motor relay No.1 71. Barometric pressure sensor

22. To other control module connected with DLC 47. Radiator cooling fan motor relay No.2

72. Engine ground

23. BCM 48. Radiator cooling fan motor relay No.3 73. Body ground

E23 C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

I4RS0A110008-01

Page 540 of 1496

Downloaded from www.Manualslib.com manuals search engine 4E-1 ABS:

Brakes

ABS

Precautions

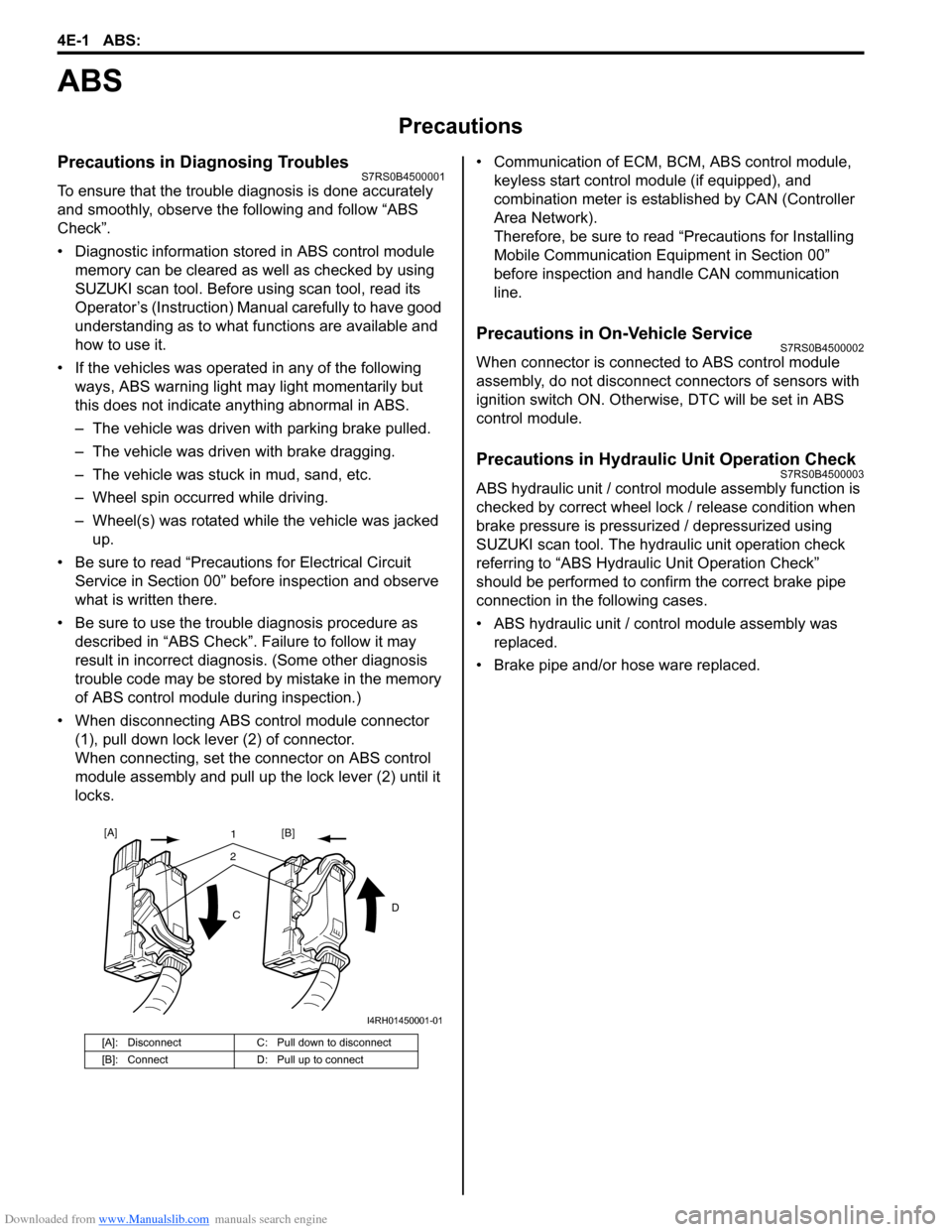

Precautions in Diagnosing TroublesS7RS0B4500001

To ensure that the trouble diagnosis is done accurately

and smoothly, observe the following and follow “ABS

Check”.

• Diagnostic information stored in ABS cont rol module

memory can be cleared as well as checked by using

SUZUKI scan tool. Before us ing scan tool, read its

Operator’s (Instruction) Manual carefully to have good

understanding as to what functions are available and

how to use it.

• If the vehicles was operated in any of the following ways, ABS warning light may light momentarily but

this does not indicate anything abnormal in ABS.

– The vehicle was driven with parking brake pulled.

– The vehicle was driven with brake dragging.

– The vehicle was stuck in mud, sand, etc.

– Wheel spin occurred while driving.

– Wheel(s) was rotated while the vehicle was jacked up.

• Be sure to read “Precautions for Electrical Circuit Service in Section 00” befo re inspection and observe

what is written there.

• Be sure to use the trouble diagnosis procedure as described in “ABS Check”. Failure to follow it may

result in incorrect diagnosis. (Some other diagnosis

trouble code may be stored by mistake in the memory

of ABS control module during inspection.)

• When disconnecting ABS co ntrol module connector

(1), pull down lock lever (2) of connector.

When connecting, set the connector on ABS control

module assembly and pull up the lock lever (2) until it

locks. • Communication of ECM,

BCM, ABS control module,

keyless start control module (if equipped), and

combination meter is established by CAN (Controller

Area Network).

Therefore, be sure to read “Precautions for Installing

Mobile Communication Equipment in Section 00”

before inspection and handle CAN communication

line.

Precautions in On-Vehicle ServiceS7RS0B4500002

When connector is connected to ABS control module

assembly, do not disconnect connectors of sensors with

ignition switch ON. Otherwise, DTC will be set in ABS

control module.

Precautions in Hydraulic Unit Operation CheckS7RS0B4500003

ABS hydraulic unit / control module assembly function is

checked by correct wheel lock / release condition when

brake pressure is pressurized / depressurized using

SUZUKI scan tool. The hydraulic unit operation check

referring to “ABS Hydraulic Unit Operation Check”

should be performed to confirm the correct brake pipe

connection in the following cases.

• ABS hydraulic unit / cont rol module assembly was

replaced.

• Brake pipe and/or hose ware replaced.

[A]: Disconnect C: Pull down to disconnect

[B]: Connect D: Pull up to connect

21

C D

[A]

[B]

I4RH01450001-01

Page 556 of 1496

Downloaded from www.Manualslib.com manuals search engine 4E-17 ABS:

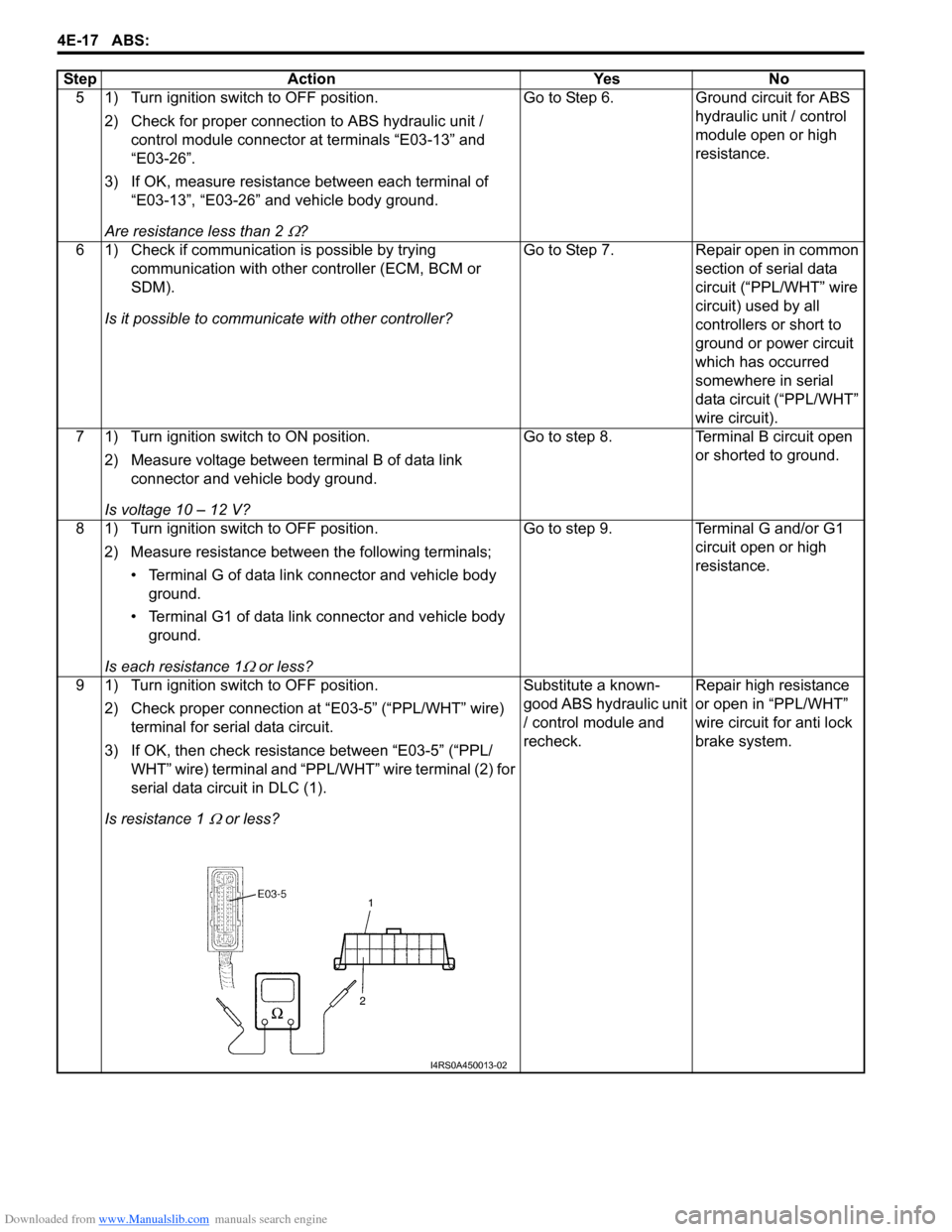

5 1) Turn ignition switch to OFF position.2) Check for proper connection to ABS hydraulic unit / control module connector at terminals “E03-13” and

“E03-26”.

3) If OK, measure resistance between each terminal of “E03-13”, “E03-26” and vehicle body ground.

Are resistance less than 2

Ω? Go to Step 6. Ground circuit for ABS

hydraulic unit / control

module open or high

resistance.

6 1) Check if communication is possible by trying communication with other controller (ECM, BCM or

SDM).

Is it possible to commun icate with other controller? Go to Step 7. Repair open in common

section of serial data

circuit (“PPL/WHT” wire

circuit) used by all

controllers or short to

ground or power circuit

which has occurred

somewhere in serial

data circuit (“PPL/WHT”

wire circuit).

7 1) Turn ignition switch to ON position.

2) Measure voltage between terminal B of data link connector and vehicle body ground.

Is voltage 10 – 12 V? Go to step 8. Terminal B circuit open

or shorted to ground.

8 1) Turn ignition switch to OFF position. 2) Measure resistance between the following terminals;• Terminal G of data link connector and vehicle body ground.

• Terminal G1 of data link connector and vehicle body ground.

Is each resistance 1

Ω or less? Go to step 9. Terminal G and/or G1

circuit open or high

resistance.

9 1) Turn ignition switch to OFF position. 2) Check proper connection at “E03-5” (“PPL/WHT” wire) terminal for serial data circuit.

3) If OK, then check resistance between “E03-5” (“PPL/ WHT” wire) terminal and “PPL/WHT” wire terminal (2) for

serial data circuit in DLC (1).

Is resistance 1

Ω or less? Substitute a known-

good ABS hydraulic unit

/ control module and

recheck.

Repair high resistance

or open in “PPL/WHT”

wire circuit for anti lock

brake system.

Step Action Yes No

I4RS0A450013-02

Page 575 of 1496

Downloaded from www.Manualslib.com manuals search engine Electronic Stability Program: 4F-1

Brakes

Electronic Stability Program

Precautions

Precautions in Diagnosing TroublesS7RS0B4600001

To ensure that the trouble diagnosis is done accurately

and smoothly, observe the following and follow

“Electronic Stability Program System Check”.

• Diagnostic information stored in ESP® control module

memory can be cleared as well as checked by using

SUZUKI scan tool. Before us ing scan tool, read its

Operator’s (Instruction) Manual carefully to have good

understanding as to what functions are available and

how to use it.

• If the vehicles was operated in any of the following ways, ESP ® warning lamp may light momentarily but

this does not indicate anything abnormal in ESP ®.

– The vehicle was driven with parking brake pulled.

– The vehicle was driven with brake dragging.

– The vehicle was stuck in mud, sand, etc.

– Wheel spin occurred while driving.

– Wheel(s) was rotated while the vehicle was jacked up.

• Be sure to use the trouble diagnosis procedure as described in “Electronic Stability Program System

Check”. Failure to follow it may resu lt in incorrect

diagnosis. (Some other diagnosis trouble code may

be stored by mistake in the memory of ESP ® control

module during inspection.)

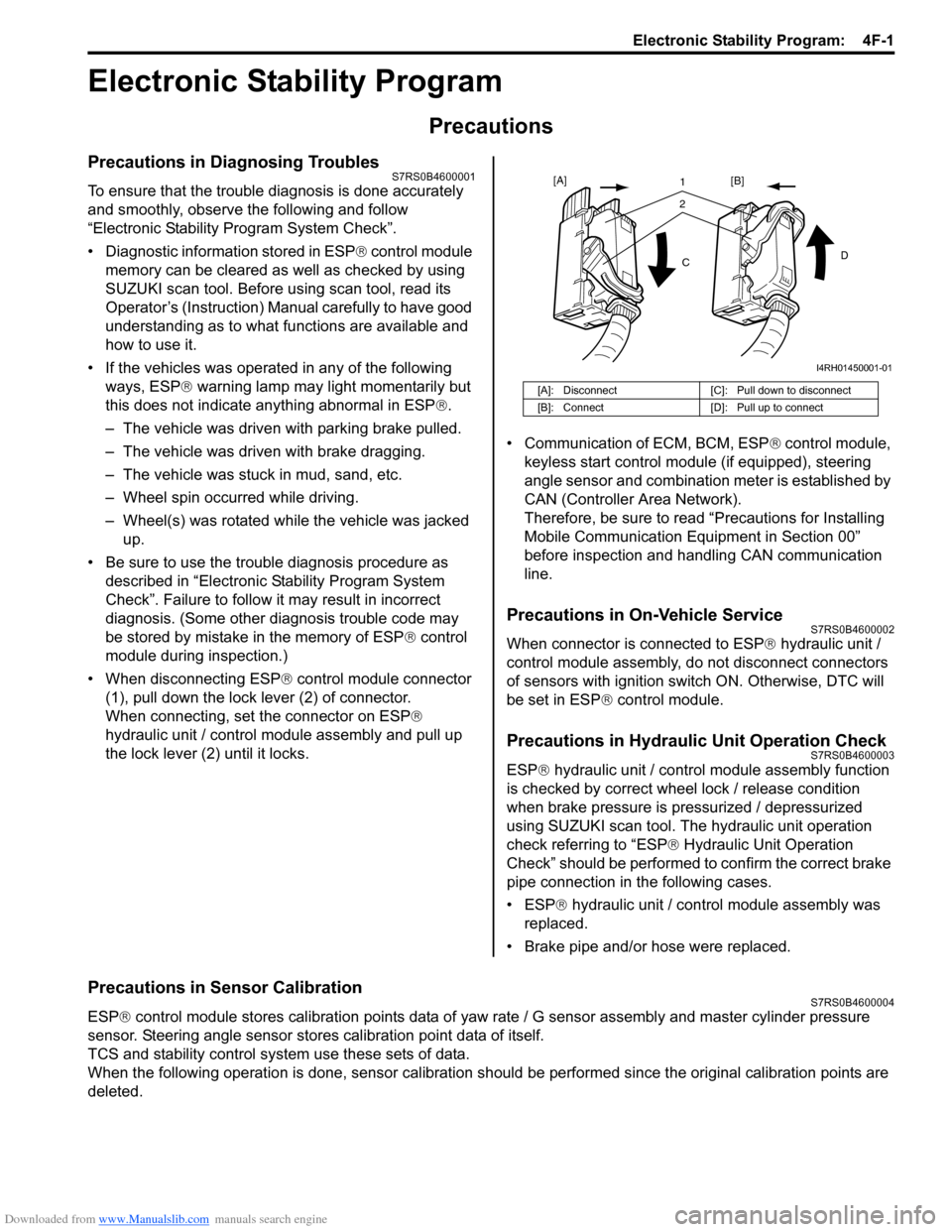

• When disconnecting ESP ® control module connector

(1), pull down the lock lever (2) of connector.

When connecting, set the connector on ESP ®

hydraulic unit / control module assembly and pull up

the lock lever (2) until it locks. • Communication of ECM, BCM, ESP

® control module,

keyless start control module (if equipped), steering

angle sensor and combination meter is established by

CAN (Controller Area Network).

Therefore, be sure to read “Precautions for Installing

Mobile Communication Equipment in Section 00”

before inspection and handling CAN communication

line.

Precautions in On-Vehicle ServiceS7RS0B4600002

When connector is connected to ESP ® hydraulic unit /

control module assembly, do not disconnect connectors

of sensors with ignition switch ON. Otherwise, DTC will

be set in ESP ® control module.

Precautions in Hydraulic Unit Operation CheckS7RS0B4600003

ESP® hydraulic unit / control module assembly function

is checked by correct wheel lock / release condition

when brake pressure is pressurized / depressurized

using SUZUKI scan tool. The hydraulic unit operation

check referring to “ESP ® Hydraulic Unit Operation

Check” should be performed to confirm the correct brake

pipe connection in the following cases.

• ESP® hydraulic unit / contro l module assembly was

replaced.

• Brake pipe and/or hose were replaced.

Precautions in Sensor CalibrationS7RS0B4600004

ESP ® control module stores calibration points data of yaw rate / G sensor assembly and master cylinder pressure

sensor. Steering angle sensor stores calibration point data of itself.

TCS and stability control system use these sets of data.

When the following operation is done, sensor calibration should be performed since the original calibration points are

deleted.

[A]: Disconnect [C]: Pull down to disconnect

[B]: Connect [D]: Pull up to connect

21

C D

[A]

[B]

I4RH01450001-01