Driver SUZUKI SWIFT 2007 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 1311 of 1496

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-16

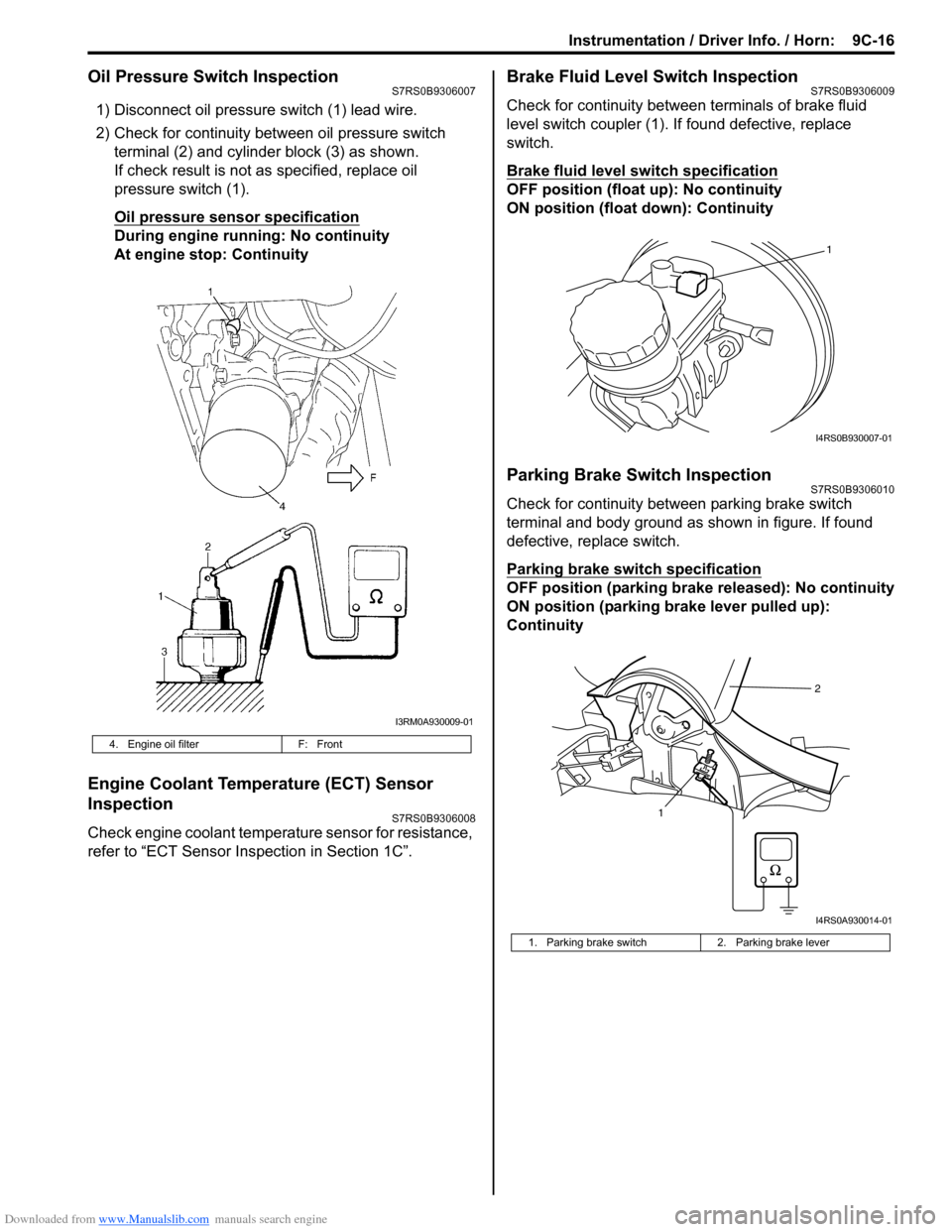

Oil Pressure Switch InspectionS7RS0B9306007

1) Disconnect oil pressure switch (1) lead wire.

2) Check for continuity between oil pressure switch terminal (2) and cylinder block (3) as shown.

If check result is not as specified, replace oil

pressure switch (1).

Oil pressure sensor specification

During engine running: No continuity

At engine stop: Continuity

Engine Coolant Temperature (ECT) Sensor

Inspection

S7RS0B9306008

Check engine coolant temperat ure sensor for resistance,

refer to “ECT Sensor Inspection in Section 1C”.

Brake Fluid Level Switch InspectionS7RS0B9306009

Check for continuity between terminals of brake fluid

level switch coupler (1). If found defective, replace

switch.

Brake fluid level switch specification

OFF position (float up): No continuity

ON position (float down): Continuity

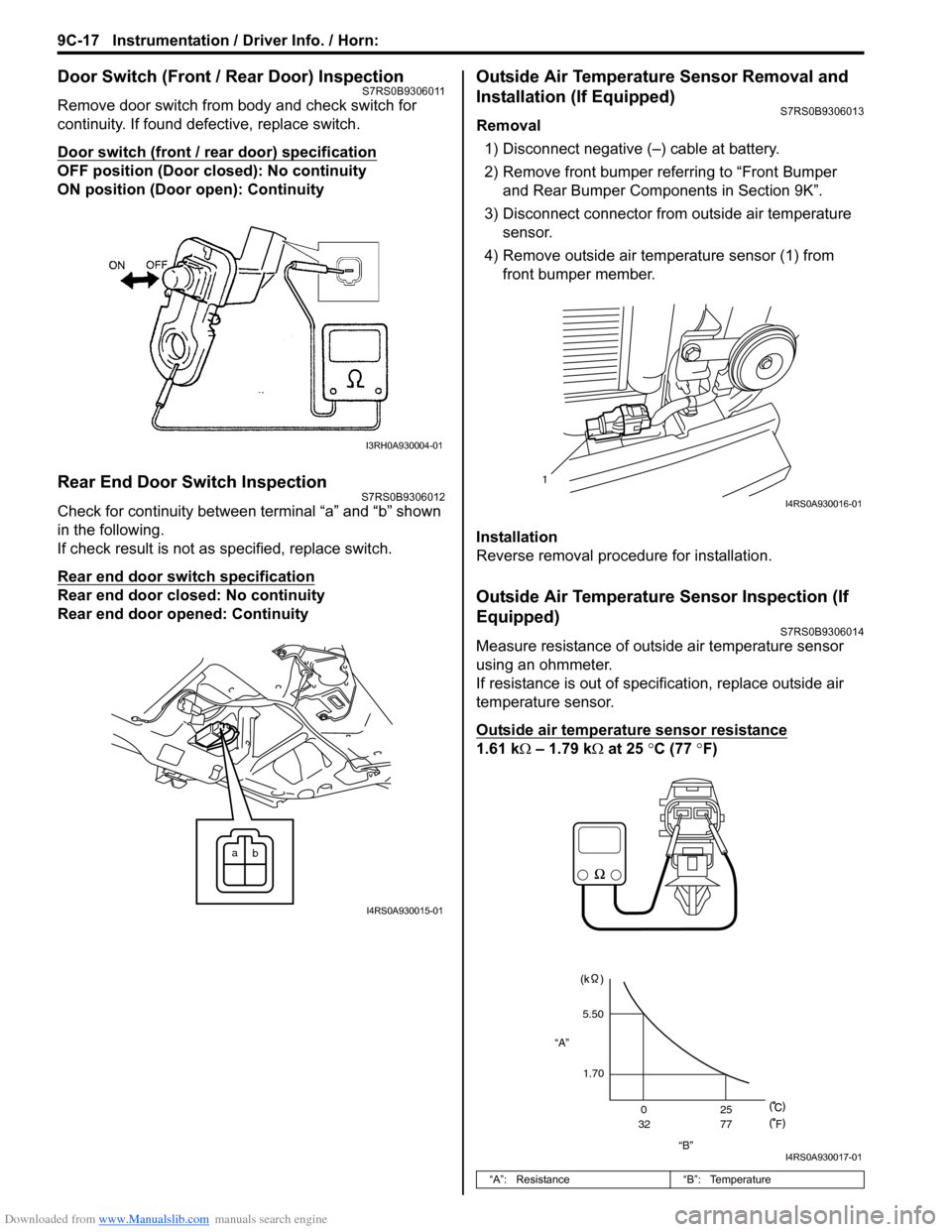

Parking Brake Switch InspectionS7RS0B9306010

Check for continuity between parking brake switch

terminal and body ground as shown in figure. If found

defective, replace switch.

Parking brake switch specification

OFF position (parking brake released): No continuity

ON position (parking brake lever pulled up):

Continuity

4. Engine oil filter F: Front

I3RM0A930009-01

1. Parking brake switch 2. Parking brake lever

1

I4RS0B930007-01

12

I4RS0A930014-01

Page 1312 of 1496

Downloaded from www.Manualslib.com manuals search engine 9C-17 Instrumentation / Driver Info. / Horn:

Door Switch (Front / Rear Door) InspectionS7RS0B9306011

Remove door switch from body and check switch for

continuity. If found defective, replace switch.

Door switch (front / rear door) specification

OFF position (Door closed): No continuity

ON position (Door open): Continuity

Rear End Door Switch InspectionS7RS0B9306012

Check for continuity between terminal “a” and “b” shown

in the following.

If check result is not as specified, replace switch.

Rear end door switch specification

Rear end door closed: No continuity

Rear end door opened: Continuity

Outside Air Temperature Sensor Removal and

Installation (If Equipped)

S7RS0B9306013

Removal

1) Disconnect negative (–) cable at battery.

2) Remove front bumper referring to “Front Bumper and Rear Bumper Components in Section 9K”.

3) Disconnect connector from outside air temperature sensor.

4) Remove outside air temperature sensor (1) from front bumper member.

Installation

Reverse removal procedure for installation.

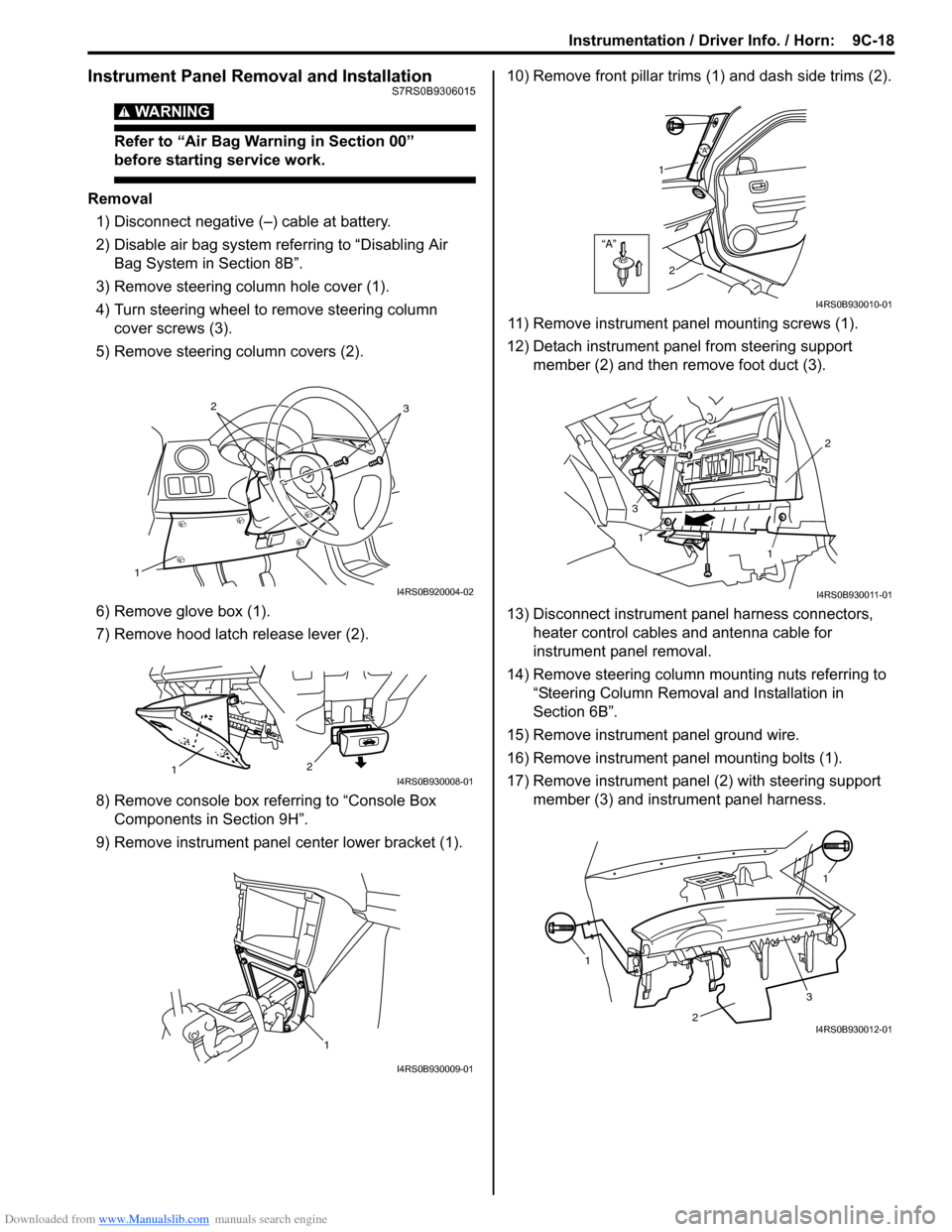

Outside Air Temperature Sensor Inspection (If

Equipped)

S7RS0B9306014

Measure resistance of outside air temperature sensor

using an ohmmeter.

If resistance is out of specif ication, replace outside air

temperature sensor.

Outside air temperature sensor resistance

1.61 kΩ – 1.79 k Ω at 25 °C (77 °F)

I3RH0A930004-01

a

b

I4RS0A930015-01

“A”: Resistance “B”: Temperature

1

I4RS0A930016-01

“B”

“A”

5.50

1.70 0

32 25

77

F

I4RS0A930017-01

Page 1313 of 1496

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-18

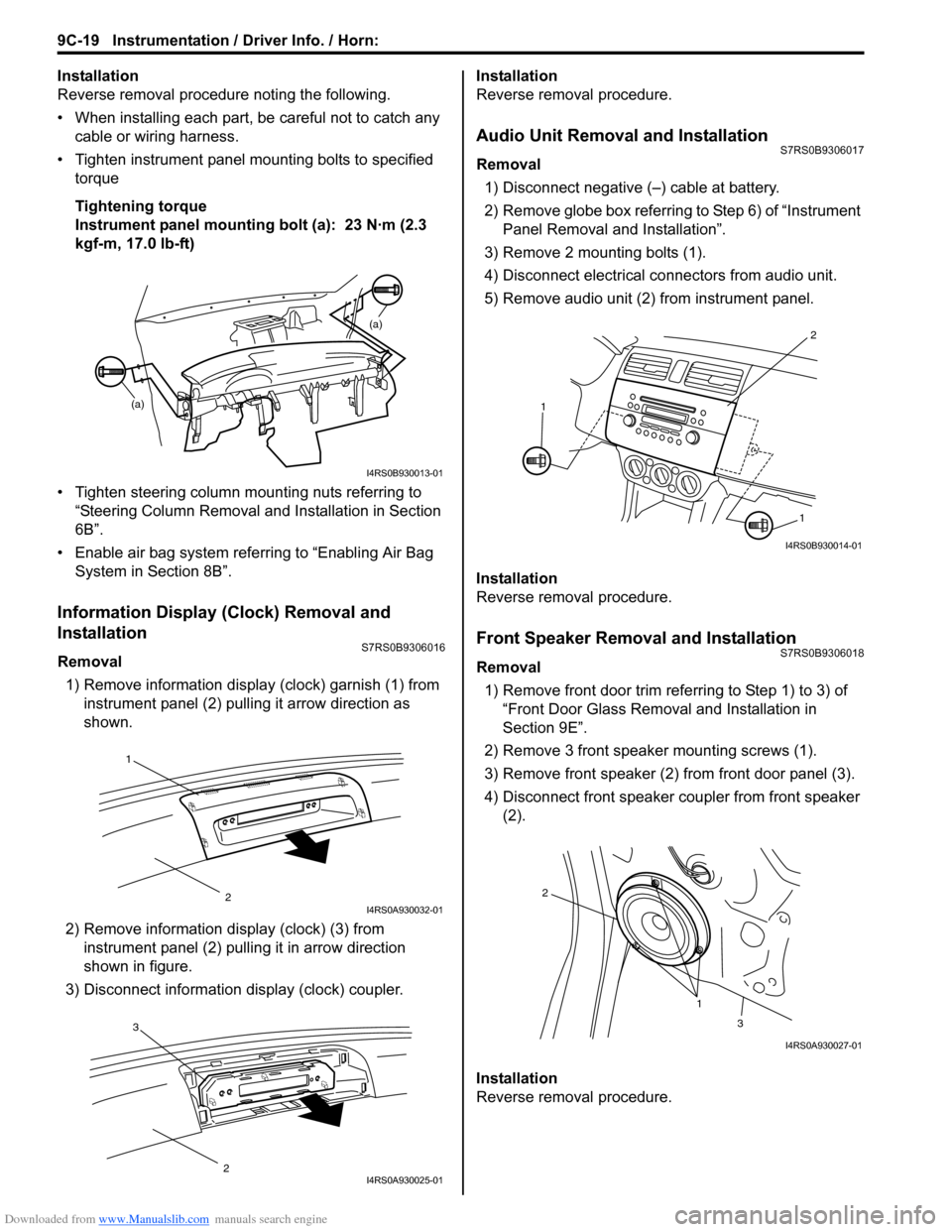

Instrument Panel Removal and InstallationS7RS0B9306015

WARNING!

Refer to “Air Bag Warning in Section 00”

before starting service work.

Removal

1) Disconnect negative (–) cable at battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove steering column hole cover (1).

4) Turn steering wheel to remove steering column cover screws (3).

5) Remove steering column covers (2).

6) Remove glove box (1).

7) Remove hood latch release lever (2).

8) Remove console box referring to “Console Box Components in Section 9H”.

9) Remove instrument panel center lower bracket (1). 10) Remove front pillar trims

(1) and dash side trims (2).

11) Remove instrument panel mounting screws (1).

12) Detach instrument panel from steering support member (2) and then remove foot duct (3).

13) Disconnect instrument panel harness connectors, heater control cables and antenna cable for

instrument panel removal.

14) Remove steering column mounting nuts referring to “Steering Column Remova l and Installation in

Section 6B”.

15) Remove instrument panel ground wire.

16) Remove instrument panel mounting bolts (1).

17) Remove instrument panel (2) with steering support member (3) and instrument panel harness.

1

32

I4RS0B920004-02

2

1I4RS0B930008-01

1

I4RS0B930009-01

“A”

“A”

1

2

I4RS0B930010-01

1

1 2

3

I4RS0B930011-01

1 1

2

3I4RS0B930012-01

Page 1314 of 1496

Downloaded from www.Manualslib.com manuals search engine 9C-19 Instrumentation / Driver Info. / Horn:

Installation

Reverse removal procedure noting the following.

• When installing each part, be careful not to catch any

cable or wiring harness.

• Tighten instrument panel mounting bolts to specified

torque

Tightening torque

Instrument panel mounting bolt (a): 23 N·m (2.3

kgf-m, 17.0 lb-ft)

• Tighten steering column mounting nuts referring to “Steering Column Removal an d Installation in Section

6B”.

• Enable air bag system referring to “Enabling Air Bag System in Section 8B”.

Information Display (Clock) Removal and

Installation

S7RS0B9306016

Removal

1) Remove information display (clock) garnish (1) from instrument panel (2) pulling it arrow direction as

shown.

2) Remove information di splay (clock) (3) from

instrument panel (2) pulli ng it in arrow direction

shown in figure.

3) Disconnect information display (clock) coupler. Installation

Reverse removal procedure.

Audio Unit Removal and InstallationS7RS0B9306017

Removal

1) Disconnect negative (–) cable at battery.

2) Remove globe box referring to Step 6) of “Instrument Panel Removal and Installation”.

3) Remove 2 mounting bolts (1).

4) Disconnect electrical connectors from audio unit.

5) Remove audio unit (2) from instrument panel.

Installation

Reverse removal procedure.

Front Speaker Removal and InstallationS7RS0B9306018

Removal 1) Remove front door trim refe rring to Step 1) to 3) of

“Front Door Glass Remo val and Installation in

Section 9E”.

2) Remove 3 front speaker mounting screws (1).

3) Remove front speaker (2) from front door panel (3).

4) Disconnect front speaker coupler from front speaker (2).

Installation

Reverse removal procedure.

(a) (a)

I4RS0B930013-01

1

2I4RS0A930032-01

3

2I4RS0A930025-01

2

1

1

I4RS0B930014-01

1

2

3

I4RS0A930027-01

Page 1315 of 1496

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-20

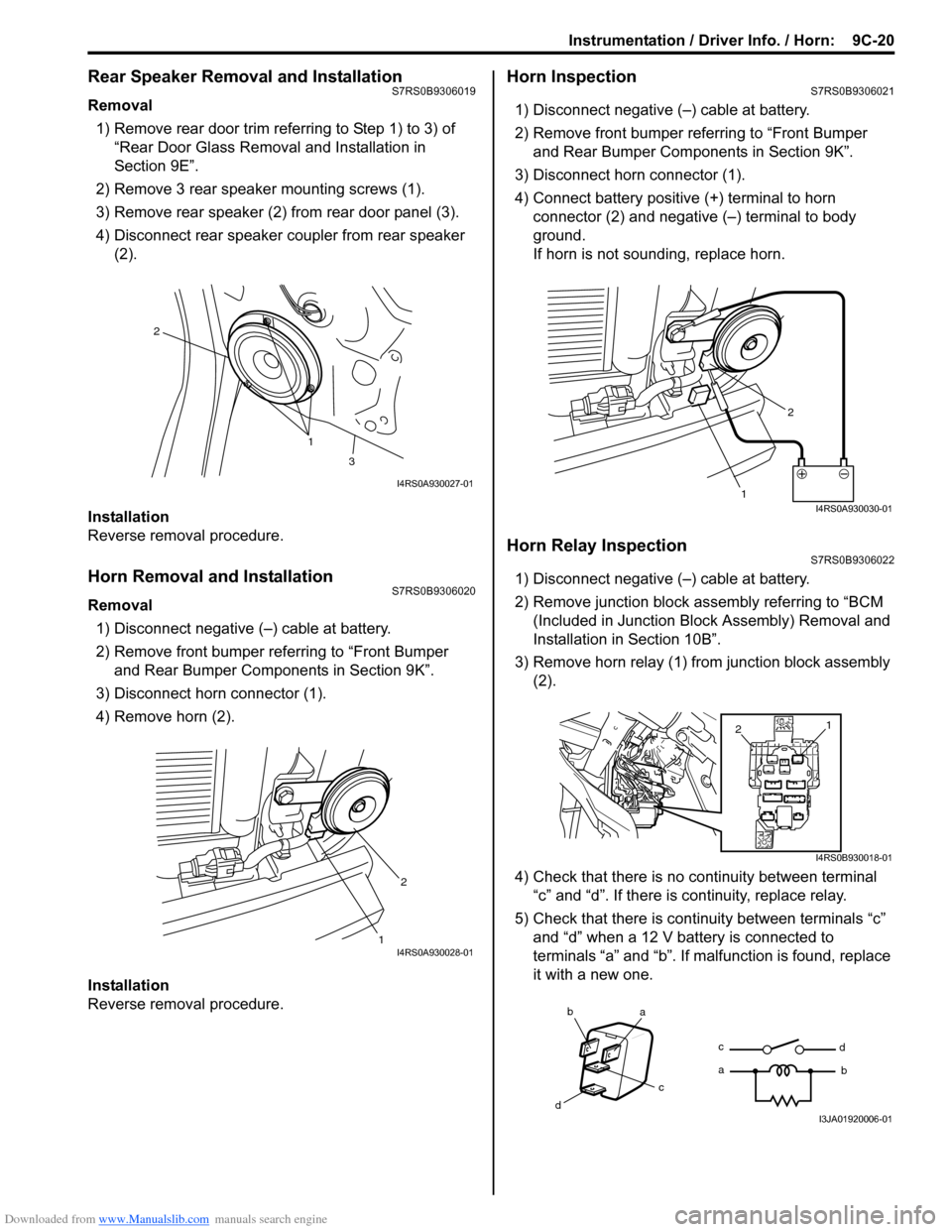

Rear Speaker Removal and InstallationS7RS0B9306019

Removal

1) Remove rear door trim referring to Step 1) to 3) of “Rear Door Glass Removal and Installation in

Section 9E”.

2) Remove 3 rear speaker mounting screws (1).

3) Remove rear speaker (2) from rear door panel (3).

4) Disconnect rear speaker coupler from rear speaker (2).

Installation

Reverse removal procedure.

Horn Removal and InstallationS7RS0B9306020

Removal 1) Disconnect negative (–) cable at battery.

2) Remove front bumper referring to “Front Bumper and Rear Bumper Components in Section 9K”.

3) Disconnect horn connector (1).

4) Remove horn (2).

Installation

Reverse removal procedure.

Horn InspectionS7RS0B9306021

1) Disconnect negative (–) cable at battery.

2) Remove front bumper referring to “Front Bumper and Rear Bumper Components in Section 9K”.

3) Disconnect horn connector (1).

4) Connect battery positive (+) terminal to horn

connector (2) and negative (–) terminal to body

ground.

If horn is not sounding, replace horn.

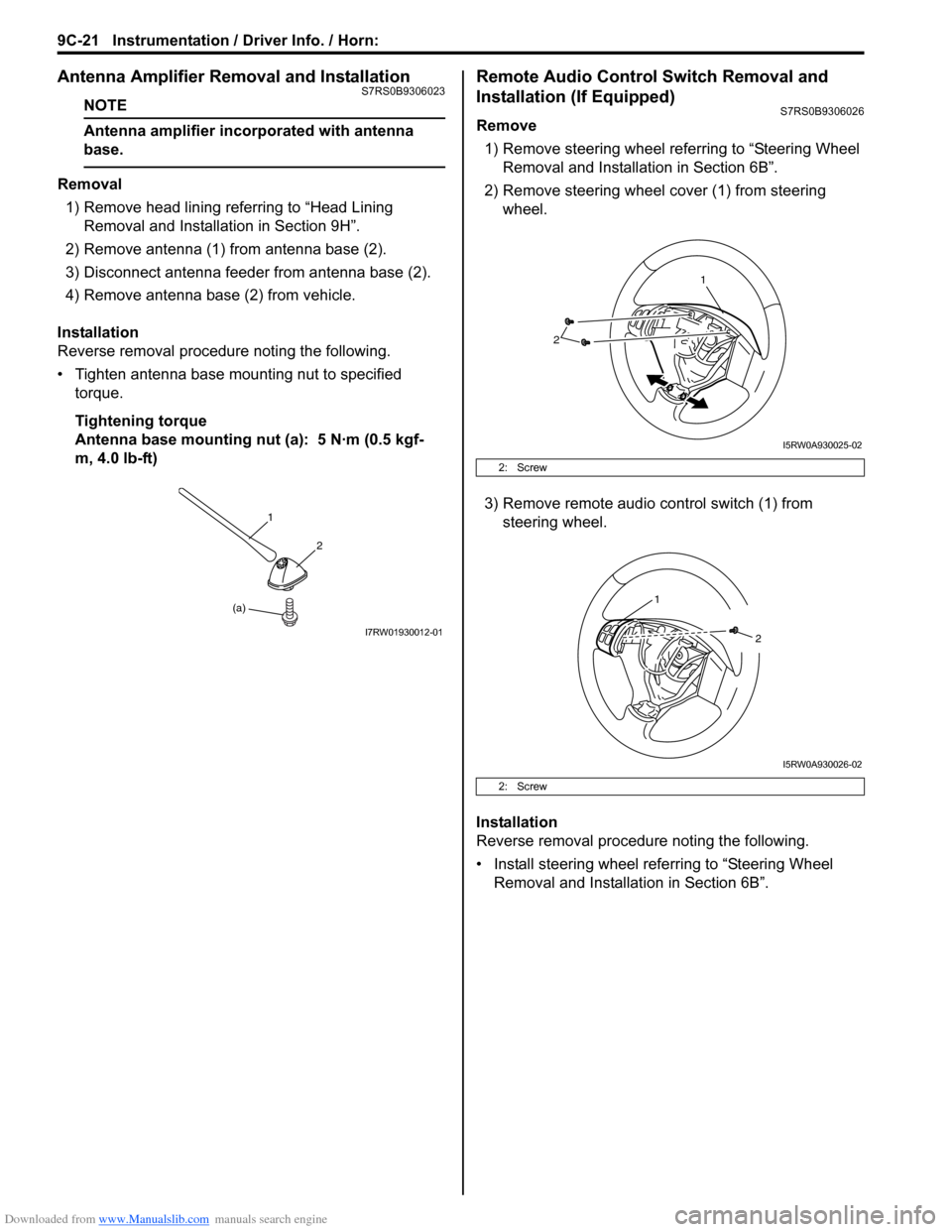

Horn Relay InspectionS7RS0B9306022

1) Disconnect negative (–) cable at battery.

2) Remove junction block assembly referring to “BCM (Included in Junction Bl ock Assembly) Removal and

Installation in Section 10B”.

3) Remove horn relay (1) from junction block assembly (2).

4) Check that there is no continuity between terminal “c” and “d”. If there is continuity, replace relay.

5) Check that there is continuity between terminals “c” and “d” when a 12 V battery is connected to

terminals “a” and “b”. If malfunction is found, replace

it with a new one.

1

2

3

I4RS0A930027-01

12I4RS0A930028-01

1 2I4RS0A930030-01

1

2

I4RS0B930018-01

ba

c

d c

a

d

bI3JA01920006-01

Page 1316 of 1496

Downloaded from www.Manualslib.com manuals search engine 9C-21 Instrumentation / Driver Info. / Horn:

Antenna Amplifier Removal and InstallationS7RS0B9306023

NOTE

Antenna amplifier incorporated with antenna

base.

Removal1) Remove head lining referring to “Head Lining Removal and Installa tion in Section 9H”.

2) Remove antenna (1) from antenna base (2).

3) Disconnect antenna feeder from antenna base (2).

4) Remove antenna base (2) from vehicle.

Installation

Reverse removal procedure noting the following.

• Tighten antenna base mounting nut to specified torque.

Tightening torque

Antenna base mounting nut (a): 5 N·m (0.5 kgf-

m, 4.0 lb-ft)

Remote Audio Control Switch Removal and

Installation (If Equipped)

S7RS0B9306026

Remove

1) Remove steering wheel re ferring to “Steering Wheel

Removal and Installati on in Section 6B”.

2) Remove steering wheel cover (1) from steering wheel.

3) Remove remote audio control switch (1) from steering wheel.

Installation

Reverse removal procedure noting the following.

• Install steering wheel referring to “Steering Wheel Removal and Installati on in Section 6B”.

(a)1

2

I7RW01930012-01

2: Screw

2: Screw

2

1

I5RW0A930025-02

1

2

I5RW0A930026-02

Page 1317 of 1496

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-22

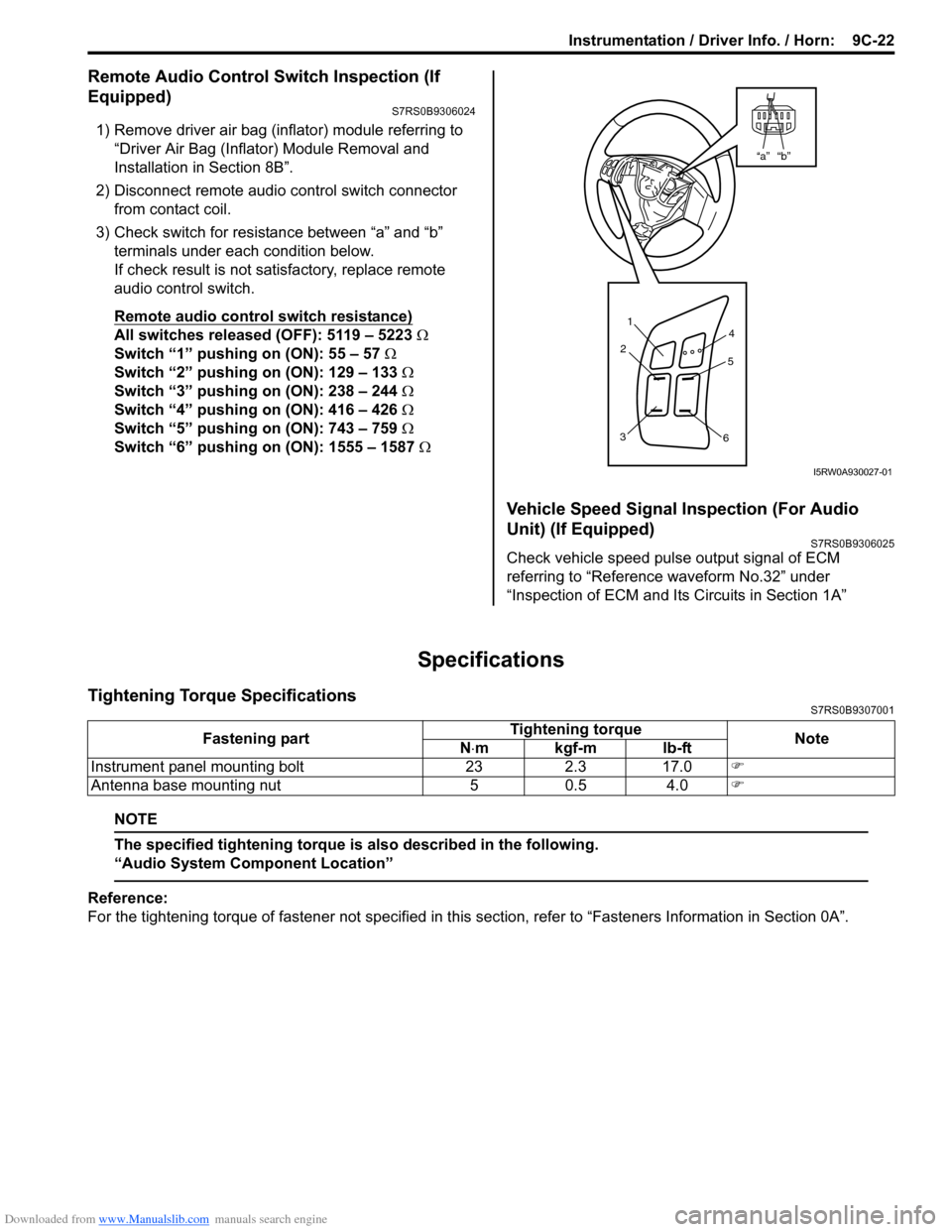

Remote Audio Control Switch Inspection (If

Equipped)

S7RS0B9306024

1) Remove driver air bag (inflator) module referring to

“Driver Air Bag (Inflator) Module Removal and

Installation in Section 8B”.

2) Disconnect remote audio control switch connector

from contact coil.

3) Check switch for resistance between “a” and “b” terminals under each condition below.

If check result is not satisfactory, replace remote

audio control switch.

Remote audio control switch resistance)

All switches released (OFF): 5119 – 5223 Ω

Switch “1” pushing on (ON): 55 – 57 Ω

Switch “2” pushing on (ON): 129 – 133 Ω

Switch “3” pushing on (ON): 238 – 244 Ω

Switch “4” pushing on (ON): 416 – 426 Ω

Switch “5” pushing on (ON): 743 – 759 Ω

Switch “6” pushing on (ON): 1555 – 1587 Ω

Vehicle Speed Signal Inspection (For Audio

Unit) (If Equipped)

S7RS0B9306025

Check vehicle speed pulse output signal of ECM

referring to “Reference waveform No.32” under

“Inspection of ECM and Its Circuits in Section 1A”

Specifications

Tightening Torque SpecificationsS7RS0B9307001

NOTE

The specified tightening torque is also described in the following.

“Audio System Component Location”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

“b”“a”

1

2

3 4

5

6

I5RW0A930027-01

Fastening part Tightening torque

Note

N ⋅mkgf-mlb-ft

Instrument panel mounting bolt 23 2.3 17.0 �)

Antenna base mounting nut 5 0.5 4.0 �)

Page 1343 of 1496

Downloaded from www.Manualslib.com manuals search engine Glass / Windows / Mirrors: 9E-16

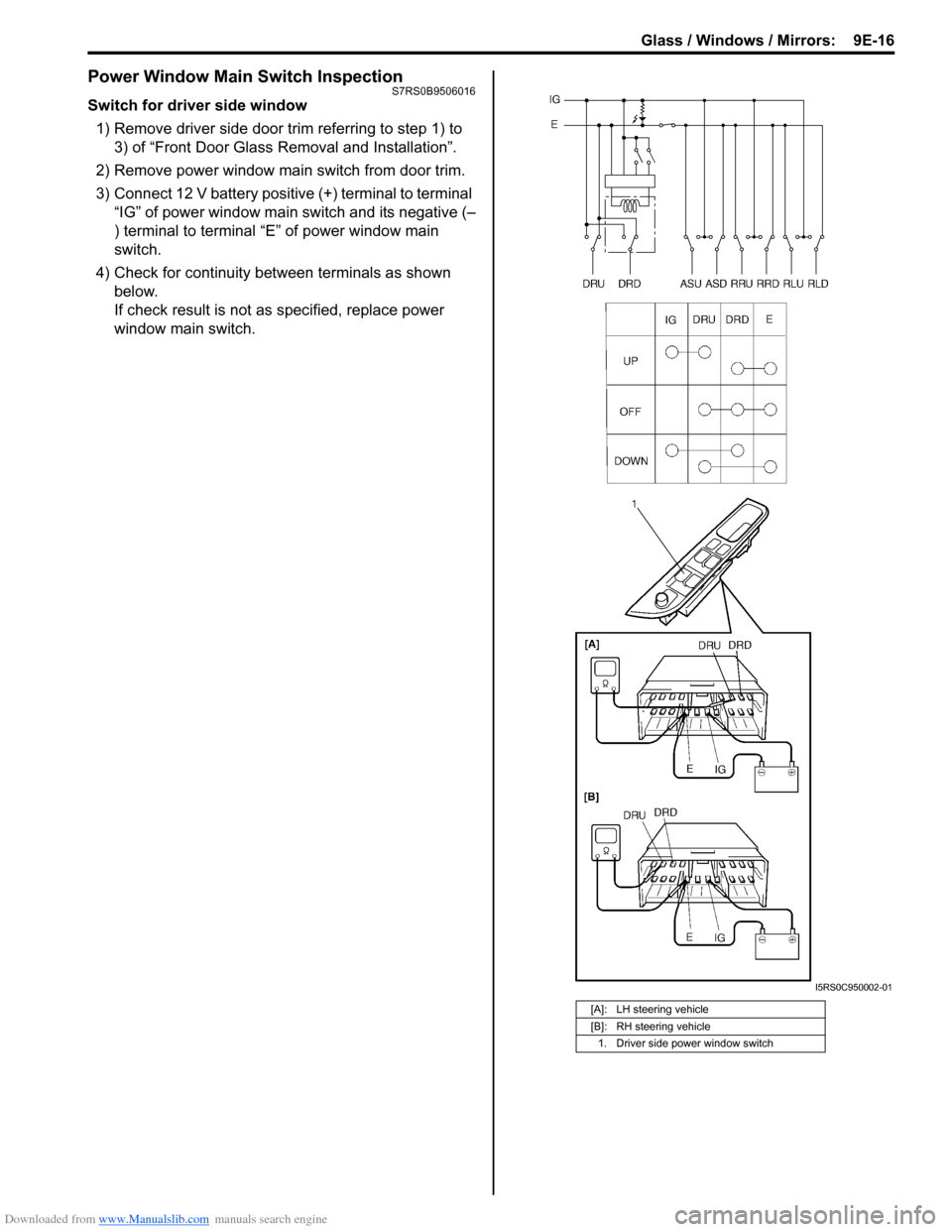

Power Window Main Switch InspectionS7RS0B9506016

Switch for driver side window 1) Remove driver side door trim referring to step 1) to 3) of “Front Door Glass Removal and Installation”.

2) Remove power window main switch from door trim.

3) Connect 12 V battery positive (+) terminal to terminal “IG” of power window main switch and its negative (–

) terminal to terminal “E” of power window main

switch.

4) Check for continuity between terminals as shown below.

If check result is not as specified, replace power

window main switch.

[A]: LH steering vehicle

[B]: RH steering vehicle

1. Driver side power window switch

I5RS0C950002-01

Page 1344 of 1496

Downloaded from www.Manualslib.com manuals search engine 9E-17 Glass / Windows / Mirrors:

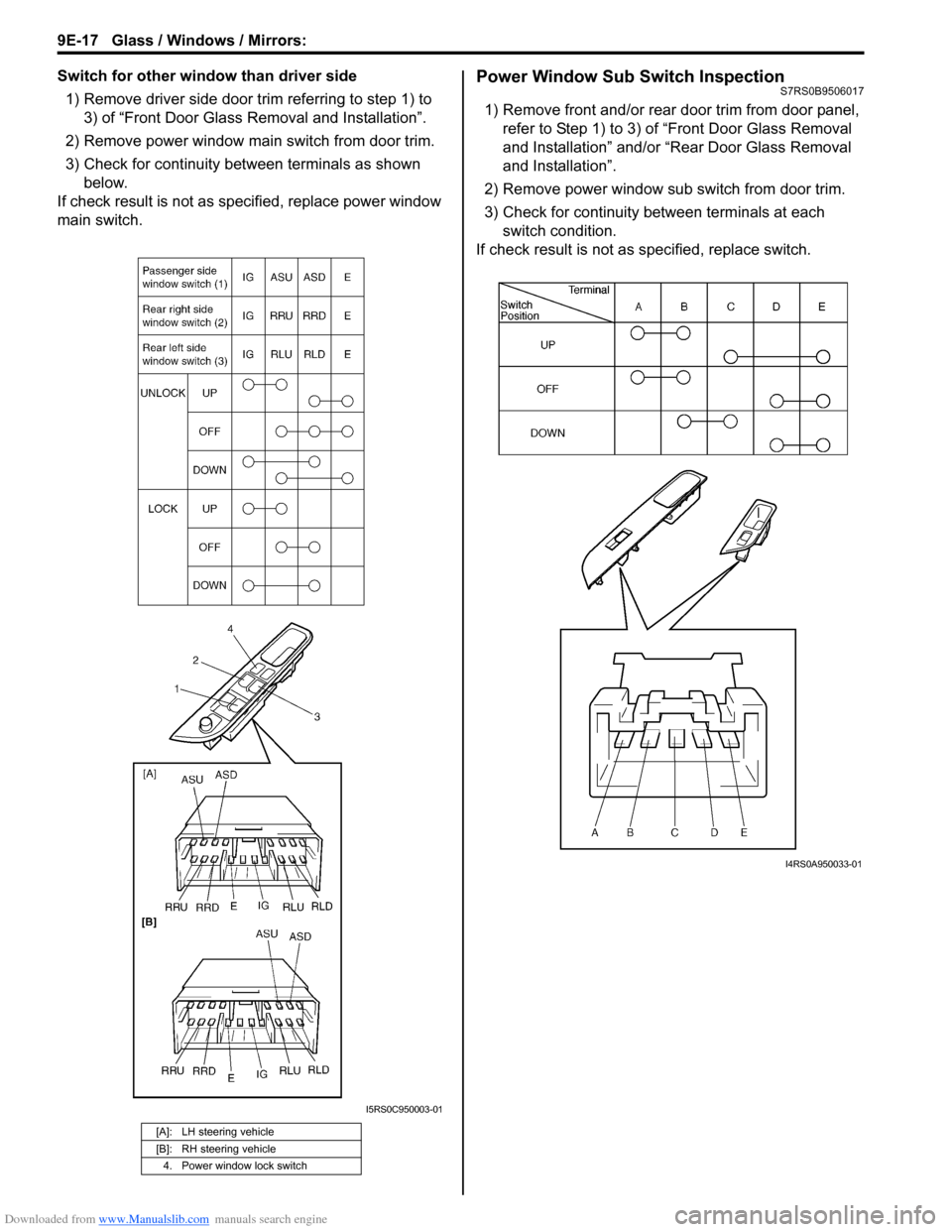

Switch for other window than driver side1) Remove driver side door trim referring to step 1) to 3) of “Front Door Glass Removal and Installation”.

2) Remove power window main switch from door trim.

3) Check for continuity between terminals as shown below.

If check result is not as sp ecified, replace power window

main switch.Power Window Sub Switch InspectionS7RS0B9506017

1) Remove front and/or rear door trim from door panel, refer to Step 1) to 3) of “Front Door Glass Removal

and Installation” and/or “Rear Door Glass Removal

and Installation”.

2) Remove power window sub switch from door trim.

3) Check for continuity between terminals at each switch condition.

If check result is not as specified, replace switch.

[A]: LH steering vehicle

[B]: RH steering vehicle

4. Power window lock switch

I5RS0C950003-01

I4RS0A950033-01

Page 1345 of 1496

Downloaded from www.Manualslib.com manuals search engine Glass / Windows / Mirrors: 9E-18

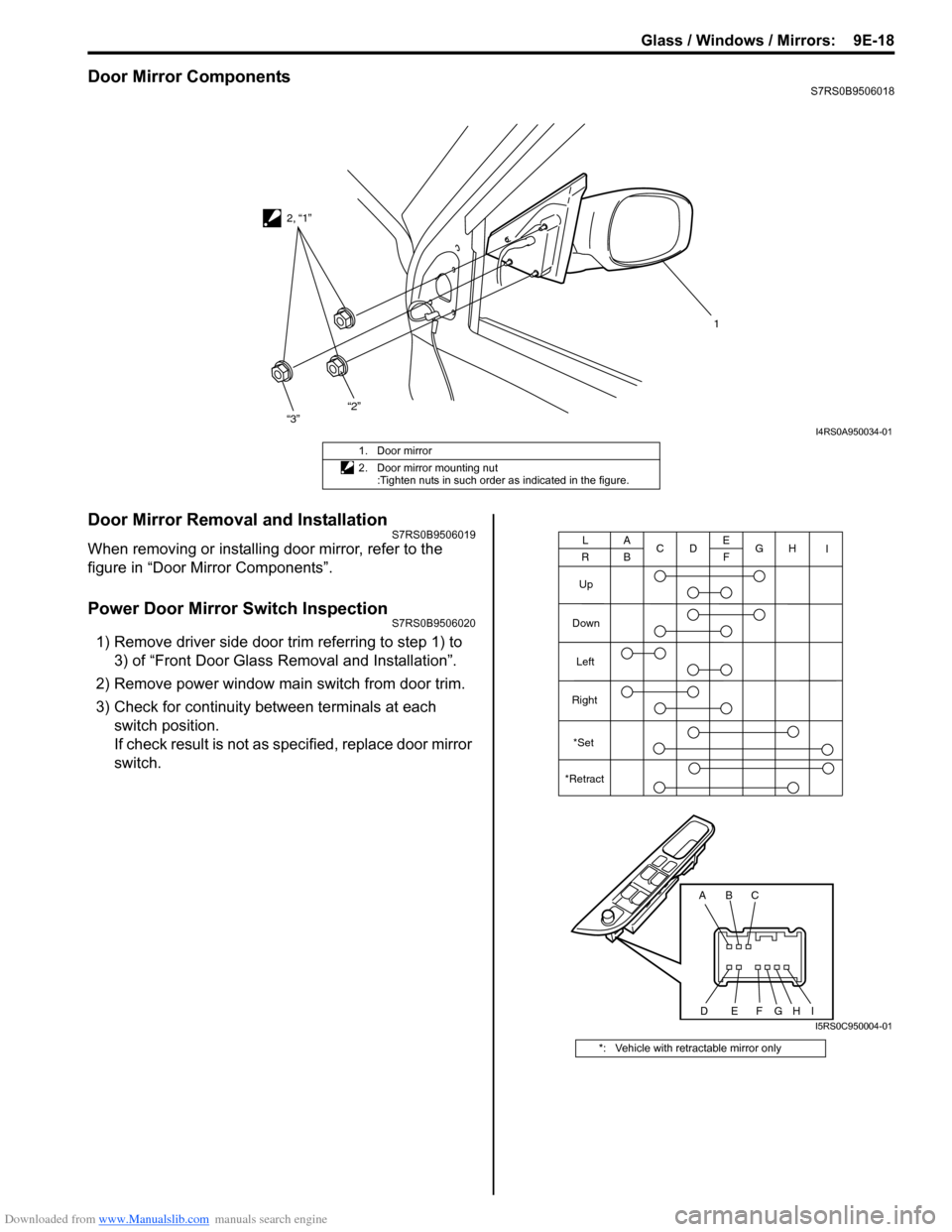

Door Mirror ComponentsS7RS0B9506018

Door Mirror Removal and InstallationS7RS0B9506019

When removing or installing door mirror, refer to the

figure in “Door Mirror Components”.

Power Door Mirror Switch InspectionS7RS0B9506020

1) Remove driver side door trim referring to step 1) to 3) of “Front Door Glass Removal and Installation”.

2) Remove power window main switch from door trim.

3) Check for continuity between terminals at each switch position.

If check result is not as specified, replace door mirror

switch.

1

2, “1”

“3”

“2”

I4RS0A950034-01

1. Door mirror

2. Door mirror mounting nut

:Tighten nuts in such order as indicated in the figure.

*: Vehicle with retractable mirror only

ABC

DEFG

A

B C

D E

F G

Up

Down Left

Right

L

RH I

*Set

*Retract

HII5RS0C950004-01