Driver SUZUKI SWIFT 2007 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 1418 of 1496

Downloaded from www.Manualslib.com manuals search engine 10B-15 Body Electrical Control System:

Without Using SUZUKI Scan Tool1) Turn ignition switch to OFF position.

2) Perform following Steps a) to d) within 10 seconds af ter ignition switch is turned ON and engine stops.

a) Turn headlight switch to “SMALL” position.

b) Turn headlight switch to “OFF” position.

c) Repeat Steps a) and b) 2 times.

d) Press and release driver side door switch 3 times.

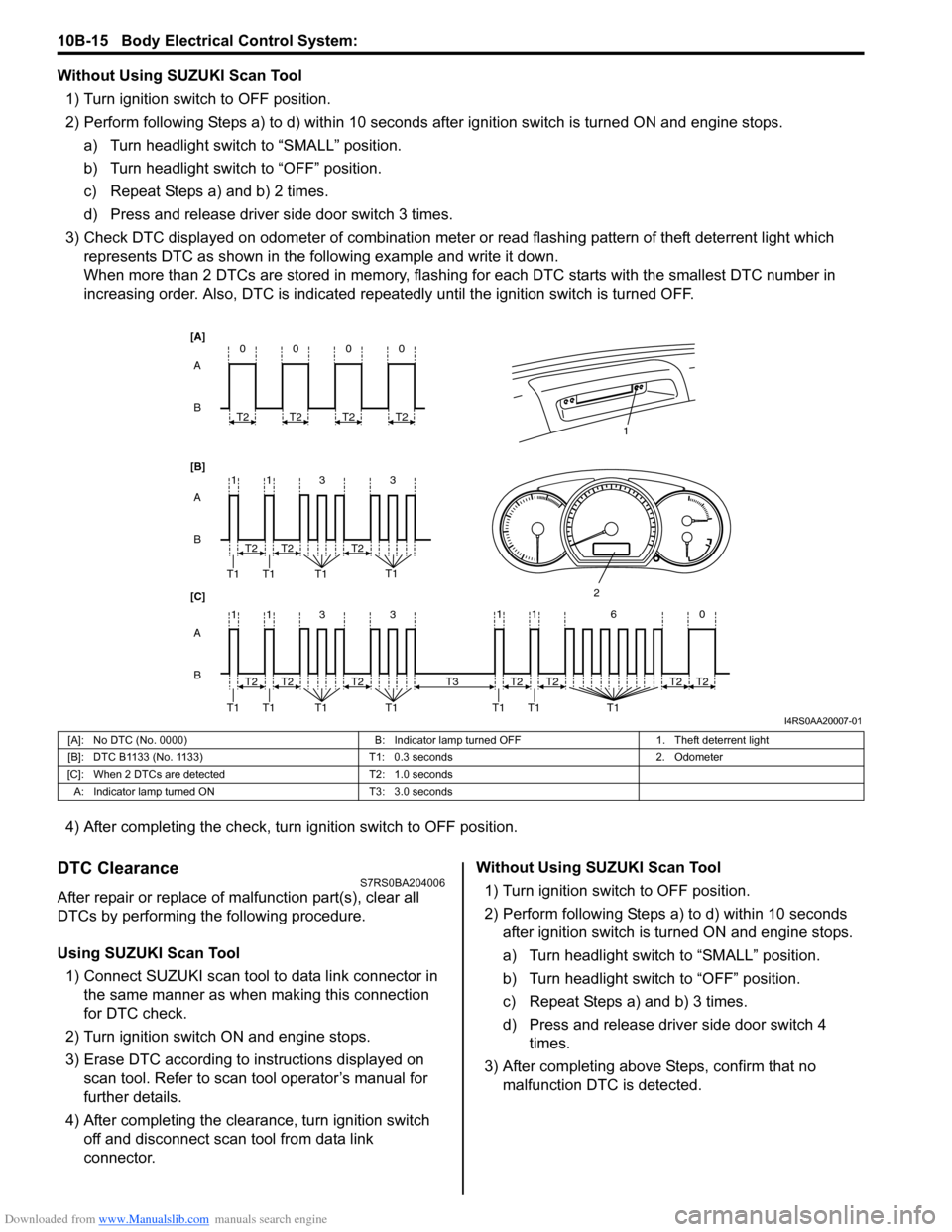

3) Check DTC displayed on odometer of combination meter or read flashing pattern of theft deterrent light which

represents DTC as shown in the following example and write it down.

When more than 2 DTCs are stored in memory, flashing for each DTC starts with the smallest DTC number in

increasing order. Also, DTC is indicated repeatedly until the ignition switch is turned OFF.

4) After completing the check, turn ignition switch to OFF position.

DTC ClearanceS7RS0BA204006

After repair or replace of malfunction part(s), clear all

DTCs by performing the following procedure.

Using SUZUKI Scan Tool 1) Connect SUZUKI scan tool to data link connector in the same manner as when making this connection

for DTC check.

2) Turn ignition switch ON and engine stops.

3) Erase DTC according to instructions displayed on scan tool. Refer to scan tool operator’s manual for

further details.

4) After completing the clear ance, turn ignition switch

off and disconnect scan tool from data link

connector. Without Using SUZUKI Scan Tool

1) Turn ignition switch to OFF position.

2) Perform following Steps a) to d) within 10 seconds after ignition switch is turned ON and engine stops.

a) Turn headlight switch to “SMALL” position.

b) Turn headlight switch to “OFF” position.

c) Repeat Steps a) and b) 3 times.

d) Press and release driver side door switch 4 times.

3) After completing above Steps, confirm that no malfunction DTC is detected.

B A

[B] [A]

[C]

B A B A

3

113

3

113

T2

T1 T1 T1 T1

1

2

T2T2

T2

T1 T1 T1 T1T2T2

0

T2

0

T2

0

T2

0

T2

11 6 0

T1 T1 T1

T2

T3T2T2T2

I4RS0AA20007-01

[A]: No DTC (No. 0000) B: Indicator lamp turned OFF1. Theft deterrent light

[B]: DTC B1133 (No. 1133) T1: 0.3 seconds2. Odometer

[C]: When 2 DTCs are detected T2: 1.0 seconds

A: Indicator lamp tur ned ON T3: 3.0 seconds

Page 1433 of 1496

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-30

6Combination meter operation check

1) Connect connectors of disconnected control modules

communicating by means of CAN.

2) Turn ignition switch to ON position.

3) Check combination meter operation for seat belt reminder light (fastening and unfastening driver side

seat belt).

Are they OK? Go to Step 7.

Check combination

meter power and

ground circuit. If circuit

is OK, substitute a

known-good

combination meter and

recheck.

7 Key indicator light operation check

1) Turn ignition switch to OFF position.

2) Push ignition knob switch of steering lock unit.

Does key indicator light turn ON? Go to Step 8.

Check keyless start

control module power

and ground circuit. If

circuit is OK, substitute

a known-good keyless

start control module and

recheck.

8 DTC check of BCM

1) Disconnect connector of any one of control module other

than BCM.

2) Recheck BCM for DTC.

Is DTC U1144 (No.1144) detected? Disconnect connectors

of control modules other

than the one whose

connector is

disconnected in Step 1)

one by one and check

that DTC U1144 is

detected by BCM each

time connector is

disconnected. When

DTC U1144 is not

detected by BCM while

checking in this way, go

to description under

“NO” below. If DTC

U1144 is detected by

BCM even when

connectors of all control

modules that use CAN

communication with

BCM are disconnected,

substitute a known-

good BCM and recheck.Check power and

ground circuit of control

module disconnected in

Step 1). If circuit is OK,

substitute a known-

good control module

disconnected in Step 1)

and recheck.

Step

Action YesNo

Page 1434 of 1496

Downloaded from www.Manualslib.com manuals search engine 10B-31 Body Electrical Control System:

Inspection of BCM and its CircuitsS7RS0BA204018

BCM and its circuits can be checked at BCM wiring couplers by measuring voltage and resistance.

CAUTION!

BCM cannot be checked by itself. It is strictly prohibited to connect voltmeter or ohmmeter to BCM

with couplers disconnected from it.

Voltage Check1) Disconnect negative (–) cable at battery.

2) Remove BCM (included in junction block assembly) refe rring to “BCM (Included in Junction Block Assembly)

Removal and Installation”.

3) Connect connectors to BCM (1) and junction block assembly (2).

4) Check voltage at each terminal number of couplers connected. For connector and terminal number, refer to “Connector Layout Diagram of BCM and Junction Block Assembly”.

NOTE

• As each terminal voltage is affected by the battery voltage, confirm that it is 11 V or more when

ignition switch is ON.

• Voltage with asterisk (*) can not be measured by voltmeter because it is pulse signal. Check it with oscilloscope if necessary.

BCM connector “L01”

1

2

1

2

I4RS0AA20030-01

Terminal CircuitNormal voltage Condition

L01-1 Passenger side door lock

actuator control

(Unlock) (if equipped) 10 – 14 V

Unlock signal is output fo

r passenger side door lock

actuator

0 V Unlock signal is not output for passenger side door lock

actuator

L01-2 — — —

L01-3 Rear end door switch 10 – 14 V Rear end door is closed

0 V Rear end door is opened

L01-4 Rear end door opener switch 10 – 14 V Rear end door switch is not pushed

0 V Rear end door switch is pushed

L01-5 Manual door lock switch

(Unlock) 10 – 14 V

Manual door lock switch is at any position other than

unlock position

0 V Manual door lock switch is at unlock position

L01-6 Parking brake switch *0 – 3 V

↑↓

10 – 14 V Refer to “Reference waveform No. 1: ”

0 V Ignition switch is at ON po

sition and parking brake lever

is pulled up

L01-7 Driver side door switch 10 – 14 V Driver side door is closed

0 V Driver side door is opened

Page 1435 of 1496

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-32

BCM connector “E46”L01-8

“3” position switch

(A/T model) *0 – 1 V

↑↓

10 – 14 V Refer to “Reference waveform No. 2: ”

0 V Ignition switch is at ON positi

on and A/T select lever is at

“2” or “3” position

L01-9 — — —

L01-10 Driver side door lock actuator

control (Unlock) (if equipped) 10 – 14 V Unlock signal is output for driver side door lock actuator.

0 V Unlock signal is not output for driver side door lock

actuator.

L01-11 Rear end door opener

actuator control 0 V Rear end door opener actuator is not in operation

10 – 14 V Rear end door opener actuator is in operation

L01-12 Manual door lock switch

(Lock) 10 – 14 V

Manual door lock switch is at any position other than lock

position

0 V Manual door lock swit ch is at lock position

L01-13 — — —

L01-14 Driver side seat belt switch *0 – 3 V

↑↓

10 – 14 V Refer to “Reference waveform No. 3: ”

0 V Ignition switch is at ON position and driver side seat belt

is unfastened

L01-15 Door switch (other than driver

side door and rear end door) 10 – 14 V

Rear right and left side door and passenger side door are

closed

0 V Any one of the door is opened (except driver side door

and rear end door)

L01-16 Driver side door key cylinder switch (Lock) 10 – 14 V

Driver side door key cylinder switch is at any position

other than lock position

0 V Driver side door key cylinder switch is at lock position

L01-17 Driver side door key cylinder

switch (Unlock) 10 – 14 V

Driver side door key cylinder switch is at any position

other than unlock position

0 V Driver side door key cylinder switch is at unlock position

L01-18 — — —

Terminal Circuit Normal voltage Condition

Terminal

CircuitNormal voltage Condition

E46-1 CAN communication line

(high) for ABS/ESP

® control

module *2.5 – 3.6 V

Refer to “Reference waveform No. 4: ”

E46-2 CAN communication line

(low) for ABS/ESP

® control

module *1.6 – 2.5 V

E46-3 — — —

E46-4 Generator “L” terminal 10 – 14 V Engine is running

0 V Ignition switch is at ON position

E46-5 Brake fluid level switch *0 – 3 V

↑↓

10 – 14 V Refer to “Reference waveform No. 1: ”

0 V Ignition switch is at ON position, parking brake lever is

released and brake fluid level is lower than MIN level

E46-6 — — —

E46-7 — — —

E46-8 Sensor ground for outside air

temperature sensor

(if equipped) 0 V

—

E46-9 Serial communication line of

data link connector for ECM,

TCM, ABS and

P/S control

module 8 – 12 V Ignition switch is at ON position

E46-10 Outside air temperature

sensor (if equipped) About 1.5 VIgnition switch is at ON position and outside air

temperature approx. 20

°C (68 °F)

Page 1439 of 1496

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-36

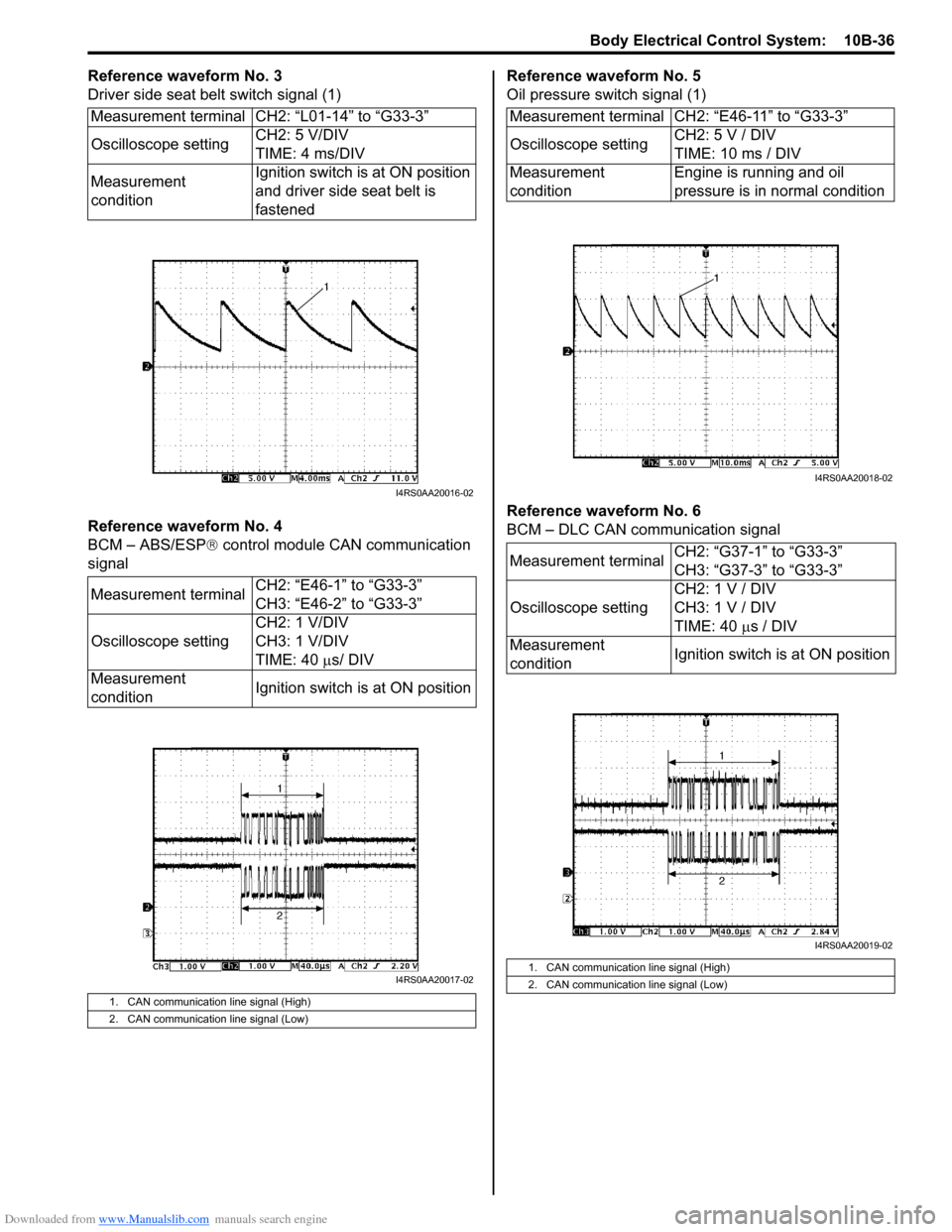

Reference waveform No. 3

Driver side seat belt switch signal (1)

Reference waveform No. 4

BCM – ABS/ESP® control module CAN communication

signal Reference waveform No. 5

Oil pressure switch signal (1)

Reference waveform No. 6

BCM – DLC CAN communication signal

Measurement terminal CH2: “L01-14” to “G33-3”

Oscilloscope setting

CH2: 5 V/DIV

TIME: 4 ms/DIV

Measurement

condition Ignition switch is at ON position

and driver side seat belt is

fastened

Measurement terminal CH2: “E46-1” to “G33-3”

CH3: “E46-2” to “G33-3”

Oscilloscope setting CH2: 1 V/DIV

CH3: 1 V/DIV

TIME: 40

µs/ DIV

Measurement

condition Ignition switch is at ON position

1. CAN communication line signal (High)

2. CAN communication line signal (Low)

I4RS0AA20016-02

I4RS0AA20017-02

Measurement terminal CH2: “E46-11” to “G33-3”

Oscilloscope settingCH2: 5 V / DIV

TIME: 10 ms / DIV

Measurement

condition Engine is running and oil

pressure is in normal condition

Measurement terminal CH2: “G37-1” to “G33-3”

CH3: “G37-3” to “G33-3”

Oscilloscope setting CH2: 1 V / DIV

CH3: 1 V / DIV

TIME: 40

µs / DIV

Measurement

condition Ignition switch is at ON position

1. CAN communication line signal (High)

2. CAN communication line signal (Low)

I4RS0AA20018-02

I4RS0AA20019-02

Page 1442 of 1496

Downloaded from www.Manualslib.com manuals search engine 10B-39 Body Electrical Control System:

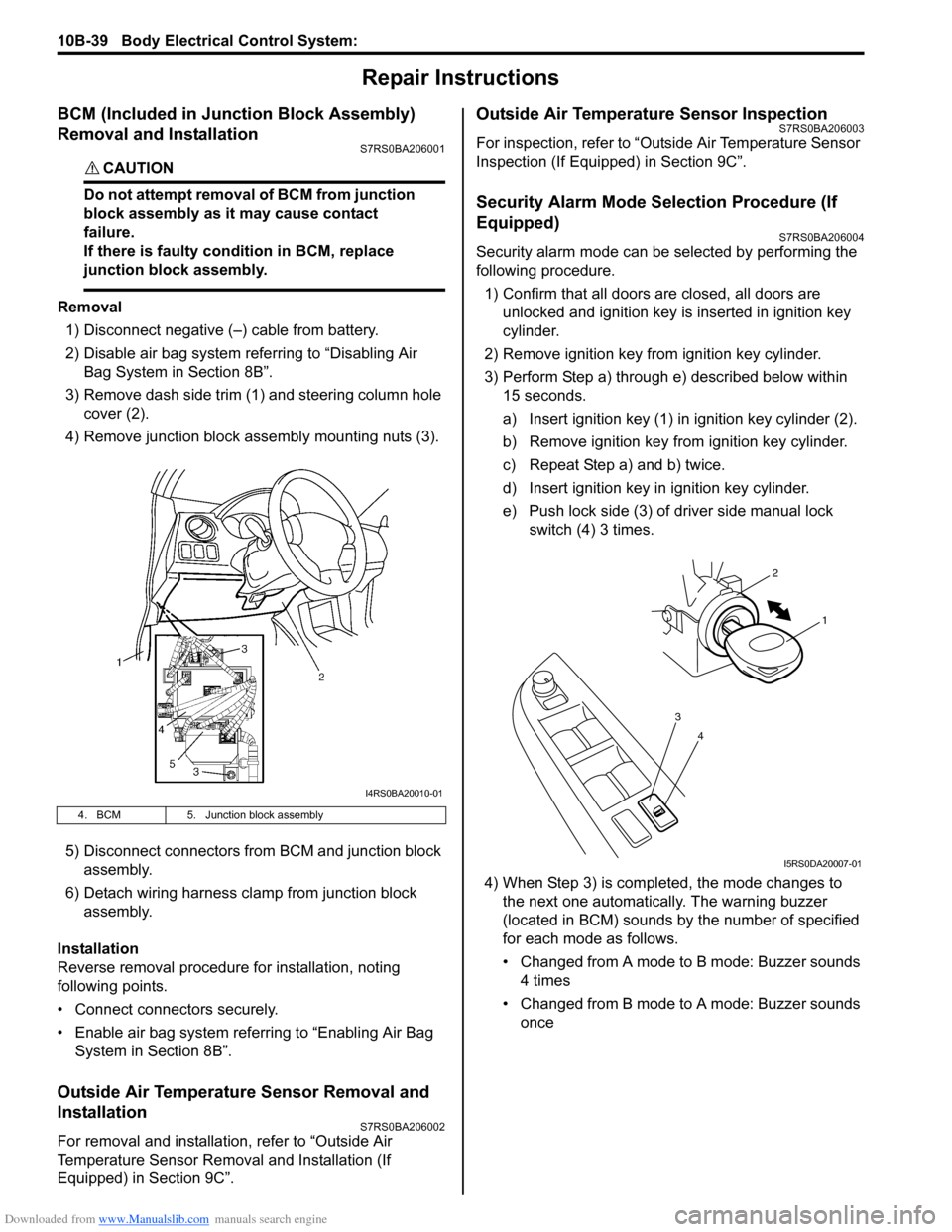

Repair Instructions

BCM (Included in Junction Block Assembly)

Removal and Installation

S7RS0BA206001

CAUTION!

Do not attempt removal of BCM from junction

block assembly as it may cause contact

failure.

If there is faulty condition in BCM, replace

junction block assembly.

Removal

1) Disconnect negative (–) cable from battery.

2) Disable air bag system referring to “Disabling Air Bag System in Section 8B”.

3) Remove dash side trim (1) and steering column hole cover (2).

4) Remove junction block assembly mounting nuts (3).

5) Disconnect connectors from BCM and junction block assembly.

6) Detach wiring harness clamp from junction block assembly.

Installation

Reverse removal procedure for installation, noting

following points.

• Connect connectors securely.

• Enable air bag system referring to “Enabling Air Bag System in Section 8B”.

Outside Air Temperature Sensor Removal and

Installation

S7RS0BA206002

For removal and installation, refer to “Outside Air

Temperature Sensor Removal and Installation (If

Equipped) in Section 9C”.

Outside Air Temperature Sensor InspectionS7RS0BA206003

For inspection, refer to “Outside Air Temperature Sensor

Inspection (If Equipped) in Section 9C”.

Security Alarm Mode Selection Procedure (If

Equipped)

S7RS0BA206004

Security alarm mode can be selected by performing the

following procedure.

1) Confirm that all doors are closed, all doors are unlocked and ignition key is inserted in ignition key

cylinder.

2) Remove ignition key from ignition key cylinder.

3) Perform Step a) through e) described below within 15 seconds.

a) Insert ignition key (1) in ignition key cylinder (2).

b) Remove ignition key from ignition key cylinder.

c) Repeat Step a) and b) twice.

d) Insert ignition key in ignition key cylinder.

e) Push lock side (3) of driver side manual lock switch (4) 3 times.

4) When Step 3) is completed, the mode changes to the next one automatically. The warning buzzer

(located in BCM) sounds by the number of specified

for each mode as follows.

• Changed from A mode to B mode: Buzzer sounds 4 times

• Changed from B mode to A mode: Buzzer sounds once

4. BCM 5. Junction block assembly

I4RS0BA20010-01

4

3

1

2

I5RS0DA20007-01

Page 1448 of 1496

Downloaded from www.Manualslib.com manuals search engine 10C-5 Immobilizer Control System:

Diagnostic Information and Procedures

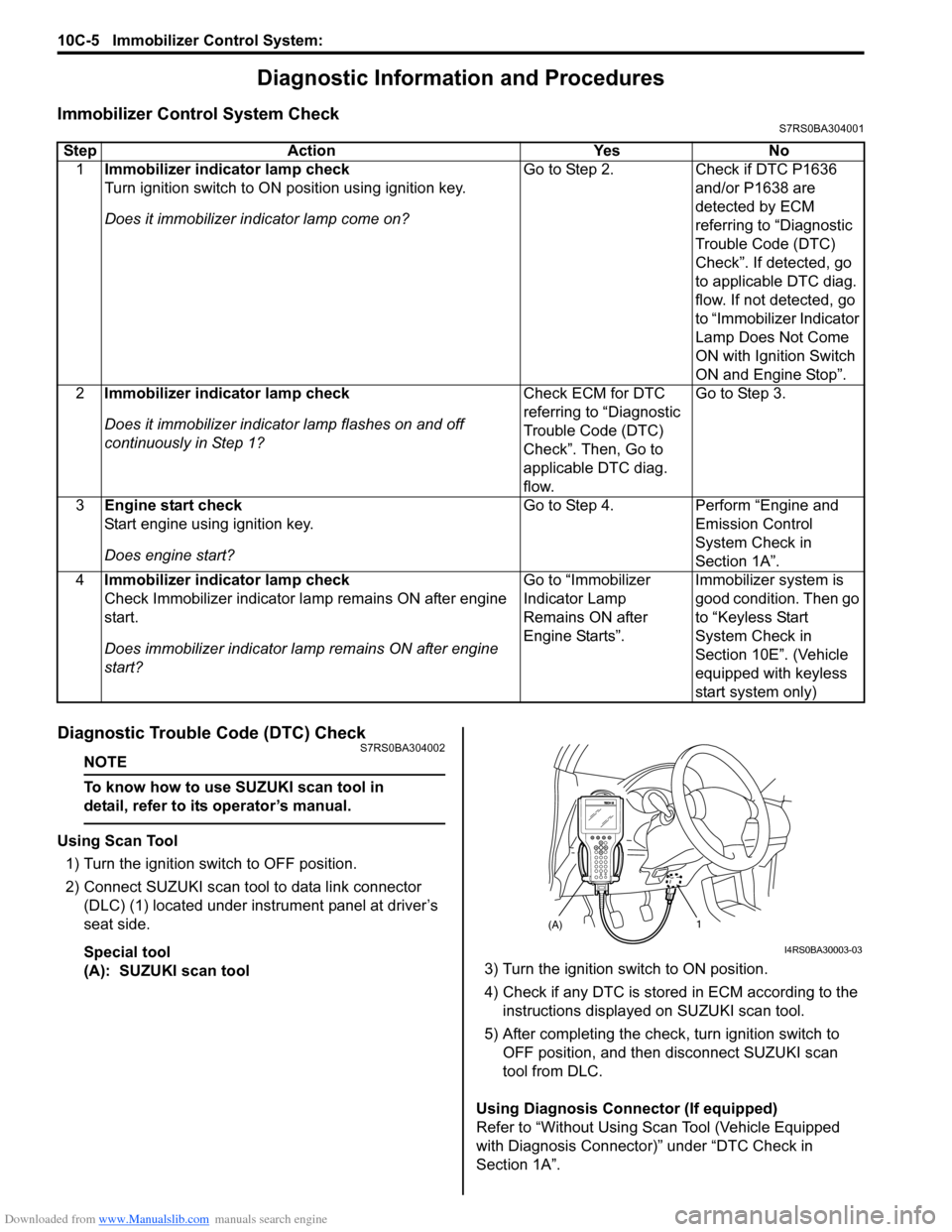

Immobilizer Control System CheckS7RS0BA304001

Diagnostic Trouble Code (DTC) CheckS7RS0BA304002

NOTE

To know how to use SUZUKI scan tool in

detail, refer to its operator’s manual.

Using Scan Tool

1) Turn the ignition switch to OFF position.

2) Connect SUZUKI scan tool to data link connector (DLC) (1) located under instrument panel at driver’s

seat side.

Special tool

(A): SUZUKI scan tool 3) Turn the ignition switch to ON position.

4) Check if any DTC is stored

in ECM according to the

instructions displayed on SUZUKI scan tool.

5) After completing the check, turn ignition switch to

OFF position, and then di sconnect SUZUKI scan

tool from DLC.

Using Diagnosis Connector (If equipped)

Refer to “Without Using Scan Tool (Vehicle Equipped

with Diagnosis Connector)” under “DTC Check in

Section 1A”.

Step Action Yes No

1 Immobilizer indicator lamp check

Turn ignition switch to ON position using ignition key.

Does it immobilizer in dicator lamp come on? Go to Step 2.

Check if DTC P1636

and/or P1638 are

detected by ECM

referring to “Diagnostic

Trouble Code (DTC)

Check”. If detected, go

to applicable DTC diag.

flow. If not detected, go

to “Immobilizer Indicator

Lamp Does Not Come

ON with Ignition Switch

ON and Engine Stop”.

2 Immobilizer indicator lamp check

Does it immobilizer indicato r lamp flashes on and off

continuously in Step 1? Check ECM for DTC

referring to “Diagnostic

Trouble Code (DTC)

Check”. Then, Go to

applicable DTC diag.

flow.Go to Step 3.

3 Engine start check

Start engine using ignition key.

Does engine start? Go to Step 4.

Perform “Engine and

Emission Control

System Check in

Section 1A”.

4 Immobilizer indicator lamp check

Check Immobilizer indicator la mp remains ON after engine

start.

Does immobilizer indicator la mp remains ON after engine

start? Go to “Immobilizer

Indicator Lamp

Remains ON after

Engine Starts”.

Immobilizer system is

good condition. Then go

to “Keyless Start

System Check in

Section 10E”. (Vehicle

equipped with keyless

start system only)

(A)1

I4RS0BA30003-03

Page 1449 of 1496

Downloaded from www.Manualslib.com manuals search engine Immobilizer Control System: 10C-6

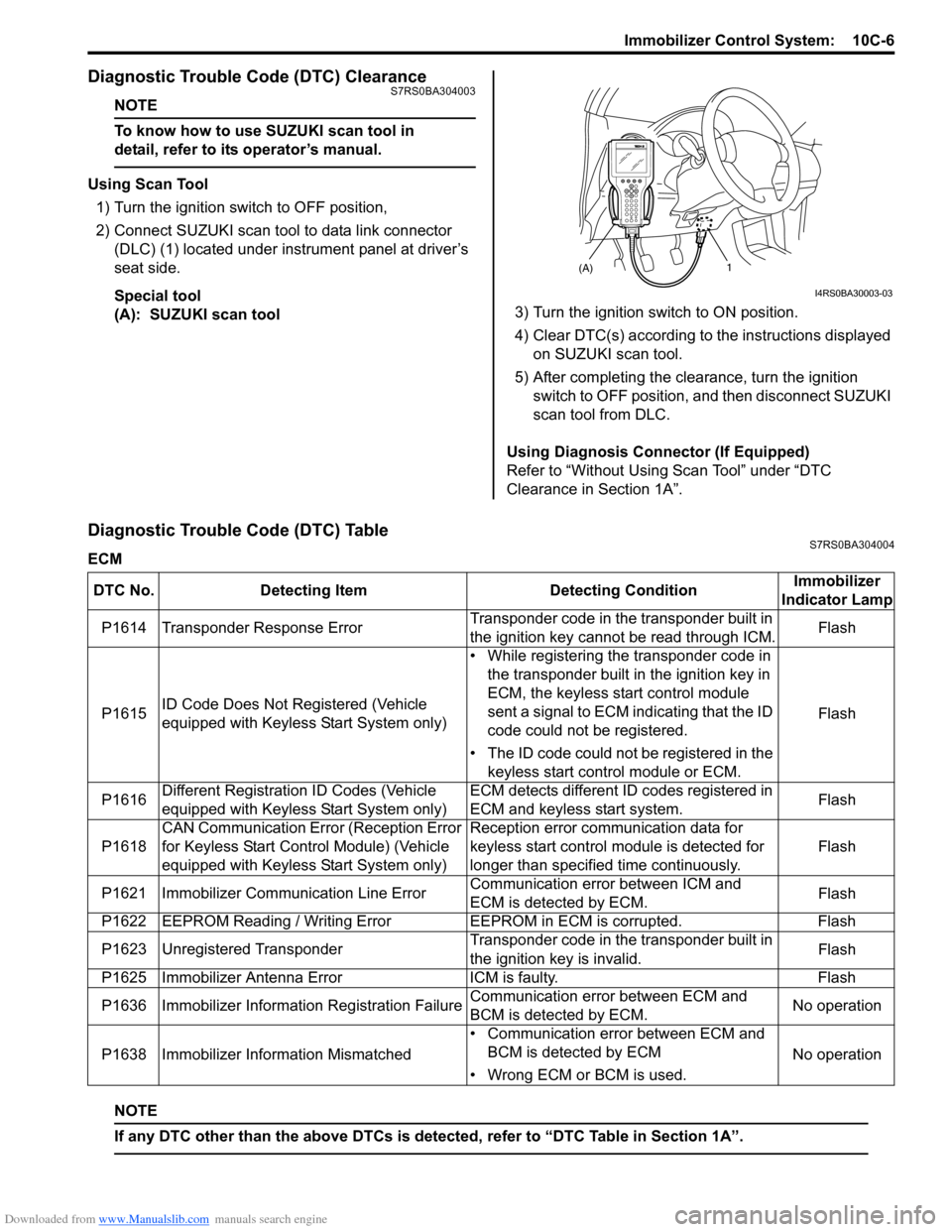

Diagnostic Trouble Code (DTC) ClearanceS7RS0BA304003

NOTE

To know how to use SUZUKI scan tool in

detail, refer to its operator’s manual.

Using Scan Tool

1) Turn the ignition switch to OFF position,

2) Connect SUZUKI scan tool to data link connector (DLC) (1) located under instrument panel at driver’s

seat side.

Special tool

(A): SUZUKI scan tool 3) Turn the ignition switch to ON position.

4) Clear DTC(s) according to the instructions displayed

on SUZUKI scan tool.

5) After completing the clearance, turn the ignition switch to OFF position, and then disconnect SUZUKI

scan tool from DLC.

Using Diagnosis Connector (If Equipped)

Refer to “Without Using Scan Tool” under “DTC

Clearance in Section 1A”.

Diagnostic Trouble Code (DTC) TableS7RS0BA304004

ECM

NOTE

If any DTC other than the above DTCs is detected, refer to “DTC Table in Section 1A”.

(A)1

I4RS0BA30003-03

DTC No. Detecting Item Detecting ConditionImmobilizer

Indicator Lamp

P1614 Transponder Response Error Transponder code in the transponder built in

the ignition key cannot be read through ICM.Flash

P1615 ID Code Does Not Re

gistered (Vehicle

equipped with Keyless Start System only) • While registering the transponder code in

the transponder built in the ignition key in

ECM, the keyless start control module

sent a signal to ECM indicating that the ID

code could not be registered.

• The ID code could not be registered in the keyless start control module or ECM. Flash

P1616 Different Registration ID Codes (Vehicle

equipped with Keyless Start System only) ECM detects different ID codes registered in

ECM and keyless start system.

Flash

P1618 CAN Communication Error (Reception Error

for Keyless Start Control Module) (Vehicle

equipped with Keyless Start System only) Reception error communication data for

keyless start control module is detected for

longer than specified time continuously.

Flash

P1621 Immobilizer Commu nication Line ErrorCommunication error between ICM and

ECM is detected by ECM. Flash

P1622 EEPROM Reading / Writing Error EEPROM in ECM is corrupted.Flash

P1623 Unregistered Transponder Transponder code in the transponder built in

the ignition key is invalid.Flash

P1625 Immobilizer Antenna Error ICM is faulty.Flash

P1636 Immobilizer Information Registration Failure Communication error between ECM and

BCM is detected by ECM.No operation

P1638 Immobilizer Info rmation Mismatched • Communication error between ECM and

BCM is detected by ECM

• Wrong ECM or BCM is used. No operation

Page 1463 of 1496

Downloaded from www.Manualslib.com manuals search engine Keyless Start System: 10E-1

Control Systems

Keyless Start System

General Description

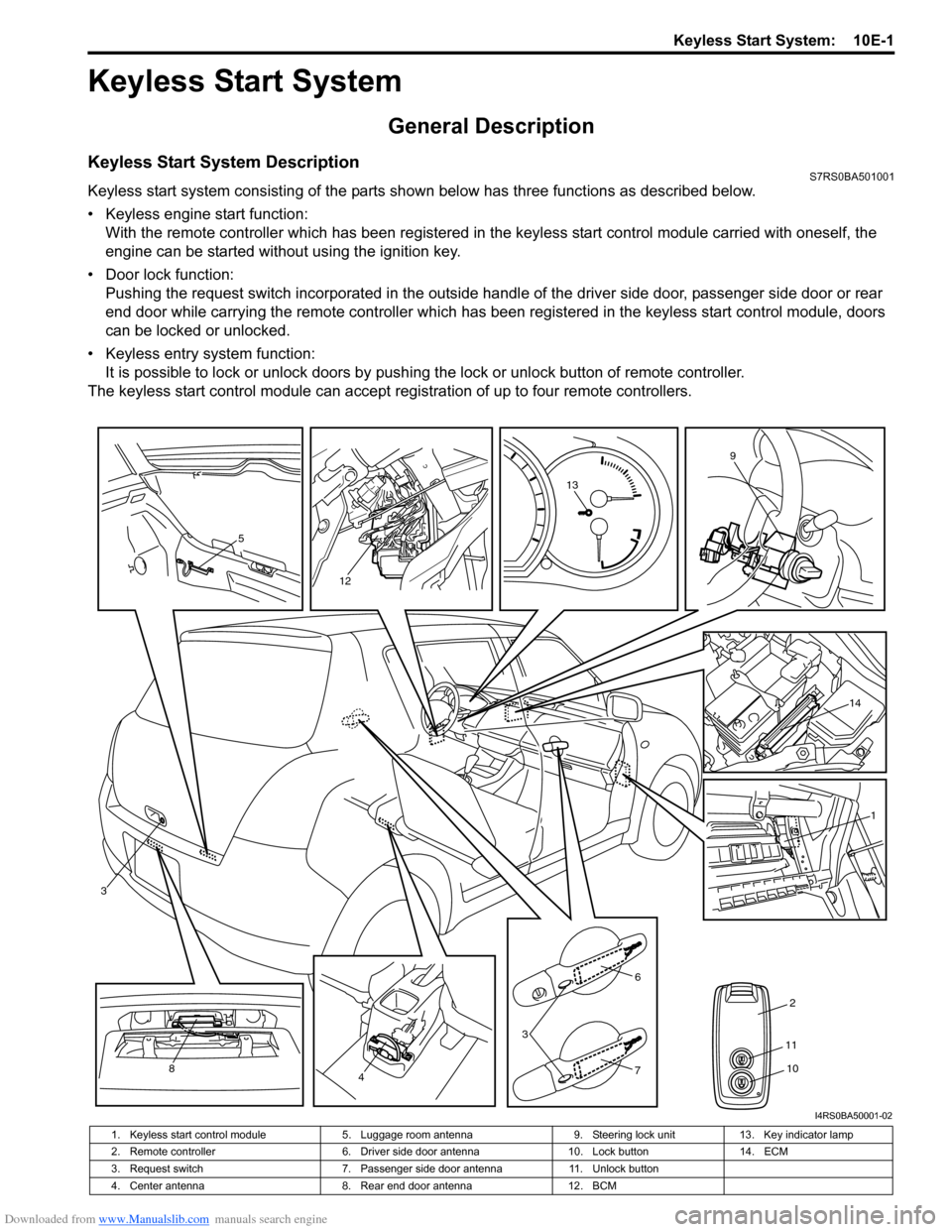

Keyless Start System DescriptionS7RS0BA501001

Keyless start system consisting of the parts shown below has three functions as described below.

• Keyless engine start function:With the remote controller which has been registered in the keyless start control module carried with oneself, the

engine can be started without using the ignition key.

• Door lock function: Pushing the request switch incorporated in the outside handl e of the driver side door, passenger side door or rear

end door while carrying the remote controller which has been registered in the keyless start control module, doors

can be locked or unlocked.

• Keyless entry system function: It is possible to lock or unlock doors by push ing the lock or unlock button of remote controller.

The keyless start control module can accept regi stration of up to four remote controllers.

5

12

13

9

14

1

2

6

3

748

3

11

10

I4RS0BA50001-02

1. Keyless start control module 5. Luggage room antenna 9. Steering lock unit13. Key indicator lamp

2. Remote controller 6. Driver side door antenna10. Lock button14. ECM

3. Request switch 7. Passenger side door antenna11. Unlock button

4. Center antenna 8. Rear end door antenna12. BCM

Page 1464 of 1496

Downloaded from www.Manualslib.com manuals search engine 10E-2 Keyless Start System:

Parts and FunctionsS7RS0BA501002

PartsFunction

Keyless start control module • Activates each antenna

• Verifies ID code of remote controller

• Requests steering lock unit to release steering lock

• Requests BCM to lock or unlock doors

• Controls key indicator la

mp in combination meter

• Transmits its ID code to ECM

Remote controller • Receives request signal from each antenna

• Transmits ID code and request signal to keyless start control module

• Request keyless start control module to lock or unlock doors (keyless entry

system function)

Request switch • Requests keyless start control module to activate each antenna

Center antenna • Transmits request signal to remote controller

Luggage room antenna • Transmits request signal to remote controller

Driver side door antenna • Transmits request signal to remote controller

Passenger side door antenna • Transmits request signal to remote controller

Rear end door antenna • Transmits request signal to remote controller

Steering lock unit • Releases steering lock

Unlock button • Transmits door unlock request signal (keyless entry system function)

Lock button • Transmits door lock request signal (keyless entry system function)

BCM • Controls each door lock actuator

• Controls warning buzzer

• Lights hazard warning lamp and interior (DOME) light (answer back)

Key indicator lamp • Indicates operation state of keyless start system (indicates check result of

remote controller ID code)

ECM • Checks keyless start control module ID code

• Transmits its ID code to keyless start control module

• Starts engine