Lock SUZUKI SWIFT 2007 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2007, Model line: SWIFT, Model: SUZUKI SWIFT 2007 2.GPages: 1496, PDF Size: 34.44 MB

Page 923 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-41

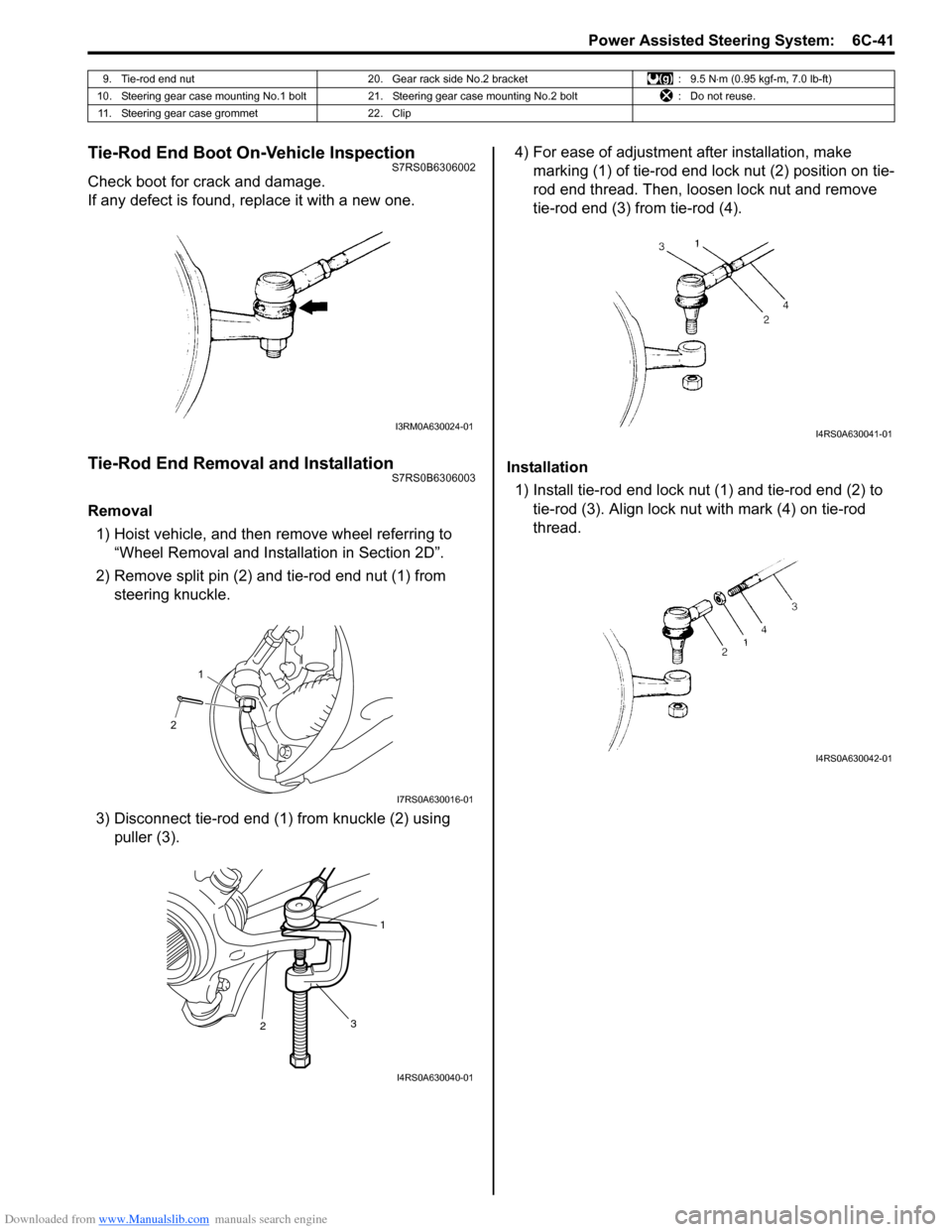

Tie-Rod End Boot On-Vehicle InspectionS7RS0B6306002

Check boot for crack and damage.

If any defect is found, replace it with a new one.

Tie-Rod End Removal and InstallationS7RS0B6306003

Removal1) Hoist vehicle, and then remove wheel referring to “Wheel Removal and Installation in Section 2D”.

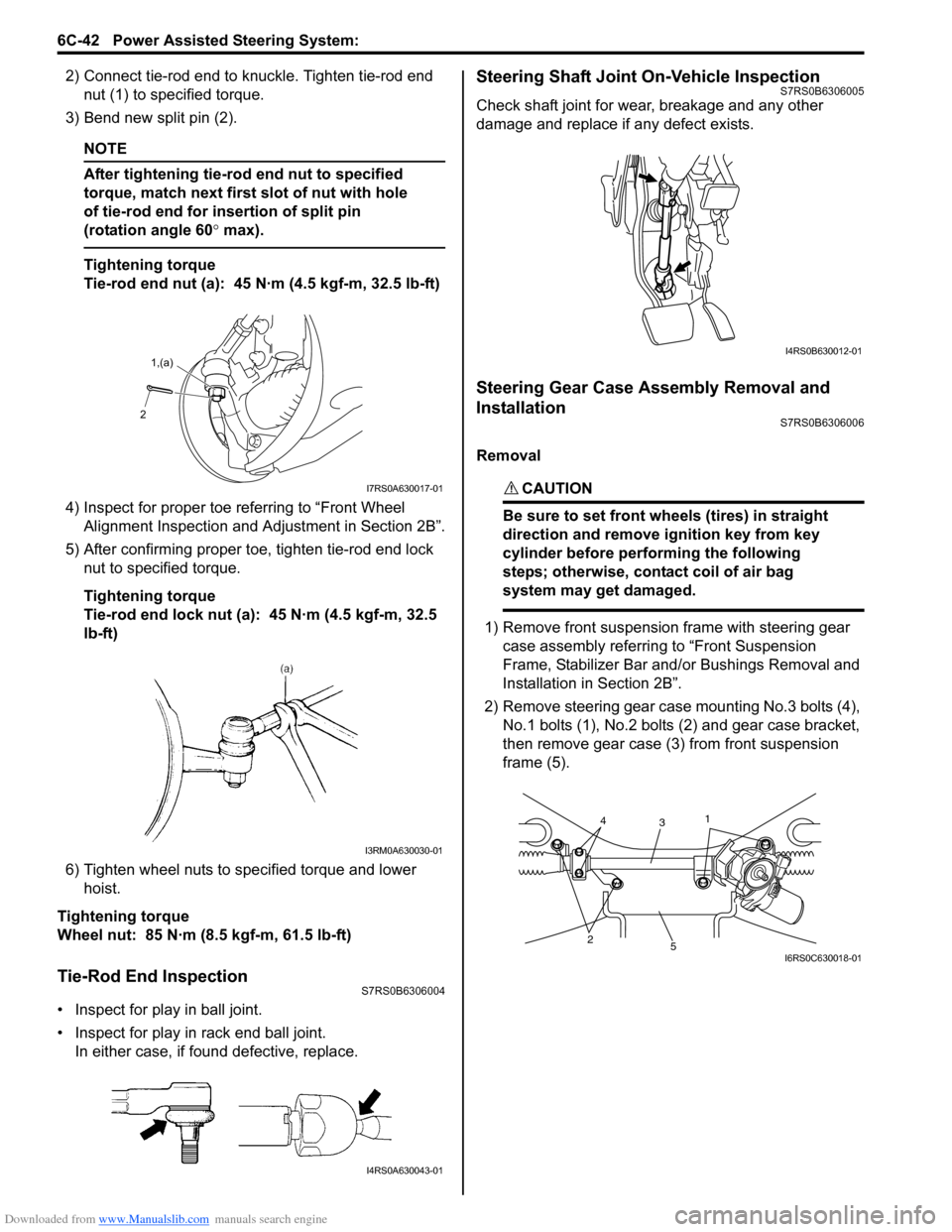

2) Remove split pin (2) and tie-rod end nut (1) from steering knuckle.

3) Disconnect tie-rod end (1) from knuckle (2) using puller (3). 4) For ease of adjustment after installation, make

marking (1) of tie-rod end lock nut (2) position on tie-

rod end thread. Then, loosen lock nut and remove

tie-rod end (3) from tie-rod (4).

Installation 1) Install tie-rod end lock nut (1) and tie-rod end (2) to tie-rod (3). Align lock nut with mark (4) on tie-rod

thread.

9. Tie-rod end nut 20. Gear rack side No.2 bracket : 9.5 N⋅m (0.95 kgf-m, 7.0 lb-ft)

10. Steering gear case mounting No.1 bolt 21. Steering gear case mounting No.2 bolt : Do not reuse.

11. Steering gear case grommet 22. Clip

I3RM0A630024-01

21

I7RS0A630016-01

2 1

3

I4RS0A630040-01

I4RS0A630041-01

I4RS0A630042-01

Page 924 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-42 Power Assisted Steering System:

2) Connect tie-rod end to knuckle. Tighten tie-rod end nut (1) to spec ified torque.

3) Bend new split pin (2).

NOTE

After tightening tie-rod end nut to specified

torque, match next first slot of nut with hole

of tie-rod end for insertion of split pin

(rotation angle 60 ° max).

Tightening torque

Tie-rod end nut (a): 45 N·m (4.5 kgf-m, 32.5 lb-ft)

4) Inspect for proper toe re ferring to “Front Wheel

Alignment Inspection and Adjustment in Section 2B”.

5) After confirming proper toe, tighten tie-rod end lock nut to specified torque.

Tightening torque

Tie-rod end lock nut (a): 45 N·m (4.5 kgf-m, 32.5

lb-ft)

6) Tighten wheel nuts to specified torque and lower hoist.

Tightening torque

Wheel nut: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

Tie-Rod End InspectionS7RS0B6306004

• Inspect for play in ball joint.

• Inspect for play in rack end ball joint. In either case, if found defective, replace.

Steering Shaft Joint On-Vehicle InspectionS7RS0B6306005

Check shaft joint for wear, breakage and any other

damage and replace if any defect exists.

Steering Gear Case Assembly Removal and

Installation

S7RS0B6306006

Removal

CAUTION!

Be sure to set front wheels (tires) in straight

direction and remove ignition key from key

cylinder before performing the following

steps; otherwise, contact coil of air bag

system may get damaged.

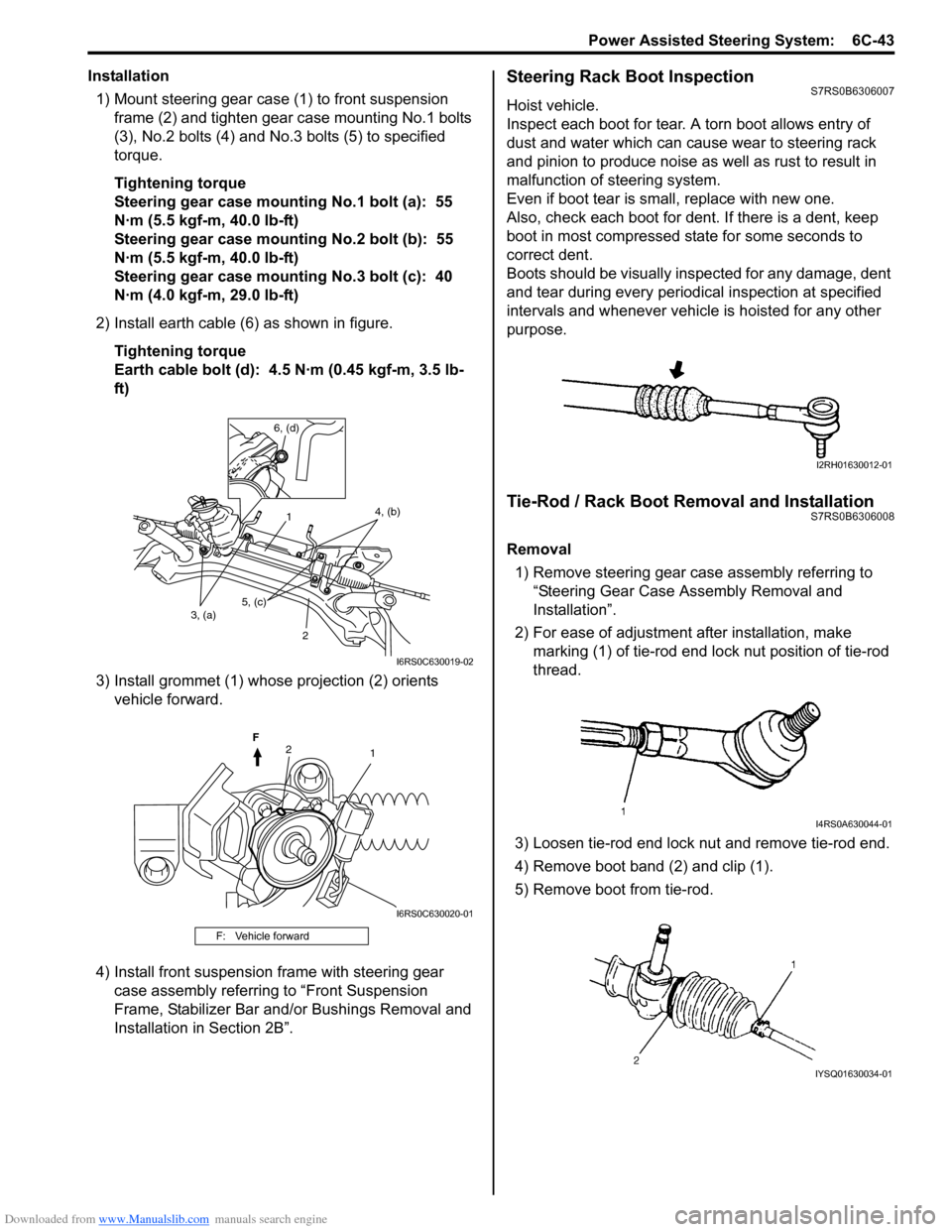

1) Remove front suspension frame with steering gear case assembly referrin g to “Front Suspension

Frame, Stabilizer Bar and/ or Bushings Removal and

Installation in Section 2B”.

2) Remove steering gear case mounting No.3 bolts (4), No.1 bolts (1), No.2 bolts (2) and gear case bracket,

then remove gear case (3) from front suspension

frame (5).

2 1,(a)

I7RS0A630017-01

I3RM0A630030-01

I4RS0A630043-01

I4RS0B630012-01

25

3

14

I6RS0C630018-01

Page 925 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-43

Installation1) Mount steering gear case (1) to front suspension frame (2) and tighten gear case mounting No.1 bolts

(3), No.2 bolts (4) and No .3 bolts (5) to specified

torque.

Tightening torque

Steering gear case mounting No.1 bolt (a): 55

N·m (5.5 kgf-m, 40.0 lb-ft)

Steering gear case mounting No.2 bolt (b): 55

N·m (5.5 kgf-m, 40.0 lb-ft)

Steering gear case mounting No.3 bolt (c): 40

N·m (4.0 kgf-m, 29.0 lb-ft)

2) Install earth cable (6) as shown in figure. Tightening torque

Earth cable bolt (d): 4.5 N·m (0.45 kgf-m, 3.5 lb-

ft)

3) Install grommet (1) whose projection (2) orients vehicle forward.

4) Install front suspension frame with steering gear case assembly referring to “Front Suspension

Frame, Stabilizer Bar and/or Bushings Removal and

Installation in Section 2B”.Steering Rack Boot InspectionS7RS0B6306007

Hoist vehicle.

Inspect each boot for tear. A torn boot allows entry of

dust and water which can cause wear to steering rack

and pinion to produce noise as well as rust to result in

malfunction of steering system.

Even if boot tear is small, replace with new one.

Also, check each boot for dent. If there is a dent, keep

boot in most compressed st ate for some seconds to

correct dent.

Boots should be visually inspected for any damage, dent

and tear during every periodical inspection at specified

intervals and whenever vehicle is hoisted for any other

purpose.

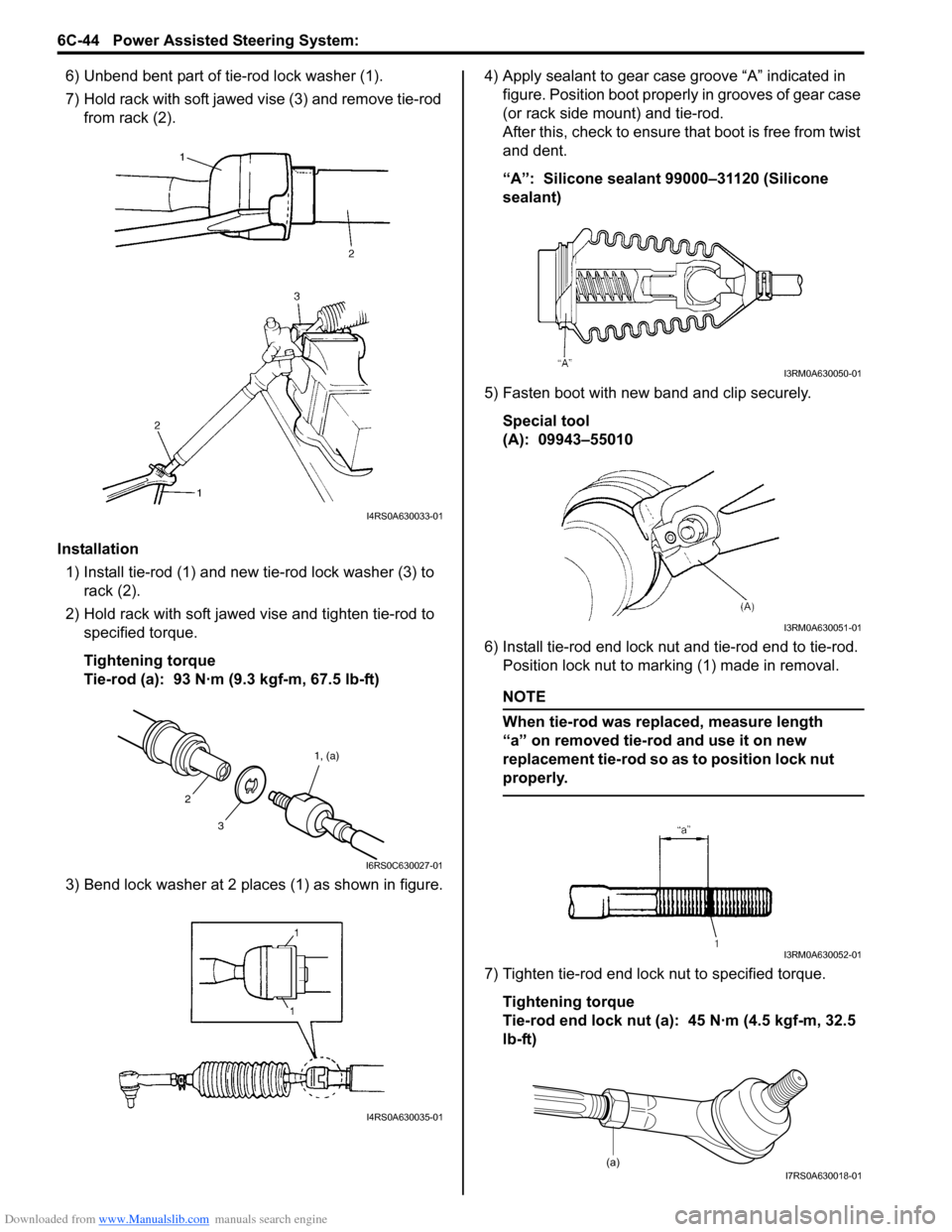

Tie-Rod / Rack Boot Removal and InstallationS7RS0B6306008

Removal

1) Remove steering gear case assembly referring to

“Steering Gear Case Assembly Removal and

Installation”.

2) For ease of adjustment after installation, make marking (1) of tie-rod end lock nut position of tie-rod

thread.

3) Loosen tie-rod end lock nut and remove tie-rod end.

4) Remove boot band (2) and clip (1).

5) Remove boot from tie-rod.

F: Vehicle forward

1 2

3, (a) 4, (b)

6, (d)

5, (c)

I6RS0C630019-02

12

F

I6RS0C630020-01

I2RH01630012-01

I4RS0A630044-01

IYSQ01630034-01

Page 926 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-44 Power Assisted Steering System:

6) Unbend bent part of tie-rod lock washer (1).

7) Hold rack with soft jawed vise (3) and remove tie-rod

from rack (2).

Installation 1) Install tie-rod (1) and new tie-rod lock washer (3) to rack (2).

2) Hold rack with soft jawed vise and tighten tie-rod to specified torque.

Tightening torque

Tie-rod (a): 93 N·m (9.3 kgf-m, 67.5 lb-ft)

3) Bend lock washer at 2 places (1) as shown in figure. 4) Apply sealant to gear case groove “A” indicated in

figure. Position boot properly in grooves of gear case

(or rack side mount) and tie-rod.

After this, check to ensure that boot is free from twist

and dent.

“A”: Silicone sealant 99000–31120 (Silicone

sealant)

5) Fasten boot with new band and clip securely. Special tool

(A): 09943–55010

6) Install tie-rod end lock nut and tie-rod end to tie-rod. Position lock nut to marking (1) made in removal.

NOTE

When tie-rod was replaced, measure length

“a” on removed tie-rod and use it on new

replacement tie-rod so as to position lock nut

properly.

7) Tighten tie-rod end lock nut to specified torque.

Tightening torque

Tie-rod end lock nut (a): 45 N·m (4.5 kgf-m, 32.5

lb-ft)

I4RS0A630033-01

3 1, (a)

2

I6RS0C630027-01

I4RS0A630035-01

I3RM0A630050-01

I3RM0A630051-01

I3RM0A630052-01

(a)I7RS0A630018-01

Page 927 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-45

8) Install steering gear case assembly referring to “Steering Gear Case Assembly Removal and

Installation”.

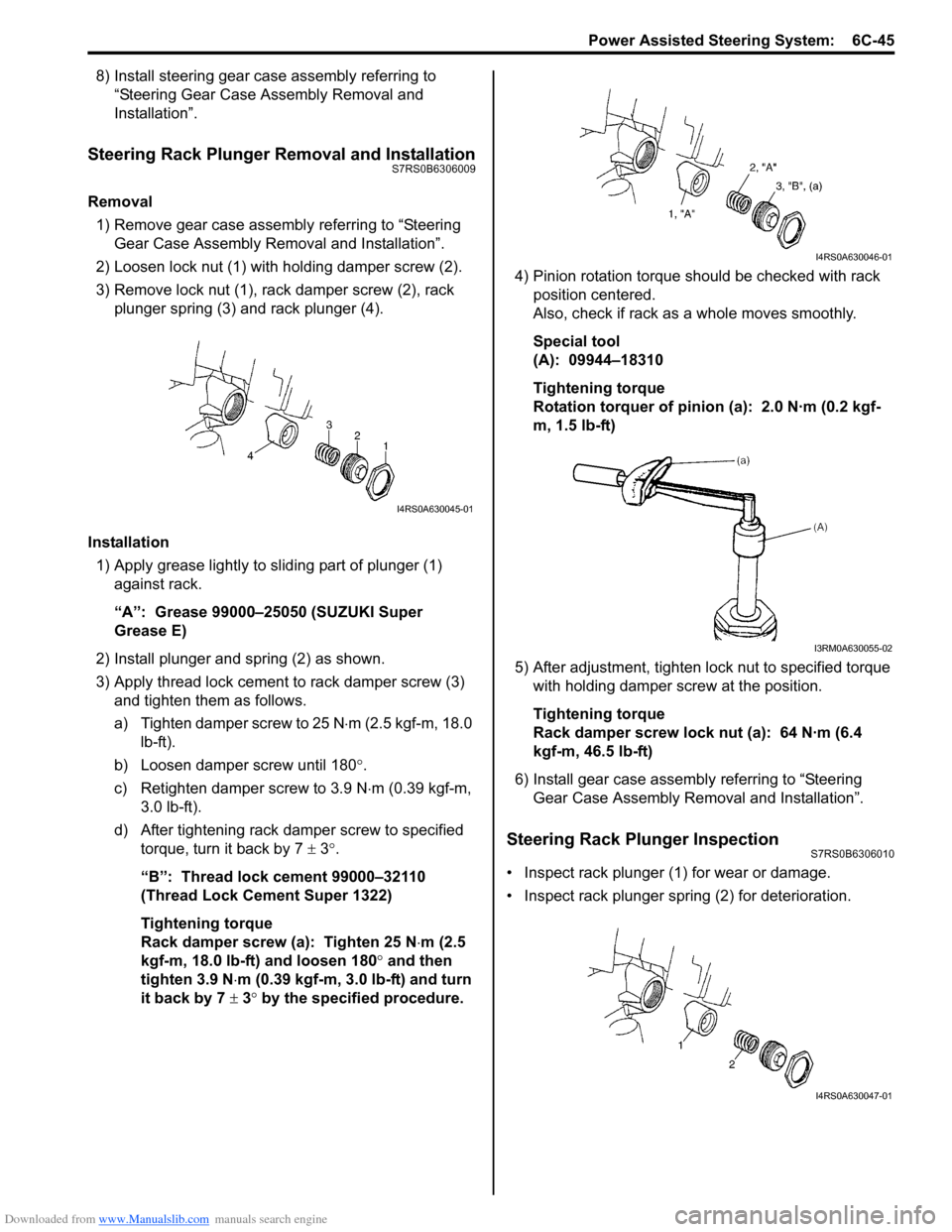

Steering Rack Plunger Removal and InstallationS7RS0B6306009

Removal

1) Remove gear case assembly referring to “Steering

Gear Case Assembly Removal and Installation”.

2) Loosen lock nut (1) with holding damper screw (2).

3) Remove lock nut (1), rack damper screw (2), rack plunger spring (3) and rack plunger (4).

Installation 1) Apply grease lightly to sliding part of plunger (1) against rack.

“A”: Grease 99000–25050 (SUZUKI Super

Grease E)

2) Install plunger and spring (2) as shown.

3) Apply thread lock cement to rack damper screw (3)

and tighten them as follows.

a) Tighten damper screw to 25 N ⋅m (2.5 kgf-m, 18.0

lb-ft).

b) Loosen damper screw until 180 °.

c) Retighten damper screw to 3.9 N ⋅m (0.39 kgf-m,

3.0 lb-ft).

d) After tightening rack damper screw to specified torque, turn it back by 7 ± 3°.

“B”: Thread lock cement 99000–32110

(Thread Lock Cement Super 1322)

Tightening torque

Rack damper screw (a): Tighten 25 N ⋅m (2.5

kgf-m, 18.0 lb-ft) and loosen 180° and then

tighten 3.9 N ⋅m (0.39 kgf-m, 3.0 lb-ft) and turn

it back by 7 ± 3° by the specified procedure. 4) Pinion rotation torque should be checked with rack

position centered.

Also, check if rack as a whole moves smoothly.

Special tool

(A): 09944–18310

Tightening torque

Rotation torquer of pinion (a): 2.0 N·m (0.2 kgf-

m, 1.5 lb-ft)

5) After adjustment, tighten lo ck nut to specified torque

with holding damper screw at the position.

Tightening torque

Rack damper screw lock nut (a): 64 N·m (6.4

kgf-m, 46.5 lb-ft)

6) Install gear case assembly referring to “Steering Gear Case Assembly Re moval and Installation”.

Steering Rack Plunger InspectionS7RS0B6306010

• Inspect rack plunger (1) for wear or damage.

• Inspect rack plunger spring (2) for deterioration.

I4RS0A630045-01

I4RS0A630046-01

I3RM0A630055-02

I4RS0A630047-01

Page 930 of 1496

Downloaded from www.Manualslib.com manuals search engine 6C-48 Power Assisted Steering System:

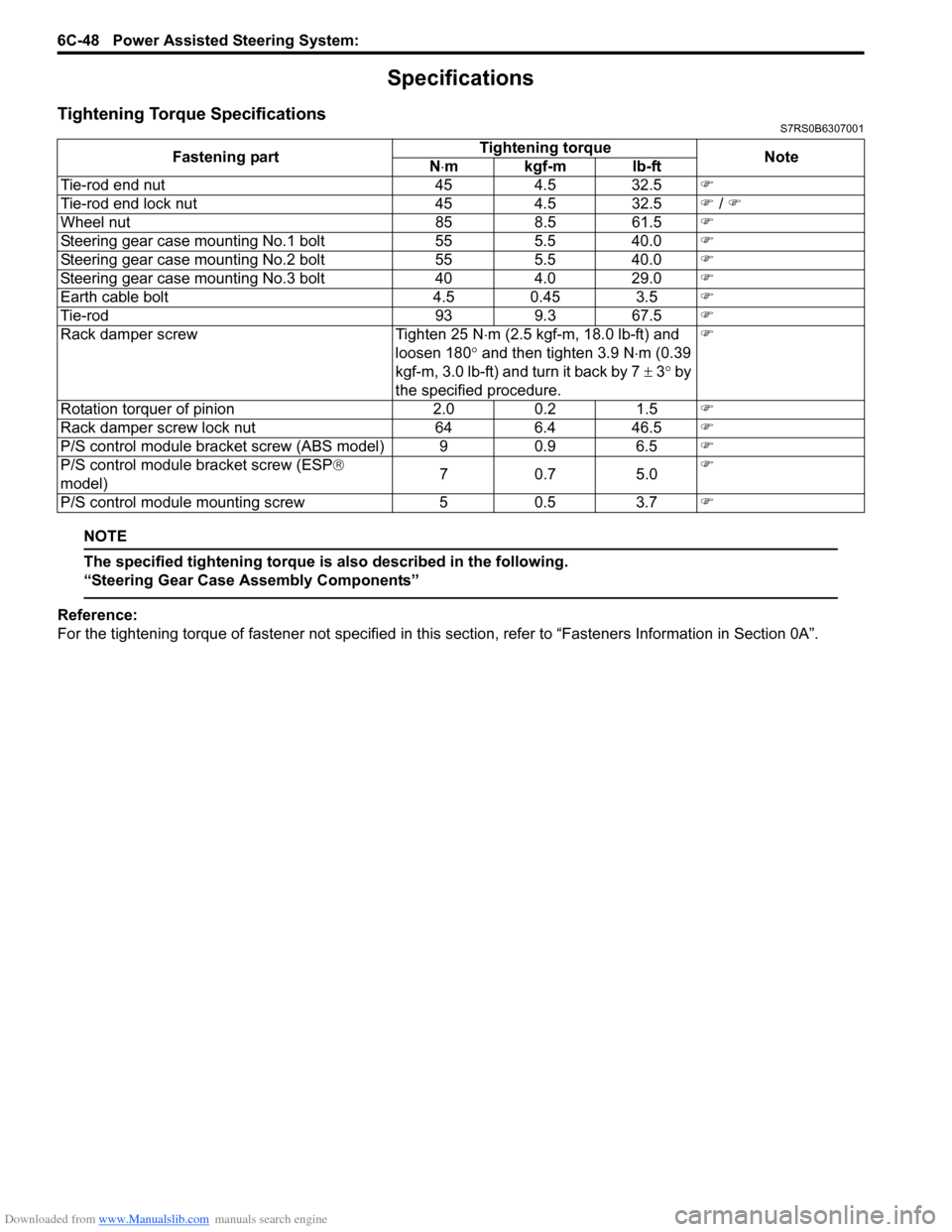

Specifications

Tightening Torque SpecificationsS7RS0B6307001

NOTE

The specified tightening torque is also described in the following.

“Steering Gear Case Assembly Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Fastening part

Tightening torque

Note

N ⋅mkgf-mlb-ft

Tie-rod end nut 454.5 32.5 �)

Tie-rod end lock nut 454.5 32.5 �) / �)

Wheel nut 858.5 61.5 �)

Steering gear case mounting No.1 bolt 555.5 40.0 �)

Steering gear case mounting No.2 bolt 555.5 40.0 �)

Steering gear case mounting No.3 bolt 404.0 29.0 �)

Earth cable bolt 4.5 0.45 3.5�)

Tie-rod 939.3 67.5 �)

Rack damper screw Tighten 25 N⋅m (2.5 kgf-m, 18.0 lb-ft) and

loosen 180 ° and then tighten 3.9 N ⋅m (0.39

kgf-m, 3.0 lb-ft) and turn it back by 7 ± 3° by

the specified procedure. �)

Rotation torquer of pinion 2.00.2 1.5 �)

Rack damper screw lock nut 646.4 46.5 �)

P/S control module bracket screw (ABS model) 9 0.9 6.5�)

P/S control module bracket screw (ESP ®

model) 70

.7 5 .0 �)

P/S control module mounting screw 50.5 3.7 �)

Page 931 of 1496

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-49

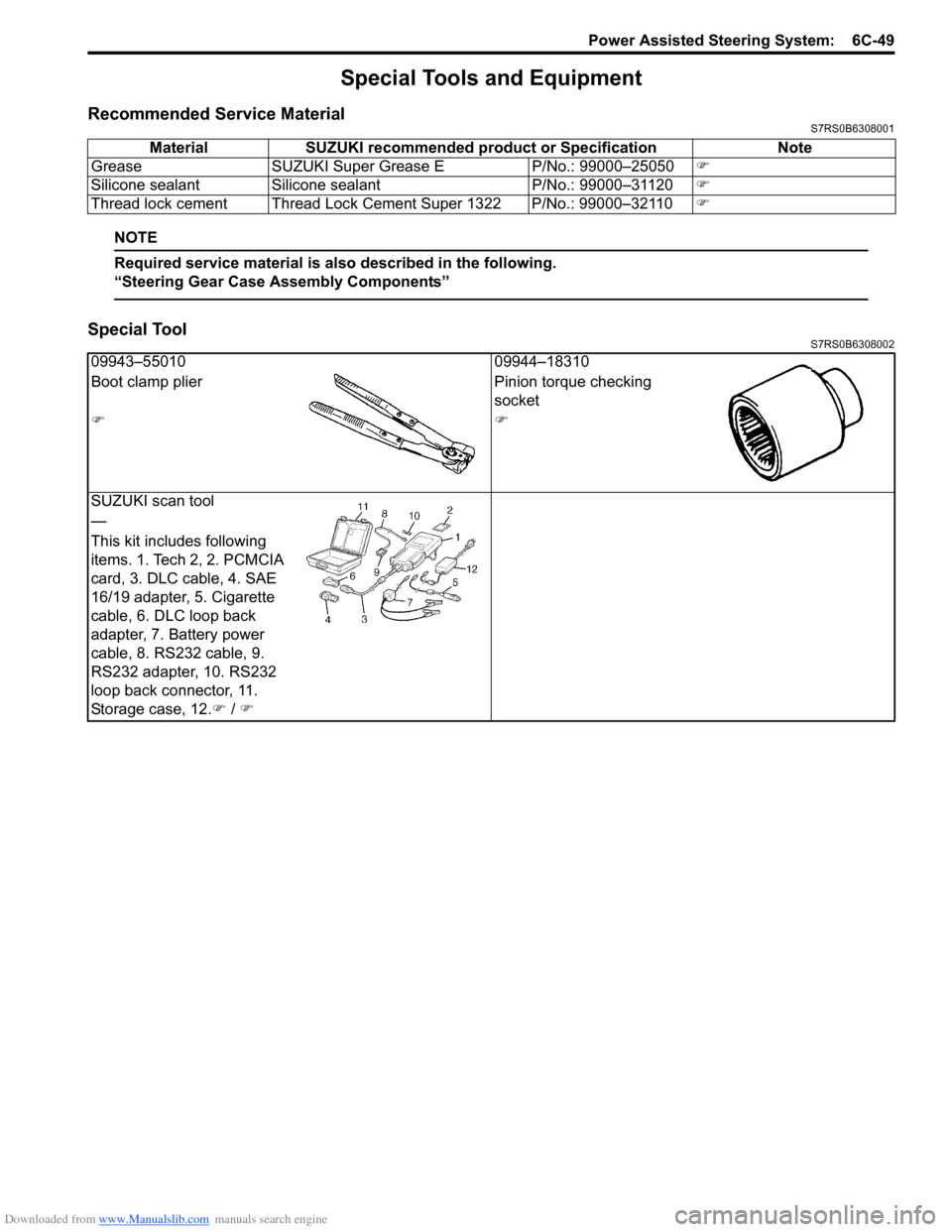

Special Tools and Equipment

Recommended Service MaterialS7RS0B6308001

NOTE

Required service material is also described in the following.

“Steering Gear Case Assembly Components”

Special ToolS7RS0B6308002

Material SUZUKI recommended product or Specification Note

Grease SUZUKI Super Grease E P/No.: 99000–25050�)

Silicone sealant Silicone sealant P/No.: 99000–31120�)

Thread lock cement Thread Lock Cement Super 1322 P/No.: 99000–32110 �)

09943–5501009944–18310

Boot clamp plier Pinion torque checking

socket

�)�)

SUZUKI scan tool

—

This kit includes following

items. 1. Tech 2, 2. PCMCIA

card, 3. DLC cable, 4. SAE

16/19 adapter, 5. Cigarette

cable, 6. DLC loop back

adapter, 7. Battery power

cable, 8. RS232 cable, 9.

RS232 adapter, 10. RS232

loop back connector, 11.

Storage case, 12. �) / �)

Page 938 of 1496

Downloaded from www.Manualslib.com manuals search engine 7A-2 Heater and Ventilation:

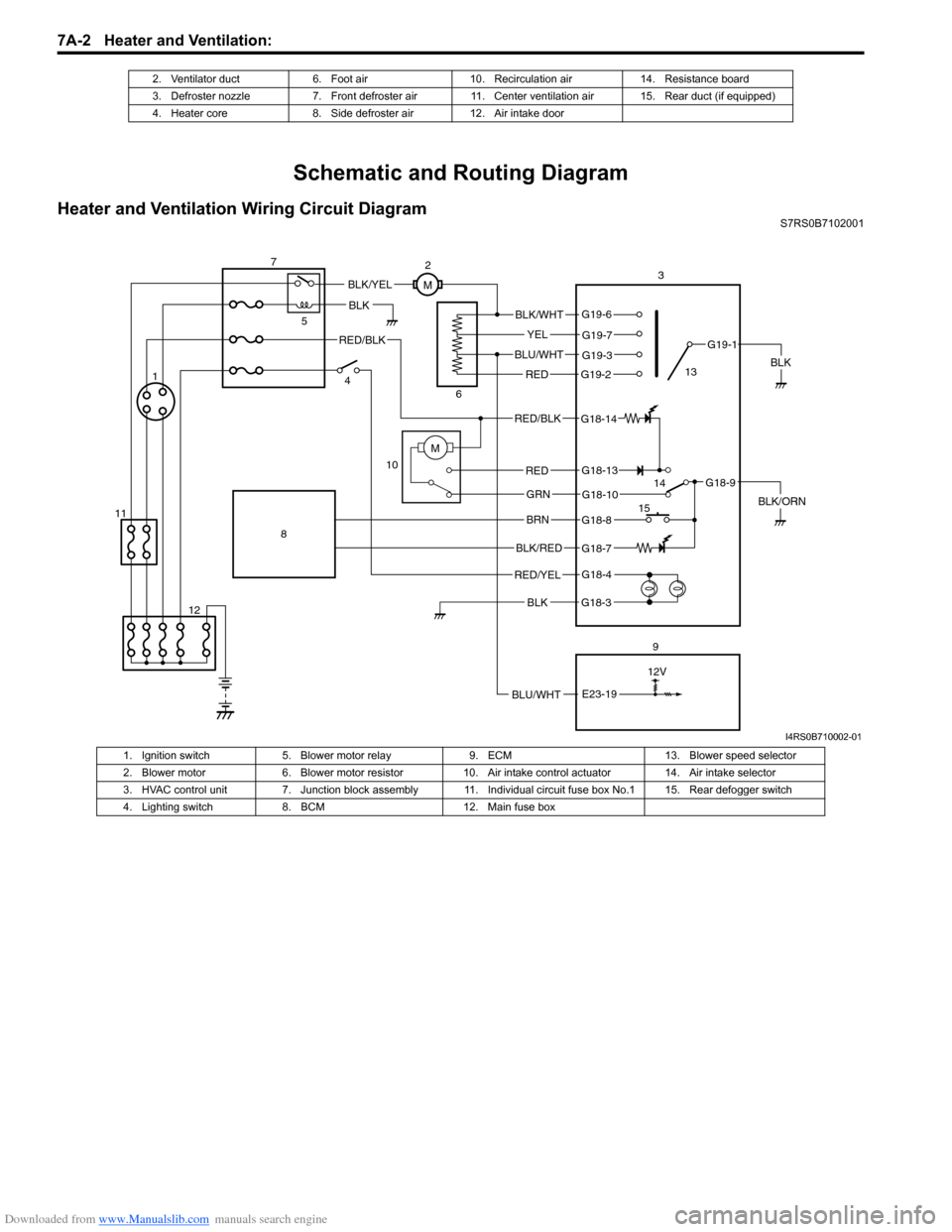

Schematic and Routing Diagram

Heater and Ventilation Wiring Circuit DiagramS7RS0B7102001

2. Ventilator duct 6. Foot air 10. Recirculation air 14. Resistance board

3. Defroster nozzle 7. Front defroster air 11. Center ventilation air 15. Rear duct (if equipped)

4. Heater core 8. Side defroster air 12. Air intake door

BLK

RED/BLK

3

5

7

BLK

2

M

12V

BLU/WHTE23-19

G18-3

G18-4

G18-7

G18-8

G18-10

G18-13

G19-2

G19-3

G19-7

G19-6

G19-1

G18-9

G18-14

BLK/WHT

YEL

BLU/WHT

RED

RED/BLK

RED

GRN

BRN

BLK/RED

RED/YEL

BLK

BLK/YEL

BLK/ORN

4

6

10

8

9

M1

12

11 13

14

15

I4RS0B710002-01

1. Ignition switch 5. Blower motor relay 9. ECM 13. Blower speed selector

2. Blower motor 6. Blower motor resistor 10. Air intake control actuator 14. Air intake selector

3. HVAC control unit 7. Junction block assembly 11. Ind ividual circuit fuse box No.1 15. Rear defogger switch

4. Lighting switch 8. BCM 12. Main fuse box

Page 942 of 1496

Downloaded from www.Manualslib.com manuals search engine 7A-6 Heater and Ventilation:

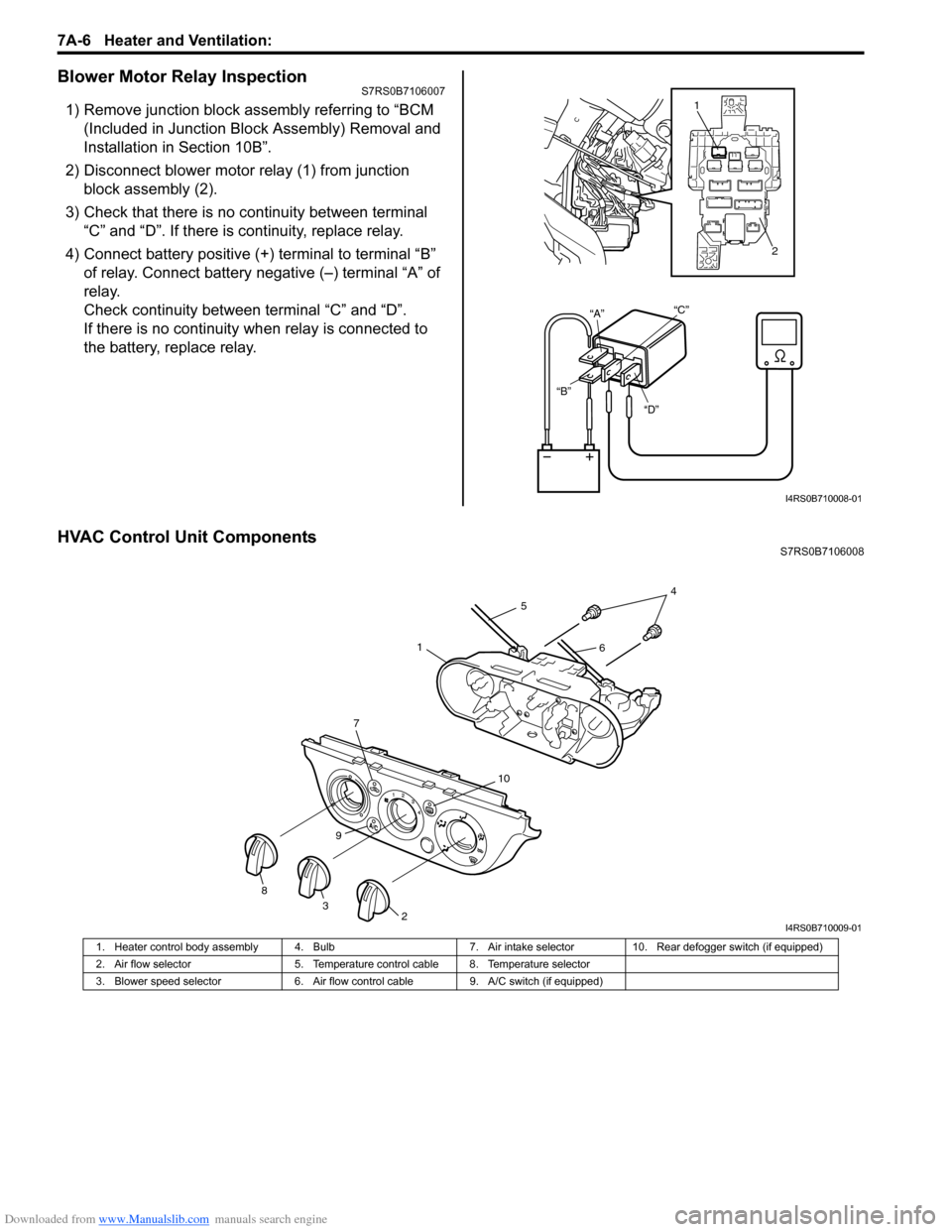

Blower Motor Relay InspectionS7RS0B7106007

1) Remove junction block assembly referring to “BCM (Included in Junction Block Assembly) Removal and

Installation in Section 10B”.

2) Disconnect blower motor relay (1) from junction block assembly (2).

3) Check that there is no continuity between terminal “C” and “D”. If there is continuity, replace relay.

4) Connect battery positive (+ ) terminal to terminal “B”

of relay. Connect battery negative (–) terminal “A” of

relay.

Check continuity between terminal “C” and “D”.

If there is no continuity wh en relay is connected to

the battery, replace relay.

HVAC Control Unit ComponentsS7RS0B7106008

“D”

“B” “A”

“C”

1

2

I4RS0B710008-01

45

61

7

10

9

238

I4RS0B710009-01

1. Heater control body assembly 4. Bulb 7. Air intake selector10. Rear defogger switch (if equipped)

2. Air flow selector 5. Temperature control cable 8. Temperature selector

3. Blower speed selector 6. Air flow control cable9. A/C switch (if equipped)

Page 944 of 1496

Downloaded from www.Manualslib.com manuals search engine 7A-8 Heater and Ventilation:

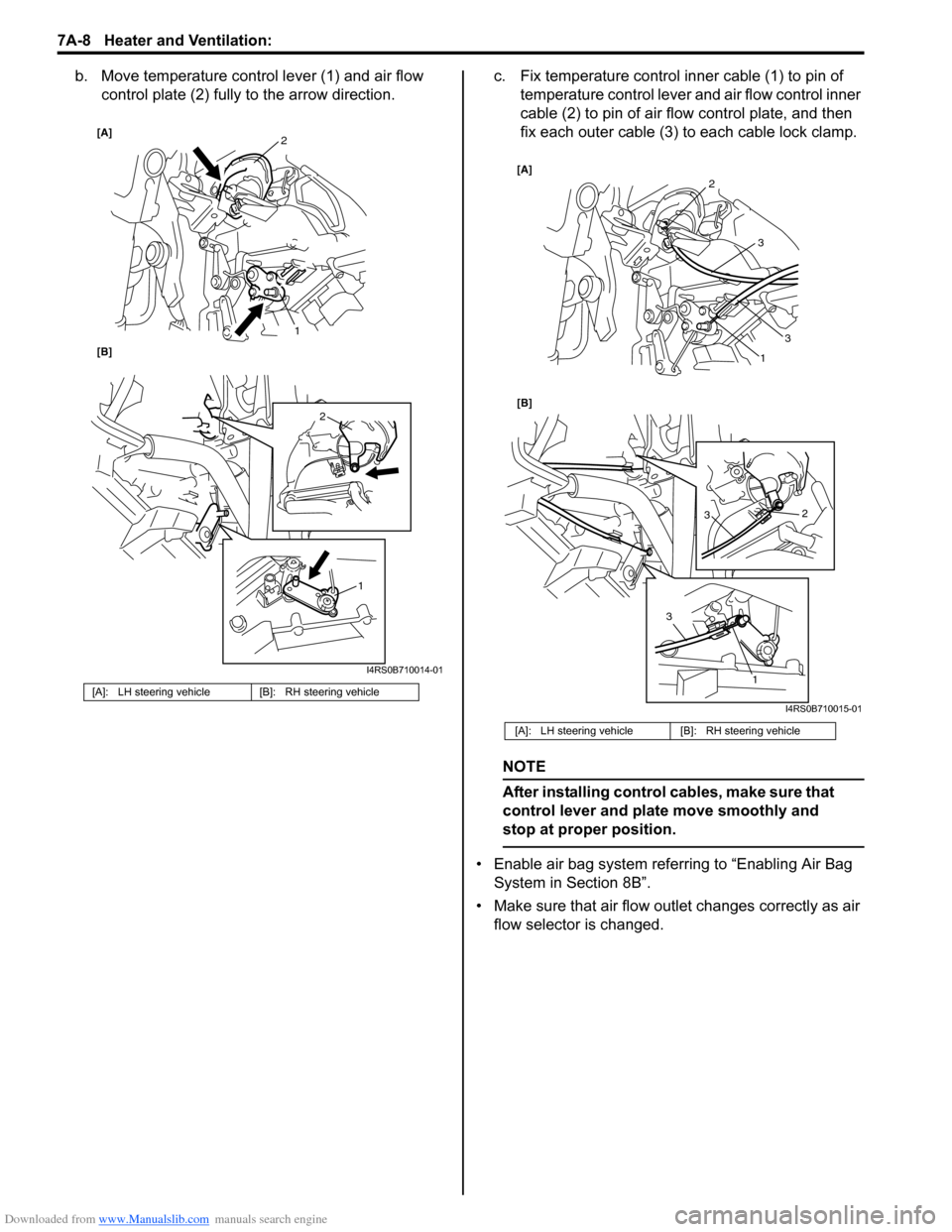

b. Move temperature control lever (1) and air flow control plate (2) fully to the arrow direction. c. Fix temperature control inner cable (1) to pin of

temperature control lever and air flow control inner

cable (2) to pin of air fl ow control plate, and then

fix each outer cable (3) to each cable lock clamp.

NOTE

After installing control cables, make sure that

control lever and plate move smoothly and

stop at proper position.

• Enable air bag system referring to “Enabling Air Bag System in Section 8B”.

• Make sure that air flow outlet changes correctly as air flow selector is changed.

[A]: LH steering vehicle [B]: RH steering vehicle

1

2

[A]

[B]

1

2

I4RS0B710014-01

[A]: LH steering vehicle [B]: RH steering vehicle

1

2

[B] [A] 3

3

1

3

23

I4RS0B710015-01